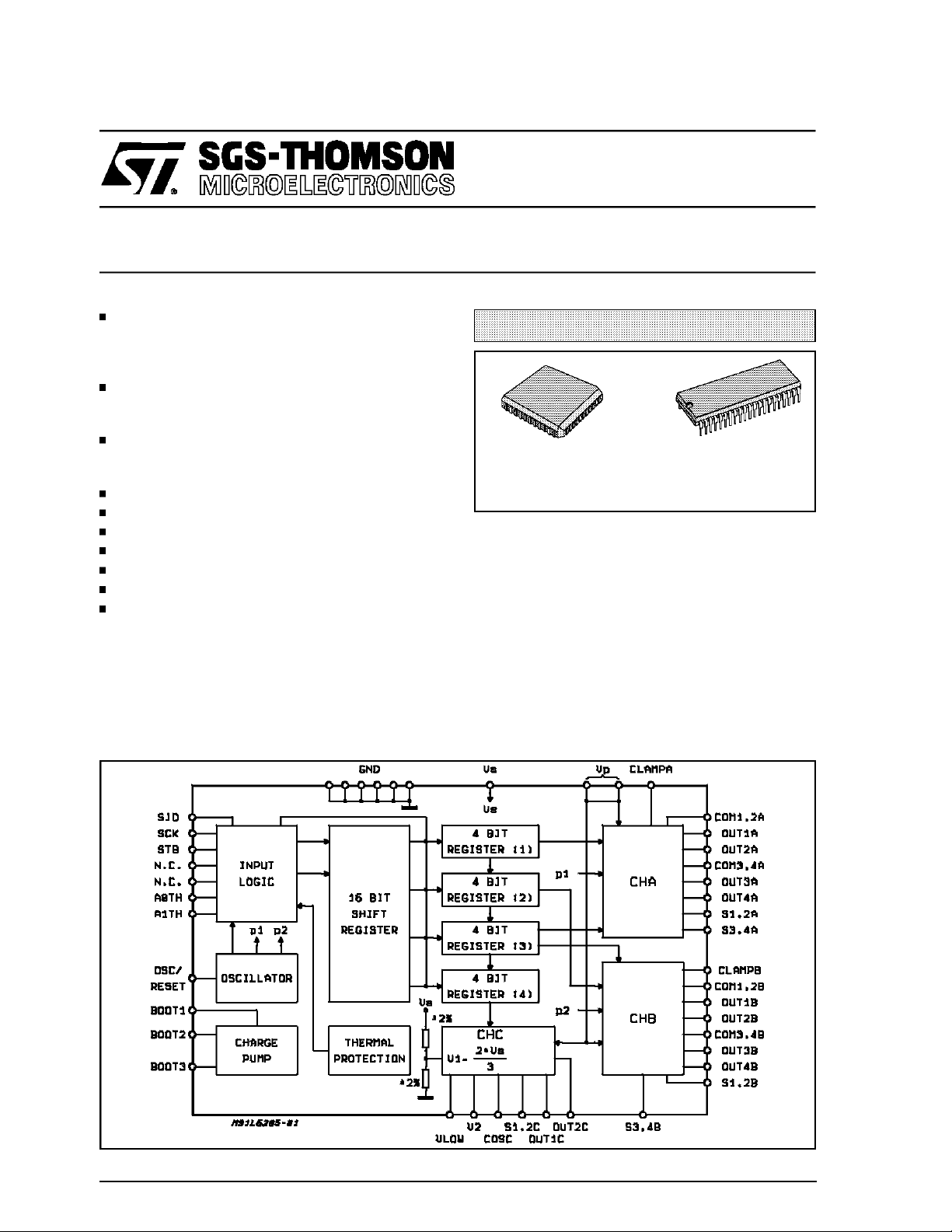

L6285

3 CHANNELS MULTIPOWERSYSTEM

ADVANCE DATA

CHANNEL-A AND CHANNEL-B FOR UNIPOLAR STEPPER MOTORS

– LOWSIDE: R

– HIGH SIDE ; R

DSON

DSON

= 1.2Ω

= 1.2Ω

CHANNEL-CFOR DC MOTORS

– LOWSIDE: R

– HIGH SIDE: R

DSON

DSON

= 1.7Ω

= 1.2Ω

CHOPPING MODE DRIVING FOR C.L. CURRENT CONTROL ON CHA AND CHB AND

O.L. VOLTAGECONTROL ONCHC.

INTERNALFOUR DRIVINGLATCHES

16 BIT INTERNAL SHIFTREGISTER

DIRECTINTERFACE TO µP

SERIALDRIVINGSEQUENCE LOADING

CMOSCOMPATIBLEINPUTS

PRE-ALARMOUTPUT SIGNAL

THERMAL SHUTDOWN

DESCRIPTION

This Combo Motor Driver uses large scale integration to incorporate several functions into the

same chip.

1) Two unipolar steppermotor driver

2) A full bridgeDC motor driver

BLOCK DIAGRAM

MULTIPOWER BCD TECHNOLOGY

PLCC44 SDIP42

ORDERING NUMBERS:

L6285 L6285S

3) Serial microprocesor interface

The poweroutput stages areDMOS and the input

can be interfaced to a CMOS Microprocessor

logic.

The phase current in the unipolar stepper motor

windings is controlled by two external sensing resistors in fixed frequency choppingmode.The oscillator block provides clocks each other 180° out

of phase to the two stepper motor driver in order

to avoidsymultaneous currentpeaks.

