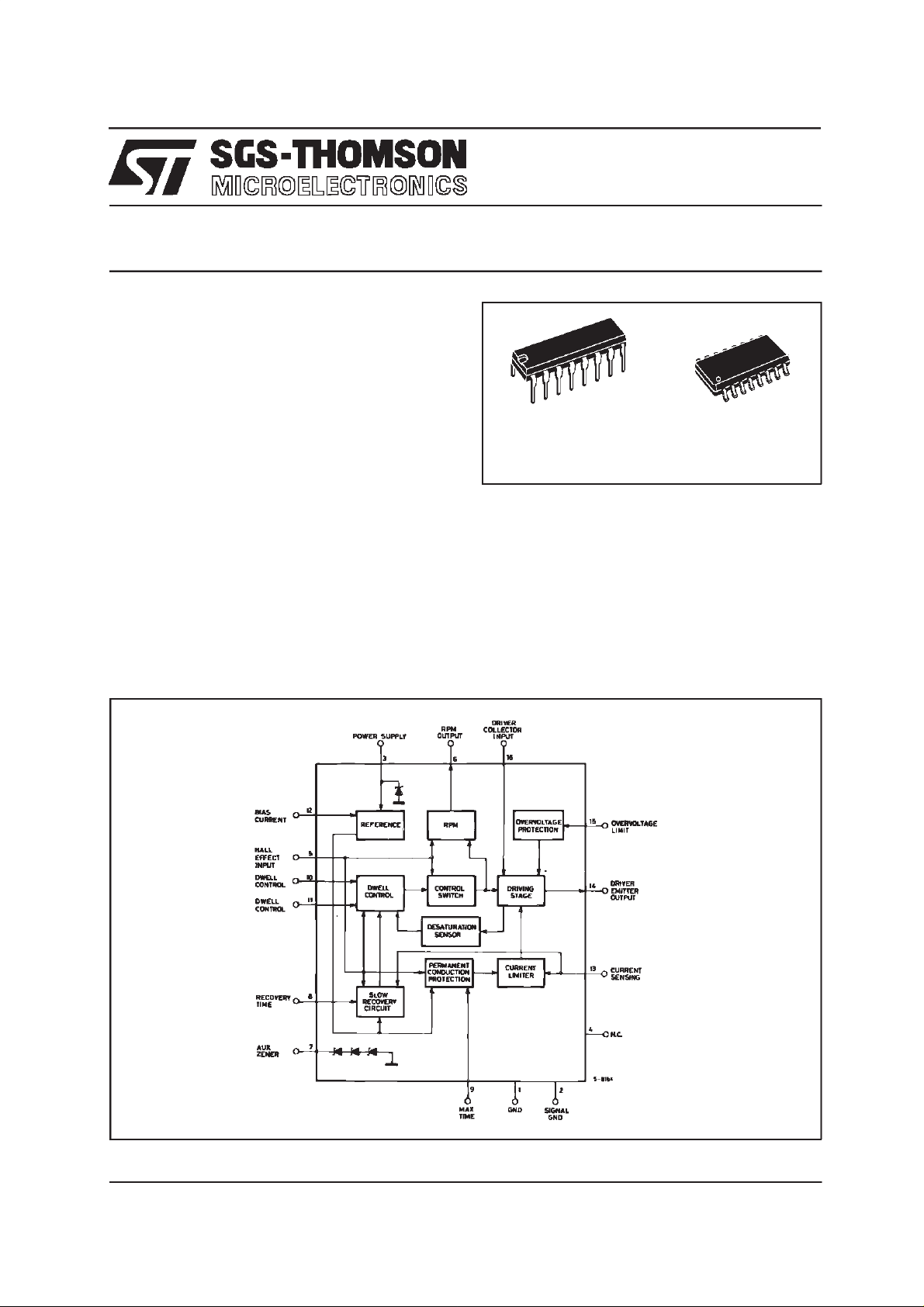

HALLEFFECT PICKUPIGNITION CONTROLLER

.DIRECT DRIVING OF THE EXTERNAL

POWERDARLINGTON

.

COIL CURRENT CHARGING ANGLE (dwell)

CONTROL

.

PROGRAMMECOILCURRENT PEAKLIMITATION

.PROGRAMMABLEDWELL RECOVERY TIME

WHEN 94 % NOMINAL CURRENT NOT

REACHED

.

