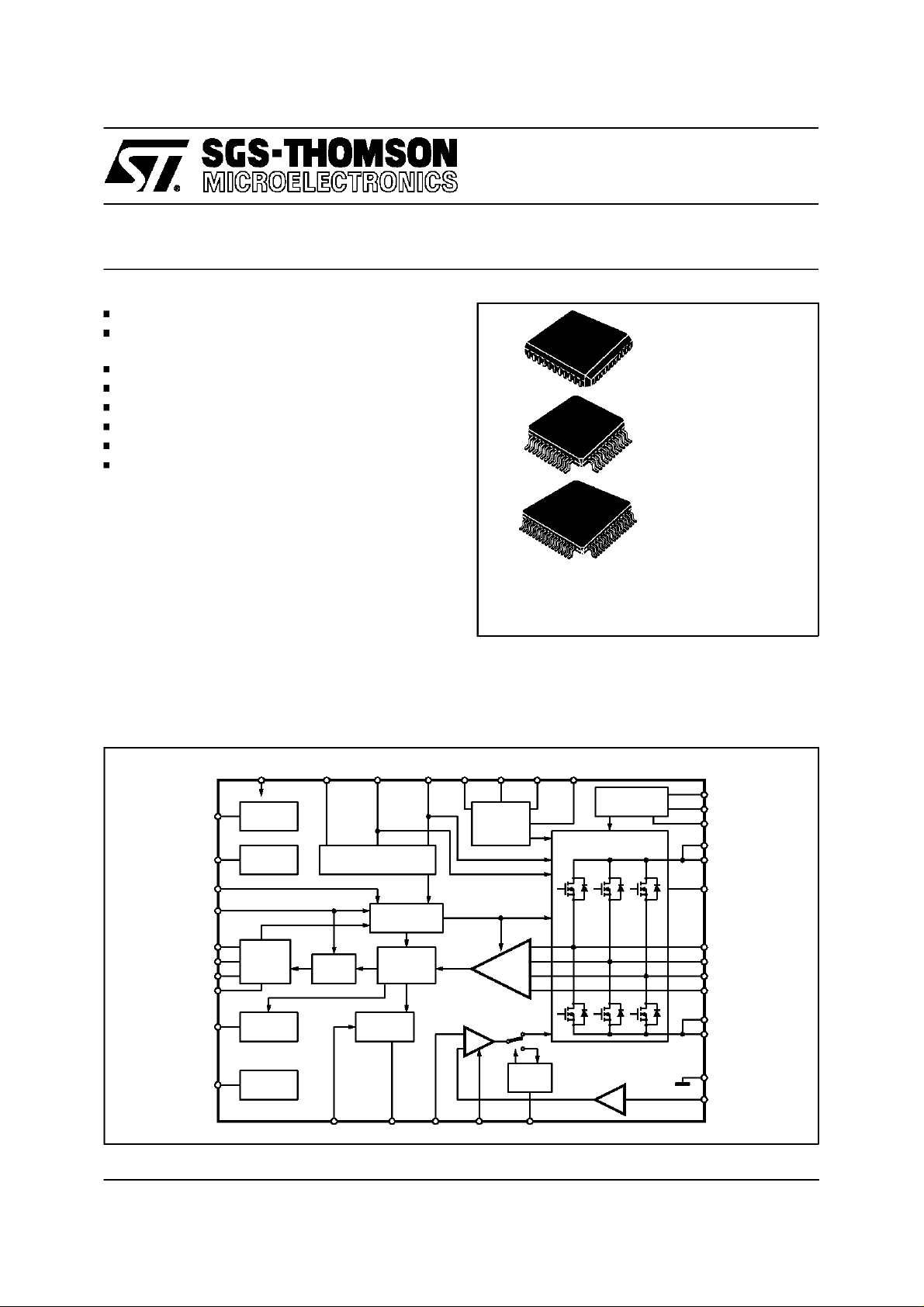

12V SENSORLESS SPINDLE MOTOR CONTROLLER

12V OPERATION

3A,THREE-PHASEDMOS OUTPUT

(TOTALR

NOHALLSENSORSREQUIRED

DIGITALBEMFPROCESSING

LINEAROR PWM CONTROL

STANDALONE OR EXT. DRIVER

SHOOT-THROUGHPROTECTION

THERMALSHUTDOWN

dson

0.52Ω)

L6238S

PRODUCT PREVIEW

PLCC44

PQFP44

DESCRIPTION

The L6238S is a Three-Phase, D.C. Brushless

Spindle MotorDriver system. This device features

boththe Powerand SequenceSections.

Higher Power Applications can be activied with

the additionof an external Linear Driver,or by operatingthe InternalDrivers in PWM.

Motor Start-Up, without the use of Hall Sensors,

can be achieved either by an internal start-up algorithm or by manually sequencing the Output

Drivers, using a variety of User-Defined Start-UP

Algorithms.

BLOCKDIAGRAM

VANALOG

SYS CLOCK

SEQ INCR

MONO/SEQ

CTRL

TDLY(0)

TDLY(1)

TDLY(2)

MASK DLY

VL

BIAS

SYSTEM

CLOCK

DIGITAL

DELAY

FALIGN

MONO

DET

OUTPUT

ENABLE

ALIGN + GO

START-UP

RUN/

BRAKE

SEQUENCER

ZERO

CROSSING

DETECTOR

TQFP64

ORDERING NUMBERS: L6238S (PLCC44)

L6238SQA (PQFP44)

L6238SQT (TQFP64)

Protection features include Stuck Rotor\Backward

Rotation Detection and Automatic Thermal Shutdown.

PWM

PWM

LIN

BEMF

SENSE

PWM

COMP

+

+

+

-

TIM

CHARGE

POWER

STAGE

PUMP

CPUMP1

CPUMP2

CPUMP3

VPOWER

BRAKE

DELAY

OUT A

OUT B

OUT C

CTR TAP

PWM/

SLEW

ONE-SHOT

SLEW-CTRL

RSENSE1

RSENSE2

GND

CSA INPUT

1/31

OT-WARN

October 1995

SPIN

SENSE

TOGGLE

THERMAL

SHUTDOWM

DIVIDE

BY N

FMTRSEL POL

VCTRL

+

-

DRV

CNTL

GATE DRIVEGM COMP

AV=4V/V

CSA

D95IN232

This isadvanced information on a new product now in development or undergoing evaluation. Details are subject to changewithout notice.

L6238S

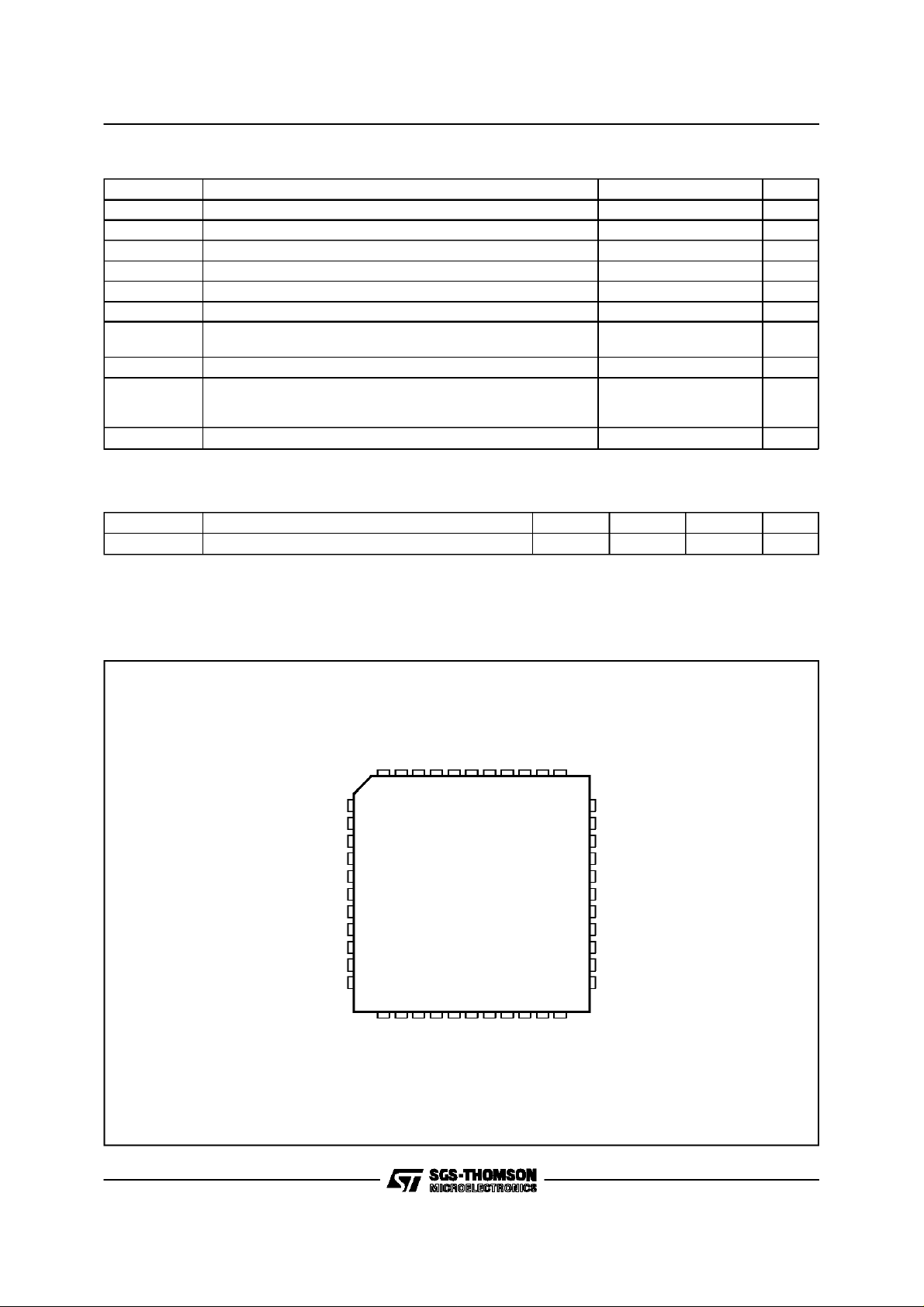

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

BV

dss

V

Power

V

Logic

V

Analog

V

in

C

storage

I

mdc

I

mpk

P

tot

Ts Storage and Junction Temperature -40 to 150 °C

THERMALDATA

Symbol Parameter PLCC44 PQFP44 TQFP64 Unit

R

th (j-amb)

Those Thermal Data arevalid if the package is mounted on Mlayer board in stillair

Output Brakdown Voltage 17 V

Motor Supply Voltage 15 V

Logic Supply Voltage 7 V

Analog Supply Voltage 15 V

Input Voltage -0.3 to 7 V

Charge Pump Storage Capacitor 4.7 µF

Motor Current (DC) (TQFP64 only)

(PLCC44 and PQFP44)

3

2.5

Peak Motor Current (Pulsed: Ton= 5ms, d.c. = 10%) 5 A

Power Dissipation at Tamb = 50 °C(PLCC44)

(TQFP64)

(PQFP44)

2.3

1.7

1.3

Thermal Resistance Junction-Ambient 34 45 45 °C/W

A

A

W

W

W

PIN CONNECTION PLCC44 (Topview)

7

GND

N.C.

GND

8

9

10

11

12

13

14

15

16

17

CHARGE PUMP 1

CHARGE PUMP 3

OUTPUT A

VPOWER

VANALOG

TDLY(0)

TDLY(1)

TDLY(2)

CHARGE PUMP 2

GND

OTWARN

SELECT POLE

BRAKE DELAY

RSENSE 1

PWM/LINEAR

PWM LIMIT TMR

OUTPUT B

SPIN SENSE

123564

2322211918 20 28272624 25

RUN/BRAKE

OUTPUT ENABLE

VPOWER

PWM/SLEW

CENTER TAP

SYSTEM CLOCK

SEQ. INCREMENT

MONO/SEQINC CTRL

GND

MASK DELAY

40414244 43

FALIGN

PWM COMP

39

38

37

36

35

34

33

32

31

30

29

GND

GATE DRIVE

GM COMP

OUTPUT C

RSENSE 2

CSA INPUT

VCONTROL

N.C.

