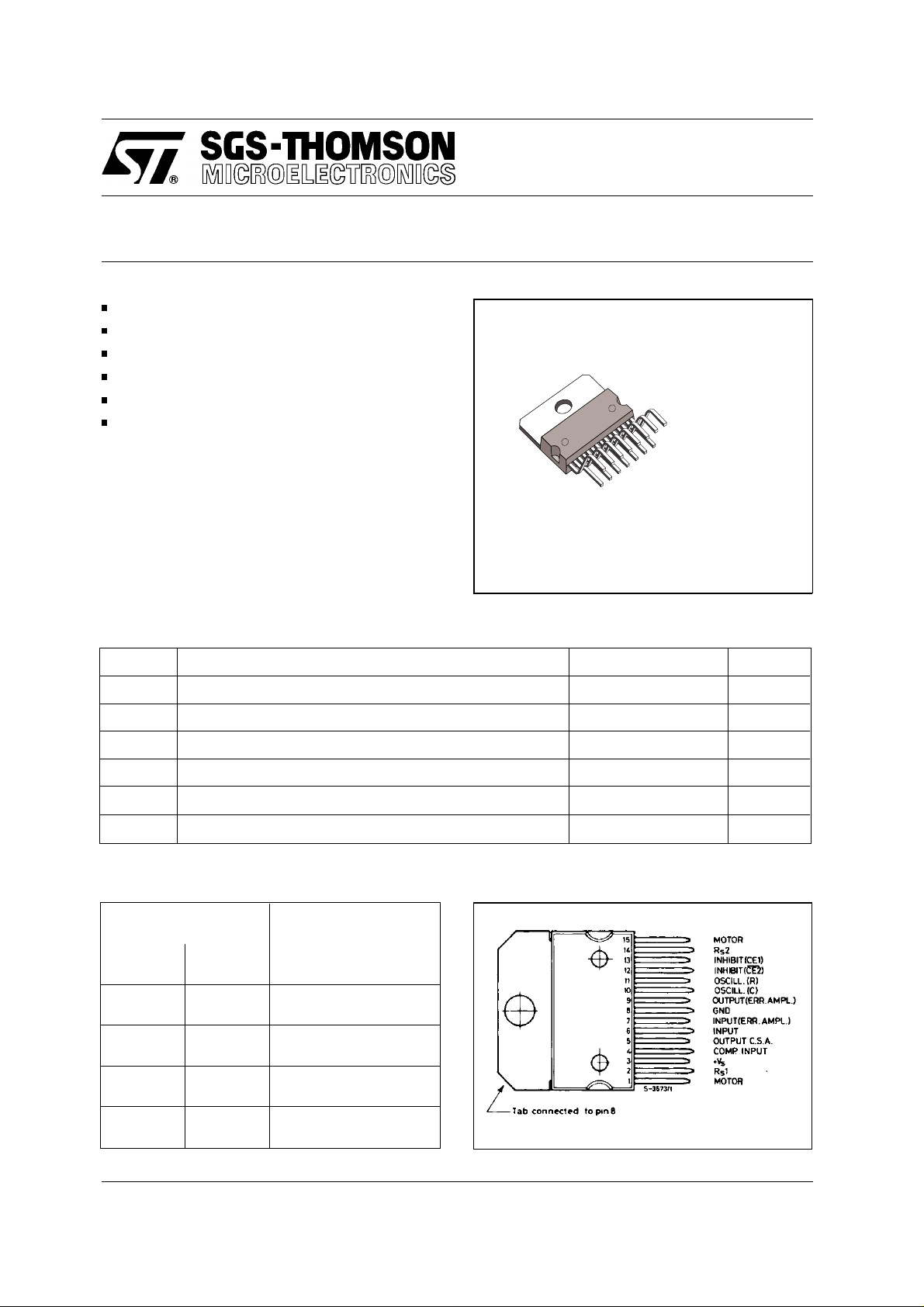

SWITCH-MODE DRIVER FOR DC M OTORS

DRIVING CAPABILITY : 2 A, 36 V , 30 KHz

2 LOGIC CHIP ENABLE

EXTERNAL L OOP GA IN ADJUSTEME NT

SINGLE PO WE R SUP P LY (18 T O 36 V)

INPUT SIGNAL SYMMETRIC TO GROUND

THERMAL PROTECTION

DESCRIPTION

The L292 is a monolithic LSI circuit in 15-lead

Multiwatt ® package. It is intended for use, together

with L290 and L291, as a complete 3-chip motor

positioning system for applications such as carriage/daisy-wheel position control in type-writes.

