L6275

5V DISK DRIVE SPINDLE & VCM, POWER

& CONTROL“COMBO”

PRODUCT PREVIEW

GENERAL

5V (+/-10%)OPERATION.

REGISTERBASEDARCHITECTURE

MINIMUMEXTERNAL COMPONENTS

BICMOS+ VERTICAL DMOS(1.5mm)

VCM DRIVER

1.5ADRIVE CAPABILITY

0.9Ω TOTALBRIDGE IMPEDANCEAT 25°C

LINEARMODE

PHASESHIFT MODULATION(PWM MODE)

INSTANTANEOUS, (GLICH FREE) SWITCH

BETWEENTHE 2 MODES

CLASS ABOUTPUT DRIVERS

ZEROCROSSOVERDISTORSION

14 BIT DACDEFINEOUTPUT CURRENT

SELECTABLETRANSCONDUCTANCE

4 PROGRAMMABLEPARKING VOLTAGE

DYNAMICBRAKE

SPINDLEDRIVER

2.0ADRIVE CAPABILITY

0.8Ω TOTALBRIDGE IMPEDANCEAT 25°C

BEMF, INTERNAL OR EXTERNAL, PROC-

ESSING

SENSOR-LESSMOTOR COMMUTATION

PROGRAMMABLE COMMUTATION PHASE

DELAY

LINEARMODEAND CONSTANT TOFF PWM

OPERATIONMODE

INTERNAL FREQUENCY LOCKED LOOP

SPEEDCONTROL (FLL)

BEMFRECTIFICATIONDURING RETRACT

BUILT-INALIGNAMENT&GOSTART-UP

INDUCTIVE SENSINGSTART UP OPTION

RESYNCHRONIZATION

DYNAMIC& REVERSEBRAKE

CONTROLLABLEOUTPUTSLEWRATE

OTHER FUNCTIONS

5V MONITORING WITH EXTERNAL SET

TRIP POINTSAND HYSTERESIS

POWERUP/DOWN SEQUENCING

LOW VOLTAGESENSE

BICMOS TECHNOLOGY

TQFP44 (10x10mm)

ORDERING NUMBER: L6275

3.3V INPUTLOGIC COMPATIBILITY

THERMAL SHUTDOWN AND PRETHERMAL

WARNING

SYSTEMCLOCK WATCHDOG

DESCRIPTION

The L6275 integratesinto a single chip both spindle and VCM controllers as well as power stages.

The device isdesigned for 12V disk drive application requiring up to 2.0A of spindle and 1.5A of

VCM peak currents.

A serial port with up to 25 MHz capabilityprovides

easy interface to the microprocessor. A register

controlled Frequency Locked Loop (FLL) allows

flexibility in setting the spindle speed. Integrated

BEMF processing, digital masking, digital delay,

and sequencingminimize the number of external

componentsrequired.

Power On Reset (POR)circuitry is included. Upon

detection of a low voltage condition, POR is asserted, the internal registers are reset, and spindle powercircuitry is tri-stated.The BEMF is rectified providing power for actuator retraction

followed bydynamicspindle braking.

The device is built in BICMOS technology allowing dense digital/analog circuitry to be combined

with a highpower DMOS outputstage.

April 1999

This is preliminaryinformation on a new product now in development. Details are subject to change without notice.

