Page 1

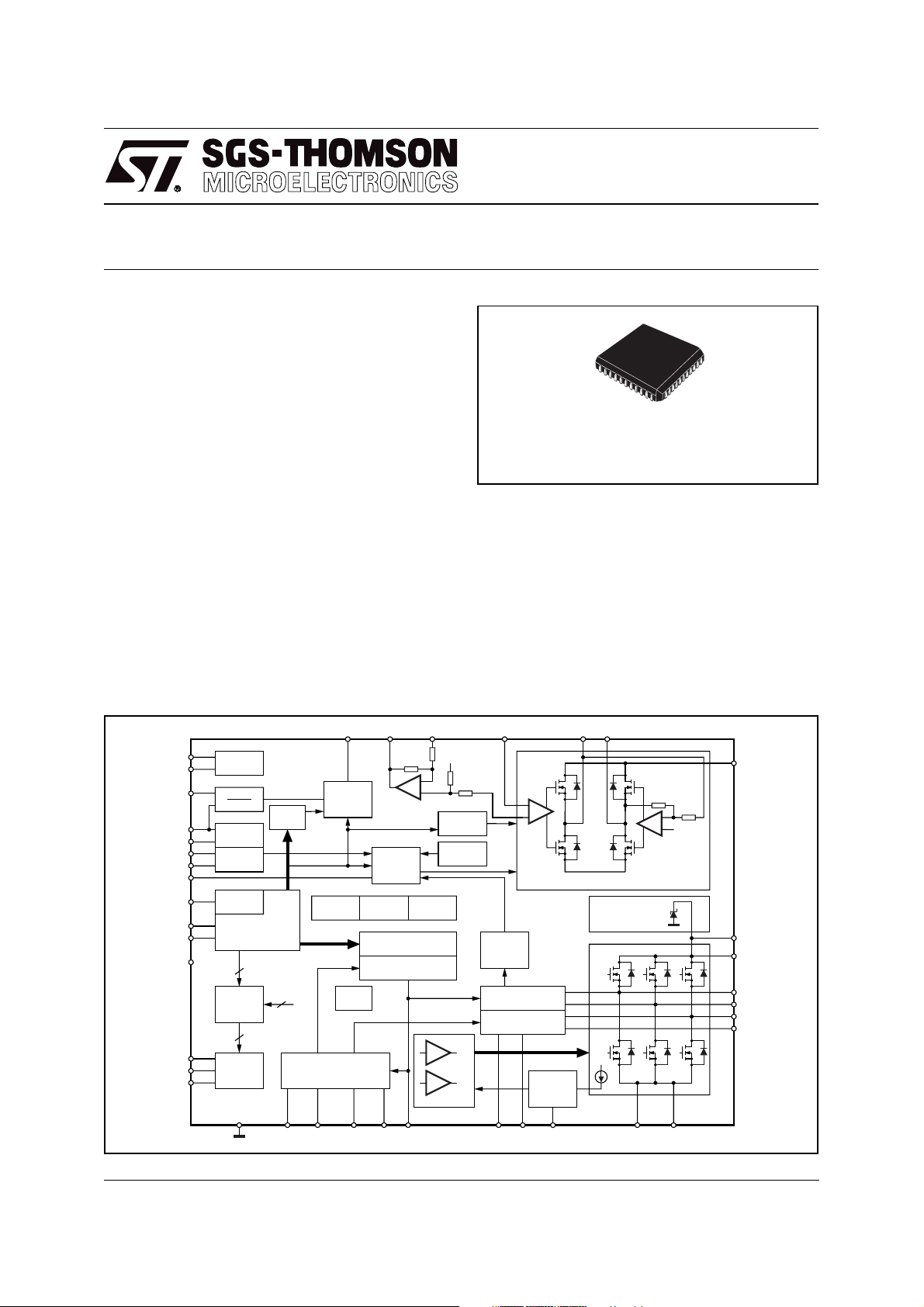

DESCRIPTION

The 12 Volt Combo chip is a combination spindle

motor driver, voice coil driver and D/A converter.

The part can be used in,application like HDD.

The VCM amplifiers drive a low impedance coil

and are set up to accept RC compensation, which

allows a wide bandwidth with absolute minimum

phase lag. The sense resistor/amplifier arrangement allows full current loop operation. The loop

gain is changeable by attenuating the VCM DAC

voltage amplitude in cascadable stages.

The Spindle driver is a PWM only voltage loop

with power supply feedforward, driving a 3 phase

sensorless brushless DC motor. Since it uses

PWM operation at full run speed, it has output

slew rate control during start and run modes.

There is an inductive clamp circuit to limit flyback

voltage transients across the supply voltage during motor phase changes and during the braking

sequence. Only the 2 phase or bipolar commutation pattern is produced by the internal commutation circuitry. A commutation register allows arbi-

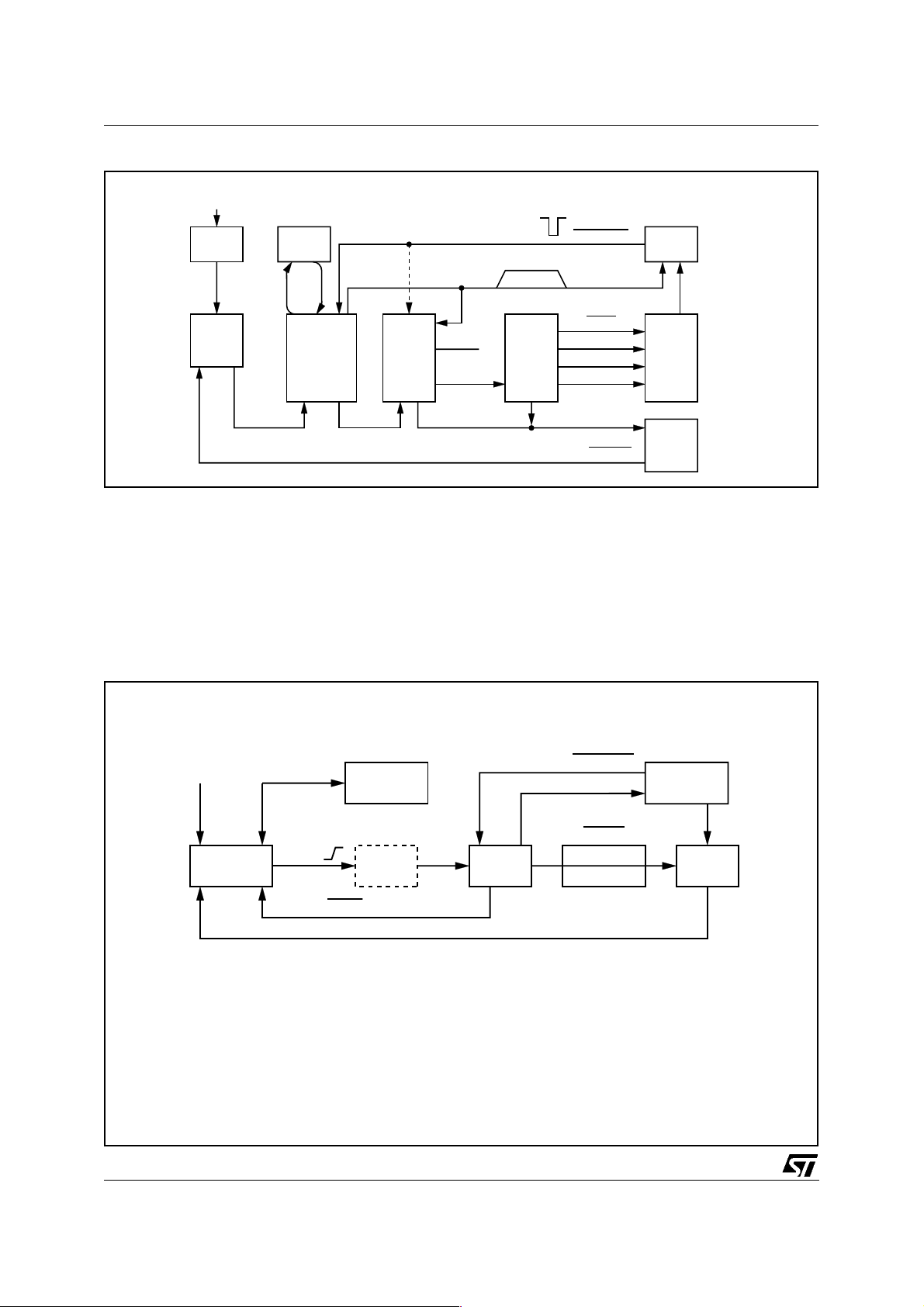

Figure 1. Block Diagram

L6256

12V COMBO

PLCC44

ORDERING NUMBER:

trary winding sequencing during certain operations. Internal protection against crossover

spikes is built in.

3 phase or tripolar commutation can be supported

in software during start by writing a commutation

pattern directly to the preload register.

Tripolar operation requires that more than two

phase drivers contribute current simultaneously.

The current limit circuitry reflects this and allows

33% higher current limit, which produces nearly

L6256

CP_OUT

CP_CAP

H_VPWR

VDD

VCC

nPOR

POR_RC

PARK

SCLK

SDIO

CSELB

BYPASSC

QDRIVE

VREG_IN

CUR_IN

December 1997

18

19

33

34

15

10

9

27

13

14

28

16

20

21

22

3.3V LINEAR

REGULATOR

6,7,17,29,39,40

CHARGE

PUMP

VPWR

2

UV

DETECT

POR

CLK

SYNC

SERIAL INTERFACE

3

ANALOG

TEST MUX

3

VCM

LOGIC

h_vpwr

BRAKE

DELAY

COUNTER

SH_

OUT

A_INI_VCIO_VC

BEMF SENSING

ZERO CROSSING

DETECTION

BEMF_

DET

DAC

VCM

COMMAND

10 BIT

DAC

8 11 36 37 5 38 12 35 44 4

R_

SLEW

CHANNEL

VCM CONTROL

BANDGAP

24

FEEDFORWARD

COMPENSATION

PWM_INPWM_DCFF_

VOLTAGE

REFERENCE

SPINDLE SEQUENCER

SYNC

CLAMP

COMP

VCM

RETRACT

CURRENT

SOURCES

SPINDLE LOGIC

SP_

CLK

THERMAL

upper

lower

PRE-DRIVERS

VCM CLASS AB

DRIVERS

-

+

A

AMP

CURRENT

LIMIT

SENSING

REF_

IN

A_OUT B_OUT

232530263132

PWR GND

SPINDLE DRIVERS

DYNAMIC

CLAMPING

SP_G2SP_

AMP

B

24

VC_PWR

-

+

h_vpwr

2

SP_P1

42

SP_P2

43

SP_A

1

SP_B

3

SP_C

41

C_TAP

D97IN571

G1

1/28

Page 2

L6256

DESCRIPTION

(Continued)

constant torque. This is a very high power dissipation mode, meant only for momentary operation in unusual circumstances.

Spindown during a power failure uses the back

EMF voltage generated by the spindle motor to

provide power to the VCM amplifier. The Spindle

motor coasts during the Brake Delay time to allow

time to park the head actuator. The park circuit is

a constant voltage circuit settable externally.

After the head is parked, braking commences.

The brake operates by shorting all 3 windings.

required to bring the motor to a complete stop,

even if no power is applied to the part.

