GS-D200

GS-D200S

2/2.5A BIPOLAR STEPPER MOTOR DRIVE MODULES

June 1994 1/17

FEATURES

Wide supply voltage range

Full/Half step drive capability

Logic signals TTL/CMOS compatible

Programmable motorphasecurrent andchopper

frequency

Selectable Slow/Fast current decay

Synchronization for multimotor applications

Remote shut-down

Home position indication

DESCRIPTION

The GS-D200 and the GS-D200S are drive modulesthat directlyinterface amicroprocessorto atwo

phase,bipolar, permanent magnet stepper motors.

The phase current is chopper controlled, and the

internal phase sequence generation reduces the

burden of the controller and it simplifies software

development.

TheGS-D200 uses bipolar power outputs whilethe

GS-D200S has powermos outputs to significantly

reduce both commutation and conduction losses.

A further benefit offered by the GS-D200S is the

completeprotection ofthe outputs againstany type

of shorts.

SELECTION CHART

Type

Ordering

Number

Phase

Current

(A)

Voltage

Drop

(V)

Supply

Voltage

(V)

GS-D200

1.0 nom.

(0.5 to 2.0)

4.1 max.

10 to 46

5.0±5%

GS-D200S

2.0 nom.

(0.5 to 2.5)

2.5 max.

12 to 40

5.0±5%

2/17

ABSOLUTEMAXIMUM RATINGS

Symbol Parameter Value Unit

V

s

DC Supply Voltage (pin 18)

GS-D200

GS-D200S

48

42

V

V

V

ss

DC Logic Supply Voltage(pin 12)

7V

T

stg

Storage TemperatureRange

– 40 to +105 °C

T

cop

Operating Case Temperature Range

– 20 to +85 °C

ELECTRICAL CHARACTERISTICS (TA=25°C and VS=24V unless otherwise specified)

Symbol Parameter Test Conditions

Value

Unit

Min Typ Max

I

s

Quiescent Supply Current Pin 18

20 mA

I

ss

Quiescent Logic Supply Current Pin 12 Vss=5V

60 mA

V

i

Input Voltage

Pin

3,4,6,7,10,1 1

Low

High

2

0.8

V

ss

V

V

I

i

Input Current

Pin

3,4,6,7,10,1 1

Vi=Low

Vi=High

0.6

10

mA

µA

V

sat

Source/Sink Saturation Voltage(GS-D200)

Pin

14,15,16,17

Io=1A

1.8 V

V

sat

Source/Sink SaturationVoltage(GS-D200S)