FMOTOR

VLOGIC

GND

D95IN245

2/31

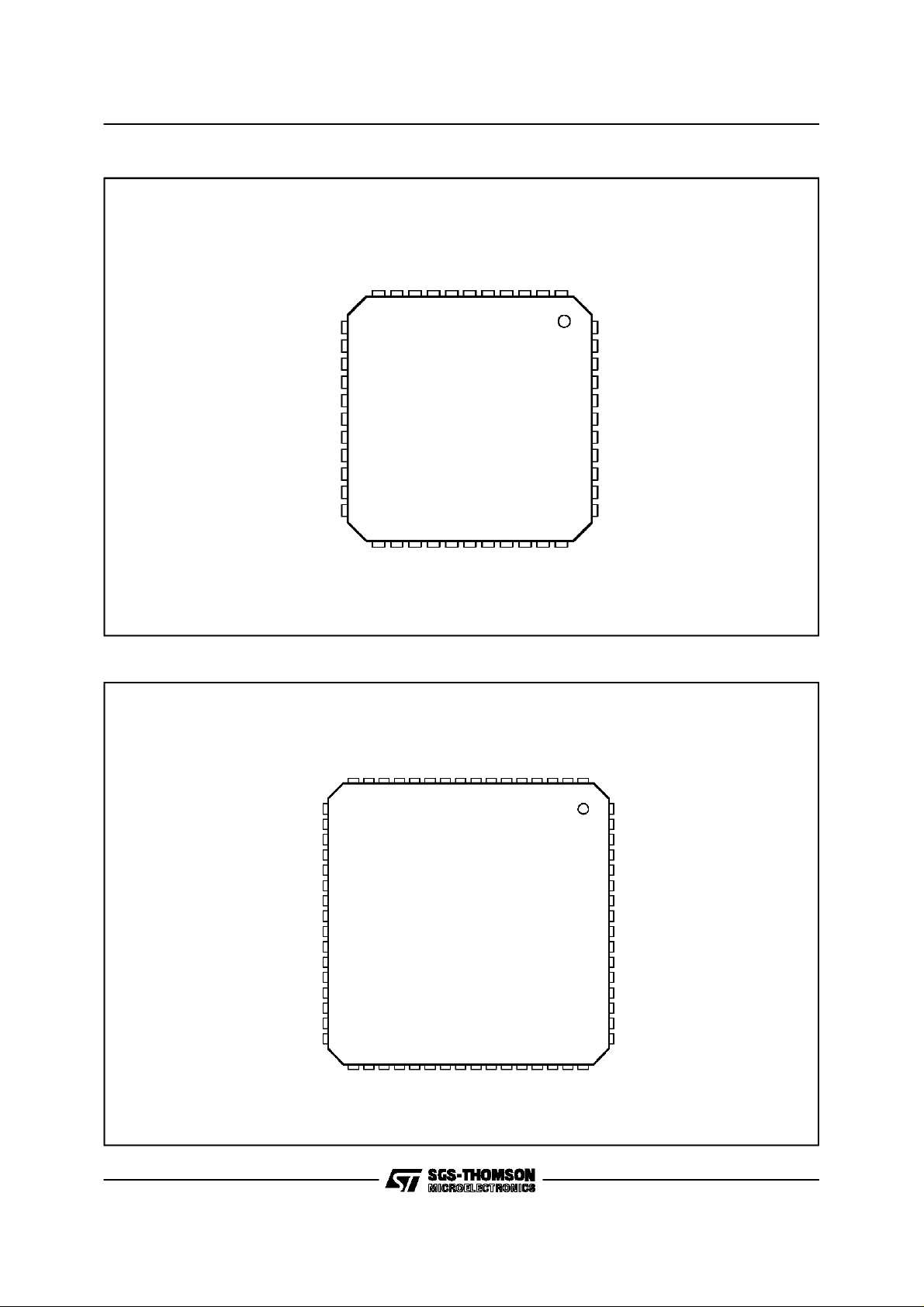

PIN CONNECTION PQFP44 (10x10)(Top view)

TDLY(2)

GND

TDLY(1)

OTWARN

SELECT POLE

PWM LIMIT TIMER

PWM/LINEAR

OUTPUT ENABLE

RUN/BRAKE

SEQ. INCREMENT

SYSTEM CLOCK

MONO/SEQINC CTRL

FALING

PWM COMP.

12

13

14

15

16

18

19

20

21

22

GND

VLOGIC

FMOTOR

N.C.

TDLY(0)

N.C.

VCONTROL

VANALOG

VPOWER

2827262423 25 33323129 30

RSENSE 2

CSA INPUT

OUTPUT A

OUTPUT C

CHARGE PUMP 1

CHARGE PUMP 3

GM COMP

GATE DRIVE

GND

123564789101711

44

43

42

41

40

39

38

37

36

35

34

GND

L6238S

GND

CHARGE PUMP2

RSENSE 1

BRAKE DELAY

SPIN SENSE

OUTPUT B

PWM/SLEW

CENTER TAP

VPOWER

MASK/DELAY

GND

D95IN243

PIN CONNECTION TQFP64 (Topview)

GND

GND

17

N.C.

18

N.C.

N.C.

GND

19

20

21

22

23

25

26

27

28

29

30

31

32

GND

OTWARN

SELECT POLE

PWM LIMIT TMR

PWM/LINEAR

OUTPUT ENABLE

RUN/BRAKE

SEQ. INCREMENT

SYSTEM CLOCK

MONO/SEQINC CTRL

FALIGN

PWM COMP

GND

GND

TDLY(1)

TDLY(2)

VLOGIC

FMOTOR

VANALOG

TDLY(0)

1213141516

37363433 35

CSA INPUT

VCONTROL

VPOWER

VPOWER

RSENSE 2

RSENSE 2

N.C.

N.C.

OUTPUT A

OUTPUT A

4342413938 40 48474644 45

OUTPUT C

OUTPUT C

CHARGE PUMP 3

GM COMP

CHARGE PUMP 1

GATE DRIVE

GND

GND

GND

GND

GND

123564789102411

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

GND

GND

GND

CHARGE PUMP 2

RSENSE 1

RSENSE 1

BRAKE DELAY

SPIN SENSE

OUTPUT B

OUTPUT B

PWM/SLEW

CENTER TAP

VPOWER

VPOWER

MASK DELAY

GND

GND

D95IN244

3/31

L6238S

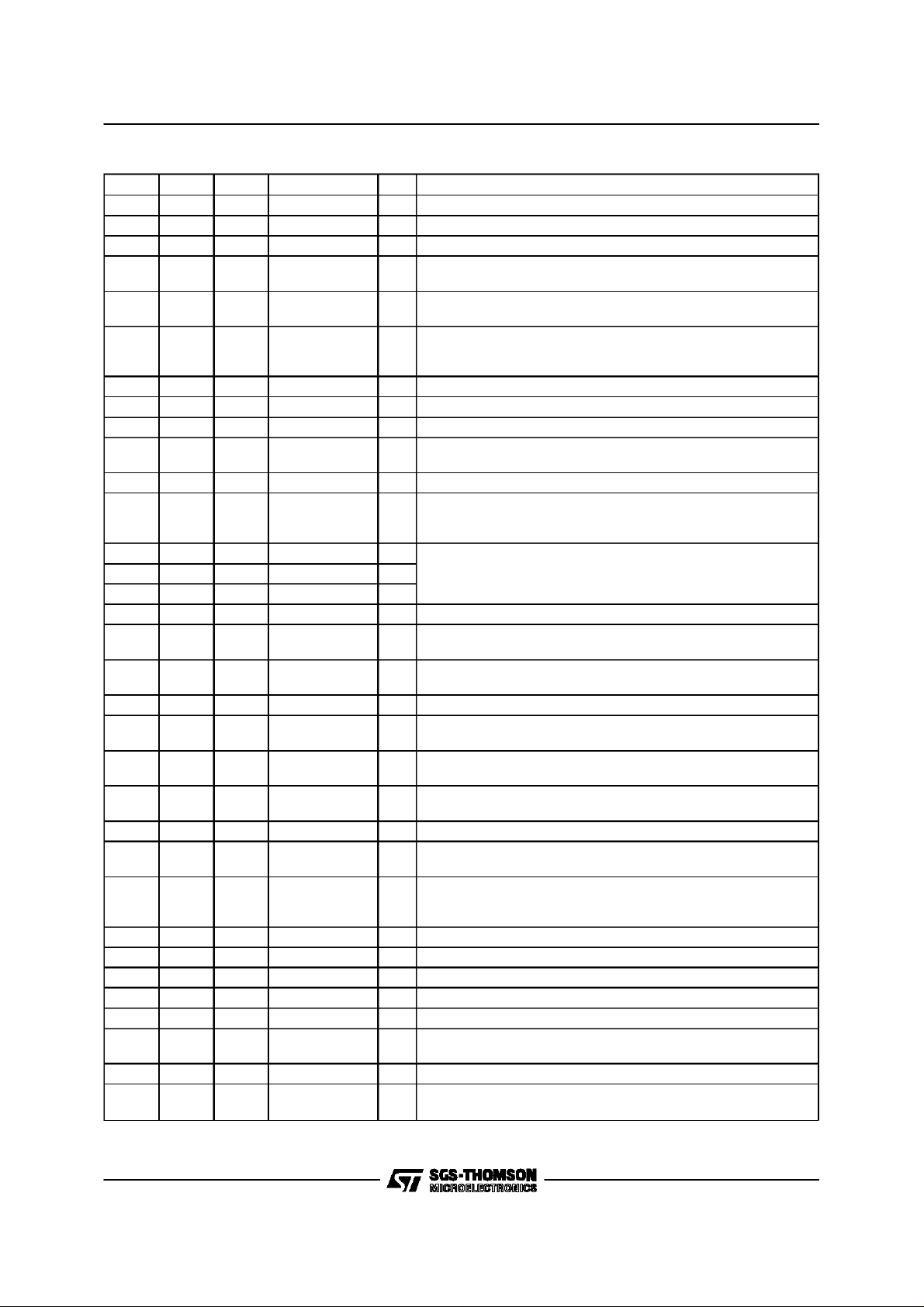

PIN FUNCTIONS

PLCC44 PQFP44 TQFP64 Name I/O Function

1 39 56, 57 OUTPUT B I/O DMOS Half Bridge Output and Input B for Bemf sensing.

2 40 58 SPIN SENSE O Toggless at each Zero Crossing of the Bemf.

3 41 59 BRAKE DELAY I Energy Recovery time constant, definedby external R-C to ground.

4 42 60, 61 R

sense 1

5 43 62 CHARGE

PUMP 2

6, 7,

17, 29,

39, 40

1, 11,

23, 33,

34, 44

* GROUND S Ground terminals.

8 2 4 CHARGEPUMP1 I Positive terminal of Pump Capacitor.

9 3 5 CHARGEPUMP3 O Positive terminal of Storage Capacitor.

10 4 6, 7 OUTPUT A I/O DMOS Half BridgeOutput and Input A for Bemf sensing.

11, 42 5, 36 9, 10,

V

power

52, 53

12 6 11 V

13, 32 7, 26 8, 18,

analog

N.C N.C Open Terminal

19, 31,

41

14 8 12 Tdly(0) I Three bits that set theDelay between the detection of the Bemf

15 9 13 Tdly(1) I

16 10 14 Tdly(2) I

18 12 20 OTWARN O Overtemperature Warning Output

19 13 21 SELECT POLE I Selects # of Motor Poles. A zero selects 8, while a one selects 4

20 14 22 PWM TIMER I Capacitor connected to this pin sets the maximum time allowed

21 15 23 PWM/LINEAR I Selects PWM or Linear Output Current Control

22 16 24 OUTPUT

ENABLE

23 17 25 SEQUENCE I Rising edge will initiate start-up. A Brakingrountine is started

24 18 26 SEQ

INCREMENT

25 19 27 SYSTEM CLK I Clock Frequency for the system timer/counters.

26 20 28 MONO/SEQ.

INC. CONTROL

27 21 29 Falign I Reference Frequency for the opt. Auto-Start Algorithm. If int.

28 22 30 PWM COMP O Output of the PWM Comparator

30 24 35 Vlogic S 5V Logic Supply Voltage.

31 25 36 Fmotor O Motor Once-per-Revolution signal.

33 27 37 Vcontrol I Voltage at this input controlshe Motor Current

34 28 38 CSA INPUT I Input to the Current Sense Amplifier.

35 29 39, 40 Rsense 2 O Output C connection forthe Motor Current SenseResistor to

36 30 42, 43 OUTPUT C I/O DMOS Half Bridge Output and Input C for Bemf sensing.

37 31 44 gm COMP I A series RC network to ground that defines the compensation of

O Outputs A+B connections for the Motor Current Sense Resistor

to ground

I Negative Terminal of Pump Capacitor.

S Power Section Supply Terminal.

S 12V supply.

zero crossing, and the commutation of the next Phase.

poles.

for 100% duty cycle during PWM operation

I Tristates Power Output Stage when a logic zero.

when this input is brought low.

I A lowto high transition on thispin increments the Output State

Sequencer.

I A logicone will disable the Monotonicity Detectorand Sequence

Increment functions.

start up is not used, this pin must be connected to the System

Clock.

ground.

the Transconductance Loop.

4/31

PIN FUNCTIONS

PLCC44 PQFP44 TQFP64 Name I/O Function

38 32 45 GATE DRIVER I/O Drivers the Ext. PFET Gate Driver for Higher Power applications.

This pin must be grounded if anexternal driver is not used.

41 35 51 MASK/DELAY O Internal Logic Signals used forproduction Testing

43 37 54 CENTER TAP I Motor Center Tap used for differentialBEMF sensing.