For the DC motor driver is used a bridge; the

RMS voltage to supply this motor is fixed by a

May 1994

This is advanced informationon a new product now in development or undergoing evaluation. Details are subject tochange without notice.

1/16

L6285

simple PWMopen loop. The 3 motorsare controlled by the micro through 4 latches of 4 bit each.

The loading of these registers is in serial mode.

The I.C. operates at 5V supply forthe logic and at

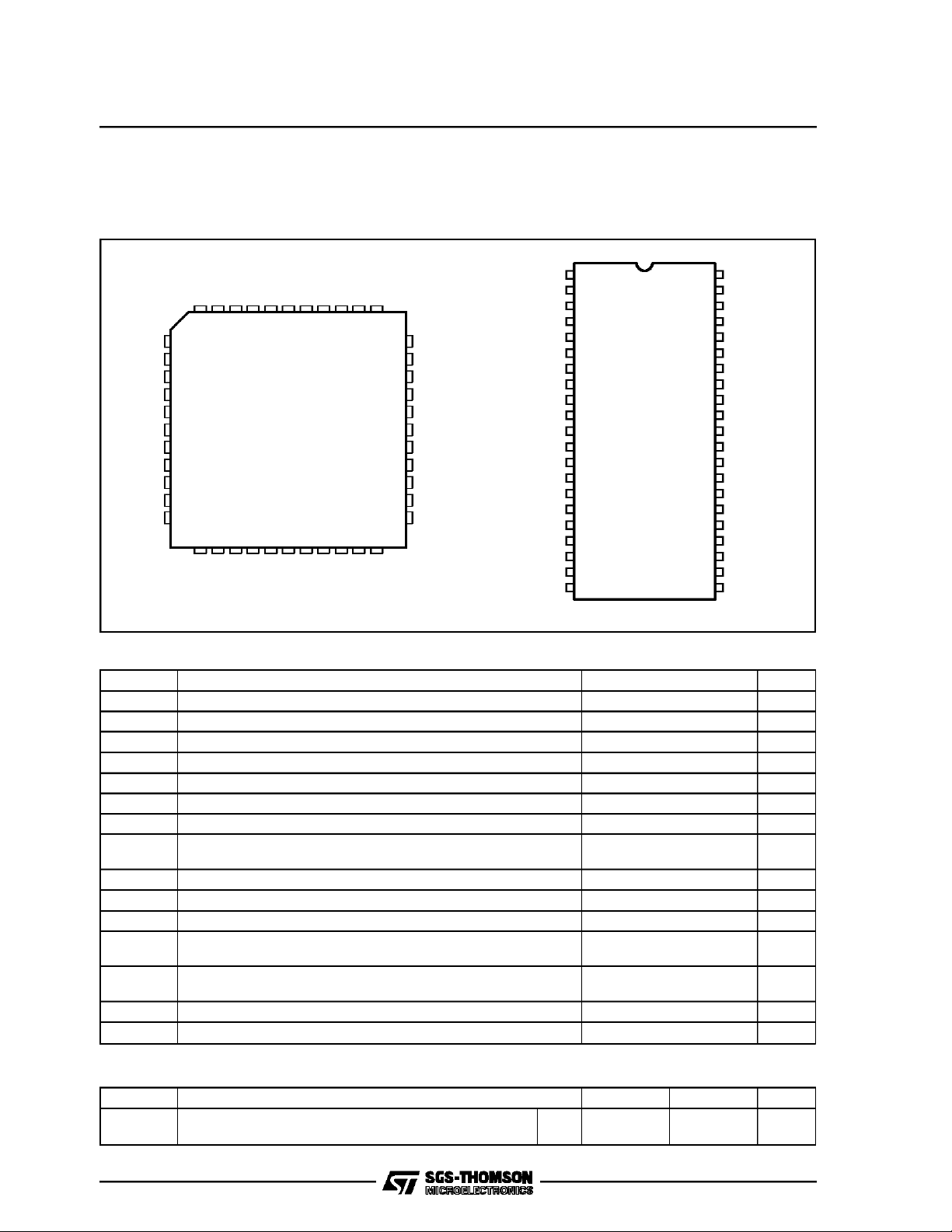

PINCONNECTION (Top view)

PWGND

OUT1A

S1,2A

OUT2A

CLAMPA

OUT3A

S3,4A

OUT4A

BOOT1

BOOT3

GND

7

8

9

10

11

12

13

14

15

16

17

COM3,4A

PWGND

SID

BOOT2

P

COM1,2A

V

PLCC44

STB

SCK

S1,2C

OUT2C

123564

2322211918 20 28272624 25

S

V

N.C.

OUT1C

COM1,2B

N.C.

A0TH

P

V

A1TH

PWGND

COM3,4B

40414244 43

39

38

37

36

35

34

33

32

31

30

29

V2

OSC RESET

PWGND

OUT1B

S1,2B

OUT2B

CLAMPB

OUT3B

S3,4B

OUT4B

VLOW

COSC

GND

D94IN067

24V supply for the power stages. The packages

are SDIP42 and PLCC44 with 6 pins devoted to

ground and to sink out the heat produced by

powerdissipation.

OUT2C

COM1,2A

COM3,4A

PWGND

OUT1A

S1,2A

OUT2A

CLAMPA

OUT3A

S3,4A

OUT4A

BOOT1

BOOT3

BOOT2

1

2

V

3

P

4

N.C. COM3,4B

5

6

7

8

9

10

SDIP42

11

12

13

14

15

16

GND

17

N.C.