The L290/1/2 system can be directly controlled by

a microprocessor.

L292

Multiwatt 15

ORDER CODE : L292

ABSOLUT E MAX IMUM R ATI NGS

Symbol Parameter Value Unit

V

s

V

i

V

inhibit

I

o

P

tot

T

stg

TRUTH TABLE

Pin 12 Pin 13

L L Disabled

L H Normal Operation

Power Supply 36 V

Input Voltage - 15 to + Vs V

Inhibit Voltage 0 to Vs V

Output Current 2.5 A

Total Power Dissipation (T

Storage and Junction Temperature - 40 to + 150

= 75 °C)

case

25 W

CONNECT ION DI AG RAM (top view)

Vinhibit

Output Stage

Condition

°C

H L Disabled

H H Disabled

March 1993

1/12

L292

THERMAL DATA

Symbol Parameter Value Unit

Rth-j-case Thermal resistance junction-case Max 3

°C/W

ELECTRICAL CHARACTERISTICS (Vs = 36 V, T

= 25 °C, f

amb

= 20 KHz unless otherwise specified)

osc

Symbol Parameter Test conditions Min. Typ. Max. Unit

Supply Voltage 18 36 V

V

s

I

Quiescent Drain Current Vs = 20 V (offset null) 30 50 mA

d

Input Offset Voltage (pin 6) Io = 0

V

os

Inhibit Low Level (pin 12, 13) 2 V

V

inh

±350

mV

Inhibit High Level (pin 12, 13) 3.2 V

Low Voltage Condition V

I

inh

High Voltage Conditions V

Input Current (pin 6) Vl = -8.8 V

I

i

Input Voltage (pin 6)

V

i

I

Output Current

I

o

V

Total Drop Out Voltage (inluding sensing

D

I

Sensing Rsistor Voltage

V

RS

Drop

Transconductance

I

o

V

i

f

Frequency Range (pin 10) 1 30 KHz

osc

(L) = 0.4 V - 100

inh

(H) = 3.2 V 10

inh

= +8.8 V

V

l

= Rs2 = 0.2Ω

R

s1

= ± 9.8 V Rs1 = Rs2 = 0.2 Ω± 2

V

l

resistors)

