1.5A MAXIMUMPEAKCURRENT

CONTROLLEDSLEWRATE

CENTRAL CHARGE PUMP

PWMAND LINEARMODES

CUTOFFTIME USER CONFIGURABLE

FAST,FREE-WHEELINGDIODESON CHIP

OVER-TEMPERATUREPROTECTION

BRAKEFUNCTIONINPUT

SPINDLE DRIVER

PLCC21+7

ORDERING NUMBER:

L6232E

L6232E

DESCRIPTION

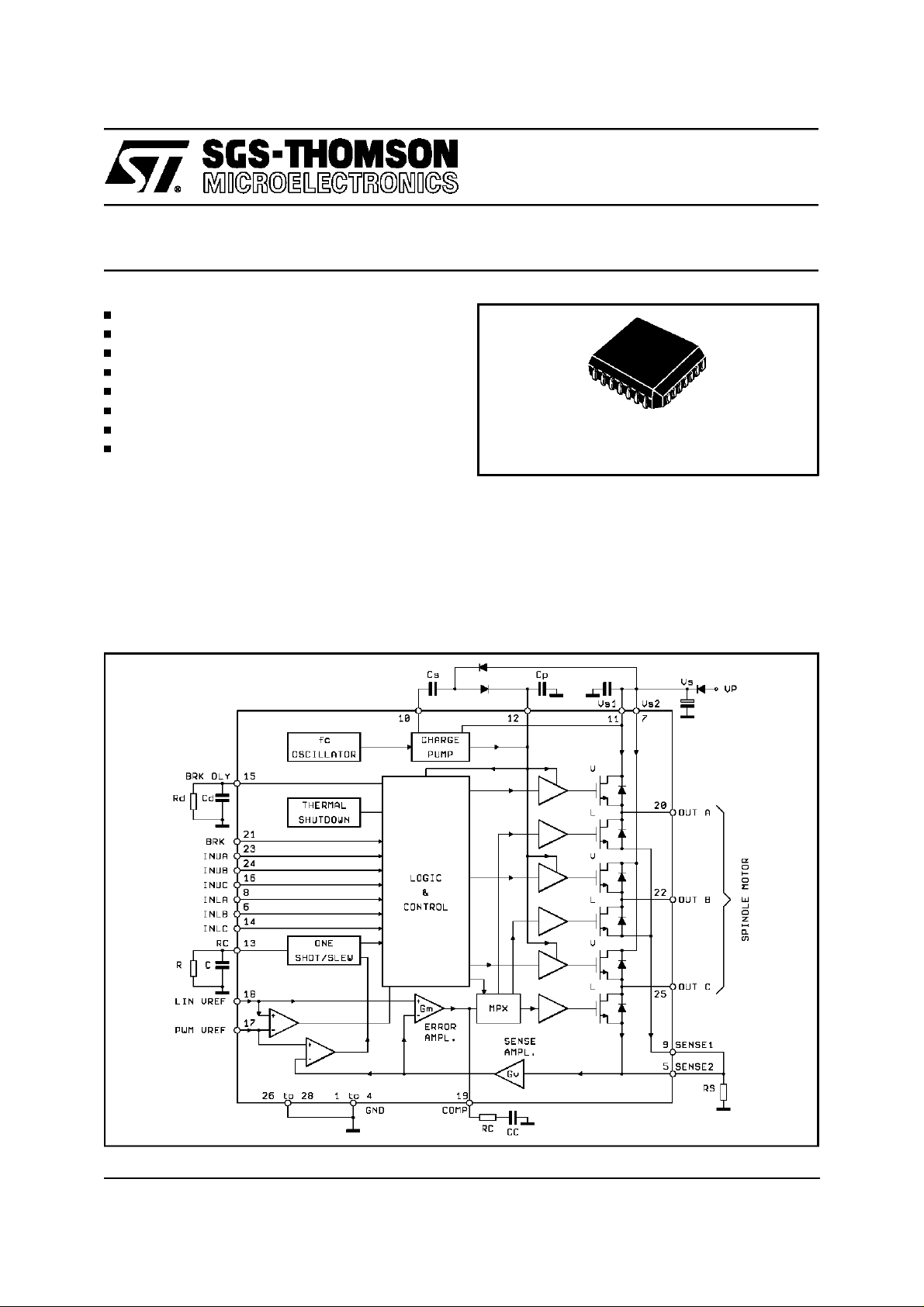

The L6232E is a triple half bridge driver intended

for use in brushless DC motor applications. This

part can be used to form the power stage of a

three-phase, brushless DC motor control loop,

and is especiallyuseful for disk drive applications.

