L6260

4.5 – 5.5V DISK DRIVER SPINDLE & VCM,

POWER & CONTROL COMBO’S

GENERAL

5V OPERATION. *REGISTERBASED ARCHITECTURE

MINIMUMEXTERNALCOMPONENTS

SLEEP AND IDLE MODES FOR LOW

POWERCONSUMPTION

SELECTABLE GAINS FOR BOTH V.C.M.

AND SPINDLE

10 BIT (+ SIGN + GAIN ) VCM & 8 BIT SPIN-

DLE DACs

HIGH BANDWIDTH SPEED REGULATION

LOOP (ONCE PER MECH\ELEC CYCLE ACCURACY)

VCM DRIVER

CURRENT SENSE CONTROL (VOLTAGE

PROPORTIONALTO CURRENT)

300mADRIVE CAPABILITY

TWO CURRENT RANGES FOR SEEKING

AND TRACKING

INTERNAL REGISTER FOR POWER AMP

CONTROLLINES

SPINDLEDRIVER

BEMF PROCESSING FOR SENSORLESS

MOTOR COMMUTATION

PROGRAMMABLE COMMUTATION PHASE

DELAY

PROGRAMMABLE SLEW-RATE FOR REDUCED E.M.I.

0.8Ω FOR ANYHALF BRIDGE WORST CASE

SYNCHRONOUS RECTIFICATION OF THE

B.E.M.F.DURING RETRACT OPERATION

BIPOLAR\ TRIPOLAR OPERATION

SYNTHESIZEDHALL OUTPUTS

1.0 AMPDRIVE CAPABILITY

OTHER FUNCTIONS

POWERUP SEQUENCING

POWERDOWN SEQUENCING

LOW VOLTAGE SENSE

ACTUATORRETRACTION

DYNAMICBRAKE

THERMALSHUTDOWN

BICMOS TECHNOLOGY

TQFP64

ORDERING NUMBER: L6260

THERMAL& CURRENT PROTECTION

DESCRIPTION

The L6260 is single chip sensorless (DC) spindle

motor and voice coil controllers including power

stages suitablefor usein smalldisk drives.

These devices have a serial interfacefor a microprocessorrunning up to 10 Mega bits per second.

There are registers on chip to allow the setting of

the desired spindle speed via the on chip FrequencyLocked Loop (F.L.L.). No externalcomponents are requiredin the sensor-lessoperation as

the control functions are integrated on chip (e.g.

B.E.M.F.processing, digital masking, digitaldelay

and sequencing).

The V.C.M. driversuses a transconductanceamplifier, able to provide 2 different current ranges,

suitable forseeking and tracking.

When a low voltage is detected,a Power On Reset (P.O.R.) is issued and the internal registers

are reset, the spindle power circuitry is tri-stated,

B.E.M.F.synchronous rectification is enabled, the

actuator retracts and then dynamic braking of the

spindle is applied.

These devices are built in BICMOStechnologyallowing dense digital circuitry to be combined with

MOS\Bipolarpower devices.

