Page 1

INTELLIGENT STEPPER MOTOR CONTROLLERS

FEATURES

Absolute and incremental positioning

Up to 999,999 step permove

Speed range to 10,000 steps/s

Ramp lenght to 999 steps

Single unregulated supply voltage

Index and velocity mode

Automatic and Home positioning

Loops and Delay execution

Conditional start and stop

Status feedback to the host

RS232 communication port

Point to point and Multipoint protocol

Closed loop operation

Counter preset (GS-C200Sonly)

Jump to (GS-C200S only)

Jump to on-condition (GS-C200Sonly)

Initialization during execution (GS-C200Sonly)

Auxiliary output voltages +5V, ± 12V

GS-C200

GS-C200S

DESCRIPTION

The GS-C200 and GS-C200Sarepowerfulstepper

motor control modules that interface every power

sequencer/driver available on themarket.

A sophisticated hardware and an easy to learn

programming language result in minimal development and debugging time of motion control systems. The modules are supported by dedicated

software thatincludes both anon-screeneditorand

a debugger that greatly improve the module ease

of use.

The instruction setscompriserespectively 25 (GSC200) and 29 (GS-C200S) different commands

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

T

T

DC SupplyVoltage

s

Storage Temperature Range

stg

Operating Temperature Range

op

Humidity (non condensing)

which can be executedeither underhost control or

in a stand alone environment. An on board EEPROM is used for program saving and retrieving.

The availability of three User inputs and three

programmable Useroutputs, eachof which can be

tested or set under program control,assures tothe

designer ahighlevelofsystempowerand flexibility.

42 V

–40to+85 °C

0to+50 °C

0to90 %

June 1994 1/31

Page 2

GS-C200/ GS-C200S

ELECTRICALCHARACTERISTICS (TA= 25C and Vs=24V unlessotherwise specified)

Symbol Parameter Min Typ Max Unit

V

V

t

cpw

t

rpw

DC SupplyVoltage

s

Quiescent Supply Current

I

s

Logic Input Voltage

V

i

(TTLcompatible)

Logic Output Voltage

o

(TTLcompatible)

Clock Pulse Width

Reset Pulse Width (Internal)

Low

High

Low

High

12 40 V

80 mA

2

2

0.8

5

0.8

5

5 µs

500 µs

V

V

V

V

MOTION CHARACTERISTICS

SPEED RANGE 10 to 10000 steps

SPEED RESOLUTION 10 steps

RAMP LENGHT 1 to 999 steps

RAMP RESOLUTION 1 step

POSITIONINGRANGE(C200)

(C200S)

SINGLE MOVEMENTRANGE 1 to 999999 steps

POSITIONINGRESOLUTION 1 step

POSITIONINGREPEA T IBILITY +/– 0 step

PROGRAM STORAGE

CAPABILITY

0 to 9999999

– 8388608 to + 8388607

119bytes

COMMUNICATION PORT CHARACTERISTICS

SIGNALLINES 3 (TxD,RxD, GND)