Power drivers are Integrated DMOS transistors

and featurefast recirculatingdiodes as an integral

BLOCK DIAGRAM

part of their structure. The logic inputs are TTLlevel compatible, with internal pull-up, allowing interfacing to open collector outputs. All necessary

circuitry to perform PWM and linear motor speed

control is included. A central charge pump is utilized to drive the upper DMOS transistors, and

also to power the braking function.The L6232E is

packagedin PLCC28.

October 1996

This is advanced information on a new product now in development or undergoing evaluation. Details are subjectto changewithout notice.

1/10

L6232E

PIN DESCRIPTION

Pin Name Function

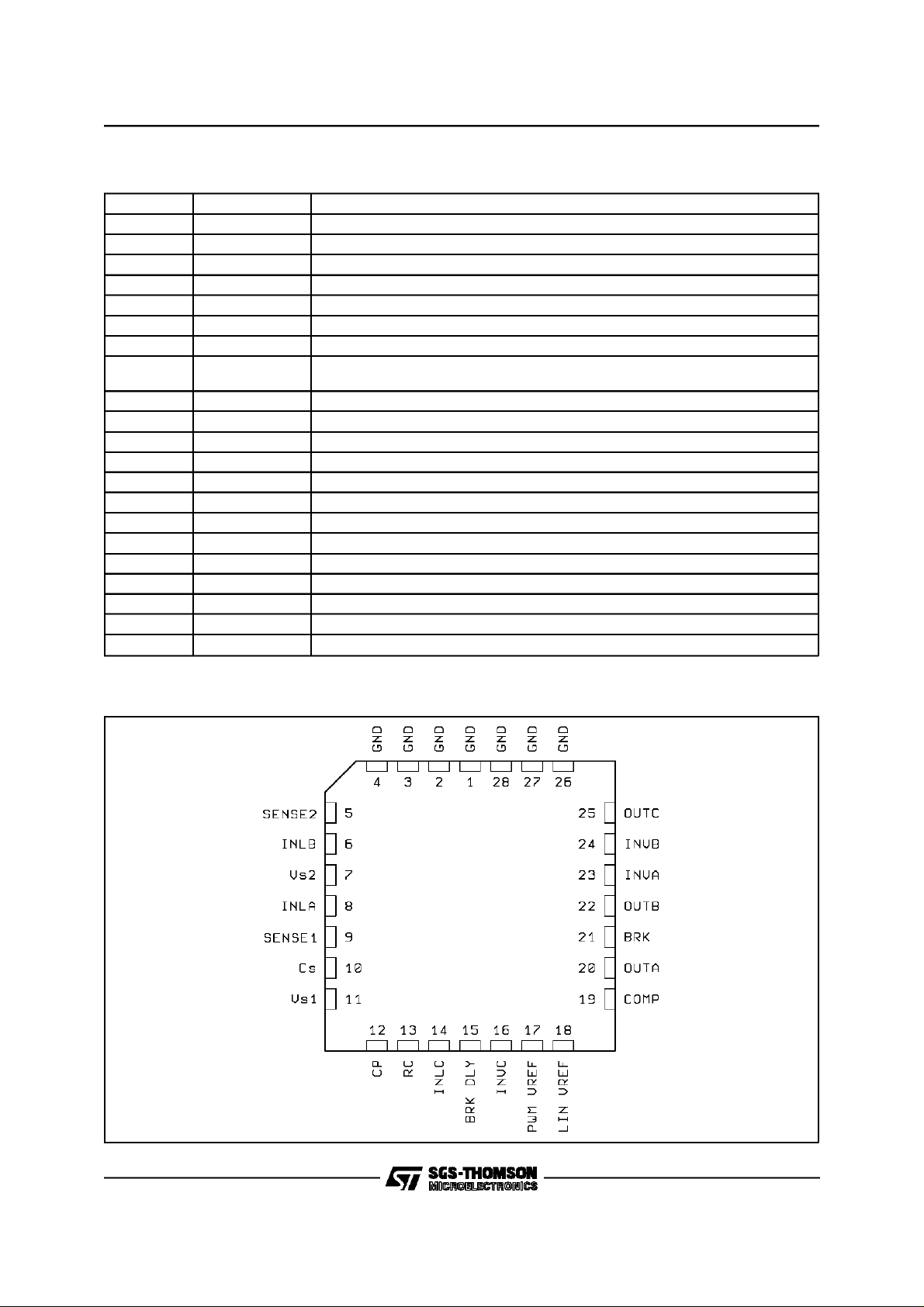

1 to 4 GND Common Ground. Also provides heat-sink to PCB.

5, 9 SENSE Output for current sense resistors.

6 INLB Logic Input to turn on the lower driver(Active High).

7, 11 V

S

8 INLA Logic input to turn on the lowey driver (Active High).

10 C

12 C

S

P

13 RC Cutoff Time RC Network in PWM mode. The Resistor value is also used to define

14 INLC Logic input to turn on the lower driver (Active High).

15 BRK DLY External RC network for the brake delay.

16 INUC Logic Input to turn on the upper driver (Active Low).

17 PWM Vref Input for Reference Controlin PWM mode

18 LIN Vref Input for Reference Controlvoltage inLIN mode

19 COMP External compensation for error amplifier

20 OUTA DMOS Half-bridgeA Out.

21 BRK Active LOW logic input thattriggers the delayed brake.

22 OUTB DMOS Half-bridgeB Out.

23 INUA Logic Input to turn on the upper drivers (Active Low).

24 INUB Logic Input to turn on the upper drivers (Active Low).

25 OUTC DMOS Half-bridgeC Out.

26 to 28 GND Common Ground. Also provides heat-sink to PCB.

Supply Voltage.

External Charge Pump Capacitor.

External Main Charge Pump capacitor.

the slew-rate in linearmode (LIN).

PIN CONNECTION

(Topview)