Pin

14,15,16,17

Io=2A

1.8 V

I

oL

Current Limit Intervention GS-D200S

5A

f

c

Chopper Frequency

17 kHz

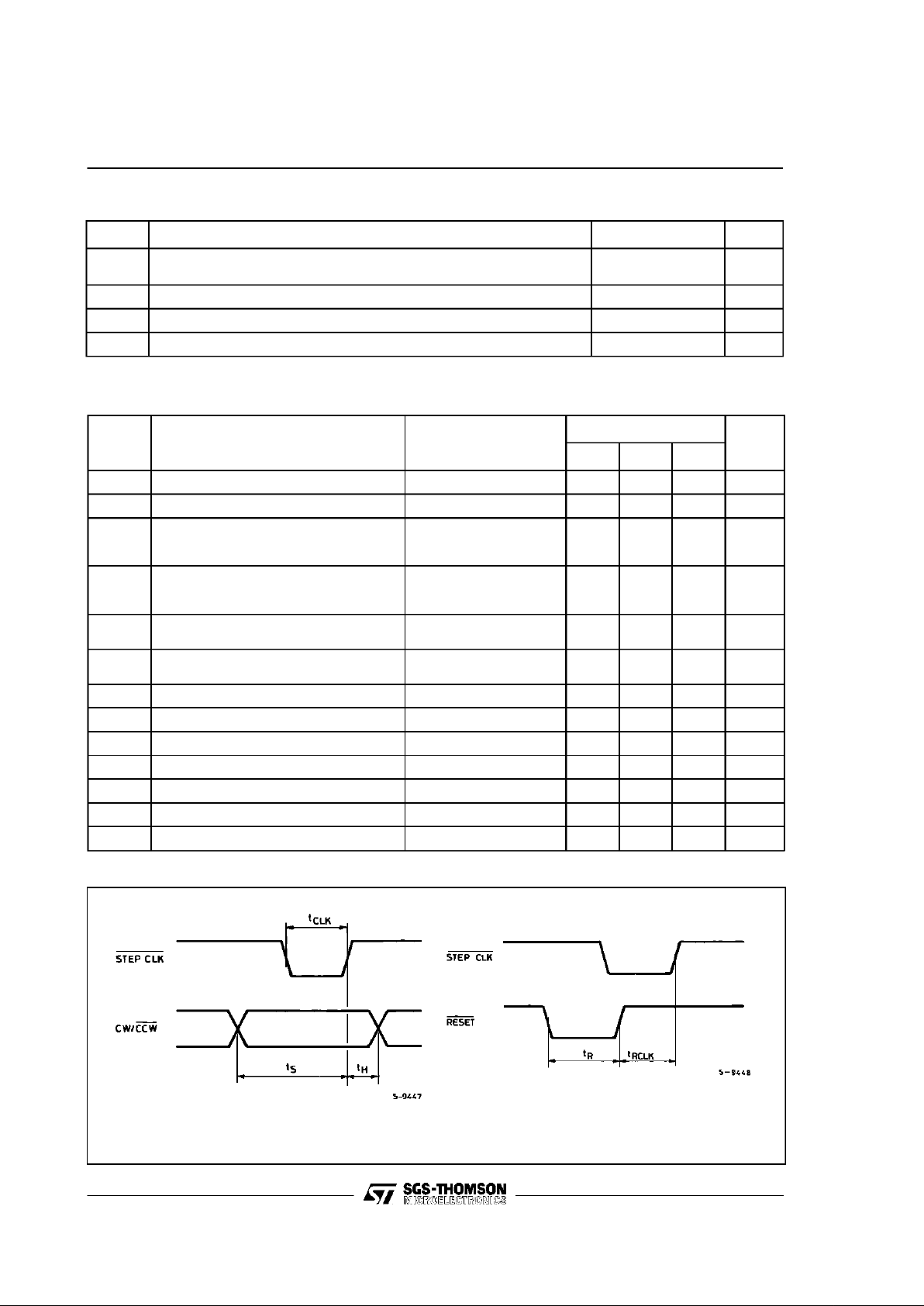

t

clk

Stepckl Width Pin6 (Seefig. 1)