RPMOUTPUT

.PERMANENTCONDUCTION PROTECTION

.

OVERVOLTAGE PROTECTION FOR EXTERNAL DARLINGTON

.

INTERNALSUPPLYZENER

.REVERSEBATTERY PROTECTION

DES CRIPTION

TheL497is anintegratedelectronicignitioncontrollerforbreakerlessignitionsystemsusingHalleffect

sensors.

L4 97

DIP16 SO1 6

ORDERING NUMBERS : L497B(DIP16)

The device drives an NPN external darlington to

controlthecoilcurrentprovidingthe requiredstored

energywith lowdissipation.

A specialfeature of the L497 is the programmable

time for the recovery of the correctdwell ratio T

whenthecoil peakcurrentfailstoreach94 % ofthe

nominalvalue.Inthis wayonlyone sparkmayhave

anenergylessthan94 % ofthenominaloneduring

fast accelerationor coldstarts.

L497D1(SO16)

/T

d

BLOCK DI AGRAM

March 1998

1/11

L497

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

200

800

3

300

600

15

35

1.2

0.65

V

V

I

V

I

V

T

j,Tstg

P

I

16

D.C. Supply current

3

Transient Supply Current (t

Supply Voltage Int. Limited to Vz

3

RPM Voltage 28 V

6

fall time constant = 100ms)

f

D.C. Driver Collector Current

Pulse ” ”(t <= 3ms)

