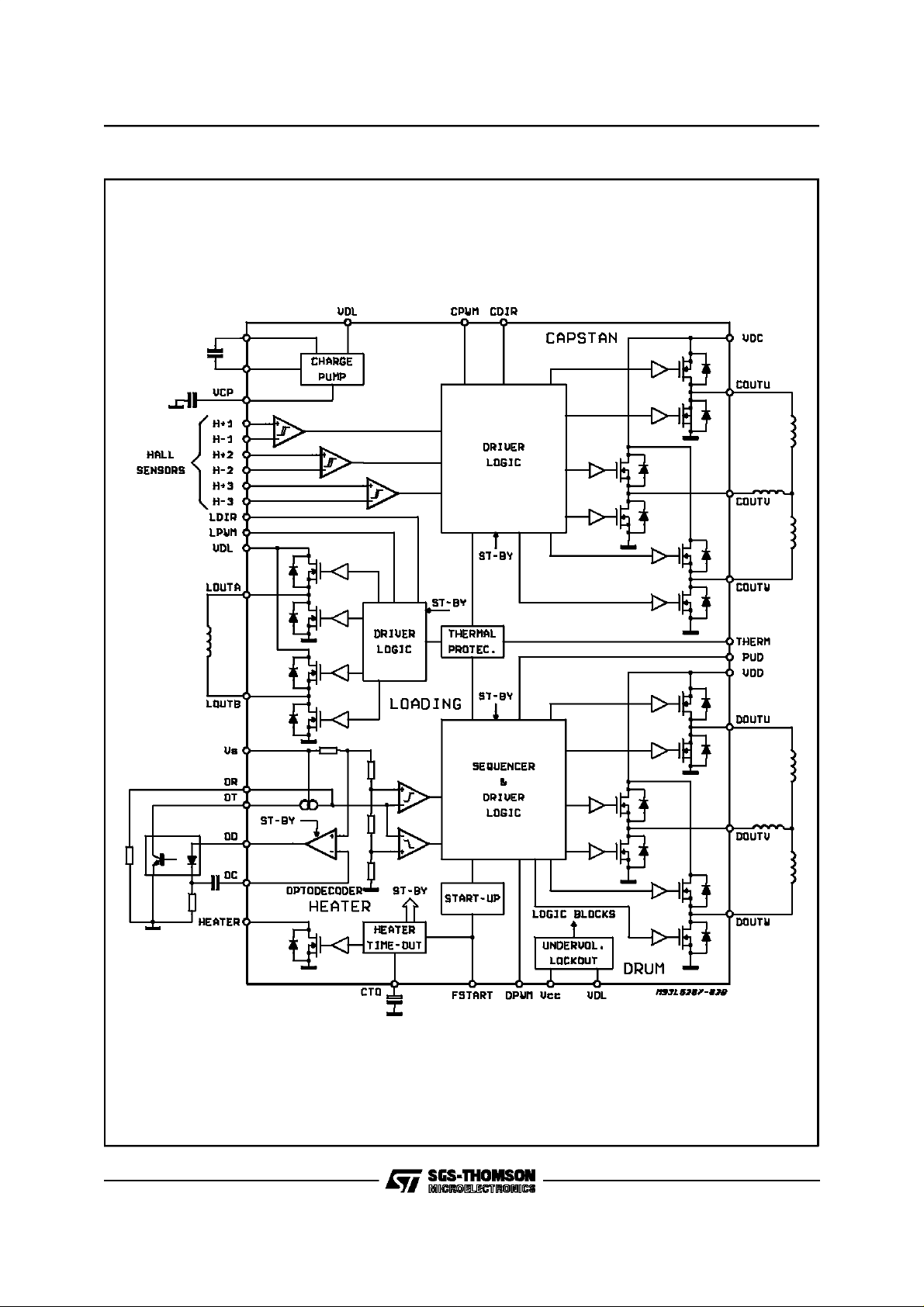

DESCRIPTION

The F-VHS Motor Driver COMBO IC includes a

double three phase brushless motor driver plus a

DC full bridge motor driverforVCRapplication.

The package is SDIP42 (38+2+2 pin ground

frame).

The device is realized in BCD technology with

power LDMOS outputstages.

The gate drive for high side stages is providedby

an internalcharge pump withtwo externalcapacitors. The first three phase motor driver is devoted

to the DRUMmotorcontrol.

