DUALSCHOTTKYDIODE BRIDGE

.MONOLITHIC ARRAY OF EIGHT SCHOTTKY

DIODES

.HIGHEFFICIENCY

.4APEAK CURRENT

.LOWFORWARDVOLTAGE

.FASTRECOVERYTIME

.TWOSEPARATED DIODEBRIDGES

DESCRIP TION

TheL6210isa monolithicICcontainingeightSchottky diodes arranged as two separated diode

bridges.

Thisdiodes connectionmakes this deviceversatile

in manyapplications.

Theyareusedparticularinbipolarsteppermotorapplications,wherehighefficientoperation,duetolow

forwardvoltagedropandfastreverserecoverytime,

arerequired.

TheL6210 is availablein a 16 PinPowerdipPackage(12+ 2 +2) designedforthe0to 70xCambient

temperaturerange.

L6210

N

DIP16

(PlasticPackage))

ORDERINGNUMBER : L6210

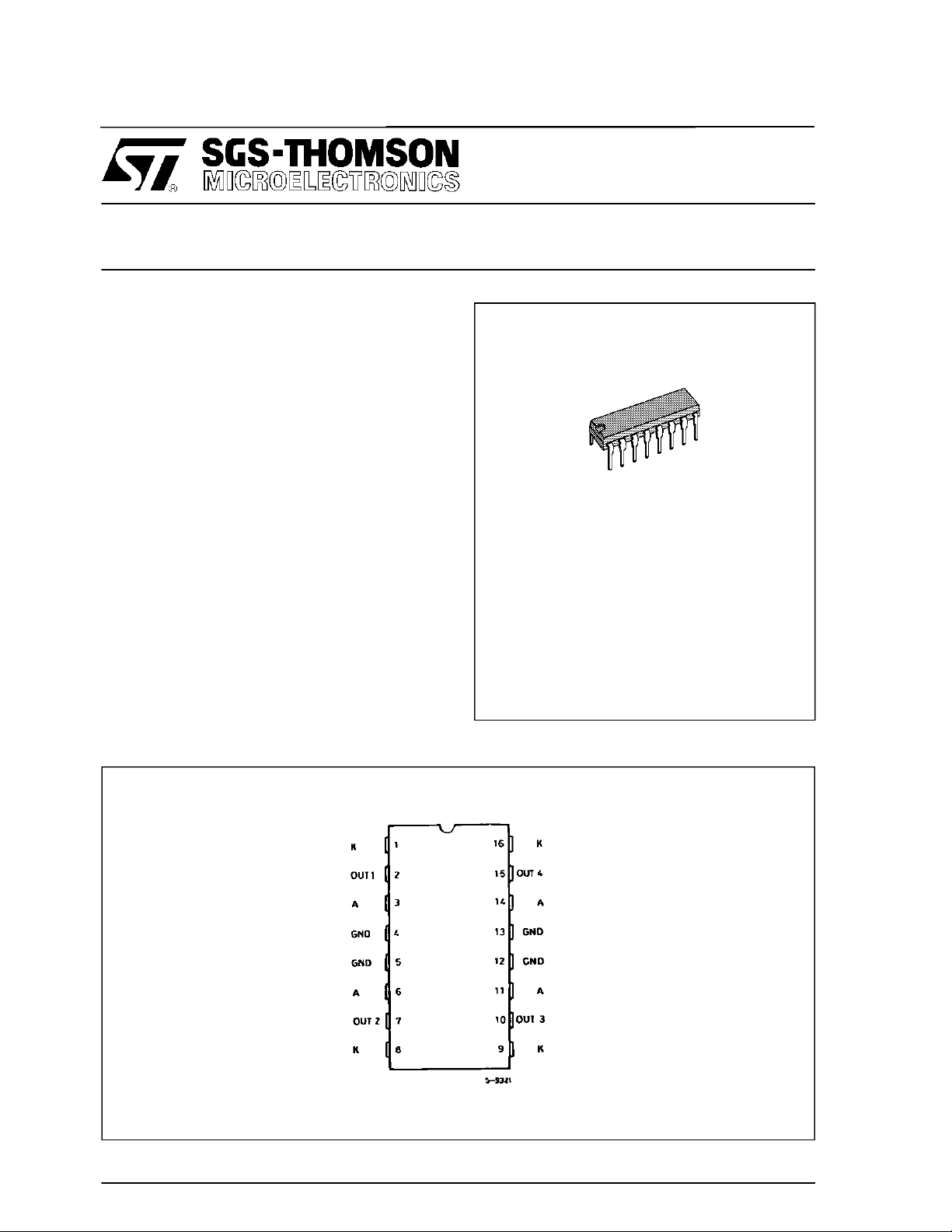

PIN CONNECTION (top view)