18

19

SID

20

SCK

21

STB

D94IN060A

42

41

40

39

38

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

S1,2C

OUT1C

COM1,2B

V

P

PWGND37

OUT1B

S1,2B

OUT2B

CLAMPB

OUT3B

S3,4B

OUT4B

V

LOW

C

OSC

GND

V2

OSC RESET

A1TH

A0TH

V

S

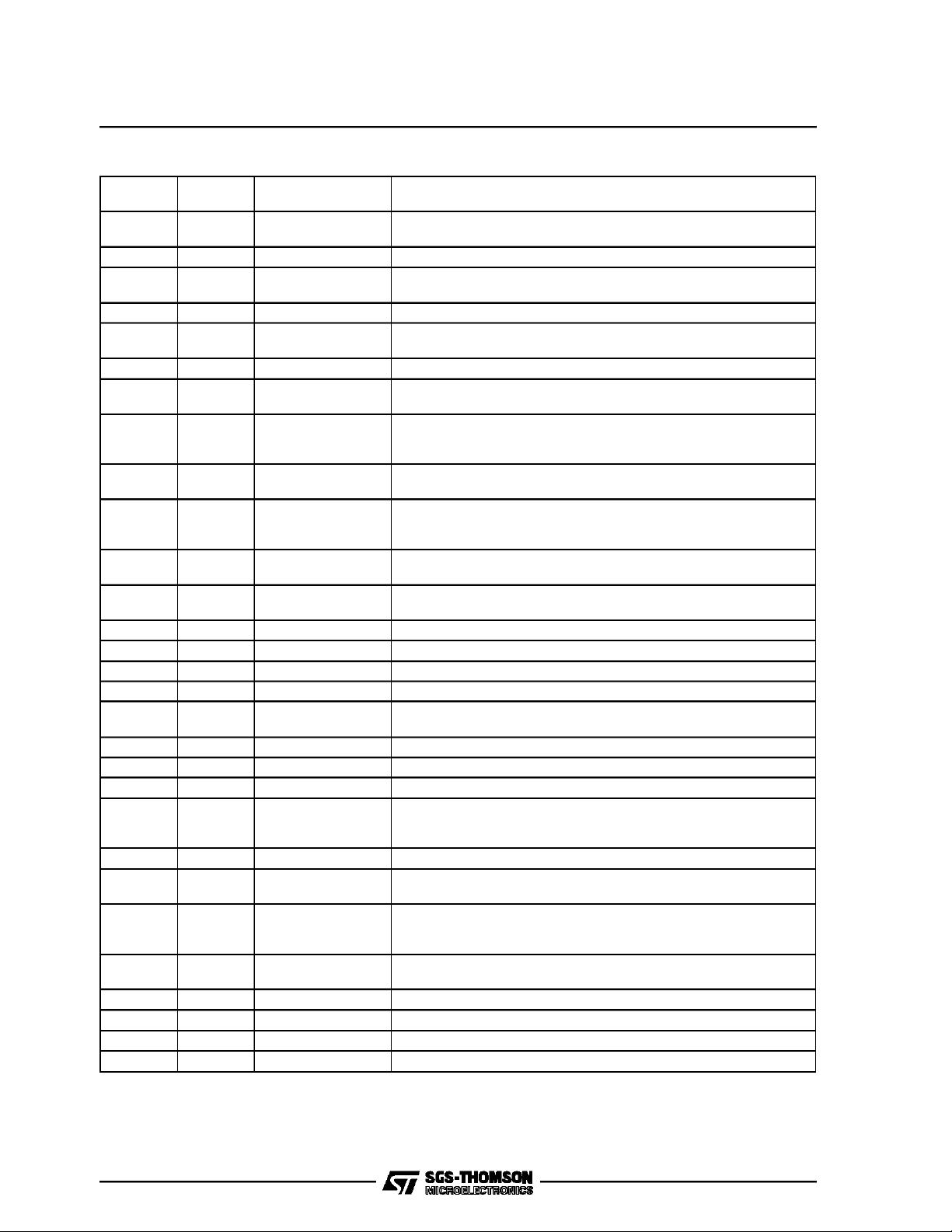

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

V

V

I

LOW

I

HIGH

I

pLOW

I

pHIGH

V

bout

Power Supply Voltage 30 V

P

Logic SupplyVoltage 7 V

S

Logic Input Voltage -0.3 toVS+ 0.3 V

in

Low Side DMOS max DC Current 1 A

High Side DMOS max DC Current 1 A

Low Side DMOS max Peak Current (1µs On; 50µs OFF) 2 A

High Side DMOS max Peak Current(1µs On; 50µsOFF) 2 A

Max Output Voltage of Stepper Motor Driver(transient

60 V

rcirculation)

V

1;2 Max Voltage ON Vsense (CHA/CHB) -1 to2 V

sense

3 Max Voltage ON V

V

sense

Ι

fdDC

Ι

fdpk

Max DC Currentof Forward Diode(DMOS Source DrainDiode) 1 A

Max Peak Current of ForwardDiode (DMOS Source Drain

(CHC) -1 to 2 V

sense

2A

Diode) (1µs On;50µs OFF)

P

tot

T

op

T

stg

Total Power Dissipation (Tpins = 90°C)

With minimized dissipatingcopper area (T

amb

=70°C)

5

1.6

Operating Temperature Range 0 to 150 °C

Storage Temperature Range -40 to 150 °C

THERMAL DATA (PLCC44)

Symbol Description SDIP42 PLCC44 Unit

R

th j-pins

R

th j-amb

Thermal Resistance Junction-pins

Thermal Resistance Junction-ambient

Max.

Max.

