®

TRIPLE OUTP U T POWE R S UPP LY CO NTR O LL ER

DUAL PWM BUCK CONTROLLERS (3.3V

and 5.1V)

12V/120mA LINEAR REGULATOR

DUAL SYNCH RECTIFIERS DRIVERS

96% EFFICIENCY ACHIEVABLE

50µA (@ 12V) STAND BY CONSUMPTION

5.5V TO 25V SUPPLY VOLTAGE

EXCELLENT LOAD TRANSIENT RESPONSE

DISABLE PULSE SKIPPING FUNCTION

POWER MANAGEMENT:

- UNDER AND OVERVOLTAGE OUTPU T

DETECTION

- POWER GOOD SIGNAL

- SEPARATED DISABLE

THERMAL SHUTDOWN

PACKAGE: TQFP32

APPLICATION

NOTEBOOK AND SUBNOTEBOOK COMPUTERS

PEN TOP AND PO RTABLE EQUIPMENT

COMMUNICATING COMPUTE RS

DESCRIPTION

The L4992 is a sophisticated dual PWM stepdown controller and power monitor intended for

Notebook computer and/or battery powered

equipment. The device produces regulated

+3.3V, +5.1V and 12V supplies for use in portable

L4992

TQFP32

ORDERING NUMBER: L4992

and PCMCIA applications.

The internal architecture allows to operate with

minimum external components count. A very high

switching frequency (200/300 KHz or externally

synchronizable) optimizes their physical dimensions.

Synchronous rectification and pulse skipping

mode for the buck sections optimise the overall

efficiency over a wide load current range (96% efficiency @1A/5.1V and 93% efficiency @

0.05A/5.1V.

The two high performance PWM controllers for

+3.3V and +5.1V lines are monitored for overvoltage, undervoltage and overcurrent conditions.

On detection of a fault, a POWER GOOD signal

is generated and a specific shutdown procedure

takes place to prevent physical damage and data

corruption.

A disable function allows to manage the output

power sections separately, optimising the quiescent consumption of the IC in stand-by conditions.

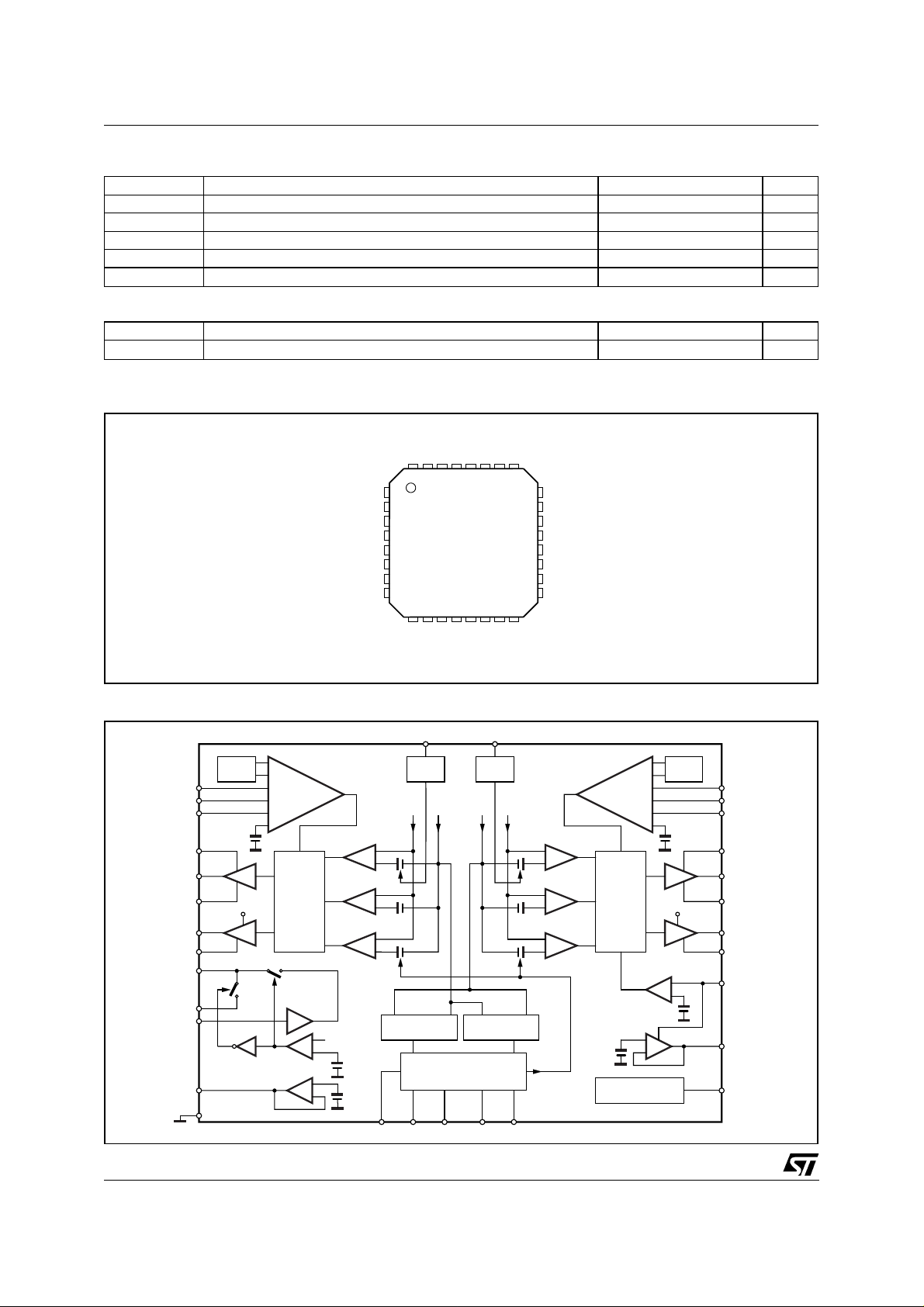

SYSTEM BLOCK DIAGRAM

5.5V

to

25V

SYNC

POWER

MANAGEMENT

& SYSTEM

SUPERVISOR

D96IN429A

June 2000

L4992

POWER

SECTION

3.3V

5.1V

12V LDO

5.1V LDO

3.39V REF

POWER GOOD

µP

MEMORY

PERIPHERALS

1/26

L4992

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

IN

V

I

I

IN

I

OUT

T

J

THERMAL DATA

Symbol Parameter Value Unit

R

TH J-amb

Power Supply Voltage on V

IN

0 to 25 V

Maximum Pin Voltage to Pins 1, 24, 25, 32 -0.5 to (VIN +5) V

Input Current Except V13IN and V

IN

-1 to +1 mA

Output Current Digital Output -15 to +15 mA

Junction Temperature -55 to 150 °C

Thermal Resistance Junction -Ambient 60 °C/W

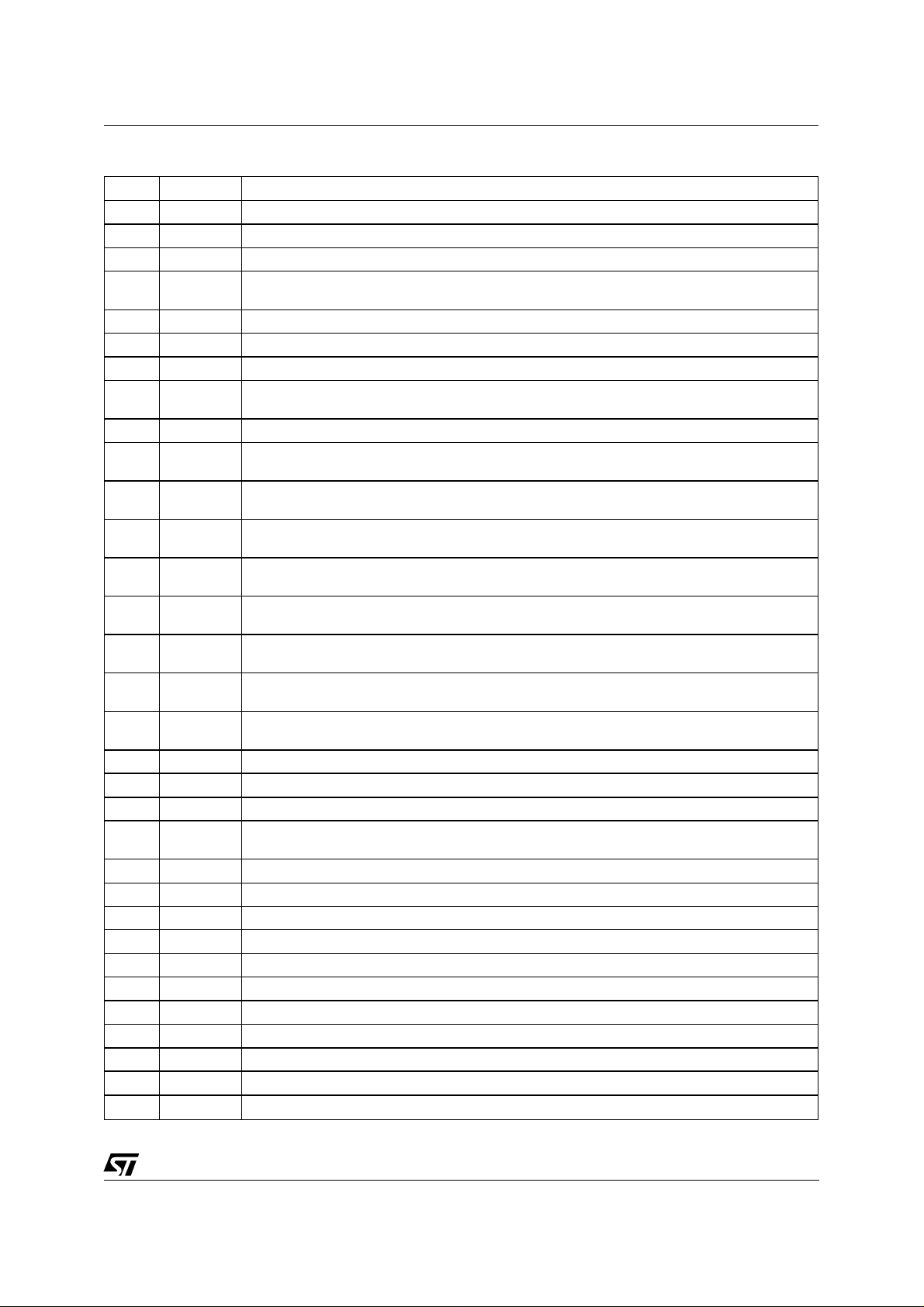

PIN CONNECTION

BLOCK DIAGRAM

6

I5SNS

5

V5SNS

7

COMP5

1

H5STRAP

32

H5GATE

31

H5SRC

30

R5GATE

29

PGND5

REG5

3

4

W5SW

2

VIN

12VREF

SGND

13

(Top view)