April1993

1/5

L6210

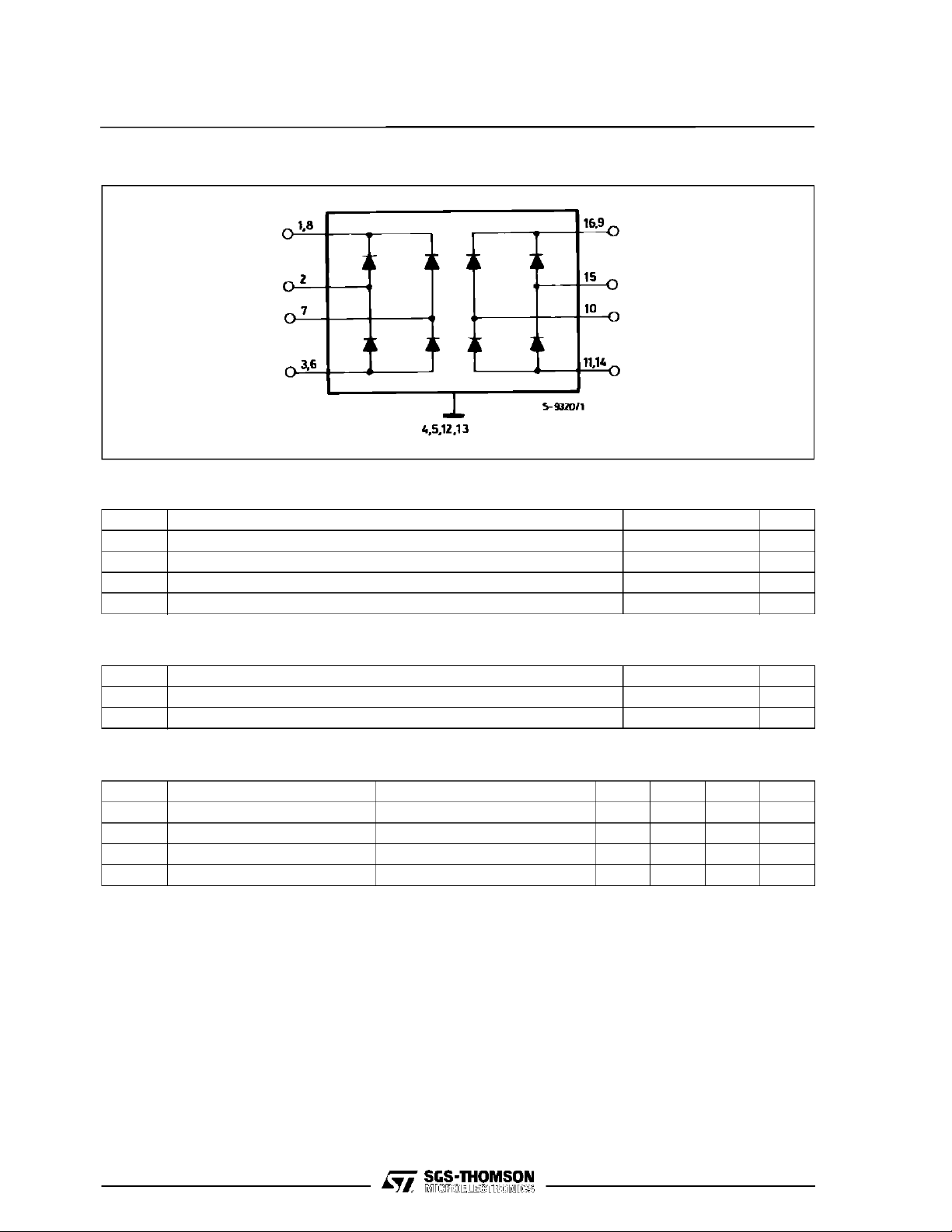

BLOCK DI AG RAM

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

Repetitive Forward Current Peak 2 A

I

f

V

T

amb

T

Peak Reverse Voltage (per diode) 50 V

r

Operating Ambient Temperature 70

Storage Temperature Range –55 to +150

stg

o

C

o

C

THERMAL DATA

Symbol Parameter Value Unit

R

th j-case

R

th j-amb

Thermal Impedance Junction-case Max. 14

Thermal Impedance Junction-ambient without External Heatsink Max. 65

o

C/W

o

C/W

ELECTRICAL CHARACTERISTICS (Tj=25oC unless otherwise specified)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

Note : At forw ard cur r ents of greater than 1A, a parasit ic current of approx imately 10mA may be col lect ed by adiacent diodes.