15

48

12

50

W

W

°C/W

°C/W

2/16

PINDESCRIPTION

SDIP42

o

N

42 1 S1,2C Full bridge common source output to separate between power GND

1,41 2,44 OUT 1C, OUT 2C Output of the channel C bridge.

2 3 COM 1,2A High side DMOS channel A for current chopping in the windings

3,39 4,42 V

4 5 COM 3,4A High side DMOS channel A for current chopping in the windings

6,37 6,7,39,40 GND PowerGround and heatsinkpins.

7,9,

11,14

8 9 S1,2A ChannelA sourcesof theDMOS OUT 1A, OUT 2A. A sensing resistor

10,33 11,35 CLAMP A, CLAMP B These pinshave to be connected to an external zener diodeto

12 13 S3,4A Channel Asources of the DMOSOUT 3A,OUT 4A. A sensingresistor

14 15 BOOT 1 A capacitor between this pin and V

15 16 BOOT 3 A capacitor between this pinand internal diodes allows the change

16,27 17,29 GND Logic Ground and Heatsink pins.

18 18 BOOT 2 Charge pump oscillator output.

19 19 SID Serial data input.

20 20 SCK Serial clock for serial data input.

21 21 STB Strobe to transfer the16 bit shift register contentsto the latch

5,17 22,24 NC Notconnected.

22,39 23 V

23,24 25,26 A0TH / A1TH Open collector outputs for thermal informations to the µP.

25 27 OSC/ RESET An RC network connected to this pin defines the oscillatorfrequency

26 28 V2 A voltage to this pindefines the outputduty cycle ofChannel C.

28 30 C

29 31 V

30,32,

34,36

31 33 S 3, 4B Same as S 3, 4A,but for channelB.

35 37 S 1, 2B Same as S 1, 2A,but for channelB.

38 41 COM 3, 4B Same as COM 3, 4A, but for channel B.

40 43 COM 1, 2B Same as COM 1, 2A, but for channel B.

PLCC44

o

N

8,10

12,14

32,34

36,38

Name Functions

and logic GND.

connected pins to OUT 1A, OUT 2A.

p

Power Supply Voltage.

connected topins OUT 3A, OUT 4A.

OUT 1A, OUT 2A

Low side DMOS outputs of channel A stepper motor driver.

OUT 3A, OUT 4A

has to be connected from this pin and ground, forcurrent controlof

phase1,2 A.

clamp the output voltage spikes of channel A/B.

has to be connected from this pin and ground, forcurrent controlof

phase3,4 A.

high side DMOS driver gate.

pump to transfer energy to the capacitor at the pin BOOT 1.

registers.

s

Logic Supply Voltage.

for stepper drivers. When OSC/RES is <1V, a reset signal is

internally generated.

osc

A capacitor connected to thispin defines the chopping frequency of

channel C.

low

This pin is low when thechopping low voltage (V2 low level) is

selected; it is in highimpedance when the chopping high voltage(V2

high level) is selected. Only for CHC operation.

OUT4B, OUT3B

Low side DMOS outputs of channel B stepper motor driver.