November 1996

1/30

L6260

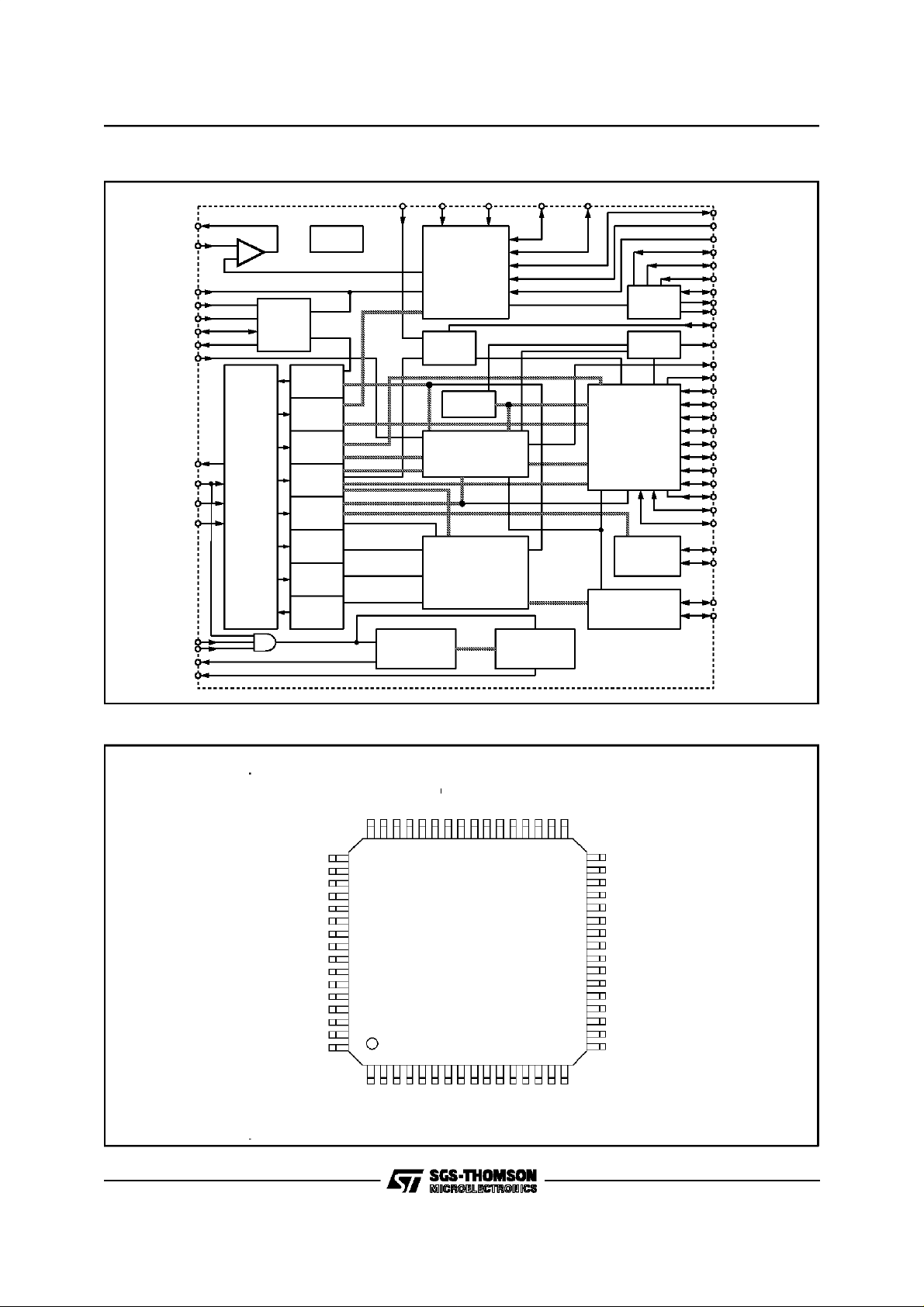

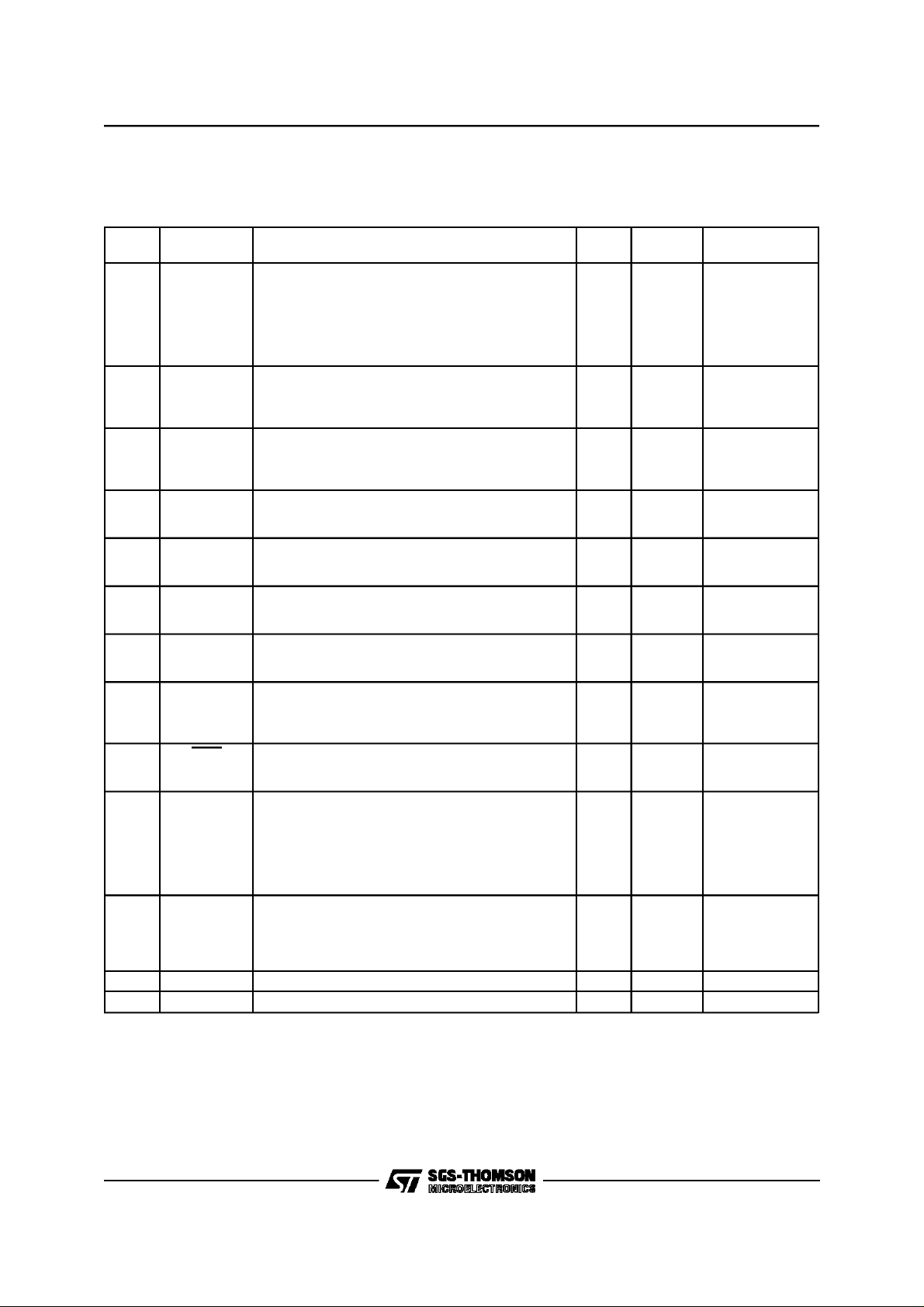

BLOCK DIAGRAM

VREFOUT

VREF/MINUS

DAC/GND

UV1

UV2

POR/DLY

POR

FCLK

SDIO

SCLK

SLOAD

R/W

TEST

TRISTATE

ATEST

DTEST

177

+

SERIAL

PORT

INTERFACE

POWER

MONITOR

CIRCUIT

REGISTER

0

REGISTER

1

REGISTER

2

REGISTER

3

REGISTER

4

REGISTER

5

REGISTER

6

REGISTER

7

BIAS

PARK/V VCM/COMP

VCM LOGIC &

VCM

PARK

ANALOG TEST

CIRCUIT

DAC

BEMF

AMP

SPINDLE

LOGIC

SPINDLE

FLL

DIGITAL TEST

CIRCUIT

VCM/PLUSVCM/I/SNS/2VCM/I/SNS/1

VOLTAGE

TRIPLER

CENTER TAP

DRIVER

SPINDLE

BLOCK

& DAC

CURRENT

GENERATOR

CHARGE

PUMP

VCM/MINUS

VVCM/2

VVCM/1

C1LOW

C1HIGH

C2LOW

C2HIGH

VHTRIP

VLTRIP

VPARKOUT

CTAP

SYNTH/HALL

VRECT

VSPIN/1

VSPIN/2

SPN/I/SNS

COIL/A

COIL/B

COIL/C

SPIN/GND1

SPIN/GND2

VPDOWN

BRK/DLY

SPN/I/COMP

SPN/SLEW

FLL/RES

SPD/COMP

SPD/COMP/SHT

D94IN087

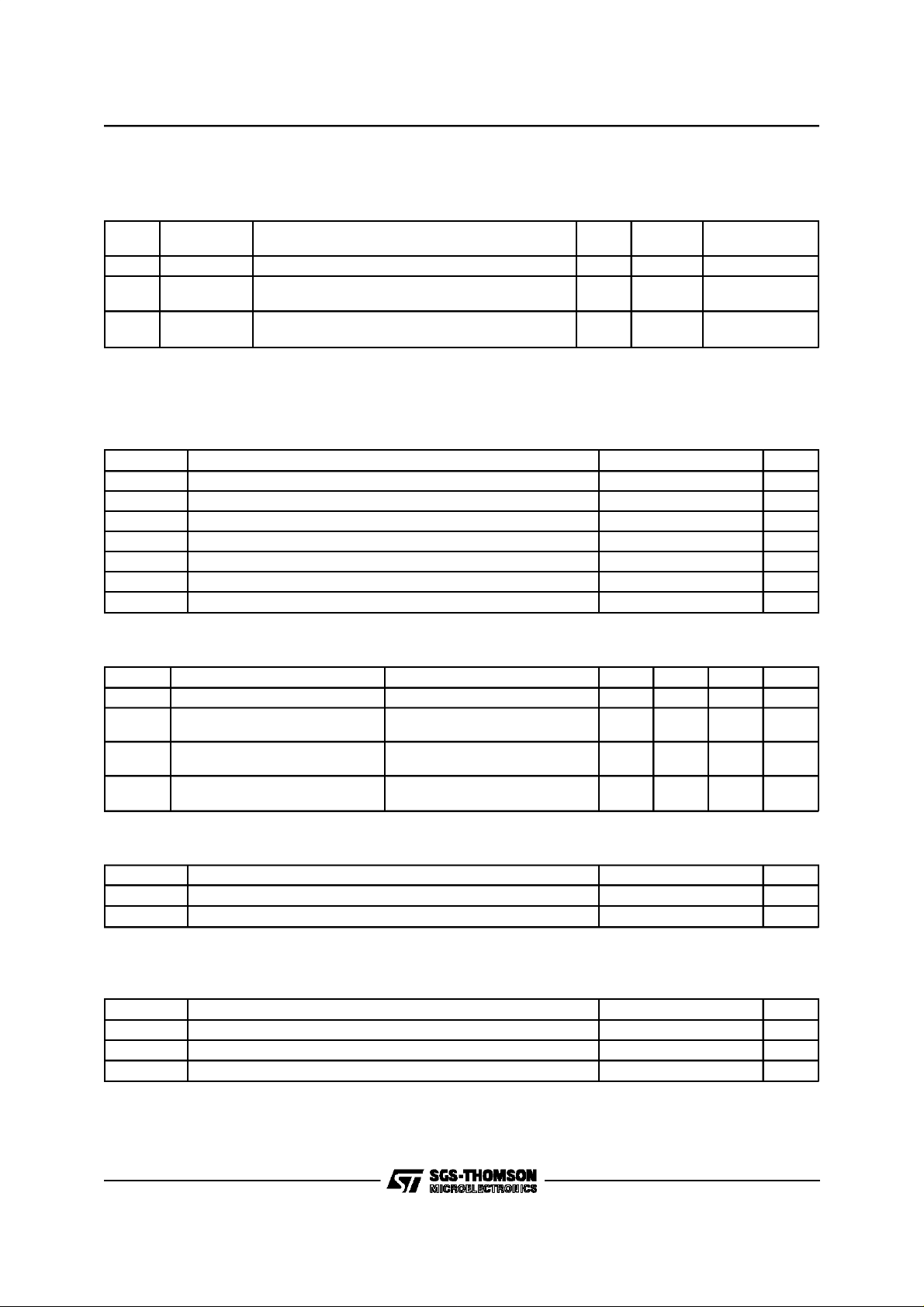

PIN CONNECTION(Top view)

SPN_DSBL_DLY

POR_DLY

VCM_I_SNS1

VVCM_1

VCM_MINUS

VCM_I_SNS2

VCM_PLUS

VVCM_2

C1HIGH

C1LOW

TRIPGND

C2HIGH

2/30

GND

UV

CTAP

ATEST

GND

GND

PARKV

AGRND

DACGND

VFER_MINUS

REF OUT

VCC

SPIN SLEW

FLL RES

SPD COMP SHT

48

49

64

116

L

ND

OW

G

2

C

RIP

T

L

V

OR

RIP

P

HT

V

P

COM

M

C

V

GND

IG

D

C

D

V

D

A

O

L

S

K

DIO

CL

S

S

SPD COMP

K

L

C

F

T

C

E

R

V

GND

S

NS

ND

I

G

N

P

S

33

GND

32

17

GND

VSPIN_2

VPDOWN

COIL_C

BRK_DLY

SPIN_GND_2

EXTFLL/DTEST

COIL_B

TRISTATE

VSPIN_1

SYNTH_HA LL

TEST

COIL_A

R/W_

SPN_GND_1

GND

GND

VPARKOUT

SPN1 COMP

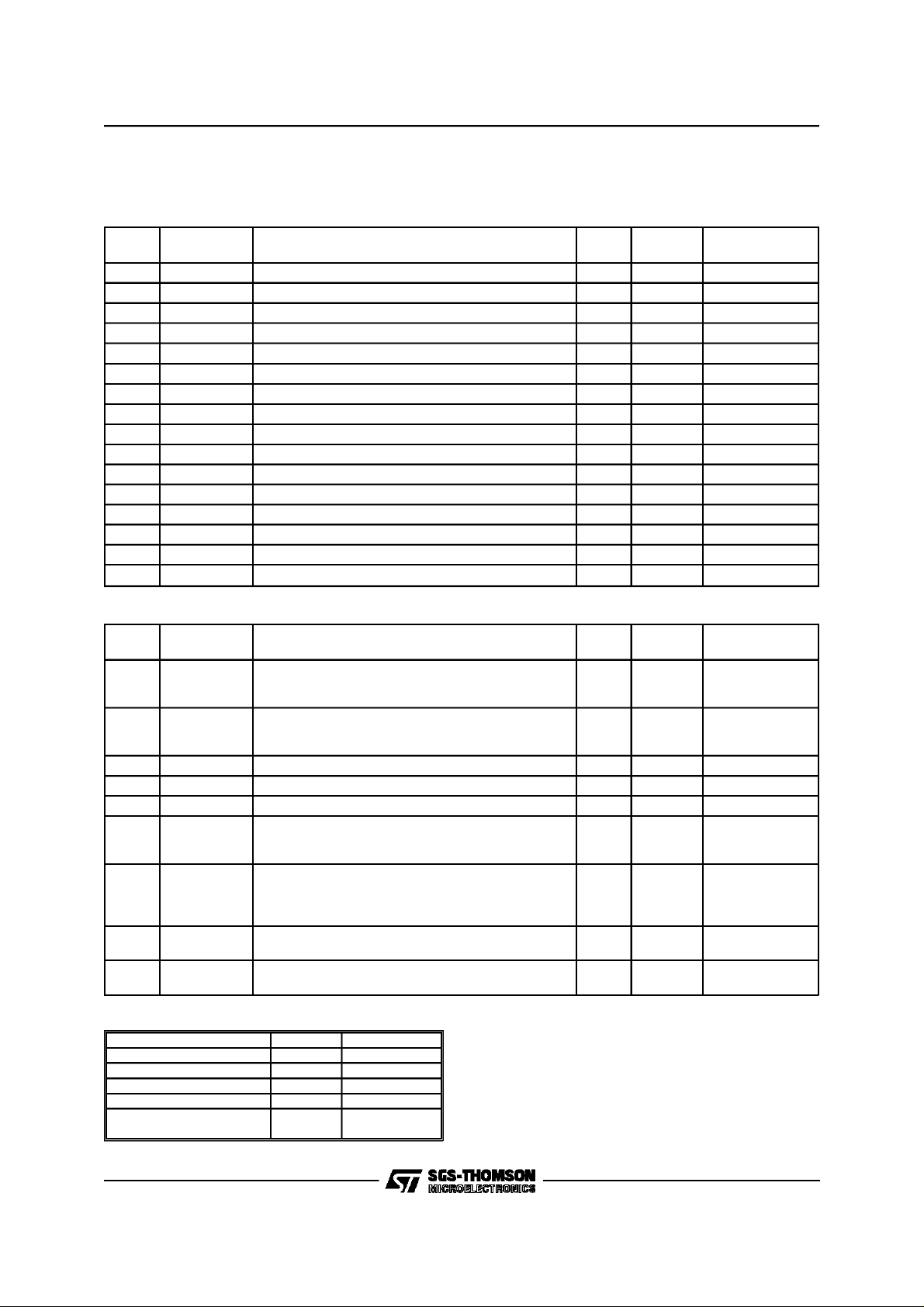

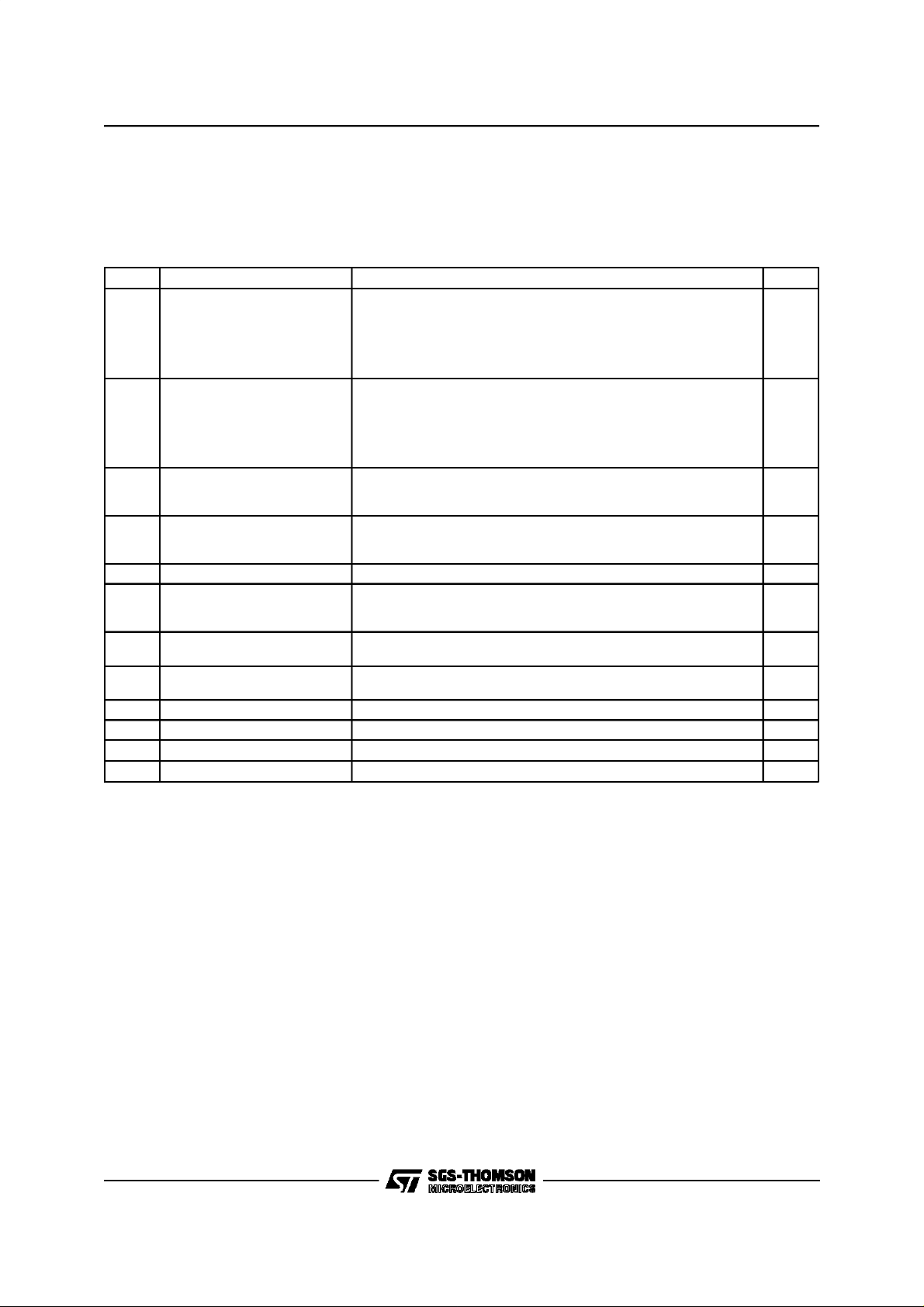

PIN DESCRIPTION

Pin Types:I = Input,O = Output,P = Power, A= Analog (passive)

Power

L6260

PIN # PIN NAME DESCRIPTION

8 VDC Digital power. Positivenominally 5V or 3V AI No No

41 VCC Analog power. Positivenominally 5Vor 3V AI No No

54 VVCM_1 VCM power supply. Positive nominally 5V or 3V AI No No

58 VVCM_2 Same as above AI No No

23 VSPIN_1 Spindle power pin.Positive nominally 5V or 3V AI No No

31 VSPIN_2 Same as above AI No No

1 GND Ground AI No No

15-17 GND Ground AI No No

32-34 GND Ground AI No No

47-49 GND Ground AI No No

18 SPN_GND_1 Ground forspindle circuit AI No No

27 SPN_GND_2 As above AI No No

44 DAC_GND Ground forall DACs AI No No

45 AGND Analog ground AI No No

7 DIG_GND Digital ground AI No No

63 TRIPGND Voltage triplerground AI No No

PIN

TYPE

I\O

MAPPED?