A Power On Reset (POR) function provides pulse

stretching for the bidirectional POR\ bus, to ensure that the processor and clocks are at running

speed before allowing them to function.

5 volt and 12 volt pins are used directly for the undervoltage detect circuit.

This allows direct use internally of both supplies.

Voltage monitor margining is supported.

An external 3.3V linear regulator is provided and

tied into the POR circuit.

The spindle output stages stay on as long as is

OPERATING CONDITIONS

= 4.5 to 5.5V

V

CC

= 10.8 to 13.2V

V

dd

0°C < T

amb

< 70°C.

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

PWR

V

PVR

V

dd

V

CC

I_VCM, Aout -2 to V

Logic I/O, SH_Out, PWM_DC -0.3 to V

All other pins -0.3 to V

T

stg

(1) Limited by chip clamp voltage.

Normal Operating Voltage 15 V

Inductive Clamp Voltage @ 2mH, 1.6A, 3% Duty Cycle <20 V (1)

Storage Ambient Temperature -65 to +150 °C

ESD capability

15 V

6.4 V

+2V

PWR

+0.3

CC

+0.3V

PWR

2kV

±

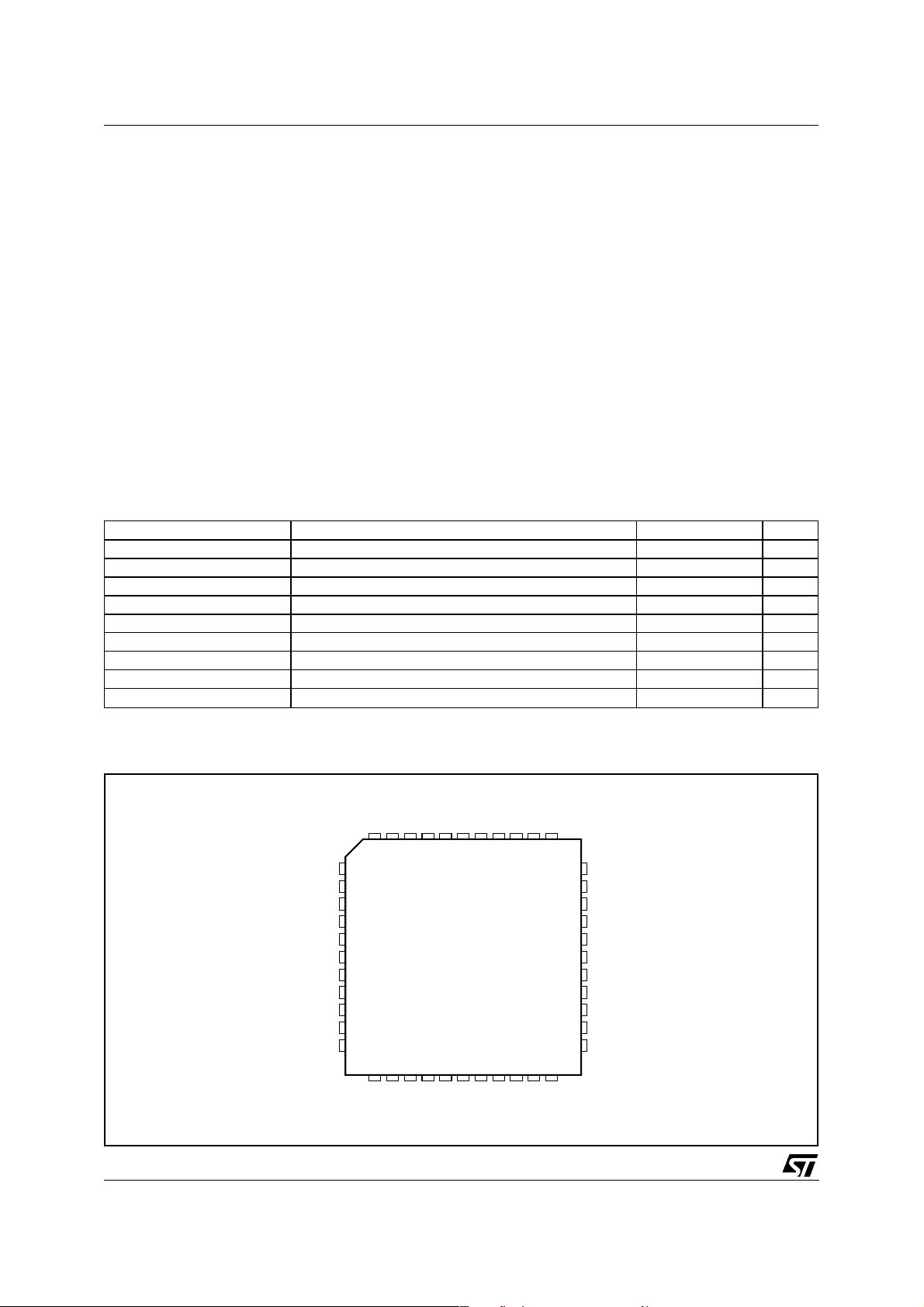

PIN CONNECTION

2/28

GND

R_SLEW

POR_RC

nPOR

PWM_IN

BEMF_DET

SCLK

SDIO

VCC

BYPASSC

5V_GND

7

8

9

10

11

12

13

14

15

16

17

SP_CLK

GND

CP_CAP

CP_OUT

SP_C

SP_G1

QDRIVE

VREG_IN

SP_B

SP_P1

123564

2322211918 20 28272624 25

B_OUT

CUR_IN

SP_G2

SP_A

A_OUT

VC_PWR

C_TAP

SP_P2

I_VC

PARK

GND

40414244 43

CSELB

39

38

37

36

35

34

33

32

31

30

29

GND

SH_OUT

FF_COMP

PWM_DC

REF_IN

VDD

H_VPWR

DAC

IO_VC

A_IN

GND

D97IN572

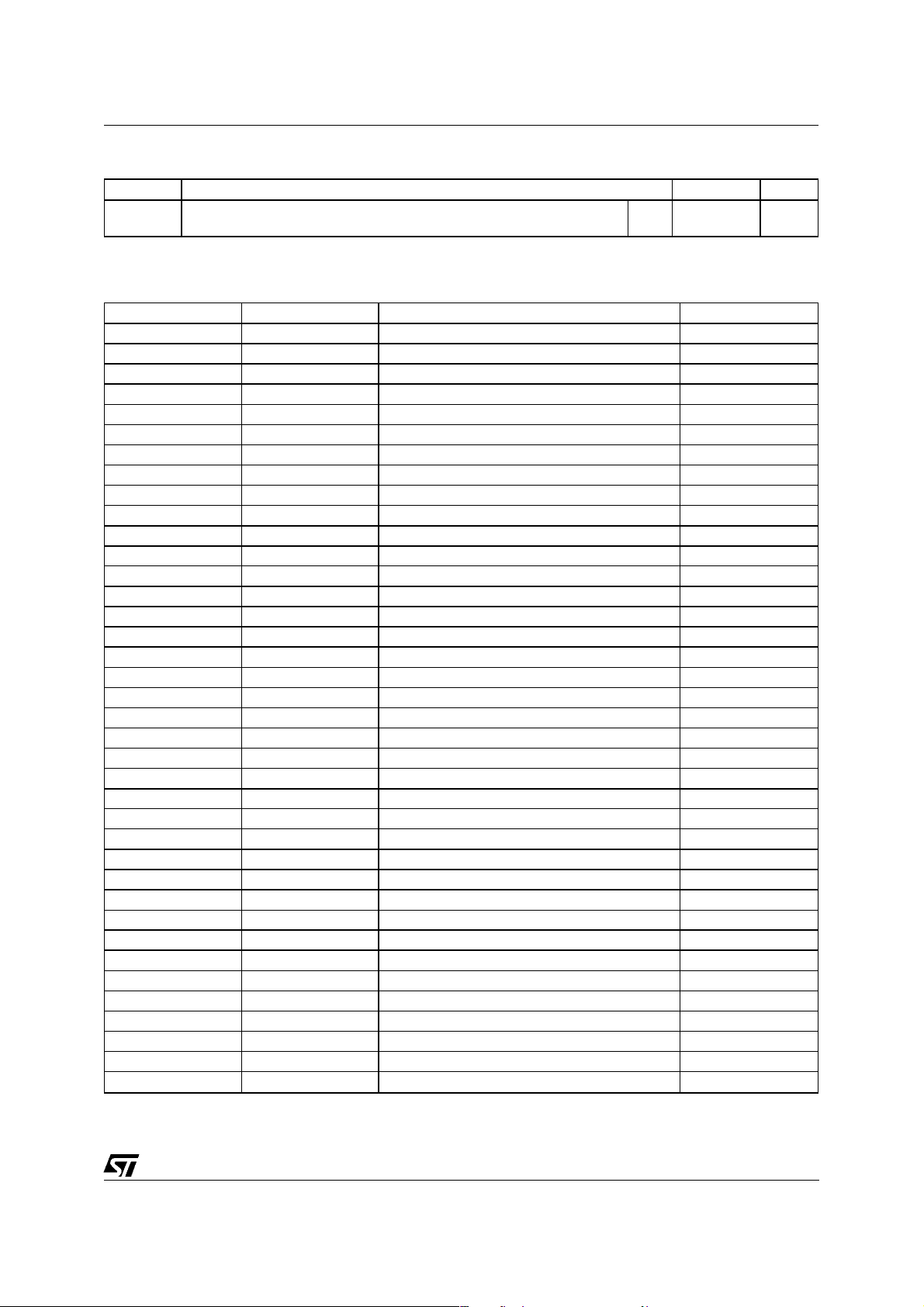

Page 3

THERMAL DATA

Symbol Description Value Unit

R

th j-pins

R

th j-amb

(*) Mounted on board with minimized dissipating copper area.

Thermal Resistance Junction-pins

Thermal Resistance Junction-ambient (*)

Max.

Max.