OUT2B ,OUT1B

stores theovervoltage for each

p

L6285

3/16

L6285

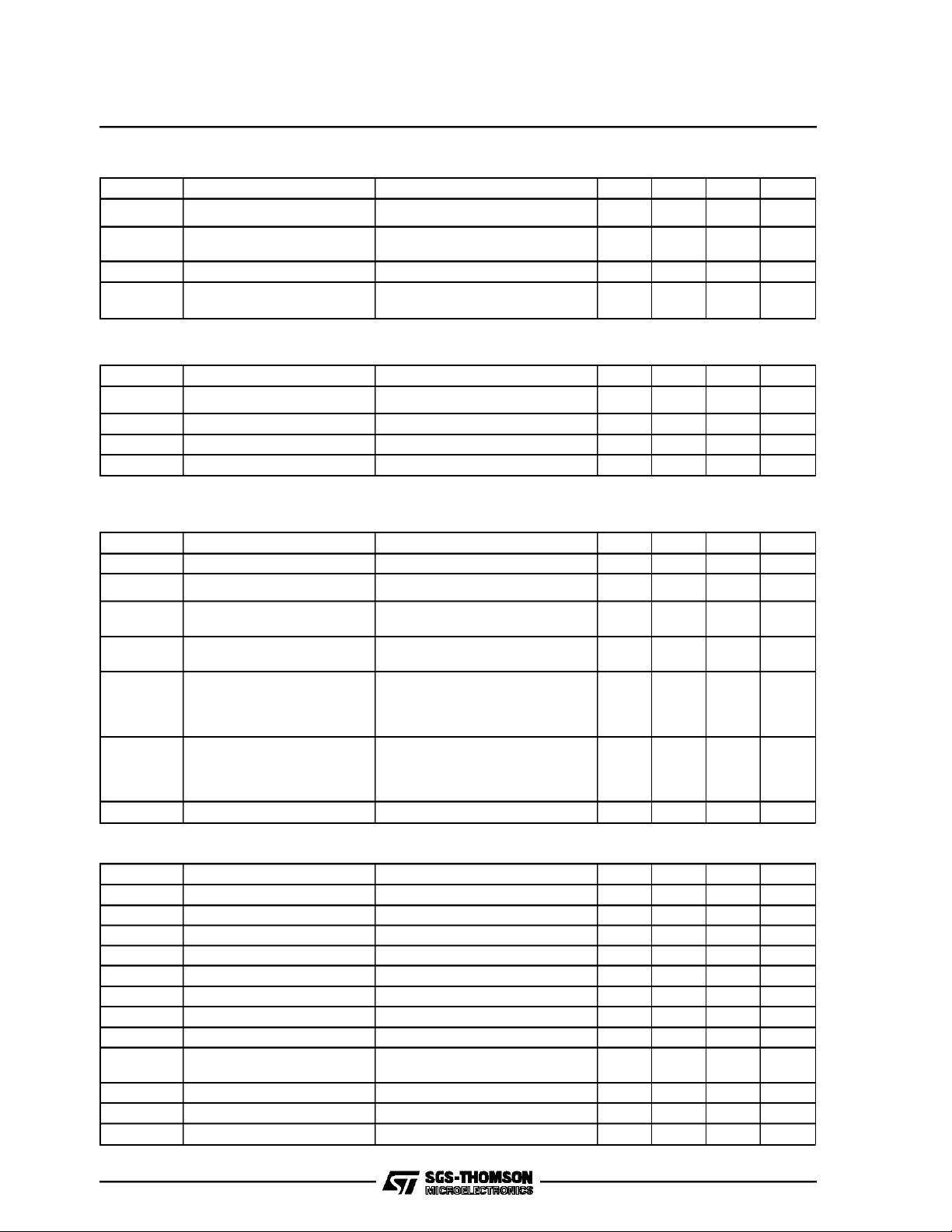

ELECTRICAL CHARACTERISTICS (Tj=25°C, Vs=5V, Vp= 24V unless othewise specified)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

p

I

p

V

s

I

s

LOGICLEVEL

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

inL

V

inH

I

inL

I

inH

CHANNEL A AND CHANNEL B (UNIPOLARMOTORS)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

R

DSONL

R

DSONH

Power Supply Voltage 9 26.5 V

Quiescent Power Supply

(note 1) 7 mA

Current

Logic SupplyVoltage 4.5 5.5 V

Quiescent Logic Supply

(note 1) 20 mA

Current

Input Low Voltage -0.3 1.35 V

Input High Voltage 3.15 VS+0.3 V

Input Low Current Vin =V

Input High Current Vin =V

inL

inH

-10 µA

10 µA

Low Side DMOS ON Res. IDS = 0.7A 1.2 Ω

High Side DMOS ON Res. IDS = 0.7A 1.2 Ω

I

DSSL

Low Side DMOS Leakage

VDS= 60V;output OFF 2 mA

Current

I

DSSH

High Side DMOS Leakage

VP = 30V; VO= 0V -1.5 mA

Current

V

REF

Voltage reference to the

Comparator

LEVEL 1

LEVEL 2

LEVEL 3

LEVEL 4

T

d

Turn OFF Delay on HIGH

Side DMOS afterthe

(note 2)

100

220

340

465

125

250

375

500

150

280

410

535

1 µs

Sensing Current Reach the

Threshold Value

f

max

Max Chopping Frequency 40 KHz

CHANNEL C (DC MOTORS)(see Fig.5)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

f

osc

DC Duty Cycle V2 = 1/2V

I

b2

V

low

R

DSONH

R

DSONL

I

LH

I

LL

V

fddc

f

max

V

boot

I

Lboot

Oscillator Frequency Cosc = 3.3nF; V1 = 2/3VS 17 22 28 KHz

S

72 75 81 %

Comparator Input Bias V2 = 200mV -1 µA

Open Drain Output I = 5mA 0.2 0.4 V

High Side DMOS ON Res. IDS= 0.7A 1.2 Ω

Low Side DMOS ON Res. IDS= 0.7A 1.7 Ω

HSD MOS Leakage Current VP= 30V; VO=0V -1 mA

LSD MOSLeakage Current VO = 30V; Vsense = 0V -1.5 mA

Forward Diode DC Voltage

I

= 0.7A 1.4 2 V

fdcc

(DMOS Diode)

Max Chopping Frequency 40 KHz

Voltage on pin Boot1 Vp+7 V

Leakage Currenton pin Boot1 V

bott=Vp

+12V; Vp= 26.5V 200 µA

mV

mV

mV

mV

4/16

ELECTRICAL CHARACTERISTICS (continued)