44 38 55 PWM/SLEW I R/C at this input set the LinearSlew Rate and PWM OFF-Time

L6238S

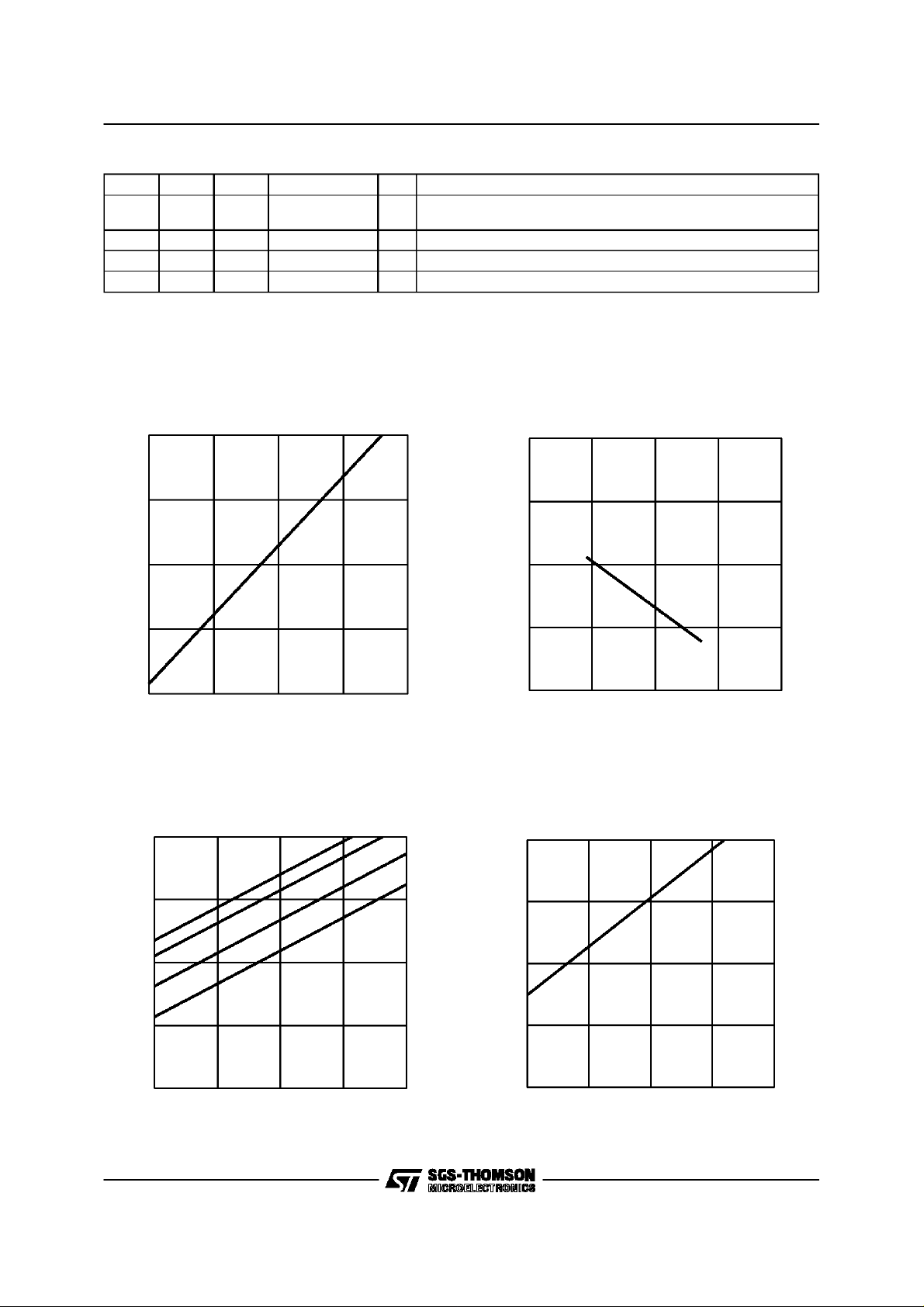

Figure1: BrakeDelay TimeoutvsC

(R

T

BD

(s)

3.0

1.0

0.3

0.0

0.0 0.3 1.0 3.0 Cb(µF)

Figure3: PWM Off - Time vs R

brake

=1Meg)

slew/Coff

brake

D95IN274

Figure 2: LinearSlew Rate vs R

S

VR

slew

(V/µs)

3.0

1.0

0.3

0.0

10 30 100 300 Rs(KΩ)

Figure 4: PWMLimit Time - Out vsC

D95IN275

timer

PWM

(µs)

D95IN276

30

10

3

1

100 300 Coff(pF)

PWM

(µs)

30

10

100 300 Ctimer(pF)

D95IN277

5/31

L6238S

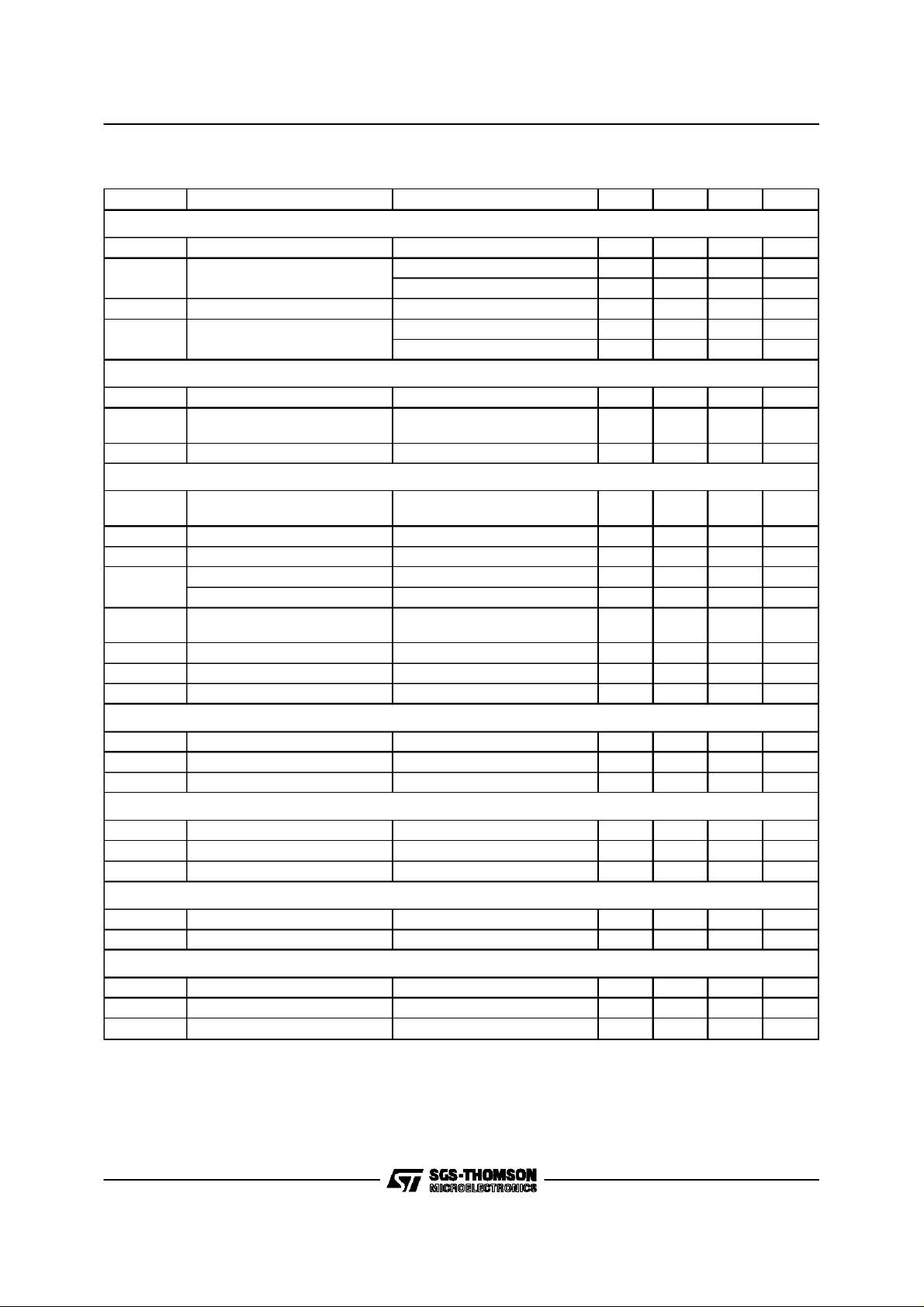

ELECTRICAL CHARACTERISTICS (T

=0to70°C; VA=V

amb

Pwr

= 12V; V

= 5V; unless otherwise

logic

specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

GENERAL

V

analog

I

analog

V

I

logic

logic

Analog Supply Voltage 10.5 13.5 V

Analog Supply Current Run Mode VA= 13.5V 1.5 2.7 4.5 mA

Brake Mode V

= 13.5V 280 800 µA

A

Logic Supply Voltage 4.5 5.0 5.5 V

Logic Supply Current Run Mode V

= 5.5V 1 2 3.2 mA

logic

Brake Mode 100 500 1000 µA

THERMAL SHUTDOWN

*T

*T

*T

sd

hys

ew

Shut Down Temperature 150 180 °C

Recovery Temperature

30 °C

Hysteresis

Early Warning Temperature Tsd-25 °C

POWERSTAGE

R

DS(on)

I

o(leak)

V

F

dVo/dt Output Slew Rate (Linear) R

I

gt

V

Gate-Drive

V

Ctrl-Range

I

in(VCtrl)

PWM OFF-TIME CONTROLLER (R

T

off

V

chrg

V

trip

Output ON Resistance per FET Tj=25°C; VA= 10.5V

T

= 125°C; VA= 10.5V

j

Output Leakage Current V

= 15V 1 mA

pwr

0.20 0.26

0.40

Body Diode Forward Drop Im= 2.0A 1.5 V

= 100KΩ 0.15 0.30 0.45 V/µs

slew

Output Slew Rate (PWM) 10 150 V/µs

Gate Drive for Ext. Power

DMOS

V

V

control

A

= 1V; V

= 10.5V

sns

= 0V;

4.5 mA

Ext Driver Disable Voltage 0.7 V

Voltage Control Input Range 0 5.0 V

Voltage Control Input Current 10 µA

= 100KΩ,C

slew

= 120pF)

off

OFF Time 9 11 14 µs

Capacitor Charge Voltage VA= 10.5V 2.31 2.65 3.1 V

Lower Trip Threshold 1.25 V

Ω

Ω

PWM LIMITTIMER

I

chrg

V

chrg

V

trip

Capacitor Charge Current V

PWM Timer

= 0V; VA= 10.5V 10.0 20.0 30 µA

Capacitor Charge Voltage VA= 10.5V 3.0 3.5 4.0 mV

Lower Trip Threshold 100 400 V

BEMF AMPLIFIER

V

Z

inCT

Bemf

Center Tap Imput Impedance 20 30 40 KΩ

Minimum Bemf (Pk-Pk) 60 mV

CURRENT SENSE AMPLIFIER

I

snsin

G

v

SR Slew Rate 0.33 0.8 V/µs

6/31

Input Bias Current VA= 13.5V 10 µA

Voltage Gain 3.8 4.0 4.2 V/V

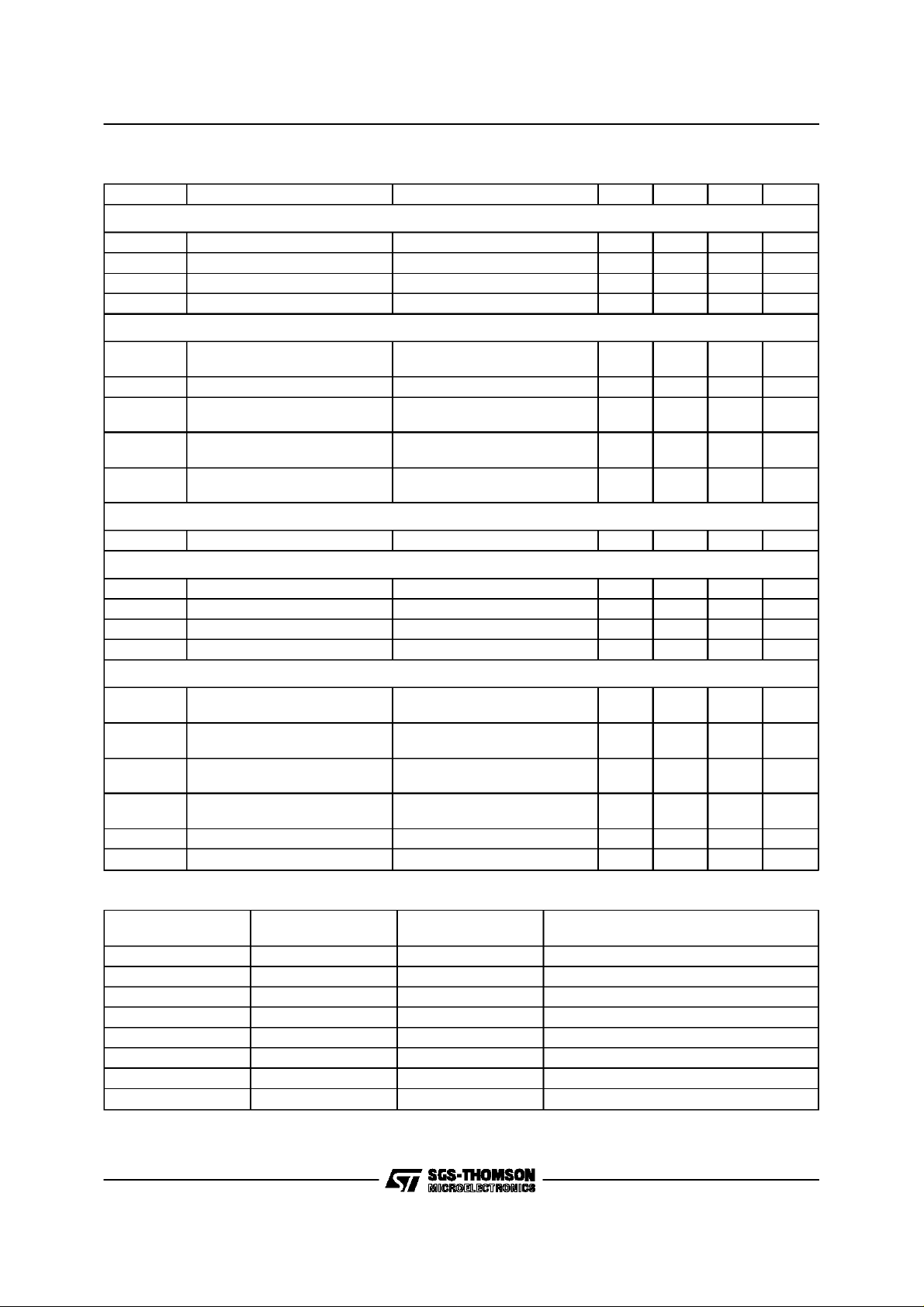

ELECTRICALCHARACTERISTICS (Continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

BRAKEDELAY

V

V

chrg

I

in

I

out3

Thres

Capacitor Charge Voltage RT= 50K 8.8 9.6 10.5 V

Input Current Vin= 5.0V 500 nA

Source Current VA= 10.5V 0.5 mA

Delay Timer Low TripThreshold 1.2 1.8 2.8 V

CHARGEPUMP

V

out

F

cp

I

in

I

brkdly

I

brake

Storage Capacitor Output

VA= 10.5V; I

= 500µA17 V

out

Voltage

Charge Pump Frequency 140 450 KHz

Vstorage Input Current (Run

V

storage

= 12V; VA=V

=0 25 µA

logic

Mode)

Vstorage Leakage Current

V

storage

= 12V; VA=V

= 0 0.4 1 µA

logic

(Brake Delay Mode)

Vstorage Leakage Current

V

storage

= 12V; VA=V

= 0 0.1 1 µA

logic

(Brake Mode)

SEQUENCEINCREMENT

t

seq

Time Between Rising Edges 1 µs

OUTPUT TRANSCONDUCTANCE AMPLIFIER Note:Measure at OTA Comp. pin.