0.5 µs

t

s

Set Up Time

”1 µs

t

h

Hold Time

”1 µs

t

r

Reset Width

”1 µs

t

rclk

Reset to Clock Set Up Time

”1 µs

Figure 1: Signals Timing

GS-D200/GS-D200S

3/17

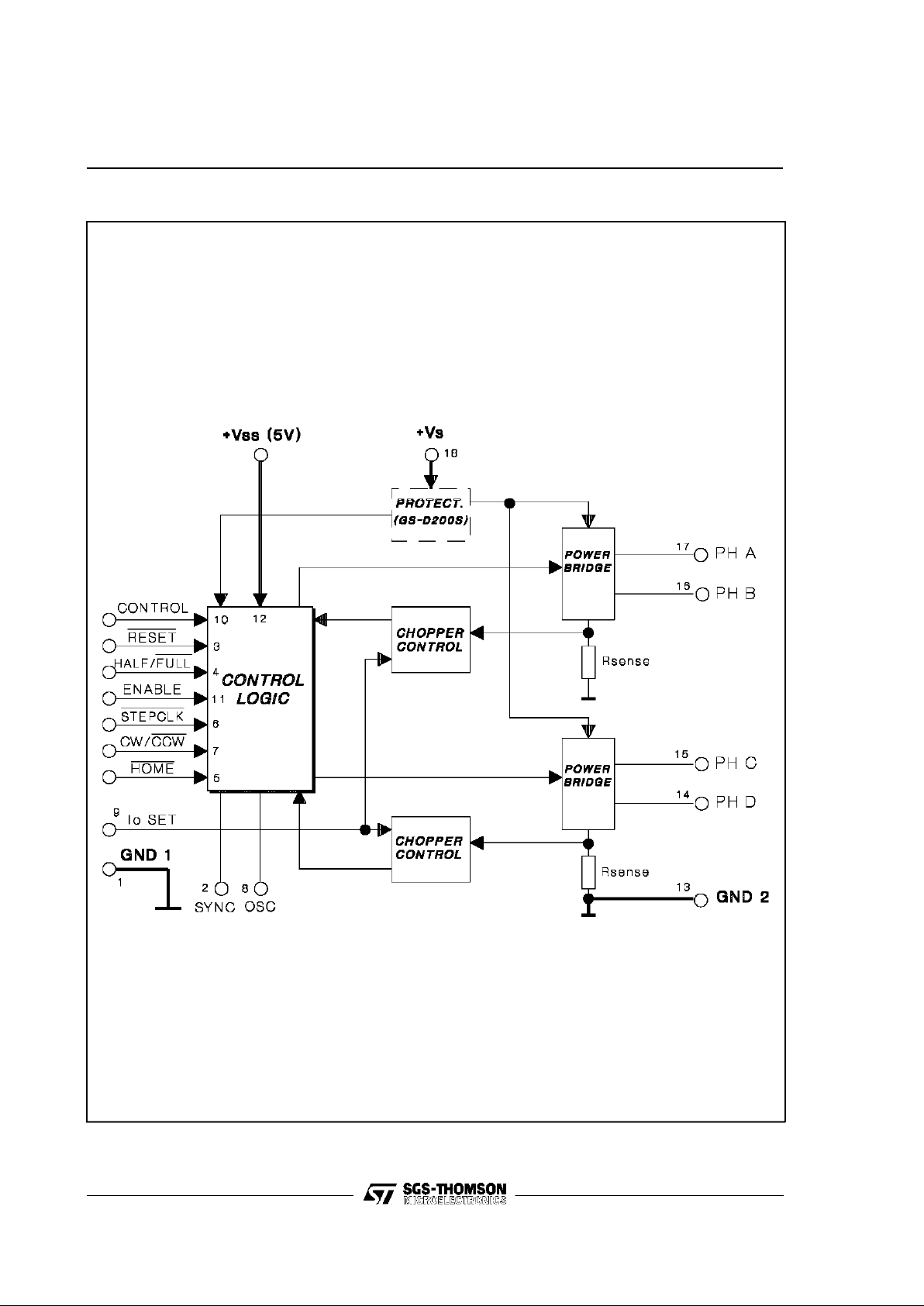

Figure2: GS-D200 and GS-D200SBlock Diagram

GS-D200/GS-D200S

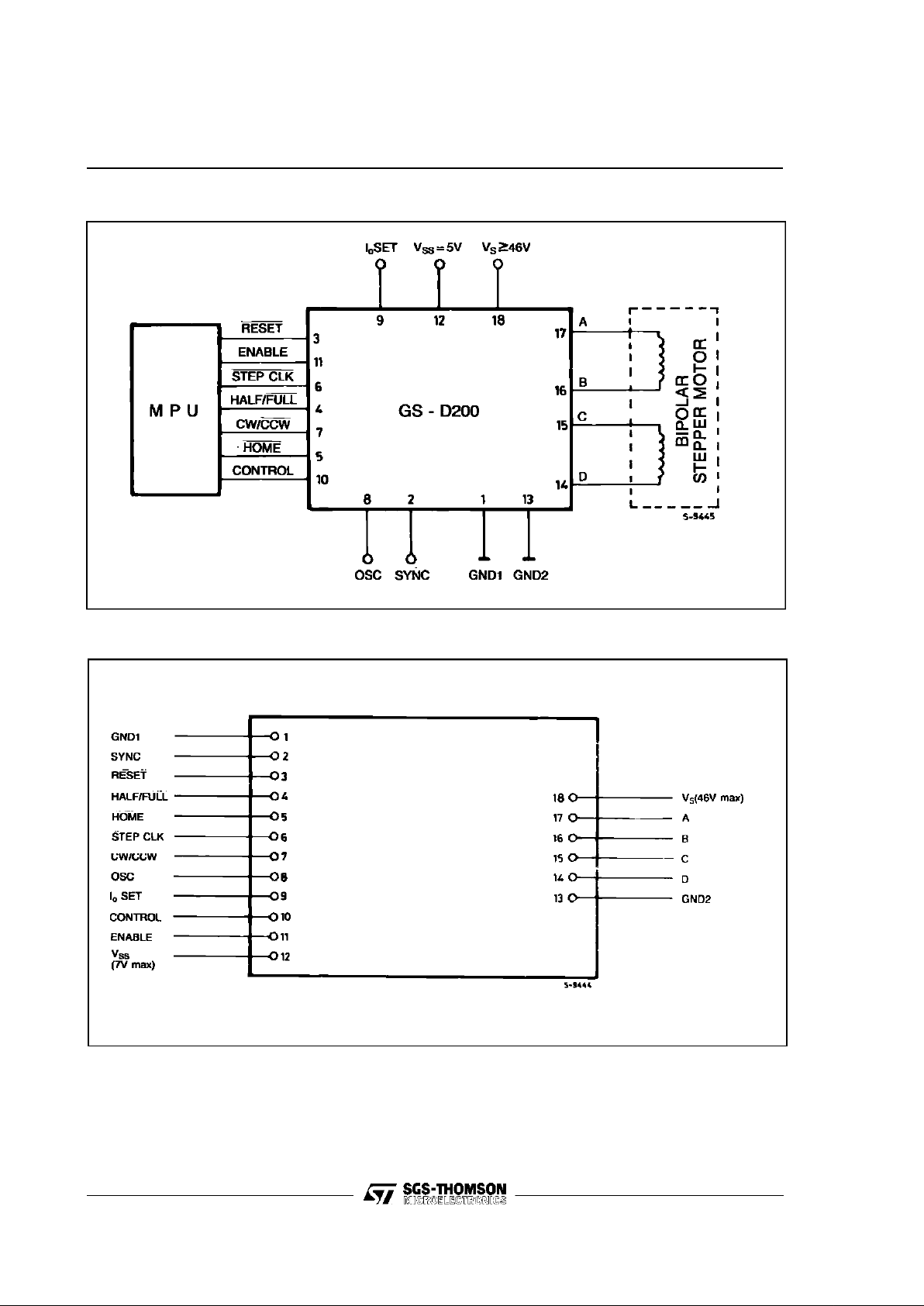

Figure 3: GS-D Modules Typical Application

4/17

Figure 4: GS-D200 and GS-D200S Connection Diagram (Topview)

GS-D200/GS-D200S

5/17

PIN DESCRIPTION

Pin Function Description

1

GND1 Return path for thelogic signals and 5V supply.

2

Sync

Chopper oscillatoroutput.

Several modules can be synchronized by connecting together all Sync pins. This pin can

be used as the input for an external clock source.

3

Reset

Asynchronousreset input. An active low pulse on this input preset the internal logicto the

initial state (ABCD=0101).

4

Half/Full

Half/Full step selection input.

When high or unconnectedthe halfstep operation is selected.

5

Home

When high, this output indicates that the internal counteris in its initial state (ABCD=0101).

This signal may be usedin conjunctionwith a mechanical switch to ground or with open

collectoroutput of an optical detector to be used as a systemhome detector.

6

Stepclk The motor is movedone stepon therisingedge of this signal.

7

CW/CCW

Direction controlinput. When high orunconnected clockwiserotation is selected. Physical

direction of motor rotationdepends also on windings connection.