H5GATE

R5GATE

H5SRC

PGND5

PGND3

R3GATE

H3SRC

H3GATE

32 3031 29 28 27 26 25

H5STRAP

(*)TO BE CONNECTED TO PIN13

+

SLOPE

VREF

Hside

REG5 REG5

Lside

COMPARATOR

VREF BUFFER

-

+

-

+

-

CONTROL

SWITCH

ERROR SUMMING

∑

LOGIC

LINEAR

REGULATOR

-

+

+

-

OVER CURRENT

COMPARATOR

ZERO CROSSING

COMPARATOR

PULSE SKIPPING

COMPARATOR

V5SNS

VREF

1

2

VIN

3

REG5

4

V5SW

5

V5SNS

6

I5SNS

7

COMP5

8

SOFT5

910

11 12 13 14 15 16

VREF

CRST

RUN5

PWROK

SOFT5

8

SOFT

I5SNS V5SNS

+

-

+

-

+

-

OVERVOLT

COMPARATOR

4.7V

RUN3 RUN5 PWROK NOSKIP CRST

POWER MANAGEMENT

&

SYSTEM SUPERVISOR

16 11 10 14 9

SGND

COMPARATOR

OSC

NOSKIP

SOFT3

17

SOFT

I3SNSV3SNS

UNDERVOLT

24

H3STRAP

23

(*)

22

REG12

21

V13IN

20

V3SNS

19

I3SNS

18

COMP3

17

SOFT3

D96IN377

RUN3

OVER CURRENT

COMPARATOR

+

-

ZERO CROSSING

COMPARATOR

+

-

PULSE SKIPPING

COMPARATOR

+

-

ERROR SUMMING

VREF

+

+

∑

+

-

VREF

CONTROL

LOGIC

13V UV Comp

+

-

OSCILLATOR &

SYNCHRONIZATION

13V

Hside

Lside

+

-

SLOPE

D96IN375

REG12

LDO

19

I3SNS

20

V3SNS

18

COMP3

24

H3STRAP

25

H3GATE

26

H3SRC

27

R3GATE

28

PGND3

21

V13IN

22

REG12

15

OSC

2/26

PIN FUNCTIONS

N. Name Description

1 H5STRAP +5.1V section bootstrap capacitor connection

2V

IN

3 REG5 +5V regulator supply. Used mainly for bootstrap capacitors. It should be bypassed to ground.

4 V5SW Alternative device supply voltage. When the +5.1V section is operating, the device is no

5 V5SNS This pin connects to the (-) input of the +5.1V internal current sense comparator

6 I5SNS This pin connects to the (+) input of the +5.1V internal current sense comparator

7 COMP5 Feedback input for the +5.1V section.

8 SOFT5 Soft-start input of the +5.1V section. The soft-start time is programmed by an external

9 CRST Input used for start-up and shut-down timing. A capacitor defines a time of 2ms/nF.

10 PWROK Power-good diagnostic signal. This output is driven high when both switching sections are

11 RUN5 Control input to enable/disable the 5.1V section. A high level (>2.4V) enables this section, a

12 VREF Internal +3.39V high accuracy voltage generator. It can source 5mA to external load. Bypass

13 SGND Signal ground. Reference for internal logic circuitry. It must be routed separately from high

14 NOSKIP Pulse skipping mode control. A high level (>2.4V) disables pulse skipping at low load current,

15 OSC Oscillator frequency control: connect to 2.5V to select 300KHz operation, to ground or to 5V

16 RUN3 Control input to enable/disable the +3.3V section. A high level (>2.4V) enables this section, a

17 SOFT3 Soft-start input for the 3.3V section. The soft-start time is programmed by an external

18 COMP3 Feedback input for the +3.3V section

19 I3SNS This pin connects to the (+) input of the +3.3V internal current sense comparator

20 V3SNS This pin connects to the (-) input of the +3.3V internal current sense comparator

21 V13IN 12V regulator input supply voltage, included between 13 and 20V. This voltage can be

22 REG12 12V regulator output voltage. It can source up to 150mA to an external load

23 SGND To be connected to pin 13

24 H3STRAP +3.3V section bootstrap capacitor connection

25 H3GATE Gate- driver output for the +3.3V high-side N-MOS

26 H3SRC +3.3V high-side N-MOS source connection

27 R3GATE Gate- driver output for the +3.3V low- side N-MOS (synchronous rectifier).

28 PGND3 Current return for +3.3V section drivers

29 PGND5 Current return for +5.1V section drivers

30 R5GATE Gate-driver output for the +5.1V low-side N-MOS (synchronous rectifier).

31 H5SRC +5.1V high-side N-MOS source connection

32 H5GATE Gate-driver output for the +5.1V high-side N-MOS

Device supply voltage. From 5.5 to 25V

longer powered through V

but through this pin.

IN

capacitor connected between this pin and SGND. Approximately, 1ms/nF @ full load.

enabled and running properly, after a delay defined by the CRST capacitor.

low level (<0.8V) shuts it down

to ground with a 4.7µF capacitor to reduce noise.

current returns.

a low level (<0.8V) enables it.

for 200KHz operation. A proper external signal can synchronize the oscillator

low level (>0.8V) shuts it down.

capacitor connected between this pin and GND. Approximately, 1ms/nF @full load.