Driver Collector Voltage 28 V

16

I

15

Auxiliary Zener Current 40 mA

7

D.C. Overvoltage Zener Current

Pulse ” ” t

Repetition Time > = 3ms

tr

ep

Reverse Battery Voltage if Application Circuit of Fig. 4 is used – 16 V

R

= 300µs,

fall

Junction and StorageTemperature Range – 55 to 150

Power Dissipation

tot

at T

=90°C for SO-16

aluminia

=90°C for DIP-16

T

amb

mA

mA

mA

mA

mA

mA

°C

W

W

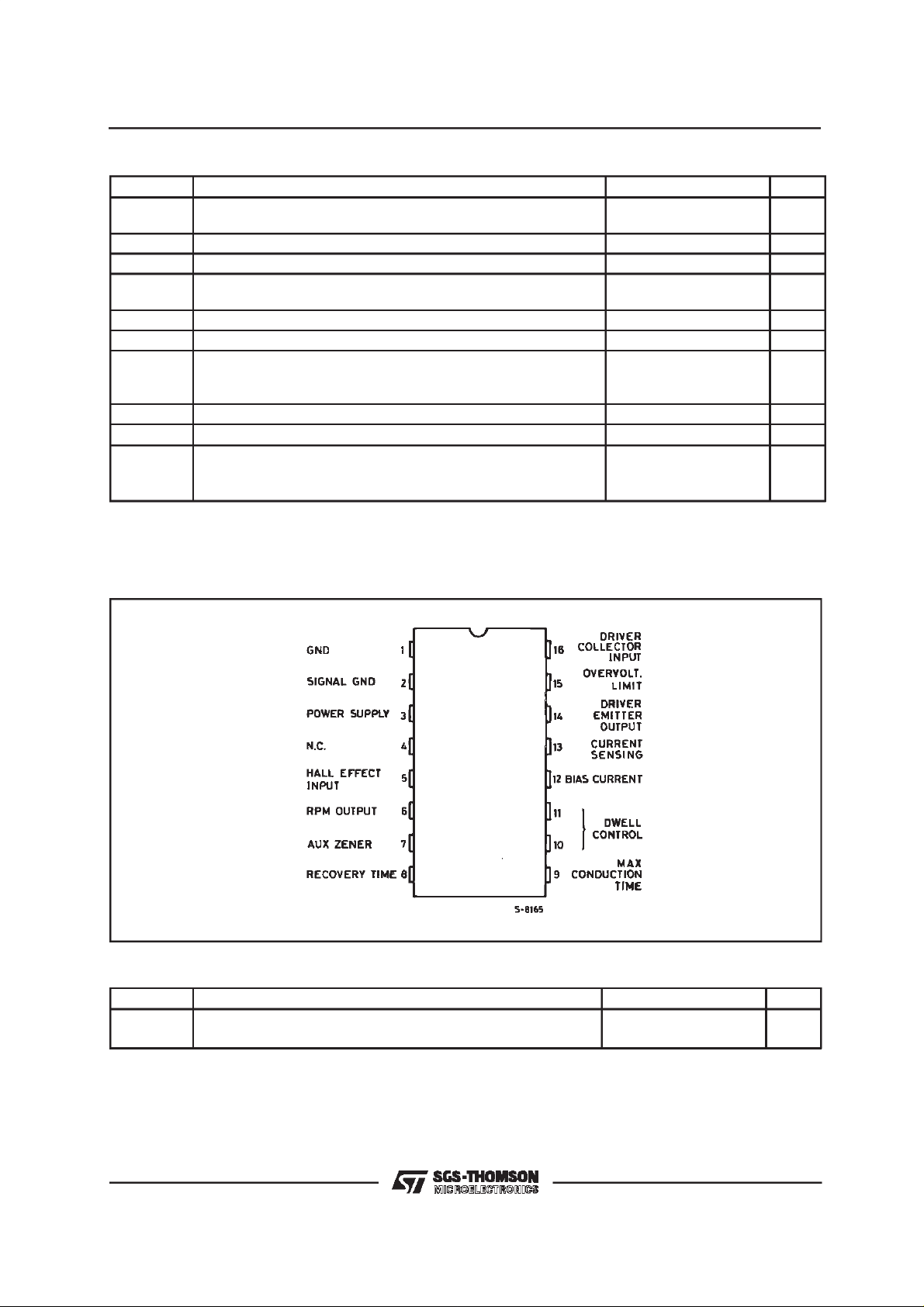

PI N CONNECTIO N (top view)

THERMAL DATA

Symbol Parameter Value Unit

R

th j-amb

R

th j-alumin

(*) Thermal resist ance junction-aluminia w ith the device soldere d on the middle of an alum inia supporti ng substrate mesuring

15 x 20 ; 0.65 mm thicknes s.

Thermal Resistance Junction-ambient for DIP-16

(*)

Thermal Resistance Junction-alumina for SO-16

Max

Max

90

50

C/W

°

°C/W

2/11

PIN FUNCTIONS (refer to fig. 4)

L497

N

°

Name Function

1 GND This pin must be connected to ground.

2 SIGNAL GND This pin must be connected to ground.

3 POWER SUPPLY Supply Voltage Input. An internal 7.5 V (typ) zener zener limits the voltage

at this pin. The external resistor R

limits the current through the zener for

5

high supply voltages.

4 N.C. This pin must be connected to ground or left open.

5 HALL-EFFECT INPUT Hall-effect Pickup Signal Input. This input is dwell control circuit output in

order to enable the current driving into the coil. The spark occurs at the

high-to-low transition of the hall-effectpickup signal.

Furthermore this input signal enables the slow recovery and permanent

conduction protection circuits. The input signal, supplied by the open

collector output stage of the Hall effect sensor, has a duty-cycle typically

about 70 %. V

is internally clamped to V3and ground by diodes

5

6 RPM OUTPUT Open collector output which is at a low level when current flows in the

ignition coil. For high voltages protection of this output, connection to the

pin 7 zener is recommended.

In this situation R

current if RPM module pad is accidentally connected to V

must limit the zener current, too, and R1limits pin 6

8

.

S

7 AUX. ZENER A 21 V (typ) General Purpose Zener. Its current must be limited by an

external resistor.

8 RECOVERY TIME A capacitor connected between this pin and ground sets the slope of the

dwell time variation as it rises from zero to the correct value. This occurs

after the detection of I

coll

94 % I

≤

, just before the low transition of the

nom

hall-effect signal pulse.

The duration of the slow recovery is given by :

= 12,9 R7C

t

src

where R

7

(ms)

src

is the biasing resistor at pin 12 (in KΩ) and C

is the delay

src

capacitor at pin 8 (inµF).

9 MAX CONDUCTION

TIME

A capacitor connected between this pin and ground determines the

intervention delay of the permanent conduction protection. After this delay

time the coil current is slowly reduced to zero.

Delay Time T

T

=16 CpR7(ms)

p

where R

is given by :

p

is the biasing resistor at pin 12 (in KΩ) and CPis the delay

7

capacitor at pin 9 (inµF).