8

Oscillator

The chopper oscillatortiming, internally fixed at 17kHz, can be modified by connecting a

resistor between this pin and Vssor a capacitor between this pin and Gnd1.

The oscillatorinput mustbe groundedwhen the unit is externally synchronized.

9

I

oset

Phase current settinginput. Aresistor connectedbetween thispin and Gnd1 or Vss,

allows the factory setted phasecurrent value (1Afor GS-D200and 2Afor GS-D200S) to

be changed.

10

Control

Logic input thatallows the phase current decay mode selection. When high or

unconnected the slow decay is selected.

11

Enable

Module enable input. When low this input floats the outputs enabling the manual

positioning of the motor.Must be LOW duringpower-up and down sequence,HIGH during

normal operation.

12

V

ss

5V supply input. Maximum voltage must not exceed 7V.

13

GND2 Return path for the power section.

14

D D output.

15

C C output.

16

B B output.

17

A Aoutput.

18

V

s

Module and motor supply voltage.

Maximum voltage must not exceed the specified values.

GS-D200/GS-D200S

6/17

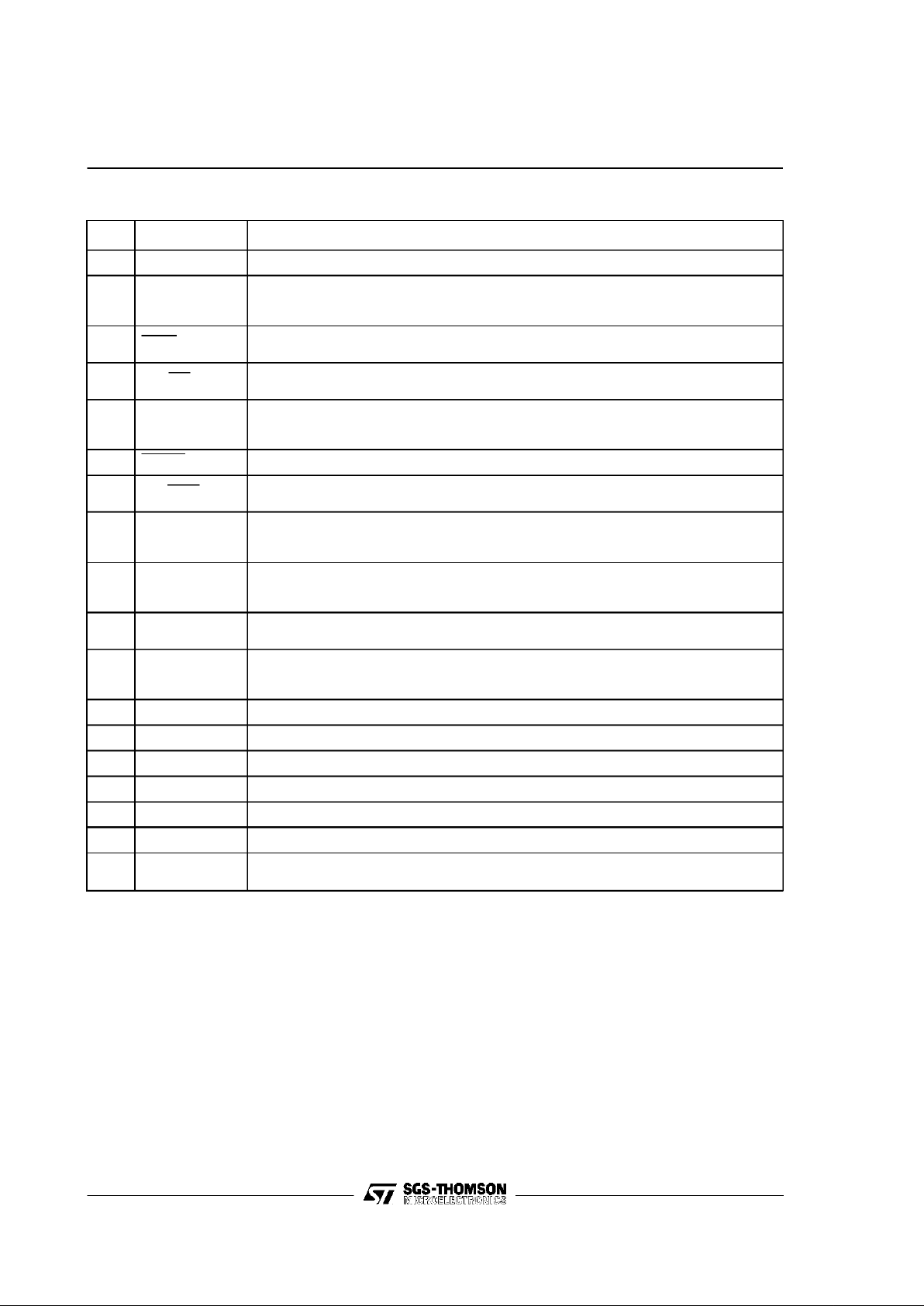

BIPOLAR STEPPER MOTOR BASICS

Simplified to the bare essentials, a bipolar permanent magnet motor consists of a rotating-permanent magnet surrounded by stator poles carrying

the windings (fig. 5).