supplied by a flyback winding on +3.3V inductor

L4992

3/26

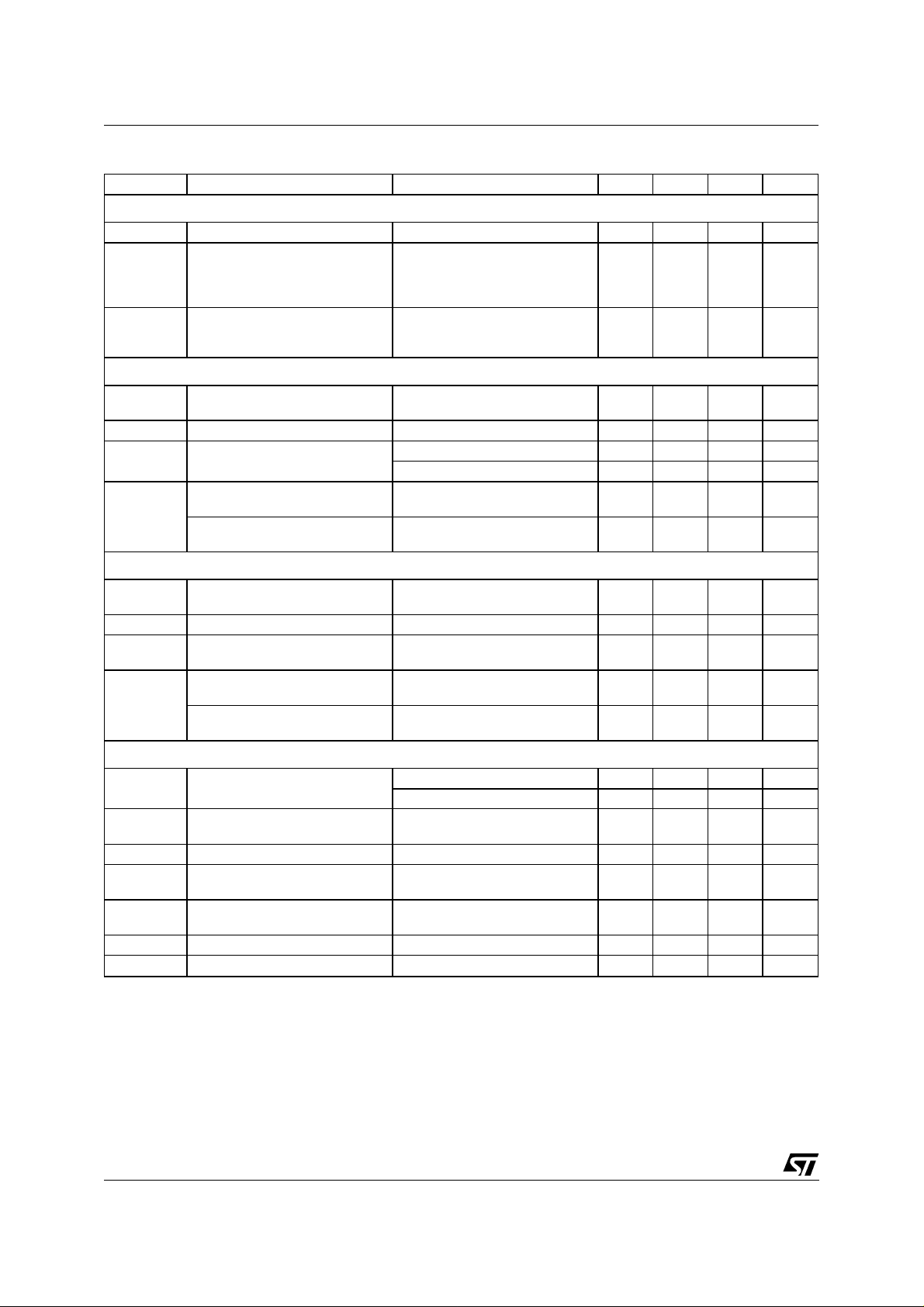

L4992

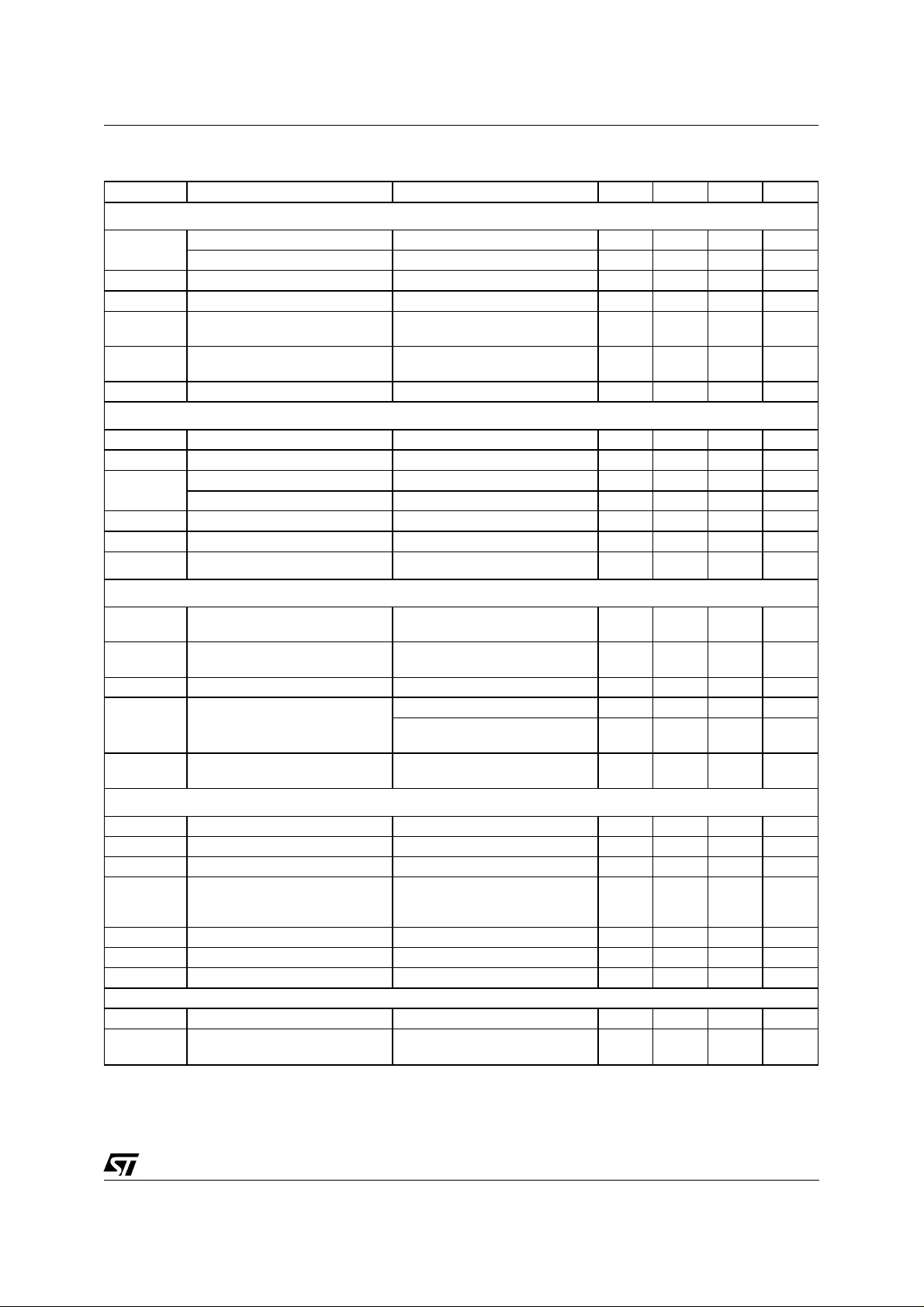

ELECTRICAL CHARACTERISTICS

IN

= 12V; TJ = 25°C; V

(V

OSC

= GND; unless otherwise specified.)

Symbol Parameter Test Condition Min. Typ. Max. Unit

DC CHARACTERISTICS

V

IN

I

2

I

2

+5.1V PWM CONTROLLER SECTION

V

5OUT

- V

V

6

V6 - V

V

5

Input Supply Voltage 5.5 25 V

Operating Quiescent Current R5GATE = R3GATE = OPEN

H5GATE = H3GATE = OPEN

RUN3 = RUN5 = REG5

(DRIVERS OFF)

Stand-By Current RUN3 = RUN5 = GND

V

V

= 12V

IN

= 20V

IN

50

60

(*) V5SNS Feedback Voltage VIN = 5.5 to 20V;

V

- V

I5SNS

Over-Current Threshold Voltage VSOFT5 = 4V 80 100 120 mV

5

Pulse Skipping Mode

5

Thereshold Voltage

VIN > 6.8V 14 26 38 mV

< 5.8V 7 13 19 mV

V

IN

= 0 to 70mV

V5SNS

Over Voltage Threshold ON

V5SNS

Under Voltage Threshold ON

V5SNS

4.85 5.13 5.25 V

5.35 5.55 5.77 V

4.54 4.69 4.87 V

1.35 mA

100

120

+3.3V PWM CONTROLLER SECTION

V

(*) V3SNS Feedback Voltage VIN = 5.5 to 20V;

3OUT

V19 - V

- V

V

19

Over Current Threshold Voltage VSOFT3 = 4V 80 100 120 mV

20

Pulse Skipping Mode Threshold

20

V

I3SNS

VIN = 5.5 to 20V; 14 26 38 mV

Voltage

V

20

Over Voltage Threshold ON

V3SNS

Under Voltage Threshold ON

V3SNS

- V

= 0 to 70mV

V3SNS

3.285 3.39 3.495 V

3.55 3.7 3.85 V

3.02 3.14 3.27 V

µA

PWM CONTROLLERS CHARACTERISTICS (BOTH SECTIONS)

F

OSC

V

15

T

OFF

T

OV

T

UV

, I

I

8

, V

V

8

(*) Guaranteed by design, not tested in production

4/26

Switching Frequency Accuracy OSC = REG5/2 255 300 345 kHz

OSC = 0 or REG5 170 200 230 kHz

Voltage Range for 300kHz

Operation

Dead Time 300 375 450 ns

Overvoltage Propagation Time V5SNS to PWROK or

V3SNS to PWROK

Undervoltage Propagation Time V5SNS to PWROK or

V3SNS to PWROK

Soft Start Charge Current 3.2 4 4.8 µA

17

Soft Start Clamp Voltage 4 V

17

2.4 2.6 V

1.25 µs

1.5 µs

L4992

ELECTRICAL CHARACTERISTICS

(Continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

HIGH AND LOW SIDE GATE DRIVER (BOTH SECTIONS)

I25, I

I32, I

R

R

V

V

T

H

L

OH

OL

CC

Source Output Peak Current C

27,

30

Sink Output Peak Current C

R

Resistance (or Impeda nce ) Driver OUT HIGH 7 Ω

DSON

R

resistance (or Impedance) Driver OUT LOW 5 Ω

DSON

Output High Voltage HSTRAP = REG5

= 1nF 0.2 0.5 A

LOAD

= 1nF 0.2 0.5 A

LOAD

4.40 5.3 5.61 V

I

= 10mA; HSRC = GND

SOURCE

Output Low Voltage HSTRAP = REG5

I

= 10mA HSRC = GND

SINK

Cross-Conduction Delay 30 75 130 ns

0.5 V

12V LINEAR REGULATOR SECTION

V

21

V

22

I

22

V

CP

Input Voltage Range 13 20 V

Output Voltage I22 = 0 to 120mA 11.54 12.0 12.48 V

Current Limiting V

Short Circuit Current V

Input Voltage Clamp I

"One Shot" Activation Threshold V

= 12V 120 mA

REG12

= 0V 150 mA

REG12

= 100µA16 V

CLAMP

Falling 12.88 13.7 14.52 V

13IN

"One Shot" Pulse 1.5 µs

INTERNAL REGULATOR (VREG 5) AND REFERENCE VOLTAGE

V

3

I

3

V

12

I

12

VREG5 Output Voltage VIN = 5.5 to 20V

I

= 0 to 5mA

LOAD

Total Current Capability VREG5 = 5.3V

V

= 6V

REG5

4.5 5.3 5.61 V

25

70

Switch-Over Threshold Voltage 4.3 4.53 4.7 V

Reference Voltage 3.35 3.39 3.43 V

Source Current at Reference

= 5.5 to 20V

V

IN

I

= 1 to 5mA

LOAD

3.32 3.39 3.46 V

5mA

Voltage

mA

POWER GOOD AND ENABLE FUNCTION

V16, V

, V

V

16

T

10

, T

T

27

SYNCHRONIZATION

RUN3, RUN5, Enable Voltage HIGH LEVEL 2.4 V

11

RUN3, RUN5, Disable Voltage LOW LEVEL 0.8 V

11

Power Good Delay C

Shutdown Delay Time before

30

Low Side Activation

(Except Over-Voltage Fault)

CRST Timing Rate 2 ms/nF

Power Good High Level I

Power Good LowLevel I

Synchronisation Pulse Width 400 ns

Synchronisation Input Voltage

(Falling Edge Transition)

= 100nF 160 200 240 ms

CRST

C

= 100nF, 160 200 240 ms

CRST

= 40µA 4.1 V

PWROK

= 320µA 0.4 V

PWROK

5V

5/26

L4992

DETAILED FUNCTIONAL DESCRIPTION

In the L4992 block diagram six fundamental functional blocks can be identified:

3.3V step-down PWM switching regulator (pins 17 to 20, 24 to 27).

5.1V step-down PWM switching regulator (pins 1, 4 to 8, 30 to 32).

12V low drop-out linear regulator (pins 21,22).

5V low drop-out linear regulator (pin 3).

3.3V reference voltage generator (pin 12).

Power Management section (pins 9 to 11, 14,16).

The chip is supplied through pin VIN (2), typically by a battery pack or the output of an AC-DC adapter,

with a voltage that can range from 5.5 to 25V. The return of the bias current of the device is the signal

ground pin SGND (13), which references the internal logic circuitry.

The drivers of the external M OSFET’s have their separate current return for each section, namely the

power ground pins PGND3 (28) and PGND5 (29). Take care of keeping separate the routes of signal

ground and the two power ground pins when laying out the PCB (see "Layout and grounding" section).

The two PWM regulators shar e the internal oscillator, pr ogr ammable or s yn chronizable through pin OSC

(15).

+3.3V AND +5.1V PWM REGULATORS

Each PWM regulator includes control circuitry as well as gate-drive circuits for a step-down DC-DC con-

verter in buck topology using synchronous rectification and current mode control.

The two regulators are independent and almost identical. As one can see in the Block Diagram, they

share only the oscillator and the internal supply and differ f or the pre- set output v oltages and f or t he c ontrol circuit that links the +3.3V section to the operation of the 12V linear regulator (see the relevant section).

Each converter can be turned on and off independently: RUN3 and RUN5 are control inputs which disable the relevant section when a low logic level (below 0.8 V) is applied and enable its operation with a

high logic level (above 2.4 V). When both input s are low the device is in stand- by condition and its current consumption is extremely reduced (less than 120µA over the entire input voltage range).