The phase sequence update signal is provided initially by an external start-up signal (FSTART),

whose frequency is internally divided by four,

while, during normal operation, is provided by an

optical tacho convertersignal.

This signalis used as clockand reset for thestate

machine.

The regulation of the speed is externally provided

by means of PWM signal generated by the µP

(DPWM), without external sensing resistor. The

feedback to theµP unit is given by a suitable

open drain output signal (PUD) synchronized by

the internal state machine.

The second three phase motor driver is devoted

to the CAPSTAN control. While the DRUM will always spin in a fixed direction, the CAPSTAN motor needs a moresophisticatedlogic to control the

changes in spindirection.

The motor position detection is carried out by

means of three comparators for Hall effect sensors. The loop regulationfor this motor is still provided by theµP with the signals CPWM and

CDIR.

The LOADINGmotor section include a full bridge

DC motor driver. The motor operations are directly set by the inputsLPWM, LDIR according to

the truth table reportedon thepage5.

The device also includes a circuit for early thermal alarm, last thermal alarm and thermal shutdown with hysteresys.The output of this stage is

an opendrain,kept ON during normaloperations.

The THERM signal follows the inverted FSTART

signal between early warning and last warning

temperature, while remains in high impedance

(OFF) after lastwarning temperature and during

thermal shutdown.

L6287

POWER COMBO DRIVER

SDIP42

ORDERING NUMBER: L6287

The STANDBY state of thedevice is imposedby

THERMALSHUTDOWN

UNDERVOLTAGEON VCC SUPPLY

EXTERNALSIGNAL FSTART;

This state is imposed automatically after a defined time-out.

The time-out is realized by sensing the falling

edges of the FSTART signal: if no edges are recorded for a time interval greater than a certain

time constant, the STANDBY condition is generated.

The time constant is defined by the external capacitorCTO.

In the STANDBY state the main functions (upper

power stages, opto decoder, etc) of the device

are turned off in order to minimize the power consumption.

The device also implement a HEATER function.

The HEATER transistor is OFF during thermal

shutdown, undervoltagecondition and during normal workingmode.

The HEATER transistor is driven ON when the

externalSTANDBY condition is present according

to the followingtable:

FSTART HIGH LOW

HEATER OFF ON

During the ON condition,thespecified heater Ron

is not guaranteed if all the voltage supplies are

not at their minimumnominal value.

February 1997

This is advanced information on a new product now in development or undergoingevaluation. Details are subject to change without notice.

