FULLY INTEGRATED STEPPER MOTOR DRIVER

■

OPERATING SUPPLY VOLTAGE FROM 8 TO 52V

■ 5A PEAK CURRENT (2.8A DC)

■

R

DS(ON)

■

BUILT-IN DECODING LOGIC

■

BUILT-IN CONSTANT OFF-TIME PWM

CURRENT CONTROL

■

FAST/SLOW DECAY MODE SELECTION

■

HIGH SIDE OVER CURRENT PROTECTION

5.6A TYP.

■

CROSS CONDUCTION PROTECTION

■

THERMAL SHUTDOWN

■ OPERATING FREQUENCY UP TO 100KHz

■

INTRINSIC FAST FREE WHEELING DIODES

■

UVLO: UNDER VOLTAGE LOCKOUT

DESCRIPTION

The L6208 is a fully integrated stepper motor driver

manufactured with multipower BCD technology,

which combines isolated DMOS power transistors

with CMOS and bipolarcircuits on the same chip.

0.3Ω TYP. VALUE @ Tj=25°C

L6208

PRELIMINARY DATA

PowerDIP24 PowerSO36 SO24

(20+2+2) (20+2+2)

ORDERING NUMBERS:

L6208N L6208PD L6208D

The logic inputs are CMOS/TTL and µP compatible.

The device also includes all the circuitry needed to

drive a stepper motor, that is the constant off time

PWM control that performs the chopping current control and the state machine that generates the stepping sequence. Other features are the protection of

the high side switches against unsafe over current

conditions and the thermal shutdown.

The L6208 is assembled in PowerDIP24(20+2+2),

PowerSO36 and SO24(20+2+2) packages.