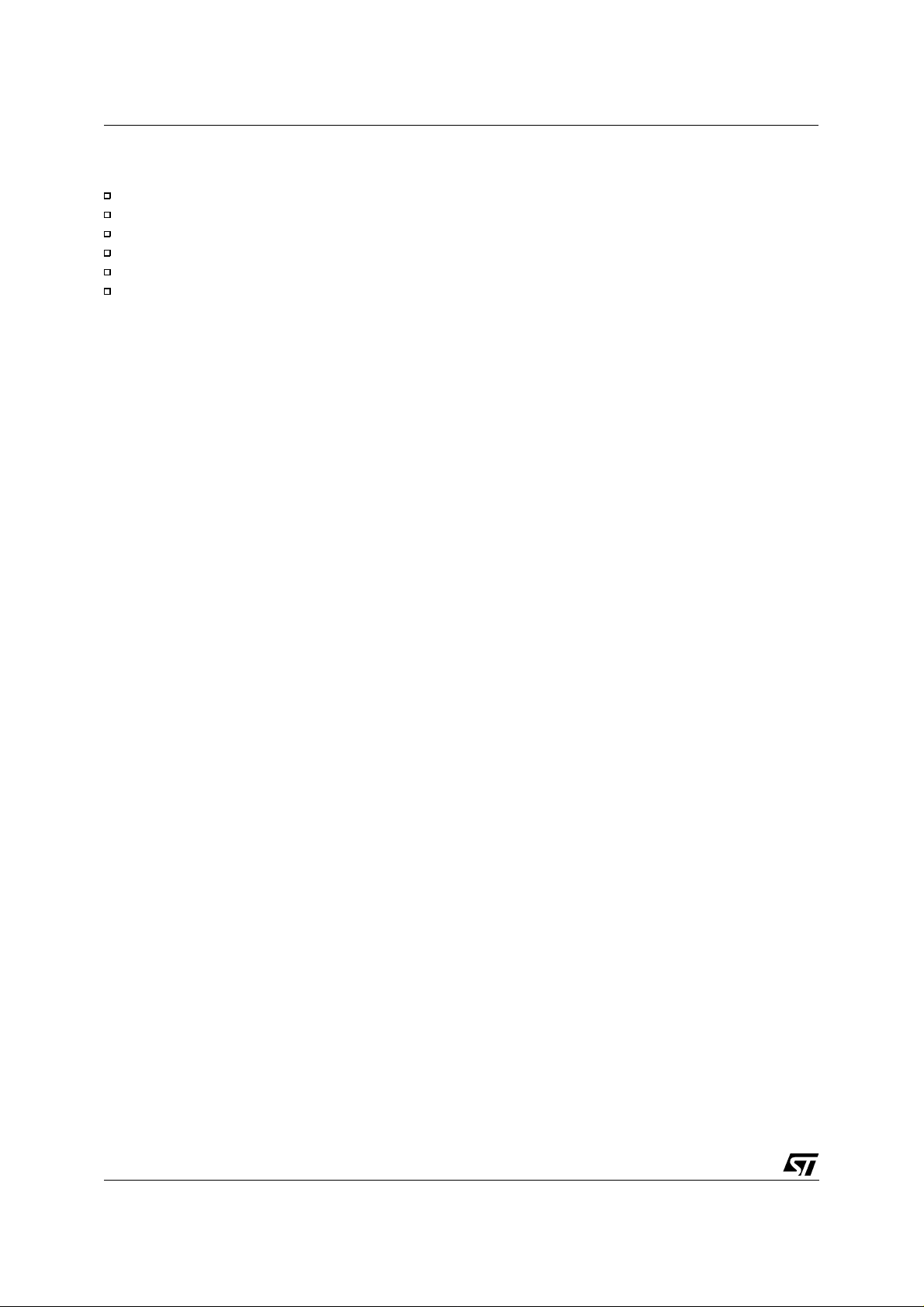

Oscillator

The oscillator, which does not require any external timing component, controls the PWM switching frequency. This can be either 200 or 300 kHz, depending on the logic s tate of the control pin OSC, or else

can be synchronized by an external oscillator.

If OSC is grounded or connected to pin REG5 (5V) the oscillator works at 200kHz. By connecting OSC to

a 2.5 V voltage, 300 kHz operation will be selected. I nstead, if pin OSC is fed with an ex ternal signal like

the one shown in fig. 1, the oscillator will be synchronized by its falling edges.

Considering the spread of the oscillator, synchronization can be guaranteed for frequencies above

230kHz. Even though a maximum frequency value is in pr actice imposed by efficiency considerations it

should be noticed t hat increasing frequency too much arises problem s (noise, subharmonic oscillation,

etc.) without significant benefits in terms of external component size reduction and better dynamic performance.

The oscillator imposes a time interval (300 ns min.), during which the high-side MOSFET is definitely

OFF, to recharge the bootstrap capacitor ( see "MOSFET’s Drivers" section). This, implies a limit on the

maximum duty cycle (88.5% @ fsw = 300kHz, 92.6% @ fsw = 200kHz, worst case) which, in turn, imposes a limit on the minimum operating input voltage.

PWM regulati on

The control loop does not employ a tradit ional error amplifier in favour of an error summing comparator

which sums the reference voltage, the feedback signal, the voltage drop across an external sense resistor and a slope compensation ramp (to avoid subharmonic oscillation with duty cycles greater then 50%)

with the appropriate signs.

The output latch of both controllers is set by every pulse coming from the oscillator. That turns off the

low-side MOSFET (synchronous rectifier) and, after a short delay (typ. 75 ns) to prevent cross-conduction, turns on the high-side one, thus allowing energy to be drawn from the input source and stored in the

inductor.

6/26

L4992

DETAILED FUNCTIONAL DESCRIPTION

Figure 1:

Figure 2:

Synchronization signal and operation.

OSC

5V

0V

H5GATE

H3GATE

L4992 Control Loop.

CLOCK

SRQ

E.S.

_

Q

+

+

-

+

(continued)

HSTRAP

REG5

SLOPE

COMP.

VREF

400ns min.

VIN

L

D97IN574

Rsense

t

t

t

Co

Ro

ESR

Rf

Cf

The error summing, by comparing the above mentioned signals, determines the moment in which the

output latch is to be reset. The high-side MOSFET is then turned off and the synchronous rectifier is

turned on after the appropriate delay (typ. 75 ns), thus making the inductor current recirculate. This state

is maintained until the next oscillator pulse.

With reference to the schematic of fig. 2, the open-loop transfer function of such a kind of control system,

under the assumption of an ideal slope compensation, is:

F(s) = A⋅

R

R

O

sense

⋅

(1 +

1 + s ⋅ ESR ⋅ C

s ⋅ R

O CO

) ⋅ (1 +

O

s ⋅ R

F CF

)

where A is the gain of the error summing comparator, which is 2 by design.

The system is inherently very fast since it tends to correct output voltage deviations nearly on a cycle-by-

cycle basis. Actually, in case of line or load changes, few switching cycles can be sufficient for the transient to expire.

The operation above illustrated is modified during particular or anomalous conditions. Leaving out other

circumstances (described in "Protections" section) for the moment, consider when the load current is low

enough or during the first switching cycles at start-up: the inductor current may become discontinuous,

that is it is zero during the last part of each cycle. In such a case, a "zero current comparator" detects the

event and turns off the synchronous rectifier, avoiding inductor current reversal and reproducing the

natural turn-off of a diode when reverse biased. Both MOSFET’s stay in off state until the next oscillator

pulse.

7/26

L4992

DETAILED FUNCTIONAL DESCRIPTION

(continued)

Synchronous rectification.

Very high efficiency is achieved at high load current with the synchronous rectification technique, which

is particularly advantageous because of the low output voltage. The low-side MOSFET, that is the synchronous rectifier, is selected with a very low on -resistance, so that the paralleled Schottky diode is not

turned on, except for the small time in which neither MOSFET is conducting. The effect is a considerable

reduction of power loss during the recirculation period.

Although the Schottky might appear to be redundant, it is not in a system where a very high efficiency is

required. In fact, it s lower threshold prevent s the lossy body-diode of the synchronous rectifier MOSFET

from turning on during the above mentioned dead-time. Both conduction and reverse recovery losses are

cut down and efficiency can improve of 1-2% in some cases. Besides a small diode is sufficient since it

conducts for a very short time.

As for the 3.3V section only, the synchronous rectifier is also involved in the 12 V linear regulator operation (see the relevant section). See also the "Power Management" to see how both synchronous rectifiers are used to ensure zero voltage output in stand-by conditions or in case of overvoltage.

Pulse-skippi ng operation.

To achieve high efficiency at light load current as well, under this condition the regulators change their

operation (unless this feature is disabled): they abandon PWM and enter the so-called pulse-skipping

mode, in which a single switching cycle takes place every many oscillator periods.

The "light load condition" is det ected when the v oltage across the external sense resistor (V

Rsense

) does

not exceed 26mV while the high-side MOSFET is conducting. When the reset s ignal of the output latch

comes from the error summing comparator while V

reset is driven as soon as V

reaches 26mV. This gives some extra energy that maintains the output

Rsense

is below this value, it is ignored and the actual

Rsense

voltage above its nominal value for a while. The oscillator pulses now set the output latch only when the

feedback signal indicates that the output voltage has fallen below its nominal value. In this way, most of

oscillator pulses is skipped and the r esulting s witching frequency is much lower, as expressed by the following relationship:

2

R

K ⋅

sense

L

⋅ I

where K = 3.2 ⋅ 10

=

f

ps

3

and fps is in Hz. As a result,

the losses due to switching and to gate-drive,

⋅ V

out

Figure 3:

out

⋅

1

V

out

−

V

in

Pulse-skipping threshold vs. input

voltage (+5.1V section only).

which mostly account for power dissipat ion at low

output power, are considerably reduced.

The +5.1V section can work with the input voltage

very close to the output one, where the current

waveform may be so flat to prevent pulse-skipping

from being activated. To avoid this, the pulse-skip-

Vth

26 mV

ping threshold (of the +5.1V section only) is

roughly halved at low input voltages, as shown in

fig. 3. Under this condition, in the above formula

the constant K becomes 12.8 ⋅ 10

3

.

13 mV

When in pulse-skipping, the output voltage is

some ten mV higher than in PWM mode, just be-

5.5V 5.8V 6.3V 20V

Vin

cause of its mode of operation. If this "load regulation" effect is undesirable for any reason, the pulse

skipping feature can be disabled (see "Power

Management" section) to the detriment of efficiency at light load.

MOSFET’s drivers

To get the gate-drive voltage for the high-side N-channel MOSFET a bootstrap technique is employed. A

capacitor is alternately charged through a diode from the 5V REG5 line when the high-side MOSFET is

OFF and then connected to its gate-source leads by the internal floating driver to turn the MOSFET on.

The REG5 line is used to drive the synchronous rectifier as well, and therefore the use of low-threshold

8/26

L4992

DETAILED FUNCTIONAL DESCRIPTION

(continued)

MOSFET’s (the so-called "logic-level" devices) is highly recommended.