V

V

outL

I

source

I

sink

oh

Voltage Output High VA= 10.5V 10 V

Output Voltage 2.0 V

Output Voltage 40.0 0.5 V

Output Sink Current 40.0 µA

L6238S

LOGICSECTION

V

inH

V

inL

V

inH

V

inL

I

inH

I

inL

V

outL

V

inL

F

sys

t

off/ton

Input Voltage (All Inputs

V

Except Run/Brake

Run/Brake Input Voltage V

Input Current

Output Voltage Vsink = 2.0mA

V

System Clock Frequency 8.0 12.0 MHz

Clock ON/OFF Time 20 ns

Phase DelayTruth Table

Tdelay (2) Tdelay (1) Tdelay (0)

1 0 1 2.0

1 0 0 9.4

1 1 1 18.80

1 1 0 20.68

0 0 1 22.56

0 0 0 24,44 (*)

0 1 1 26.32

0 1 0 28.20

(*) Input Default

= 4.5 to 5.5V 3.5

logic

= 4.5 to 5.5V 2.0

logic

= 2.0mA 4.5

source

1.5

1.0

1.0 µA

-1.0

0.5 V

Commutation Phase Delay,

in Electrical Degrees

V

V

V

V

mA

V

7/31

L6238S

FUNCTIONAL DESCRIPTION

1.0 INTRODUCTION

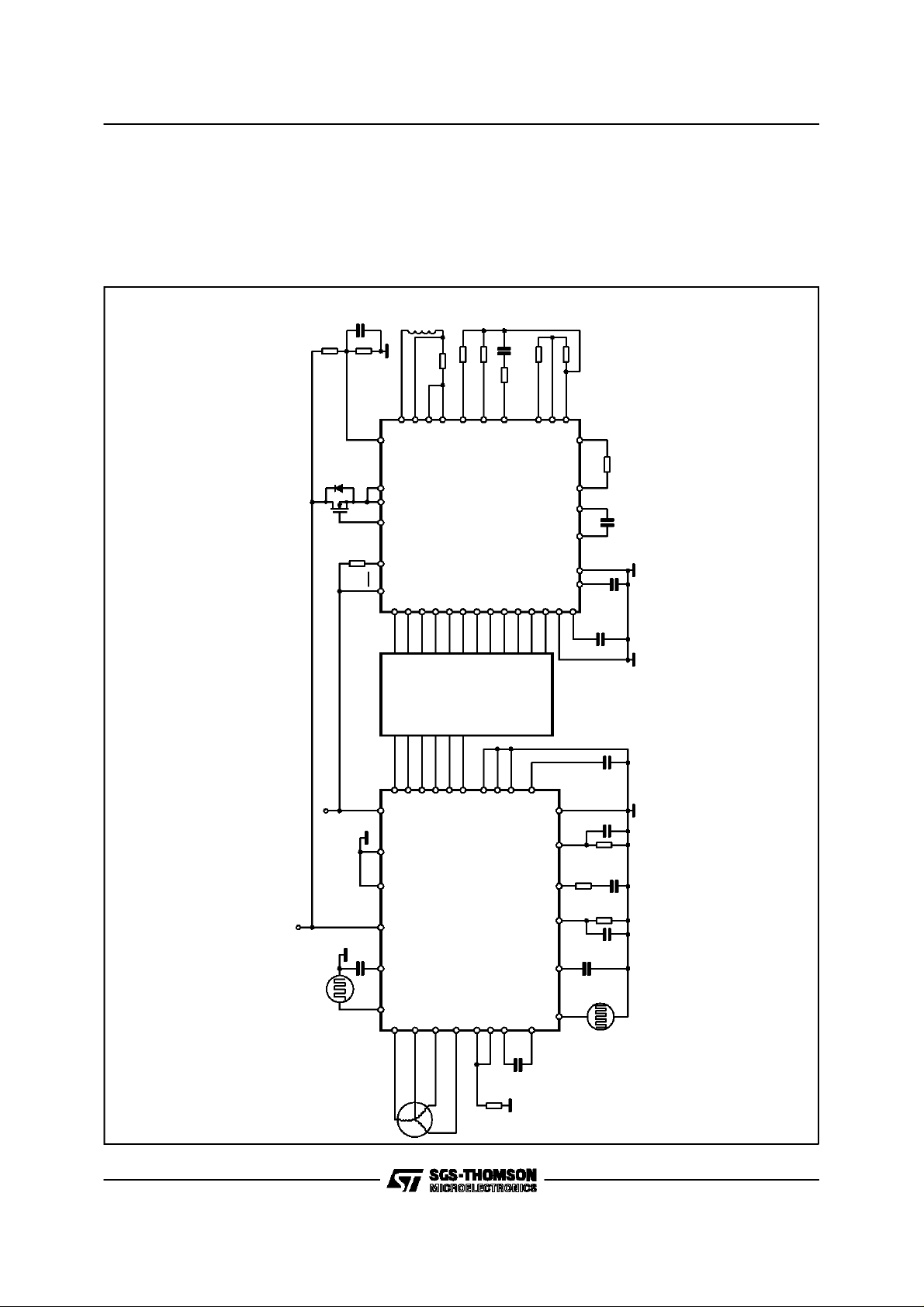

1.1 Typical Application

In a typical application,the L6238Swill operatein

conjunction with the L6244 Voice Coil Driver as

Figure1-1

27K

10K

0.1µF

3.6K

SENSE

V

Vpower

GATE

POR

V

VCM

SENSE +INPUT

SENSE -INPUT

OUT A

CC

458

38

42

44 9 37

DRIVE

43 35

19

LOGIC

data(0)20data(1)21data(2)22data(3)23data(4)24data(5)25data(6)26data(7)

shown in Fig. 1-1.

This configurationrequires a minimum amount of

external components.

1.2 Input Default States

Figure 1-2 depicts the two possible input structures for the logic inputs. If a particular pin is not

360K

14

10K

GAIN1-IN

ERROR

AMP OUTPUT

13

11

36WR28A027A118

CS

100K

GAIN2-IN

DA0Out

10

15

314 31 33

6,7,17,29,39,40

41

GND

POR DLY

CC/2

V

PROG

V

CP2CP1

PUMP

V

D95IN278

Rprogram

0.01µF

1µF

0.068µF

360K

360K

Rs 0.4

OUT

DA2

SENSE OUT

OUT B

12

L6244

VOICE COIL DRIVER

8/31

12V

60-90Hz

Note: If the internal Start-up

Algorithm is not used,

VLOGIC(5V)

connect this pinto SYS_CLK

MONO

GATE

22µF

LOGIC

V

SEQ.

DRV

ANLG

V

PWR

V

ALIGN

F

OUT ENA

38 26

12 39

27 11,42

OUT A

22

10

CTRL

RUN/BRK

V

33

23

43

CTR TAP

SEQ INC

34

1

OUT B

MTR

F

31

OUT C

OT WARM

18

L6238S

36

CONTROLLER

DLY(0)TDLY(1)TDLY(2)

T

16

15

14

SPINDLE MOTOR DRIVER

4.35

346.33

5

CSA

RSENSE

CHRG PUMP 2

10nF

20

8

PWM

TMR

6,7,17,

CHRG PUMP 1

29,39,40

GND

3

BRK

37

GM

44

PWM

CHRG

25 9

SYS CLK

DLY

COMP

SLEW

PUMP 3

10K

4.7µF

220pF

0.1µF

0.068µF

100K

400pF

8.12MHz

L6238S

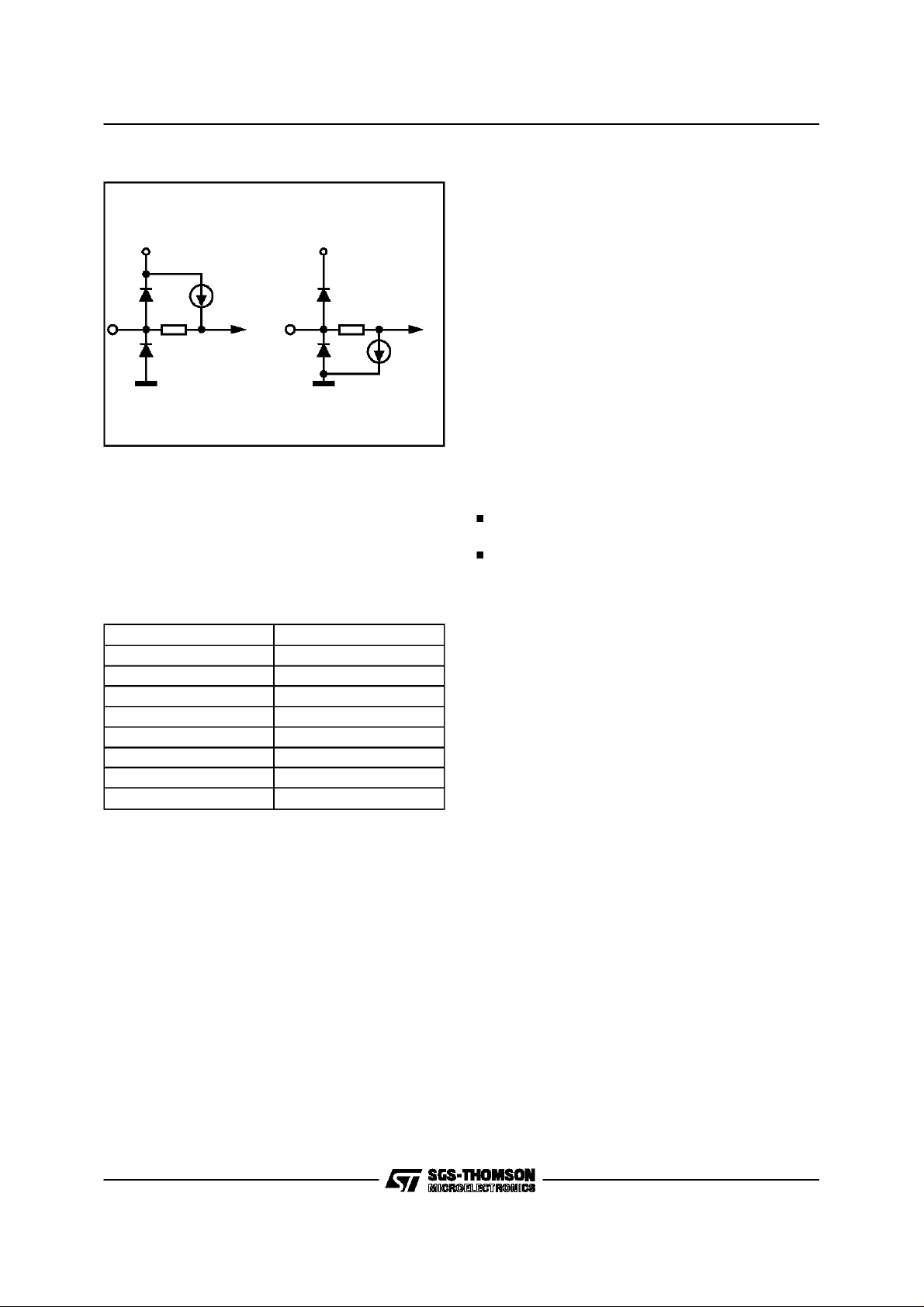

Figure1-2

V

LOGIC

10µA

330

PULL-UP PULL-DOWN

D95IN279

V

LOGIC

330

10µA

used in an application, it may either be connected

to ground or VLOGICas required, It may also be

simplyleft unconnected.

If no connection is made, the pin is either pulled

high or low by internal constant current generatorsas shownabove.

A listing of the logic and clock inputs is shown in

Table1 with the correspondingdefault state.

Table 1

Pin Function Configuration

Tdly (0,1,2) Pull-Down

Select Pole Pull-Down

PWM/Linear Pull-Down

Output Enable Pull-Down

Run/Brake Pull-Up

Sequence Increment Pull-Down

System Clock Pull-Up

Faling Pull-Up

1.3 Modes ofOperation

Thereare 5 basicmodes of operation.