T

= 150°C

j

= Rs2 =0.2Ω

R

s1

R

= Rs2 = 0.4Ω

s1

I

= 2A 9.1 V

o

= -2A -9.1 V

o

A

Io = 2 A

= 1 A 3.5 V

o

I

= 2 A 0.44 V

o

205 220 235 mA/V

120 mA/V

µA

µA

-1.8

0.5

mA

mA

5V

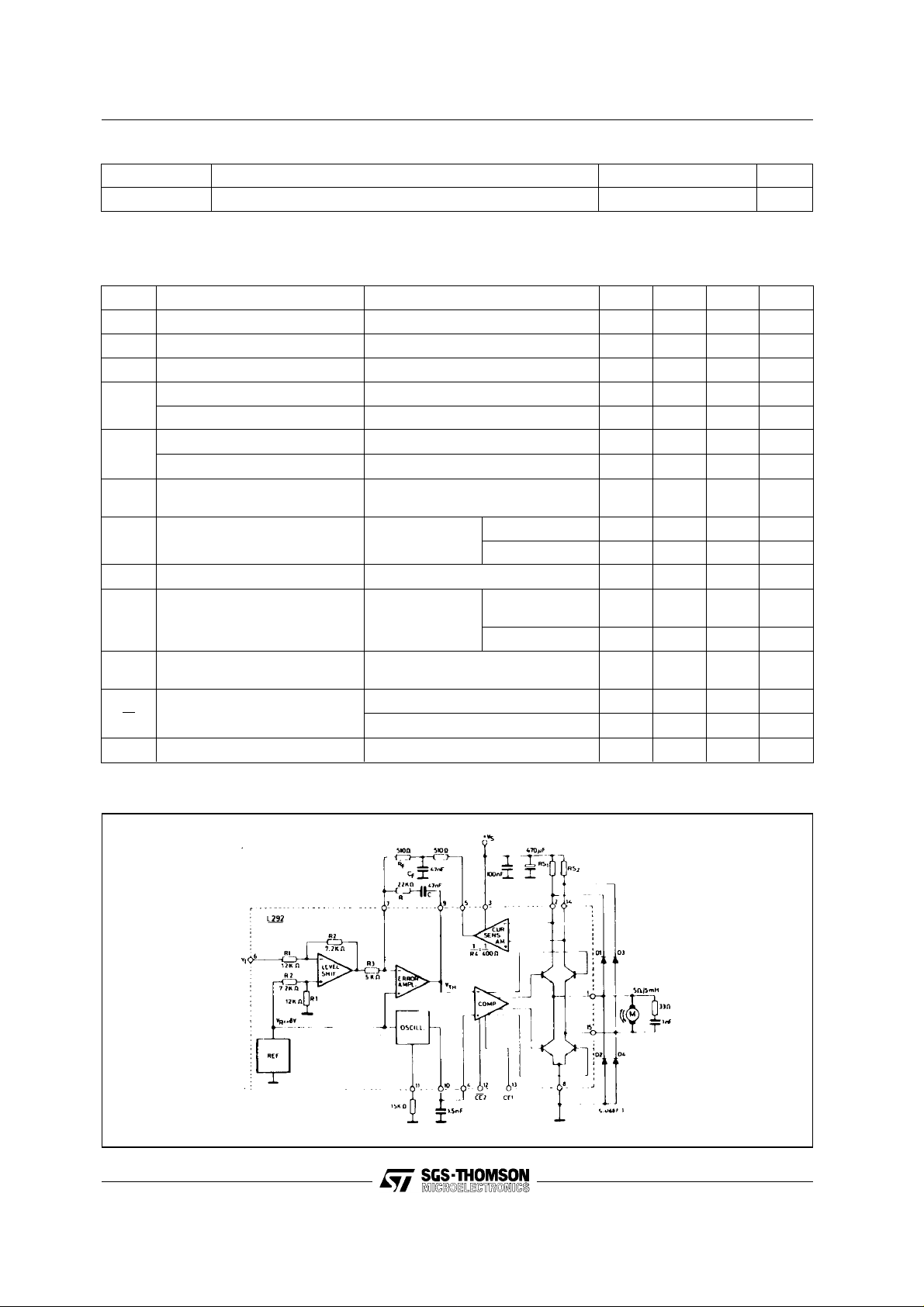

BLOCK DIAGRAM AND TEST CIRCU IT

2/12

SYSTEM DESCRIPTION

The L290, L291 and L292 are intended to be used

as a 3-chip microprocessor controlled positioning

system. The device may be used separately - particularly the L292 motor driver - but since they will

usually be used together, a description of a typical

L290/1/2 system follows.