Figure 5: Simplified Bipolar Two Phase Motor

Bidirectional drive current is imposed on windings

A-B and C-D andthe motor is stepped by commutating the voltage applied to the windings in sequence. For a motor of this type there are three

possible drive sequences.

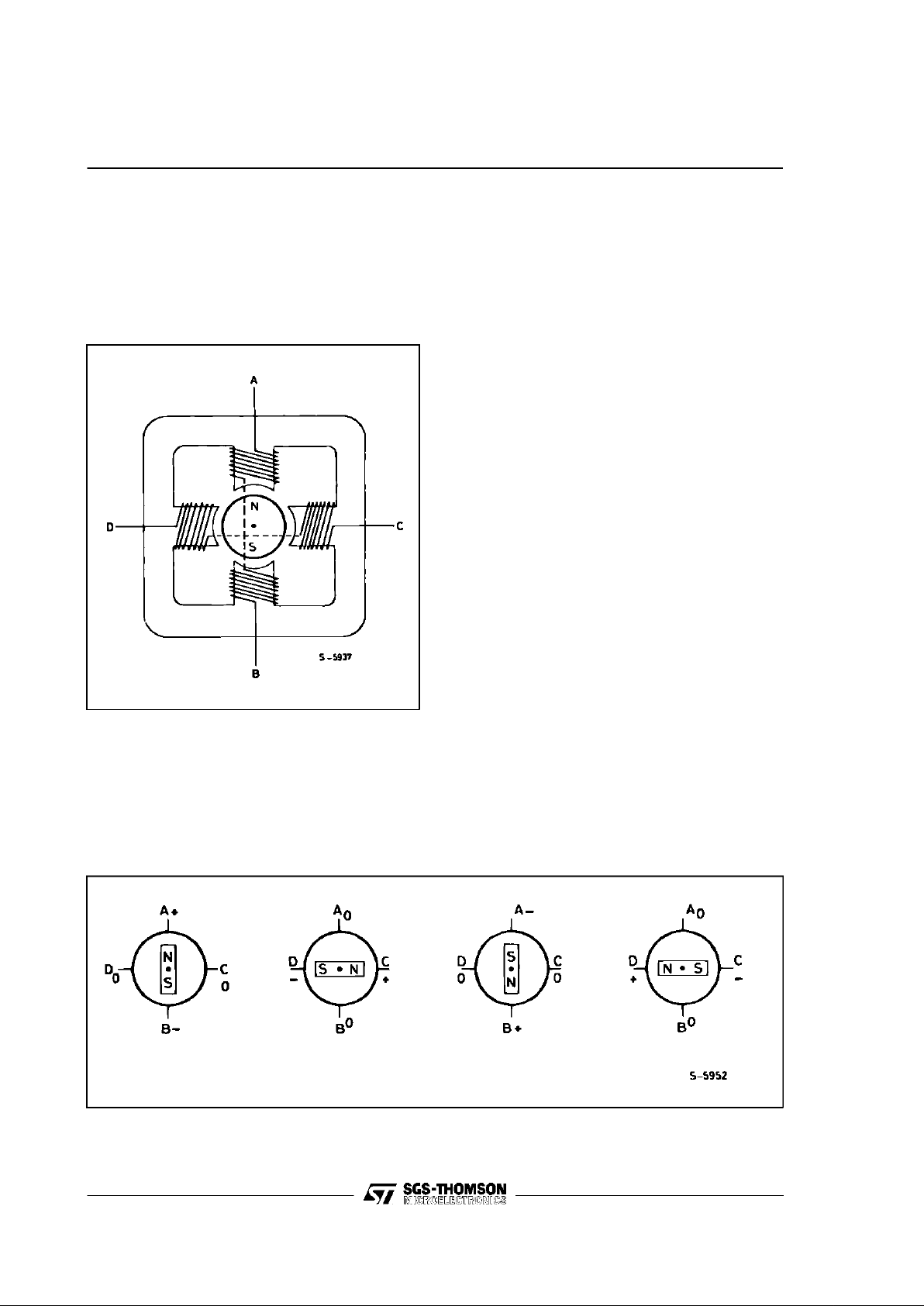

Figure 6: One-Phase-on (Wave Mode) Drive

One-Phase-on or Wave Drive

Only one winding is energized at any given time

according to thesequence :

AB - CD - BA - DC

(BAmeans that the current is flowing from Bto A).

Fig.6 showsthe sequence for a clockwiserotation

and the corresponding rotor position.

Two-Phase-on or NormalDrive

Thismode givesthe highesttorque sincetwo windings are energized at any given time according to

the sequence (for clockwiserotation).

AB & CD ; CD & BA; BA & DC; DC & AB

Fig. 7 shows the sequenceand the corresponding

positionof the rotor.

Half Step Drive

This sequence halves the effective step angle of

the motorbut gives aless regular torque being one

winding or two windings alternatively energized.

Eight steps are required for a complete revolution

of the rotor.

The sequence is:

AB ; AB& CD ; CD ; CD & BA; BA; BA& DC;

DC ; DC& AB

as shown in fig. 8.

By theconfigurations of fig. 6, 7,8 the motor would

have astep angle of90 ° (or 45° inhalf step). Real

motorshave multiplepoles pairsto reducethe step

angle to a fewdegrees but the number of windings

(two) and the drive sequence are unchanged.