2/10

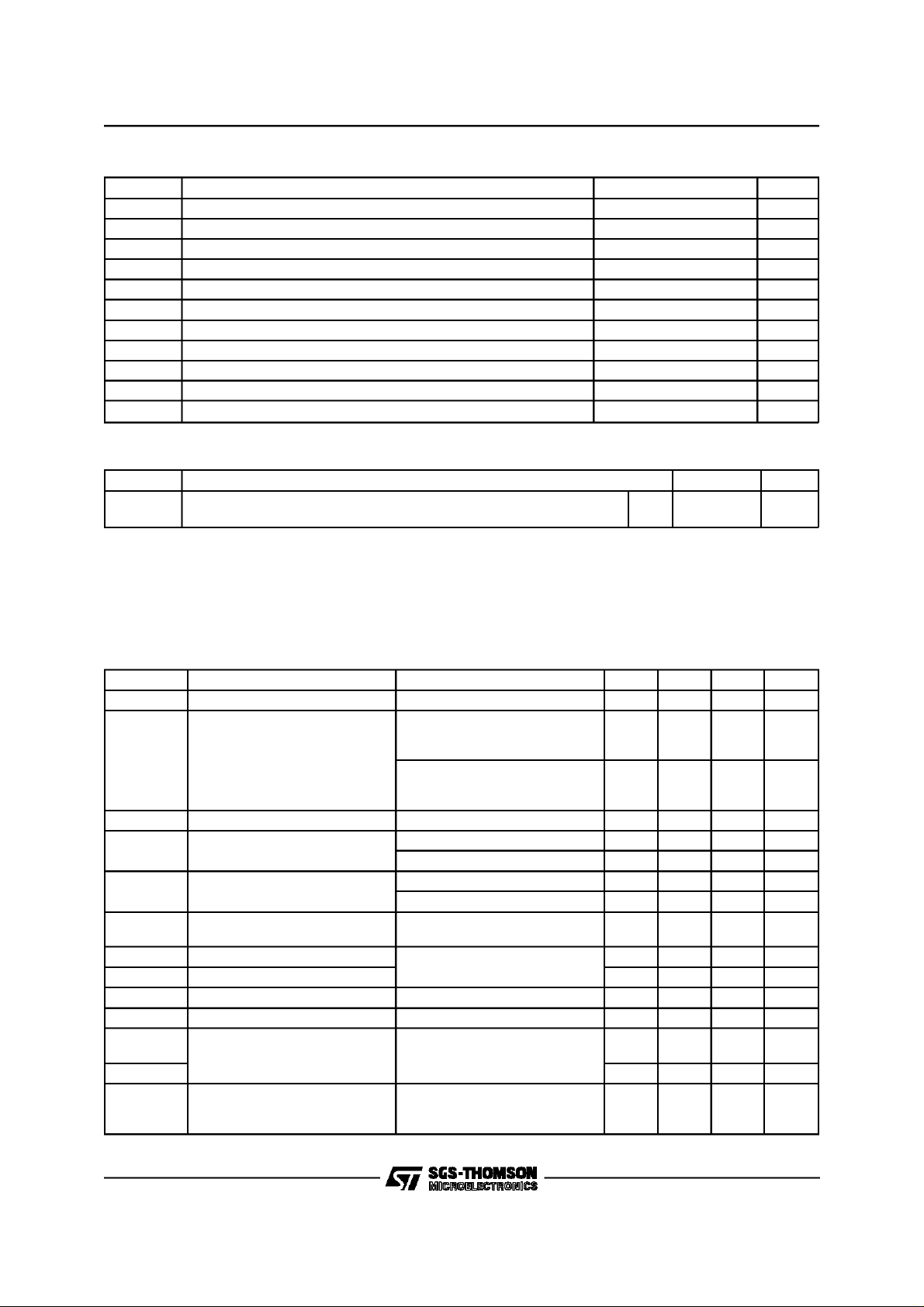

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

DS sus

V

V

Opeak

V

V

V

P

T

stg,Tj

Cp

V

REF

I

p

I

O

tot

Peak Output Sustaining Voltage 15 V

Supply Voltage 15 V

S

Output Peak Voltage (tpK =5µsec; 10% d.c.) 18 V

Charge Pump Input Voltage 30 V

Logic Input Voltage -0.3 to 7 V

i

PWM VREF--LIN VREF Input Voltage -0.3 to 7 V

Sense Input Voltage -1 to 7 V

is

Sink-Source Peak Output Current (*) 3.5 A

Sink-Source DC Output Current 1.8 A

Total Power Dissipation (T

=70°C) 1.5 W

amb

Storage and Junction Temperature -40 to 150

THERMAL DATA

Symbol Description Value Unit

R

th j-pin

R

th j-amb

Notes

(*) Pulse width (limited only by junction temperature and by the transient thermal resistance.

(**) Mounted on board with 16cm

Thermal Resistance Junction-pins

Thermal Resistance Junction-ambient (**)

2

35µm thickness copperarea on board heatsink.

Max.

Max.

14

52

L6232E

C

°

°C/W

C/W

°

ELECTRICALCHARACTERISTICS

=25°C, unless otherwise specified)

T

j

(See the block diagram, V

=12V,R = 100KΩ; C = 180pF;

S

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

S

I

S

Supply Voltage 10.5 12 13.5 V

Quiescent Supply Current BRK = L; INUA = INUB = INUC

0.3 0.5 mA

= L; INLA = INLB = INLC = H;

Table 1

BRK = H; INUA = INUB = INUC

46mA

= H; INLA = INLB = INLC = L;

Table 1

I

OL

R

DSon

R

DSon

V

F

Output Leakage Current VO=VS= 13.5V 1 mA

Sink Out ON Resistance Tj=25°C (see Fig.4) 0.42 0.47 Ω

= 125°C 0.7

T

j

Source Out ON Resistance Tj=25°C (see Fig.4) 0.42 0.47

= 125°C 0.7 Ω

T

j

Body Diode Forward Drop (sink

IDS= 1A (seeFig. 6) 1 1.5 V

and source)

t

d(BRK)