1/17

L6275

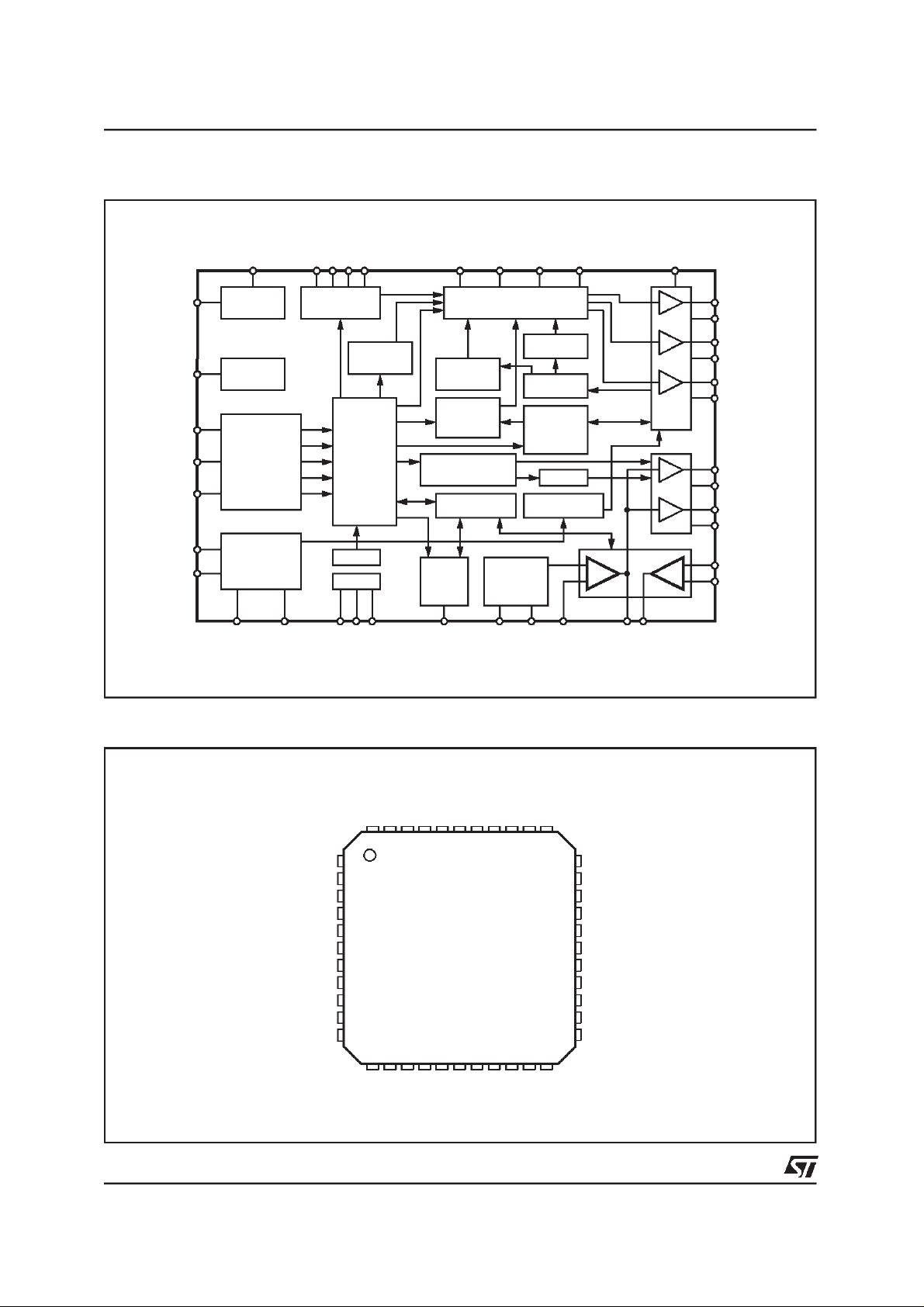

BLOCK DIAGRAM

SW1

SDATA

SCLK

SDEN

CLK_MON

TR_5V

CS

CP

CHARGE

PUMP

ISO

DRIVER

SERIAL

INTERFACE

SUPPLY

CLOCK FAULT

&

MONITORS

POR_DELAY

PORB

FLL_RES

FLL_FILTER

INDEX

FREQUENCY

LOCK LOOP

START-UP

REGISTERS

THERMAL

SUPPLY

VDD

SYS_CLK

GND

DGND

FCOM

SPINDLE SEQUENCER

RE_SYNC

DYNAMIC/

REVERSE

BRAKE

VCM CURRENT

CONTROL PSM/LIN

VCM

CALIBRATION

BIT

DAC

REFERENCE

GENERATOR

14

VCM DAC

SPN_COMP

PROCESSING

ZERO CROSS

VOLTAGE

V5/2

BRK_CAP

PWM/SLEW

BEMF

DETECTION

SPINDLE

CURRENT

CONTROL

PWM/LIN

PARKING

BEMF

RECTIFICATION

VCM_CAL

ERROR_IN

+

-

A

B

C

A+

A-

A=4

SENSE_OUT

ERROR_OUT

VDD

+

D99IN1050

OUT_A

CTAP

OUT_B

RSENSE

OUT_C

ISENSE

VCM_A+

VDD

VCM_AVCM_GND

SENSE_INSENSE_IN+

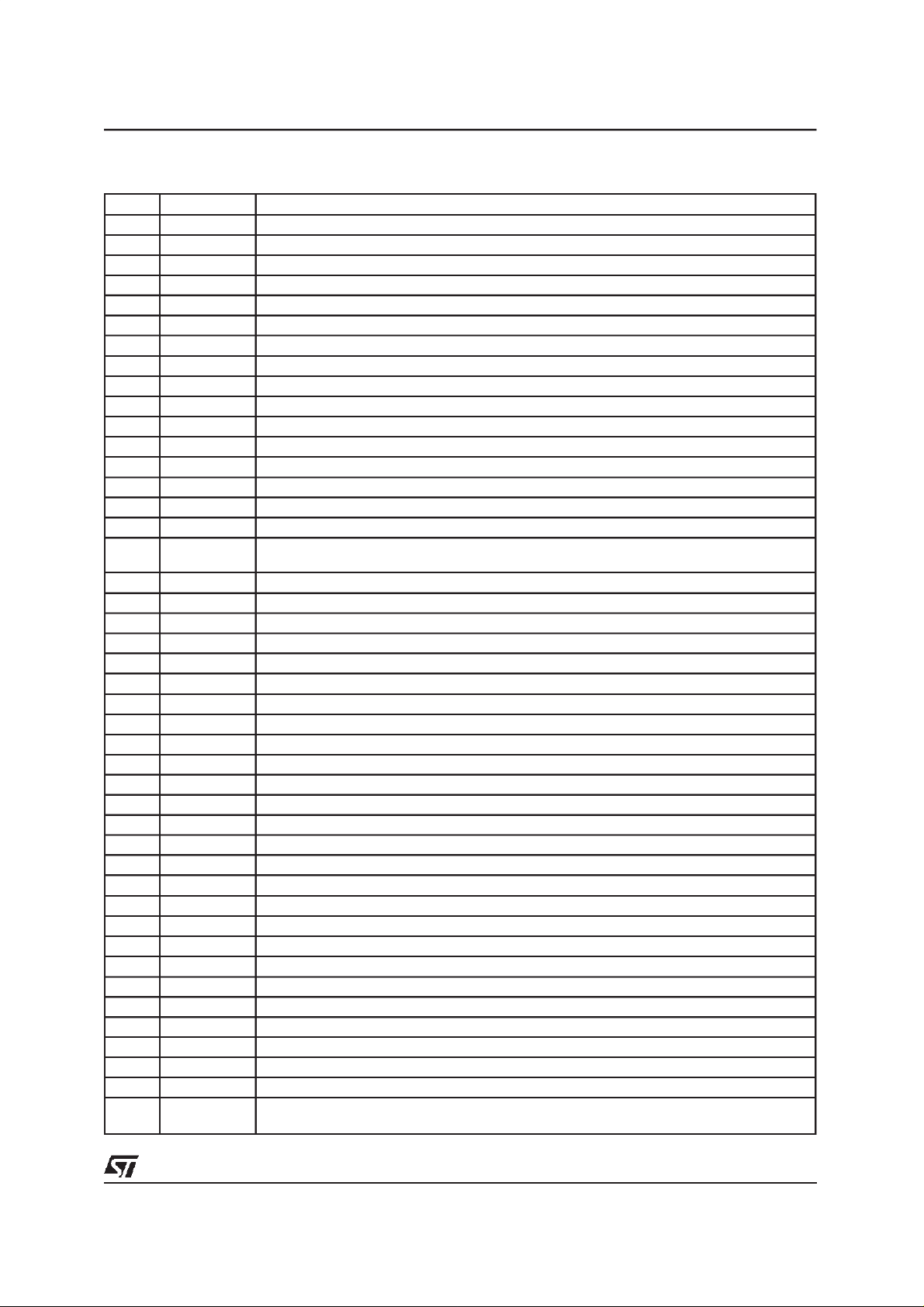

PIN CONNECTION

2/17

FCOM

CTAP

PWM/SLEW

OUT_C

I_SENSE

R_SENSE

OUT_B

GND

R_SENSE

OUT_A

INDEX

SPN_COMP

VDD

AGND

DAC

ERROR_IN

CLK_MON

ERROR_OUT

SENSE_OUT

44 43 42 41 3940 38 37 36 35 34

1

2

3

4

5

6

7

8

9

10

12 13 14 15 16

VDD

BRK_CAP

DGND

SDEN

SYS_CLK

171118 19 20 21 22

VDD

SCLK

SDATA

POR_DELAY

TR_5V

PORB

V5/2

VCM_CAL

FLL_FILTER

33

32

31

30

29

28

27

26

25

24

23

SW1

FLL_RES

VDD

VCM_A+

SENSE_INVCM_GND

SENSE_IN+

VCM_AVDD

CS

CP

D99IN1051

PIN DESCRIPTION(PinTypes: D = Digital,P = Power,A = Analog)