1) Tristate

When Output Enable is low, the output power

driversare tristated.

2) Start-Up

With Output Enable high, bringing Run/Brake

from a low to a high will energize the motor and

the system will be driven by the Fully-Integrated

StartUpAlgorithm.

A user-defined Start-Up Algorithm, under control

of a MicroProcessor,can also be achieved via the

sequenceincrementinput.

3) Run

Run mode is achieved when the motor speed

(controlled by the external microprocessor)

reaches the nominalspeed.

4) Park

When Run/Brake is brought low, energy to park

the heads may be derivedfrom the rectified Bemf.

The energy recovery time is a function of the

Brake Delay Time Constant. In this state, the quiescent current of the device is minimized (sleep

mode).

5) Brake

After the Energy Recovery Time-Out, the device

is in Brake, with all lower Drivers in full conduction.

There are two mutually exclusive conditions

which may be present during the Tristate Mode

(wake up):

a)the spindleis stopped.

b)the system is still running at a speed that

allows for resynchronization.

In order to minimize the ramp up time, the microcontrollerhas thepossibility to:

check the SPIN SENSE pin, (which toggles at

the Bemf zerocrossing frequency)

enable the power to the motor based on the

previous information.Otherwise the µP may issue a Brake command, followed by the startup procedureafter the motorhas stoppedspinning.

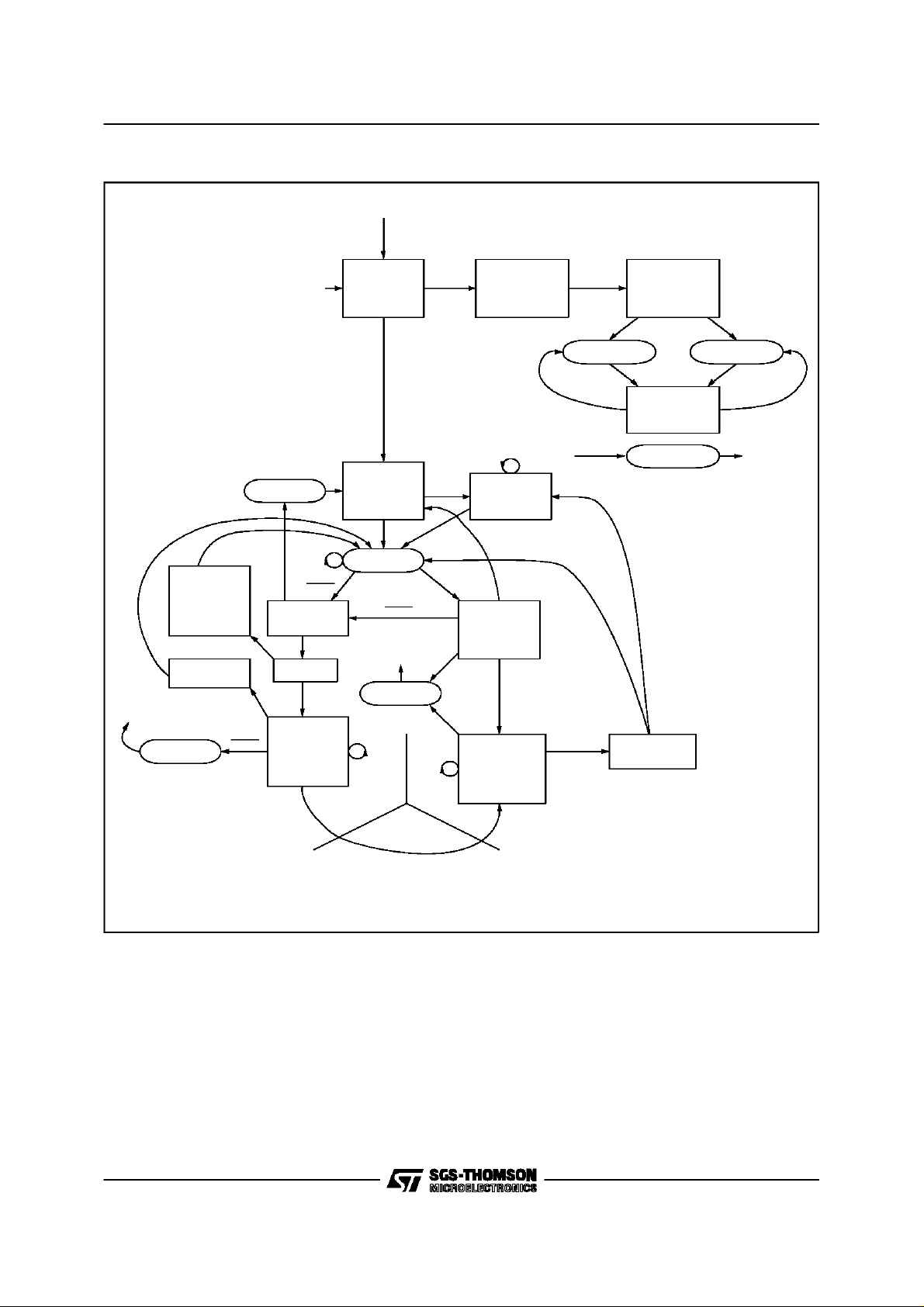

2.0 STATEDIAGRAMS

2.1 StateDiagram

Figure 2-1 is a complete State Diagram of the

controllerdepicting the operationalflow asa function of the control pins and motor status. The flow

can be separatedinto fourdistinct operations.

2.2 Align + Go

Figure 2-2 represent the normal flow that will

achieve a spin-up of the spindle motor using the

internallygenerated start up algorithm.

Upon power up, or from any state with

Run/Brake low the controller first sets the state

machine for State=1with the Outputs Tristated.

The period counter that monitors the time between zero crossing is stopped, analog with the

phase and maskdelay counters.

When Run/Brake is brought high, the motor is in

the firstpart of the align mode at State 2 (Output

A high and Output C low). If Output Enable is

high, thecontrollerfirst checks to determine if the

motor is still spinning for a time of 21Ω (with

Sys_Clk = 10MHz). The drivers are now enabled

and after the align time-out, (64/Falign), the sequencer double increments the outputsto State 4

(Output B high and Output A low). The first part

of this align mode is used to reduce the effectsof

stiction

9/31

L6238S

Figure2-1

RUN/BRK=0

DRIVERS OFF

OUTENA=1

OUTENA=1

DRIVERS OFF

STATE=STATE+1

MIN CLOCK DELAY

LOAD MIN DELAY

LOAD MAX MASK

DELAY COUNT

STATE=STATE+1

MASK COUNT

DRIVERS OFF

MIN CLOCK DELAY

PERIOD STOP

OUTENA=0

SYS_CLK

OUTENA=0

21

2

RUN/BRAKE=0

FROM ANY STATE

STATE=STATE+2

DRIVERS ON

PERIOD STOP

DELAY STOP

MASK STOP

STATE=STATE+2

STATE=STATE+1

LOAD DELAY=MIN

LOAD MASK=MAX

PERIOD COUNT

DELAY COUNT

STATE=STATE+1

MASK COUNT

21

2

SYS_CLK

64/FALIGN

192/FALIGN

POR=0

FROM ANY STATE

(FOR IS GENERATED INTERNALLY

BY MONITORING VLOGIC)

STATE= 1

DRIVERS OFF

MIN CLOCK DELAY

PERIOD STOP

DELAY STOP

MASK STOP

RUN/BRAKE=1

DRIVERS OFF

MIN CLOCK DELAY

LOAD MIN MASK***

PERIOD STOP

DELAY COUNT

STATE=STATE+1

MASK COUNT

OUTENA=1

CHECK FOR ZcBEMF

21

2

SYS_CLK

RUN/BRK=0

DRIVERS OFF

BEMF

SEQLNC=1 &

OUTENA=0

RUN/BRK=X

OUTENA=1

BEMF

RUN

MODE

BEMF

LOAD DELAY=MIN

LOAD MASK=MIN

RESET PERIOD

PERIOD COUNT

DELAY COUNT*

STATE=STATE+1

MASK COUNT

MONO=0**

DRIVERS ON

LOAD DELAY=PERIOD

LOAD MASK=PERIOD

RESET PERIOD

PERIOD COUNT

DELAY COUNT*

STATE=STATE+1

MASK COUNT

INT. START-UP DISABLED

MIN. CLOCK DELAY

LOAD MIN. DELAY

LOAD MIN. MASK***

BEMF

LOAD MIN. DELAY

LOAD MIN. MASK***

DELAY COUNT

STATE=STATE+1

MASK COUNT

BEMF

RUN/BRK=1 &

OUTENA=1

STATE=STATE+1*

MASK COUNT

SEQINC=1

FROM ANY STATE

WITH SEQ_INC=0

OUTENA=1

OUTENA=0

DRIVERS ON

PERIOD COUNT

DELAY COUNT

SEQINC=0 SEQINC=1

BEMF BEMFSEQINC=0 SEQINC=1

LOAD DELAY=PERIOD

LOAD MASK=PERIOD

RESET PERIOD

PERIOD COUNT

DELAY COUNT**

STATE=STATE+1

* VALID IF SEQINC=0, AND DELAY TIMES OUT

** CLOCK DELAY=F(TDLY_[2:0])

WHEN BEMF PERIOD <3.3ms @ 10MHz

(SPEED >12.7Hz FOR 8 POLES)

BEMFOUTENA=1

DRIVERS OFF

MIN CLOCK DELAY

PERIOD STOP

MASK COUNT

RETURN TO

PREVIOUS STATE

(CHANGING SEQINC=1)

ALIGN &

GO MODE

* CLOCK DELAY=F(TDLY [2:0] WHENBEMF PERIOD <3.3ms@ 10MHz (SPEED>12.7Hz FOR 8 POLES)

BEMF: BEMF RISING WITH PNSLOPE=1 OR BEMF FALLING WITH PNSLOPE=0

BEMF1: BEMF RISING WITH PNSLOPE=0 OR BEMF FALLING WITH PNSLOPE=1

**MONO=0 WHEN FREQ(BEMF)=2*FREQ(PHASE)

***MIN MASK=192/SYS_CLK(I.E. WITH SYS_CLK=10MHz,MIN MASK=19.2µs)

BEMF

After the next align time-out 192/Falign), the controller enters the Go mode, were the sequencer

again double increments the output phase upon

detectionof themotor’s Bemf.

The align time-outmay be optimized for the application by changing the Faling reference frequency.

A Watch-Dog Timer protection feature is built into

the control logic to monitor the Falign pin for a

clockingsignal. This circuitry, shown in Figure2-3

will prevent start up the device if the Falign clock

isnot present.

10/31

RESYNCHRONIZATION

MODE

D95IN280

Without this feature, the output would remain in

the first phase under high current conditions, if

the clockwere not present.

If the external sequencer is used to provide start

up, thesystem clock may be tied to the Falign pin

to satisfy the requirements of the Watch-Dog

Timer.

2.3 Resynchronization

If power is momentarily lost, the sequencer can

automatically resynchronize to the monitored

L6238S

Figure2.2

RUN/BRK=0

FROM ANY STATE

Figure2-4

POR=0

FROM ANY STATE

STATE=1

DRIVERS OFF

MIN CLOCK DELAY

PERIOD STOP

DELAY STOP

MASK STOP

RUN/BRAKE=1

DRIVERS OFF

MIN CLOCK DELAY

LOAD MIN DELAY

LOAD MIN MASK

PERIOD STOP

DELAY COUNT

STATE=STATE+1

MASK COUNT

OUTENA=1

CHECK FOR Zc

21

2

SYS_CLK

BEMF: BEMF RISING WITH PNSLOPE=1 OR BEMF FALLING WITH PNSLOPE=0

BEMF: BEMF RISING WITH PNSLOPE=0 OR BEMF FALLING WITH PNSLOPE=1

***MIN MASK=192/SYS_CLK (I.E. WITH SYS_CLK=10MHz, MIN MASK=19.2µs)

DRIVERS ON

PERIOD STOP

DELAY STOP

MASK STOP

64/FALIGN

CHECK FOR Zc

192/FALIGN

STATE=STATE+1

LOAD DELAY=MIN

LOAD MASK=MAX

PERIOD COUNT

DELAY COUNT

STATE=STATE+1

MASK COUNT

BEMF

DRIVERS ON

LOAD DELAY=PERIOD

LOAD MASK=PERIOD

RESET PERIOD

PERIOD COUNT

DELAY COUNT*

STATE=STATE+1

MASK COUNT

BEMF

BEMF

D95IN310

Bemf. This resychronization can either occur

whenever Output Enable or Run/Brake is first

brought low then high.

Referring to figure 2-4, the ”Hold for Resync”

state is brought low. The controller leaves this

state and enters ”Start Resync” when Output En-

able is high.