BAUD RATERANGE 110 to 9600

FORMAT 1 Start Bit

7 Data Bit

2 Stop Bit

Odd parity

STORAGECAPACITY

MINIMUM NUMBER OF COMMANDS 30

MAXIMUM NUMBER OF COMMANDS 45

2/31

Page 3

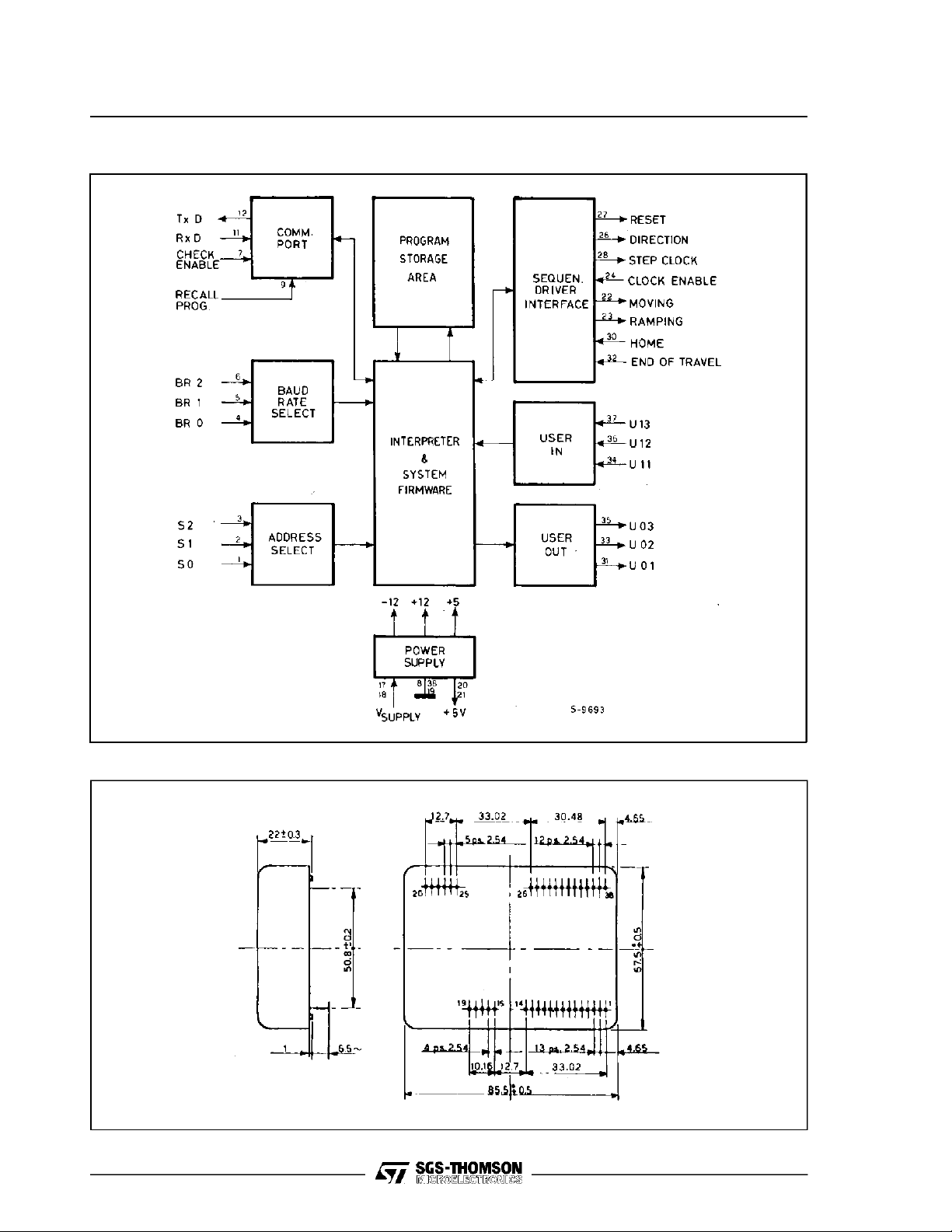

Figure 1. Block Diagram

GS-C200/ GS-C200S

CONNECTION DIAGRAM AND MECHANICALDATA

Dimensions in mm.