TRI-STATE

@SLEEP/@POR

Serial Interface& Test Pins

PIN # PIN NAME DESCRIPTION

12 FCLCK System clock. 4-12MHz selectable via the

CLK_PRESCALE bit inthe System Control Register

B (Reg 4 Bit 4).

11 SDIO Serial port data I/O running up to 10MHz. For full

details of allserial port signals see theCircuit

Description section.

10 SCLK Serial port clock (max 10Mbits/s) DI Yes No

19 R/W Read / Write signal for serial interface DI Yes No

9 SLOAD Chip select input. DI Yes No

21 TEST Used to enable one of the test modes. The mode is

selcted in conjunction with the TRISTATE pin (see

below for more details).

24 TRISTATE Used to enable one of the test modes. The mode is

selcted in conjunction with the TEST pin (see below

for more details).This pin has no effect on the

spindle or VCM drivers, this is a test pin only.

60 ATEST Analog test pin. This pin carries the required analog

signal to allow external testing.

26 DTEST Digital Test Output Pin. This pin also doubles as the

Clock input if an external FLL is used.

PIN

TYPE

DI Yes No

DI/O Yes Yes

DI No No

DI No No

AO No No

DI/O No No

I\O

MAPPED?

TRI-STATE

@SLEEP/@POR

Test Mode TEST pin TRISTATE pin

IOMAPPING Test 1 0

DIGITAL Test* 1 1

ANALOG Test* 1 1

TRISTATE Test 0 1

Normal Operation (non

test mode)

00

For a detailed description please refer to the Test

Circuit section of the CIRCUIT OPERATION portion ofthis datasheet

* These two test modes operatesimultaneously through separate

test pins (ATESTand DTEST).

3/30

L6260

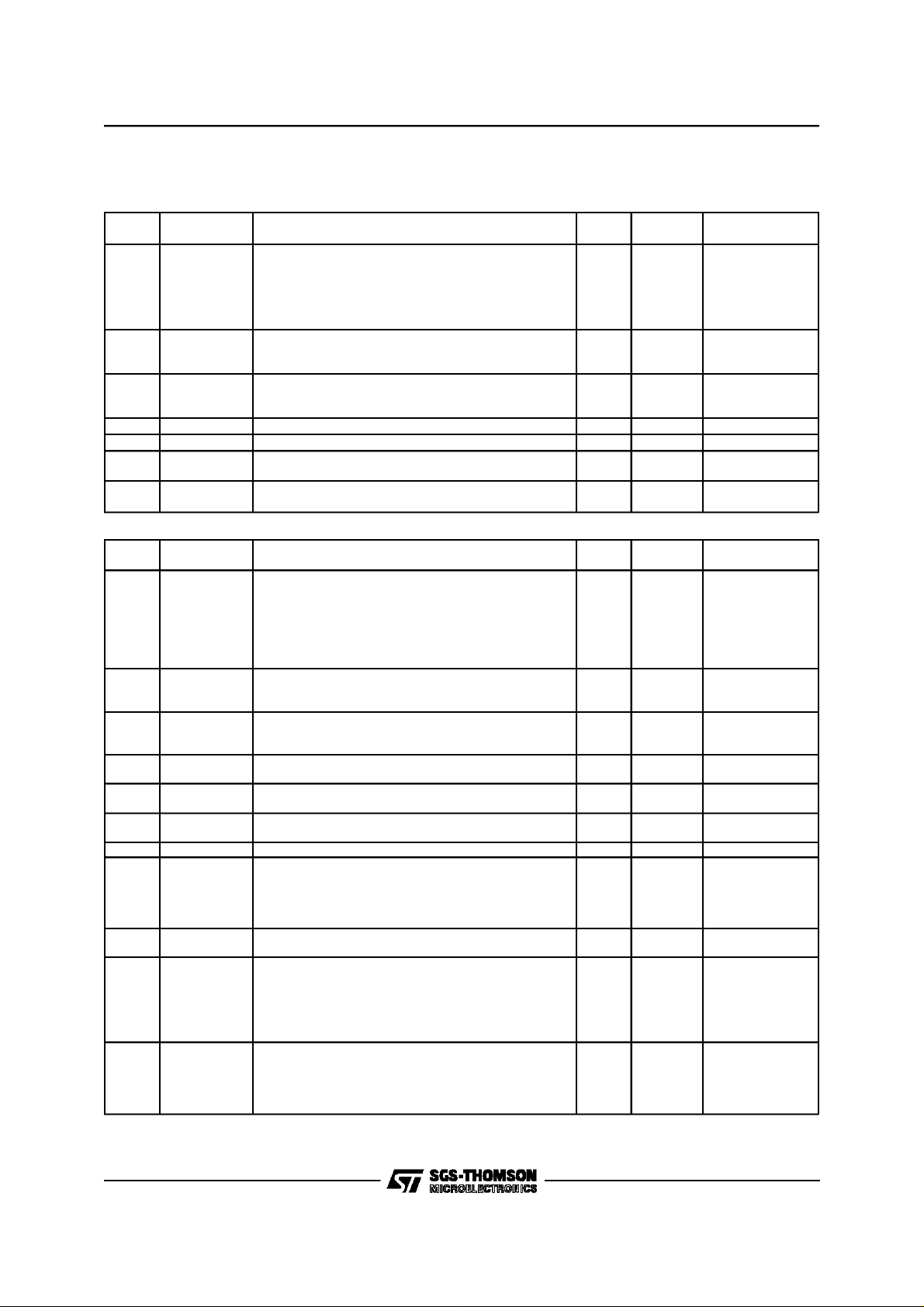

PIN DESCRIPTION(continued)

Pin Types:I = Input,O = Output,P = Power, A= Analog (passive)

VCM Driverand DAC

PIN # PIN NAME DESCRIPTION

53 VCM_I_SNS1 High side ofVCM sense resistornetwork. This pin

provides the current to the network as well as

sensing the total voltage across both sense

resistors. Sensing the total drop across both

resistors results in the low transconductancegain

feedback used fortrack following.

56 VCM_I_SNS2 Sensing across the lower VCM sense resistor for

high transconductance gain feedback for seek

operations.

6 VCM_COMP VCM compensation network. Typically, 200KΩin

series with 100nF is connected from this pin to

Ground.

57 VCM_PLUS VCM Power Amplifierpositive output terminal A No No

55 VCM_MINUS VCM Power Amplifier negativeoutput terminal A No No

46 PARK_V A resistor conneced between this pin and

VCM_PLUS determines the Parking Voltage

35 VPARKOUT Output from the retract circuit. This pinis usually

directly connected to the VCM_MINUS.

PIN

TYPE

ANo No

ANo No

ANo No

ANo No

AO No No

Spindle Driver and DAC

PIN # PIN NAME DESCRIPTION

40 SPN_SLEW The External.SpindleDriver Slew Rate resistor

(Rslew), typically250K isconnected from thispin to

Ground. When in nExternal Slew Rate Mode

(System Control Register B, Bit 10=0), the slew rate

is determined by:

SlewRate = (0.5Vto Rslew) X (DACslew+1) +20pF

DAC slew = System Control Register bits 7 - 9.

36 SPN_I_COMP A seroies RC network from this pin to ground sets

the spin drivercompensation. Typical a single 4nF

capacitor will provide adequate compensation.

14 SPN_I_SNS A current sensing resistor (2.5KΩTypical ).is

connected from this pin to ground. See the Circuit

Operation section for details.

20 COIL_A Spindle Power Amplifieroutput A. Also serves as

BEMF sensing forPhase A.

25 COIL_B Spindle Power Amplifieroutput B. Also serves as

BEMF sensing forPhase B.

29 COIL_C Spindle Power Amplifier output C. Also serves as

BEMF sensing forPhase C.

59 CTAP Spindle Motor Center Tap connection A No No

22 SYNTH_HALL CMOS level spindle speed output.When SYNHALL

(System Control Register B, bit 5) is set to 0, this

output switches stateat every zerocrossing of any

phase. With SYNHALL = 1, the output only switches

every zero crossingof Phase A.

37 SPD_COMP Change Pump RC network connection pin for FLL

mode operation.

38 SPD_COMP_SHTThis pin allows for shorting ofto the Charge Pump

Network resistor. This operation provides a quick

charge on the Charge Pump capacitor, reducing

settling time oncedesired speed isreached.

Operation is controlledby bit 9 of System Control

Register A.

39 FLL_RES Frequency LockedLoop charge pump gain resistor.

(Rep), typically 12.5KΩ , is connectedfrom this pin

to Ground. Change Pump current is determined by:

I = (0.5Vto Rcp) X (FLLGAIN DAC +1)

FLLGAIN DAC = System Control Register B bits 0-4

PIN

TYPE

ANo No

ANo No

AO No No

ANo No

ANo No

ANo No

DO Yes Yes

ANo No

ANo No

ANo No

I\O

MAPPED?

I\O

MAPPED?

@SLEEP/@POR

@SLEEP/@POR

TRI-STATE

TRI-STATE

4/30

PIN DESCRIPTION(continued)

Pin Types:I = Input,O = Output,P = Power, A= Analog (passive)

Power down sequencing, POR, other voltage pins

L6260

PIN # PIN NAME DESCRIPTION

13 VRECT Outputofthe synchronous rectifiersupplying powerto

28 BRK_DLY An external parallel RC network from thispoint to

30 VPDOWN Voltage triplerreservoir capacitor. Thisis used for

61 C1HIGH Positive terminalof charge pump capacitor.

62 C1LOW Negative terminal of charge pump capacitor.

64 C2HIGH Positive terminalof charge pump capacitor for

2 C2LOW Negative terminal of charge pump capacitor for

52 POR_DLY An external capacitor from this pinto ground sets

5 POR Power On Reset. Thisopen drain output goeslow

50 UV1 Under voltage detector 1.This defines the

51 SPN_DSBL_

DLY

4 VHTRIP High tripler/Doubler output. 330nF (typ). 11V max. AO No No

3 VLTRIP Low tripler/Doubler output. 330nF (typ). for stability. AO No No

theretractcircuitry.Filteredbyan internal 400pF

capacitor.Normally notexternallyconnected.However,

ifretractcommandistobeused, asmall signalsilicon

diodemustbeconnectedbetweenthispinandVcc

(Cathode to VRECT)to supply theadditional current

whichmaybe requiredtobrakethe VCM.

ground sets the Brake dELAY:T= 0.45 RC.

Typical values are R = 4MΩ, C=0.1µF (0.16sec,

delay).

the brake operation when power is removed from

the chip. NoDC load allowed.1µF minimum, 10µF

prefered.