12

50

PIN DESCRIPTION

Pin # Pin Name Pin Description Type

1 SP_B Spindle Output, Ph B Power/Output

2, 42 SP_P1, SP_P2 Spindle driver Supply Power/Input

3 SP_C Spindle Output, Ph C Power/Output

4,44 SP_G1,SP_G2 Spindle Driver Ground Power/Output

5 SP_CLK Spindle Clock Input Cmos/Input

6,7,29,39,40 GND Power Ground Ground/Heatsink

8 R_SLEW Spindle Slew/FeedFwd Osc. Freq. Analog/Input

9 POR_RC Ext. POR Timing Cap. Analog/Output

10 nPOR POR Reset (Active LOW) Cmos/BIO

11 PWM_IN Spindle PWM Input Cmos/Input

12 BEMF_DET Spindle BEMF Output Cmos/Output

13 SCLK Serial Data Clock Cmos/Input

14 SDIO Bidirectional Serial Data I/O Cmos/BIO

15 VCC 5V Digital Supply Supply/Input

16 BYPASSC Not to be used -

17 5V_GND 5V Supply Ground Ground/Output

18 CP_OUT Charge Pump Pumping Cap Analog/Output

19 CP_CAP Charge Reservoir Cap Analog/Input

20 QDRIVE 3.3V Regulator Base Drive Analog/Output

21 VREG_IN 3.3V Regulator Voltage Feedback Analog/IO

22 CUR_IN 3.3V Regulator Current Feedback Analog/IO

23 B_OUT VCM Driver Output, B Power/Output

24 VC_PWR VCM Drivers Supply Power/Input

25 A_OUT VCM Driver Output, A Power/Output

26 I_VC VCM Sense Amplifier Input Analog/Input

27 PARK VCM Park Pin Analog/Input

28 CSELB Chip Select -

30 A_IN VCM A-Amplifier Input Analog/Input

31 IO_VC VCM Sense Amplifier Output Analog/Output

32 DAC VCM DAC Command Output Analog/Output

33 H_VPWR VCM Vpwr/2 Reference Voltage Analog/Output

34 VDD 12V Analog Supply Supply/Input

35 REF_IN Spindle Current Limit/Win Threshd Analog/Input

36 PWM_DC Spindle Filtered PWM Input Analog/Input

37 FF_COMP Spindle Feedforwd Ramp Generator Analog/Input

38 SH_OUT Spindle BEMF Sample/Hold Analog/Output

41 C_TAP Spindle Centre Tap Analog/Input

43 SP_A Spindle Output, Ph A Power/Output

L6256

C/W

°

C/W

°

3/28

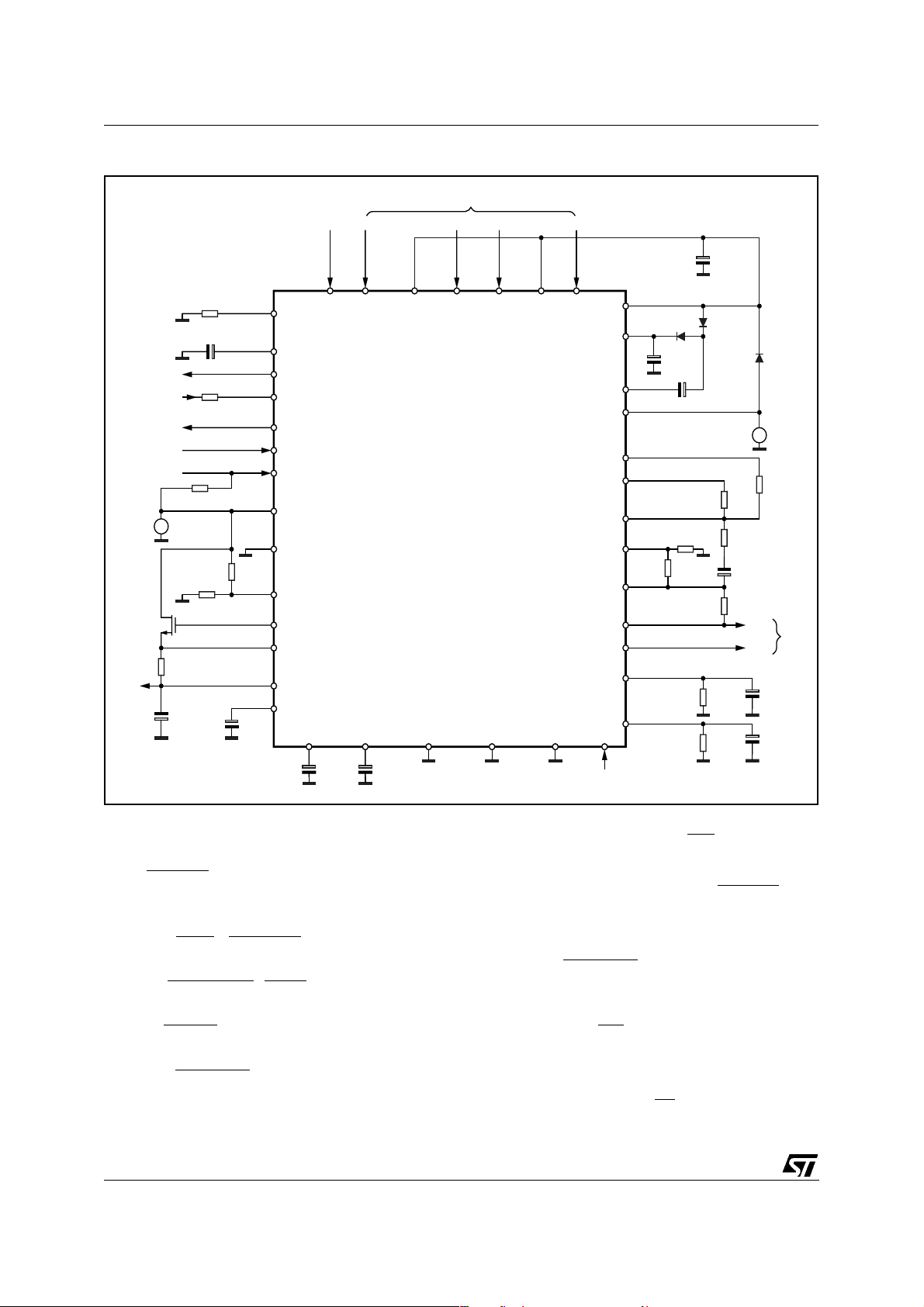

Page 4

L6256

TYPICAL APPLICATION DIAGRAM

SP_CLK SP_C SP_B SP_A C_TAP

SP_C SP_B SP_A C_TAP

SP_CLK

5

33

H_VPWR

BEMF_DET

V

3.3V

C3

22µF

esr 0.5Ω

nPOR

PWM

SCLK

SDIO

CC

R

1.5Ω

S

+

V

-

R

SLEW

100KΩ

C2 47nF

R

PWM

33KΩ

RDIO 1.2KΩ

R

REF2

R

REF

62.5KΩ

Cbyp

10nF

R_SLEW

POR_RC

nPOR

PWM_IN

BEMF_DET

SCLK

SDIO

VCC

5V_GND

120KΩ

REF_IN

QDRIVE

CUR_IN

VREG_IN

BYPASSC

C

HVPWR

100nF

8

9

10

11

12

13

14

15

17

35

20

22

21

16

37

FF_COMP

SP_P1

C

ffc

470pF

SPINDLE

vpwr

C1

4.7µF

D4

33nF

51KΩ

p1

R

p2

100KΩ

R

sh

pwindc

25V

D5

D1

+

V

V

DD

-

R

b

4.3KΩ

R

a

1.5KΩ

R

fb

120KΩ

C

fb

390pF

R

SENSE

0.75Ω

I_VC

VCM

B_OUT

C

sh

3.3nF

C

dc

10nF

SP_P2

414313

SP_G2

42

6,7,29,39,40

GND

CSelB (from µP)

2

4

SP_G1

44

28

24

19

18

34

32

31

30

27

25

26

23

38

36

CSELB

VC_PWR

CP_CAP

CP_OUT

VDD

DAC

IO_VC

A_IN

PARK

A_OUT

I_VC

B_OUT

SH_OUT

PWM_DC

C

PCAP

2.2µF

35V

C

POUT

R

100KΩ

R

100KΩ

D97IN573

DESIGN FORMULAS:

1.

Spindle Run Mode Slew Rate:

1500 ⋅ 10

SR

=

2.

Feedforward Compensation:

Fpwm =

Dout =

=

V

ref

Vrslew =

Fpwm = PWM chopping frequency

Din = Input duty cycle at pwm_in

Dout = Spindle output duty cycle

4/28

Rslew

1

Tpwm

Tpwm

Tpwm

Rpwmdc

Rpwm

Vpwr

(

3

(Volts

=

Cffc

+ 0.7µs

⋅ 2.47 (V

0.8

+

1.86

/µs

)

(V

⋅

⋅

)

1

Rslew

Vref

Vrslew

)

)

(

Hz

⋅

Din

Vcc

3.

Current Limit: Ilimit = 20 ⋅ 10

4.

BEMF Zero Crossing Detector:

- Slope Compensation: Csh ⋅ Rsh =

Vbemf = Amplitude of bemf

3

(A

⋅

Rref

)

5.9683

Vbemf

⋅ N

(sec

)

N = Run mode speed of the motor in RPM

)

- Window width:

t

= 15404

win

5.

VCM PARKING VOLTAGE:

V

= 0.5

A,park

6.

3.3V REGULATOR:

Max Load Current: I

Vcc ⋅ Rref

⋅

Rref

1 +

⋅

Rref2

+

Rp2

Rp1

MAX

⋅ Vbemf ⋅ N

V

)

(

0.3

=

Rs

Polepair (µs

⋅

(A)

)

Page 5

L6256

GENERAL BLOCK DESCRIPTIONS

(see figure 1)

Charge Pump

The Charge Pump provides bias for the upper drivers, for the brake circuit, and for internal circuitry as

required for normal and spindown operation. Slew

rate control is built in for quiet operation.

Serial Interface

The serial interface will transfer all control, status

and data to and from the processor. Internal testing provisions have also been made through this

port. The interface is compatible with an

8X196MP,NU or K17 series processor at low

speed only, due to internal limitations of the processors. External chip select is mandatory on the

L6256. Chip Select is also used to reset and synchronize the serial port. The serial port is used to

indicate thermal shutdown of the Dolphin chip.

Brake Delay Timer

The brake delay will, upon start of a park or brake

sequence, delay 128 negative zero crossings of

the A spindle phase to allow the park circuit to operate. (The delay will typically be on the order of

400 msecs.) Then the braking sequence can begin. The output of this timer is provided to the serial port registers to indicate the start of the brake

action, and to indicate the start and end of the

park period.

Spindle Section

SPINDLE CURRENT LIMIT

The spindle current limit value in start mode is set

by the value of the external resistor on the Ref_In

pin during start (which at start is shorted to Vcc,

and the current out of the pin sets the current limit

value).

During run, various internal methods are used to

set a nominal maximum current value for circuit

protection only. Consult the data sheets and application notes for a description of this circuitry.

Current limit operates on a cycle by cycle basis.

The current limit comparator output is provided to

the serial port to indicate when the spindle is in

current limit. The current limit bit is reset when

the status register is read.

NOTE: Current limit operation involves chaotic

states, and careful firmware control can be used,

if desired, to prevent audible squels. Actual current limit value is also affected significantly by

motor inductance. See application notes.

COMMUTATION COUNTER (CCTR)

The Commutation Counter provides commutation

control for the spindle motor. It advances the

spindle phases according to the bipolar phase

control sequence, every time a SPIN_CLK positive edge is received. Its reset state (B C\) is governed by the Commutation Preload Register

(CPR). Operation of the register is synchronous

with SP_CLK, but the reset is asynchronous.

3.3V Regulator

The 3.3V external regulator provides a logic 3.3V

using an external pass element (N channel FET),

tied into the undervoltage detection system. It has

the following features:

●

Voltage mode control, using no external compensation.

●

3:1 foldback current limit to protect the pass

element in case of component failure.

●

Absolute regulation of 8% under all operating

conditions

Control Registers

See serial port section.

Internal Testing

This circuitry is per vendor’s specifications. No

test functions actuated by the serial port software

allow chip or drive damage to inadvertently occur.

Double level write enabling is used. Differing vendor test requirements are accomodated using the

unique vendor code bits. Various external pins

are used for this function; consult the manufacturer’s data sheets.

COMMUTATION PRELOAD REGISTER (CPR)

During the initial start period, phase on/off control

is preloaded into the counters from the Commutation Preload Register, which is loaded from the

serial port. This allows direct commutation control from the processor. Various commutation

schemes are implemented during startup by software through this register. High side bits take

precedence over low side bits.