GS-D200/GS-D200S

7/17

Figure 7: Two-Phase-on(Normal Mode) Drive

Figure 8: Half Step Sequence

GS-D200/GS-D200S

8/17

PHASE SEQUENCE GENERATION INSIDE THE

GS-D200/GS-D200S

The modules contains a three bit counter plus

some combinational logic which generate suitable

phase sequences for half step, wave and normal

full step drive. This3 bit countergenerates a basic

eight-step Gray code master sequence as shown

in fig. 9. To select thissequence, that corresponds

to half step mode, the HALF/FULL input (pin 4)

must be kept high or unconnected.

The full step mode (normal and wave drive) are

both obtainedfrom theeightstep mastersequence

by skipping alternate states. This is achieved by

forcing the step clock to bypass the first stage of

the 3 bit counter. The least significant bit of this

counteris not affectedandtherefore the generated

sequence depends on the state of the counter

when full step mode is selected by forcing pin 4

(HALF/FULL)low. If full step isselected when the

counter is at any odd-numbered state, the twophase-on (normal mode) is implemented (see fig.

10).

On the contrary, if the full mode is selected when

the counter is at an even-numbered state, the

one-phase-on (wave drive) is implemented (see

fig. 11).

Figure 9: The Eight Step Master Sequence corresponding to Half Step Mode.

GS-D200/GS-D200S

9/17

Figure 10: Two-Phase-on (NormalMode) Drive Figure 11: One-Phase-on (Wave Mode) Drive

RESET, ENABLE AND HOME SIGNALS

The RESET is an asynchronous reset input which

restores the module to the home position (state1 :

ABCD= 0101). Resetis activewhen low.

The HOME output signals this condition and it is

intendedto beANDed withthe outputofa mechanical home position sensor.

The ENABLEinput is used to start up the module

after the system initialization. ENABLE is active

when high or unconnected.

MOTOR CURRENT REGULATION

The two bipolar winding currents are controlled by

two internal choppers in a PWM mode to obtain

good speed andtorque characteristics.

An internaloscillatorsuppliespulses atthe chopper

frequency to both choppers.

When the outputs areenabled, the currentthrough

the windings raises until a peak value set by I

oset

and R

sense

(see the equivalent block diagram) is

reached. At this moment the outputs are disabled

andthe currentdecaysuntilthe nextoscillatorpulse

arrives.

The decay time of the current can be selected by

theCONTROLinput(pin 10). Ifthe CONTROLinput

is kept high or openthe decay is slow,as shownin

fig. 12, where the equivalent power stage of GSD200, the voltages on A and B are shown as well

as the current waveform on winding AB.

When the CONTROLinput is forcedlow, the decay

is fast as shown in fig. 13.

The CONTROL input isprovided on GS-D200 and

GS-D200S to allow maximum flexibility in application.

If the modules must drive a large motor that does

not store muchenergy inthe windings, the chopper

frequency must be decreased: this is easily obtainedby connecting an externalcapacitorbetween

OSC pin and GND1.

In these conditions a fastdecay (CONTROLLOW)

would imposea low averagecurrent andthe torque

could be inadequate. By selecting CONTROL

HIGH, the average current is increased thanks to

the slow decay.

When the GS-D200S is used in the fast-decay

mode it is recommended to connect external fast

recovery, low drop diodes between each phase

output and the supply return (GND). The slow-decay should be the preferredoperating recirculation

mode because of the lower power dissipation and

low noise operations.

GS-D200/GS-D200S

10/17

Figure 12: Chopper Control with Slow Decay

Figure 13: Chopper Control with Fast Decay

drivecurrent(Q1,Q2ON)

––––recirculation current

(Q

1

ON,Q2OFF,D1ON)

drivecurrent (Q

1,Q2

ON)

– – – – recirculation current

(Q

1,Q2

OFF,D1,D2ON)

GS-D200/GS-D200S

11/17

USER NOTES

Supply Voltage

The recommended operating maximum supply

voltage must include the ripple voltage for the V

s

rail, and a 5V±5% for the Vssline is required.

The two supply voltages must to be correctly sequenced to avoidany possible erroneous positioning of the power stages.The correctpower-up and

power-down sequences are:

Power-up 1) Vss(5V) is applied with Enable =Low

2) Vs (the motor supply voltage)

is applied

3) Enable is brougth High

Power-down 1) Enable is brougth Low

2) Vsis switched off

3) Vssis switched off.

Case Grounding

The module case is internally connected to pin 1

and 13. To obtain additional effective EMI shield,

the PCB areabelow the modulecan be used as an

effective sixth side shield.

Thermal Characteristics

The case-to-ambient thermal resistanceof the GSD modules is 5°C/W. This produces a 50°C temperature increase of the modulesurface for 10Wof

internal dissipation.

According to ambient temperature and/or to power

dissipation, an additional heatsink or forced ventilation may berequired. (See derating curves).

Supply Line Impedance

The module has an internal capacitor connected

accross the supply pins (18 and 13) to assure the

circuit stability. This capacitor cannot handle high

values of currentripple, andwould be permanently

damaged if the primary energy source impedance

is not adequate.