10 DWELL CONTROL

TIMER

A capacitor C

HAll effect output is High and is discharged at the High to Low transition of

connected between this pin and ground is charged when the

T

the Hall effect signal.

The recommended value is 100 nF using a 62 KΩ resistor at pin 12.

11 DWELL CONTROL The average voltage on the capacitor CW connected between this pin and

ground depends on the motor speed and the voltage supply. The

comparison between V

dwell control. For the optimized operation of the device C

and VCTvoltage determines the timing for the

CW

=CW; the

T

recommended value is 100 nF using a 62 KΩ resistor at pin 12.

12 BIAS CURRENT A resistor connected between this pin and ground sets the internal current

used to drive the external capacitors of the dwell control

(pin 10 and 11) permanent conduction protection (pin 9) and slow recovery

time (pin 8). The recommended value is 62 KΩ.

13 CURRENT SENSING Connection for the Coil Current Limitation. The current is measured on the

sensing resitor R

and taken through the divider R10/R11. The current

S

limitation value is given by :

I

sens

= 0.32 ⋅

R

10

RS⋅ R

+ R

11

11

3/11

L497

PIN FUNCTIONS (continued)

N

°

14 DRIVER EMITTER

Name Function

Current Driver for the External Darlington. To ensure stability and precision

OUTPUT

of T

desatCc

and R9must be used. Recommended value for R9is 2 KΩ in

order not to change the open loop gain of the system.

may be added to Ccto obtain greater flexibility in various application

R

c

situations.

and Rcvalues ranges are 1 to 100 nF and 5 to 30 KΩ depending on the

C

c

external darlington type.

15 OVERVOLTAGE LIMIT The darlington is protected against overvoltage by means of an internal

zener available at this pin and connected to pin 14. The internal divider

defines the limitation value given by :

R

3/R2

22.5

16 DRIVER COLLECTOR

INPUT

V

ovp

=

+

R

3

The collector current of the internal driver which drives the external

darlington is supplied through this pin. Then the external resistor R

5.10

−3

R

22.5

+

2

the maximum current supplied to the base of the external darlington.

ELECTRICAL CHARACTERISTICS

= 14.4V, – 40 °C<Tj< 125 °C unless otherwise specified)

(V

S

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

I

V

V

V

Min Op. Voltage 3.5 V

3

Supply Current V3=6V

3

Voltage Supply 28 V

S

Supply Clamping Zener Voltage IZ3= 70 mA 6.8 7.5 8.2 V

Z3

Input Voltage Low Status

5

V

=4V

3

5

7

18 25

13

0.6 V

High Status 2.5

Input Current V5= LOW – 400 – 50

5

Darlington Driver Sat. Current I14=50mA

= 180 mA

I

14

Current Limit. Sensing Voltage VS= 6 to 16 V 260 320 370 mV

CWCharge Current VS= 5.3 to 16V

V

= 0.5V

11

– 11.0 – 9.3 – 7.8 µ

0.5

0.9

V

V

I

16–14

SENS

I

11C

T = 10 to 33ms

I

11D

CW Charge Current VS= 5.3 to 16V

= 0.5V

V

11

0.5 0.7 1.0

T = 10 to 33ms

I

11C/I11D

VS = 5.3 to 16V

= 0.5V

V

11

7.8 22.0

T = 10 to 33ms See Note 1

I

SRC

I

SENSE

T

SRC

V

Z15

T

Percentage of Output Current

Determining the Slow Recovery

Control Start (fig. 2), note 1

Duration of Altered Small Contr.

Ratio after SRC Function Start

(fig. 2)

External Darlington over V Prot.

Zener Voltage

Permanent Conduction Time V5= High

P

=1µF

C

SRC

=62K

R

7

I15=5mA

=2mA

I

15

=1µF

C

P

= 62KΩ

R

7

Ω

90 94 98.5 %

0.8 s

19

18

22.5

21.5

26

25

0.4 1.1 1.8 s

6

limits

mA

mA

V

A

µ

V

V

A

µA

V

V

4/11

ELECTRICAL CHARACTERISTICS (continued)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

I

6 leak

V

V

6SAT

Z7

12

RPM Output Saturation Voltage I6= 18.5 mA

=25mA

I

6

RPM Output Leakage Current VS=20V 50

Auxiliary Zener Voltage I7=20mA 19 27 V

Reference Voltage 1.20 1.25 1.30 V

0.5

0.8

L497

V

V

A

µ

Notes : 1.

td/tdesaturation ratio is given by:

2.