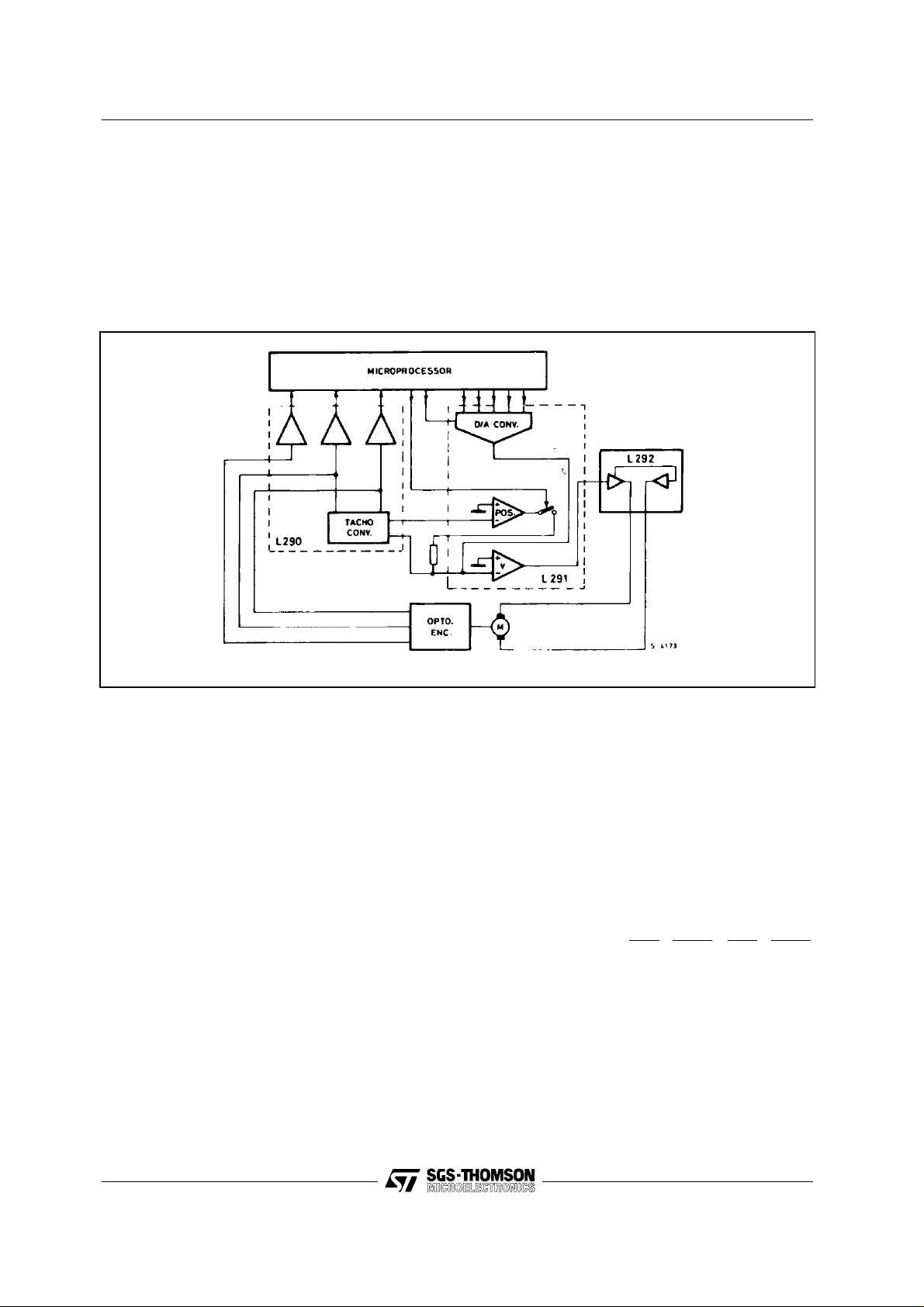

Figure 1. System Block Diagram

L292

At the time, the microprocessor orders a switch to

the position mode, (strobe signal at pin 8 of L291)

and within 3 to 4 ms the L292 drives the motor to

a null position, where it is held by electronic "detenting".

The mechanical/electrical interface consists of an

The system operates in two modes to achieve high

speed, high-accurancy positioning.

Speed commands for the system originate in the

microprocessor. It is continuosly updated on the

motor position by means of pulses from the L290

tachometer chip, whitch in tur gets its information

from the optical encoder. From this basic input, the

microprocessor computes a 5-bit control word that

sets the system speed dependent on the distance

to travel.

When the motor is stopped and t he microprocessor

orders it to a new positio, the system operates

initially in an open-loop configurat ion as there is n o

feedback from the tachometer generator. A maximum speed is reached, the t achometer chip out put

backs off the processor signal thus reducing accelering torque. The motor continues to run at rop

speed but under closed-loop control.

As the target pos ition is approached, the microprocessor lowers the v alue of the speed-dem and wor d;

this reduces the voltage at the main summing point,

in effect braking the motor. The braking is applied

progressively until t he motor is r unning at minimum

speed.

optical encoder which generates two sinusoidal

signals 90° out of phase (leading according to the

motor direction) and proportional in frequency to the

speed of rotation. The optical encoder also provides

an output at one position on the disk which is used

to set the initial position.