T

BRK

I

B(LIN)

I

B(PWM)

LIN V

PWM V

G

v

Brake Delay Time See Fig. 1, 3; note1 210 ms

Braking Time 10 s

LIN Vref Input Bias Current LIN V

PWM Vref Input Bias Current PWM V

Reference Voltage Input Note 2; RS= 0.5Ω

ref

I

ref

I

Sense Amplifier Voltage Gain PWM V

LIN V

R

= 0.4 to 5.5V 400 950 nA

ref

= 0.4 to 5.5V 400 950 nA

ref

(PWM) = 1A

motor

(LIN) = 200mA

motor

= 2.5V,

ref

= 0.4V,

ref

= 0.5Ω; Note 2

S

3.7 4 4.3 V/V

2V

0.4 V

Ω

Ω

3/10

L6232E

ELECTRICALCHARACTERISTICS

(continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

G

m

LIN Error Amplifier

0.8 mA/V

Transconductance

Zout Error Amplifier Output

2MΩ

Impedance

V

INH

V

INL

I

INH(leak)

I

INL

t

donU

t

donL

t

doffU

t

doffL

dV/dt Source DMOS Slew-Rate

Logic Input Voltage BRK; INUA;

INUB; INUC; INLA; INLB; INLC

Logic Input Current BRK;INUA;

INUB; INUC; INLA; INLB; INLC

Vi= 2.7V -1 mA

Vi= 0.4V -0.1 mA

2V

0.8 V

Upper/Lower Turn-on Delay Table 1 see Fig. 3 0.7 µs

0.15 µs

Upper/Lower Turn-off Delay 15 µs

0.5

see Fig. 3 10 V/µs

(PWM)

dV/dt Source DMOS Slew-Rate (LIN) see Fig. 3 1 V/µs

dV/dt Sink DMOS Output Turn-off

Note 3; R = 100KΩ 0.15 V/µs

Slew-Rate

F

C

T

off

Internal Clock Frequency 380 KHz

PWM Cutoff Time R=100KΩ; C=180pF, Note 4;

40 µs

see Fig. 2

T

sd

T

sdr

Notes:

1) The Head Park time must be shorter than the Brake Delay time t

2) Both in PWM and in LIN mode the Ref. Voltage must agree to V

3) The resistance of theRC network defines the dv/dt value.

= 1.8RC + 6 ⋅ 10

4) t

off

Shutdown Temperature 160 °C

Recovery Temperature 120

d(BRK)=RdCd

ref=GVRSImotor

-6

s

µ

C

°

Table 1

INPUT STATE OUTPUT STATE

INUA INUB INUC INLA INLB INLC A B C

LLLHHH* * *

LLLLLLHHH

HHHLLL * * *

HHHHHHLLL

H = The Upper DMOS is ON

L = The Lower DMOS is ON

* = Tristatecondition

4/10

L6232E

Figure 1: Brake Delay and Brakingtiming of the L6232E.At the timet1 a VPPowerdownthreshold

detectordrives low the BRK input; at time t2 the Charge Pump voltage becomesinadequate

to maintain ON the lower DMOS.

FUNCTIONAL DESCRIPTION

(Refer to the

Block Diagram)

The commutation sequence is provided by the

user via six inputs. INUA,INUB,INUC turn on the

three upper DMOS drivers when held at logic

LOW, and inputs INLA,INLB,INLC turn on the

three lower DMOS drivers when held at logic

HIGH.

The BRK and BRK DLY inputs offer flexibility to

the system designer in the implementation of the

braking function. The BRK logic input, when

pulled low will turn-off all upper and lower Dmos

drivers. The low transition at BRK will produce a

delayed negativetransition at the BRKDLY input,

configurable by connection of a capacitor Cd and

a resistor Rd from the BRK DLY pin to ground.

The negative transition at BRK DLY will initiate

the braking of the motor by turning on all lower

Dmos, while keeping all upper DMOS turned-off.