1/9

L6287

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

DD

V

DC

V

DL

UPPER POWER

DS MAX

V

LOWERPOWER

V

DS MAX

V

CC

V

S

I

p1 Loading Motor Peak Current (T

pd Drum Motor Peak Current (T

I

pc Capstan Motor Peak Current (T

I

il Logic Input Low State Voltage -0.1 V

V

V

ih

V

therm

V

heat

(**) Not operative - STANDBYcondition

(***) Each motor driver

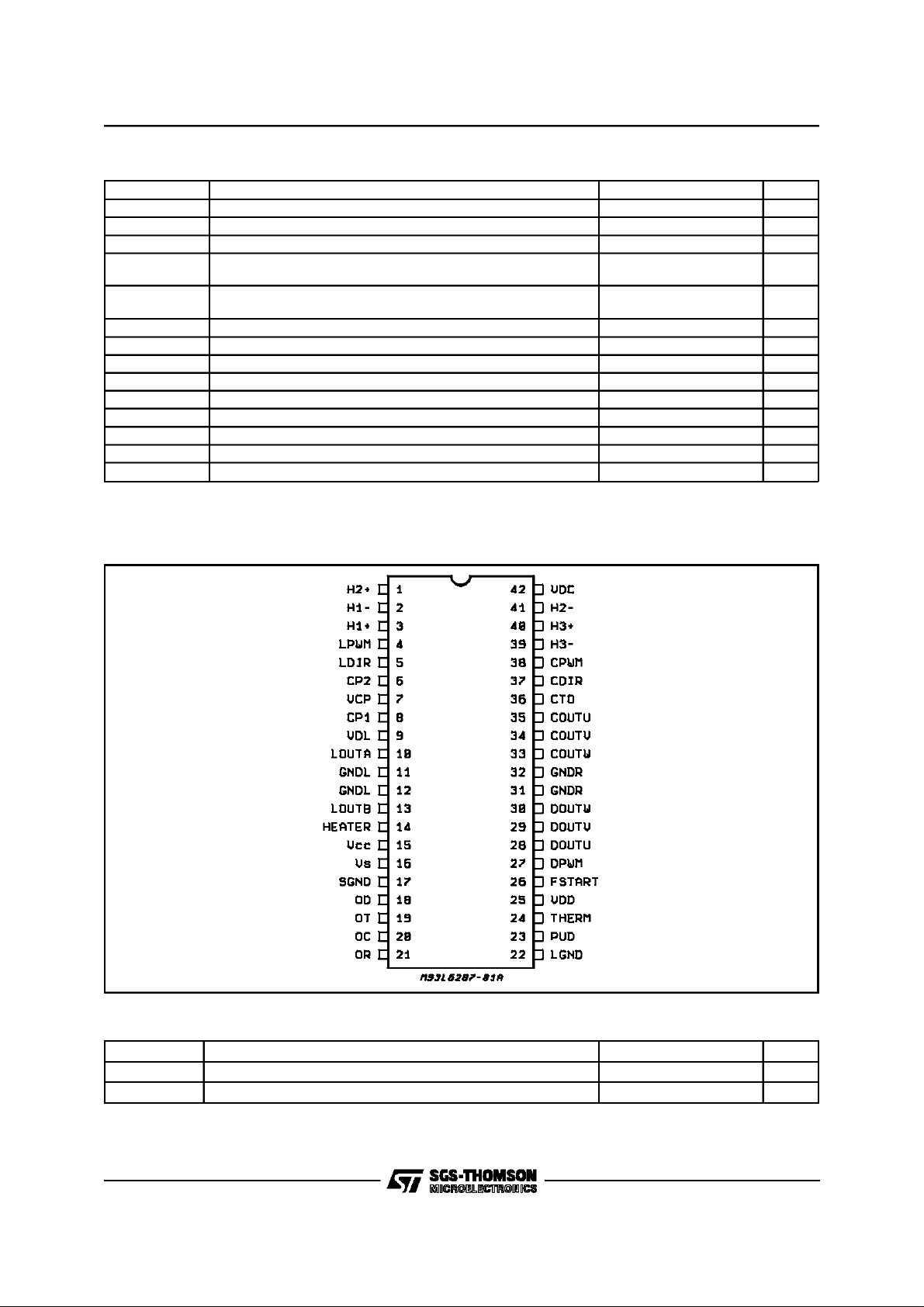

PINS CONNECTION

Drum Supply Voltage 20 V (**)

Capstan Supply Voltage 20 V (**)

Loading Supply Voltage 20 V (**)

Motor Output to Ground Voltage 20 V(***)

Motor Output to Supply Voltage 20 V (***)

Logic Supply Voltage 7 V

Special Supply Voltage 7 V

=1µs Duty Cycle = 2%) 1.6 A

on

=1µs Duty Cycle = 2%) 1.4 A

on

=1µs Duty Cycle = 2%) 1.8 A

on

Logic Input High StateVoltage 7 V

Open Drain Maximum Voltage 7 V

Open Drain Maximum Voltage 20 V (**)

THERMAL DATA

Symbol Parameter Value Unit

R

thj-amb

R

th j-pins

Note: Batwing pin.

2/9

Thermal Resistance Junction toAmbient 48 °C/W

Thermal Resistance Junction toPin 15 °C/W

BLOCK DIAGRAM

CP1 = 0.01µF

CP2 = 0.1µF

L6287

3/9

L6287

PIN DESCRIPTION

VOLTAGE SUPPLIES (The power supply voltage VDD,VDC,VDL must be connected toghetherexternally)

V

DD

V

DC

V

DL

CC Logic voltage supply

V

GND Logic Ground

L

GND R Capstan + drum power ground

GND L Loading + Charge pump Power ground

S Analog voltage supply

V

GND Analog ground

S

Note: The V

DRUM MOTOR

D

OUTU

OUT V Winding Output V

D

OUTW Winding Output W

D

PWM PWM logic pulse input. Controlsignal generated by µP for dump motor current regulation.

D

UD Logic output position feedback generated by the translator logic

P

OD Optocoupler diode output

OC External capacitor fortacho-converter integrator

OT Input foroptocoupler transistor

OR Tacho-converter external resistor. This resistor defines the full-light currentlevel of the tacho.