N. Name Function

1 FCOM Output of the Spindle zero cross or Current Sense circuit.

2 CTAP Spindle Central Tap used for differential BEMF sensing.

3 PWM/SLEW RC network sets the Spindle Linear Slew Rateand PWM OFF-Time.

4 OUT_C Spindle DMOS Half Bridge Output and Input C for BEMF sensing.

5 I_SENSE Input to sense the voltage the SPINDLE Sense Resistor.

6 R_SENSE Output connection for the Motor Current Sense Resistor to ground.

7 OUT_B Spindle DMOS Half BridgeOutput and Input B for BEMF sensing.

8 GND Spindle Ground (Substrate).

9 R_SENSE Output connection for the Motor Current Sense Resistor to ground.

10 OUT_A Spindle DMOS Half Bridge Output and Input A for BEMF sensing.

11 INDEX Input to allow Spindle to be locked to Index (servo) pulse.

12 BRK_CAP Storage Capacitor for brake circuit. typically 5.9V.

13 VDD +5V Power Supply for Spindle Power section.

14 DGND Digital Ground.

15 SYS_CLK Clock Frequency for system timers and counters.

16 SDEN Serial DataEnable. Active high input pin for the serial port enable.

17 SDATA Serial Port Data. Input/Output pin for serial data, 8bits of instruction/address followed by 8

bits of data. Open pin is at logic low as an input.

18 SCLK Serial Port Data Clock. Positive edge triggered clock input for the serial data.

19 VDD Digital/Analog power supply. +5V nominally.

20 V12/2 Reference Output for VCM control loop. Typically, half of the VCC except when parking.

21 FLL_FILTER Speed loop R/C compensation connection used for FLL mode operation.

22 VCM_CAL VCM loop offset voltage used forcalibration.

23 CP External Main Charge Pump Capacitor, Typically, Vz+Vcc is about 17.8V

24 CS External Charge Pump Capacitor.

25 VDD +5V Power Supply for VCM Power section.

26 VCM_A- VCM Power Amplifier negative output terminal.

27 SENSE_IN+ Non inverting Input of the Sense Amplifier for VCM block.

28 VCM_GND Ground for VCM Power section.

29 SENSE_IN- Inverting Input of the Sense Amplifier for VCM block.

30 VCM_A+ VCM Power Amplifier positive output terminal.

31 VDD +5V Power Supply for VCM Power section.

32 FLL_RES Resistor for setting accurate bias current sources for the chip (62K required).

33 SW1 External ISOFET driver.

34 PORB Power on Reset Output. Low signal indicates the failure of the supplies.

35 TR_5V Set Point Input for 5V Supply Monitor ( 2Vthreshold, 100mV Hysteresis)

36 POR_DELAY Capacitor connection to set the Power on Reset Delay (3V threshold, 2µA charging)

37 SENSE_OUT Output of the Sense Amplifier.

38 ERROR_OUT Output of the Error Amplifier.

39 ERROR_IN Inverting Input of the Error Amplifier.

40 CLK_MON Watchdogclock monitoring pin

41 DAC Output of the VCM DAC.

42 AGND Analog Ground. For bang gap voltage reference.

43 VCC +12V Power Supply for Spindle Power section.

44 SPN_COMP External RC network that defines the compensation of theSpindle Transconductance Loop

in Linear Mode.