The opto encoder signals, FTA and FT B are filtered

by the networks R

and R3 C3 (referring to Fig.4)

2C2

and are supplied to the FT A/FTB inputs on the L290.

The main function on the L290 is to implement the

following expression:

Output signal (T ACHO) =

dV

FTA

AB

•

dt

| FTA |

−

dV

FTB

AA

•

dt

| FTB |

Thus the mean value of TACHO is proportional to

the rotation speed and its polarity indicates the

direction of rotation.

The above function is performed by amplifying the

input signals in A

and A2 to obtain VAA and V

1

AB

(typ.7 Vp). From VAA and VAB the external differentiatior RC networks R

and VMB which are fed to the multipliers.

V

MA

and R4 C4 give the signals

5 C6

3/12

L292

The second input to each multipler consists of the

sign of the first input of the other multiplier before

differentiation, these are obtained using the comp arators C

C

SB

and Cs2. The multiplier outputs, CSA and

s1

, are summed by A3 to give the final output

signal T ACHO. The peak-topeak ripple signal of the

T ACHO can be found from the following express ion:

V

ripple p −

( √ 2 − 1 ) • V

p

4

thaco

DC

π

=

The max value of TACHO is:

V

tacho max

=

π

√ 2 • V

4

thaco DC

Using the coparators C1 and C2 another two signals

from V

and VAB are derived - the logic signals STA

AA

and STB.

This signals are used by the microprocessor to

determine the position by counting the pulses.

The L2910 internal reference voltage is also derived

from V

and VAB:

AA

= | VAA | + | VAB |

V

ref

This reference is used by the D/A converter in the

L291 to compensate for variations in input levels,

temperature changes and ageing.

The "one pulse per rotation" opto encoder output

is connected to pin 12 of the L290 (FTF) where it is

squared to give the STF logic output for the microprocessor .

The T ACHO signal and V

filter networks R

8 C8 R9

are sent to the L291 via

ref

and R6 C7 R7 respectively.

Pin 12 of this chip is the main summing point of the

system where T ACHO and the D/A converter output

are compared.

The input to D/A converter consists of 5 bit word

plus a sign bit supplied by the microprocessor. The

sign bit represets the direction of motor rotation.

The (analogue) output of the D/A conveter DAC/OUT - is compared with the T ACHO signal and

the risulting error signal is amplified by the error

amplifier, and subsequently appears on pin 1.

The ERRV sognal (from pin 1 , L291) is fed to pin

6 of the final chip, the L292 H-bridge motor-driver.

This input signals is bidirectional so it must be

converted to a positive signal bacause the L292

uses a single supply voltage. This is accom plished

by the first stage - the level shifter, which uses an

internally generated 8 V reference.

This same reference voltage supplies the triangle

wave oscillator whose frequency is fixed by the

external RC network (R

, C17 - pins 11 and 10)

20

where:

1 f

osc

=

1

(with R ≥ 8.2 K Ω)

2RC

The oscillator determines the switching frequency

of the output stage and should be in the range 1 to

30 KHz.

Motor current is r egulated by an internal loop in the

L292 which is performed by the resistors R

18

, R

19

and the differential curr ent sense amplifier, the output of which is filtered by an external RC network

and fed back to the error amplifier.

The choise of the extern al components in thes e RC

network (pins 5, 7, 9) is determined by the motor

type and the bandwidth requirements. The values

shown in the diagram are for a 5Ω, 5 MH motor.

(See L292 Transfer Function Calculation in Application Information).

The error signal obtained by the addition of the input

and the current feedback signals (pin 7) is used to

pulse width modulate the oscillator signal by means

of the comparator. The pulse width modulated signal controls the duty cycle of the Hbr idge to give an

output current corresponding to the L292 input

signal.

The interval between one side of the bridge swit ching off and the other switching on, τ, is programmed

in conjuction with an internal resistor Rτ.

by C

17

This can be foud from:

= R τ • C

τ

(C17 in the diagram)

pin 10.

Since Rτ is approximately 1.5 KΩ and the recommended τ to avoid simultaneous conduction is 2.5

µs C

The current sense r esis tors R

should be around 1.5 nF.

pin 10

and R19 should be

18

high precision types (maximum tolerance ± 2 %)

and the recommended value is given by:

• Io

R

max

≤ 0.44 V

max

It is possible to synchroniz e two L292 ’ s, if desired,

using the network shown in fig. 2.