Figure 2.3: Watch-DogTimer

OVER TEMP SHUTDOWN

S

TO START-UP

Q

LOGIC

Q

S

OUTPUT

ENABLE

RUN/

BRAKE

FALIGN

D95IN311

BEMF

RUN/BRK=0

DRIVERS OFF

BEMF

RUN

MODE

LOAD MIN DELAY

LOAD MIN MASK***

DELAY COUNT

STATE=STATE+1

MASK COUNT

BEMF

CHECK FOR Zc

LOAD DELAY=MIN

LOAD MASK=MIN

PERIOD COUNT

DELAY COUNT*

STATE=STATE+1

MASK COUNT

MONO=0** BEMF

DRIVERS ON

LOAD DELAY=PERIOD

LOAD MASK=PERIOD

RESET PERIOD

PERIOD COUNT

DELAYH COUNT*

STATE=STATE+1

MASK COUNT

RESYNCHRONIZATION MODE

OUTENA=1

BEMF

OUTENA=1

OUTENA=0

BEMF

DRIVERS OFF

MIN CLOCK DELAY

PERIOD STOP

HOLD FOR RESYNC

D95IN312

*CLOCK DELAY=(TDLY [2:0]WHEN BEMF PERIOD <3.3ms @ 10MHz (SPEED>12.7Hz FOR 8 POLES)

BEMF: BEMF RISINGWITH PNSLOPE=1 ORBEMF FALLING WITH PNSLOPE=0

BEMF: BEMF RISINGWITH PNSLOPE=0 ORBEMF FALLING WITH PNSLOPE=1

** MONO=0 WHENFREQ (BEMF)=2*FREQ(PHASE)

*** MIN MASK=192/SYS_CLK(I.E.WITH SYS_CLK=10MHz, MIN MASK=19.2µs)

11/31

L6238S

Figure2-5

SEQINC=0

POR=0

FROM ANY STATE

STATE=1

DRIVERS OFF

MIN CLOCK DELAY

PERIOD STOP

DELAY STOP

MASK STOP

SEQINC=1 &

OUTENA=0

RUN/BRK=X

INT START-UP DISABLED

MIN CLOCK DELAY

LOAD MIN DELAY

LOAD MIN MASK

RUN/BRK=1 &

OUTENA=1

DRIVERS ON

PERIOD COUNT

DELAY COUNT

SEQINC=1

STATE=STATE+1

SEQINC=0

FROM ANY STATE

WITH SEQ_INC=0

MASK COUNT

SEQINC=1

*VALID IF SEQINC=0, ANDDELAY TIMES OUT

**CLOCK DELAY=F(TDLY_[2:0])

WHEN BEMF PERIOD <3.3ms @ 10MHz (SPEED >12.7Hz FOR 8 POLES)

BEMF

LOAD DELAY=PERIOD

LOAD MASK=PERIOD

RESET PERIOD

PERIOD COUNT

DELAY COUNT**

If zero crossings are detected,the sequencer will

automaticallylock on to the properphase.

This resynchronization will take effect with the

motor speed running as low as typically 30% of

it’snominal value.

2.5 ExternalSequencing

Although the user-defined Start-Up Algorithm is

flexible and will consistently spin up a motor with

no external interaction, the possibility exists

where certain applicationsmight require complete

microprocessorcontrol of start-up.

The L6238S offers this capability via the SE-

QUENCE INCREMENT input. Referring to figure

2-5, during initial power-up with Output Enable

low, the controlleris in the ”Hold and Wait for Decision” state. If the SEQUENCE INCREMENT pin

is brought high during this state, the Auto StartUp

Algorithm is disabled and the sequencer can be

controlledexternally.

When Output Enable and Run/Brake are

brought high, the sequencer is incremented on

each positive transition o the SEQUENCER IN-

12/31

MASK COUNT

STATE=STATE+1

BEMF

PREVIOUS STATE

(CHANGING SEQINC=1)

SEQINC=1

RETURN TO

D95IN313

CREMENT pin. During the time that this pin is

high, all Bemf information is masked out. Whenit

is low, the Bemf informationcan be detected normally after the internal mask time. The minimum

mask time is 192/Sys_Clk (i.e. with Sys_Clk =

10MHz, min. mask = 19.2µs) Therefore to insure

that the sequencer is under complete control of

the state machine, the time that the SEQUENCE

INCREMENT pin is held lowshould be much less

then the min. mask time,but greater then1µs.

When the motor has reached a predetermined

speed, the SEQUENCE INCREMENT pin can be

left low and the L6238S Motor Control logic will

take over and automatically spin up the motor to

the desiredspeed

.

3.0 START-UPALGORITHMS

3.1 Spin-UpOperation

The spin operationcan be separatedinto 3 parts:

1) Open Loop Start-Up - The object is to create

motion in the desired direction so that the Bemf

voltages at the3 motor terminals can providereliable information enabling a transition to closed

loop operation.

Figure3-1: Align+Go

L6238S

RUN/BRAKE

SEQUENCER

A

OUT

10V

1

B

OUT

10V

2

C

OUT

10V

3

ALIGNMENT GO

*0.711s *2.133s

STATE 2

A=HIGH

B=FLOAT

C=LOW

DOUBLE INCREMENTS

STATE 4

A=LOW

B=HIGH

C=FLOAT

STATE 6

A=FLOAT

B=LOW

C=HIGH

2) Closed Loop Start-Up - The Bemf voltage

zerocrossings provide timing information so that

the motor can be accelerated to steady state

speed.

3) Steady-State Operation - The Bemf voltage

zero-crossings provide timing information for precisionspeed control.

The L6238S contains features that offer flexible

control over the start-upprocedure. Either the onboard Auto-StartAlgorithm can be used to control

the start-up sequence or more sophisticated extenal start-up algorithms can be developedusing

the Serial Port and key control/sense functions

broughtout to pins.

3.2 Auto-Start Algorithm

When initially powered up, the controller defaults

to the internal AutoStart Mode. When Run/Brake

is low, the L6238S is in brake mode, and the

Auto-Start Algorithm is reset. In the brake mode,

all of the lower DMOS drivers are ON,and the up-

500ms/DIV* FALIGN=90Hz

D95IN314

per drivers are OFF.

The Auto-Start Algorithm is based on an Align &

Go approachand can be visualized by referringto

Figure 3-1. Shown are the Run/Brake controlsignals, sequencer function, and the three output

voltage waveforms.

Referring to figure 3-1, the following is the sequence of events duringAuto-Start:

With Output Enable =1,Run/Brake =0

- State Machine is set to State 1 with the drivers

Trisatted.

AlignmentPhase (1)

Run/Brake =1

- Output Stageis sequencedto State 2 and the

drivers energized with OUTPUT A high and

OUTPUT C low for 64/Falignseconds.

AlignmentPhase (2)

- Output Stage is double sequenced to State 4

with OUTPUT B high and OUTPUT A lowfor

13/31

L6238S

192/Falign seconds.

- During the alignment phase, the SEQ INCRE-

MENT signalis ignored.

Go Phase

- The internal sequencer double increments the

output stage to State 6, whichshould produce

torque in the desireddirection.

- with SEQ INCREMENT held low, the se-

quencer is now controlled by the Bemf zero

crossings, and the motor should ramp up to

speed.

3.3 ExternallyControlled Start-Up Algorithms

Enhanced Start-Up Algorithms can be achieved

by using a µProcessor to interact with the

L6238S.’ The L6238S has the ability to transition

to Closed Loop Start-Up at very low speeds, reducing the uProcessor task to monitoring status

rather than real time interaction.Thus, it is a perfectapplication for an existing µProcessor.

The following control and status signals allow for

very flexiblealgorithm development:

SEQ_INCR A low tohigh transitionat thisinput

isused to increment the state of thepower output stage. It is useful during start-up, because

the µProcessor can cycle to anydesired state,

or cycle through the states at any desiredrate.

When held high, it inhibits the BEMF zero

crossings from incrementing the internal sequencer.

SPIN SENSE This output is low until the first

detected Bemf zero crossing occurs. It then

toggles at each successivezero crossing.This

signal serves as a motion detector and gives

useful timing information as well as the slope

of the Bemf.

3.4 Start UpApproaches

Align & Go Approach The Align & Go approach

provides a very time efficient algorithm by energizing the coils to align the rotor and stator to a

known phase. This approach can be achievedvia

the sequencingSEQINCR. SPIN SENSE can be

monitored to assure that motion occurred. Once

ample time is given for alignment to occur, SEQ

INCR can be double incremented, and the SPIN

SENSE pincan be monitored todetect motion.

When SEQ INCR is pulled low, control is transferred to the internal sequencer, and the L6238S

finishes the spinup operation. If no motion is detected, SEQINCR can be incrementedto a different phase and the process can be repeated.The

alignment phase may cause backward rotation,

which on the average will be greater than the

StepperMotor approach.

The Auto-Start algorithm described earlier is an

Align & Go approach. The main advantages of

the integratedAuto-Start are that the µP is not involved real-time, and there are a minimum of interface pins required to the spindle control system.

Stepper Motor Approach This approach minimizes backward rotation by sequencing SEQ

INCR at an initial rate that the rotor can follow.

Thus, it is driven in a similar fashion to a stepper

motor. The rate is continually increased until the

Bemf voltage is large enough to reliably use the

zero-crossings for commutation timing. SEQ

INCR is held low, causing control to be passed to

the L6238S’sinternal sequencer as in the Align &

Go approach.

The Stepper Motor approach takes longer than

the Align & Go approach because the initial commutation frequency and subsequent ramp rate

must be low enough so that the motor can follow

without slipping. This implies that to have a reliable algorithm, the initial frequency and ramp rate

must be chosen for the worst case motor under

worst case conditions.

4.0 MOTORDRIVER

4.1 Output Stage

The output stage forms a 3-Phasefullwave bridge

consisting of six Power DMOS FET High output

currents are allowed for bbrief periods. High output currents are allowed for brief periods. Output

Power exceeding the stand-alone power dissipation capabilities of the L6238S can be increased

with the addition of an external P-FET or by the

use of Pulse-Width-Modulation.

Table 4-1 is a reference diagram that liststhe parameters associated with 8-pole motors operating

at 3600 and 5400 RPM.

Figure 4-1 represents the waveforms associated

with the output stage. The upper portion of figure

4-1 shows the flow of current in the motor windings for each of the 24 phase increments. A rotational degree index is shown as a referencealong

with a base line to indicate the occurrence of a

zero crosing. The outputwaveforms are a digitally

reproduced voltage signals as measured on samples.The feedback Input is multiplexed between

the internal Bemf Zero Crossing Detector and an

externallyprovided sync pulse (EXTINDEX)

Shown in figure 10 is the classical state diagram

for a phase detector along with waveform examples.

A typical sequence starts when the outputs

switch states. Referring to figure 4-1, during

phase 1, output A goes high, while outputBis low.

During this phase, output C is floating, and the

Bemf is monitored. The outputs remain in this

state for 60 electrical degrees as indicated by the

first set of dashed lines. After this period the out-

14/31

Table 4-1

L6238S

Rotational Speed 3600rpm 5400rpm

Rotational Frequency 60Hz 90Hz

Rotational Period 16.667ms 11.111ms

Electrical Period 4.167ms 2.778ms

Phase Period 694.5µs 463.0

Figure4-1: Waveforms

15/31

L6238S

put switched to phase 2 with output A high and C

lowwith the Bemfamplifier monitoring outputB.

In order to prevent commutation currentnoise being detectedm as a false zero crossing, a masking circuit automatically blanks out all incoming

signals as soon as a zero crossing is detected.

When the next commutation occurs an internal

counter starts counting down to set the time that

the maskingpulse remains.

The counter is initially loaded with a number that

isequal to time thatis always25% of the previous

phase period or 15 electrical degrees. The timeout of the masking pulse shown for reference at

the bottom of figure 4-1. Thus the actual masking

period is the total of the time from the detected

zero crossing to the phase commutation, plus

25% of the previous period. The mask pulse operation is further discussed in section 4.6, Slew

RateControl and PWM operation.

Afterthe maskingperiod, the Bemfvoltage at output B is monitored for a zero crossing. Upon detection of the crossing, the output is commutated

after the selected phase delay insuring maximum

Figure4-2

torque. The spin sense waveform atthe bottom of

the figure indicates that this output signal toggles

with each zero crossing.

4.2 Brake Delay

When Run/Brake is brought low, a brake is initiated. Referring to figure 4-2, SW1 is opened and

the brake delay capacitor, C

discharge towardsgroun via R

, is allowed to

brake

.

brake

At the same time, switches SW2 through SW7

bring the gates of the output FETs to groundhalting conduction,causing the motor to coast. While

the motor is coasting, the Bemf is used to park

the heads. When Cbrake reaches a voltage that

is below the turn ON threshold of Q1, Switches

SW8, 9, and 10 bring the gates of the lower drivers to V

potential. This enables the lower

brake

FETs causing abraking action.

The analog and logic suppliesare not monitored

in the L6238S, since the L6244 alreadymonitors

this voltage and initiates a Park function when

either supply dropsto a predeterminatedlevel.

16/31

Figure4-3

L6238S

4.3 Charge Pump

The charge pump circuitry is used as a means of

doubling the analog supply voltage in order to allow the upper N-channel DMOS transistors to be

driven like P-channel devices. The energy stored

in the reservoircapacitor is also used to drive the

lower driversin a brakemode if the analog supply

is lost. Figure 4-3 is a simplifiedschematiocof the

chargepump circuitry.

Figure4-4

SW2

UPPER A

VCTRL

+

A2

-

LOWER A

A3

SW3

1

0

I2

Islew

X4

VANALOG

A capacitor, C

, is used to retrieve energy

pump

from the analog supply and then ”pumps” it into

the storage capacitor,C

resvr

.

An internal300KHz oscillatorfirst turns ON Q2 to

quickly charge C

to approximately the rail

pump

voltage. The oscillator then turns ON Q1 while

turning OFF Q2. Since the bottom plate of C

is now effectivelyat therailvoltage via D2.