The drivers are of "dynamic" type, which means they do not give origin to current consumption when

they are in static conditions (ON or OFF), but only during transitions. This featur e is aimed at minimizing

the power consumption of the device even during stand-by when both low-side MOSFET’s are ON.

Protections

Each converter is fully protected against fault conditions. A monitoring system checks for overvoltages of

the output, quickly disabling both c onverters in case such an event occurs. This condition is latched and

to allow the device to start again either the supply voltage has to be removed or both RUN3 and RUN5

pins have to be driven low.

Undervol tage condit ions are de tected as wel l but do n ot cau se int errupt ion of t he op erat ion of the conve rters. O n ly PWROK si gnal (a t p in 10) reveal s t h e anoma ly with a low outp ut level .

If the chip overheats (above 135 °C typ.) the device stops operating as long as the temperature falls below a

safe value (105 °C typ.). The overtemperature condition is signalled by a low level on PWROK as well.

A current limitation comparator prevents f rom excessive current in case of overload or short-circuit. It intervenes as the voltage VRsense exceeds 100 mV, turning off the high-side switch before the error summing does. By the way, this also gives the designer the ability to program the maximum operating current

by selecting an appropriate sense resistor.

This pulse-by-pulse limitation gives a quasi-constant current characteristic. If a "folded back" characteristic, like the one shown in Fig. 4a, is desired the external circuit of Fig. 4b can be used. The circuits

acts on the current limitation and is extremely simple and cheap. The advantage of such a technique i

that a short circuit will cause a current much lower than the maximum to flow. Th e stress of the power

components will be very litt le and no overheating will occur. The part values shown in Fig. 4b produce

IFOLD = 1A in the Demo Board (see the relevant section).

Inrush current at start-up is reduced with soft-start. An external capacitor (one for each converter) is

charged by an internal 4µA current generator and its linearly ramping volta ge increases the setpoint of

the current limit comparator, starting from zero up t o the f inal value of 100 mV. Thus duty cycle reaches

gradually its steady-state value and dangerous current peaks as well as overshoots of the out put voltage

are avoided.

+12 V LINEAR REGULATOR

The +12V Linear regulator is capable of delivering up to 120 mA to an external load through pin REG12.

It is supplied from pin V13IN which accepts voltages included in the range of 13 to 20V.

If the application works with input volt ages included between 14 and 20V, the supply for the regulator

can be obtained directly from the input source. If such is not the case, the most convenient way to get

the supply is to use an auxiliary winding on the 3.3 V section inductor with a catch diode, Ds, and a filter

capacitor, Cs, as shown in fig. 5. This winding delivers energy t o pin V13IN during the r ecirculation period of each switching cycle with a voltage determined by the turns ratio n and little dependent on the input voltage.

Figure 4.

V

IN

V

REF-VF

V

-0.1

O

I

FOLDImax

(a)

32(25)

31(26)

30(27)

L4992

I

O

6(19)

5(20)

1N4148

12

L

6.8KΩ

(3.9KΩ)

(b)

R

sense

100Ω

5V(3.3V)

D98IN815

C

O

9/26

L4992

DETAILED FUNCTIONAL DESCRIPTION

(continued)

An auxiliary winding could be used also on the choke of the +5.1V section, either to power the +12V linear regulator or to derive a further supplemental output, however the 3. 3 V section has been provided

with some features aimed at ensuring a proper operation under all circumstances.

For a correct operation of the regulator, the voltage at pin V13IN must not be too low. The flyback connection of the two windings ensures a well regu lated voltage, provided t here is good m agnetic coupling.

The coupled inductors configuration, however, is not able to sustain the auxiliary voltage if the main output is lightly loaded: the secondary voltage drops and the system goes out of regulation.

To overcome this problem, when the V13IN voltage f alls below a certain threshold (13.7 V +/- 5%) because of too light a load on the 3.3V section, the relevant synchronous rectifier is turned on for 1.5 µs

max. during the interval in which the inductor current is zero ("one-shot" feature, see fig. 6). In this way,

the inductor current reverses and draws from the output capacitor energy which is forward transferred to

the auxiliary output.

In case the 3.3V section is wor king at f ull load and the linear regulator is lightly loaded, the voltage at pin

V13IN can exceed the expected value. In fact, Ds and Cs act as a peak-holding circuit and V13IN is influenced by the voltage spikes at switching transients. An internal clamp limits the voltage but, in case of

intervention, the chip power dissipation will rise.

When the 3.3V regulator is disabled, the linear regulator is disabled as well and is plac ed in a low-power

mode to reduce device consumption.

Figure 5:

12V regulator supply with auxiliary winding.

D

S

n

1

3.3V

to V13IN

C

S

Figure 6:

"One shot" feature to sustain V13IN voltage.

H3GATE

1.5µs

L3GATE

IL

V13IN

13.7V

D97IN575

D97IN576A

t

t

t

t

10/26

L4992

DETAILED FUNCTIONAL DESCRIPTION

(continued)

+5 V LINEAR REGULATOR & +3.3 V REFERENCE VOLTAGE GENE RATOR

This low drop-out regulator power s almost all the internal circuitry, that is the +3.3V reference voltage

generator, amplifiers, comparators, digital logic, and MOSFET drivers. Its output is externally available

through pin REG5.

The typical external use of this generator is to c harge the boot strap capacitors used to produce the gatedrive voltage for the high-side MOSFET’s of both PWM converters.

At start-up and when the 5V section is not operating, this regulator is powered by the chip input voltage.

To reduce power consumption, the linear regulator is turned off and the REG5 pin is internally connected

to the 5V PWM regulator output via V5SW pin, when the 5V PWM regulator is active and its output voltage is above the switchover threshold, 4.5V.

The 5V regulator is always active, even if both PWM regulators are disabled, as long as power is applied

to the chip.

The 3.3V reference voltage generator, which is active only when either PWM converter is enabled, provides comparison levels for threshold detection and device operat ion. It is allowed to source up to 5mA

to an external load from its buffered output, externally available through pin VREF.

If either REG5 or VREF does not deliver the correct voltage, the device is shut down.

POWER MANAGEMENT

The L4992 is provided with some control pins suitable to perform some functions which are commonly

used or sometimes required in bat tery-operated equipment. Besides, it features controlled timing sequences in case of turn-on/ off and device shutdown for a safe and reliable behaviour under all conditions.

As above mentioned, RUN3 and RUN5 pins allow to disable separately both PWM converters by means

of logic signals (likely coming from a µP) as mentioned earlier.

NOSKIP can disable the pulse-skipping feature: when it is held high neither of the PWM regulators is allowed to enter this kind of operation.

The PWROK output signal drives low immediately when either PWM regulator output falls below its own

undervoltage threshold or when either of them is disabled. It is high when both regulator run properly.

A capacitor connected between CRST and ground fixes a time, in the order of 2ms/nF, which delays the

transition low-high of PWROK. This happens at start-up or after recovering an undervoltage condition,

provided both RUN3 and RUN5 are high. The delay starts from the moment in which the output voltage

has reached its correct value for both sections.

The same delay intervenes also in another circumstance: when a section is disabled (because its RUN is

driven low or owing to a thermal shutdown), the relevant synchronous rectifier is turned on after the

above delay in order to make sure that the load is no longer supplied.

This delay, however, does not intervene in case of overvoltage: the synchronous rectifier is immediately

turned on after the shutdown, thus acting as a built-in "crowbar".

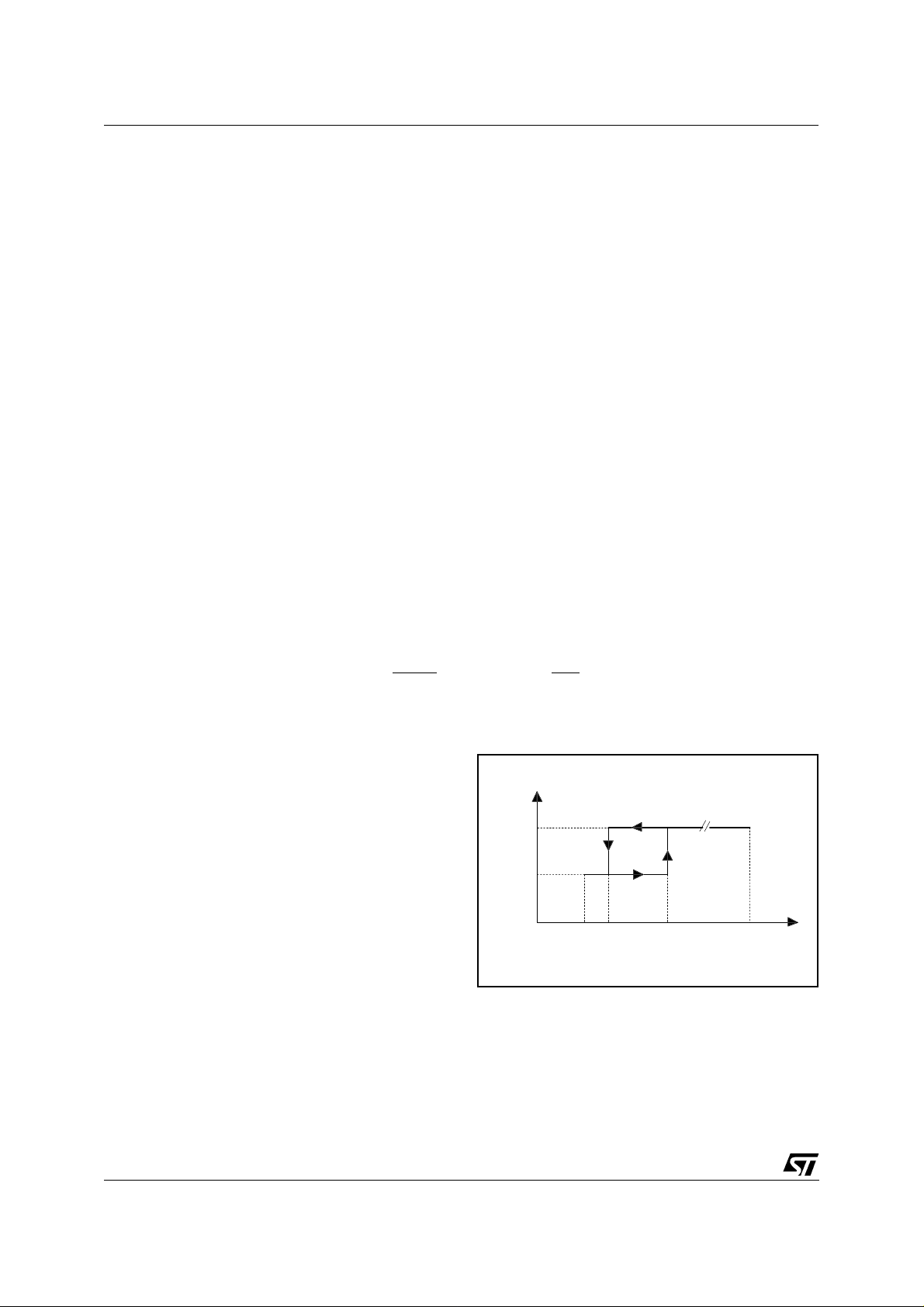

All these timing sequences are illustrated in Fig 7.