L6275

3/17

L6275

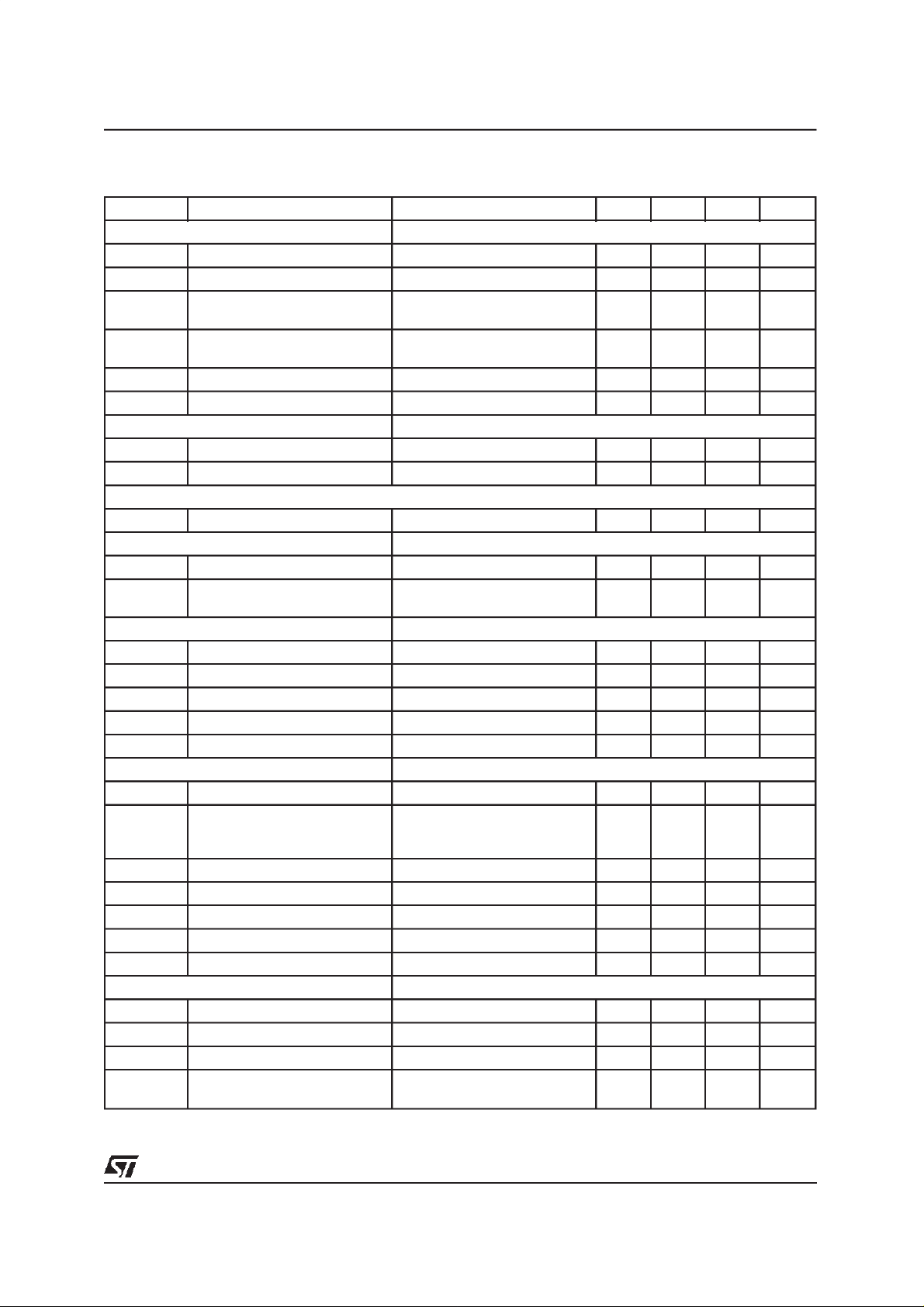

ABSOLUTEMAXIMUM RATINGS

Symbol Parameter Value Unit

V

CC

V

dd

V

in max

V

in min

SPINDLE I

VCM I

peak

P

(*) Maximum Total Power Dissipation ≈ 1.7 W

tot

T

stg,Tj

THERMAL DATA

Symbol Parameter Value Unit

R

th j-case

R

th j-amb

(*) In typicalapplication with multilayer 120X120mm Printed Circuit Board

Maximum Supply voltage -0.5 to 14 V

Maximum Logic supply -0.5 to 6 V

Maximum digital input voltage Vdd+0.3V V

Minimum digital input voltage GND - 0.3V V

Spindle peak sink/source output current 2.1 A

peak

VCM peak sink/source output current 1.6 A

Maximum Storage/Junction Temperature -40 to 150 °C

Thermal Resistance Junction to Case ≈ 20 °C/W

(*) Thermal Resistance to Junctionto ambient

40 °C/W

≈

RECOMMENDED OPERATINGCONDITIONS

Symbol Parameter Value Unit

V

dd

T

amb

T

j

ELECTRICAL CHARACTERISTICS

Supply Voltage 4.5 to 5.5 V

Operating Ambient Temperature 0 to 70 °C

Junction Temperature 0 to 125 °C

(All specifications are for 0 < T

<70°C, VCC= 12V; VDD= 5V,

amb

FLL_RES= 62kΩ, unlessotherwisespecified.)

Symbol Parameter Test Condition Min. Typ. Max. Unit

POWER SUPPLIES

V

rectified

V

dd

I

Vdd

THERMAL SENSING

T

SD

T

HYS

T

EW

VCCSupply Rectified 3.5 13.2 V

5V supply 4.5 5.5 V

5V supply SPINDLE + VCM 6 mA

SPINDLE ONLY 7 mA

VCM ONLY 12 mA

Shutdown Temperature 150 180 °C

Hysteresis 60 °C

Early Warning TSD-25 °C

4/17

ELECTRICALCHARACTERISTICS (Continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