A zener-referencedseries-pass regulatorsupplies

OUTPUT

BC

L1 L2

L3

OUTA

RSENSE

CSA

R

S

V

PUMP

1

0

VPOWER

Q1

Cfet

I1

Islew

Q2

Cfet

pump

,

Q3 Q4

REFERENCE CURRENT

Q5

PWM SLEW/RC

R

SLW

3.1VSLEW RATE

D95IN315

17/31

L6238S

a voltage,V

, duringbrakemode.

brake

The maximum capacitance specified for the Storage Capacitor is 4.7µF.For applications requiring

a larger value, an external diode should be connected between Vanalog and the Storage Capacitor to prevent excessive inrush current from

damaging the charge pump circuitry. A small

value resistor (i.e. 50W) may instead be inserted

in series with the StorageCapacitorto limit the inrushcurrent.

4.4 Linear Motor CurrentControl

The output current is controlled in alinear fashion

via a transconductanceloop. Referring to Figure

4-4 the sourcing FET of one phase is forced into

full conduction by connecting the gate to V

pump

while the sinking transistor of an appropriate

phase operates as a transconductance element.

To understand the current control loop, it will be

assumed that Q2in figure 4-4 is enabled via SW3

by the sequencer. Duringa run condition, the currentin Q2 ismonitored by a resistorR

to the R

sense

input.

The resulting voltage that appears across R

connected

s

s

amplified by a factor of four by A3 and is sent to

A2where it is compared to the CurrentCommand

Signal. A2 provides sufficientdrive to Q2 in order

to maintain the motor speed at the proper levelas

commandedby the Speed Controller.

The pole/zero locations are adjusted such that a

few dB of gain (typ. 20dB) remains in the transconductanceloop at frequencieshigher than the

zero.

The inductive characteristic of the load provides

the pole necessary for loop stability. Thus the

loop bandwidth is actually limited by the motor itself.

Figure 4-5 shows the completetransconductance

loop including compensation, plus the response.

The Bode plot depicts the normal way to achieve

stability in the loop. The pole andzero are used to

set a gain of 20dB at a higher frequency and the

pole of the motor cuts the gain to achieve stability.

Loop instability maybe causedby two factors:

,

1)The motorpole is tooclose to thezero. Referring to figure 4.6, the zero is not able to decrementthe shiftof phase, and when the effect

of the pole is present, the phase shift may

reach 180° and the loop will oscillate. To rectify this situation, the pole/zero must be

shifted at lower frequencies by increasing the

is

compensationcapacitor.

Figure 4-6

4.5 TransconductanceLoop Stability

The RC network connected to the Compensation

pin provides for a single pole/zero compensation

scheme. The pole/zero compensation scheme.

Figure4-5

Figure 4-7

18/31

L6238S

Figure4-8

2)The motor capacitance, CM, itself can interfere with the loop, creating double poles. If

the gain at higher frequencies is sufficiently

high, the double pole slope of 40dB/decade

can cause the phase shift to reach 180°,

re sulting in oscillation.

Figure 4-8 is a Bode plot showing how to correct

this situation.The bold line indicates the response

with relatively high gain at the higher frequencies.

Byleaving the pole unchangedand increasingthe

zero, the response indicated by the dashed lines

canbe achieved.

4.6 SlewRate Control

A 3-phase motor appears as an inductive load to

the power supply. The power supply sees a dis-

turbance when one motor phase turns OFF and

another turns ON because the FET turn-OFFtime

is much shorter than the L/R rise time. Abrupt

FET turn-OFF without a proper snubbing circuit

can even cause current recirculationback intothe

supply.

However, the need for a snubber circuit can be

eliminated by controlling the turn-OFF time of the

FETs.

The rate at which the upper and lower driversturn

OFF is programmable via an external resistor,

connected to the SLEW RATE pin. This re-

S

slew

sistor defines an internal current source that is

utilized to limit the voltage slewrate at theoutputs

during transition, thus minimizing the load change

that the powersupply sees.

To insure proper operation the range of resistor

values indicated should not be exceeded and in

some applications values near the end points

should be avoidedas discussed below.

Low Values of Rslew - If a relativelylow valueof

Rslew is selected, the resultant fast slew rate will

result in increased commutation cross-over current, higher EMI, and large amount of commutation current.

This last case can cause voltage spikes at the

output that can go as much as lV below ground

level. This situation must be avoided in this integrated circuit (as in most) since it causes unpredictable operation.

High Values of Rslew - Higher values of Rslew

result of course in slow slew rates at the outputs

which is, under most conditions, the desired case

since the problemsassociated with fast rates are

reduced. The additional advantage is lower

acoustical noise.

Problems can occur though if the slew rate for a

Figure4-9: Effect of Slow Slew Rate.

19/31

L6238S

Figure4-10: ExternalP-Fet.

given application is too slow. Figure 4-9 is an oscillographtaken on a device thathad a fairlylarge

value for Rslew and failed to spin up and phase

lock a motor.

The problem manifests itself as the motor begins

to spin up.At lowerRPMs, the Bemf of the motor

is relatively small resulting in higher amounts of

commutation current. In figure 4-9, the upper

waveform is the voltage appearing at OUTPUT

relative to the CENTER TAP input. The lower

waveform is the actual output of the Bemf amplifier availableon specialengineering prototypes.

The oscillograph was taken just as the problem

occured. The period between zero crossings was

~800µsresulting in a masktime period of 200µs.

As can be seen, the excessively long slew rate

actually exceeded the mask period and was detected as a zerocrossing.

This resulted in improper sequencing of the outputsrelative to the proper phases and caused the

motor to spindown.

4.7 Ext PFETDriver

The power handling capabilities of the 3 phase

output stage can be extended with the addition of

a single P-ChannelFET.

Figure 4-10 shows the Ext FET connection and

demonstrates how the L6238S automatically

senses the FETs presence. When the voltage at

the Gate Drive pin is ≥ 0.7V, the output of comparator A3 goes high, removing the variable drive

A1 from the internal FETs and connects them instead to Vanalogvia thecommutation switches to

facilitate full conduction.

The upper FETs drive paths are not shown for

clarity. A3 also closes SW2 allowing A1 to linearly

drive the external P-Channel FET Q1 via inverter

A2.

4.8 Bemf Ampolifier

Since no Hall Effect Sensors are required, the

commutation informationis derived from the Bemf

voltage zero-crossingsof the undriven phase with

respect to the center tap. The Bemf comparator

and associatedsignal levels are depicted in figure

4-11. For reliable operation, the Bemf signal amplitude should be a minimum of ± 60 mV to be

properly detected. In order to provide for noise

immunity, internal hysteresis is incorporated in

the detectioncircuitry to prevent false zero crossing detection.

For laboratory evaluation purposes, a simple re-

20/31

Figure 4-11:Bemf Amplifier.

Vo

BEMF

-35 -25 0 25 35

SLOPE=0 SLOPE=1

Vi

D95IN316

L6238S

BEMF(mV)

sistive network as shown in figure 4.12 can be

usedto emulatethe Bemf ofthe motor.

The actual Bemf zero-crossingis 30 electrical degrees (50% of a commutation interval) away from

the optimal switch point. A digital counter circuit

measures 50% of the previous interval to determine the next interval’s commutation delay from

the zero crossing. During the low RPM stages of

start up the long commutation intervals may

cause the counter to overflow, in whichcase 50%

of the max count will be less than 50% of the

ideal commutation interval. Therefore, the torque

Figure4-12: Bemf Emulator

will not be optimal until the desired commutation

interval is less than the dynamic range of the

counter.

4.9 Center TapProtection

Spindle Motors with a high number of windings

exhibit a transformer coupling effect that in some

cases can cause relatively high currents to flow

through the centertap input.

Current flowing out of the center tap pin as high

as 25mA has been observed with certain motors.

Figure 4-13

TO CENTER

R1 1K

TAP INPUT

D95IN317

DS1

21/31

L6238S

The high current flows from the grounded substrate of the integrated circuit (p-type material),

throughone ormoreepitaxialpockets(n-type material)and outthecenterpar pin.

This current can cause adverse operation of the

controllet due to substrate injection and might

possibility damage the internal metalization runs.

The normal current for this input is in the 200µA

range.

Referring to figure 4-13, a simple protection

scheme consisting of a 1K resistor and a low current Schottky diode should be added if the application causes excessive current (i.e. >1mA) to

flow throughthe center tap pin.

5.0 PWM MOTOR CURRENTCONTROL

A unique feature of the L6238S in the optional

Pulse Width Modulation (PWM) control of motor

current.

Using Variable-frequency, Constant-OFF time

Current-Mode control, the L6238S can drive

higher power motorswithout the need forexternal

drivers, while minimizing internal power dissipation.

Additional benefits include reduced power supply

consumption(up to 50% savings)and lowerwattage requirementsfor the current sensingresistor.

Constant-OFF time Current-Mode control, operates on the principle of monitoring the motor current and comparison it to a reference or control

level.

When the motorcurrent reachesthis commanded

level, the output drivers turn OFF and remain

OFFfor a Constant-OFFtime. After this OFF time

the drivers turn backONto repeatthe cycle.

Figure 5.1 is a block diagram of the PWM control

circuitry. When using PWM as opposed to linear

control, two changes are made to the control

loop:

1.The slew rate control is disabled,allowing the

outputs to slew at a minimum rate of 10V/µs.

This is accomplished by closing SW3 and

SW5.

2.The OTA amplifier is taken out of the control

loop via SW6. The lower drivers are now

driven into hard conductionby tying the gates

to the analog supply during the On time of the

PWM cycle.

The current in the motor windingsis monitoredvia

the voltage dropped in the sensing resistor,

.

R

sense

This voltage is multiplied by a factor of 4 in the

Current Sense Amplifier (CSA) and sent to negative input of the PWMComparator (A2).

The control voltage,V

, isapplied to the posi-

control

tive input of A2. When the output of the CSA

reaches a level that is equal to the commanded

level, the output of A2 switches low, toggling the

latch comprised of N1 and N2. This causes the

upper drivers to turn off andopens SW1. Q3 turns

OFF allowing the Constant-OFF time capacitors,

Figure5-1

PWM/SLEW

COFFRSLEW

VANALOG

SLEW RATE

REFERENCE

CURRENT

Q3

1.2V

3.1V

PWM/LIN

CONTROL

SW1

+

A1

-

UPPER A

LOWER A

N1

N2

N3Q1 Q2

SW3

SW5

A3

SW2

SW4

A2

VPOWER

V

PUMP

1

0

I1

Islew

1

0

Islew

+

-

CSA

Cfet

I2

V

ANALOG

SW6

FROM TRANS. LOOP

X4

1

0

Q4

Cfet

Q5

D95IN318

OUTPUT

BC

L1 L2

L3

OUTA

RSENSE

VCTRL

CSA

R

SLW

22/31

C

to discharge to dischargtethrough R

off

slew

, initiating the Constant-OFF time-out. When the voltage on C

reaches 1.2V,comparator A1switches

off

state toggling the latch in the opposite state, turning the upper driver back ON. SW1 also closed

quicklycharging up C

for the nextcycle.

off

5.1 PWM DesignConsiderations

In order to select the parameters associated with

PWM operation, the following factors must be

takeninto consideration:

1. PWM SwitchingFrequency

2.Duty Cycle

3. Motor Currents

4. Minimum ON Time

5.Noise Blanking

6. Bemf Masking/Sampling

5.1.1. PWM Switching Frequency

The PWM switching frequency F

pwm

is found

from:

F

pwm

1

=

+ T

T

on

off

(5.1.1)

where:

= The time requiredfor the motor current

T

on

to reach the commandedlevel.

T

= The programmedOFF time.

off

The two main considerations for this parameter

are the minimum and maximum switching frequency.

The maximum switching frequency occurs during

the Start-upand should be keptbelow 50KHzdue

tointentional bandwidth limitations and output

switching losses.

5.1.2 Duty Cycle

Besides reducing the power dissipation of the

controller output stage, running in PWM offers 2

additional”free” benefits:

A. ReducedPowe SupplyCurrent at StartUp

B. Lower PowerRating for the Motor Current

SenseResistor.

Figure 5-2 is the current path during the ON time

of a phase period. The current from the supply

passes through the upper sourcing DMOS, Q3

transistor through the two driven winding, the

lower DMOS, Q2 and finally through the current

sensing resistor R

. Since both Q3 and Q4 are

sns

ON, while Q3 is turnedOFF. The voltage, causing

the current to continue to flow through Q2, and

Q4.

If the duty cycle is nearor at 50%, then for 1/2 the

PWM cycle, no current is flowing from the power

supply or the sense resistor while current is still

flowing in the motor. This lowers the requirement

L6238S

Figure 5-2

V

POWER

Q1

Q2

D1

L1 L2

OUTPUTA OUTPUTB

D2

R

R

SNS

D3

D4

SENSE

D95IN319

Figure 5-3

V

POWER

Q1

Q2

D1

L1 L2

OUTPUTA OUTPUTB

D2

R

R

SNS

D3

D4

SENSE

D95IN320

for both the Power Supply and the Power Rating

for the sensing resistor.

5.1.3 Motor Currents

Note: It is not theobjective of thissection to describe the principles

of brushless DCmotor, but to provide sufficient information about the

parameters associated with PWMoperation in order to optimizean

application.

A simplified modelof a motor is shown in figure 5-

4. For this discussion, lower order effects due to

mutual inductance between windings, resistance

due to losses in the magnetic circuit, etc. are not

shown.

The motor at stall is equalto a resistance, Rmtr,

in serieswith aninductance, Lmtr. When the mo-

tor is rotating, there is an induced emf that appears across the armaure terminals and is shown

in figure 5-4 as an internally generated voltage

Ibemf), Eg.