The use of a low ESR, high ripple current 470µF

capacitor located as close to the module as possible is recommended. Suitable units are the SPRAGUE type 672D, the SPRAGUE 678D, the RIFA

type PEG 126 or any equivalent unit. When space

is a limitation, a 22µF ceramic multilayer capacitor

connected across the module input pins must be

used.

Module Protections

The GS-D200 outputs are protected against occasional and permanent short-circuits of the output

pin to the supply voltage. The GS-D200S outputs

are also protected against short circuits to ground

and to another output. When the current exceeds

the maximum value, the output is automatically

disabled.

The GS-D200S protection is of the latching type,

i.e. when an overload condition is detected the

unit outputs are disabled. To restart the operations it is necessary to disable the unit (pin

11=Low) or to switch off the supply voltage for at

least 100ms.

Motor Connection

The motorisnormally quitefar fromthe moduleand

long cables are needed for connection. The use of

a twistedpair cable with appropriate cross section

for eachmotor phase isrecommended to minimize

DC losses and RFIproblems.

Unused Inputs

All the GS-D200 and GS-D200S logic inputs have

an internal pull-up, andthey are highwhen unconnected.

Phase Current Programming

The output current of the GS-D200is factoryset to

1A while the GS-D200S has a standard 2A value.

The phase current value can be changed by connecting an appropriate resistor between pin 9 and

ground or Vss(see fig. 14). In the first case the

phase current will decrease, in the latter it will

increase.

The maximum phase current must be limited to 2A

for the GS-D200 and 2.5A for the GS-D200S to

avoid permanent damage to the module.

GS-D200 phase current programming:

I>1A Ri =

10 − I

0.993 ⋅ I− 1

= kΩ Ri≥ 8.2 kΩ

I<1A Rd =

I

1− 0.993 ⋅ I

=kΩ

GS-D200Sphase currentprogramming:

I>2A Ri =

10 − 0.33 ⋅I

0.473 ⋅ I− 1

= kΩ Ri≥ 50 kΩ

I<2A Rd =

I

3.03 − 1.43 ⋅ I

= kΩ

GS-D200/GS-D200S

12/17

12

9

1

12

9

1

Figure 14: GS-D200 and GS-D200S Phase Current Programming

12

8

1

12

8

1

oscosc

fC< 17 KHz

fC>17KHz

Figure 15: Chopper Frequency Programming

Chopper Frequency Programming

The chopper frequency is internally set to 17kHz,

and it can be changed by addition of external

components as follows. To increase the chopper

frequency a resistor must be connected between

Oscillator (pin 8) and Vss(pin12, see fig. 15).

The resistor value is calculated according to the

formula:

Rf =

306

fc − 17

= kΩ where fc = kHz Rf≥ 18kΩ

To decrease the chopper frequency a capacitor

must be connected between Oscillator(pin 8) and

Gnd1 (pin 1). The capacitor value is calculated

according to theformula:

Cf =

80.5 − 4.7fc

fc

= nF where fc = kHz

GS-D200/GS-D200S

13/17

Figure 16: GS-D200 Free Air Derating Curve Figure 17: GS-D200S Free Air Derating Curve

MULTI MODULES APPLICATION

Incomplex systems, many motors mustbe controlled and driven. In such a case more than one

GS-D200 or GS-D200 S mustbe used.

To avoid chopper frequencies noise and beats, all

the modules shouldbe synchronized.

If all the motors are relatively small, thefast decay

maybe used, thechopper frequency does notneed

any adjustementand fig.18 shows howto synchronize several modules.

When at least one motor is relatively large a lower

chopper frequency and a slow decay may be required: In such a case the overall system chopper

frequency is determined bythe largestmotor in the

system as shown in fig. 19.

Figure 18: Multimotor Synchronization. Small Motor and Fast CurrentDecay

Tamb(°C)

Tamb(°C)

GS-D200/GS-D200S

14/17

Figure 19: Multimotor Synchronization. Large and Small Motor. Slow Current Decay

THERMAL OPERATING CONDITIONS

In many cases the modules do not require any

additional coolingbecause the dimensions and the

shape of the metal box are studied to offer the

minimum possible thermal resistance case-to-ambient for a given volume.

It should be remembered that these modules area

power deviceand, depending onambient temperature, an additional heath-sink or forced ventilation

or bothmay be requiredto keep the unitwithin safe

temperature range. (Tcase

max

<85°C during op-

eration).

The concept of maximum operating ambient tem-

perature is totally meaningless when dealing with

power components because the maximum operating ambienttemperature depends on how a power

device is used.

What can be unambiguously defined is the case

temperature of the module.

To calculate the maximumcase temperature of the

module in a particular applicative environment the

designer must know the following data:

– Input voltage

– Motor phase current

– Motor phase resistance

– Maximum ambient temperature

From thesedata itis easy to determinewhether an

additional heath-sink is required or not, and the

relevant size i.e. the thermal resistance.

The stepby stepcalculation isshown for thefollowing example (GS-D200).