10nF (typ) for Tripler operation;

330nF (typ0 or Doubler operation

10nF (typ) for Tripler operation;

330nF (typ)or Doubler operation

Tripler operation. 330nF (typ).

Connected tp VHRTRIP for Doubler operation.

Tripler operation. 330nF (typ).

Not connected forDoubler operation.

the duration of POR after power has been re-

established. T (por)= 32 X C (por)

where: C (por)is in pFand T is expresssed in µs.

when the voltageat either UV1 or UV2 goesbelow

1.25V.

VOLTAGE GOOD thresholdby comparing the

voltage on this pin to the internal 1.25V reference.

An external resistor divider network and capacitor

filter provides the selection of threshold and supply

noise rejection. There is an internal pull-up (2µA

max). Hysteresis is 20mV.

Spindle Disable Delay. A capacitor connected

between this pin and Vcc programs the delay

between POR and the disabling of the Spindle

section..

Delay = 80 xC (C in pF; Delay in µs)

PIN

TYPE

AO No No

ANo No

ANo No

ANo No

ANo No

ANo No

ANo No

ANo No

DO Yes No

AI Yes No

AI Yes No

I\O

MAPPED?

TRI-STATE

@SLEEP/@POR

5/30

L6260

PIN DESCRIPTION(continued)

Pin Types:I = Input,O = Output,P = Power, A= Analog (passive)

AuxiliaryFunctions

PIN # PIN NAME DESCRIPTION

PIN

TYPE

I\O

MAPPED?

TRI-STATE

@SLEEP/@POR

42 REFOUT Output from auxiliaryOPAMP. A No No

43* VREF_MINUS

(L6260 only)

26 EXTFLL/

DTEST

Negative input toauxiliary OPAMP. This is prsent

ONLY on the L6260.

See previous description of this pin(Serial interfaca

& Test Pinsection).

ANo No

DI/O No No

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Units

V

dd,Vp max

V

in max

V

in min

I

peak

I

dc

P

tot

T

stg,Tj

Maximum Supply voltage 6.5 V

Maximum input voltage Vdd + 0.3V V

Minimum input voltage GND - 0.5 V V

Peak sink/source output current 1.5 A

DC sink source output current 1.0 A

Maximum Total Power Dissipation 1.0 W

Maximum storage/junction temperature -40 to 150 °C

POWERDISSIPATION

Symbol Parameter Test Condition Min. Typ. Max. Units

V

dd,Vp

READY QUIESCENT CURRENT VCM ENABLED SPINDLE

IDLE QUIESCENT CURRENT VCM DISABLEDSPINDLE

SLEEP QUIESCENT CURRENT VCM DISABLEDSPINDLE

Supply voltage range 4.5 5.5 V

20 mA

ENABLED

10 mA

ENABLED

5mA

DISABLED

THERMAL DATA

Symbol Parameter Value Unit

R

th j-case

R

th j-amb

(*) In typical application with multiplayer printed circuit board.

Thermal Resistance Junction to Case 10

(*) Thermal Resistance Junction toCase 41.5

RECOMMENDED OPERATING CONDITIONS

Symbol Parameter Value Unit

Supply Voltage 4.5 to 5.5 V

Operating Ambient Temperature 0 to 70 °C

Junction Temperature 0 to 125 °C

6/30

V

ddn

T

amb

T

j

C/W

°

C/W

°

ELECTRICALCHARACTERISTICS

VCM Driver

Symbol Parameter Test Condition Min. Typ. Max. Units

I

ocr

I

ofr

ABEF Source & Sink On Resistance

R

dson

R

dson

V

jump

V

deadband

I

csbias

PSRR DC Power Supply Rejection

BW Current LoopBandwidth La = 1mH Ra=40ohms

Max Current Coarse Range 300 mA

Max Current Fine Range 75 mA

Coarse

Tj=125 °C,

= 300 mA

I

load

1.0 2.5 Ohms

CD Sink On ResistanceFine Range C, D VCM drive transistors 5.0 10.0 Ohms

Current SenseJump

1 LSB

Discontinuity

Current SenseDeadband 200 µV

Current SenseBias Current 1 µA

4.5 to5.5 V 50 dB

V

Ratio

dd

20 KHz

I

=75mA

max

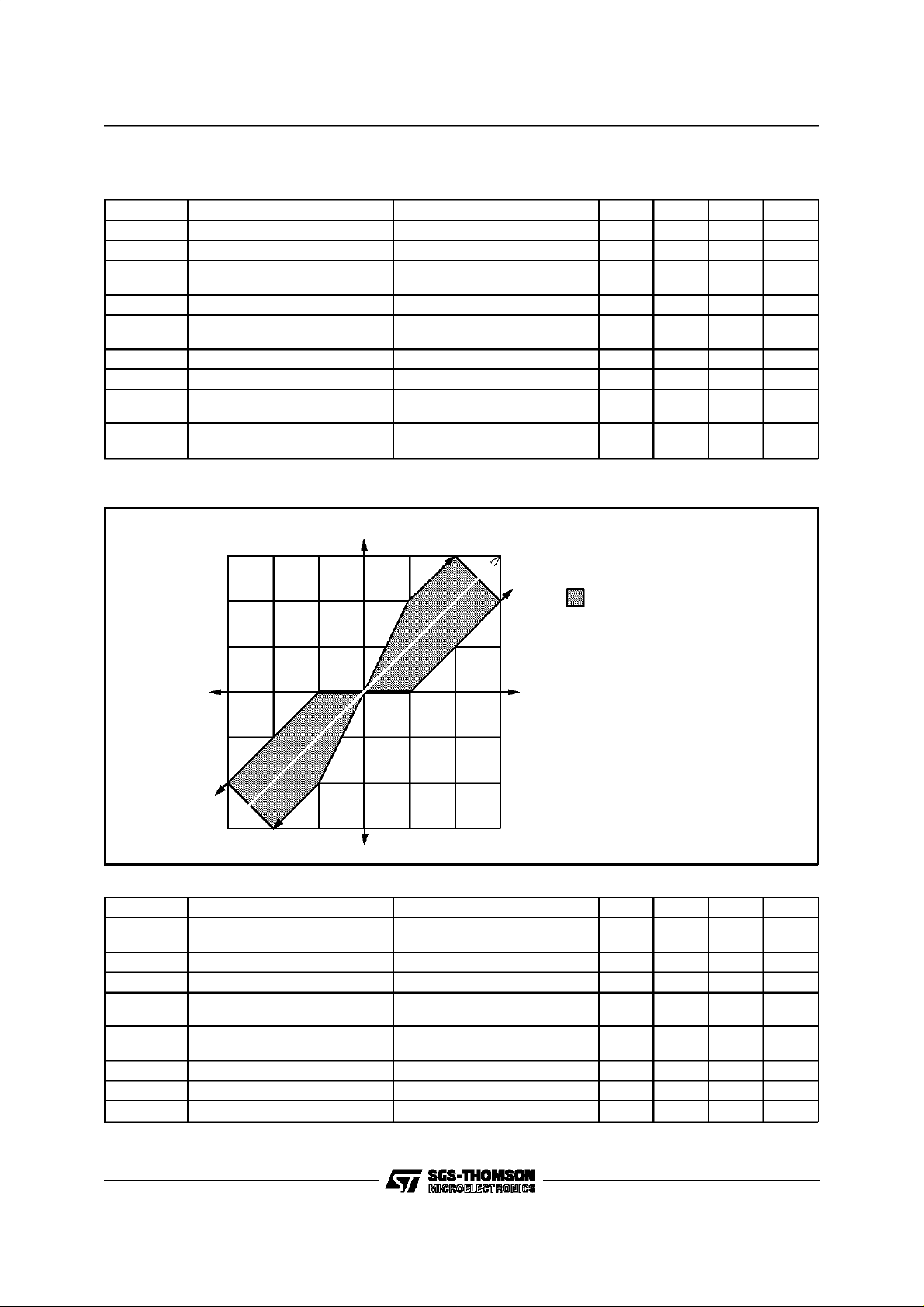

Figure 1: Vjumpvs. Deadband

Y(at) UNITS imax 1024

+3

L6260

+2

Operational

Nominal

Area

+1

UNITS L.D.D.

X(in) DAC

JT

Register

Value

-1

-2

-3

+3 +2 +1 +1 +2 +3

D94IN090

VCM DAC

Symbol Parameter Test Condition Min. Typ. Max. Units

R

es

Resolution 10 Bits Resistive

Ladder PlusSign (1 Bit)

N.L. Differential Non-Linearity 1 LSB

I.N.L. Integral Non - Linearity 3.0 LSB

C

T

Conversion Time 0 - 90 % From Input Of LastBit (for any

FSTC Full ScaleTemperature

Coefficient

Voh High Output Voltage 25 °C, No Load 0.240 0.250 0.260 V

Vol Low output Voltage 25 °C, No Load 100 µV

PSRR Power SupplyRejection 50 dB

Unipolar 11 bits

1.0 µs

change of code)

0 to 125°C 250 ppm/C

7/30

L6260

ELECTRICALCHARACTERISTICS(continued)

Spindle Motor

Symbol Parameter Test Condition Min. Typ. Max. Units

I

o

R

Sink Sink On Resistance Tj=125°C,I

dson

Total Total drive resistance

R

dson

dv/dt Voltage Slew Rate 0.2 2 V/µs

Spindle Current Sense FET

linearity

Large signal

Linearity

small signal

BW Current loopbandwidth small

FS Full scale current error 5 %FS

matching Current sense matching 25 to 250 mA 5 %

DAC AccelerationControl

res Resolution Full scale 8 bits

NL Differential Non-linearity 0.5 LSB

INL Integral Non-linearity 1 LSB

FS Full scale accuracy 5 %

CT Conversion time 10 ms

FSTC Full ScaleTemp Coefficient 250 ppm/°C

V

oh

V

ol

Gain1X Current SenseGain at 500:1 502 525 554

Gain5X Current SenseGain at 2500:1 2400 2900

Step-up Converter

V

su3

Digital Inputs (Alldigital inputs are CMOS compatible)

V

ih

V

il

V

oh

V

ol

I

in

Power On Reset(Either lowvoltage detectorcan be disabled bytrying the dividerto a high voltage)

T

delay

V

ref

Retract

Maximum Output Current 1 A

= 1A 0.4 Ohms

load

T

R

dson

sink +R

dson

source

Current sense circuit linearity

=125 °C, I

j

1% to fullscale current 5 %FS

= 1A 0.8 Ohms

load

(spin-up). 2000:1 current sense.

Current sense circuit linearity(at

1% to 10%full scale 0.5 %

speed). 500:1current sense.

Lmotor 100µHto1µH 20 KHz

signal (atspeed)

1.235 1.25 1.245 V

0 0.2 0.3 V

Step-up converter voltage

(using Tripler as a doubler)

= 4.5 to 5.5 volts,

V

dd

Maximum load

6V

above 5V.

High level input voltage Iin= TBD 30%

V

dd

Low level inputvoltage Iin= TBD 70%

V

dd

High level output voltage I

Low level outputvoltage I

= TBD Vdd-0.6 V

out

= TBD 0.4 V

out

Input leakage current Tj=125°C+1-1

Minimum delay powerOK to

RESET high

C

POR_DELAY

= 0.22*H 50.32 70.4 64.46 ms

Voltage reference 1.235 1.25 1.265 V

V

V

A

µ

I for V

8/30

T

R

retract

dson

Retract time beforebrake power low detected

= 0.4 x RC

T

retract

TBD TBD ms

Total switch circuitresistance 10 Ohms

2 quadrant retract voltage V

retract

> PARK_Voltage 11 13 15 µA

BEMF

INTERNAL REGISTERDEFINITION

System Status Register(Reg 0)

Reg: 0

Name: SystemStatus Register

Type: Readonly.

BIT LABEL DESCRIPTION @POR

0 THERMAL Thermal shutdown = 1, normal = 0.One signifies that the chip

temperature has exceeded the 180°C. The bit will reset when the

temperature falls from 180°C to 140°C (the hysteresis prevents

rapid changing ofthis bit). When this bitis activated,the spindle

logic will tristateboth high and low side driversto allow thedisk to

coast and cooldown the chip.