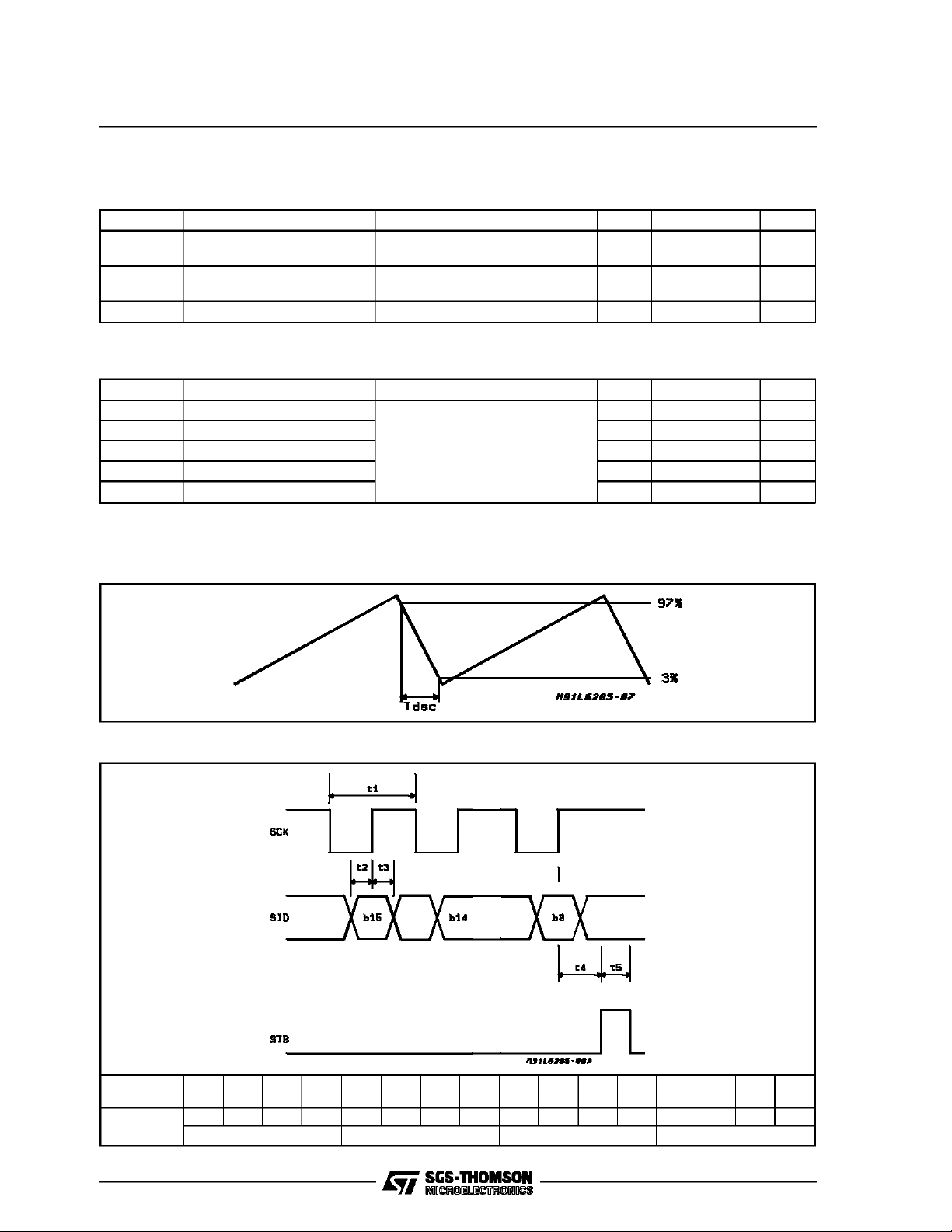

OSCILLATOR (see Fig.6)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

f

osc

Oscillator Frequency

COSC = 3.3nF; R

= 10KΩ 27 41 46 KHz

OSC

Pin OSC/RESET

V

T

dsc

reset

Capacitor Discharge Time

(protect deadtime)

C

= 3.3nF; R

OSC

(see Fig.1)

OSC

= 10KΩ

0.8 1.4 2 s

Reset Threshold Voltage 1 V

INTERFACE TIMING

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t1 SCK Data Clock Cycle (see Fig. 2) 200 ns

t2 SCK Data Set-upTime 30 ns

t3 SCK Data Hold Time 20 ns

t4 SCK-STB Interval Time 30 ns

t5 STB Pulse Width 100 ns

Note 1: No output loaded; all register tolow condition;no resetapplied; VP= 26.5V;VS= 5.5V

Note 2: The effectof theinternal filter (RC Network)is not considered.

L6285

µ

Figure 1: Discharge timet

or ProtectionTime

dsc

Figure 2: InterfaceTiming (Serialloading Mode)

Serial

Input Data

b15

b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

D15

D3 D2 D1 D0 D3 D2 D1 D0 D3 D2 D1 D0 D3 D2 D1 D0

Register 4 Register 3 Register 2 Register 1

D0

5/16

L6285

BLOCK DIAGRAM DESCRIPTION

(see Block Diagram)

Inside the I.C. there are two unipolarstepper mo-

tor drivers,one bridge driver for DC motor, 4x4 bit

latch registers, one shift register. the input logic,

the charge pump, and the thermal protection.

The following conditions are valid for all the 3

driver sections:

1)When the osc/respin is tied to GND, an internal reset signal is generated which switches

off all the outputs and resets the internal registers.

2)The conditions1 is valid also duringpower on

and power off transitions.

3)During power on and power off, the I.C. is

safe for any conditionsof V

and V

S

p

3)If Vpis present and VSdesappears, the outputs are switchedoff.

InputLogic

The input CMOS logic interfacesthe microprocessor logic to the 4 registers. An integrated Schmitttrigger circuit is used to improve noise immunity

ateach logic input.

The datais introducedin the 16bitshift register by

the SID pin. The first bit b 15 after 16 clock applied to SCK pin will be the D15 of the shift register.

On the falling edge of STB the 16 bits of the shift

register are transferred to the outputs of the 4

latchregisters. Fig 2shows the timing.

CHA and CHB Stepper Motor Drivers

Registers

The ComboMotor Driver controlsthe 3 channels using 4 latch registersof 4 bit each:

CHANNEL A

CHANNEL A

CHANNEL A

CHANNEL A

CHANNEL B

CHANNEL B

CHANNEL B

CHANNEL B

LEAST

MOST

LEAST

MOST

CHANNEL C

CHANNEL C

CHANNEL C

CHANNEL C

REGISTER 1

REGISTER 2

REGISTER 3

REGISTER 4

D0

D1

D2

D3

D0

D1

D2

D3

D0

D1

D2

D3

D0

D1

D2

D3

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

PHASE 1A

NPHASE 2A

PHASE 3A

NPHASE 4A

PHASE 1B

NPHASE2B

PHASE 3B

NPHASE4B

D/A CHANNEL A

D/A CHANNEL A

D/A CHANNEL B

D/A CHANNEL B

INPUT 1

INPUT 2

V2 VOLTAGE

V2 VOLTAGE

Register 1/2 Output Status (CHA and CHB). See note 1

D0 D1 D2 D3 OUT1 A/B OUT2 A/B OUT3 A/B OUT4 A/B

0

1

1

0

0

0

0

0

1

0

0

0

0

1

1

1

0

0

ALL THE OTHERS OFF OFF OFF OFF

0

0

1

1

1

0

0

0

0

0

0

0

0

0

0

1

1

1

OFF

ON

ON

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

OFF

OFF

OFF

OFF

Register 3 Current Reference (D/AOUTPUT)