I

sense=Icoil

whenthe external Darlingtonis in theactiveregion.

APP LICATION INFORMAT I ON

Figure1 : MainWaveforms.

td

T

1

=

1 + I

⁄ I

11C

11D

5/11

L497

DWELLANGLECONTROL

The dwell angle control circuit calculates the con-

ductiontimeD forthe outputtransistorinrelationto

the speed of rotation,to the supply voltage and to

the characteristicsof the coil.

On the negativeedgeof the Hall-effectinputsignal

thecapacitorC

currentl

11D

beginsdischargingwithaconstant

W

. Whenthesetpeakvalueof thecoilcurrent is reached,this capacitor charges with a constant currentI

11C

= 13.3 x I

, and the coil current

11D

is kept constantby desaturationofthe drivenstage

and the externaldarlington.

The capacitor C

starts charging on the posi-

T

tive.edgeof the Hall-effectinput signal with a constant current I

. The dwell angle, and conse-

10C

quentlythestartingpointof the coilcurrentconduction,isdecidedbythe comparisonbetweenV

.

V

11

10

and

A positivehysteresisis added to the dwell comparatorto avoidspuriouseffectsandC

israpidlydis-

T

charged on the negative edge of Hall-effects input

signal.

In thisway theaverage voltageon C

increasesif

W

the motor speeddecreasesand viceversa in order

t

d

tomaintainconstanttheratio

t

d

is kept constant(and not

T

atanymotorspeed.

T

D

= cost)to control

T

the power dissipationand to have sufficienttimeto

avoidlow energy sparksduringacceleration.

DESATURATIONTIMESIN STATIC

CONDITIONS

InstaticconditionsandifC

T=CW

asrecommended

andif thevaluesoftheapplicationcircuitoffig.4are

used.

t

d

=

T

1 + I

1

11C/I11D

DESATURATIONTIMESIN LOWAND HIGH

FREQUENCYOPERATION

Dueto theupperlimitofthevoltagerangeofpin11,

if the componentsof fig.4 are used, below 10 Hz

(300 RPM for a 4 cylinder engine) the OFF time

reachesitsmaximumvalue(about50 ms)andthen

the circuit graduallylosescontrolof the dwellangle

becauseD = T – 50ms.

Over200Hz(6000RPMfora 4cylinderengine)the

availabletimeforthe conductionislessthan3.5ms.

Iftheusedcoilis6 mH,6A,theOFFtimeisreduced

to zeroand the circuitlosesthe dwellanglecontrol.

TRANSIENTRESPONSE

The ignition system must deliver constant energy

evenduringtheconditionofaccelerationand decelerationofthemotorbelow80Hz/s.Theseconditions

can be simulatedby means of a signal gene-rator

with a linearlymodulatedfrequencybetween 1 Hz

and200 Hz (thiscorrespondsto a changebetween

30 and 6000 RPM for a 4cylindersengine).

CURRENT LIMIT

Thecurrentin thecoilismonitoredbymeasuringthe

currentflowing in the sensing resistor Rson

I

sense

theemitterof theexternaldarlington.I

sense

isgiven

by :

I

sens e=Icoi l+I14

WhenthevoltagedropacrossRsreachestheinternalcomparatorthresholdvaluethefeedbackloopis

activatedandI

keptconstant(fig.1)forcing the

sense

externaldarlingtonin the active region.In this condition:

I

sense=Icoil

WhenaprecisepeakcoilcurrentisrequiredRsmust

betrimmedor anauxiliaryresistordivider(R

10,R11

added:

Icpeak(A)=

0.320

RS)

⋅

R10

R11

+1

SLOWRECOVERYCONTROL (fig.2)

If I

hasnot reached 94 % of thenominalvalue

sense

justbeforethenegativeedgeoftheHall-effectinput

signal, the capacitor C

and CWare quickly dis-

src

chargedaslongasthepick-upsignalis”low”.Atthe

next positive transition of the input signal the load

currentstartsimmediately,producingthe maximum

achievable T

; then the voltage on C

desat

SRC

increaseslinearlyuntilthestandbyisreached.During

thisrecoverytimetheC

voltageis convertedinto

SRC

a current which, substratedfrom the chargingcurrentof thedwellcapacitor,producesaT

lation.This means thatthe T

untilitsvaluereaches,afteratimeT

decreasesslowly

desat

SRC

modu-

desat

,thenominal

7% value.