Vin=40V,I

phase

= 1 A, RphPhase resistance =

=10Ω, max. TA=50°C

● Calculate the power dissipated from the indexer

logic and the level shifter (see electrical characteristics):

P

logic

=(5V•60 mA) +(40 V • 20 mA) = 1.1 W

● Calculatetheaverage voltageacross the winding

resistance:

V

out

=(Rph• I

out

)=10Ωζ1A=10V

● Calculatethe required ONdutycycle (D.C.)of the

output stage to obtain the average voltage (this

D.C. is automatically adjusted by the GS-D200):

D.C. =

V

out

V

in

=

10

40

= 0.25

● Calculate the power dissipation of the GS-D200

output power stage. The power dissipation depends on twomain factors:

– the selected operating mode (FAST or SLOW

DECA Y)

– the selected drive sequence (WAVE, NORMAL,

HALF STEP)

FAST DECAY. For this mode of operation, the

internal voltage drop isVsat

source

+Vsat

sink

during

the ON period i.e. for 25 % of the time.

During the recirculation period (75 % of the time),

the current recirculates on two internal diodes that

have avoltage dropVd=1 V,andtheinternal sense

resistor (0.5 Ω). For this example, by assuming

maximum values for conservative calcu lations,the

power dissipation during one cycle is:

Ppw= 1.1 • [2 V

sat

• Iph• D.C.+ 2 Vd• Iph•

(1 - D.C.)+ 0.5 • Iph]

GS-D200/GS-D200S

Ppw=1.1•[2•1.8•1•0.25+2•1•1•0.75 + 0.5 • 1]

Ppw=1.1•[0.9 + 1.5 + 0.5] = 3.19 W

The factor 1.1 takes into account the power dissi-

pation during the switching transient.

SLOW DECAY. The power dissipation during the

ON period is the same. The RECIRCULATION is

made internally t hrough a power transistor

(V

satsink

) and a diode. The power dissipation is,

therefore:

Ppw= 1.1•[2 V

sat•Iph

•D.C.+(V

sat+Vd

)•I

ph

•(1-D.C.)]

Ppw=1.1•[2•1.8 •1•0.25 + (1.8+ 1) • 1 • 0.75]

Ppw=1.1•[0.9 + 2.1] = 3.3 W

WAVE MODE. When operating in this mode the

power dissipation is given by values of FASTand

SLOW DECAYmode, because one phase is energized at any given time.

NORMALMODE. At any given time, two windings

are alwaysenergized. The powerdissipation ofthe

power output stage is therefore multiplied by a

factor 2.

HALF STEP. The power sequence, one-phase-on,

two-phase-on forces the power dissipation to be

1.5 times higher than in WAVE MODE when the

motor is running. In stall condition the worst case

for power dissipation is with two-phase-on i.e. a

powerdissipation as in NORMAL MODE.

The following tablesummarizes the power dissipations of the output power stage of the GS-D200

when running for this example:

Wave Normal Half Step

Fast Decay

3.19W 6.38 W 6.38W

Slow Decay

3.30W 6.60 W 6.60W

● Calculate the total power dissipation for the GS-

D200 :

P

tot=Plogic+Ppw

In this example, for slow decay and normal mode

P

tot

= 1.1 +6.6 =7.7 W

● The case temperature can now be calculated:

T

case=Tamb

+(P

tot•Rth

) = 55 + (7.7 • 5) = 93.5 °C

● If the calculated case temperature exceeds the

maximum allowed case temperature, as in this

example,an externalheat-sink is required and the

thermalresistance canbe calculated according to:

Rth

tot

=

T

cmax

− Tamb

P

tot

=

85 − 55

7.7

= 3.9°C

and then

Rthhs=

Rth ⋅ Rth

tot

Rth − Rth

tot

=

5 ⋅ 3.9

5 − 3.9

= 17.7°C

The following table gives the thermal resistanceof

some commerciallyavailable heath-sinksthat fit on

the GS-D200 module.

ManufacturerPart Number Rth(°C/W) Mounting

Thermalloy

6177 3 Horizontal

Thermalloy

6152 4 Vertical

Thermalloy

6111 10 Vertical

Fischer

SK18 3 Vertical

Assman

V5440 4 Vertical

Assman

V5382 4 Horizontal

15/17

GS-D200/GS-D200S

MECHANICAL DATA

2.54 (0.1)

5.04 (0.2)

5.04 (0.2)

5.04 (0.2)

2.54 (0.1)

2.54 (0.1)

18.4

(0.72)

29.5

(1.16)

2.2 (0.87)

2.2 (0.87)

1.2 (0.47)

66.67 (2.62)

78.5 (3.09)

82.3 (3.24)

85.5 (3.37)

18.5 (0.73)

20.5 (0.81)

0.5 (0.02)

7 (0.28)

23.0

(0.90)

4 (0.16)

Dimensions in mm

MOTHER BOARD LAYOUT

16/17

GS-D200/GS-D200S

17/17

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or otherrights of third parties which may result from its use. No

license is granted by implicationor otherwise under any patent or patent rights of SGS-THOMSONMicroelectronics.Specification mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSONMicroelectronics products are not authorized for use as critical components in lifesupport devices or systems without express

written approval of SGS-THOMSON Microelectronics.

1994 SGS-THOMSON Microelectronics – All Rights Reserved

SGS-THOMSON MicroelectronicsGROUP OF COMPANIES

Australia - Brazil - China - France - Germany - Hong Kong- Italy- Japan- Korea - Malaysia - Malta - Morocco - The Netherlands-

Singapore- Spain - Sweden- Switzerland- Taiwan- Thailand - United Kingdom - U.S.A.

GS-D200/GS-D200S

Loading...

Loading...