CAPSTAN MOTOR

C

OUTU

OUT V Winding Output V

C

OUTW Winding Output W

C

PWM PWM logic pulse input. Controlsignal generated by µP for current regulation.

C

DIR Motor Direction Logic Input Signal

C

H1+

H1-

H2+

H2-

H3+

H3-

LOADING MOTOR

OUT A Winding Output A

L

OUT B Winding Output B

L

PWM PWM logic input.

L

DIR Directionlogic input

L

SERVICES

HEATER Open drain output forheater resistor

V

CP

CP1 Bootstrap Capacitor pin

CP2 Bootstrap Capacitor pin

THERM Open drain thermal alarm output

START Start-up logic signal for drum motor

F

CTO Time out capacitor output

Power supply voltage fordrump motor

Power supply voltage forcapstan motor

Power supply voltage forloading motor and charge pump

and VSPower Supply must betogether either at maximum or minimum value.

CC

Winding Output U

Winding Output U

Hall sensor differential input

Hall sensor differential input

Hall sensor differential input

Charge pump storage capacitor pin

4/9

L6287

ELECTRICALCHARACTERISTICS (Tj =0 to125°C; VCC=VS=5V±5%;VDC=VDL=VDD= 10 to 18V;

unless otherwisespecified.)

POWERSUPPLY

Symbol Parameter Test Condition Min. Typ. Max. Unit

(#)V

(#)V

(#)V

V

CC

V

S

V

CCth

# WARNING

The functionalityof the I.C. is guaranted in this voltage range. Nevertheless the specified operating voltages (V

according to the load characteristics.Proper cautions must be taken in the application in order to assure that the drain-source voltage across

each output power transistor does not exceed 20V max.

LOADING MOTOR

ACTIVATIONTRUTH TABLE

Drum Power Supply Voltage 10 18 V

DD

Capstan Power Supply Voltage 10 18 V

DC

Loading Power Supply Voltage 10 18 V

DL

Logic Power Supply Voltage 4.5 5.5 V

Sensor Power Supply Voltage 4.75 5.25 V

Undervoltage Threshold 3.6 4.4 V

DC,VDD,VDL), must be selected

INPUT OUTPUT

LPWM LDIR LOUTA LOUTB

0 0 LOW LOW

0 1 LOW LOW

1 0 HIGH LOW

1 1 LOW HIGH

Symbol Parameter Test Condition Min. Typ. Max. Unit

R

R

(*)I

(*)I

DSH

DSL

OL

High Side R

DSonH

Low Side RDSonL 2 Ω

DC Output Current 800 mA

Peak Output Current DUTY CYCLE = 10%;

pl

t

ON

=500ms

2 Ω

1A

DRUM MOTOR

Symbol Parameter Test Condition Min. Typ. Max. Unit

DC Output Current 400 mA

Peak Output Current 600 mA

Peak Output Current DUTY CYCLE = 10%;

t

= 500ms

ON

800 mA

High Side RDSonH 1.6 Ω

Low Side RDSonL 1.6 Ω

(*)I

(*)I

R

R

I

cd

cdp

pdb

DSH

DSL

CAPSTANMOTOR

Symbol Parameter Test Condition Min. Typ. Max. Unit

I

co

(*)I

cop

(*)I

pob

R

DSH

R

DSL

(*) WARNING

These current values are compatible with the structure of the IC power structure. Nevertheless the use of these current levels could produce

junction temperatures thatforce IC outsideof the operative range due to the thermalcharacteristics of the choosen package.

DC Output Current 800 mA

Peak Output Current 1 A

Peak Output Current DUTY CYCLE = 10%;

t

= 1ms

ON

1.5 A

High Side RDSonH 1 Ω

Low Side RDSonL 1 Ω

5/9

L6287

ELECTRICALCHARACTERISTICS (continued)