Q3

Q4

Q3

Q4

23/31

L6238S

Figure5-4

Lmtr

Rmtr

+

Eg

-

D95IN321

Therelation between thesevariablesis given by:

V = L

mtr

dt

R

mtrimtr

+ E

g

(5.1.2)

di

mtr

where:

V = AppliedVoltage

i

= Motor Current

mtr

= Total inductance of the motor

L

mtr

windings

= Resistancein serieswith the motor

R

mtr

E

= The internally generated voltage of

g

the motor, proportional to the motor

velocity

Since:

E

=KEω (5.1.3)

g

The above equations can be combined to form

the basicelectrical equation fora motor:

di

mtr

dt

mtr

R

mtrimtr

+ KEω (5.1.4)

V = L

Figure 5.5 is a simplified electrical equivalent of

the output stage of the L6238S along with the

model of the motor during the time that the OutputDrives areconducting.

Figure5-5

UPPER

Rdson

Lmtr

The additionalresistance associated with the output stage and sensing resistor are also in series

with the motor. If we let R

equal the total series

s

resistence:

R

= 2*R

s

dsON+Rmtr+Rsense

(5.1.5)

then (5.1.4) becomes:

di

mtr

dt

mtr

Rsi

mtr

+ E

g

(5.1.6)

V = L

Figure 5-6

Lmtr

Rmtr

-

KEW

+

LOWER

Rdson

D95IN323

LOWER

Rdson

Figure 5-6 is an equivalent circuit of the output

stage during the Constant-OFFperiod. During the

OFF time the lower driver for the particular phase

beign drivenremains ON.

The internally generated voltage forces the path

of current though the motor, its series resistance,

the RdsONof the LowerDriver and finallythrough

the oppositelowerdriver.

PWM Example (Referto Figure5-7)

The following is an example on how to select the

timing parameters.

Given:

DCStartCurrent = 1.25A

RippleCurrent = 100mA

Duty Cycle = 50%

24/31

D95IN322

KEW

Rmtr

+

LOWER

Rdson

Rsense

Motor Interface(L) = 880µH

TotalSeries Resistance(R

) = 4.8Ω

s

If the worst case start current is 1.25A and the

duty cycle is 50%, then the Peak Current, It will

be:

= 1.25+

i

t

0.1

2

it=1.30A

L6238S

TheValley current, Ibwill thereforebe:

i

= 1.30 - 0.1A

b

i

= 1.20A

b

During the Align and Go Phase (where the power

dissipation requirements are highest, Eg is zero.

The initial time required to reachthe Peak current

is:

± L

=

t

init

ln

1 ±

R

I,R

V

(5.1.7)

Substitutingvalues:

=

t

init

t

=134.6µs

init

± 880e

4.8

± 6

1.3 ⋅ 4.8

±

ln

1

12

The ON timecan be calculated from:

L

t

=

on

ln

R

s

V

± i

b

R

s

V

± i

t

R

s

(5.1.8)

Substitutingvalues:

± 1.2

± 1.3

t

on

880E ± 6

=

4.8

12

4.8

ln

12

4.8

the voltage drop remains constant across the

windings.

The time required for the inductor currentto reach

the valleycurrent is given by:

I

ln

t

I

b

(5.1.9)

L

=

t

off

R

Substitutingvalues:

±6

880e

=

t

off

4.8

t

= 14.67µs

off

Note: thatthe parameters forthis examplewere selected to arrive at

a 50%duty cycle. This will notalways be thecase due to factors such

as fixed motorparameters, etc.

1.3

ln

1.2

The Constant Off timer period can be determined

from:

V

= R

t

off

slew

⋅ C

off

⋅ ln

V

chrg

trip

(5.1.10)

Where:

= Constant-OFFTime

T

off

= Slew Rate Resistor

R

slew

C

= Off Time Capacitor

off

V

= Initial Capacitor ChargeVoltage

chrg

= Capacitor Lower Trip Threshold

V

trip

Substitutingnominal valuesgiven:

t

=14.67µs

on

Figure5-7

D95IN324

It=1.3A

Ib=1.2A

Iavg=1.25A

Iout A

200mA

4

20µs/DIV

During the OFFtime, the motor currentcontinues

to flow through the DMOS transistorsand threfore

=0.75 ⋅R

T

off

Solving for C

T

=

0.75R

off

C

off

off

slew

slew

⋅ C

off

In the example, to set the OFF timer for a 50%

duty cycle:

Given:

T

= 14.67µs

off

= 100KΩ (typicalValue)

R

slew

C

off

C

off

14.67e

=

≈ 146pF

100e

±6

3

5.1.4 Minimum ONTime

The bandwidth of the PWMloop was optimizedto

reject unwanted switching noise while providing

25/31

L6238S

sufficient response, commensurate with the

switching speed of the output drivers. At higher

frequencies the switching losses inherent in the

drivers start to negativeany of the power dissipationsavingsgained with PWMoperation.

The current sense amplifier has a minimum slew

rate of 0.31V/µs. With a worst case Motor peak

start-up current of 2.5A and Sense Resistor of

0.33, the resultant R

voltage would be equal

sense

to 825mV. With a minimum gain of 3.8V/V, the

CSA output voltage would have to slew to 3.14V.

Therefore it wouldrequire approximately10µs for

the output voltage to reach the required commanded level.

If an ON time were selected that was less than

this time, the motor current would overshoot the

desired level resulting in incorrect current control

possibly exceeding the output capabilities of the

drivers.

5.1.5 Noise Blanking

Referring to Figure 5-8, when operating with

lower levels of current (i.e. < 700mA, with Rsense

= 0.33Ω), the possibility exiss where the noise

due to output Turn-ON can exceed the Commanded Current Level causing prematire TurnOFF.

In order to provide noise immunity from this

switching noise, a blanking circuit automatically

rejects any signal appearing at the output of the

CSA fora 3µs period.

Figure 5-9 is an additional block diagram of the

PWM controlloop includingthe noise blanking circuit. The output of A3 goes high when ever the

voltage at theCSA input is more positive then the

Control Voltage.

This is the case when either the motor current or

the turn-ON transient has reached the commanded level. The output of A3 is gates by N11.

In order to providea blankingperiod, Q1 is turned

Figure 5-8

D95IN325

3µs BLANKING PULSE

COMMANDED

CURRENT LEVEL

Vrsense

1

10µs/DIV

Figure5-9

CLK_BEMF

2.4V

SW1

N12

N1

C1

8pF

5µA

N2

Q1

I1

N3

N4

PWM/LIN

DELAY

TO OUPUT

DRIVERS

N5

N6

N7

N8

I2

20µA

RUN/BRAKE

Q2

N12

N9

N10

N11

+

A2

- 1.2V

A3

+

-

Q3

X4

D95IN326

PWM_SLEW

R1

CSA INPUT

VCONTROL

PWM COMP

PWM TIMER

C4

C3

26/31

L6238S

ONduring the Constant-OFFtime, chargingC1 to

the internal rail. At the end of the OFFtime, Q1 is

turned OFF allowing current source I1 to discharge the capacitor towards ground. While the

voltage on C1 is above the low input threshold of

N1, the output of N1 is low, preventing any

change of state at the output of N11 due toa high

A3output. Whenthe capacitor reachesthe lowinput threshold of N1, N1 chnges state allowing A3

to controlthe stateof N11.

5.1.6 Masking/Bemf Sampling inPWM

The method of sampling the floatingphase for the

bemf zero crossing defers between Linear and

PWMoperation. In Linear Mode, the bemf is sampled continuously after the mask time-out, until

the zero crossing is detected. Then the mask is

enabled for a time based on the commutation

phase delayplus theadditional timebased on the

previousperiod as explained earlier.

With PWM operation however, the switching

noise at turn ON (after the Constant-OFF time)

can be significant, especially at low RPMs where

the bemf is the lowest. In order to provide the

greatest noise immunity in PWM, the floating

phase is monitored only at the point where the

output isabout to be turnedOFF.

In operation, when the motor current reaches the

commandedlevel, the floatingphase is first monitored to determine if the bemf has crossed the

zero. The output is then turned OFF for the Constant-OFFtime out.

As the motor current increases through, the increasing bemf causes the motor current to naturally decrease. Eventually a point is reached

where the PWM is running at 100% duty cycle

and the motor current cannot reach the commanded level. At this time the bemf is no longer

smpled, preventing further commutation of the

output.

The PWM Limit Timer is used to set up a maximum ON time. When this limit is exceeded the

method of sensing the bemf is essentially the

same as in the case ofoperatingin linearmode.

Figure 5-10 is an oscillographof the controlleroperating in PWM mode. The top trace is A

out

. The

2nd trace is the voltage seen at the PWM/SLEW

pin indicating the exponential discharging of the

timing capacitor during the OFF time. Trace 3 is

the voltageappearing on the PWM Timercapacitor, while trace 4 is the motor current.

Referring again to Figure 5-9, and 5-10 transistor

Q2 is turned ON at the beginningof the OFF time,

discharging the external capacitor C4 to near

ground level. At the end of the OFF-Time, Q2 is

turned off and C4 starts charging linearly via I2.

C4 is again discharged at the beginning of the

OFF time and the cycle repeats. As long as C4

does not reach the threshold of A1 (typically

3.5V), the bemf is only sampled just before turnoff of the output. As the motor isstartingup in figure 5-10, the duty cycle is roughly 50%. The

PWM limit timer is reset to ground by the start of

the OFFtimer before reaching the 3.5V threshold.

In figure 5-11, as the motor spins up, the on time

of the output increases and the PWM limit timer

reaches the 3.5V. Eventually the duty cycle

reaches 100% and the sampling of the bemf is

essentiallythe sameas in the linear mode.

The selectionof componentsfor the PWM timer is

not critical. Since the objective is to sample the

bemf only at turn OFF to maximize the signal to

noise ratio, the PWM timer slope canbe set up to

convert to thefull bemfsampling aftera few revolutions of the motor when the bemf has reached

an appropriatevoltage output.

Figure5-10

1

PWM/Slew

2

PWM Limit

Timer

3

4

500mV

Iout A

Aout

10v

2V

1A

Fpwm=50KHz

Coff=120pF

Ctmr=220pF

20µs/DIV

D95IN327

Figure 5-11

10V

1

PWM/Slew

2

PWM Limit

Timer

500mV

3

Iout A

4

Aout

2V

1A

D95IN328

Fpwm=12KHz

Coff=120pF

Ctmr=220pF

50µs/DIV

27/31

L6238S

PLCC44PACKAGE MECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 17.4 17.65 0.685 0.695

B 16.51 16.65 0.650 0.656

C 3.65 3.7 0.144 0.146

D 4.2 4.57 0.165 0.180

d1 2.59 2.74 0.102 0.108

d2 0.68 0.027

E 14.99 16 0.590 0.630

e 1.27 0.050

e3 12.7 0.500

F 0.46 0.018

F1 0.71 0.028

G 0.101 0.004

M 1.16 0.046

M1 1.14 0.045

mm inch

28/31

PQFP44PACKAGE MECHANICAL DATA

L6238S

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 3.40 0.134

A1 0.25 0.010

A2 2.55 2.80 3.05 0.100 0.110 0.120

B 0.35 0.50 0.0138 0.0197

C 0.13 0.23 0.005 0.009

D 16.95 17.20 17.45 0.667 0.677 0.687

D1 13.90 14.00 14.10 0.547 0.551 0.555

D3 10.00 0.394

e 1.00 0.039

E 16.95 17.20 17.45 0.667 0.677 0.687

E1 13.90 14.00 14.10 0.547 0.551 0.555

E3 10.00 0.394

L 0.65 0.80 0.95 0.026 0.0315 0.0374

L1 1.60 0.063

K 0°(min.), 7°(max.)

D

D1

2333

11

PQFP44

22

L1

E

L

E3D3E1

12

0.10mm

.004

SeatingPlane

K

34

B

44

1

e

A

A2

A1

B

C

29/31

L6238S

TQFP64PACKAGE MECHANICAL DATA

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.60 0.063

A1 0.05 0.15 0.002 0.006

A2 1.35 1.40 1.45 0.053 0.055 0.057

B 0.18 0.23 0.28 0.007 0.009 0.011

C 0.12 0.16 0.20 0.0047 0.0063 0.0079

D 12.00 0.472

D1 10.00 0.394

D3 7.50 0.295

e 0.50 0.0197

E 12.00 0.472

E1 10.00 0.394

E3 7.50 0.295

L 0.40 0.60 0.75 0.0157 0.0236 0.0295

L1 1.00 0.0393

K 0°(min.), 7°(max.)

D

D1

49

B

64

1

e

3348

32

E3D3E1

17

16

TQFP64

E

L1

L

K

0.10mm

Seating Plane

B

A1

A

A2

C

30/31

L6238S

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights ofthird parties which mayresult from its use. No

license isgranted by implication or otherwiseunder any patent or patentrights of SGS-THOMSONMicroelectronics. Specification mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied. SGSTHOMSON Microelectronics products are not authorized for use as critical components in life support devices or systemswithout express

written approval of SGS-THOMSON Microelectronics.

1995SGS-THOMSON Microelectronics – Printed in Italy –All Rights Reserved

Australia -Brazil - Canada - China - France - Germany - Hong Kong -Italy - Japan - Korea- Malaysia -Malta - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland- Taiwan - Thailand - United Kingdom- U.S.A.

SGS-THOMSON MicroelectronicsGROUP OF COMPANIES

31/31

Loading...

Loading...