1 UV Under Voltage=0, good voltage =1. This signals whether the under

voltage circuit has been activatedor not. NOTE: When UV=0,the

POR is activated and allserial port controllogic is reset. This

means that writes are impossible, however, the user can still poll

the status ofthis registerprovided the logicvoltage is sufficient for

the logicto function.

2 FLL_UP Providing mainly for testing. When the FLL is sourcing current into

the charge pump capacitor this isset to 1. A 0 means that the

sourcing current isdisabled.

3 FLL_DOWN Providing mainly for testing. When the FLL is sinking current from

the charge pump capacitor this isset to 1. A 0 means that the

sourcing current isdisabled.

4 BEMF_SENSE Toggles with BEMF. 0

5 MASK_TIME Mask time currently in use = 1. When 1this means theBEMF

comparator will notsense the zero crossingat this time. A 0

means zero crossingsensing will occur.

6 DELAY Delay time currently in use = 1. e.g. A commutation delay isactive

and at theend of this delay the next commutation is executed.

7 AT_SPEED 1=spindle is at speed (set by the first ”down pulse”of the FLL.It is

reset at POR.

8 UNUSED 0

9 UNUSED 0

10 UNUSED 0

11 UNUSED 0

L6260

0

0

0

0

0

0

0

9/30

L6260

VCM DAC Register(Reg 1)

The VCM DAC register is used to control the current in the voice coil motor. All 10 bits are part of

a resistor divider network. Bit 10 is the sign bit

and logically controlsthe current direction through

the VCM. Bit 11 selects the currentsense resistor

to use for current control. A 0 selects coarse and

therefore only the lower sense resistor, a 1 selects the top of both resistors so that the sense

resistor is the sum of the coarse and fine resistance’s.

To clarify the manner in which the 2’s complementis used hereare someexamples:

Value entered to

register (0x means hex)

0x000 0x000 + 0

0x800 0x000 + 1

0x3FF 0x3FF + 0

0x400 0x3FF - 0

0x401 0x3FF - 0

0x7FF 0x001 - 0

DAC value Sign Gain

Reg: 1

Name: VCMDAC Register

Type: Write only.

BIT LABEL DESCRIPTION @POR

0 VDAC BIT 0 LSB resistor ladder of the 10 bit VCM DAC. This is a trueunsigned 0

1 VDAC BIT 1 representation of the DAC input. The valueentered here isa 2s- 0

2 VDAC BIT 2 complement of the required DAC value encodedacross eleven bits 0

3 VDAC BIT 3 (10 bit data and 1 sign bit encoded into 11 bits in 2s-complement) 0

4 VDAC BIT 4 0

5 VDAC BIT 5 0

6 VDAC BIT 6 0

7 VDAC BIT 7 0

8 VDAC BIT 8 0

9 VDAC BIT 9 MSB resistor ladder. 0

10 VCMSIGN Sign bitof the above2s-complement number. 0

11 VCMGAIN This changes the gain of the VCM DAC 0

Spin Control Register(Reg 2)

The spincontrol register has two functions:

(1) The first (bits 0-7) is to program the current to

the spindle motor to allow motor control and

to presetthe ”at speed”voltage for the charge

pump.

(2) The second (bits 8-11) is to set the phase lag

from when a BEMF zero crossing occurs to

the next commutation. Nominally the delay

would be 30 electrical degrees but it often is

better to advanced the commutation, due to

the presence of other sources of delay, related to switching. The range is from 1.875

through to 28.125 electrical degree delay at

1.875degree increments.

Reg: 2

Name: SpinControl Register

Type: Write only.

BIT LABEL DESCRIPTION @POR

0 SPIN_DAC BIT 0 Spindle current limit LSB (LSB of 8 bits written to the spindle DAC) 0

1 SPIN_DAC BIT 1 0

2 SPIN_DAC BIT 2 0

3 SPIN_DAC BIT 3 0

4 SPIN_DAC BIT 4 0

5 SPIN_DAC BIT 5 0

6 SPIN_DAC BIT 6 0

7 SPIN_DAC BIT 7 Spindle current limit MSB 0

8 SPINDLY BIT 0 Spindle commutation delay LSB 0

9 SPINDLY BIT 1 0

10 SPINDLY BIT 2 0

11 SPINDLY BIT 3 Spindle commutation delayMSB 0

10/30

System Control Register A (Reg 3)

Reg: 3

Name: SystemControl RegisterA

Type: Write only.

BIT LABEL DESCRIPTION @POR

L6260

0 SPIN_ENABLE Enable spindle functions(1 = enabled; 0 = Disabled). Together

with VCM_ENABLE, determinethe Normal,Idle or Sleep mode of

operation. See Mode Table for details.

1 VCM_ENABLE Enable VCM functions (1 = enabled;0 = Disabled). Together with

SPIN_ENABLE, determine the Normal, Idle orSleep mode of

operation. See Mode Table for details.

2 SRESET Reset spindle state machine (sequencer). 0=Reset. All spindle

and FLL registersare also reset. Also used tocontrol the charge

pump (1 = off).

3 INCRE A 0 to 1 transitionof this bit increments the spindle state machine.

Normally used in SEARCH mode. Must be set to 1 in RUN Mode.

4 RUN_SRCH 1=Auto-increment enabled (RUN Mode)

0 = Auto-increment disabled (SEARCH MODE)

5 8_12P Selects8/12 pole motor:1 = 8pole, 0 = 12 pole 0

6 BIP_TRIP Define Tristate, Bipolar, or Tripolaroperation: 0

7 UNI_TRIP See Spindle Drive Mode Table. 0

8 VCMRET Activated VCM Retract:1 = retract. 0

9 SPEED Programs theSpindle Speed Control Method.

SPEED= 0: The L6260 operates open loop, with speed error

sensing performed externallyand speed effortwritten into the

SPIN_DAC.

SPEED = 1: The speed is controlled internally through the built-in

control loop.

0

0

0

0

0

0

10 EL_MECH Specifies electrical or mechanical cycle for the FLL control.

1 = Electrical, 0 = Mechanical

11 TEST_COUNT_RESET Writinga 0 resets the test sequence. Must be set to 1 toallow

ATEST and DTEST functions.

MODE OFOPERATION (REGISTER3 BITS 0 AND 1)

SPIN_ENABLE VCM_ENABLE MODE DESCRIPTION

(0) DISABLED (0) DISABLED SLEEP MINIMUM POWER DISSIPATION.

(0) DISABLED (1) ENABLED NOT NORMAL VCM IS FORCED TO A PARK CONDITION

(1) ENABLED (0) DISABLED IDLE VCM DISABLED FOR REDUCED DISSIPATION

(1) ENABLED (1) ENABLED NORMAL NORMAL MODE OF OPERATION

SPINDLEDRIVE MODE(REGISTER 3 BITS6 AND 7)

BIP_TRIP UNI_TRIP SPINDLE DRIVE MODE

0 0 TRISTATE

0 1 NOT DEFINED

1 0 BIPOLAR

1 1 TRIPOLAR

0

0

11/30

L6260

System Control Reg B (Reg4)

Reg: 4

Name: SystemControl RegisterB

Type: Write only

BIT LABEL DESCRIPTION @POR

0 FLLGAIN BIT 0 Frequency Locked Loop (FLL) gain control. A gain factor of 1 to 8

1 FLLGAIN BIT 1 0

2 FLLGAIN BIT 2 0

3 EXT_INT External or internalspindle loop feedback. This bit is programmed

4 CLK_PRESCALE This selectsa one bit pre-scaler for the internal clock,minimizing

5 SYNHALL This selectsthe signal at the SYNTH_HALL pin.

6 SFETGAIN Selects the gain of the sense FET circuit of the spindle driver.

7 SLEW BIT 0 Slew ratecontrol Bit 0 ( LSB) 0

8 SLEW BIT 1 Slew ratecontrol Bit 1 0

9 SLEW BIT 2 Slew ratecontrol Bit 2 (MSB) 0

10 SLEW BIT 3 Setting this bit to 1 selects an internal 250K slew rate resistor.

11 MASK_PHASE Selects between 7.5°and 15°mask time (0=15°, 1=7.5°)

can be programmed, This register value varies the FLL gain by

changing the Integrator Current. Bit 0 isthe LSB.

to 0 for BEMF feedback, 1 forexternal feedback. External

feedback is connected via the DTESTpin, which is configured as

an inputin this mode.

the effectof differing fequencies on the FLL and logic counters.

Set to 1for 4-6MHz system clock,Set to 0 for 8-12MHz system

clock

When set to0, Synth Hallpin will producea once perBEMF

crossing signal (from BEMF comparitor). Setting the bit to 1,

Synth Hall pin will give a once per electrical cycle signal (from zero

crossing detector).

0 = Spindle is high transconductance loop gain, 1 = low gain

Setting it to 0 allows slew rate control by an external resistor.

0

0

0

0

0

0

Figure 2: Thefollowing diagramexplainsbits 5 ”SYNTH HALL”and the effectit has on thepin named

SYNTH_HALL

MOTOR PHASES

Below are the threepossible waveforms

available from the SYNTH-HALL pin.

The desired waveform is selected via

”Synth Hall” bits inthe System Control

Register B.

Once per ”BEMF Crossing”

(Once per zero cross)

Once per ”electricalcycle”

D94IN091

12/30

L6260

FrequencyLocked Loop Coarse Counter (Reg 5)

This register contains the ”coarse” FLL counter

value for the FLL. This register givesa worst case

resolution of 16µs with the worst case (i.e. slowest) 4MHz clock and has a valid range of 001 to

FFF hex.

Reg: 5

Name: FLLCoarse Counter Register

Type: Write Only

BIT LABEL DESCRIPTION @POR

0 CLATCH BIT 0 FLL Coarse counterLSB 0

1 CLATCH BIT 1 0

2 CLATCH BIT 2 0

3 CLATCH BIT 3 0

4 CLATCH BIT 4 0

5 CLATCH BIT 5 0

6 CLATCH BIT 6 0

7 CLATCH BIT 7 0

8 CLATCH BIT 8 0

9 CLATCH BIT 9 0

10 CLATCH BIT 10 0

11 CLATCH BIT 11 FLL Coarse counterMSB 0

Frequency Locked Loop Fine Counter (Reg 6)

This register contains the ”fine” counter value of

the FLL. The worst case resolution (i.e. with a

4MHz clock) is 1µs. It is important that the

most significant bit of this register must be a

zero when a write is made. Valid writes to this

registermust be between001 and 7FFhex.

Reg: 6

Name: FLLFine Counter Register

Type: Write only.

BIT LABEL DESCRIPTION @POR

0 FLATCH BIT 0 FLL Fine counter LSB 0

1 FLATCH BIT 1 0

2 FLATCH BIT 2 0

3 FLATCH BIT 3 0

4 FLATCH BIT 4 0

5 FLATCH BIT 5 0

6 FLATCH BIT 6 0

7 FLATCH BIT 7 0

8 FLATCH BIT 8 0

9 FLATCH BIT 9 0

10 FLATCH BIT 10 0

11 FLATCH BIT 11 FLL Fine counterMSB -NOTE: Ona writeto this register, this bit

must be zero.

0

13/30

L6260

Frequency Locked Loop Fine Error Counter

(Reg 7)

This register contains the error detected between

the ”fine” counter value of the FLL and the actual

spindle rotationtime (in either mechanicalor electricalmode).

Reg: 7

Name: FLLFine Error CounterRegister

Type: ReadOnly

BIT LABEL DESCRIPTION @POR

0 FINEC BIT 0 FLL Fine errorcount LSB 0

1 FINEC BIT 1 0

2 FINEC BIT 2 0

3 FINEC BIT 3 0

4 FINEC BIT 4 0

5 FINEC BIT 5 0

6 FINEC BIT 6 0

7 FINEC BIT 7 0

8 FINEC BIT 8 0

9 FINEC BIT 9 0

10 FINEC BIT 10 0

11 FINEC BIT 11 FLL Fine errorcount MSB 0

CIRCUIT OPERATION

General

This device includes a sensorless spin driver,

VCM driver, power sequencing, actuator retraction with dynamic braking, serial interface for a

microprocessor and frequency locked loop for

speed control. The device is register based and

designed to operate via either 3V or 5V power

supply.