DO D1 REFER. VOLTAGE CHANNEL A

0.125 V

0.250 V

0.375 V

0.500 V

6/16

0

0

1

1

0

1

0

1

D2 D3 REFER. VOLTAGE CHANNEL B

0

0

1

1

0

1

0

1

0.125 V

0.250 V

0.375 V

0.500 V

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

REGISTER4 (CHC).See note 2

D0 D1 D2 D3 OUT1 C OUT2 C

OFF

X

0

1

0

1

1

0

1

0

0

1

0

1

X

0

0

1

1

0

1

0

1

0

1

0

1

0

1

1

1

1

1

1

0

0

1

1

0

0

0

OFF

1

V

1

1

1

0

0

1

1

0

0

1

1

P

GND

GND

V

P

CHOPPING; V2 LOW LEVEL

V

P

CHOPPING; V2 HIGH LEVEL

OFF

V

P

OFF

V

P

OFF

OFF

GND

V

P

GND

CHOPPING; V2 LOW LEVEL

V

P

CHOPPING; V2 HIGH LEVEL

V

P

OFF

V

P

OFF

V

P

L6285

Note 1: Low side DMOS status (DM1/2 inFig. 4)

Note 2: Bridge status(see Fig. 3): OFF = tristate;V

P

Figure 3: CHC Chopping Characteristics

=,DM3/4ON; GND =DM1/2 ON

7/16

L6285

These two channels drive two unipolar stepper

motorsin choppingmode. The basic channel configuration is shown in Fig 4. by considering well

known the PWM Current Control Loop behaviour

here below only particular trick are underlined.

During DM3 off period the low side DMOS DM1

and DM2 are switched on to reduce the power

dissipation.

Figure.4: Unipolarmotor driver CHA(or CHB)

The drain overvoltagesgenerated because of the

stray inductance of the motor windings are limited

by connecting the DZ1 externalzener diode to the

clamp pin.. The diodes CL1 and CL2 are integrated as far as the CL3 diode which limits the

negative voltage at pin COM1.2. An internal RC

network (1µs) is realized to filter the sensing resistor signal.

8/16

L6285

CHC DC MotorDriver

The DC motor driver is a DMOS full bridge with a

PWM Open Loop Voltage Control. Fig.5 shows

the theory of operation. The C

Capacitor is

osc

charged by a constant current source. The oscillating voltage value is from 0V to the V1 level internally fixed at V1 = 2/3 V

. The output duty cy-

S

Figure.5:DC MotorDriver CHC

cle is controlled by the V2 voltage. The operational range of V2 is from 200mV to V1. Fig.3

shows the DMOS status during PWM: t

t

bridge configurations. While the PWM Duty

OFF

ON

and

Cycle defines the motor speed (not controlled

since the loop is open),the logic level of IN1 and

IN2 can choose the directionof the motor.

9/16

L6285

OscillatorFor Clock and Reset Generation

The oscillatorblock provides for two functions:

1)Generate an internal reset signal when the

voltage at pin osc/res is below 1V. The reset

signal switches off all the outputs and resets

the logic registers.

2)Generate,when the pin osc/resis left freetwo

syncro signals p1 and p2 for the clock of the

PWM Current Control of the two stepper

driverblocks

The oscillator operates like the 555 concept in

Figure 6: Oscillator Concept

which the capacitor voltage oscillates between

1/3V

2/3VS(Fig.6). The oscillator frequencyis 2

S

times the choppingfrequency in orderto generate

the two syncro signals at operative 20KHz PWM.

The t

V

TH1

The discharge time T

= charge timeof Cosc is defined by R

CH

and V

( thresholdvoltages)and C

TH2

is practically only defined

dsc

osc

osc

.

by Cosc and the internal discarge resistor Rdsc.

The t

is also the time lockout during which the

dsc

RS FF cannot read the Comparator output (see

Fig. 4)

,

10/16

L6285

Charge Pump

The charge pump circuitry generates the overvoltage needed to drive the gate of the high side output DMOS power transistors.It is realized by using two external capacitors (C1 and C2) and two

integrateddiodes thatoperate as a fullwave recti-

Figure 7: Charge Pump Circuit

fier (see Fig. 7). The oscillator peak to peak output voltage is stored by C2 and summed to the

Power Supply Voltage V

..

p

The voltagepresent at the pin BOOT1,is then the

overvoltageneeded to supply the gate of the high

side DMOS drivers.

THERMAL PROTECTION

The thermal protection shuts down the chip be-

A0TH A1TH THERMAL PROTECTION CIRCUIT STATUS

0

1

1

0

0

0

1

1

OK

PREALARM

ALARM

NOT POSSIBLE

APPLICATION INFORMATION

A typical application circuit is shown in Fig.8. By

this application it is possible to drive twounipolar

stepper motors (M1,M2) and one DC motor(M3).