Thetime T

= 12.9R7 C

T

rsc

whereR

C

thecapacitorat pin 8 (in µF).

src

isgivenby:

SRC

(ms)

SRC

isthebiasingresistoratpin12(inKΩ)and

7

)

6/11

L497

Figure2 : SRC : I

HJ: Input signal

I

: Coil current

C

Failureand Time Dependenceof ActiveRegion.

coil

: Voltageon capacitor C

V

CM

DST: Percentageof imposed desaturation time.

SRC.

Figure3 : PermanentConductionProtection.

PERMANENTCONDUCTION PROTECTION

(fig.3)

The permanentconductionprotectioncircuit monitorstheinputperiod,chargingCPwitha costantcurrentwhenthe sensorsignalishigh anddischarging

it whenthesensorsignalis low.Ifthe inputremains

highfora timelongerthan T

thevoltageacrossC

P

reachesan internallyfixedvalueforcingtheslowdecrease of coil current to zero. A slow decrease is

necessaryto avoidundesiredsparks.When the input signal goes low again C

is swiftly discharged

P

and the currentcontrolloop operatesnormally.

Thedelaytime T

is givenby :

P

(sec) = 18 CPR

T

P

7

WhereR7isthebiasingresistoronpin12 (in K)and

Cp the delaycapacitorat pin 9 (in µF).

P

7/11

L497

OTHER AP PLI CAT I O N NOTES

DUM P PROTECTION

Loaddump protectionmust be implemented by an

externalzenerif this functionis necessary.In fig.4

protects the driver stage, the connection be-

DZ

2

tweenpin 6 and 7 protectsthe output transistor of

pin6.MoreoverDZ

protectsboththepowersupply

1

input(pin 3) and Hall-effectsensor.

ResistorR

isnecessaryto limitDZ1currentduring

4

loaddump.

OVERVOLTAGELIMITATION

The external darlingtoncollectorvoltage is sensed

bythe voltagedividerR

increasesrisingR

or decreasingR3.

2

Due to theactivecircuit used,an R

. Thevoltagelimitation

2,R3

oCo

seriesnet-

Figure4 : ApplicationCircuit.

work is mandatory for stabilityduring the high voltagecondition.

valuesdepend on the darlingtonused in the

R

oCo

application.

Moreover the resistor R

is suggested to limit the

13

overvoltage even when supply voltage is disconnectedduringthe highvoltagecondition.

REVERSEBATTERYPROTECTION

Duetothepresenceofexternalimpedanceatpin6,

3, 16, 15 L497 is protectedagainstreverse battery

voltage.

NEGATIVESPIKEPROTECTION

If correct operation is requestedalso during short

negativespikes,thediodeD

andcapacitorCsmust

S

beused.

8/11

DIP16PACKAGE MECHANICAL DATA

L497

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.51 0.020

B 0.77 1.65 0.030 0.065

b 0.5 0.020

b1 0.25 0.010

D 20 0.787

E 8.5 0.335

e 2.54 0.100

e3 17.78 0.700

F 7.1 0.280

I 5.1 0.201

L 3.3 0.130

Z 1.27 0.050

mm inch

9/11

L497

SO16PACKAGEMECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.75 0.069

a1 0.1 0.2 0.004 0.008

a2 1.6 0.063

b 0.35 0.46 0.014 0.018

b1 0.19 0.25 0.007 0.010

C 0.5 0.020

c1

D 9.8 10 0.386 0.394

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 8.89 0.350

F 3.8 4.0 0.150 0.157

L 0.5 1.27 0.020 0.050

M 0.62 0.024

S

mm inch

45° (typ.)

8°(max.)

10/11

L497

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for

the consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its

use. No license is granted by implicationor otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specification

mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously

supplied. SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems

withoutexpress writtenapproval of SGS-THOMSON Microelectronics.

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands-

1998 SGS-THOMSON Microelectronics – Printedin Italy – AllRights Reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

11/11

Loading...

Loading...