POR & UnderVoltage

The L6260 has an on chip power monitoring system that controls all aspects of powering up,

Power On Reset of the Logic (POR), low voltage

detection and power down sequencing. The circuitry consists of a Bandgap referencegenerator,

hysteresis comparitor (for low voltage detection)

and a POR timer circuit (which controls the duration of the reset).

Four external pins determine the behavior of this

circuit.

UV1 & UV2: These two pins are provided to

the user to connect to the supply voltages for

14/30

low voltage detection. The voltage on these

pins is compared to the internal Bandgap voltage to determineif a low voltage on one of the

supplypins has been detected.The comparitor

has built in hysteresis to reduce the effects of

noise on the supply lines triggering a false

POR. In other words, if either one of these inputs falls below 1.25V then the supply is regarded as being ”under voltage”. Normally one

of thesepins will be connectedto allow a sensing of a 3V supply and the other to the5V supply but thisis arbitrary

POR_DLY:This is a pin from whicha capacitor

can be connected to ground. This sets the duration of the reset state of the this chip. On

power up, an internal current source charges

the capacitor with a current of approximately

2mA. Whenthe voltage onthis pin reaches the

bandgap voltage, the chip comes out of its reset state. The duration of this reset is determined by the size of an external capacitor to

ground.

POR: The POR pin is an output from the chip

for resettingother devices.

APPLICATIONDIAGRAM

L6260

5V

4 - 12MHz

1.5nF

220pF

VREFOUT

VREF/MINUS

DAC/GND

SPN-DSBL-DLY

POR/DLY

POR

FCLK

SDIO

SCLK

SLOAD

TEST

TRISTATE

ATEST

DTEST

VCM coil

VCM/MINUS

VVCM/2

VVCM/1

C1LOW

C1HIGH

C2LOW

C2HIGH

VHTRIP

VLTRIP

VPARKOUT

CTAP

SYNTH/HALL

VRECT

VSPIN/1

VSPIN/2

SPN/I/SNS

COIL/A

COIL/B

COIL/C

SPIN/GND1

SPIN/GND2

VPDOWN

BRK/DLY

SPN/I/COMP

SPN/SLEW

250KΩ typical

12.5KΩ typical

FLL/RES

SPD/COMP

TBD

SPD/COMP/SHT

330nF (Typ)

330nF (Typ) for Tripler

operation not

used

for Doubler operation

330nF(Typ)

330nF(Typ)

V

CC

e.g. 2.5KΩ

1µFmin(10µF Recommended)

1nF 4MΩ

4nF

10nF

62K

Connected

for

Doubler

operation

CIRCUIT

100nF

VCM LOGIC &

DAC

VCM

PARK

BEMF

AMP

SPINDLE

LOGIC

SPINDLE

FLL

0.83Ω (min)3.3Ω (min)220KΩ

DIGITAL TEST

CIRCUIT

VCM/PLUSVCM/I/SNS/2VCM/I/SNS/1

VOLTAGE

TRIPLER

CENTER TAP

DRIVER

SPINDLE

BLOCK

& DAC

CURRENT

GENERATOR

CHARGE

PUMP

D94IN089A

0.5V

40KΩ FOR

RETRACT

PARK/V VCM/COMP

BIAS

POWER

MONITOR

CIRCUIT

REGISTER

0

REGISTER

1

REGISTER

2

REGISTER

3

REGISTER

4

REGISTER

5

REGISTER

6

REGISTER

7

ANALOG TEST

177

+

UV1

SERIAL

PORT

INTERFACE

R/W

15/30

L6260

Figure 3.

BANDGAP

1.25V reference

REFERENCE

1.25V(rising)

1.23V(falling)

UV1 pin

UV2 pin

+

Comp

-

+

Comp

-

HYSTERESIS

CONTROL

POR

TIMER

POR pin

POR-DLY pin

External Cap

RESET DURATION =

C

POR_DLY

X 1.25

D94IN092

2E -6

POR Parameters

SYMBOL PARAMETER MIN. TYP. MAX UNITS

C

PORDLY

T

delay

UV

rise

UV

fall

T

UVD

(*) Seeprevious equation

(**) Seehysteresis transferfunction below

POR delay capacitor 220 2200 4700 pF

Delay time (*) (*) (*)

Rising edge reference 1.25 V (**)

Falling edgereference 1.23 V (**)

Under voltage detect to POR low 250 ns

Figure 4: HysteresisComparitor TransferCharacteristicfor UnderVoltage Detection.

1.25V (POWER GOING UP)

POWER OK

UV/2

UNDER VOLTAGE DETECTED

1.23V (POWER GOING DOWN)

16/30

D94IN093

L6260

The duration of the brake delay is defined by an

external resistor and capacitor connected to the

brake delay pin (BRK_DLY). Charge stored in an

external capacitor connected to the Voltage Tripler (VPDOWN)is used to supply the brakedelay

circuit afterthe loss of power.

During the application of power to the IC, the

power on reset signal (POR) is asserted, forcing

all registersto their default state (see @POR column of the register definitions) and disabling the

VCM and spindle drivers. Once the supply voltage has exceeded the Voltage Good (VGT)

threshold, the POR delay begins.When this delay

has expired, POR is de-asserted. It is this delay

whose duration is determined by an external capacitor connectedto the POR_D

LY

pin.

When a low voltage condition is detected (the

supply voltage falls below the VGT) the following

happens (inorder):

SYMBOL DESCRIPTION MIN. TYP. MAX. UNITS

t

RWS

t

SLS

t

RWH

t

SLH

t

SCKD

t

RWD

t

AS

t

DS

t

AH

t

DH

t

SDZ

t

RWZ

t

PER

t

REC

(*) For 10MHz system clock operation (in other words. 1 or moreclock cycles of SCLK).

R/W setup time to SCLK going high 100 ns

SLOAD setup time to SCLKgoing high 100 ns

R/W hold time after SCLK going high 100 ns

SLOAD hold timeafter SCLK goinghigh 100 ns

SCLK high toData Valid 30 50 ns

R/W High to Data Valid

Data bit D[0] valid from HiZ

Address setup time to SCLK goinghigh 30 ns

Data setup time to SCLK going High 30 ns

Address Hold afterSCLK going high 10 ns

Data Hold time after SCLK going High 10 ns

SDIO tri-state after SLOAD going High 30 ns

SDIO tri-state after R/W going low 30 ns

Minimum SCLK period 100 ns

(*) Recycle - Time between successive accesses 100 ns

1) Internal registers are reset and POR is asserted.

2) The automatic parking of the actuator is enabledand the brake delaystarts.

3) After thebrake delay expires,all lowside drivers areenabled to brakethe spindle.

SerialInterface

The serial interface is designed to be compatible

with the Intel 80196 (and other similarmicros) serial interface but is capable of faster data rates,

up to 10 MHz. All read and write operationsmust

consist of 16 bits, with the 80196 this would be

two 8 bit accesses. The first four bits are address

and the next 12 are data. If the address is a read

register then the L6260 will use the SCLK from

the systemto shift out 12 bits of data from the addressed register. The system must provide 16

SCLK pulses to insure that the read operation

completes.

30 50 ns

Serial InterfaceTruthTable

R/W SLOAD SDIO DIRECTION

1 1 Tri-state (Port unselected) Tri-state

0 1 Tri-state (Port unselected) Tri-state

0 0 Address/Data input Input

1 0 Data output Output

17/30

L6260

Figure 5: SerialWrite Timing Diagram

R/W

t

RWS

SLOAD

t

SLS

t

SCLK

SDIO

A0 A1 A2 A3 D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11

PER

4 bit address (FIXED) 12 bit data (FIXED)

The write cycle has a fixed address and data

length. Four bits of address and 12 bits of data

must be clocked in to allowthe data to be loaded

into the desired register. The write cycle is initiated by settingSLOAD and R/W low. SettingR/W

low causes the SDIO line to be tri-stated for data

input. SLOAD low enables the internal counter to

increment on the rising edge of SCLK. The address and data are clocked into the chip serially

Figure 6: SerialReadTiming Diagram

t

RWH

t

SLH

D94IN094

on each rising edge of SCLK as shown above.

When boththe 4 bits of addressand the 12 bits of

the data have been clocked in, then the addressed register will be written to with the provided data. Setting SLOAD high will clear the internal logic and tri-state the SDIO line. This also

provides a way of safely aborting a write by simply forcing SLOAD high. NOTE: SLOAD must be

kept low during the entire duration of the 16 write

clocks.

R/W

SLOAD

t

SCLK

SDIO

A0 A1 A2 A3 D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11

PER

t

INPUT OUTPUT

RWD

HiZ

DATA

INVALID

t

RWS

t

SLS

t

SCKD

The read cycle is initiated by setting SLOAD low

and clocking in a valid read address. Only four

bits of address are necessary, if more than four

bits are clocked in, the four MSBs will be ignored

(i.e. only the first four bits will be used). If a valid

address is detected, the rising edge of R/W will

load the desired register into the internal serial/parallel register ready for clocking out. The

18/30

D94IN095

data in the serial/parallel register is then serially

clocked out on every rising edge of SCLK (LSB is

clocked out first). Additional padded bits clocked

out willbe zero.

Note: If SLOAD is set low with R/W high, the current contents of the internal shift register can be

clocked out. Thisis useful for a ”read back” of the

data last written into therequired register.

L6260

Figure 7: SystemLevel Interface

MICRO

D94IN096

CLK

DATA

CS1

R/W

CS2

SCLK

SDIO

SLOAD

R/W

R/W

CLK

DATA

CS

L6260

OTHER

DEVICE

System clock(FCLK input)and its Pre Scale

System clock (FCLK input) and its Pre Scale The

chip must be clocked via the FCLK pin at one of

two possible input frequency ranges, 4-6MHz or

8-12MHz. The required range is set up via register bit 4.3 (System Control Register B, Sys Clock

Prescale bit) where 0 selectsthe lower frequency

of 4-6MHz and a 1 selects the higher input range

of 8-12MHz.

VCM System

The following functions are provided: Voltage

controlled retract including sourcing and sinking

current, two quadrant retract, with ”Spindle Powered” or ”Commanded” Retract. The VCM DAC

register is accessed via the serial port and allows

the DAC value to be changed. This drives the

VCM DACand in turn theVCM driver.

VCM Compensationand Loop Equations

This information will be included in the next version ofthis datasheet.

VCM Driver

The VCM driver is capable of supplying +/- 300

mA of current although higher peak currents are

acceptable for short periods of time. Closed loop

control of the load current is provided by the

power amplifier which consists of an error amplifier followed by an H bridge output section. The

loop is compensated by an external RC network

connectedto the VCM_C

OMP pin.

The direction of the currentflowing in thebridge is

determined by the sign bit. The H bridge has two

pairs of lower drivers, only one of which is selected at a given time. Such a configuration

makes it possible to choose between two values

of transconductance by selecting the appropriate

pair of drivers. This gain selection is accomplished usingthe VCM DAC Register.

The VCM currentsense amplifierproduces a voltage whichis proportional to the currentflow in the

voice coil. When the system is operating in a linear fashion, the steady state voltage at the

VCM_I_SNS pins is approximately equal to the

voltagecommanded by the DAC. However,under

Figure 8.

VCM

DAC

REGISTER

(REG 1)

DAC BIT 9

DAC BIT 8

DAC BIT 7

DAC BIT 6

DAC BIT 5

DAC BIT 4

DAC BIT 3

DAC BIT 2

DAC BIT 1

DAC BIT 0

VCM

DAC

DACOUT

REF/5

VREF 1.25V

0.0 - 0.25V

AUTOZERO

OFFSET

+

OTA

VCM

DRIVER

LOGIC

+COURSE

VCM

DRIVER

LOGIC

-COURSE

POS

NEG

+FINE

-FINE

COURSE/FINE

D94IN097A

INDUCTOR

19/30

L6260

certain transientconditions, the control loop which

regulatesthe load current canrecirculate, causing

the VCM_I_SNS voltage to be different from the

commanded voltage. This information is useful in

optimizing thecommandprofile during a seek.

The retractvoltage is set byexternal components.

The current loop bandwidth is greater than

20Khertz.