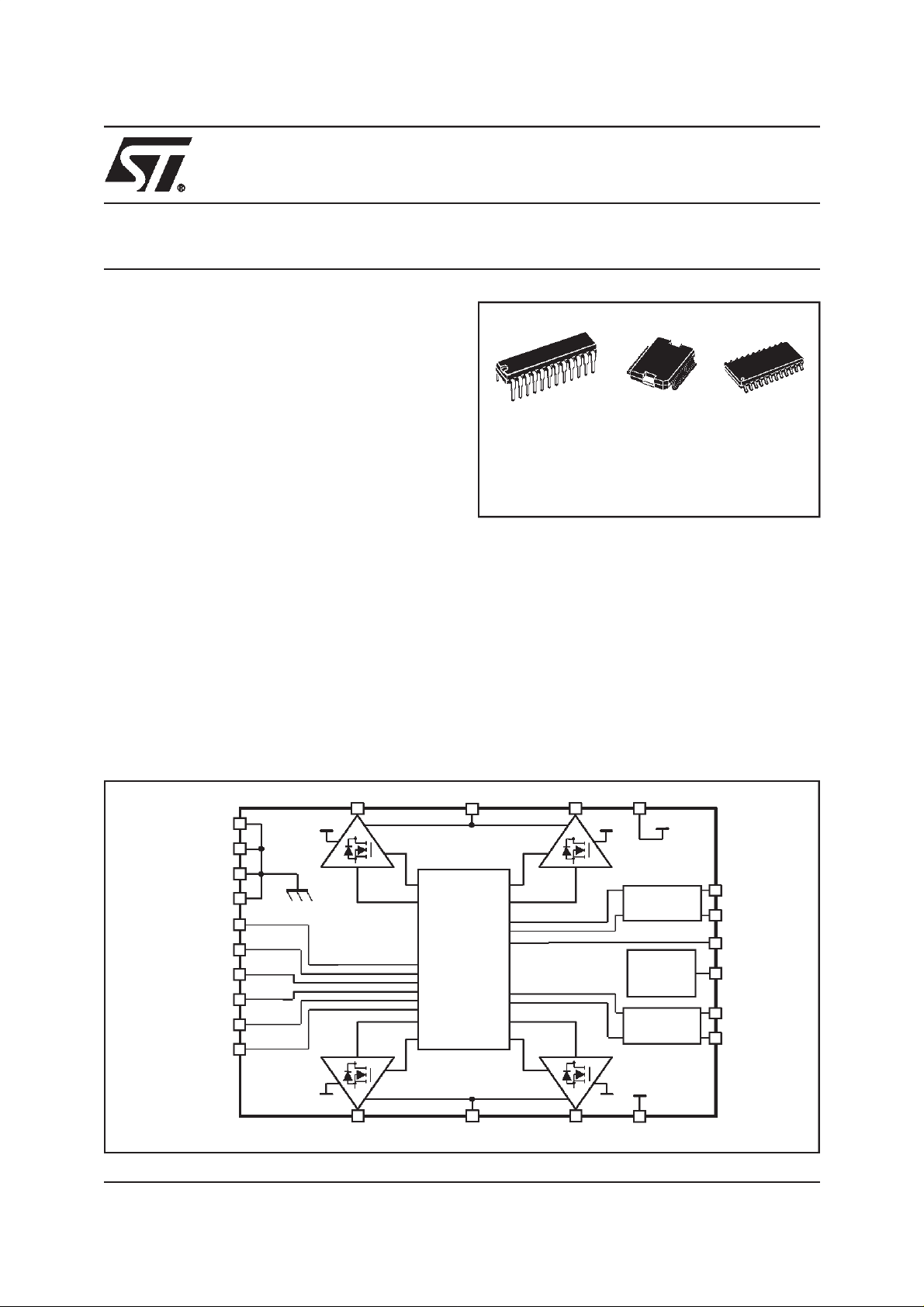

BLOCK DIAGRAM

OUT2

OUT2

V

A

B

SA

V

V

SB

V

SB

SA

PWM

Charge

Pump

PWM

V

A

B

RC

V

V

V

RC

ref A

A

BOOT

CP

ref B

B

VSAVSA

V

SB

GND

GND

GND

GND

EN

Reset

Clock

CW/CCW

HALF/FULL

Control

VSB

OUT1

OUT1

A

B

SENSE

Logic

&

Drivers

SENSE

A

B

January 2001

This ispreliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

1/15

L6208

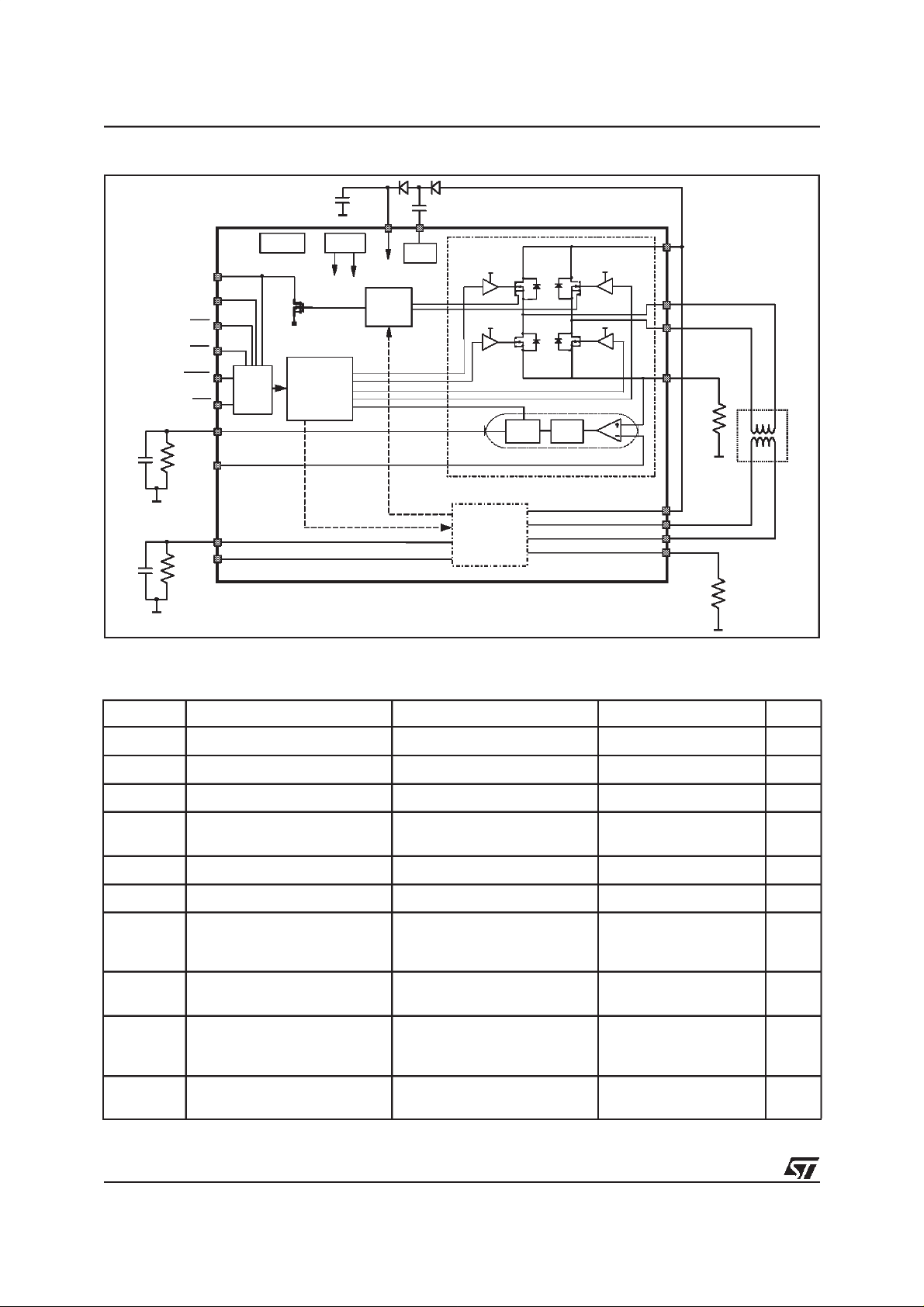

FUNCTIONAL BLOCK DIAGRAM

CONTROL

HALF/FULL

Clock

RESET

CW/CCW

RCA

VrefA

RCB

VrefB

Vboot

10V

Decoding

Logic

Voltage

Regulator

5V

Current

Detection

Vboot

Over

Thermal

Protection

EN

Input

Interface

Charge

Pump

VCP

Vboot

10V

One Shot

Masking

Time

Vboot

10V

Sense

Comparator

VSA

OUT1A

OUT2A

SENSE A

PWM

BRIDGE A

VSB

BRIDGE B

OUT1B

OUT2B

SENSE B

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Test conditions Value Unit

V

V

IN,VEN

V

refA,VrefB

V

RCA,RCB

V

SENSE

V

BOOT

I

S(peak)