Forward Voltage Drop If= 100 mA 0.65 0.8

f

= 500 mA 0.8 1 V

i

f

= 1 A 1 1.2

I

f

Leakage Current VR=40V,T

I

L

=25oC1mA

amb

2/5

L621 0

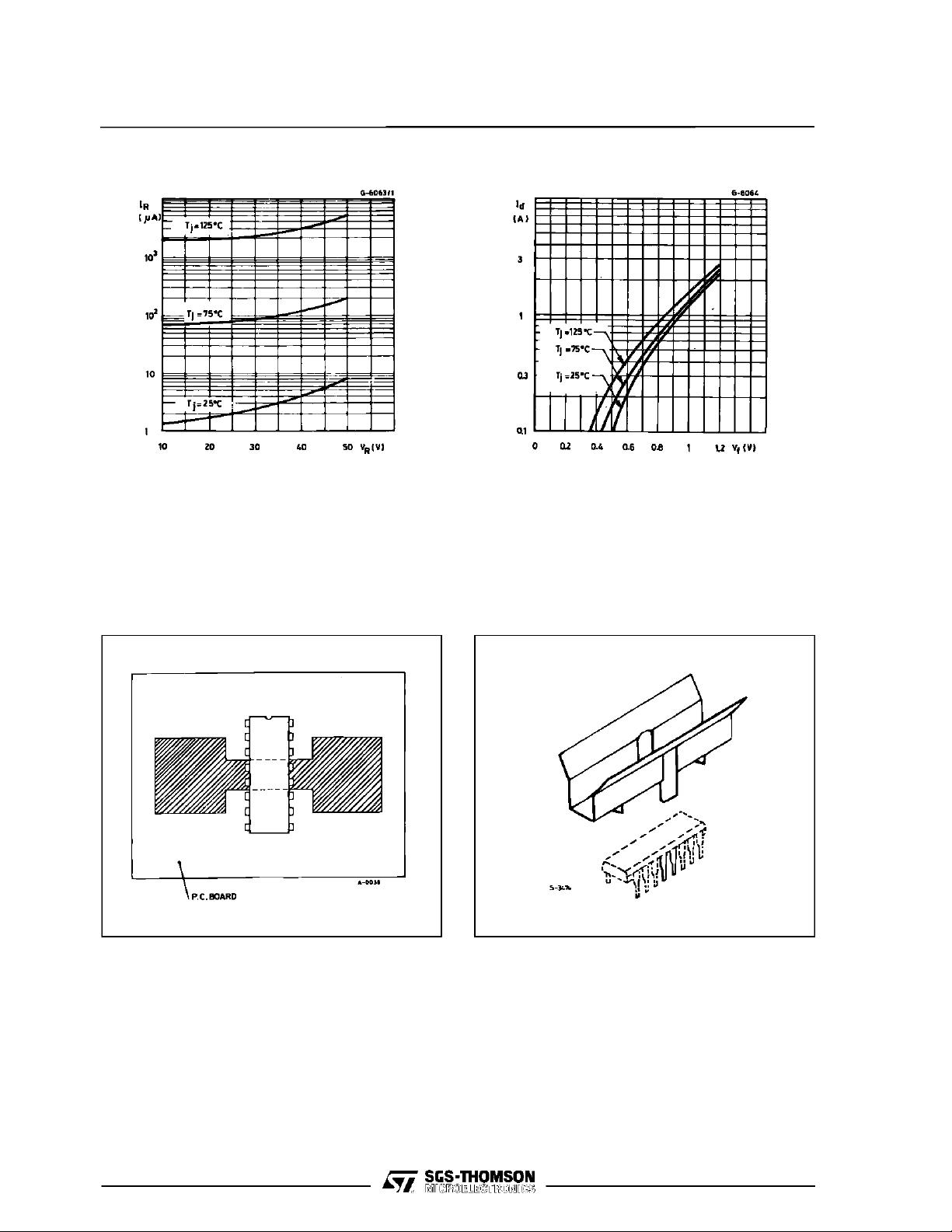

Figure 1 : Reverse Current verus Voltage Figure 2 : Forward Voltage versus Current

MOUNTING I NST RUCTI ONS

o

TheRthj-ambof the L6210canbe reducedby solderingthe GND pins to suitablecopper area of the

printedcircuit boards as shown in figure 3 or to an

externalheatsink(figure 4).Duringsolderingthepin

temperaturemustnotexceed260

ingtime must not be longerthen 12s. Theexternal

heatsinkorprintedcircuit copperareamustbe connectedto electrical ground.