Finally, two enable inputs are provited on the L292

(pins 12 and 13-active low and high respectively).

Thus the output stage may be inhibited by taking

pin 12 high or by taking pin 13 low. The output will

also be inhibited if the supply voltage falls below 18

V.

4/12

L292

The enable inputs were implemented in this way

because they are intended to be driven directly by

a microprocessor . Currently available micropr ocessors may generates s pikes as high as 1.5 V during

Figure 2.

Figure 4 . Applic ation Circui t.

power-up. These inputs may be used for a variety

of applications such as motor inhibit during reset of

the logical system and power-on reset (see fig. 3).

Figure 3.

5/12

L292

APPLICATION INFORMATION

This section has been added in order to help the designer for the best choise of the values of external

components.

Figure 5. L292 Block Diagram.

The schematic diagram used for the Laplace analysis of the system is shown in fig. 6.

Figure 6.

R

= RS2 = RS (sensing resistors )

S1

1

= 2.5 • 10-3 Ω (current sensing amplifier transconductance)

R

4

= Motor inductance, RM = Motor resistance, IM = Motor current

L

M

Gmo =

current (I

IM

| s = 0 (DC transfer function from the input of the comparator (VTH) to the motor

)).

M

6/12

Neglecting the VCEsat of the bridge transistors and the VBE of the diodes:

2

=

1

G

mo

R

V

s

M

where : VS = supply voltage (1)

V

R

VR = 8 V (reference voltage)

DC TRANSFE R FU NCT ION

In order to be sure that the current loop is stable the following condition is imposed :

L

1 + sRC = 1 + s

from which RC =

M

(pole cancellation) (2)

R

M

L

M

(Note that in practice R must greater than 5.6 KΩ)

R

M

The transfer function is then,

L292

I

M

(s) =

V

I

R

R

2

R1 R

4

Gmo

3

Gmo Rs + s R4 C + s2 RF CF R4 C

1

+ s R

F CF

(3)

In DC condition, this is reduced to

R

I

M

(o) =

V

I

R

2

R1 R

4

3

•

0.044

1

=

R

R

s

A

[

s

] (4)

V

OPEN-LOOP GAIN AND STABILITY CRITERION

For RC = L

Aβ =

/ RM, the open loop gain is:

M

1

sR subF C

• G

mo

R

R

s

1 + s RF C

4

R

F

F

=

Gmo R

R

4

s

C

(1 + s R

s

1

(5)

C

)

F

F

In order to achieve good stability , the phase margin must be greater than 45° when | A β | = 1.

That means that, at f

| A β | f =

2 π R

1

F CF

=

F

=

2 π R

G

mo Rs

R

4

1

must be | A β | < 1 (see fig. 7), that is :

F CF

C

R

F

C

F

< 1 (6)

2

√

Figure 7. Open Loop Frequency Response

7/12

L292

CLOSED-LOOP SYSTEM STEP RESPONSE

a) Small - signals an alysi s.

The transfer function (3) can be written as follows :

I

M

(s) =

V

I

where wo =

√ R4 C

ξ =

4 R

0.044

√

R

CF Gmo R

F

R

s

G

mo

C RF C

4

1 +

1 +

R

s

is the cutoff frequency

F

is the dumping factor

s

By choosing the ξ value, it is possible to determine

the system response to an input step signal.

Examples :

1) ξ = 1 from which

I

M

(t) =

0.044

R

s

[ 1 − e −

2R

2 ξ

2 ξs + s

ωo ω

t

F CF

(1 +

s

ω o

o

4 R

2

t

F CF

2

(7)

) ] • V

Figure 8. Small Signal Step Response

(normalized amplitude vs.

t / R

= 200 mV/div.

V

7

= 100 mA/div.

I

M

FCF

).

t = 100 µs/div.

= 1.5 Vp.

with V

I

i

(where Vi is the amplitude of the input step).