I

S

V

OD

T

stg,TOP

Supply Voltage 60 V

S

Input and Enable Voltage Range -0.3 to +7 V

Voltage Range at V

Voltage Range atRCAand RC

pins -0.3 to +7 V

ref

B

-0.3 to +7 V

pins

DC Sensing Voltage Range -1 to +4 V

Bootstrap Peak Voltage VS+10 V

Pulsed Supply Current (foreach

V

pin), internally limited by the

S

< 1ms 7.1 A

t

PULSE

overcurrent protection.

DCvSupply Current (foreach V

S

2.8 A

pin)

Differential Voltage Between

60 V

VSA,OUT1A,OUT2A,SENSEAand

VSB, OUT1B, OUT2B, SENSE

Storage and Operating

B

-40 to 150 °C

Temperature Range

2/15

RECOMMENDED OPERATING CONDITIONS

Symbol Parameter MIN MAX Unit

L6208

V

V

OD

Supply Voltages 12 52 V

S

Differential Voltage Between

VSA, OUT1A,OUT2A,SENSEAand

VSB, OUT1B, OUT2B, SENSE

V

SENSE

Sensing voltage

(pulsed tw<t

V

I

OUT

ref

T

f

c

V

Operating Voltage -0.1 5

ref

DC Output Current 2.8 V

Operating Junction Temperature -25 +125 °C

j

Commutation Frequency 100 kHz

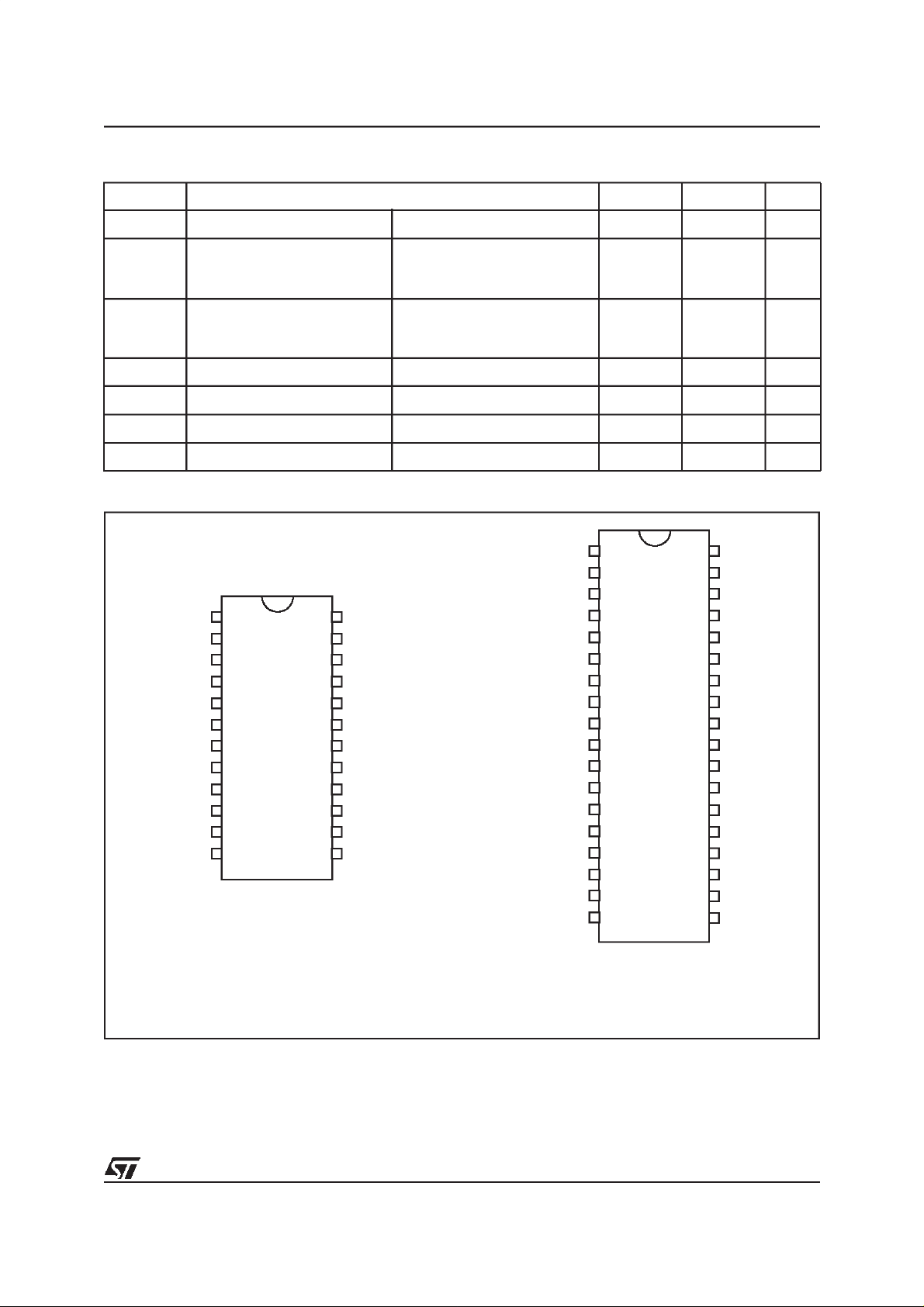

PIN CONNECTIONS(Top View)