This feature provides a time interval where the

motor BEMF can be used to power the head

parking function before the braking procedure is

iniziated. External detection of the supply(VP)

drop-off is necessary to provide the appropriate

logic signal to the BRK input. (see Fig. 1)

The brake function utilizes the energy stored in

the central charge pump capacitor(Cp) to turn-on

or turn-off the DMOS drivers. This allows for

completion of the braking procedure after the VP

supply has powered down.

The L6232E is capable of driving the motor in

either pulse width modulation (PWM) or linear

(LIN) mode. The driving mode is determined by

the smaller of two analog voltages inputs, LIN

Vref and PWM Vref. The motor current is controlled by LIN Vref and PWM Vref and the current

sense resistor Rs connected to the SENSE output. The SENSE output provides for connectionof

a resistor in series with the source of all lower

DMOS drivers. The voltage at this pin provides

the error signal wich is utilized internally to regulate the motor current Im. The current in both

PWM and linear mode is determined by the expression:

V

ref

=

I

m

G

⋅ R

V

S

in wich Gv is the voltage gain of the sense amplifier. In linear mode, the current is regulated by a

linear control loop wich drives the lower DMOS.

Compensation of the linear control loop is

achieved by connection of a series network

(Rc,Cc) from the transconductance amplifier output (Gm) and ground. Control is passed to each

lower DMOS in succession during the commutation sequence(MPX).

The rate at which the upper and lower drivers

turns-off during linear mode operation is configurable externally by the value of the resistor R used

at the RC pin. This defines a current which is utilized internally to limit the voltage slew-rate at the

outputs during transitions. The output slew-rate is

internally adjusted for fast slewing during PWM

operation to reduce losses, and a relatively

slower rate during linear mode operation to mini-

5/10

L6232E

mize noise effects(EMI). LIN Vref and PWM Vref

are connected to a comparator whose output is

fed to the logic . The upper and lower DMOS

driver slew-rates are controlled by the internal

logic.

In PWM mode, the upper driver is turned-offwhen

the motor current reaches the intended value. An

internal One-Shot pulse determines the lenght of

time the upper driver stays off before turning on

again. The pulse width, and thus the cutoff time

(toff), is configurableby means of the externalRC

networkconnectedto the RC pin. (see Fig. 2). The

resistor at the RC pin, therefore determines both

the driver output slew-rate during linear mode and

the off-time constantduringPWM. The lowerdriver

is always on during PWM mode of operation; an

on-chip 2µs mask can prevent the beginning of a

new cutofftime becauseof transientcurrent spikes

causedby theupper driversturn-on.

The driving mode is determinedby the smaller of

the two controlling input voltages. In a typical application the motor start-up would occur in PWM

mode to limit power dissipation, with on-speed

control then performedin linear mode.

Thermal protectioncircuitry will shut-off all drivers

when the chip junction temperature exceeds the

threshold temperature. A small amount of hysteresis is included to prevent rapid on/off cycling of

the power stages.

Additionalprotectionis providedagainstdriverinput

combinationswhere the upperand lower drivers of

a half bridge are turnedon simultaneusly, resulting

in a short from supplyto ground.The chip logic will

causeboth the upperand lower driversinvolvedto

turn-off.(seeTable1)

APPLICATIONINFORMATION

A typical application configuration of the L6232E

driving a three-phase brushless DC motor is

shown in Fig.3. The spindle motor is a 4 ohm2mH per phase, star connected. This load requires a suitable compensation of the linear control loop that can be achieved by Rc= 10 Kohm

and Cc= 10nF (R3;C8). Changing the motor characteristics, the RcCc network would be modified

for the best performances of the system. At the

start-up the spindle is driven in PWM mode fixed

toff time.