VCM DAC

The VCM DAC consists of 10 bits via the DAC, 1

bit sign and 1 gain bit. However, externally this

can be viewed as being a single 11 bit signed

value with a gainbit in the MSB position.The sign

bit controls the direction of the current. Positive

values of the DAC are regarded as moving the

actuator towards the inside diameter (this is required for parking/braking).The magnitude is converted to a voltage which is used for closed loop

regulation of the magnitude of the load current.

The gain bit

Retract

Automaticactuator retraction isinitiated when any

of the following conditions occur: disabling the

spin system while the VCM system is still enabled, excessive junction temperature (thermal

shutdown), loss of power or microprocessor issued retract. In all cases except the loss of

power, the voltage applied to the voice coil is limited by an active clamp. When power is lost, the

BEMF generated by the spinning motor is rectified and applied across the voice coil to perform

the parkingoperation.

Command retract is activated via the System

Control Register.

VCM Gain Considerations

I

OUT

= ± 0.25⋅

DAC_VALUE

1024

1

⋅

(High current

R

S1

setting)

or

= ±

I

OUT

current

0.25

⋅

DAC_VALUE

1024

1

⋅

+

R

R

S1

S2

(Low

setting)

Modes of Operation

The L6260 provides for four different modes of

operation, namely, Unipolar, Bipolar, Tripolar and

Tristate. The Tripolar mode is includedfor achieving reliable start-ups in a stuck rotor condition

(lengthening drive life-time). These modes are initiated via the System Control Register A, bits 7 &

8 as follows:

20/30

Bit 6 Bit 7 # of driverson

Tristate 0 0 None

Unipolar 0 1 1 low side, no highside

Bipolar 1 0 1 low side and 1high side

Tripolar 1 1 1 high side and2 low side

OR 2 highside and 1 low

side

Spindle compensationand Loop Equations

This material will be available in the next version

of thisdatasheet.

Spindle State Machine

The spindle state machine provides the logic and

timing signals to the spindle driver in support of

the variousmodes of operation.

When the spindle driver is disabled (via the System Control Register), the state machine puts the

spindle driver into a high impedance mode and

places all spindle related circuit into a reduced

powermode.

After a POR, at boot up or after RESET (via System Control Register) the state machine is in the

known state as defined by the System Control

Registers (A & B) initial condition after POR (see

the @PORcolumn of theseregisters).

When in Unipolar mode the commutation sequence is CTR/lA, CTR/lB CTR/lC where lA =

lower A driver (NOTE: Unipolar mode is only

guaranteed at 3V operation). In Bipolar the commutation sequence is uA/lB (upper A and lower

B), uA/lC, lC/uB, uB/lA, lA/uCand uC/lB. In Tripolar mode the state machine does not auto commutate, the microprocessor must increment the

state. The sequence is uA/lBC (upper A and

lower B & C), uAB/lC, uB/lAC, uCB/lA, uC/lAB

and uAC/lB. The Uni/Bi/Tri-polar operation is set

by two bits in the System Control Register A (3.7-

3.8) describedabove (Modes of Operation).

If the RUN/SEARCH bit (SystemControl Register

A, bit 4) is false or 0 (SEARCH mode), the commutation state only increments when the INC

STATE bit is strobed (also in the same register,

bit 3). If the RUN/SEARCH bit is true or 1 (RUN

mode) the state will increment either on a INC

STATE strobe or if a qualified BEMF CROSSING

occurs thestate will increment afterthe commutation delaytimes out.

If either THERMAL=1 (register.bit 0.0) or the

POR=0, all the drivers are turned off. Tristate is

the default mode of operationat power up.

Period counters and delay and masking functions

The period counter is an internal 11 bit register

that is used to time the interval between successive zero crossings. Whenever a zero crossing is

encountered, the period counter is loaded into

L6260

both a mask counter (9 bits) and a delay counter

(11 bits). The period counter is automatically reset to count thenext zero crossing period.

The clock used for the period and mask counters

is a function of the system clock.If the FCLK (the

system clock) is set to the 8-12MHz range then

the period and mask countersare clocked at 1/64

of the system clock, other wise the registers are

clocked at 1/32 of the system clock. The delay

counter clockis programmablevia the SPINCOM

DLY bits in the Spin Control Register (2.8-2.11).

This value is used to divide down the system

clock. Since there is 60 electrical degrees between zero-crossings, the delay counter can provide 1.875 throughto 28.125 electricaldegree delay at 1.875 degreeincrements.

When the period counter reacheszero, the masking of the zero-crossing starts (to avoid seeing

current recirculation spikes). The delay counter

then starts to count down and when it reaches

zero the masking of the BEMF is released so that

zero crossings can once again be detected. The

masking hides the commutation of the motor

which takesplace during themask.

The clocking frequency of the mask and delay

counters is identical. However, thedelay is 11 bits

and the mask only 9 bits. This means that the

mask can provide 15 electrical degrees of masking time. In the System Control Register B, bit

MAKE_PHASE (4.11) a bit value of zero gives

this 15 electrical degrees mask time but a one

gives 7.5 electricaldegrees of mask.

Speed Control & F.L.L.

The rotational position of the motor is inferred

from the BEMF wave form generatedby the floating coil. The chip uses the instant of a particular

zero-crossingand the period between successive

zero crossings to dictate the commutation timings. The completecontrol loop is on chip andthe

speed is controlled bya reference clockFCLK.

The speed control loop uses a frequency locked

loop whichin conjunctionwith an externalcompensation network brings the frequency of the tachometersignalto be equalto the internallygenerated reference frequency. The tachometer signal

can either be the BEMF signal divided down to a

once per mechanical revolution signal or an externally generated tachometer signal, sector burst.

The output of the speed control is a current demandsignalthatgoesto theSpindleDriver.

The spindle current and the commutation delay is

programmed via the Spin Control Register. There

is a ”fine” and a ”coarse” counter that defines the

speed of themotor.

In more detail, the two registers are used in conjunction with two down counters which form a frequency detector that in turn creates feedback

through to a charge pump to maintain the motors

speed regulation.

The course counter is 12 bits and is clocked at

th

the rate of the frequencyclock (FCLK). The

1/64

fine counteris clocked at 1/4th FCLK. The onchip

Frequency Locked Loop (FLL) uses the electrical

cycle pulses (”ec pulse”) to time the motors rotation. Upon the first ec pulse, the course register’s

contents (loaded via the serial port) is loaded into

the internal course counteris then loaded from its

correspondingregister. Thefine counterthen also

immediately starts to count down. In theory (but

not normally in run mode, possibly at start up) the

fine counter could count down through zero an

continue counting down the 2’s complement of

the originalfine counter value.

The period betweenthe start of the course counter

and the zero crossing during the fine counter operation is the programmed period. Any differences

betweenthe desiredperiod and the ec pulse(zero

crossing) is the error in the transconductanceloop

and corrective action is take by the charge pump.

Thiserroris a numbergivenfrom acounterstarting

when the fine counter reaches zero and resetting

when the BEMF pulse occurs. Thevice versa happens if the BEMF anticipatethe ending of the fine

counter.Theerrornumberis loadedin REG.7.

The course and fine counter arrangemen t is

guarateedto work in allpossiblecircumstances (providing there is enough BEMF). For example if the

zero crossing is within or outsidethe finewindow or

even if the zero crossing is in the course register

range.Thissystemwill evenwork ifthe zerocrossing

occursacrossmultiple course/finecycles.

The FLL has a prescaler (defined by the System

Control Register bits EL_MECH and 8_12P (3.10

& 3.5) that changes the cycle counting mechanism between electrical,8 pole or 12 pole (i.e. dividing theec clock by 1,4or 6) respectively.

The procedure for setting the motor speed is as

follows:

let’s call T0 this quantity. T0=

T0⋅0.9⋅FCLK

Doing

64

weobtain Ncourse e.g.

60

SPEED

the number to load in the course register. If this

number exceed 4096 the desired speed is not

achievable. Let’s call ErrNc the decimal part of

Ncoursedoing

T0⋅ 0.1 ⋅ Fclk

4

ErrNc

+

⋅ 16 we obtainNfine e.g.

thenumberto loadin thefineregister.If thisnumber

exceed 2048 all the procedure must be repeated

changing0.9with0.91and0.1with0.09andsoon.

The spindle is enabled via the System Control

Registers.

The slew rate is defined by attaching a resistor to

ground from the S

_SLW pin. The current loop

PN

has a compensation RC network on the

PN_I_COMP pin and the sense resistor is at-

S

PN

tachedto the S

_I_SNSpin(to ground).

21/30

L6260

Figure 9.

Counter value

FLL

Course

register value

FLL

Fine

register value

Course

counter

counting down

Fine

counter

counting down

Zero

expected here

crossing

Course

counter

counting down

Fine

counter

counting down

”Previous”

crossing

Figure 10.

zero

Desired period

between zero crossings

MECH CYCLE

SYSTEM

STATUS

(REG 0)

SYSTEM

CONTROL

(REG 3)

ELEC CYCLE

BEMF CYCLE

MASK

DELAY

CONTROL

SPIN ENABLE

RESET

INC STATE

RUN/SEARCH

SPIN GAIN

8/12 POLE

BRAKE/BI/TRI

ELEC/MECH

SPEED CONTROL

SPIN

(REG 2)

e.g. Actual

zero crossing

12

e.g. Actual

zero crossing

Actual error between expected zero

and actual zero crossing. This value isfed into

the charge pump to either speedup or slowdown the rotation.

HIGH

SIDE

PREDRIVER

CONTROL

LOGIC

LOW

SIDE

PREDRIVER

BEMF

DETECT

crossing

N-MOS

Time

D94IN098

FLL SATURATION

FLL DOWN

FLL COURSE

FLL UP

FLL

(REG 5)

(REG 4)

FINE

FREQUENCY

LOCKED

LOOP

A SyntheticHall output is also provided from this

chip once per electrical orBEMF crossing.

Using the remote current sensing of the Spindle current

The remote currentsensing allows the connection

of the powerdrivers directly to ground.The bene-

22/30

+

-

D94IN099

I SENSE

fit here is the elimination of the externalsense resistor.

Under normal operation there is a 500:1 difference between the current seen on the sense pin

and the current in the spindle power drivers. At

start up this ratio is changed to 2500:1 (five time

the normal operation).The recommended voltage

at thesense pin is approximatelyone volt.

L6260

Example

Assuming that your motor requires 200mA run

current then the sense current would be 200/500

= 400µA. Therefore for 1 volt at the sense pin a

2500 Ohm resistor is required (R = 1/400µA).

Also assuming you require 1 Amp start-up current. You need to change the sense range to 5X.

This also gives1A/2500 = 400µA or1V on a 2500

Ohm resistor.

In the normal ”at-speed” running the voltage at

this pin will vary between 0 and 2 volts approximately (e.g.when using the FLL).When using the

spindle DAC the voltage swing is from 0 to 1.25

Volts

Using the Spindle DACfor Start-Up

When the SPEED bit in the System Control Register A (Register 3.9) is set (to 1), the speed control is given to the DAC (i.e. control is removed

from the FLL). The normal method of start-up is

achieved using the DAC rather than the FLL.

However the FLL can be used from zero speed

with an align-and-goalgorithm but start-up will be

slower. The 8-bit DAC gives 4.88mVper step with

a maximumvoltage of 1.25V.

Start-Upexample

Assume that oneneeds 1A max. start currentand

expects a runningcurrent of 200mA.

For startup, one would program the SFETGAIN

bit to 0 and the SPEED bit to 1. With this value,

1A spindle current results in 1A/3000,or 333µAat

the SPN_I_SNS pin. Using a 3300Ωresistor and

programmingthe Spindle DACto 1V resultsin the

desired 1A startupcurrent.

The startup algorithm is implemented by writing

into theSpindle Control Register A.

Once running speed is attained, the AT_SPEED

bit (System Status Register, bit 7) will go to a 1.

The CPU then sets the SFETGAIN bit to 1 and

the SPEED bit to 1. The normal running current

of 200mA again results in 200mA/600, or 333µA

at the SPN_I_SNS pin. The FLL will regulate the

speedwith a npminal valueof 1V.