RC

RC

V

refB

1

2

3

A

4

A

5

A

6

7

8

B

9

B

10

B

11

12

24

23

22

21

20

19

18

17

16

15

14

13

Clock

CW/CCW

SENSE

OUT1

GND

GND

OUT1

SENSE

HALF/FULL

B

)

rr

(DC)

V

refA

Reset

V

CP

OUT2

V

SA

GND

GND

V

SB

OUT2

V

BOOT

EN

Control

52 V

-6

-1

GND

OUT2

A

Reset

V

Clock

CW/CCW

B

SENSE

OUT1

GND

NC

NC

V

NC

V

refA

RC

NC

NC

NC

SA

CP

1

2

3

4

5

A

6

7

8

9

10

11

12

A

13

A

14

15

A

16

17

18

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

6

1

GND

NC

NC

V

SB

OUT2

B

NC

V

BOOT

EN

Control

HALF/FULL

V

refB

SENSE

RC

B

B

NC

OUT1

B

NC

NC

GND

V

V

PDIP24/SO24 PowerSO36

3/15

L6208

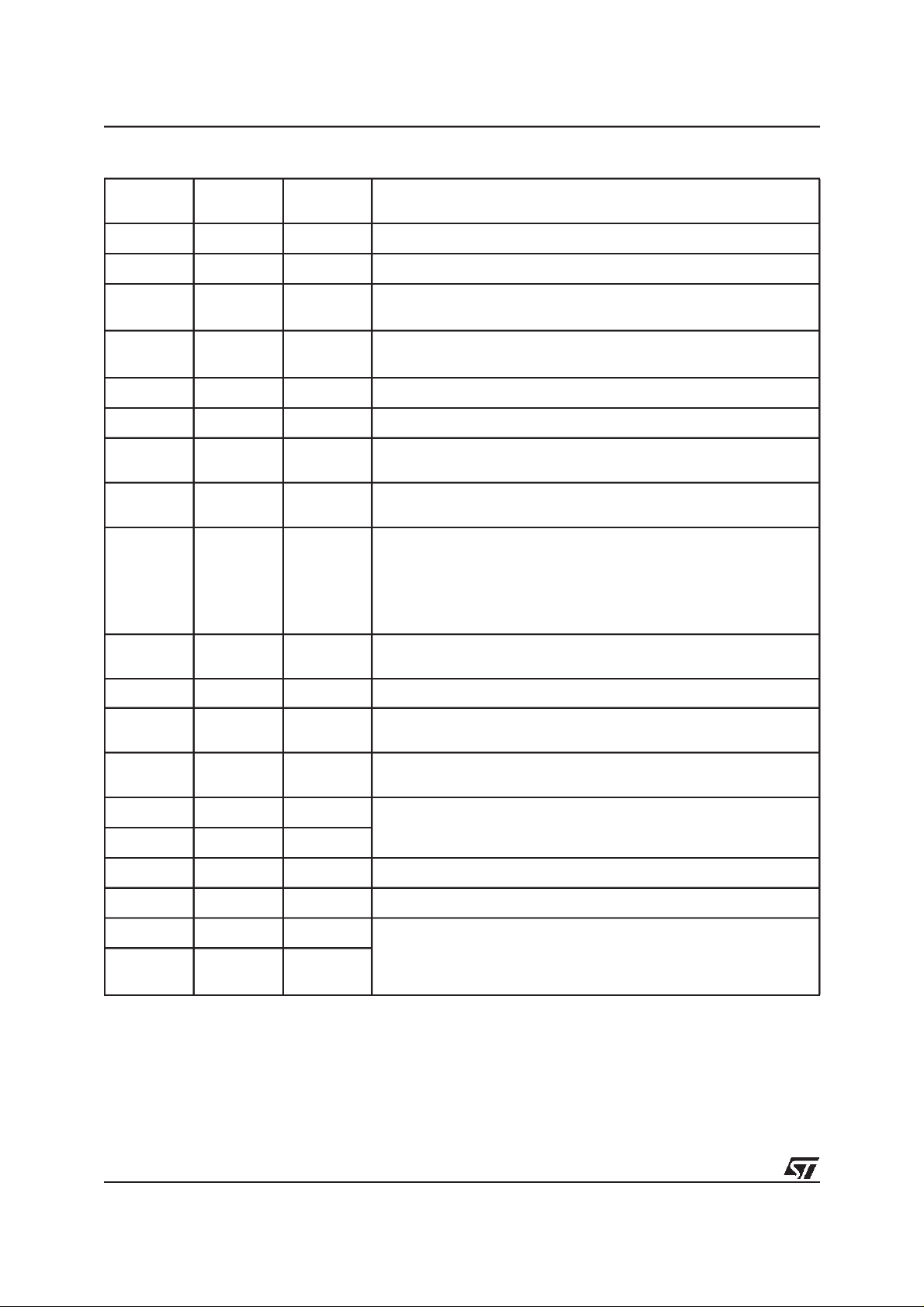

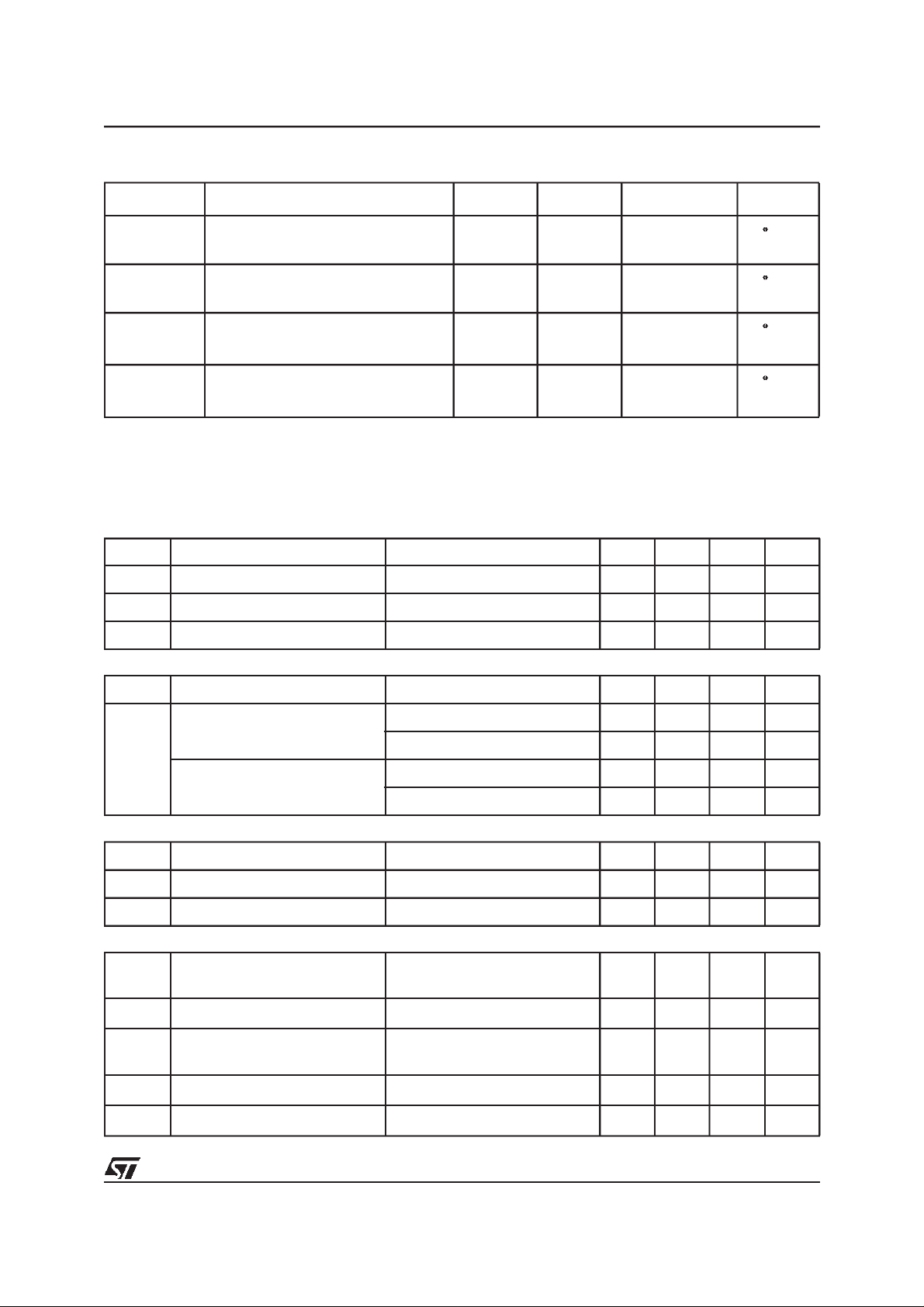

PIN DESCRIPTION

Name PowerSO36

PDIP24/

SO24

Function

V

SA

V

SB

OUT1

A

OUT2

A

OUT1

B

OUT2

B

SENSE

SENSE

A

B

GND 1, 18, 19, 36 6, 7,

4 20 Supply voltage of the bridge A.

33 17 Supply voltage of the bridge B. Must be connected to VSA.

15

5

22

32

21

16

5

8

Bridge A outputs.

Bridge B outputs.

12 3 Sense resistor for the bridge A.

25 10 Sense resistor for the bridge B.

Common ground terminals. In Powerdip and SO packages, these pins

18, 19

are also used for heat dissipation toward the PCB.

EN 29 14 Chip Enable. A Low logic level applied to this pin switches Off all the

power DMOSs.