11/26

L4992

DETAILED FUNCTIONAL DESCRIPTION

Figure 7:

L4992 controlled timing sequences.

RUN3

VOUT3

RUN5

VOUT5

CRST

PWROK

a) TURN-ON TIMING SEQUENCE

(continued)

t

t

t

t

t

t

RUN3

t

VOUT3

t

H3GATE

t

R3GATE

t

CRST

t

PWROK

t

RUN5

t

VOUT5

t

H5GATE

t

RUN3

VOUT3

H3GATE

R3GATE

CRST

PWROK

RUN5

VOUT5

H5GATE

R5GATE

c) SHUTDOWN TIMING SEQUENCE (2)

R5GATE

t

t

VOUT3

t

H3GATE

t

R3GATE

t

CRST

t

PWROK

t

VOUT5

t

H5GATE

t

R5GATE

t

b) SHUTDOWN TIMING SEQUENCE (1)

d) OVP TIMING SEQUENCE

D97IN577

t

t

t

t

t

t

t

t

12/26

L4992

DESIGN PROCEDURE

Basically, the application circuit topology is fixed, and the design procedure concerns only the selection

of the component values suitable for the voltage and current requirements of the specific application.

The design data one needs to know are therefore:

Input voltage range: the minimum (V

tion is expected to operate;

Maximum load current for each of the three sections:

- I

for the +3.3V section;

out3

- I

for the +5.1V section:

out5

- I

for the +12V section;

out12

Maximum peak-to-peak ripple amplitude of the output voltage for each switching section:

for the +3.3V section;

- V

rpp3

- V

for the +5.1V section;

rpp5

The operating frequency fsw (200/300 kHz or externally synchronized).

It is worth doing some preliminary con siderations. The selection of the switching frequency depends on

the requirements of the application. If the aim is to minimize the size of the external components, 300

kHz will be chosen. For low input voltage applications 200 kHz is preferred, since it leads to a higher

maximum duty cycle.

As for the switching regulators, the inductance value of the output filter affects the inductor current ripple:

the higher the inductance the lower the ripple. This implies a lower current sense resistor value (for a

given I

), lower core losses and a lower output voltage ripple (for a given output capacitor) but, on the

out

other hand, more copper losses and a worse transient behaviour due t o load ch anges. Usually the maximum ripple peak-to-peak amplitude (which occurs at V

load current. It is convenient to introduce a ripple factor coefficient, RF, that is therefore a number between 0.15 and 0.5.

As for the linear regulator, its input voltage V

winding should be dimensioned to get this voltage with a certain margin (say, 14V). Conversely, an

higher input voltage leads to higher losses inside the regulator, to the detriment of efficiency, and to

higher total current on the +3.3V inductor. Besides it implies a higher turns ratio and therefore a worse

magnetic coupling, which affect energy transfer during flyback.

) and the maximum (V

inmin

inmax

should not fall below 13V and therefore the auxiliary

inlin

) voltage under which the applica-

inmax

) is chosen between 15% and 50% of the full

SWITCHING REGULATORS

+5.1V Induct or

To define the inductor, it is necessary to determine firstly the inductance value. Its minimum value is

given by:

and a value L5 > L5

should be selected.

min

L

5min

=

5.1

V

in max

(

⋅

V

max

in

f

⋅

⋅

sw

− 5.1

I

out5

)

⋅ RF

Core geometry selection is connected to the requirements of the specific application in terms of space

utilization and other practical issues like ease of mounting, availability and so on. As to the material, the

choice should be directed towards ferrite, molypermalloy or Kool M

®

µ

, to achieve high efficiency. These

materials provide low core losses (ferrite in particular), so t hat the design can be concentrated on preventing saturation and limiting copper losses.

Saturation must be avoided even at maximum peak current:

I

L5pk

= I

out5

+

5.1

2

⋅

V

in max

⋅

⋅

f

L5 ⋅ V

sw

− 5.1

in max

)

(

To limit copper losses, the winding DC resistance, RL, should be as low as possible (in the range of mΩ).

AC losses can usually be neglected. A practical criterion to minimize DC resistance could be to use the

largest wire that fits the selected core.

Anyway the best solution, whenever possible, is to use an off-the-shelf inductor whic h meets the requir ements in terms of inductance and maximum DC current. Nowadays there is a broad range of products

13/26

L4992

DESIGN PROCEDURE

(continued)

offered by manufacturer, also for surface mount assemblies.

+3.3 V Transformer

The primary winding carries the secondary power as well, thus the total primary average current is:

V

⋅ I

inlin

I

= I

out3

+

where V

tot3

is the voltage generat ed during the recirculation of the primary and fed into t he input of the

inlin

+12V linear regulator. The turns ratio 1:n of the transformer is chosen so that V

3.3

out12

is above 13V. To re-

inlin

duce the turns ratio in order to minimize stray parameters, the secondary is referred to the 3.3V output,

and therefore the minimum value is given by:

V

− 3.3 + V

min

3.3

inlin

=

n

f

where Vf is the forward drop ac ross the rectifier ( assume 1V to be conservative). Make sure the secondary is connected with the proper polarity (see fig. 6).

The minimum primary inductance value can be expressed as:

2

−

)

⋅ I

out12

− 3.3

in

3.3

in

−

3.3) − n

in

⋅

Vin ⋅ I

out12

]

)

3

⋅

=

4

L

3pmin

where RF, to get positive values for L

3.3 ⋅ (V

Vin ⋅ fsw ⋅ [I

, must satisfy the inequality:

3pmin

RF

⋅ RF ⋅ (V

tot3

n

>

I

tot3

⋅

V

in

(

⋅

V

and where Vin can be either V

With a primary inductance L

inmin

3p

> L

or V

3pmin

, whichever gives the higher value for L

inmax

3pmin

.

the primary peak current, whic h must not saturat e the magnetic

core, will be:

−

)

I

L3pk

=

I

tot3

+

2 ⋅

3.3 ⋅ (V

f

sw

⋅

in max

L

3p

3.3

+ n ⋅ I

⋅

V

in max

out12

As to the transformer realization, the considerations regarding to the +5.1V inductor can be here repeated.

Power MOSFET’s and Schottky diodes

Since the gate drivers of the L4992 are powered by a 5V bus , the use of logic-level MOSFET’s is highly

recommended, especially for high current applications. Their breakdown voltage V

greater than V

The R

DS(ON)

with a certain margin, so the selection will address 20V or 30V devices.

inmax

can be selected once the allowable power dissipation has been established. By selecting

(BR)DSS

must be

identical power MOSFET’s as the main switch and the synchronous rectifie r, the total power t hey dissipate does not depend on the duty cycle. Thus, if P

power), the required R

where I

cient of R

is either I

out

DS(ON)

tot3

(typically, α = 5

(@ 25 °C) can be derived from:

DS(ON)

DS(ON

)

or I

R

, according to the section under consideration, α is the temperature coeffi-

out5

-3

⋅

10

°C-1 for these low-voltage classes) and ∆T the admitted tempera-

is this power loss (few percent of the rated output

ON

P

2

⋅ (1 + α

out

ON

⋅

∆T)

=

I

ture rise.

It is worth noticing, however, that generally the lower R

leads to a higher gate drive consumption. In fact, each switching cycle, a charge Q

, the higher is the gate charge Qg, which

DS(ON)

moves from the in-

g

put source to ground, resulting in an equivalent drive current:

⋅

I

= Q

g

f

sw

g

14/26

L4992

DESIGN PROCEDURE

(continued)

which affects efficiency at low load currents. Besides, this current is drawn from the REG5 line whose

source capability, I

FET total gate charge (@ Vgs = 5V);

assuming four identical MOSFET’s.

(25mA min), must not be exceeded, thus a further constraint concernes the MOS-

SRC

I

SRC

≤

Q

g

,

⋅

f

4

SW

The Schottky diode to be placed in parallel to the synchronous rectifier must have a reverse voltage

VRRM greater than Vinmax. Since it conducts for less than 5% of t he switching period, the cur rent r ating

can be much lower than Iout. The selection criterion should be:

V

(schottky) < Vf(body-diode) @ I = I

f

Lpk

Sense Resistors

The sense resistor of each section is selected according to their respective maximum output current. The

current sense comparator limits the inductor peak current and therefore the maximum DC output current

is the peak value less half of the peak-to-peak ripple. The intervention threshold is set at 100 mV for both

sections, thus the resistor values should be:

R

sense5

R

sense3

=

=

100

I

L5pk

100

I

L3pk

[m

[m

Ω]

Ω]

Since the comparator threshold that triggers pulse-skipping mode is 26mV, the output current at which

the system enters this kind of operation is approximately one fourth of the maximum output current.

The sense resistors values are in the low milliohms thus it is important to take correctly the current sense

signals. Make sure that the Kelvin connections between the current sense pins of the IC and the sense

resistor do not carry the output current.

Input Capacitors

A pulsed current (with zero average value) flows through the input capacitor of a buck converter. The AC

component of this current is quite high and dissipates a considerable amount of power on the ESR of the

capacitor:

P

Cin

= ESR

V

⋅ (Vin − V

out

2

⋅

⋅

I

out

2

V

in

out

)

It is easy to find that PCin has a maximum equal to (1/2) ⋅ Iout (@ Vin=2 ⋅ Vout, that is, 50% duty cycle).

The input capacitor of each section, therefore, should be selected for a RMS ripple current rating as high

as half the respective maximum output current.

The capacitance value is not very important but in reality a minimum value must be ensured for stability

reasons. In fact, switching regulators exhibit a negative input impedance that, at low frequencies, is:

2

V

in

−

=

Z

)

in(DC

thus, if the impedance of the power source is not well below the absolute value of Z

V

⋅ I

out

out

at frequencies

in(DC)

up to the bandwidth of the regulator control loop, there is the possibility for oscillations. To ensure stability, the following condition must be satisfied:

L

C

in

>>⋅

ESRin ⋅ | Z

eq

in

(DC)

|

where Leq is the inductance of the circuit upstream the s witching regulator input and ESRin is related to

the input capacitor itself.