DRUM TACHO CONVERTER

Symbol Parameter Test Condition Min. Typ. Max. Unit

I

od

I

ot

I

oc

vs I

I

ot

V

ref

V

OC

V

thr1

V

thr2

t

pud

I

pud1

Note 1: The suggested C

Open Loop OutputCurrent Vod= 1V; Ioc= 100µA (Note 1) 30 60 mA

Full Light Current Range 0.5 3 mA

Sink Current Vor=0;Iod= 0 0.2 0.5 µA

Mismatch 5 10 %

or

Opto Resistor Reference

Voltage

Open Loop OptoCapacitor

Voltage

VS = 4.75V 3.36 3.72 V

S = 5V 3.54 3.91 V

V

= 5.25V 3.72 4.11 V

V

S

VOD= 1V see Fig.1

V

V

V

S

S

S

= 4.75V

=5V

= 5.25V

2.75 V

Clock Threshold Voltage VS= 4.75V 2.19 2.42 V

= 5V 2.30 2.54 V

V

S

= 5.25V 2.42 2.67 V

V

S

Reset Threshold Voltage VS= 4.75V 0.30 0.33 V

= 5V 0.32 0.35 V

V

S

S = 5.25V 0.33 0.37 V

V

µP Syncro Pulse Duration 1 3 µs

Open Drain Sink Current VO = 0.4V 5 mA

external capacitor value is 5µF(±5%)

opt

HALL COMPARATOR

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

in

I

b

V

of

V

hy

Input Voltage Range 0.5 2.7 V

Input Bias Current 1

µ

Input Offset Voltage 8 mV

Switchable Hysteresys Vref = 1.5V; 10 40 mV

A

THERMAL PROTECTION

Symbol Parameter Test Condition Min. Typ. Max. Unit

I

therm

T

s

T

sdh

T

al1

T

al2

NOTE 1: Therm output stage is on in the normal temperature range

NOTE 2: In the Tal-Tll temperature range therm signal follows the inverted Fstart signal. After Tll temperaturethisoutput is always in high

Open Drain Sink Current V

Shutdown Temperature 155 170 185

Shutdown Hysteresis 60

Early Warning Temperature Ts -40

Last Warning Temperature (see note 2) Ts -20 °C

impedance.If thermal shutdown is reached this pin will remain in this state until the shutdown hysteresys will be recovered.

= 0.4V (seenote 1) 5 mA

out

o

C

o

C

o

C

HEATER

Symbol Parameter Test Condition Min. Typ. Max. Unit

R

V

dsheat

heat

Heater R

DSon

Heater Voltage 18 V

3 ohm

6/9

ELECTRICALCHARACTERISTICS (continued.)

L6287

LOGIC LEVELS FOR DIGITALINPUTS(C

A pull up resistor R

i

is connected between the C

PWM,CDIR,DPWM,FSTART,LPWM,LDIR

DIR,FSTART,LPWM,LDIR

inputs pads; C

)

and D

PWM

are left unconnected.

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

il

ih Input High Voltage 2 V

V

i Pull Up Resistor 3.5 10.5 Kohm

R

Input Low Voltage 0.8 V

TIME OUT STAGE

Symbol Parameter Test Condition Min. Typ. Max. Unit

I

cto

Note 1: The suggestedexternal capacitor value is Cto=1µF(±20% max) for f

Time Out Output Current (Note 1) 5 20 uA

= 20KHz.

START

Figure 1: OptocircuitOpenLoop OC Voltage.

PWM

7/9

L6287

SDIP42PACKAGE MECHANICAL DATA

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 5.08 0.20

A1 0.51 0.020

A2 3.05 3.81 4.57 0.120 0.150 0.180

B 0.38 0.46 0.56 0.0149 0.0181 0.0220

B1 0.89 1.02 1.14 0.035 0.040 0.045

c 0.23 0.25 0.38 0.0090 0.0098 0.0150

D 36.58 36.83 37.08 1.440 1.450 1.460

E 15.24 16.00 0.60 0.629

E1 12.70 13.72 14.48 0.50 0.540 0.570

e 1.778 0.070

e1 15.24 0.60

e2 18.54 0.730

e3 1.52 0.060

L 2.54 3.30 3.56 0.10 0.130 0.140

E

E1

A2

A1

LA

BeB1

D

42

1

22

21

c

SDIP42

e1

e2

E

.015

0,38

Gage Plane

e3

e2

8/9

L6287

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specification mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are notauthorized foruse as criticalcomponentsin lifesupport devicesor systemswithout express

written approval of SGS-THOMSON Microelectronics.

1997SGS-THOMSON Microelectronics – Printedin Italy – All Rights Reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - France - Germany - HongKong -Italy- Japan - Korea - Malaysia - Malta - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

9/9

Loading...

Loading...