SUPPLY MONITOR

V

TR

V

HYS

I

DLY

R

on_por

V

DLY

I

IN

VOLTAGE BOOST

V

BOOST

F

osc

SYSTEM CLOCK WATCHDOG

Min_Clk Min. System Clock Time 7 10 13 µs

SW1 OUTPUT

R

GATE

V

GATE

DIGITAL LOGIC LEVELS

V

IH

V

IL

V

OH

V

OL

F

SYSCLK

VCM, DAC

T

C

VCM, ERROR AMPLIFIER

A

VOL

V

OS

I

IB

V

ICM

Trip Point Input Rising 1.92 2 2.08 V

Hysteresis Voltage Input falling 100 mV

Porb Delay Current TR_5V, TR_12V > V

TR

1.5 2 2.5

Vpordly = 2V

Porb Pull Down Ron Vdd> 2V and sink 1mA

V

=2V

pordly

Porb Dly Threshold TR_5V > V

TR

2.0 V

500

Input Current VIN<4V -1 1 µA

Output Voltage Vdd+5 Vdd+6.3 V

Internal Oscillator 130 200 250 kHz

Gate Driver for External Mosfet Internal Resistor to CP 200 kΩ

Off Gate State Voltage for

IO= 1mA Vdd= 3.5V 0.7 V

External Mosfet

Input Logic ”1” 2.5 V

Input Logic ”0” 0.5 V

Output Logic ”1” I

Output Logic ”0” I

=20µAV

SOURCE

= -400µA 0.4 V

SOURCE

-0.2 V

dd

System Clock 20 25 MHz

Resolution 14 Bits

Differential Linearity 1 LSB Change

-Tested

-By design

-1

-0.5

1

0.5

Integral Linearity 9 Bits

Midscale Offset Referenced to V

/2 -5 5 mV

CC

Convertion Time 5 µs

Full Scale Voltage Referenced to V

/2 ±1V

CC

Full Scale Error -4 4 %

Open Loop Gain DC 50 db

Input Offset Voltage -5 5 mV

Input Bias Current --250 250 nA

Input Common Mode Range VCC/2-

0.5

VCC/2+

0.5

L6275

A

µ

Ω

LSB

V

5/17

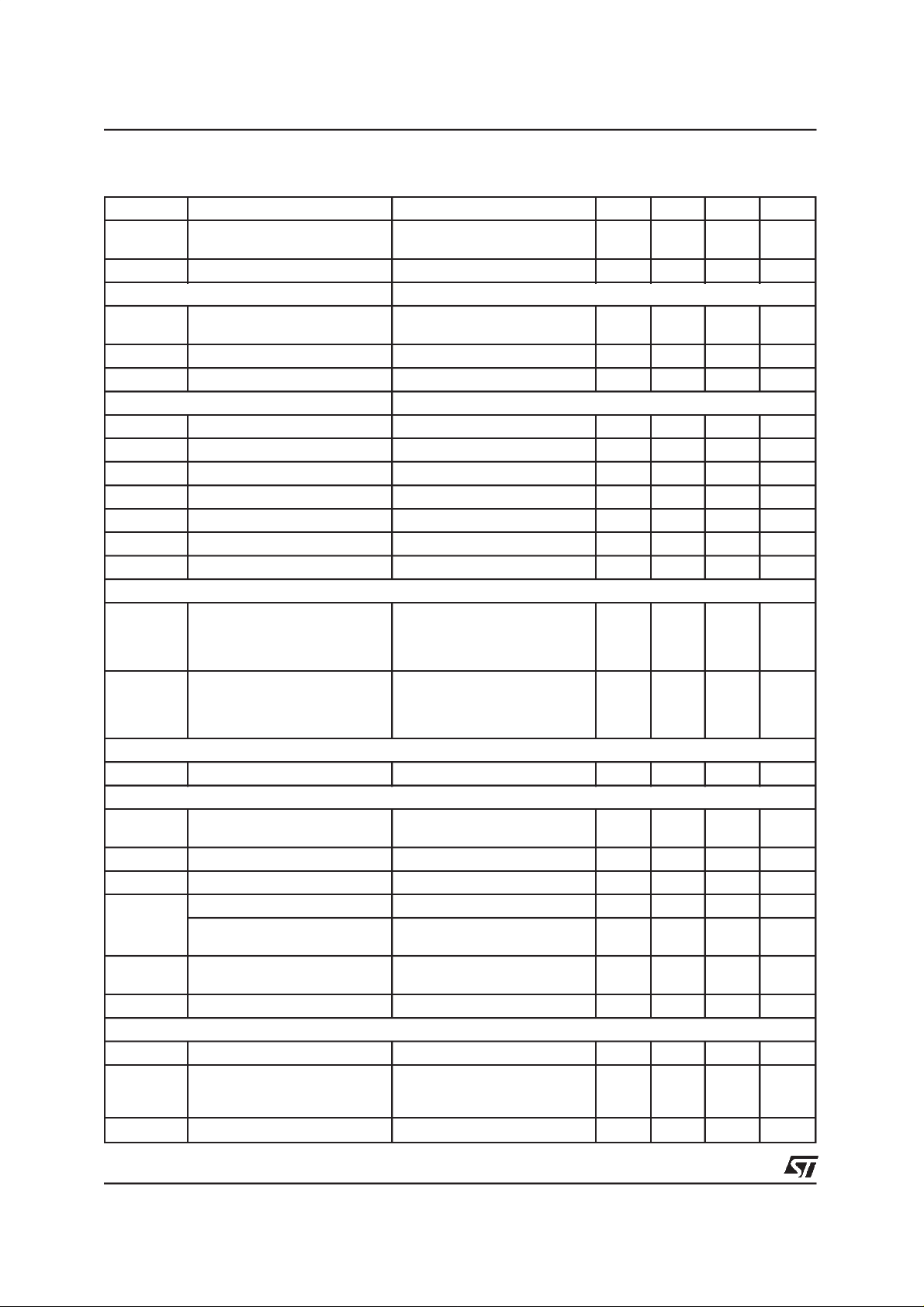

L6275

ELECTRICALCHARACTERISTICS (Continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

Vclamp Output Clamp Voltage -1mA < I

Lowside/Highside clamp

F

ODB

Unity Gain Bandwidth 10 MHz

VCM, POWER STAGE

R

DS(ON)

I

O

I

O(LEAK)

Output ON Resistance (Each

device)

Tj=25°C

T

= 125°C

j

Operating Current 1.3 A

Output Leakage Current VCC= 5.5V 1.0 mA

VCM, CURRENT SENSEAMPLIFIER

V

V

F

A

OCM

V

V

ICM

OS

3dB

Voltage Gain 3.88 4 4.12 V/V

Input Common Mode Range -0.3 Vdd+0.3 V

Output Common Mode Range -3mA < IO<3mA 2 Vdd-2 V

Output Offset Voltage SENSE_IN (±)=Vdd/2 -15 15 mV

3dB Bandwidth 1 MHz

CMRR Input Common Mode Rejection 50 dB

PSRR Power Supply Rejection Ratio 60 dB

VCM, RETRACT

V

park

RETRACT VOLTAGE PKV_1= 0 & PKV_2 = 0

PKV_1 = 0 & PKV_2 = 1

PKV_1 = 1 & PKV_2 = 0

PKV_1 = 1 & PKV_2 = 1

Tretract Retract Time

limited by the internal oscillator

200kHz

RT0 = 0 & RT1 = 0

RT0 = 0 & RT1 = 1

RT0 = 1 & RT1 = 0

RT0 = 1 & RT1 = 1

SPINDLE, PWM CURRENT SENSE COMPARATOR

T

DLY

Delay to FCOM Out 200 500 ns

SPINDLE, POWER STAGE

R

DS(ON)

I

O

I

O(LEAK)

dV

O/dt

Output On Resistance (Each

device)

Tj=25°C

T

= 125°C

j

Start-Up Current 2A

Output Leakage Current VCC = 14V 1.0 mA

Output Slew Rate (Linear) R

slew

Output Slew Rate (PWM) Reg#8Eh, Bit 0 = 0

Reg#8Eh, Bit 0 = 1

BEMF

Minimum BENF Voltage for

MIN

Detection

V

HYS

Hysteresis 15 mV

FLL CHARGE PUMP OUTPUT

I

LEAK

I

O

Off State Leakage 0 < Vfll_res , 3V -50 +50 nA

On State Current FLL_RES = 62k

ICP = ”1”

ICP = ”0”

V

RCP

Current Set Voltage FLL_RES = 62k

<1mA

O

Vdd/2

±

1.4V

0.5

0.8

0.850

0.650

1.600

1.150

160

320

80

160

0.45

0.74

= 100kΩ 0.2 0.3 0.5 V/µs

10

20

20 28 40 mVp-p

Ω

22

80

Ω

1.18 1.225 1.25 V

25

100

32

120

V

Ω

Ω

mV

mV

mV

mV

ms

ms

ms

ms

Ω

Ω

V/µs

V/µs

µA

A

µ

6/17

ELECTRICALCHARACTERISTICS (Continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

CURRENT SENSE AMPLIFIER

I

BIAS

Av Voltage Gain 3.8 4.0 4.2 V/V

dV

o/dt

SERIAL PORT

Symbol Parameter Min. Typ. Max. Unit

T

SCK

T

CKL

T

CKH

T

SDENS

T

SDENH

T

DS

T

DH

T

SDENL

T

SDV

T

SDV

Input Bias Current 2

Output Slew Rate 20 V/µs

SCLK Period 40 ns

SCLK low time 15 ns

SCLK high time 15 ns

Enable to SCLK 35 ns

SCLK to disable 20 ns

Data set-up time before rising edge SCLK 10 ns

Data Hold Time 10 ns

Minimum SDEN Low Time 50 ns

SCLK falling edge (A6) to SDATA valid on READ op. 3 10 ns

SCLK rising edge (D0-D7) to SDATA Transition onREAD op. 5 35 ns

L6275

A

µ

Figure 1. SerialPort Timing Information.