The use of high performance electrolytic capacitors is recommended. If a higher cost is of no concern,

OS-CON capacitors are an excellent choice because they offer the smallest size for a given ESR or current rating. Tantalum capacitors do not tolerate pulsed current, so their use is not advisable.

15/26

L4992

DESIGN PROCEDURE

(continued)

Output Capacitors

The output capacitor selection is based on the output voltage ripple requirements. This ripple is related to the

curren t r ippl e t hr ough th e ind uct or an d is alm ost e nt ire ly due t o the ESR of t he ou tp ut cap aci tor . Th ere fore,

the goal is to achieve an ESR lower than a certain value, regardless of the actual capacitance value.

The maximum current ripple of the +5.1V section is:

∆

= 2 ⋅ (I

I

L5

L5pk

- I

out5

)

considering the values obtained in the paragraph "+5.1 V Inductor".

As for the +3.3V, the maximum ripple is given by:

∆

I

= n ⋅ I

L3

where VIN is V

inmin

or V

, as selected in the "+3.3V transformer" section.

inmax

Anyhow, the maximum ESR will be:

out12

⋅

Vin − 3.3

ESR

⋅ (

V

+

∆

rppx

I

Lx

3

4

3.3

⋅

fsw ⋅ L3p ⋅ V

V

V

in

≤

x

)

−

3.3

in

in

where the subscript x refers to either section.

In pulse-skipping operation, the capacitive component of the output ripple is comparable to the resistive

one, thus both should be considered:

(R)

V

= 0.025

rppx

L

(C)

V

rppx

= 3.1

⋅

10

x

−

6

⋅

⋅

C

outx

If specification on the output ripple under pulse-skipping condition is also given, C

2

R

sensex

ESR

X

⋅

R

sense

x

1

⋅

V

in min

1

−

V

out

1

−

V

out

and ESRX must

outx

comply with it as well.

Further constraints on the minimum output capacitance can arise from specifications regarding the maxi-

mum undershoot, ∆V

-

, or overshoot, ∆V

out

C

>

out

∆

V

−

out

⋅ (V

+

, due to a step-load change ∆I

out

2

∆

⋅

I

L

in min

out

⋅

D

max

; C

V

−

out

out

)

>

∆

L ⋅ ∆I

+

V

out

:

out

2

out

V

⋅

out

whichever is greater, and where D

is the maximum duty cycle and the quantities are relevant either to

max

the +3.3V or +5.1V section.

High performance capacitors should be employed to reduce the capacitance needed for a given ESR, to

avoid paralleling several parts with a considerable waste of space. Although ex cellent elec trolytic capacitors are available, OS-CON or tantalums may be preferred especially if very compact design is required,

or in case of surf ace mount assemblies. Multilayer ceramic capacitors with extremely low ESR are now

available, but they have a large spread of the capacitance value, so they should be paralleled with another more stable, high-ESR capacitor.

Miscellaneous components

The feedback loop has virtually un limited bandwidth, thus a filter is necessary to make the system insensitive to the switching frequency ripple and, in gener al, to prevent noise from disturbing the correct operation of the error summing comparator. Anyway, the cut-off frequency of this filter can be very high, so

that line and load transient response is extremely fast. This filter is a simple R-C type where resistance

and capacitance can be chosen for a typical 3dB cut-off frequency of 60 kHz.

As to the bootstrap diodes, even though small signal p-n diodes might be effectively used, it is preferable

to employ low-power Schottky rectifiers, since that increase slightly the gate drive voltage, in favour of efficiency. The bootstrap capacitor can be a 100nF film capacitor.

The soft-start capacitors determin e the time during which the current limitation circuit moves gradually the

setpoi nt from ze r o up to 100 mV in order to lim it the cu rrent inf low at start-up. Thi s r am p lasts appr ox im ately

1 ms per nF of s oft-start capaci tance (10 to 100 nF typical values), but the a ctual time necessary to the ou tput voltage to reach the steady-state value depends on the load current and the output filter capacitance.

There are some critical points of the IC that may require by-pass capacitors to prevent nois e from dis-

16/26

L4992

DESIGN PROCEDURE

(continued)

turbing the circuit. These points are t he reference voltage VREF, the IC supply pin VIN, the REG5 line

and the alternative supply pin V5SW. Use film capacitors suitable for AC decoupling.

+12 V LINEAR REGULATOR

Catch Diode

The diode which steers the current generated by the secondary winding of the +3.3V transformer should

be a p-n fast-recovery one, with a breakdown voltage greater than:

V

RR

= (V

- 3.3) + n ⋅ (V

inlin

in max

- 3.3)

with a certain safety margin. The diode has to withstand a pulsed current whose peak value is approximately:

I

13pk

≅ I

out12

V

in min

⋅

V

in min

− 3.3

,

while its RMS value is given by:

out12

⋅

V

in min

−

3.3

The DC value is obviously I

out12

I

= I

13RMS

.

V

in min

√

Filter Capacitors

The most stringent requirement on the input f ilter c apacitor (connected between V13IN and ground) is its

RMS ripple current rating, which should be at least:

I

13AC

= I

out12

⋅

− 3.3

V

in

min

3.3

√

The working voltage should be higher than the voltage generated when t he regulator is lightly loaded.

Also for this part the use of high quality electrolytic or OS-CON capacitors is advised.

LAYOUT AND GROUNDING

The electrical design is only the first step in the development of a switching converter. Since currents

ranging from µAmperes to some Amperes, both DC and switched, live together on the same circuitboard, the PCB layout is vital for a correct operation of the circuit but is not an easy task.

A proper layout process generally includes careful component placing, proper gr ounding, correct traces

routing, and appropriate trace widths. Fortunately, since low voltages are involved in this kind of applications, isolation requirements are of no concern.

Refer r in g to li ter ature for a de t a iled analys is of this m a t ter , only few impo r tant po in t s will be here r emind ed.

1) All current returns (signal ground, power ground, etc.) should be mutually isolated and should be con-

nected only at a single ground point. Ground planes may be extremely useful both to arrange properly

current returns and to minimize radiation (see next 2 points), even though they cannot solve every

problem

2) Noise coupling between adjac ent circuit ry can be r educed minimizing the ar ea of t he loop where cur-

rent flows. This is particularly important where there are high pulsed currents, that is the circuit including the input filter capacitor, the power switch, the synchronous rectifier and the output capacitor. The

next priority should be given to the gate drive circuits.

3) Magnetic field radiation (and stray inductance) can be reduced by keeping all traces which carry

switched currents as short as possible.

4) The Kelvin-connected traces of current sense should be kept short and close together.

5) For high current paths, the traces could be doubled on the other side of the PCB whenever possible:

this will reduce both the resistance and the inductance of the wiring.

6) In general, traces carrying signal currents should run far from traces carrying pulsed currents or with

quickly swinging voltages. From this viewpoint, particular c are should be t aken of t he high im pedance

paths (feedback input, current sense traces... ). It could be a good idea to route signal traces on one

17/26

L4992

DESIGN PROCEDURE

(continued)

PCB side and power traces on the other side.

7) Use heavy copper traces: this will reduce their resistance, increasing overall efficiency and will im-

prove their heat-sinking ability.

L4992 EVAL-KIT

The L4992 EVAL KIT is a fully assembled and tested demonstration board that implements a standard

application circuit, configured according to the following specifications:

Input Voltage Range: 6 to 25 V

3.3V Output: I

5.1V Output: I

12 V Output: I

= 3 A, V

out3

= 3 A, V

out5

out12

rpp3

rpp5

= 120 mA

≤ 30 mV

≤ 50 mV

Switching frequency: fsw = 300 kHz

The electrical schematic, illust rated in fig. 9, shows that some pull-up/down resistor are added to the

components strictly needed in a real application. Along with a quad dip-switch, they allow to set manually

the logic signals that control the chip operation. These signals are in the present case:

- Switch 1: RUN5 (0= 5.1V OFF, 1= 5.1V ON)

- Switch 2: NOSKIP (0= pulse-skipping ON, 1= pulse-skipping OFF)

- Switch 3: OSC (0= 200 kHz, 1= 300 kHz)

- Switch 4: RUN3 (0= 3.3V OFF, 1= 3.3V ON)

The demonstration board is delivered with the switches configured as illustrated in fig. 8.

Figure 8:

Default switches configuration

0

1

1234

Switches 1 and 4 enable/disable the t wo PWM sections (switch 4 manages the +12V linear regulator as

well). They must be set on 1 to turn on the regulators.

Please note that as l ong as each regulator is disabled, the relevant low-side MOSFET is in ON state.

Hence, if the load is capable of sourcing current, it will be short-circuited to ground through the choke

and the low-side MOS.

Although the default switching frequency is 300 kHz (switch 3 set on 1) and the passive components

have been selected for this frequency, the demo board will work satisfactorily at 200 kHz as well. Actually, at 200 kHz the regulators exhibit the maximum efficiency and the maximum extension of the input

voltage range downwards. On the other hand, the output ripple is greater and the dynamic behaviour

slightly worse.

The demostration board, as it is, does not provide an interface for synchronization. Anyway, it is possible

to synchronize the oscillator (with an appropriate signal: 5V amplitude pulses, spaced out by 400 ns

min.), provided the switch is set on 1, simply by feeding the signal into the middle of the divider R8-R9. In

this way, synchronization can be achieved at a frequency higher than 300 kHz. To synchronize the oscillator to a frequency between 200 and 300 kHz, heavier interventions on the board are needed.

18/26

L4992

DESIGN PROCEDURE

Figure 9a:

V

OUT1

5.1V/3A

Evaluation Board Circuit.