The off-time is calculatedby the formula:

toff = 0.69R2 C7

See fig.2 for a quick choiceof the needed capacitor, after the resistor has been fixed. The value of

the resistor defines the rate at which the upper

and lower drivers turn-off during linear mode operation to avoid EMI effects. During turn-off, the

slew rate is constant for the sink stage, while it

has a varying slope for the source stage because

of thenon linear change of the gate to source impedance of the DMOS transistor. Practically, the

Figure2: Typicalt

vs. Capacityof C

off

slowest slew rate is obtainedat the sink transistor

switch-off time (see fig. 5), then it increases during the first period of the source transistor switchoff (source,1st)and it becomes the fastest during

the final portion of the turn-off duration (source,

2nd). The PWM to linear mode of operation is

switched by decreasing the LIN Vref level under

the PWM Vref value that could be fixed and calculatedby:

PWMVref = 4 Rs Ip

where Ip is the peak chopping current in the motor windings. Of course, when the required RPM

is reached, it become of no need a strong torque

and the LIN Vref starting from a value higher than

the calculated PWM Vref, decreases to the value

:

LINVref = 4 Rs Im

whereIm, smaller thanIp, is the neededmotorcurrentto keep constantspin. This last referencevoltage is generally a PLL output driven by speed

transducerscoupled to the spindle (like Hall effect

sensors or BEMF processors). To drive the upper

DMOS and during the brake function a voltage

higher than the supply Vs is needed. The charge

pump integrated in the L6232E keeps C3 at the

correct voltage. To guarantee efficient braking of

the motor , C3 must be chosen of adeguatequality

(very high equivalent parallel resistance). C4 can

be a ceramic disk capacitor . The typical application od the L6232E is in HDD systems on which

thereis theneed to park theRead-WriteHeads before the motor braking. This behavior is possible

with the circuit of Fig.3.At PowerSupplyswitch-off

(see Fig. 1), VP falls down and drives down the

BRK input (Active Low). D1 insulates the L6232E

from the power suppyoutput while the power output stage is switched in a high impedance state.

Thespindlemotor actingas a three-phasealternator supplies the Heads voice coil motor driven

through integrateddiodesthat rectifiethe EMF. After a delay longer than the parking time, the lower

outputDMOSare switched-onand the spindlemotor is braked.The brake delaytime is tipically 150

msecand it isdefinedby :

6/10

L6232E

td(BRK)= 1.4 R1 C6

The sensing resistor value is generally lower

than 1ohm, but a wire wounded type must be

avoided. In Fig.3 the 0.33 ohm sensing resistor

is shown as three parallel 1ohm metal film resis-

Figure 3:

TypicalApplicationCircuit

tors. Care must be taken in the PC Board design

particularly about ground loops and ground copper area. ThetypicalThermalResistancejunction

to ambient versus PC Boardcopper area (Fig.7)

is shown in Fig 8. For Transient Thermal Resistancesee Fig. 9.

Figure 4: Typical NormalizedR

JunctionTemperature

DS (on)

vs.

Figure5: OutputVoltageSlewRate Control vs.

Value

1/R

2

7/10

L6232E

Figure 6: Typical Body Diode Forward Drop vs.

Drain to SourceCurrent.

Figure 8:

TypicalR

vs. On-Board Heatsink

th j-amb

Sidel.

Figure7:

Figure9:

OnBoard Dissipation Copper Area Size

TypicalTransient R

in SinglePulse

th

Condition.

8/10

PLCC28 PACKAGEMECHANICALDATA

L6232E

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 12.32 12.57 0.485 0.495

B 11.43 11.58 0.450 0.456

D 4.2 4.57 0.165 0.180

D1 2.29 3.04 0.090 0.120

D2 0.51 0.020

E 9.91 10.92 0.390 0.430

e 1.27 0.050

e3 7.62 0.300

F 0.46 0.018

F1 0.71 0.028

G 0.101 0.004

M 1.24 0.049

mm inch

M1 1.143 0.045

9/10

L6232E

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specification mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are notauthorized foruse as criticalcomponents in lifesupport devices or systems without express

written approval of SGS-THOMSON Microelectronics.

1996 SGS-THOMSON Microelectronics – Printed in Italy – All Rights Reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil - Canada- China - France - Germany - HongKong - Italy - Japan - Korea - Malaysia - Malta- Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland- Taiwan- Thailand - UnitedKingdom - U.S.A.

10/10

Loading...

Loading...