During ”DAC control” the FLL change pump capacitor is shorted to the Spindle DAC voltage..

This allows for a smoothertransition from DAC to

FLL control.

Power Devices

When S_BIPLOAR (internal) is turned on and

saturated when the spindle driver is placed in

unipolarmode and has anRdson of 1 Ohm (worst

case over temperature). To support retract without requiring an isolation diode the transistor is

designed so as not to conduct current from

source to drain even if the supplies Vp and Vdd

are at ground and the source is at a positive voltage.

S_A_U, S_B_Uand S_C_U are the upper spindle

drive transistors. They are active whenever the

drive is in bipolar mode and can be turned on in

pairs in tripolar mode. To support retract without

requiring an isolation diode these transistors are

designed so as to not conduct current from

source to drain even if the supplies Vdd and Vp

are at ground and the source is at a positive voltage.

S_A_L, S_B_L and S_C_L are the lower spindle

drive transistors. Theyare activein unipolar,bipolar and tripolar drive. In linear mode the active

transistor’s gate drive is controlled so as to bring

the current in the motor to the level set by the

speed control compensation circuit or the current

Figure 11.

B-POLAR

SPINDLE MOTOR

S-A-U S-B-U S-C-U

PHASE A

PHASE B

PHASE CCENTER TAP

S-A-L S-B-L S-C-L

SR-A

VRECT

VPARK

SR-B

SR-C

PARK

CONTROL

VDD

VCM-A-U VCM-B-U

VCM

VCM-A-L VCM-B-L

D94IN100

23/30

L6260

limit DAC.

The power circuits will be as shown in the follow-

ing figure 11.

Synth Hall

The Synth Hallpin can be programmedto provide

one of two possible outputwave forms (seeregister definitions). Bysetting the SYNTH_HALL bit in

register System Control Register B (4.5) to zero,

the signal is a once per BEMF crossing signal

which has the same phaseas the BEMFamplifier

on chip with all the noise and false transitionsremoved. With this bitset to one, a onceper electrical cyclesignal with 50%duty cycle is produced.

Brake

The BRAKE mode commands a retract & then

turns on the lower three drivers, S_A_L, S_B_L

and S_C_L, to cause immediate braking of the

spindle.

Retract

The retract voltage is defined by a resistor to

ground fromthe R

ETRACT_

V pin.

Test Circuits

1) I/O Mapping Test Mode. This mode is activated by taking the TEST pin high and hold-

ing the TRISTATE pin low. This puts the device into a test mode that allows certain pins

to be directly internally connected to other

pins for the purpose of testing continuity of

solder joints on a board. The following table

defines which pins are I/O mapped and which

is an input and which is an output. Noticethat

I/O mapped pins in one group are not physically adjacent in the package allowing more

thoroughtestability.

INPUT PIN #

20 R/W 11 SDIO

9 SLOAD 11 SDIO

10 SCLK 22 SYNTH_HALL

12 FCLK 22 SYNTH_HALL

50 UV1 5 POR

51 UV2 5 POR

INPUT PIN

NAME

OUTPUT

PIN #

OUTPUT PIN

NAME

2) Digital and Analog Test Mode. This mode is

activated by taking both the TEST pin and

TRISTATEpin high. Once this hasbeen done

the SCLK pin of the serial interfaceis used to

clock out digital data through the DTEST pin.

Simultanously, the ATEST pin cycles through

carrying different analog signals from around

the chip.

SCLK ATEST pin carries... DTEST pin carries...

1 Nominal Bandgap Voltgage (normally 1.25V) Postive/Negative incrementing of theFLL

2 Low Bandgap Voltage (normally 1.23V) Spindle mask

3 Bias Voltage(normally 0.5V) Spindle delay

4 Spindle DAC Output FCLK/16 or FCLK/32 depending on

5 VCM DAC Output BEMF Comparitor output (raw)

6 Temperature Shutdown Voltage (input- used to

alter the point at which thermalshutdown starts

operation)

7 Connected to the A gate of the spindles Low Side

Driver. Allows Rds(on) testing.

3) Tristate Test Mode. This mode is activated by

keeping the TEST pin low and taking the

TRISTATE pin high. This disables the digital

CLK_PRESCALE bitin System Control Reg B (4.4)

VCM predriver(A)

VCM predriver(F).

SDIO.

4) No Test Modes. All test modesare disabledby

keepingthe TEST pin & TRISTATEpin low

outputs, specifically SYNTH_HALL, POR &

Sleep & IdleFunctions

MODE STATE POWER LEVEL POWER DISS.

Ready Spin & VCM enabled Full 20mA

Idle Spin enabled, VCM disabled Reduced 10mA

Sleep Both spin and VCM disabled Minimum 2mA (typical) 5mA(max)

INVALID Spin disabled, VCM enabled*

Spindle set to lowgain

If the spindleis disabledwhile the VCM is enabledthe automaticparking functionis invoked.

24/30

Figure 12: VCMEqivalentCircuit

L6260

5V

R1Rn

Figure 13: VCMModel

Ron

gmn

(Vdac)

Con

+

gmn

-

opened

(Loop

X

here for analysis)

gm1

(Vdac)

gm1

(Vz)

Ron

+

-

Con

Ro1 Ro

gm1+X1

Co1 Cc

ViVz

Rc

Co1

D96IN357

+

-

Vi

Rc

Vg

Cgd

Ra

Cgs

Vi

gm2

(Vgs)

Ro1

Cc

Csb

Cs

L1

Vo

Vg

Vs

Rs

Vd

Ro2

R1

Rn

Cdb

Vs

Rs

L

Cs

D96IN358

25/30

L6260

MATCAD ANALYSIS OF l6286 VCM CURRENT CONTROL LOOP(High Gain)

(User specifiedparameters)

Rc: =240 ⋅ 10

: = 240 ⋅ 10

C

c

R1 : = 20 Coil resistance

L : =1.1 ⋅ 10

: = 100⋅10

C

s

: = 75 Snubber resistance

R

n

:=40⋅10

V

dac

: = 0.8 Sense resistance

R

s

d :=

I

(Device Parameters)

gmn : = 24.2⋅ 10

: = 3.18 ⋅ 10

R

on

:=50⋅10

C

on

gm1 : = 1100 ⋅ 10

o1 : = 1.773 ⋅ 10

R

o1 : = 1.6⋅ 10

C

gm2 = 0.964√ I

VA = 68.7 Early voltage of FET, with±5% variations

R

=

o2

Ra: = 420 Predriver output resistance,with±20% variation

: =10.2⋅10

C

sb

:=49⋅10

C

db

:=11⋅10

C

gd

: = 156 ⋅ 10

C

gs

V

R

VA

dac

I

3

-9

-3

-9

-3

s

-6

6

-12

-6

6

-12

d

d

-12

-12

-12

-12

Compensation resistance

Compensation capacitance

Coil inductance

Snubber capacitace

DAC Voltage

Output current Id = 0.05

Nulling OTA transconductance, with ± 20% variation

Nulling OTA output resistance,with ± 50% variation

Nulling OTA output capacitance,with ± 10% variation

Main OTA transconductance,with ± 20%variation

Main OTA output resistance, with ± 50% variation

Main OTA output capacitance, with ± 10% variation

FET transconductance,with æ 10% variation gm2 = 0216

FET output resistance Ro2= 1.374 ⋅ 10

3

FET source-bulk capacitance, with±10% variation

FET drain-bulk capacitance, with ± 10% variation

FET gate-draincapacitance, with ± 10% variation

FET gate source capacitance, with ±10% variation

1ST STAGE(OTA) TRANSFER FUNCTION:

√

-1

i: =

f(n) : = 10

S(n) : = 2⋅i

n

n

⋅π ⋅

10

n : = 2, 2.01,⋅7

A1: = gmn⋅ Ron ⋅ gm1 ⋅ Ro1 A1 = 1.501⋅ 10

fp1=

1

π ⋅ Ron⋅ C

2⋅

fp1 = 1.001 ⋅ 10

fp2

=

1

⋅

π ⋅

2

R

eq

fp2 = 4.706 ⋅ 10

26/30

on

fz1=

3

⋅

C

o1

5

fz1 = 7.703 ⋅ 10

fzc

fzc = 6.631

gmn

π ⋅ C

2⋅

=

⋅

π ⋅

2

5

⋅

R

Rc

on

Req =

4

1

⋅

R

C

c

c

Req = 2.114⋅ 10

fpc

Ro1 +Rc

=

⋅

π ⋅ (

2

o1

5

1

+

R

c

) ⋅

R

C

o1

c

fpc =0.791

L6260

H1(n) := A1 ⋅

1 +

2 ⋅

1 +

S(n)

π ⋅ fzc

2 ⋅

⋅

)

S(n

π ⋅ fzc

1 +

⋅

S(n)

2 ⋅ π ⋅

2ND STAGE(POWER NMOS) TRANSFER FUNCTION:

1

Zsn(n): = Rn +

ZL(n) : =

H2(n) : =

Cs⋅S(n

Zsn(n) ⋅ ZLo(n)

Zsn(n)+ZLo(n)

(snubber)

)

(load)

1

+ Ci·S(n)

Ra

- (Cgs·S(n) + gm2)

Co·S(n) +

1 +

fp1

S(n

2 ⋅

π ⋅ fz1

⋅

1 +

)

S(n)

2 ⋅ π ⋅

fp2

(OTA)

ZLo(n) : +LS(n) + R1 (motor)

Ci : = Cgs = Cgd Co : =Cgd + Cdb

- (Cgd·S(n)

1

Ro2

1

-0

Ro2

+- (Cgd·S(n) - gm2)

1

ZL(n)

1

Ra

0

{H2

(

n

)=

left|[{matrix{ccol

1

+ Ci·S(n)

Ra

- (Cgs·S(n) + gm2)

- (Cgd·S(n)

Co·S(n) +

-

1

Ro2

1

Ro2

+- (Cgd·S(n) - gm2)

1

ZL(n)

- (Cgs·S(n)

- gm2 +

D96IN361

1

Ro2

1

Ro2

1

+(Cgs + Csb)·S(n) + gm2 +

Rs

27/30

L6260

OPEN LOOPRESPONSE: H(n): = H1(n)⋅H2(n) |H(0)|= 1.367⋅10

MAGNITUDE RESPONSE(dB)

(dB)

70

60

50

40

20⋅ log( H(n) )

30

20

10

0

-10

-20

100 1K 10K 100K 1M f(n)

4

|H2(0)|= 0.145

D96IN359

PHASE RESPONSE(%)

(dB)

135

90

45

arg(H(n))⋅

360

2⋅π

0

-45

-90

-135

-180

100 1K 10K 100K 1M f(n)

D96IN360

28/30

TQFP64 PACKAGE MECHANICAL DATA

L6260

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.60 0.063

A1 0.05 0.15 0.002 0.006

A2 1.35 1.40 1.45 0.053 0.055 0.057

B 0.18 0.23 0.28 0.007 0.009 0.011

C 0.12 0.16 0.20 0.0047 0.0063 0.0079

D 12.00 0.472

D1 10.00 0.394

D3 7.50 0.295

e 0.50 0.0197

E 12.00 0.472

E1 10.00 0.394

E3 7.50 0.295

L 0.40 0.50 0.75 0.0157 0.0236 0.0295

L1 1.00 0.0393

K

(min.), 7°(max.)

0°

D

D1

TQFP64

3348

32

E3D3E1

17

16

E

L1

L

K

0.10mm

SeatingPlane

49

B

64

1

e

A

A2

A1

B

C

29/30

L6260

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibilityfor the

consequences of useof such information nor for any infringement of patents or other rights ofthird partieswhich may result from its use. No

license is granted by implication or otherwise under any patent or patentrights of SGS-THOMSON Microelectronics. Specificationmentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied. SGSTHOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems without express

written approval of SGS-THOMSON Microelectronics.

Australia - Brazil - Canada- China - France - Germany - HongKong -Italy- Japan - Korea - Malaysia - Malta - Morocco - The Netherlands -

1996SGS-THOMSON Microelectronics – Printedin Italy– All Rights Reserved

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

SGS-THOMSON Microelectronics GROUP OF COMPANIES

30/30

Loading...

Loading...