For both high and low drivers, logic high input to

this register turns on the respective driver. Any

pattern other than all 1’s holds the CCTR in reset,

and sets the MUX to bring data from the CPR

register for the drive pattern. An all 1’s pattern

(an illegal state) releases the CCTR reset and

switches the MUX to read the CCTR.

An all 0 pattern in the CPR spindle control bits

both tristates the spindle drivers and resets the

commutation counter.

The commutation latch holds data from either the

CPR or the CCTR depending on whether all 1’s

are loaded into the CPR. The latch loads the previous state of the counter when the SP_CLK edge

comes in. The latch circuitry also provides chop

commutation information.

5/28

Page 6

L6256

UPPER AND LOWER SPINDLE DRIVERS

The spindle drivers provide commutation

switches. Internal inductive flyback protection is

provided, dumping the energy into Vpwr node.

This protection network also provides the energy

transfer to the VCM to allow parking after power

is lost.

The high/low and low/high slew rate of the drivers

during run mode is controlled by the R_Slew pin

to ensure that cross conduction with the lower

drivers does not occur, and that excessive voltage slew rates are not produced. Provisions are

made to drive inductive loads due to the possible

filtering requirements. Windings must be damped

with suitable external resistors to allow back EMF

to be detected through the chopping waveform.

INDUCTIVE CLAMP CIRCUIT

The inductive clamp is applied to the motor pins

to prevent the energy from the spindle motor coils

from producing excessive voltages on the part,

when the spindle drivers are tristated or when

commutation occurs.

Back Emf Detect

The back EMF voltage from the spindle motor is

monitored by a sample/hold circuit. First order

slope compensation, set by the value of Rsh and

Csh on the SH_Out pin, is used to reduce jitter.

Sampling will occur during the spindle PWM on

time, and hold during the off time and the

ON_DELAY time. Slope compensation must be

optimized for operation at run speed. During

startup, the zero crossings are detected from all

three phases. During run, only the falling edge of

phase A is useful for timing. A very small amount

of hysteresis is provided to prevent noise glitches.

A fixed offset of approximately

Vebias

millivolts is

internally introduced to the comparator during

start mode.

The inductive flyback pulse must be masked by

the width of the SP_CLK pulse provided by the

Western Digital controller chip. The width of this

pulse is affected by motor speed and current, as

well as inductance.

Additional back EMF conditioning circuitry is being provided by Western Digital’s digital controller

chip. The back EMF_Det pin is masked for approximately 1/4 of the expected commutation cycle, and is latched to prevent multiple transitions.

At power on reset, BEMF_Det is tristated to allow

for in circuit testing.

During run mode, the Ref_In pin sets a prequalifier comparator voltage level, which enables the

zero crossing detection circuit about 20µs ahead

of the actual position. Once speed has been stabilized, the spindle phase advance is used to adjust the EMF crossing to be coherent with the

PWM timing. This is done by observing the output

of the preqalifier comparator and comparing it

with the ON_DELAY signal internal to the chip.

This output comparison is provided through the

serial port.

Feedforward Compensation (FFWD Comp)

Any VPWR variations are nulled out by the ratiometric adjustment of the PWM duty cycle. This

circuit converts the fixed processor PWM frequency down to a frequency determined by the

R_Slew resistor and the FF_Comp capacitor.

This frequency is very constant over the entire

specified supply voltage range.

VCM Section

VCM DAC

The VCM DAC buffer brings the VCM_DAC out-

put up to the required drive capability. A 10 bit

monotonic DAC is provided for the VCM.

ATTENUATOR SWITCHES

These provide variable attenuators for the VCM

current control loop, settable from the control register. Attenuation settings are cascadable in binary form, thus requiring 1 bit for each attenuator.

Ratios of 1.5:1, 2:1 and 4:1 give the additional

combinatorial gains of 3:1 (1.5*2), 6:1 (1.5*4), 8:1

(2*4) and 12:1 (all 3 attenuators on simultaneously). Attenuator gain ratios are not precisely

controlled relative to one another and differ

slightly between manufacturers.

An overall attenuator enable bit has been added

to the VCM_DAC register address field. If this bit

is a 1 (Combo compatible mode), then the attenuators are enabled. If the bit is a 0, then full gain is

requested. This enables the VCM_DAC write to

accomplish a complete gain shift and DAC write

in a single serial port operation (2 bytes).

LEVEL SHIFT

The level shift circuitry shifts the center voltage of

the VCM current command up to approximately

half of the supply voltage, to provide for symmetric operation of the VCM power amplifiers.

The reference voltage output is a high impedance

input point of approximately

Rref

ohms to allow

for external bypassing.

VCM AMPLIFIERS

The VCM amplifiers are complementary class AB

output amplifiers, with Bout having higher gain

than the Aout amplifier. This ensures uniform

saturation in either direction.

6/28

Page 7

SATURATED SEEK BIT

The processor can command the VCM amplifiers

to hard saturate, in the polarity determined by the

sign bit of the DAC. The saturation detector bit is

not the echo of this bit, but is a separate comparator bit representing the true state of the amplifier. Thus, it can be used for loopback testing of

the DOLPHIN.

VCM CURRENT SENSE AMPLIFIER

The input differential voltage of the amplifier can

be limited to low voltage, but common mode rejection is very high. The amplifier is capable of

operating smoothly when the VCM amplifiers are

saturated, providing no input charge buildup or

other anomalies. Charge does not build up on

the inputs even when VCM inductance forces the

inputs substantially above the supply or below

ground.

SATURATION DETECTOR

This detector notifies the processor when the

commanded VCM current does not match the actual VCM current. The threshold is set by

VC_Sat.

L6256

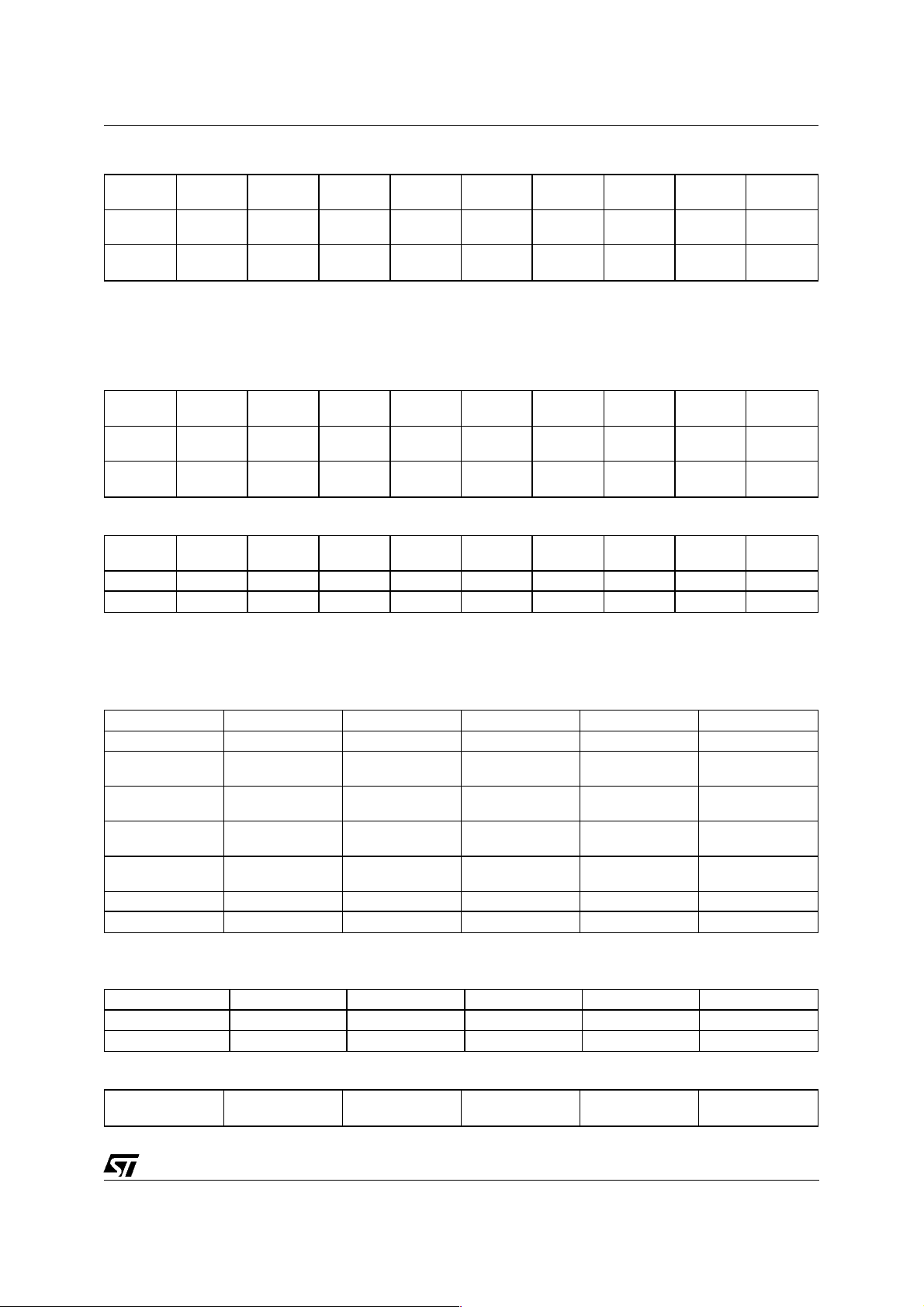

●

An interlock circuit which provides for discharge of the one shot, and a clamp to hold

the POR\ line low during the timing interval.

●

Circuitry to pull POR\ high quickly after the 1

shot has timed out.

●

A current source or weak pullup to pull the

POR\ line high against external leakage currents.

Undervoltage conditions override external inputs

and force POR\ low. External inputs do not cause

pulse stretching; all internal inputs do.

PCBA in-circuit testing can arbitrarily pull this line

low as necessary to restart the system. Alternately, a 1 milliamp current can be introduced to

the timing capacitor to speed up the POR timeout.

THERMAL LIMIT

The thermal limit of the chip is set for

THhyst

relative voltage, above

degrees of hysteresis. Thermal limit is a

Thwarn

sons, and must protect the part; it indicates that

thermal limit is taking place by disabling the serial

port (see serial port section). A park and a spindle driver tristate is performed when thermal limit

occurs.

THlimit

with

for tolerance rea-

Fault Detection

UV DETECTION

The power supply undervoltage protection is set

up for the appropriate tolerances, and causes a

low signal on POR\. A small hysteresis is included on the voltage comparators, and bandwidth limiting techniques are used. Current limit

from the 3.3V regulator has been added to the

POR error inputs.

POWER ON RESET (see appendix B)

The power on reset circuit provides the following

functions:

●

A retriggerable one shot of several milliseconds.

THERMAL WARNING

Thermal warning is made available to the proces-

sor as a status bit in every register, to allow a

modified control algorithm strategy that reduces

power dissipation and drops chip temperature.

PARK CIRCUIT

The park circuit provides smooth head retraction.

In Park, the VCM is switched to voltage mode.

Bout

is grounded. The A amplifier’s positive input is switched from the normal half supply reference down to

Vpark

age determined by

Vpark

, and

Aout

applies the volt-

Rp1

and

and

Rp2

. This

damps any motion that may been in progress and

causes the head to retract into the latch.