HALF/FULL 27 12 Logic input. When high, HALF STEP operation is selected; a Low logic

level selects FULL STEP operation.

ONE-PHASE-ON FULL STEPMODE (

selecting FULLwhen the state machine is at an

TWO-PHASE-ON FULL STEPMODE (

selecting FULLwhen the state machine is at an

Reset 8 23 Logic input. A Low logic levelrestores the

wave mode

even

normal mode

odd

home

state (state 1) on the

) is obtained by

numbered state.

) is obtained by

numbered state.

state machine.

Clock 10 1 Logic input. Step Clock. The step occurs on the rising edge of this signal.

CW/CCW 11 2 Logic input. Logic High sets clockwise direction. Logic Low sets

counterclockwise direction.

Control 28 13 Logic input. Selects chopping style. FAST DECAY is selected with logic

Low. A logic High selects SLOW DECAY.

V

ref A

9 24 A voltage applied to these pins sets the reference voltage of the sense

comparators, determining the output current in PWM current control.

V

V

V

BOOT

RC

ref B

CP

A

26 11

7 22 Bootstrap oscillator. Oscillator output forthe external charge pump.

30 15 Supply voltage to overdrive the upper DMOSs.

13 4 A parallel RC network connected tothese pins sets the OFF time of the

low-side power DMOS of the correspondent bridge. The pulse generator

RC

B

24 9

is a monostable triggered by the output of the sense comparator of the

bridge (t

= 0.69 RC).

OFF

4/15

THERMAL DATA

Symbol Description PDIP24 SO24 PowerSO36 Unit

L6208

R

th-j-pins

MaximumThermal Resistance

18 14 -

C/W

°

Junction-Pins

R

th-j-case

Maximum Thermal Resistance

-- 1°C/W

Junction-Case

R

th-j-amb1

R

th-j-amb2

<(1)>Mounted on a multiplayer PCB with a dissipating copper surface on the bottom side of 2 x 12mm x 25mm (with athickness of

<(2)>It’s the same condition of the point above, without any heatsinking surface on the board.

MaximumThermal Resistance

Junction-Ambient

Maximum Thermal Resistance

Junction-Ambient

at least 35 µm).

(1)

(2)

42 50 35 °C/W

58 77 62 °C/W

ELECTRICAL CHARACTERISTICS

(T

=25°C, Vs= 48V, unless otherwise specified)

amb

Symbol Parameter Test Conditions Min Typ Max Unit

V

Output DMOS Transistors

I

DSS

R

DS(ON)

Source Drain Diodes

Supply Voltage 8 52 V

S

I

Quiescent Supply Current All Bridges OFF 5.5 10 mA

S

T

Thermal Shutdown Temperature 150 °C

j

Leakage Current VS= 52V 1 mA

High-side Switch ON Resistance Tj=25°C 0.34 0.4

T

=125°C 0.53 0.59

j

Low-side SwitchON Resistance T

=25°C 0.28 0.34

j

T

=125°C 0.47 0.53

j

Ω

Ω

Ω

Ω

V

Forward ON Voltage ISD= 2.8A, EN = LOW 1.2 1.4 V

SD

t

Reverse Recovery Time If= 2.8A 300 ns

rr

t

Forward Recovery Time 200 ns

fr

Switching Rates

t

D(on)

Output to out Turn ON Delay

Time

t

ON

Output Rise Time

t

D(OFF)

Enable to out Turn OFF Delay

Time

t

OFF

t

DCLK

Output FallTime

Clock to output delay time

(3)

(3)

(3)

(3)

(3)

I

=2.8A 110 250 400 ns

LOAD

I

=2.8A 20 105 300 ns

LOAD

I

=2.8A 240 580 760 ns

LOAD

I

=2.8A 20 78 300 ns

LOAD

I

=2.8A 2 µs

LOAD

5/15

L6208

ELECTRICAL CHARACTERISTICS

(T

=25°C, Vs= 48V, unless otherwise specified)

amb

(continued)

Symbol Parameter Test Conditions Min Typ Max Unit

t

Dead Time Protection 1

dt

t

blank

InternalBlanking Timeon SENSE

1 1.5 µs

pins

f

Charge pump frequency 0.75 1 MHz

CP

UVLO comp

V

th(ON)

V

th(OFF)

TurnON threshold 6.6 7 7.4 µs

TurnOFF threshold 5.6 6 6.4 µs

Logic Input

V

V

I

INH

I

t

CLK

t

RCLK

Low levellogic input voltage -0.3 0.8 V

INL

High levellogic input voltage 2 7 V

INH

High levellogic input current V

Low levellogic input current V

INL

Minimum clock time

t

S

Minimum set up time

t

H

Minimum hold time

t

R

Minimum reset time

(4)

Minimum reset to clockdelay

(4)

(4)

(4)

(4)

=5V 70 µA

IN, EN

= GND -10 µA

IN, EN

see Fig. 2 0.1 1 µs

1 µs

1 µs

1 µs

1 µs

s

µ

Over Current Protection

I

S OVER

Input supply over current

protection threshold

V

DIAG

Open drain low level output

voltage

Comparator and Monostable

I

RCA,RCB

V

Source current at RC pins VRC=2.5 V 3 5 mA

Input common mode comparator

ref

voltage range

V

Comparator threshold voltage on

th

SENSE pins

t

prop

t

OFF

I

bias

TurnOFF propagation delay

PWMRecirculation time

Input bias current at V

<(3)>Resistive load used. See Fig. 1.