SDEN

SCLK

SDATA

SDEN

SCLK

SDATA

0A0A1

1st Byte 2nd Byte

1A0A1

1st Byte 2nd Byte

A6 D0 D1 D2 D7

SERIAL PORT WRITE TIMING

A6 D0 D1 D2 D7

SERIAL PORT READ TIMING

D98IN844

7/17

L6275

SERIAL PORTOPERATION

The serial port interface is a bi-directionalport for reading and writing programming data from/to the internal registers of this device. For data transfers SDEN* is brought high, serial data is presented at the

SDATA pin, and a serial clock is applied to the SCLK pin. After the SDEN* goes high , the first 16 pulses

applied to the SCLK pin will shift the data presented at the SDATA pin into an internal shift register on

the rising edge of each clock. An internal counterprevents more than 16 bits from being shifted into the

register. The data in the shift register is latched after the 16th SCLK pulse. If less than 16 clock pulses

are provided beforeSDEN* goes low,thedata transferis aborted.

All transfers are shifted into the serial port LSB first. The first byte of the transfer is for R/W and address

and instructioninformation.Thefirst bit is R/W instructionbit, 0 is for WRITE and 1 is for READ.

Following7 bitsare Address.

Figure 2. SerialPort Data Transfer Format.

SDEN

SDATA

INSTRUCTION, 1 BIT

ADDRESS, 7 BITS

DATA, 8 BITS

SCLK

D98IN845

INTERNALREGISTER DEFINITION

Reg:

Name:

Type:

Address:

BIT LABEL DESCRIPTION

0 VDAC BIT8 VCM DAC bit 8

1 VDAC BIT9 VCM DAC bit 9

2 VDAC BIT10 VCM DAC bit 10

3 VDAC BIT11 VCM DAC bit 11

4 VDAC BIT12 VCM DAC bit 12

5 VDAC BIT13 MSB resistor ladder of the14 bit VCM DAC

6 PSM/LINEAR Selects Voice Coil PSM or Linear Output Current Control. 1=PSM

7 VCM_CAL VCM calibration. 1 = Enables VCM control circuits and tristates

0

VCM DAC (High)Register

Write only

0Eh

0=Linear.

VCM power transistors.

8/17

L6275

INTERNALREGISTER DEFINITION

VCM DAC (High and Low)Registers

Bit 0 through 5 of the VCM DAC (High) Registers and bit 0 through 7 of the VCM DAC (Low) Registers

control the absolute value of the voice coil current. Bit is the sign bit, controlling the current direction. All

the 13 bits are part of a resistordividernetwork.

Note. Itis requiredto write on register 1 to make effectivechangeson register 0.

Reg:

Name:

Type:

Address:

BIT LABEL DESCRIPTION

0 VDAC BIT0 LSB resistor ladder of the 14 bit VCM DAC

1 VDAC BIT1 VCM DAC bit 1

2 VDAC BIT2 VCM DAC bit2

3 VDAC BIT3 VCM DAC bit3

4 VDAC BIT4 VCM DAC bit4

5 VDAC BIT5 VCM DAC bit5

6 VDAC BIT6 VCM DAC bit6

7 VDAC BIT7 VCM DAC bit7

Reg:

Name:

Type:

Address:

1

VCM DAC (Low) Registers

Write only

1Eh

2

Spindle ControlRegister

Write only

2Eh

BIT LABEL DESCRIPTION

0 INCRE_SEQ A 0 to 1 transition of this bit increments the spindle Sequencer.

1 START_UP 1 = Spindle Internal start up, 0 = Spindle External start up

2 R_SEQ Reset Spindle sequencer. 1 = Reset sequencer to phase 1.

3 RUN 1 = Start Spindle ALIGN & GO, 0 = Reset Spindle control logic.

4 SPIN_EN Enable Spindle section. 1 = Enable, 0 = Disable.

5 MEC/ELEC Specifies electrical or mechanical cycle for Spindle FLL control.

6 PWM/LINEAR Selects Spindle PWM or Linear Output Current Control. 1 = PWM,

7 EXT/INT External or internal Spindle loop feedback. 1 = external feedback

1=Electrical, 0 = Mechanical.

0=Linear.

via index pin.

9/17

L6275

INTERNALREGISTER DEFINITION

Reg:

Name:

Type:

Address:

BIT LABEL DESCRIPTION

0 MASK_TIME Spindle BEMF Mask Time. 0 = 15 degree, 1 = 7.5 degree

1 MIN2 Control Spindle PWM on time Min 1 Min2 Min.on Time

2 MIN1 0 1 1.4µs

3 8_12_POLE Selects 8 or 12 pole motors.1 = 8 pole, 0 = 12 pole.

4 SD3 Spindle commutation delay MSB

5 SD2 Spindle commutation delay bit

6 SD1 Spindle commutation delay bit

7 SD0 Spindle commutation delay LSB

3

Spindle DelayRegister

Write only

3Eh

0 0 5.9µs

10 12

1 1 5.21µs

s

µ

SPINDLEPHASE DELAY

SD3-0 set the phase delay from BEMF zero crossing to the next commutation.The30 theoreticaldegree

value can be changed to compensatefor switching and other delays that are always present. The delay

adjustmentrange is from 1.875 throughto 30 electricaldegreesin 1.875 degree increments.

Reg:

Name:

Type:

Address:

BIT LABEL DESCRIPTION

0 C4 Bit 4 of Spindle FLL Coarse Counter

1 C5 Bit 5 of Spindle FLL Coarse Counter

2 C6 Bit 6 of Spindle FLL Coarse Counter

3 C7 Bit 7 of Spindle FLL Coarse Counter

4 C8 Bit 8 of Spindle FLL Coarse Counter

5 C9 Bit 9 of Spindle FLL Coarse Counter

6 C10 Bit 10of Spindle FLL Coarse Counter

7 C11 MSB of Spindle FLL Coarse Counter

10/17

4

FLL Coarse Counter Register

Write only

4Eh

INTERNALREGISTER DEFINITION

L6275

Reg:

Name:

Type:

Address:

BIT LABEL DESCRIPTION

0 F8 Bit 8of Spindle FLL Fine Counter

1 F9 Bit 9of Spindle FLL Fine Counter

2 F10 MSB of Spindle FLL Fine Counter

3 Unused. Set = 0

4 C0 LSB of Spindle FLL Coarse Counter

5 C1 Bit 1 of Spindle FLL Coarse Counter

6 C2 Bit 2 of Spindle FLL Coarse Counter

7 C3 Bit 3 of Spindle FLL Coarse Counter

Reg:

Name:

Type:

Address:

5

FLL Coarse/FineCounter Register

Write only

5Eh

6

FLL Fine CounterRegister

Write only

6Eh

BIT LABEL DESCRIPTION

0 F0 LSB of Spindle FLL Fine Counter

1 F1 Bit 1of Spindle FLL Fine Counter

2 F2 Bit 2of Spindle FLL Fine Counter

3 F3 Bit 3of Spindle FLL Fine Counter

4 F4 Bit 4of Spindle FLL Fine Counter

5 F5 Bit 5of Spindle FLL Fine Counter

6 F6 Bit 6of Spindle FLL Fine Counter

7 F7 Bit 7of Spindle FLL Fine Counter

11/17

L6275

INTERNALREGISTER DEFINITION

Reg:

Name:

Type:

Address:

BIT LABEL DESCRIPTION

0 THERMAL Thermal Shutdown = 0 indicates that the chip temperature has exceeded 160°C.

1 THERM_WARN Thermal ShutdownWarning=0 indicates that the chip temperature is

2 ROTOR_STUCK 0 = A sequential Spindle BEMF has not been detected

3 FAULT 1 = Rapid deceleration of the Spindle motor or High frequency on FCOM signal.

4 MASK_TIME Mask Time toggled to ”0” indicates that the Spindle BEMF is masked.

5 ERROR_LOCK 0 = Indicates error Spindle speed > 16msec/sample, either electrical or

6 ALIGN 0 indicate that the Spindle is in the Internal Start-Up Align Phase.

7 GO 0 indicate that the Spindle is in the Internal Start-Up Go Phase.

Reg:

Name:

Type:

Address:

7

Spindle Status Register

Read only

7Eh

The bit will reset (=1) when the temperature falls below 130°C. When Thermal

Shutdown =0, the spindle logic will tristate both high and low side drivers,

protecting the output circuitry.

approximately 25°C before the device goes in thermal shut down.

mechanical.

8

Spindle FLLRegister

Write only

8Eh

BIT LABEL DESCRIPTION

0 SSLEW Spindle PWM (chopping) Slew Rate. 0 = 10VµS, 1 = 20Vµs

1 ICP Spindle FLL Charge pump current. 1= 25µA, 0 = 100µA.

2 Unused. Set = 0.

3 ISNS 1 = Puts outputof the Spindle sense amplifier on FCOM pin and changes limit to

4 IL1 Adjust maximum voltage on Spindle Rsense

5 IL0 Adjust maximum voltage on Spindle Rsense

6 CPL 1 = Spindle FLL Charge pump low

7 CPH 1 = Spindle FLL Charge pump high

”IL0” ”IL1” ”ISNS” V(I_SENSE) LIMIT (±10%)

0 0 0 0.45V

1 0 0 0.50V

0 1 0 0.55V

1 1 0 0.75V

0 0 1 0.15V

1 0 1 0.20V

0 1 1 0.25V

1 1 1 0.30V

12/17

roughly 1/3 of normal.

INTERNALREGISTER DEFINITION

L6275

Reg:

Name:

Type:

Address:

BIT LABEL DESCRIPTION

0 PKV_1 VCM Parking Voltage

1 PKV_2 VCM Parking Voltage

2 VR 1 = connects internal VR reference (2V) to level shift Opamp (for

3 RT0(*) VCM Retract Time

4 DOUBLE 1 = Spindle Internal Start-Up Align and Energization time doubled.

5 VCM_EN EnableVCM section. 1 = Enable, 0 = Disable.

6 RT1(*) VCM Retract Time

7 RETRACT 1= VCM retract

(*) When program Retract Time (RT0and RT1), Bit 2 REG#8Eh must be always written to0.

9

SystemControl Register

Write only

9Eh

Vcm calibration).

”PKV_1” ”PKV_2” ”PARKING VOLTAGE”

0 0 0.850V

0 1 0.650V

1 0 1.600V

1 1 1.150V

”RT0” ”RT1” ”RETRACT TIME”

0 0 160ms

0 1 320ms

1 0 80ms

1 1 160ms

13/17

L6275

INTERNALREGISTER DEFINITION

Reg:

Name:

Type:

Address:

BIT LABEL DESCRIPTION

0 Unused. Set = 0

1 Unused. Set = 0

2 Unused. Set = 0

3 Unused. Set = 0

4 FLL_OUT 1 = Spindle Mech/Elec (see bit 5 register 2) output, 0 = Spindle

5 REV_BRAKE Spindle Reverse Brake command. 1 = Brake. “0” has to be

6 Unused. Set = 0

7 VB/DIS 1 = Disable Vboost

Reg:

Name:

Type:

Address:

10

Test ControlRegister

Write only

AEh

zero crossing output.

reinserted to enable the spindle start up.

11

VCM ControlRegister

Write only

BEh

BIT LABEL DESCRIPTION

0 VCMS VCM PSM (chopping) Slew Rate. 0 = 10V/µs, 1 = 20V/µs

1 VCMH 1 = Forces VCM outputs to be High in PSM mode.

2 SLEEP Unused (for future power saving mode).

3 COMSLEW SpindlePWM (phase commutation) Slew Rate. 0 = 30Vµs, 1 =

4 Unused. Set = 0

5 1 = Tristate the VCM outputs for half of the Retract Time during

6 1 = Brakes the VCM outputs for half of the Retract Time during

7 Unused. Set = 0

14/17

2Vµs.

retract.

retract.

INTERNALREGISTER DEFINITION

L6275

Reg:

Name:

Type:

Address:

12

Chip ID Register

Read only

FFh

BIT LABEL DESCRIPTION

0 ID_REV_0 Minor Revision Bit 0.

1 ID_REV_1 Minor Revision Bit 1.

2 ID_REV_2 Minor Revision Bit 2.

3 ID_REV_3 Minor Revision Bit 3.

4 ID_REV_4 Minor Revision Bit 0.

5 ID_REV_5 Minor Revision Bit 1.

6 ID_REV_6 Minor Revision Bit 2.

7 ID_REV_7 Minor Revision Bit 3.

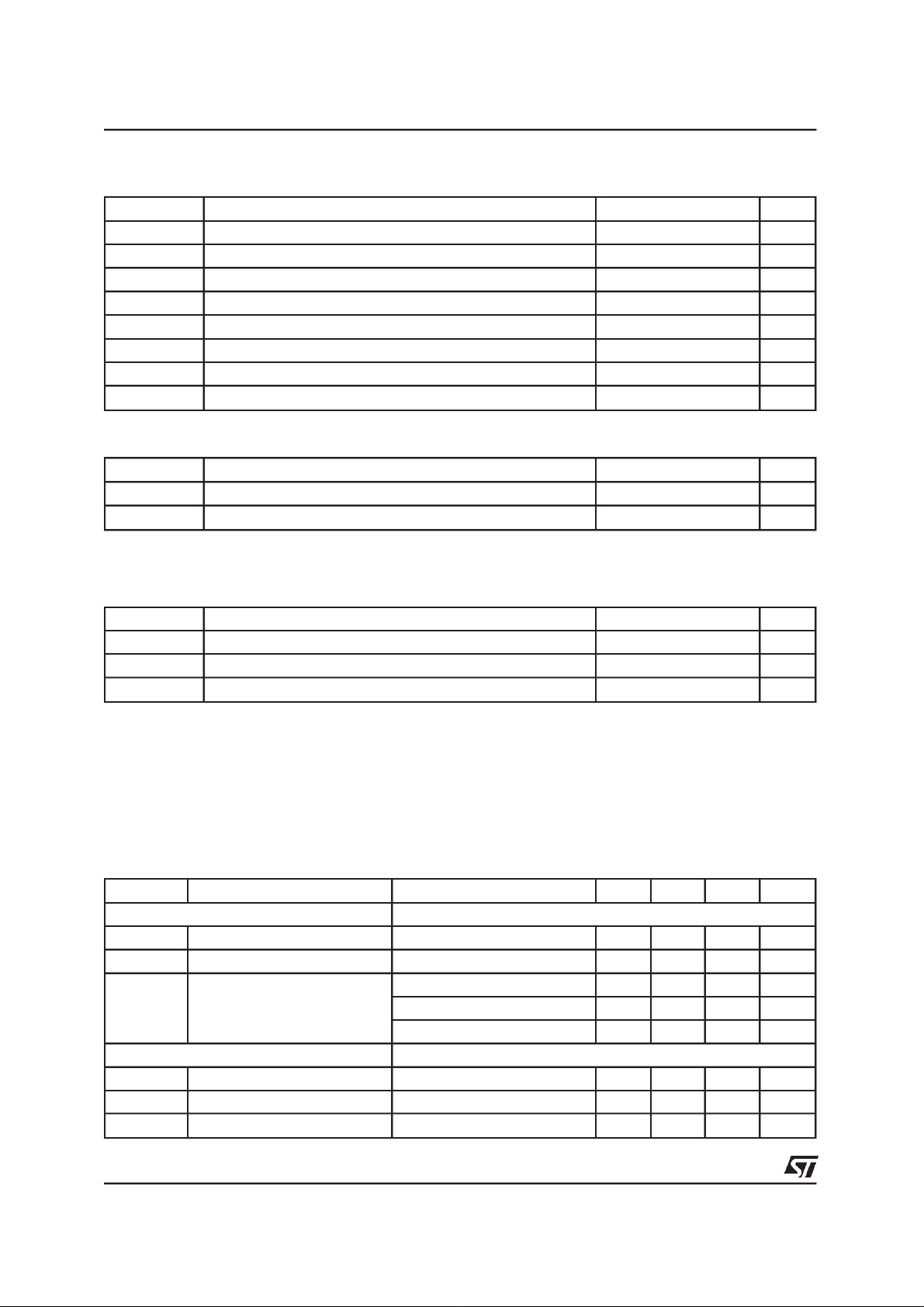

Figure 3. ApplicationCircuit.

5V_VDD

22µF

16V

(1)

1µF

12V_VCC

5V_VDD

STN4NE03

5K(4)

20K

18.2K

100nF

2.2µF

220pF(3)

5K(4)

15K

22µF

16V

(1)

1N4148

51K

10nF(4)

VCC

20µH

1Ω

2N2222

POR_DELAY

100nF

22µF

16V

(1)

CS

CP

SW1

BRK_CAP

PWM/SLEW

DGND

SPN_COMP

AGND

CLK_MON

GND

VDD

TR_5V

Voice Coil Ground

Power Ground

100nF

VCC RSENSE ISENSE2CTAP

24

23

33

36

12

3

14

44

42

40

8

19

35

VCM_CAL22V12/2 DAC ERROR_IN ERROR_OUT SENSE_OUT

0.3(1W)

13,43 6,9 5

20 41 39 38 37

10K 62K 10K

Analog Ground (1) This capacitor must be

Digital Ground

CTAP

OUT_A

OUT_A

1nF

(2) Place these components close to thedevice

(3) Do not mount this component if Spindle Linear mode is used

(4) Do not mount this component if Spindle Pwm mode is used

OUT_B

10

Tantalum

OUT_B

7

OUT_C

OUT_C

4

28

26

27

30

29

21

32

25,31

11

1

34

15

18

17

16

VCM_GND

VCM_A-

SENSE_IN+

VCM_A+

SENSE_INFLL-FILTER

FLL_RES

VCC

INDEX

FCOM

PORB

SYS_CLK

SCLK

SDATA

SDEN

D99IN1052

VCM_A-

0.25(1W)

62K

4.7K

1µF

VCM_A+

620K

100nF

VCC

INDEX

FCOM

5V_VDD

PORB

SYS_CLK

SCLK

SDATA

SDEN

15/17

L6275

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.60 0.063

A1 0.05 0.15 0.002

0.006

A2 1.35 1.40 1.45 0.053 0.055 0.057

B 0.30 0.37 0.45 0.012 0.014 0.018

C 0.09 0.20 0.004

0.008

D 12.00 0.472

D1 10.00 0.394

D3 8.00 0.315

e 0.80 0.031

E 12.00 0.472

E1 10.00 0.394

E3 8.00 0.315

L 0.45 0.60 0.75 0.018 0.024 0.030

L1 1.00 0.039

K 0°(min.), 3.5°(typ.), 7°(max.)

OUTLINE AND

MECHANICAL DATA

TQFP44 (10 x 10)

D

D1

A1

2333

34

B

44

1

e

11

TQFP4410

22

E

E1

12

L

0.10mm

.004

Seating Plane

B

K

A

A2

C

16/17

L6275

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is

granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mentioned in this publication are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical components in life support devices or systems without express written approval ofSTMicroelectronics.

The ST logois a registered trademark of STMicroelectronics

1999 STMicroelectronics – Printedin Italy– All RightsReserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - France - Germany - Italy- Japan - Korea- Malaysia - Malta - Mexico - Morocco - The Netherlands-

Singapore- Spain - Sweden- Switzerland- Taiwan - Thailand - United Kingdom- U.S.A.

http://www.st.com

17/17

Loading...

Loading...