7/28

Page 8

L6256

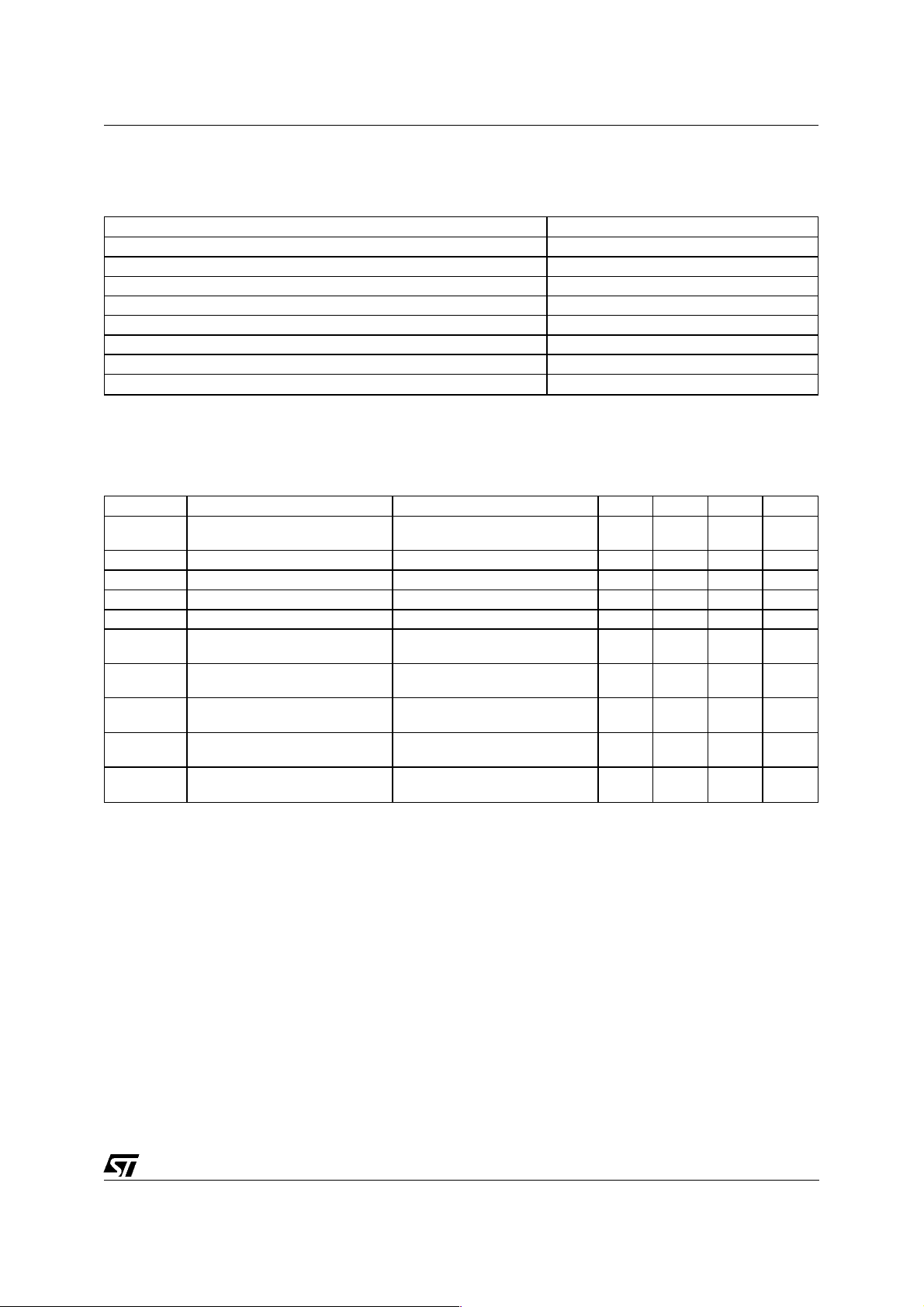

Figure 2:

Spindle State Diagram.

POWER

UP

CPR*

CPR

BRAKE

CPR

START

NO SLEW

3ph EMF

CPR

limit

POR

SPINDLE

Z

(defaults)

START*

SP_EN*

SP_CLK

CPR=1's*

SP_CLK

START

CCTR

No Slew

3ph EMF

limit

START*

SP_CLK

D97IN585

UV

POR

RUN

SLEW

1ph EMF

CCTR

No limit

SP_CLK*

SP_EN*

START*

REG BRAKE

SP_EN

POR

REG BRAKE

UV

THSHUT

THWARN

UV

BRAKE

FAULT

TRISTATE

THERMAL

TRISTATE

BRAKE

DELAY

NOTE: In the spindle state diagram, in transitioning from Start mode to Brake, the CPR register is shown

as being one possible path. The CPR register can be used to command a brake, which then causes the

outputs to brake. This is called CPR Brake mode. However, a true brake state does not really occur.

Specifically, current limit is still active.

NOTE: START and SP_EN bits and CPR is rewritten to get out of Spindle Z state. SP_EN must be

pulsed.

NOTE: All spindle state transitions require an SP_CLK edge.

Figure 3:

VCM section state diagram.

POWER

ON

GROUNDED

VCM_TRISTATE

VCM

VC_EN

VC_EN

(FAULT)= POR or UV or TH_LIMIT

TRISTATE

DELAY

DAC

VCM

ACTIVE

REG PARK

REG PARK

REG BRAKE

(DONE=1)

SP_ENB

FAULT

D97IN586

REGISTER

PARK

FAULT

FAULT

PARK

BRAKE

DELAY

NOTE: VC_EN must be rewritten to get out of VCM Grounded state.

NOTE: At start, the spindle and VCM can now be simultaneously enabled. This is a VERY HIGH

POWER DISSIPATION mode. If this is done, be sure to use the SAT_SK bit and duty cycle the

VCM to keep chip power dissipation at a reasonable level.

8/28

Page 9

L6256

ELECTRICAL CHARACTERISTICS

Power On Reset Section

POR SPECIFICATIONS

Specification Parameter Required Value

Vcc max undervoltage detect trip point, Vuv 4.06 to 4.3

Vcc trip point hysteresis 1%

Vdd undervoltage detect trip point Vuvd 9.3 to 9.8 volts

Vdd trip point hysteresis 1%

Max POR\ delay timing 100 msecs

Forcing current to reset POR_RC (for in circuit test only) nominal 1 milliamp

AC UV detection - nondetectable pulse Tuvmin (1) 1 µsec

AC UV detection - detectable pulse Tuvmax (1) 20 µsecs

(1) AC detection test: done on either supply. With either supply at 0.2 volts above the trip point, a 1.2 volt negative pulse is applied.

Chip must not respond to pulse width of Tuvmin, and must respond to Tuvmax.

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

min

Required VCC or Vdd for valid

POR\@25°C (7)

V

tcap

V

cth

T

strech

T

% POR\ pulse tolerance

tol

T

pmin acc

Timing Cap timeout threshold 2/3 V

Timing Cap threshold (10)

POR\ pulse strech width 5 40 100 ms (5)

external POR\ input required

pulse width

V

lw

Voltage measurement point for

Tpmin

I

weak

Pullup Current, POR\, steady

100

state (at 3V)

T

rise

Rise time on POR\, internal

driver with 100pF load (2)

I

pullup

Pullup Current, POR\,

3.2 mA

momentary

Notes

:

(1) dVmarg% The margining limit is determined as a fraction of the actual chip margin circuitry.

(2) hysteresis on POR\ is optional.

Load: POR\ will see approximately 90 pF plus an external pullup source of approximately 6k ohms. No external bulk capacitance is used

on POR\.

(3) fall time measured from 2 volts to 0.8 volts.

(4) pulse width measured from Vporint volts on falling edge to 1.6 volts on rising edge.

(5) is capable of meeting this timing with a 0.1µF or less, 20% tolerance ceramic capacitor. Nominal design point, .047µF is 40 ms ±20%.

(6) Timing tolerance on POR pulse width irrespective of external parts.

(7) POR\ is valid if either Vcc or Vdd exceeds this voltage.

(8,9) Tpmin acc is the minimum POR\ pulse width which the combo must recognize as a valid external POR. This corresponds to the width of

the reset pulse from the processor. Pulse widths narrower than this may or may not be recognized. Tpmin rej is the value of pulse width

above which the combo should not recognize a pulse.

(10) V

in order to prevent deadly embrace with the microprocessor. The specified value is needed with 3.3V logic circuitry.

is caused by the transition between the external POR circuit and the internal POR clamp circuitry.

bounce

1.3 2.0 V

CC

20% (6)

±

300 ns (9)

0.8 V

µ

100 ns

V

A

9/28

Page 10

L6256

Figure 4:

Power On Reset Waveforms and Timing

V

CC

V

tcap

POR\

V

min

V

porint

V

ccmin

V

tcap

V

min

t

V

t

fall

cth

pmin

V

Internal POR

t

lw

stretch

V

min

D97IN587

Thermal Shutdown Section

Symbol Parameter Value Unit

T

Hlimit

T

hhyst

T

hwarn

(1) Guaranteed by design

Thermal Shutdown Die Temperature (1) 15 ±5 above Thwarn °C

Thermal Shutdown Hysteresis (1) 10 °C

Thermal Warning (1) 145 ±15 °C

SERIAL PORT SECTION

General Specification

Data rate 6 to 12.5MHz

Clock Byte Synchronization internal

Max load to external parts 15pF

Max external load 5mA or 1.2K pullup

Max bus load capacitance 60pF

Output Drive Structure 3 state, active high and

low (not open drain)

Min Speed without dead bit 7MHz (see timing

section) (1)

Internal pullup resistor none

(1) Clock duty cycle of 40% to 60%

Protocol (general):

This protocol is part of a multiple chip protocol

which affects several different Western Digital

chip specifications. Changes to this protocol will

affect several vendors.

Specifications for this chip conform to the timing

specification

The serial protocol used to communicate with the

chip is based on a fixed length 2 byte write or 3

byte read cycle (packets). Each packet sent to

the chip is qualified by Dolphin chi select and by

the address section of the first byte sent to the

chip (bits transferred on clock cycles 2 through 4).

The R/W bit determines packet length and bus direction.

At the end of the 16th bit (write) the data is transferred to the appropriate registers.

At the end of the 8th (read) bit, the internally addressed registers is ready to be placed on the serial bus. A dead bit is provided in all cases as the

first bit read back from the Dolphin, to allow internal propagation delays and to provide for use of

the clock to gate data into the internal shift register. At high data rates the processor has to insert

some time in order to turn the bus around from

write to read mode.

Multiple packets can be sent back to back without

a dead space in between when other chips are

addressed (except for the specified clock cycles

inserted by the processor hardware). The chip is

able to decode this case.

At high data rates, a dead space of at least 1

clock cycle must be allowed in between bytes of

the packet for propagation delays internally.

10/28

Page 11

L6256

Read and write clock rates may differ by as much

as 2:1. Clock rates may differ between different

chips using the bus.

A logic inversion may be used by other chips on

the bus. If this is done, use of the chip select line

after transmissions to the other chips is mandatory.

Chip Select

The external chip select masks out any incoming

data. When inactive, the serial port bit clocking

state machine is cleared, providing a resync

mechanism. The chip select may not change

states between every packet transmission, so it

should not be counted on as a continuous signal.