<(4)>See Fig. 2.

<(5)>Defined as the time between the voltage at the input of the current sense reaching theV

switch beginning to turn off. The voltage at SENSE pin is increased instantaneously from V

Tj =25 °C 4 5.6 7.1 A

I = 4 mA 0.4 V

-0.1 5 V

V

(5)

V

20 kΩ <R<100kΩ

= 0.5 V V

ref A, B

= 0.5 V 0.1 0.2 0.3 µs

ref A, B

- 5mV V

ref

0.67RC 0.69RC 0.71RC s

ref

+ 5mV

0.1 nF < C < 100 nF

pins 0.2 µA

ref

threshold and the lower DMOS

ref

-10mVtoV

ref

+10 mV.

ref

6/15

Figure 1. Switching Rates Definition

En

50%

L6208

I

OUT

90%

10%

CLK

t

50%

I

OUT

Figure 2. MinimumTiming Definition

D(OFF)tOFF

t

DCLK

t

D(ON)t(ON)

t

t

t

t

CLOCK

CLOCK

Logic Inputs

RESET

t

CLK

t

CLK

t

S

t

R

t

RCLK

t

H

7/15

L6208

Figure 3. Typical Quiescent Currentvs. Supply

Voltage

Iq [mA]

5.6

5.4

5.2

5.0

4.8

4.6

0 102030405060

fc= 1kHz Tj=25°C

[V]

V

S

=85°C

T

j

T

j

= 125°C

Figure 4. Normalized Typical Quiescent

Current vs. Switching Frequency

Iq / (Iq @ 1 kHz)

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0 20406080100

f

[kHz]

SW

Figure 6. Typical High-Side RDS(ON) vs.

Supply Voltage

R

[Ω]

DS(ON)

0.380

0.376

0.372

0.368

0.364

0.360

0.356

0.352

0.348

0.344

0.340

0.336

0 5 10 15 20 25 30

Figure 7. Normalized R

Tj=25°C

V

[V]

S

DS(ON)

vs.Junction

Temperature (typical value)

R

/(R

DS(ON)

1.8

1.6

1.4

1.2

1.0

0.8

0 20 40 60 80 100 120 140

DS(ON)

@25°C)

Tj [°C]

Figure 5. Typical Low-Side R

DS(ON)

Voltage

[Ω]

R

DS(ON)

0.300

0.296

Tj=25°C

0.292

0.288

0.284

0.280

0.276

0 5 10 15 20 25 30

8/15

[V]

V

S

vs. Supply

Figure 8. Typical Drain-Source Diode Forward

ON Characteristic

ISD[A]

3.0

Tj=25°C

2.5

2.0

1.5

1.0

0.5

0.0

700 800 900 1000 1100 1200 1300

VSD[mV]

L6208

CIRCUITDESCRIPTION

The L6208 isafully integrated bipolar stepper motor driver withtwo full bridge having power DMOS with atypical

RDSON of 0.3

as a constant T

The decoding logic generates three different sequences, selected by the HALF/FULL input. These are normal

(two phases ), wave drive (one phase energized) and half-step (alternately one phase/two phases energized).

The decoding logic generates three different sequences, selected by the HALF/FULL input. These are normal

(two phases energized), wave drive (one phase energized) and half-step (alternately one phase/two phases energized).

The constant T

When the current in each phase of the motor reaches the value set by the correspondentV

it will be forced to decrease for a constant Toff time, set by the RC network applied to the RCAand RCBpins. If the

Control pin isat a High logiclevel, duringthe off-time the voltageapplied to the motorphase willbe approx.0 V,turning

on the high-side MOSFETs of the bridge (slow decayrecirculation); if control is Low, instead, the voltage applied to

the phase will be reversed, turning off the low side MOSFET that was on and turning on the opposite low-side (fast

decay recirculation).

Figure 9.

Ω each. All the circuitry to implement the phase generation (decoding logic)is integrated, as well

PWM control for the current, separately for any of the two winding of the driven motor.

off

PWM current control consists ina sense comparator and a monostable.

off

voltage(V

ref

ref/RSENSE

),

V

S

On Time

Slow-Decay

Figure 10. PWM Chopping Current Control

I

OUT

T

ON

V

ref/RSENSE

Threshold

V

S

Off Time in

Recirculation

Off Time in

Fast-Decay

V

S

Recirculation

T

OFF

(Recirculation)

t

9/15

L6208

A non-dissipative current sensing on the high side power DMOSs, an internal reference and an internal open

drain, with a pull down capability of 4mA (typical value), that goes LOW under fault conditions, ensure a protection against short circuit to GND or between two phases of each of the two full bridges. The trip point of this

protection is internally set at 5.6 A (typ. value). By using an external R-C on the EN pins, the off time before

recover normaloperation conditions after a fault can be easily programmed, by means of the accuratethreshold

of the logic inputs. Note that protection against short to the supply rail is typically provided by the PWM current

control circuitry.