As it can be seen, only two external Zener diodes

(D1,D2) are needed to clamp the voltage transients generated by the stray inductance of the

motor windings. This is recommended when the

peak current is not more than three to four hundred mAmps. For a power supply voltage of

=24V ±10%, D1=D2 must be 30V ±5%-1W

V

P

(1N4751A or equivalent).Both the V

and the V

P

pins need bypass capacitors (C1,C2,C3); to supply the high-side DMOS (Source Transistors) at

pin.15 ,only two externalcapacitors (C4,C5) complete the charge pump circuitry. The oscillator frequency, that is twice the chopping frequency for

M1 and M2, is mainly defined by the network

R6C6:

=[0.69 (Rch+Rdsc)C

f

osc

R

=R6 ; R

ch

dsc

=600 ohm typ.

]-1, where

osc

fore itcan reach adangerous temperature.

Additional informations to the microprocessor are

availableat the A0TH, A1THpins.

OPERATING

OPERATING

THERMAL SHUTDOWN

At the same time, the lockoutduration (or protection window) needed for a correct chopping behavior,is given by :

lockout

= 0.69 R

dscCosc

T

The shown values (fig.8) give a nominal fre-

quency a little bit more than 41KHz and a protectionwindow of 1.4 µs roughly.The Schottkydiode

D3 and thepull-up resistor R5 driven viaan opencollector transistor can generate the Reset function. The chopping current is sensed across R1

A/B; R2 A/B that must be of a not inductive type.

S

The DC motor PWM Open Loop Voltage Control

operates at a frequency defined by C7, charged

with a typical constant current source (I = 240

µA), up to V1 = 0.67 V

S

time is very short,it can be written:

f

osc

=I/C

V1, where C

osc

Tha values indicated in figure give a typical frequencyof about 22 KHz.

. Since the discharge

= C7.

osc

11/16

L6285

Figure 8: Typical Application Circuit

The duty cycle DC can be chosen between two

possibilities (High and Low ) than can be defined

externally by the resistors R7, R8 and R9: Fig.5

let well understand how to calculate the dividers

that fix V2 H (wider t

) and V2 L (wider t

on

off

). It

may be needed to drive stepper motors that require a higher peak current than told above. In

this case each motor phase requires a particular

application arrangement(see Fig.9b).In Fig.9aall

Figure 9a: Output Configuration as it is obtained

by the ApplicationCircuit

the protection components are integratedwith the

exception of Z1. In Fig.9b the clamp of the voltage spikes generated by the stray inductance Ls

is achieved using Transil protection T1 and T2

that works also as additional diodes during current recirculation at the phase change. The diode

D1, externally connected, is recommended at the

highest working current levels and/or when the

supplied voltage (plus Back EMF) at the end of

the motor windingis too much unbalanced.

Figure9b: OutputConfiguration at HigherOper-

ating Currents

12/16

L6285

THERMAL CHARACTERISTICS

The cooling of the device is obtained by soldering

its ground pins on a proper p.c.b copper side ,

acting as a true heatsink. By considering four

squared side as in Fig.10, the junction to ambient

Figure 10: Four ”on board” Square Heatsink

thermal resistance has been measured (see

Fig.11). The typical transient thermal resistance

versus values of single pulse width of power is

shown in Fig.12. In general these thermal characteristics are very important to the designer to optimizethe L6285 applications.

Figure 11: Typical R

vs.lenght ”l” (Fig. 10)

th j-amb

Figure12: TypicalTransient Thermal Resistance

vs.Time or PulseWidth

13/16

L6285

SDIP42PACKAGE MECHANICALDATA

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 5.08 0.20

A1 0.51 0.020

A2 3.05 3.81 4.57 0.120 0.150 0.180

B 0.36 0.46 0.56 0.0142 0.0181 0.0220

B1 0.76 1.02 1.14 0.030 0.040 0.045

c 0.23 0.25 0.38 0.0090 0.0098 0.0150

D 37.85 38.10 38.35 1.490 1.50 1.510

E 15.24 16.00 0.60 0.629

E1 12.70 13.72 14.48 0.50 0.540 0.570

e 1.778 0.070

e1 15.24 ‘0.60

e2 18.54 0.730

e3 1.52 0.060

L 2.54 3.30 3.56 0.10 0.130 0.140

E

E1

A2

A1

LA

BeB1

D

42

1

22

F

21

c

SDIP42

e1

e2

E

.015

0,38

Gage Plane

e3

e2

14/16

PLCC44 PACKAGE MECHANICAL DATA

L6285

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 17.4 17.65 0.685 0.695

B 16.51 16.65 0.650 0.656

C 3.65 3.7 0.144 0.146

D 4.2 4.57 0.165 0.180

d1 2.59 2.74 0.102 0.108

d2 0.68 0.027

E 14.99 16 0.590 0.630

e 1.27 0.050

e3 12.7 0.500

F 0.46 0.018

F1 0.71 0.028

G 0.101 0.004

M 1.16 0.046

M1 1.14 0.045

mm inch

15/16

L6285

Information furnished is believed to be accurateand reliable. However, SGS-THOMSON Microelectronicsassumes no responsibility for the

consequences of use of such informationnor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of SGS-THOMSON Microelectronics.

1994 SGS-THOMSON Microelectronics - All RightsReserved

SGS-THOMSON Microelectronics GROUP OFCOMPANIES

Australia- Brazil- France - Germany -Hong Kong - Italy - Japan- Korea -Malaysia - Malta - Morocco - The Netherlands- Singapore - Spain

- Sweden- Switzerland - Taiwan - Thaliand - United Kingdom - U.S.A.

16/16

Loading...

Loading...