If the Dolphin is the only chip on the serial port,

the chip select will only be used an emergency resync if the chip doesn’t answer queries.

Figure 5. Serial Port Chip Select Operation.

If an address byte is received that is not addressed to the Dolphin while chip select is active,

the Dolphin will ignore the transmission.

A metal option in the chip select circuit will allow

for either polarity of active level. Present intention

is for an active high level on the chip select pin.

Logic Inversion on Serial Port

If a logic inversion is used by other chips on the

serial bus, the R/W bit will assume the wrong

state and the Dolphin state mechanism will lose

synchronization. In this situation, it will be mandatory for the processor to deassert the chip select

to mask the serial port data intended for the other

chip.

Typical bus waveforms are shown below, with the

resultant activity.

1) Block Mode Write - To other chip

SCLK

SDIO

CSELB

2) Valid Writes to L6256

SCLK

SDIO

CSELB

B (All Data Written)

A1DA2D

wrong

address

(A1 and A2 ignored)

A1 D A2 D

D97IN588

11/28

Page 12

L6256

Figure 6. Serial Port Chip Select Operation.

Transfer Protocol Formats

Read: 3 Bytes dead

Bit #01234567

clock #12345678

Bit R/W- S0 S1 S2 R0 R1 R2 R3 1 cycle

Reply:

Bit D0

(null)

Bit D8

(null)

(1) normally, this dead cycle time is met by the serial port turnaround delay time.

D1 D2 D3 D4 D5 D6 D7

D9 D10 D11 D12 D13 D14 D15

Format for write to the Dolphin DAC, 12V Combo Compatible mode:

Write: 10 Bits to DAC dead

Bit R/W- S0 S1 S2 A0 (1) A1 D8 D9 1 cycle

D0 D1 D2 D3 D4 D5 D6 D7 1 cycle

12/28

cycle

min (1)

cycle

min

min

Page 13

Format for write to the Dolphin DAC:

L6256

Write: 10 Bits to DAC dead

cycle

Bit R/W- S0 S1 ATT_ENB

(*)

A0 (1) A1 D8 D9 1 cycle

min

D0 D1 D2 D3 D4 D5 D6 D7 1 cycle

min

(*) indicates a change in the specification.

If the ATT_ENB is a 1, then the DAC output attenuation will be enabled, and the attenuation will be whatever has been previously written in the VCM control register (this may include no attenuation at all). If the

bit is 0, the attenuator is disabled and high gain is forced.

Format for write to all other Dolphin registers:

Write: 10 Bits to DAC dead

Bit R/W- S0 S1 S2 A0 (1) A1 D8 D9 1 cycle

D0 D1 D2 D3 D4 D5 D6 D7 1 cycle

cycle

min

min

Format for write to the chips other than the 12V combo:

Write: 1Byte dead

BitR/W-S0S1S2A0A1A2A3none (1)

D0 D1 D2 D3 D4 D5 D6 D7 none (1)

(1) There may not be a dead cycle between write addresses and their data bits when data is addressed to another chip on the serial port.

NOTE: All registers are accessible during POR to allow for in circuit testing. Appropriate functional chip changes may be occurring during the

reset.

cycle

Serial Port Timing Specifications

Parameter From/To Min. Typ. Max. Units

T

setup

T

hold

Vdh or Vdl to V

SCLK high to

ch

45 ns

0ns

invalid SDIO, read

T

suw

valid SDIO to

10 ns

SCLK high

T

holdw

SCLK high to

5ns

invalid SDIO, write

T

csck

CSELB low to

133 ns (1)

first falling clock

T

cschigh

last rising clock to 133 ns (1)

CSELB high

(1) CSELB specifications apply to both read and write operations. Timing is only shown in the read operation digram.

Minimum Timing for non-dead bit operation:

Timing Parameter Ref Point Min. Typ. Max. Units

T

sclklow

T

sclkhigh

SCLK Vdl to Vdh 56 ns

SCLK Vdh to Vdl 56 ns

Threshold voltage for SDIO, internal to Dolphin:

V

th

SDIO Logic

Threshold

1.0 1.2 1.7 V

13/28

Page 14

L6256

Test conditions for serial port timing spec:

Parameter From/To Min. Max. Units

, T

T

r

f

V

dh

V

dl

V

ch

Note: The serial port must meet these specifications up to the thermal shutdown temperature.

Figure 7. Serial Port Read Timing Waveforms

SCLK rise, fall 5 ns

2.4 V

0.8 V

2.4 V

Figure 8. Serial Port Write Timing Waveforms

Table of Address Values

S0, S1, S2 always 1 - any other value indicates a

packet for use by another chip.

S2 may be used only as part of the VCM register

address, as ATT_EN.

Register A0-3 R/W

VCM DAC 11xx Write Only

Aux Control Register 0111 R/W

VCM Control Register 0001 R/W

Commutation Preload

Register (CPR)

Test Register (*) 1000 R/W

Status Register 0100 Read only

0011 Write Only

REGISTER BIT DEFINITIONS

All bits in the control registers are asserted (true)

when positive. The appropriate status bit answers

to the same address and bit location as the writable bit which causes the action.

This means that when a read is performed, the

actual value read back is not just an echo from

the write register, but represents the status of the

function requested. In most cases this is a direct,

unlatched output from internal circuitry.

Most status bits are reset after being read once.

The control registers have control bits as follows:

(*) represents revised specification.The test register is now implemented in both chips

14/28

Page 15

L6256

VCM Control Register Address: 0001

Bit Function Mnemonic Bit # Init State R/W Read 1 indicates:

VCM DAC attenuation

switches - 3 bits (5)d

1.5:1 ATT0 0 xxx W N/A

2:1 ATT1 1 xxx W N/A

4:1 ATT2 2 xxx W N/A

Thermal Limit TH_LIM 3 0 Read Th Limit

Register Park RPARK 4 On R/W Park Delay is

Saturate Seek SAT_SK 5 0 R/W Driver Saturated (2)

VCM Tristate VCM_3S 6 xxx W Tristated (3)

VCM loopback (read)

Done Disable (write) (6)

(1) Register park will not cause a brake to occur. The register park bit will also go low during a register brake, indicating to the firmware that

the brake sequence has been initiated.

(2) Saturated seek bit, when 1, will cause the VCM drivers to saturate, with the polarity of the sign bit in the VCM DAC register. A read of this

bit indicates that the commanded current differs from the actual current (output of the saturation comparator). NOTE: this is not just an

echo of the state of the written bit, but actually represents the true status of the VCM current loop.

(3) This bit tristates but leaves internal circuitry active for external test (ST), or is unused (Unitrode). The DONE_DIS bit has been moved

(see note 4).

(4) VCM loopback is optional. Use the saturated seek bit for test purposes. The DONE_DIS bit is used to end the park timer cycle, which

may be necessary if the chip is ever put into run mode at low speed.

(5) Exact attenuation ratios may vary slightly between manufacturers. See data sheets. Attenuators are now gated by ATT_EN, which is lo-

cated in S2 in the address space of the VCM register. IfATT_EN is high, the attenuation is set by the value in this register. If ATT_EN is

low, full gain (no attenuation) is selected. This allows rapid switching between low and high gain with the same write packet as that used

to write to the DAC.

(6) DONE_DIS MUST be cleared when entering run mode, or the park timer will stay off. This bit should never be used except during error

recovery.

VCM_LP

DONE_DIS

7

7

xxx Read

Write

Occuring (1)

Current

Outside

Window (4)

Commutation Preload Register (CPR-Write only) Address: 0011

Bit Function Bit Address

Spindle ABC low enb (3 bits) initial state: XXX (2)

A low enb Bit 0

B low enb Bit 1

C low enb Bit 2

Spindle ABC high enb (3 bits) initial state: XXX (2)

A high enb Bit 3

B high enb Bit 4

C high enb Bit 5

Spare Bit 6

Spare Bit 7

NOTES:

- All bits become valid only on a rising SP_CLK edge, except CHB_ENB.

- Spindle high bits override low bits. Transition from low to high and vice versa are interlocked against simultaneous enables or momentary

shootthrough.

- An all 1’s pattern in this register, bits 0 through 5, causes the internal Commutation Counter to begin operation on the next SPIN_CLK input

edge. Any other pattern causes the spindle Commutation Counter to reset (BC\ state).

(1) CHB_ENB, when high (the POR and default condition), allows the back EMF chop blanking comparator to disable spindle PWM off peri-

ods during the A phase negative crossing (see back EMF detection section). Initial state varies between vendors.

(2) the 6 bits which determine the spindle driver must be set to all 1’s before entering run mode or the CCTR will not run.

15/28

Page 16

L6256

Auxiliary Control Register Address: 0111

Bit Function Mnemonic Init State R/W Bit # Read 1 indicates:

Start (1) START xxx W 0 N/A

VCM enable (2) VC_EN 0 W 1 enabled (5)

Spindle enable (3) SP_EN 0 W 2 enabled (5)

Thermal Limit OVTEMP 0 R 3 Th Limit

Test Enable (7) T_EN 0 W 4 enabled (5)

Software POR SPOR off W 5 always 0 (5)

Spare

Register Brake RBRAKE disabled (4) R/W 7 Braking * (6)

NOTES:

(1) Start disables slew rate control. It also changes the back EMF detection circuitry from 3 phase to single phase.

(2) shuts down active circuitry and drives to the ground state when 0. A transition on this bit is required to reactivate the VCM. see state dia-

gram.

(3) shuts down active circuitry and tristates when 0. A transition on this bit is required to reactivate the spindle circuitry. see state diagram.

(4) Writing to brake will cause a register park, then a brake sequence (an internal POR), without causing an external POR\. Thus, the rest of

the system including the processor will not be reset.

(5) Optional bits.

(6) The register brake function has been redesigned to allow use of a momentary, current limited brake during start mode only. Asserting this

bit overrides the CCTR or CPR register contents without disturbing them, and causes a brake on the spindle outputs.

Resetting the bit restores the previous state ( the outputs were in before the bit was asserted). DO NOT attempt to change the CCTR or

CPR, or send a SP_CLK while this bit is asserted.

(7) Test Enable is used to enable manufacturer specific test circuitry within the chip. This bit should be initialized with a 0 value and left at 0

at all times. Do not attempt to use this bit for any reason unless you have complete manufacturer specific information.

Test Register Address: 1000

Bit Function Init State R/W Read 1 indicates:

Bits: TBD up to 16 read, 8 write

NOTE: The test register requires 2 level access. That is, the test enable bit in the Aux Control Register must be written to with a 1 or the test

register is locked out.

Status Register (read only) Mnemonic Address: 0100

Status Bit High Indicates Address

Dead Bit (unusable for timing reasons) - n/a Bit 0

UV detect UV_DET * Undervoltage Occuring Bit 1

Overtemperature Warning TWARN Exceeded Warning Temp Bit 2

Overtemperature Shutdown OVTEMP Exceeded Shutdown Temp (1) Bit 3

Version Number (2 bits) VERS * (2) 4 = Bit 0

5 =Bit 1

Vendor Number VENDOR (2) Bit 6

Spindle Current Limit SILIM Current Has Exceeded

Bit 7

threshold (7) (8)

Dead Bit (unusable for timing reasons) n/a Bit 8

EMF XOR Output EMFX Changes state on XOR of

Bit 9

Comparator A, B, C

EMF A Comparator Output EMFA Positive High Bit 10

DAC write XOR Write (3) Bit 11

Transmission Error

TX_ERR *

CSELB occurs during active

Bit 12

transmission (4) (7)

Aux_Write

Phase Detect

Spindle Forward

AUX_WR

PH_DET

SP_FWD *

Toggles (5) Bit 13

Correct PWM phasing (6) Bit 14

Reports correct spindle

Bit 15

rotation direction

NOTE: the status register is readable during a POR\ for in circuit testability.