C3

R3

C9 C11 C12 C13 C14

(continued)

L1R1

D1Q1Q3

C16 C7

R5 R6

S3 S4

V

=6 to 25V

IN

+-

C1 C5

D3

29 30 31 32 1 2 3 24 25 26 27 28

6

5

4

7

11

14

C6 C2

D4

C15

L4992

PWROK

221013129178

21

19

20

18

16

15

REG12

C18

Q2

Q4C8D2

C17

D5

T1

R8R7

S2S1 R9

D96IN426A

V

R2

C4

C10

OUT2

3.3V/3A

R4

V

OUT3

12V/0.12A

Table 1:

L4992 EVAL-KIT parts list

Component Refer. Value Description

Resistors R1 25mΩ 1%, 0.5W. DALE. p.n. WSL-2512R0251

R2 20mΩ 1%, 0.5W. DALE. p.n. WSL-2512R0201

R3, R4 270Ω 1%,SMD

R5, R6, R7, R8, R9 1MΩ SMD

Capacitors C1, C2 100µF 20V. SANYO OS-CON. p.n. 20SA100K

C3, C4 220µF 10V. SANYO OS-CON. p.n. 10SA220K

C5, C6, C12, C13 100µF SMD

C7, C8, C15, C16 1µF SMD

C9, C10, C11 10nF SMD

C14, C18 4.7µF 16V. Tantalum. SMD

C17 15µF 25V. SANYO OS-CON. p.n. 25SC15M

Magnetics L1 10µH 2.65A. SUMIDA. p.n. CDR125-100

T1 10µH 1:4 ratio. TRANSPOWER. p.n. TTI5902

MOSFET’s Q1, Q2, Q3, Q4 Si9410DY SILICONIX

Diodes D1, D2 TMBYV10-40 ST. MELF package

D3, D4 TMMBAT46 ST. MINIMELF package

D5 SMBYW01-200 ST.SOD6 package

Switches S1, S2, S3, S4 - Quad dip-switch

19/26

L4992

DESIGN PROCEDURE

Figure 9b:

PCB and component Layout of the Evaluation Board of Figure 9a.

(continued)

Top Layer + Silk (56 x 61mm)

Power Ground Plane

Signal Ground Plane

Bottom Layer

20/26

L4992

DESIGN PROCEDURE

(continued)

Pulse-skipping operation is enabled by de fault in order to maximize efficiency also in low load current

range. The transition bet ween PWM and pulse-skipping occurs approximately below 1A, however there

is a region in which the two operation modes coexist rather than a definite boundary. That can be seen

on the scope as an irregularity of the waveforms but does not hav e m uch influence both on output ripple

and efficiency.

Those who do not appreciate asynchronous operation of t he puls e-skipping mode can disable it for both

regulators, by setting switch 2 on 1. That maintains PWM operation up to very low output currents where,

however, the regulation becomes incompatible with the switching frequency. This means that the minimum ON-time of the high-side MOSFET is too long for the thruput energy level at the operating frequency. Thus the control system begins skipping conduction cycles to avoid the output voltage drifting

upwards.

Table 1 shows the complete L4992 EVAL KIT parts list. Critical components characteristics are given in

detail.

DEMO BOARD EVALUATION

The following diagrams and tables show the typical performance of the demonstration board in terms of

efficiency, line regulation and load regulation. The 12V linear regulator and REG5 are also characterized.

Table 2:

+3.3V Maximum Efficiency RUN3 = RUN5 = HIGH, NOSKIP = LOW

+5.1V Maximum Efficiency RUN3 = LOW, NOSKIP = LOW

PWM Regulators: Optimum Efficiency

Parameter Test Condition Value Unit

Vin = 6V, Iout = 0.5 A, f

Vin = 6V, Iout = 1A, f

Vin = 6V, Iout = 1A, f

Vin = 6V, Iout = 1A, f

SW

SW

SW

= 200 kHz

SW

= 300 kHz

= 200 kHz

= 300 kHz

95.2

94.6

96.4

95.8

%

%

Table 3:

+3.3V Line Regulation RUN5 = LOW, NOSKIP = LOW, 6 < Vin < 20V

+5.1V Line Regulation RUN3 = LOW, NOSKIP = LOW, 6 < Vin < 20V

+3.3V Load Regulation RUN5 = LOW, NOSKIP = LOW, 5 mA < Iout < 3A

+5.1V Load Regulation RUN3 = LOW, NOSKIP = LOW, 5 mA < Iout < 3A

PWM regulators: Line and Load Regulation.

Parameter Test Condition Value Unit

Iout = 0.1 A, f

Iout =1A, f

Iout = 0.1A, f

Iout = 1A, f

Vin = 6 V, f

Vin = 15V, f

Vin = 6 V, f

Vin = 15V, f

= 200 kHz

SW

= 200 kHz

SW

= 200 kHz

SW

= 200 kHz

SW

= 200 kHz

SW

= 200 kHz

SW

= 200 kHz

SW

= 200 kHz

SW

2

mV

15

mV

3

20

mV

85

70

mV

90

75

21/26

L4992

DEMO BOARD-EVALUATION

Figure 10:

5.1V Output (RUN3=LOW, RUN5 =

HIGH, OSC = GND, NOSKIP = LOW)

V

O

(V)

Vin=20V

5.12

5.10

Vin=6V

5.08

5.06

Vin=15V

5.04

5.02

0.001 0.005 0.01 0.05 0.1 0.5 1 5 IO(A)

Figure 12:

Demo Board Efficiency vs Output Cur-

rent

EFF.

(%)

90

Vin=6V

(continued)

D97IN579

D96IN420

Figure 11:

V

O

(V)

3.38

3.36

3.34

3.32

3.30

0.001 0.005 0.01 0.05 0.1 0.5 1 5 IO(A)

Figure 13:

EFF.

(%)

90

3.3V Output (RUN3=HIGH, RUN5 =

LOW, OSC = GND, NOSKIP = LOW)

D97IN580

Vin=6V

Vin=15V

Vin=20V

Demo Board Efficiency vs Output Cur-

rent

D96IN421

Vin=6V

80

70

60

50

0.001 0.005 0.01 0.05 0.1 0.5 1 5 IO(A)

Figure 14:

EFF.

(%)

90

80

70

60

Vin=20V

Vin=15V

VO=5.1V

f

=200KHz

SW

RUN3=GND

NOSKIP=GND

Demo Board Efficiency vs Output Cur-

rent

D96IN422A

Vin=6V

Vin=20V

VO=3.3V

=200KHz

f

Vin=15V

SW

RUN5=GND

NOSKIP=GND

80

70

60

50

0.001 0.005 0.01 0.05 0.1 0.5 1 5 IO(A)

Figure 15:

EFF.

(%)

90

80

70

60

Vin=20V

Vin=15V

VO=5.1V

fSW=300KHz

RUN3=GND

NOSKIP=GND

Demo Board Efficiency vs Output Cur-

rent

D96IN423A

Vin=6V

Vin=20V

VO=3.3V

=300KHz

f

Vin=15V

SW

RUN5=GND

NOSKIP=GND

22/26

50

0.001 0.005 0.01 0.05 0.1 0.5 1 5 IO(A)

50

0.001 0.005 0.01 0.05 0.1 0.5 1 5 IO(A)

L4992

DEMO BOARD-EVALUATION

Figure 16:

Demo Board Overall Efficiency (Iout3

= 3A, REG12 = OPEN, OSC = GND)

EFF.

(%)

93

92

Vin=6V

91

90

89

Vin=20V

88

87

0.001 0.005 0.01 0.05 0.1 0.5 1 5 I

Figure 18:

Switching Frequency vs Output Cur-

rent (pulse skipping)

f

s

(KHz)

(continued)

D97IN581

D96IN427A

OUT5

Figure 17:

Demo Board Overall Efficiency (Iout5

= 3A, REG12 = OPEN, OSC = GND)

EFF.

(%)

93

Vin=6V

92

91

Vin=20V

90

(A)

89

0.001 0.005 0.01 0.05 0.1 0.5 1 5I

Figure 19:

Switching Frequency vs Output Cur-

D97IN582

OUT3

(A)

rent (pulse skipping)

f

s

(KHz)

D96IN428A

100

10

1

0.1

0.001 0.005 0.01 0.05 0.5

Figure 20:

V

OUT

(V)

5.05

5.00

4.95

4.90

Vin=6V

Vin=20V

VO=3.3V

REG12=OPEN

OSC=2.5V

IO(A)0.1

REG5 Regulator Characteristic (Vin =

6V, RUN3 = RUN5 = LOW, Tj = 25°C)

D97IN583

100

10

1

0.1

0.001 0.005 0.01 0.05 0.5

Figure 21:

V

OUT

(V)

12

10

8

6

4

2

Vin=6V

Vin=20V

VO=5.1V

OSC=2.5V

IO(A)0.1

12V Linear Regulator Characteristic

(V13IN = 15 V, RUN 3 = HIG H, Tj = 25 °C)

D97IN584

4.85

0 20406080100I

OUT

(mA)

0

0 50 100 150 200 I

OUT

(mA)

23/26

L4992

APPLICATION ID EAS

Figure 22:

V

OUT1

5.1V/3A

R3

Application with Split Supply

L1R1

C3

C9 C11 C12 C13 C14

D1Q1Q3

C16 C7

R5 R6

S3 S4

C1 C5

29 30 31 32 1 2 3 24 25 26 27 28

6

5

4

7

11

14

D3

C15

L4992

C6 C2

D4

PWROK

221013129178

REG12

C18

Q2

Q4C8D2

21

19

20

18

16

15

12V BUS

5V BUS

C17

D5

T1

R8R7

S2S1 R9

D98IN813

V

R2

C4

C10

OUT2

3.3V/3A

R4

V

OUT3

12V/0.12A

Figure 23:

Low output voltage.

L4992

22 7(18)

12V

C18

RB BALANCES ZCD COMPARATOR

<5.1V

V

R

sense

R

B

(V

O

<3.3V)

O

MIN.

LOAD

6(19)

5(20)

R

A

R3(R4)

C9

(C10)

D98IN814

24/26

L4992

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.60 0.063

A1 0.05 0.15 0.002 0.006

A2 1.35 1.40 1.45 0.053 0.05 5 0.057

B 0.30 0.37 0.45 0.012 0.015 0.018

C 0.09 0.20 0.004 0.008

D 9.00 0.354

D1 7.00 0.276

D3 5.60 0.220

e 0.80 0.031

E 9.00 0.354

E1 7.00 0.276

E3 5.60 0.220

L 0.45 0.60 0.75 0.018 0.024 0.030

L1 1.00 0.039

K 0°(min.), 7°(max.)

mm inch

OUTLINE AND

MECHANICAL DATA

TQFP32

D

D1

D3

1724

25

B

32

1

16

E3

9

8

E1

E

0.10mm

.004

Seating Plane

e

L1

L

A1

B

C

A

A2

K

TQFP32

25/26

L4992

Information furnishe d is beli eved to be accu rate and reliable. However, STMicroelec tronics assumes no res ponsibility for the consequences

of use of such i nformation nor for any i nfringement of patents or ot her rights of third par ties which may result from its use. No license i s

granted by impli cation or otherwis e under any patent or patent righ ts of STMicroelect ronics. Specifica tion mentioned in this publication are

subject to change without notic e. This public ation supers edes and replaces all information prev iously supplied. STMic roelec tronic s products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelect roni cs

© 2000 STMicroelectronics – Printed in Italy – All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

26/26

Loading...

Loading...