C andthesolder-

Figure 3 : Exampleof P.C. Board Copper Area

which is used as Heatsink

Figure 4 : Example of an External Heatsink

3/5

L6210

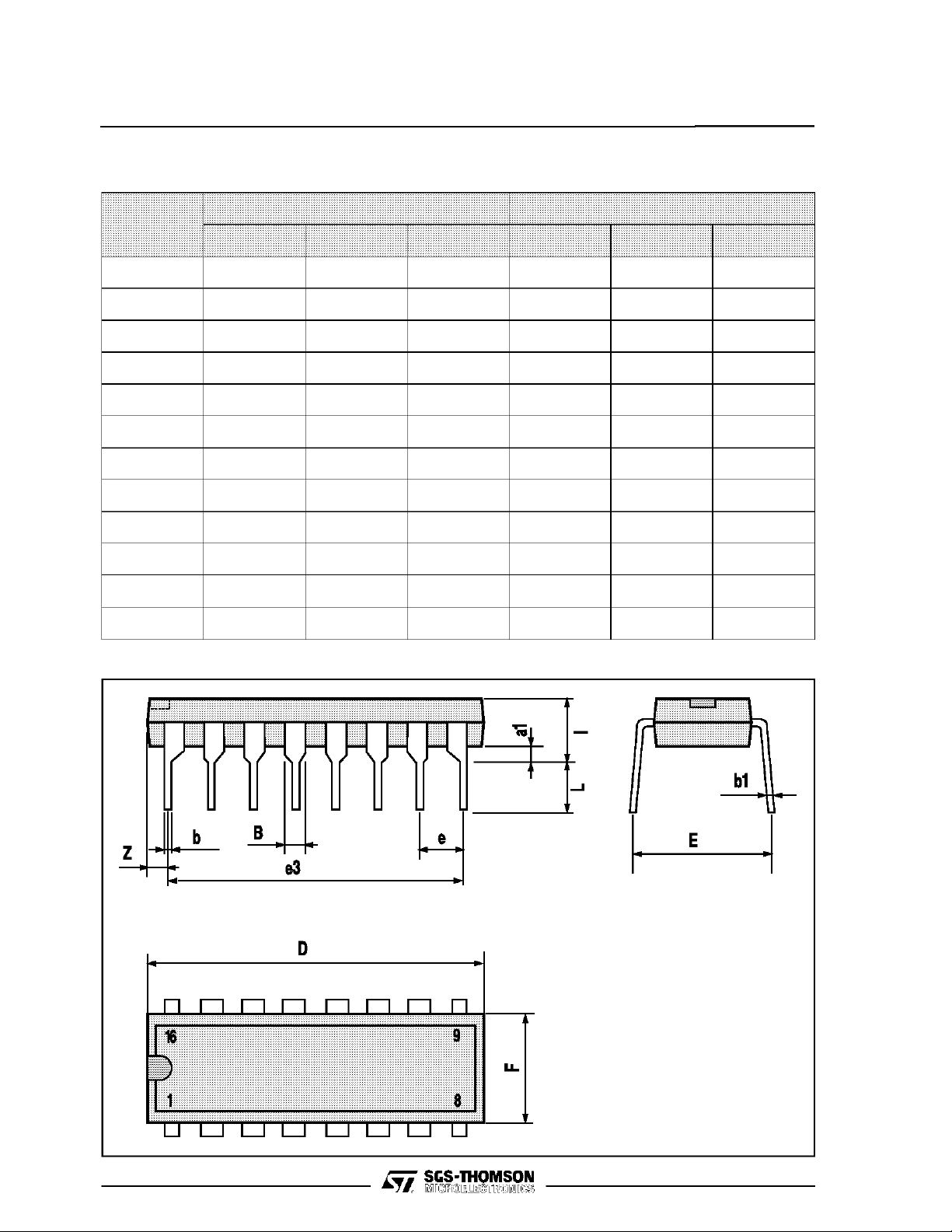

POWERDIP16PACKAGE MECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.51 0.020

B 0.85 1.40 0.033 0.055

b 0.50 0.020

b1 0.38 0.50 0.015 0.020

D 20.0 0.787

E 8.80 0.346

e 2.54 0.100

e3 17.78 0.700

F 7.10 0.280

I 5.10 0.201

L 3.30 0.130

Z 1.27 0.050

mm inch

4/5

L621 0

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for

the consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its

use. No license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied. SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or

systems withoutexpress written approval of SGS-THOMSON Microelectronics.

1994 SGS-THOMSON Microelectronics - All Rights Reserved

Australia - Brazil - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands - Singapore -

SGS-THOMSON MicroelectronicsGROUP OF COMPANIES

Spain - Sweden - Switzerland - Taiwan - Thaliand - United Kingdom - U.S.A.

5/5

Loading...

Loading...