(1) Overtemperature Shutdown or Warning do not cause POR\. This arrangement allows graceful recovery from overtemperature conditions.

(2) Vendor bit = 0 for Unitrode, 1 for ST. Version number, Bits 0,1 allow 4 chip versions. For the Dolphin: Bit 0 = 1, Bit 1 = 0. This allows de-

16/28

Page 17

L6256

tection of the 12V Combo vs. a Dolphin chip

(3) the DAC write bit toggles every time a byte is written to the DAC. This provides confirmation that the write actually took place.

(4) Detects spurious or missing SCLK edge count between CSELB edges.

(5) flips state whenever either ACR or VCR is written to successfully. This bit can be used together with the

was changed in the Dolphin.

(6) If the back EMF chop blanking comparator goes high during the PWM

(7) bit is reset every time the register is accessed by the processor.

(8) current limit bit works in run mode as well as in start mode. If current limit is ever detected in run mode, the chip should be immediately

tristated.

(9) A1 in this bit indicates the correct (forward) phasing has been detected by the back EMF circuitry. Specifically, at the negative edge of

SP_CLK the back EMF comparator must be in the expected state, or else the bit is cleared. Updated on every negative SP_CLK edge.

On_Del

period, this bit is set to a one. See the back EMF section.

SPINDLE CIRCUITRY SPECIFICATIONS

Spindle Circuitry Specifications

Symbol Parameter Test Conditions Min. Typ. Max. Unit

T

brake

Braking Time V

Start Mode Current Limit (bipolar) R

Start Mode Current Limit

Tolerance

SR Slew Rate At speed (3) 12 15 V/µs

Vpwr current spiking At run speed 25% above spindle

Slew Rate range adjustment 0.5:1 2:1 (4)

Run Mode Current Limit 0.7 1.0 1.6 A

Spindle Output Current Leakage

(6)

Snubber caps 0 0.01

(1) braking on the spindle motor must remain active for the full braking time. This parameter is guaranteed by a leakage specification. Full

power brake is 3 seconds maximum.

(2) excluding Vcc tolerances.

(3) Slew rate at startup is limited by the parasitic diode revrse recovery timeso that the peak current spikes in the power supply are no larger

than 25% above the motor run current.

(4) Slew circuitry must internally be able to drive stated snubber loads and be adjusted from 0.5 to 2 times the nominal value. This implies

that Rslew is able to be adjusted from 51K to 200K without causing circuit problems within the chip.

(5) Run mode current limit is strictly a protection mechanism to protect against spurious SP_CLKs or improperly programmed timing. Max

limit is a manifacturer limit determined by safe operating area considerations for the spindle FETs. The minimum limit determines the

maximum chip loading during run time. Since this is strictly an internal limit, tolerances on this value are very wide.

(6) Spindle Output Leakage must not interfere with back EMF sensing at any time.

= 7V 8 s (1)

emf

= 62.5K 1% 1.6 A

ref

Startup I

peak

Tristate -100 +100

TX_ERR

bit to see whether data

7% of programmed

±

current (2)

run current

F 20%

µ

A

µ

Feedforward Circuitry Specifications

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

off min(1)

Minimum off time 20/SR

PWM to DC Conversion (2) 100 110 % of full scale

Chop Frequency (3) 22 - KHz

PSRR, Spindle (4) 32 - - dB

(1)The purpose of

timing circuit which determines

small as possible.

NOTE: dynamic current limit considerations will usually limit the off time even further.

(2) For the PWM to DC conversion, the following standard conditions apply:

Rpwm = 33K 5%

Input impedance of processor driver, 100 ohms

Assume driver is at 100% duty cycle

Rpwmdc = 100K 5%

Cdc = .0033 µF 5%

At these values, the output produces

(3) With Rslew = 100K 1%, Cffc = 470 pF 5%, and including chip input capacitance, the output must not go below 20 Khz over the range of

toff min values.

(4) PSRR is defined as the ratio of average output voltage to the motor over the Vpwr change: -20log10(dVout/dVpwr)

It is tested by injecting a 0.6V peak square wave on Vpwr and Vdd from 1 Hz to 10 kHz. The specification applies over the entire Vpwr

range.

toff min

is to guarantee a full rise and fall time of the spindle chopper output circuitry at the minimum supply voltage. The

toff min

internally tracks the slew rate circuitry to keep this relationship true, while keeping

toff min

at Vpwr = 10 volts so that full scale is reachable.

s

µ

toff min

17/28

as

Page 18

L6256

Spindle Logic Interface Specifications

The digital interface to the controller chip has the following specifications:

Parameter Min. Max. Units

SP_CLK, V

SP_CLK, V

EMF_Det V

EMF_Det V

oh

ol

it+

it-

EMF_Det Hysteresis 0.1V

EMF_Det I

EMF_Det I

il

ih

EMF_Det Load 30pF, 1.6mA

The SP_CLK is a CMOS output. The EMF_Det input is a schimitt trigger with the specified thresholds

and leakage currents.

Vpwr Blocking Diode

The blocking diode in the Vpwr line is optionally a non-schottky part. If this occurs, schottkys should be

used in the charge pump to provide the proper voltage at minimum supply. If regular diodes are used in

both places, the part is functional (at 10% increased Rdson in all drivers) at the lowered Vpwr voltage.

Figure 9a. Run Mode Spindle Voltage Waveforms

VCC-0.8 V

0.5 V

0.7 V

CC

0.2Vcc V

CC

0.3V

CC

-1

1

V

V

A

µ

A

µ

Figure 9b. Start Mode Spindle Voltage Waveforms

18/28

Page 19

L6256

Motor Waveform Specs. / Diagrams

It is necessary to center the center tap voltage by

using symmetrical drive waveforms on the spindle

motor drivers. This necessitates a chopped

waveform on both the high and low side drivers.

The pattern alternates between a high and low

chop on every back EMF cycle during run mode.

NOTE: the off time of the PWM chopping cycle is

not disturbed when switching chop polarities for

audible noise reasons. The change of polarity is

produced by checking the EMF state at the start

of the on portion of the chop cycle.

NOTE: SP_CLK positive pulse width (

tblank

) is

25 +/- 6% of the commutation period.

Supply Voltage Feedforward Compensation

The power supply voltage ripple arriving at the

spindle power input pins would normally directly

feed through into the spindle motor, causing unacceptable speed deviations. The feedforward circuitry cancels the voltage ripple on the power

supply by correcting the PWM duty cycle appropriately. It also reduces the PWM chop frequency

to the minimum required to reduce noise and allow slower slew rates. Finally, it adds substantially

to the resolution of the control loop by removing

supply tolerances from the required range calculations, and by cancelling power supply variations

which would normally have to be taken into account by the loop.

Supply Feed Forward Circuitry

The feedforward circuitry consists of:

Bias Generator

Commutation State Table

This circuitry generates a fixed current level that

generates a very stable frequency in the local oscillator that is independent of supply voltage.

PWM_DC converter

The processor PWM input has several problems

which prevent it from being used directly. The

PWM_DC converter converts the PWM input to a

DC voltage so it can be rechopped.

The bias generator provides a reference voltage

that is used to convert the PWM_IN\input from a

voltage to a DC current value (set by Rpwm, the

input resistor). The duty cycle on this pin thus produces a duty cycled current on the PWM_DC pin.

The RC time constant and the valueof the resistor

on the PWM_DC pin then converters this pulsed

current into a DC voltage with a small amount of

ripple.

Level Shift

The level shift takes the voltage on the PWM_DC

pin and scales it to the resistor ladder reference

(Vrh) to set the ratio of DC voltage to reference

voltage properly.

Local Oscillator

The local oscillator produces a sawtooth wave

whose amplitude is directly proportional to the

power supply voltage. It does this using the slew

rate resistor (Rslew) instead of the bandgap reference, and Cffc, the oscillator capacitor. The local

oscillator must maintain a constant frequency so

that it can be easily synchronized with the back

EMF detection circuitry. Note the diode in the resistor ladder network, which compensates for the

Bipolar

BC/ State 0 (reset)

BA/ State 1

CA/ State 2

CB/ State 3

AB/ State 4

AC/ State 5

NOTE: Before attempting Tripolar operation, consult the application notes.

Tripolar

ABC

High Low High

High Low Low

High High Low

Low High Low

Low High High

Low Low High

19/28

Page 20

L6256

output stage flyback diode voltage.

Off Time One Shot

The off time one shot guarantees that a minimum

off time occur in the output of the spindle PWM

waveforms. This prevents subharmonic cycling,

and prevents partial transition in the output waveform. Additionally, it provides a fixed time delay

which allows acurate synchronizing of the PWM

waveform with the commutation input (SP_CLK).

Finally, it prevents tolerance buildups in the circuitry because the PWM_DC circuitry can be designed to allow higher than full scale voltage with-

Figure 10. Supply Feedforward Circuit Diagrams.

out fear for causing audible subharmonics.

Output Comparator

This comparator produces the PWM chop duty

cycle for use within the spindle drivers, now corrected for power supply variation.

On delay Comparator

The on delay comparator provides a warning sig-

nal for the back EMF detection circuit brackets

the worst part of the turnon transient that occurs

on the back emf detection winding.

20/28

Page 21

Figure 11. Supply Feedforward Support Circuitry.

L6256

Figure 12. Ramp Oscillator Waveforms.

NOTE: toff min is greater than the total fall and

rise time of the spindle output waveforms. This

ensures that a complete off cycle always occurs.

Ideally, toff and the slew rate would be related.

Tond is used by the back EMF detection circuitry

and is nominally about 20% of the total duty cycle.

21/28

Page 22

L6256

Back Emf Detection

Back EMF detection has 2 different modes of operation: Start mode (detemined by the manufacturer),

and Run Phased mode. These are determined by the state of the Start bit.

BACK EMF RUN MODE SPECIFICATIONS

Parameter Test Conditions Min. Typ. Max. Units

Rshold Output Impedance 25°C 150 250

Chop Blank Pulse width tchb (1) 23.5 25 27.5

On Delay width (2) 20 22 24 % of ramp

BEMF start mode detect offset - Vebias

BEMF detect hysteresis 10mV nominal

(1) At 6000 rpm, 8 pole motor, sinusoidal EMF from center tap to the A phase of 8 volts p-p, Rref = 62.5K 1%, Rref2 = 120K 1%.

(2) on delay width is from the end of off time to the end of On_Del. Measured at max duty cycle (no off time due to feedforward compensa-

tion). Specification allows for toff min, to set nominally 20% width of total cycle time.

40mV

±

Ω

s

µ

rise time

START MODE

During startup, all 3 back EMF phases are used.

The output going to the BEMF_Det line is the exclusive or of all 3 phases, and follows the polarity

of whichever phase is currently tristated (relative

to the center tap voltage). If the processor is driving the motor directly from the CPR, the back

EMF circuitry is still active. Tripolar mode by nature prevents EMF detection. EMF transitions are

partially blanked by the controller chip in all

modes.