1

2) ξ =

(t) =

I

M

from which

2

√

0.044

(1 − cos

R

s

2 R

t

F CF

e −

2 R

t

F CF

) V

i

8/12

L292

It is possible to verify that the L292 works in "closedloop" conditions during the entire motor current

rise-time: the voltage at pin 7 inverting input of the

error amplifier) is locked to the reference voltage

, present at the non-inverting input of the same

V

R

amplifier.

The previous linear analysis is correct for this example.

Descresing the ξ value, the rise- time of the current

decreases. But for a good stability , from relationship

(6), the maximum value of ξ is:

CLOSED LOOP SYSTEM BANDWIDTH.

A good choice for x is the value 1 / √2. In this case :

I

M

(s) =

V

I

0.044

R

s

1 + 2s RF CF + 2s 2 RF 2 CF

The module of the transfer function is :

I

|

V

M

| =

I

0.044

R

s

2

[ ( 1 + 2 ω RF CF ) 2 + 1 ] • [ ( 1 − 2 ω RF CF ) 2 + 1 ]

√

ξmin =

1

(phase margin = 45°)

4

2

√

2

b) Large sign al rep ons e

The large step signal response is limited by slewrate and inductive load.

In this case, during the rise-time of the motor

current, The L292 works is open-loop condition.

1

+ s R

√1 + ω

F CF

2

RF 2 CF

2

2

(8)

(9)

The cutoff frequency is derived by the expression (9) by putting |

which :

ω

T

=

0.9

f T =

R

F CF

2π

0.9

R

F CF

I

M

| = 0.707 •

V

I

0.044

(−3 dB), from

R

s

9/12

L292

Example :

a) Data - Motors characterist ics: LM = 5 mH

RM = 5 W

L

/ RM = 1msec

M

- Voltage and current char acter ist ics :

V

- Closed loop bandwidth : 3 kHz

b) Calculation - From relationship (4) :

and from (1) :

- RC = 1 msec [from expression (2) ].

- Assuming ξ = 1/ √2 ; from (7) follows :

= 20 V IM = 2 A VI = 9.1 V

s

0.044

=

R

s

G

=

mo

VI = 0.2 Ω

I

M

2V

S

RM V

R

= 1 Ω

−1

c) Summarising

1

2

ξ

=

=

2

- The cutoff frequency is :

143

f

=

T

- RC = 1.10

1000 C

-

R

F CF

- R

F CF

-3

sec

= 1

≅ 47 µs

4R

• 10

RF C

400 C

F CF

−3

F

• 0.2

= 3 kHz

C = 47 nF

R = 22 KΩ

For R

= 510 Ω → CF = 92 nF

F

10/12

MULTIW ATT15 P ACKA GE ME CHANI CAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 5 0.197

B 2.65 0.104

C 1.6 0.063

D 1 0.039

E 0.49 0.55 0.019 0.022

F 0.66 0.75 0.026 0.030

G 1.02 1.27 1.52 0.040 0.050 0.060

G1 17.53 17.78 18.03 0.690 0.700 0.710

H1 19.6 0.772

H2 20.2 0.795

L 21.9 22.2 22.5 0.862 0.874 0.886

L1 21.7 22.1 22.5 0.854 0.870 0.886

L2 17.65 18.1 0.695 0.713

L3 17.25 17.5 17.75 0.679 0.689 0.699

L4 10.3 10.7 10.9 0.406 0.421 0.429

L7 2.65 2.9 0.104 0.114

M 4.25 4.55 4.85 0.167 0.179 0.191

M1 4.63 5.08 5.53 0.182 0.200 0.218

S 1.9 2.6 0.075 0.102

S1 1.9 2.6 0.075 0.102

Dia1 3.65 3.85 0.144 0.152

mm inch

L292

11/12

L292

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implicat ion o r otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications menti oned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are not a uthorized for use as critical components in life support devices or systems without ex press

written approval of SGS-THOMSON Microelectronics.

© 1994 SGS-THOMSON Microelectronics - All Rights Reserved

SGS-THOMSO N Microelec tronics G ROUP OF COMP ANI ES

Australia - Brazil - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands - Singapore -

Spain - Sweden - Switzerland - T aiwan - Thaliand - United Kingdom - U.S.A.

12/12

Loading...

Loading...