These features make the L6208 a complete bipolar stepper motor driver that outperforms the components currently available on the market

MOTOR DRIVING PHASE SEQUENCE

The decoding logic integrated in the L6208 generates thesequences for normal drive, wave drive and half step

modes. The state machine sequences and the output currents (neglecting, for simplicity, the PWM control) are

shown below, in the case of clockwise rotation. For counterclockwise rotation the sequences are simply reversed. The state machine advances on the rising edge of the Clock signal, and a Low logic level on the Reset

input restores the logic to state 1.

HALF STEP MODE

Half step mode is selected by a high logic level on the HALF/FULL pin.

Figure 11.

345

2

1

6

78

I

OUT1A

I

OUT2A

I

OUT1B

I

OUT2B

Clock

81234567

10/15

L6208

NORMALDRIVE MODE

(Full-step two-phase-on)

Normal drive mode is selected by a Low level on the HALF/FULL input when the state machine is at an odd

numbered state.

Figure 12.

I

OUT1A

I

OUT2A

345

2

1

6

78

I

OUT1B

I

OUT2B

Clock

71357135

WAVEDRIVE MODE

(Full-step one-phase-on)

Wave drive mode is selected by a Low level on the HALF/FULL input when the state machine is at an even

numbered state.

Figure 13.

I

OUT1A

345

I

OUT2A

2

1

6

78

I

OUT1B

I

OUT2B

Clock

82468246

11/15

L6208

DIM.

MIN. TYP. MAX. MIN. TYP.

A 4.320

A1 0.380

A2 3.300

B 0.410 0.460 0.510 0.016 0.018

mm inch

MAX.

0.170

0.015

0.130

0.020

B1 1.400 1.520 1.650 0.055 0.060 0.06

c 0.200 0.250 0.300 0.008 0.010

D 31.62 31.75 31.88 1.245 1.250 1.255

E 7.620 8.260 0.300

e 2.54

0.100

0.012

0.325

E1 6.350 6.600 6.860 0.250 0.260 0.27

e1

L 3.180 3.430 0.125

7.620

M0°min, 15°

max.

0.300

0.135

OUTLINE AND

MECHANICAL DATA

5

0

Powerdip 24

E1

A2

A

13

12

A1

SDIP24L

e1

c

M

L

B

D

24

1

B1

e

12/15

L6208

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 2.35 2.65 0.093 0.104

A1 0.10 0.30 0.004 0.012

A2 2.55 0.100

B 0.33 0.51 0.013 0.0200

C 0.23 0.32 0.009 0.013

D 15.20 15.60 0.598 0.614

E 7.40 7.60 0.291 0.299

e 1.27 0,050

H 10.0 10.65 0.394 0.419

h 0.25 0.75 0.010 0.030

k0°(min.),8° (max.)

L 0.40 1.27 0.016 0.050

mm inch

OUTLINEAND

MECHANICAL DATA

SO24

0.10mm

.004

Seating Plane

1

A2

A

Be

A1

K

D

1324

E

12

hx45°

L

A1 C

H

SO24

13/15

L6208

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

A 3.60 0.141

a1 0.10 0.30 0.004 0.012

a2 3.30 0.130

a3 0 0.10 0 0.004

b 0.22 0.38 0.008 0.015

c 0.23 0.32 0.009 0.012

D (1) 15.80 16.00 0.622 0.630

D1 9.40 9.80 0.370 0.385

E 13.90 14.50 0.547 0.570

e 0.65 0.0256

e3 11.05 0.435

E1 (1) 10.90 11.10 0.429 0.437

E2 2.90 0.114

E3 5.80 6.20 0.228 0.244

E4 2.90 3.20 0.114 0.126

G 0 0.10 0 0.004

H 15.50 15.90 0.610 0.626

h 1.10 0.043

L 0.80 1.10 0.031 0.043

N10°(max.)

S8°(max.)

(1):”D” and”E1” donot include mold flash or protrusions

- Moldflash or protrusionsshall not exceed0.15mm(0.006 inch)

- Criticaldimensionsare”a3”, ”E” and ”G”.

OUTLINE AND

MECHANICALDATA

PowerSO36

E2

hx45°

NN

a2

A

1936

0.12 A B

⊕

e

E1

M

DETAIL A

118

A

e3

H

D

b

DETAIL B

lead

a3

B

Gage Plane

PSO36MEC

BOTTOM VIEW

DETAIL B

0.35

S

L

c

a1

E

DETAIL A

slug

E3

D1

-C-

SEATING PLANE

GC

(COPLANARITY)

14/15

L6208

Information furnished is believed tobe accurate and reliable. However,STMicroelectronics assumes no responsibility for the consequences

of useof such information nor for any infringementof patents or other rightsof third partieswhich may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products arenot

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2001 STMicroelectronics - All Rights Reserved

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta- Morocco - Singapore - Spain

STMicroelectronics GROUP OF COMPANIES

- Sweden- Switzerland - United Kingdom - U.S.A.

http://www.st.com

15/15

Loading...

Loading...