Figure 13. Back EMF Chop Blanking Mode

Waveforms

Run Phased Mode

The Run Phased Mode is now the default (and

only) state in the DOLPHIN during run mode.

The chop waveform is injected into the back emf

waveform of the unused winding due to transformer coupling and the action of the center tap.

Most of the transient is removed by using a high

CMRR amplifier before the signal gets to the

sample/hold circuit, and by holding during the off

time of the chop. However, a small residual is left

on the sample/hold waveform. This small transient must be kept away from the back EMF

crossing point or it will cause an unstable loop.

This can only be done if the PWM on edge is at

the proper timing relative to the back EMF point.

A comparator is provided internally that generates

the proper delay point by comparing the back

EMF waveform against a small offset voltage

(settable externally). The programmer must then

vary the commutation timing until the

PH_DET

bit

goes high, indicating that the chop and EMF

crossing waveforms are properly phased. This

timing is produced by modifying the phase delay

in the controller chip until

Note that the

PH_DET

PH_DET

is high.

bit is updated at the rising

edge of the chop blanking comparator. If the

On_Del signal (the blanking signal that frames the

EMF on transient) is high during the edge, then

the transient is in the proper position.

The timing of the proper position is set by several

external variables; the PWM frequency, the running RPM speed, and the external reference voltage.

The relationships of the chop blanking comparator, the On_Del signal, and the Ph_Det bit in the

serial port are illustrated in fig. 13.

22/28

Page 23

L6256

Figure 14. Back EMF Phase Detection Timing Relantionships

TRANSITIONS

Transitioning from blind table drive to a back EMF mode drive is handled in the following manner. Re-

member, data written to the CPR takes effect only when SP_CLK receives a positive transition. The following steps must be taken:

●

The programmer must ensure that the last state before state 0 has been output to the CPR and

clocked in using SP_CLK.

●

An all 1’s value is written to the CPR to enable the state counter.

●

The next SP_CLK will then produce a state 0 from the sequencer.

Voice Coil Driver (Vcm) Section

VCM SECTION SPECIFICATIONS

Parameter Test Conditions Min. Typ. Max. Units

Large Signal Voltage gain Output Swing from 1 to

Gain Bandwidth Product, A-Amp 4.5 MHz

3dB BW, total loop 25 kHz

Phase Margin, A Amp 45 °

Slew Rate, A Amp 1.4 2 V/µs

Gain, B Amp -1.17 *A gain

3dB Bandwidth, B 2.3 MHz

Total A+B saturation Resistance I = 600mA 2 3

Offset reflected to I

Vpwr/2 Input Impedance 25°C 38 50 65 k

Loopback Output Threshold (2) 25°C 50 mA/

Saturated seek comparator threshold Output saturated either

V

sst

(1) Total current offset of VCM loop must not exceed 3% of full scale current.

(2) Optional.

sense

10V

D/A reg @ 0 30 mV (1)

30 50 70 mV

polarity

70 dB

Ω

Ω

Ω

23/28

Page 24

L6256

CURRENT SENSE AMPLIFIER SPECIFICATIONS

Parameter Test Conditions Min. Typ. Max. Units

Current Amp Gain Over Temp 2.35 2.4 2.45 V/V

Available Output Current

Current Amp CMRR Including inductive

flyback range, to 25kHz

(1) Charge buildup on current amp input must not occur.

DAC SECTION SPECIFICATION

General Parameters

Parameter Test Conditions Min. Typ. Max. Units

Differential Non linearity 1LSB

Integral Non lineraity Best Fit 2 LSB

PSRR 10 - 14V 60 dB

Settle Time 90% 0.5 1.2

Output Voltage Span Vmin to Vmax

Voltage Span Tolerance -7 +7 %

Output Amp Impedance full temp 5

Output Short cct Current output shorted 1 mA

Coding 2’s Complement

600

±

60 dB (1)

2.5 V

±

A

µ

s

µ

Ω

PARK SECTION SPECIFICATIONS

Parameter Test Conditions Min. Typ. Max. Units

Park Voltage 0.45 0.5 0.55 V

3.3V Voltage Regulator

VOLTAGE REGULATOR SPECIFICATIONS

Current Sense Comparator

Parameter Test Conditions Min. Typ. Max. Units

DC Output Voltage T

= 0 to 160°C 3.135 +3.465 V

j

AC transient 1mA to full load 3% of DC Out.

Volt. (3)

Vilimit (1) T

= 0 to 160°C 0.24 0.3 0.36 V

j

Foldback Current Limit Ratio (2) Output Shorted to Ground 3:1 Ratio

(1) Vilimit is the voltage at which current limit begins to occur, as seen across Rcl (see block diagram) as measured by the UV detection oc-

curing.

(2) Foldback current limit prevents excessive power dissipation in the pass element under short circuit conditions. The ratio is the current

flowing at current limit when the pass element under short circuit conditions. The ratio is the current flowing at current limit when the pass

element is delivering full voltage (when UV first occurs), over the current in the pass element when the output is shorted to ground.

(3) DC and AC transient requirements may be mixed, as long as the total deviation from 3.3V does not exceed Dvreg as specified under the

critical specifications in section 6 of this specification.

DRIVER OUTPUT

Parameter Test Conditions Min. Typ. Max. Units

Output Current V

Output High Voltage I = -0.1mA, V = 5V Vdd-2 V

Output Impedance 25°C 50

< 3.5V 0.5 mA

O

Ω

24/28

Page 25

L6256

Operational Description

At power up, the regulator saturates the pass element until 3.3V is reached. If the 5V supply rises

quickly, the regulator will current limit until 3.3V is

reached. The initial current limit level is about 1/3

of the full voltage current limit level, to limit power

dissipation in the pass element.

Once the 3.3V regulation level is reached, the

regulator mantains thi svoltage regardless of load

changes, even if the DOLPHIN goes into thermal

limit. Current limit provides a signal which also

causes UV and a POR to occur.

If the 5V input is shut down before the 12V supply

is removed, the pass element will drag down the

3.3V due to the internal diode. This prevents back

biasing effects from occuring in the chips powered by the regulator.

Rgate (see block diagram) is provided to desensitize the pass element to layout problems.

In most applications it will not be needed.

Charge Pump

CHARGE PUMP SPECIFICATION

Parameter Conditions Min. Typ. Max. Unit

Slew Rate Run Mode 600 V/µs

RMS Current All Conditions 400 mA

Peak Current All Conditions 600 mA

APPLICATION NOTES AND REQUIREMENTS

Serial Port

NOTE: this was necessary in order to guarantee

that all FF’s would truly represent only a thermal

shutdown situation.

GENERAL FORMAT REQUIREMENTS

1. Serial Port Packets must be sent without intervening data. The dead space between data

bytes and after write packets addressed to

this chip must be observed.

Read:

2.

A turnaround delay of 1 cycle minimum

is expected on a read packet, between the address byte (written) and the first data byte

read back. This is necessary only for data ad-

VCM DRIVER

Software must set the VCM gain to 12:1 before

enabling the VCM coil after spinup. A transient

will occur while the amplifier slews up to its bias

point. Allow a transient settle time of several microseconds before the VCM driver has settled to

its fully enabled state.

dressed directly to the combo, and is normally

satisfied by the processor port turnaround requirements.

Write:

3.

Both bytes must be written to the serial

port in rapid succession, disabling interrupts

during the write period.

4. If the dead cycle between write packets to the

DOLPHIN is not observed, an error will also

occur. This is important at high data rates.

(see manufacturer data specs).

5. Read: same as 4.

SPINDLE DRIVER

Brake/Park

The register bits have been carefully arranged to

allow the VCM software driver to run by looking

only at the VCM control register. A register brake

would normally be initiated by the spindle driver

routine, by setting the register brake bit in the Aux

Control Register. The Dolphin will then raise the

park delay bit in the VCM Control Register, which

the VCM driver can then use to indicate that a

park has commenced. Thus, there is no need for

the drivers to be directly linked through software

THERMAL SHUTDOWN

The serial port becomes inoperative during ther-

mal shutdown. All data coming back is high. If

the chip receives data words in which all bits are

flags. The register brake bit function has been

changed to allow intermittent duty cycling during

start mode, to supply additional damping. There

are some restrictions on its use.

high, the chip is non-functional. This is invisible to

the processor when compared with the thermal

time constants and the detector hysteresis built

into the chip.

Bit 3 of all registers is dedicated to thermal shutdown detection. If it is faster to check just a single bit rather than using a full compare, bit 3 is

Back EMF Detection - Initialization

The back EMF detection in start differs from that

in run. When transitioning from start to run, the

first detected phase will always be the A negative

crossing.

available in every read register.

25/28

Page 26

L6256

RESYNC ALGORITHM

The firmware must use start mode to resync the

back EMF signal when attempting to resynchronize the spindle speed. Please consult the Motion

Control Group for more details. The spinup algorithm is available as a separate specification.

DESIGN FORMULAS

Spindle startup current

Spindle startup current is set up using the follow-

ing formula:

Imax = Rref ⋅

The Vcc tolerances are added to the final design

value.

Back EMF window width

Window width is calculated for other than the

nominal conditions by ratioing the window voltage

against the current nominal design point:

⋅

= 25

tw

Where:

Vemf is the nominal expected back emf to peak

voltage, RPM is the target RPM of the drive;

tw is the resultatnt window width.

1.6

62.5k

Rref

Rref + Rref

in amps

62.5 + 120

⋅

62.5

⋅

8V

Vemf

⋅

6000

RPM

If the window is too small or too large, transients

will affect the detection.

CHOPPING WAVEFORM

There is a requirement on the back EMF wave-

form. The chopping transients must die out before the waveform is sampled or speed errors will

result.

This puts limits on the damping resistors if present, which depend on motor inductance, eddy

current losses and the like.

SH_OUT COMPONENTS

The SH_Out components must be designed so

that the rate of droop of the capacitor matches

the back EMF waveform at its negative going

zero crossing point when the drive is on speed.

Components for one part will work for the other

part, but voltage waveforms are scaled differently

between the two parts.

The SH_Out resistor should be as large as possible. This minimizes the internal impedances and

sample/hold errors. 100K is the nominal design

point.

Additional design formuals are included in the

applications notes for each vendor’s parts and in

Western Digital’s internal application notes.

26/28

Page 27

PLCC44 PACKAGE MECHANICAL DATA

L6256

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 17.4 17.65 0.685 0.695

B 16.51 16.65 0.650 0.656

C 3.65 3.7 0.144 0.146

D 4.2 4.57 0.165 0.180

d1 2.59 2.74 0.102 0.108

d2 0.68 0.027

E 14.99 16 0.590 0.630

e 1.27 0.050

e3 12.7 0.500

e4 1.98 0.078

F 0.46 0.018

F1 0.71 0.028

G 0.101 0.004

M 1.16 0.046

M1 1.14 0.045

mm inch

27/28

Page 28

L6256

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specification mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied. SGSTHOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems without express

written approval of SGS-THOMSON Microelectronics.

© 1997 SGS-THOMSON Microelectronics – Printed in Italy – All Rights Reserved

SGS-TH OMSON Microelectronics GROUP OF COMPAN IES

Australia - Brazil - Canada - China - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

28/28

Loading...

Loading...