Bottomview

3/31

Page 4

GS-C200/ GS-C200S

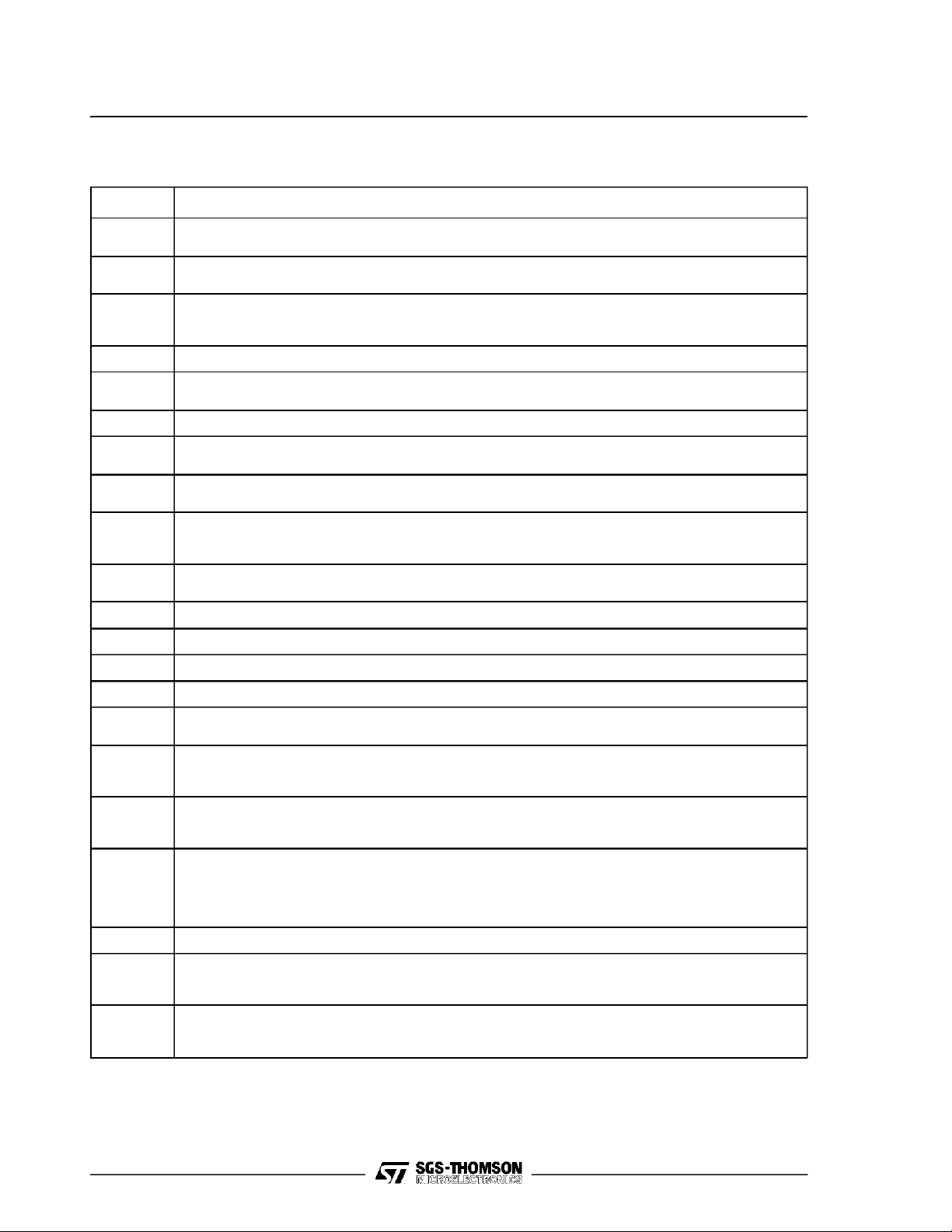

PIN DESCRIPTION

Pin Function Description

SEL0 Protocol/addressLSB select input

1

SEL1 Protocol/addressSSB select input

2

SEL2 Protocol/addressMSB select input

3

BR0 Baud rate LSB select input

4

BR1 Baud rate SSB select input

5

BR2 Baud rate MSB select input

6

CHS Checksum enable input

7

GND Ground

8

REC Program autorecall input

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Notes: 1– Maximum available current is 10mA

RXD RS232 received data input

TXD RS232 transmitteddata output

TXPD Transmitted data pull-down resistor

RDY Status logic output

–VSL Unregulated –12V supplyoutput (note 1)

+VSL Unregulated +12V supply output (note 1)

V

s

V

s

GND Ground

5V 5V Auxiliary output(note 2)

5V 5V Auxiliary output(note 2)

MOV Motor moving logicoutput

RAMP Motor ramping logicoutput

ENABLE Stop enable logic input

DIR Direction selection logic output

RESET Power driver Reset logic output

CLOCK Step clock logic output

HOME Home position logic input

UO1 User 1 logic output

EOT End of travel switch logic input

UO2 User 2 logic output

UI1 User 1 logic input

UO3 User 3 logic output

UI2 User 2 logic input

UI3 User 3 logic input

GND Ground

2 – Maximumavailable current is 100mA

Must be connected to pin 8

Supply voltage input

Supply voltage input

Not connected

Not connected

4/31

Page 5

GS-C200/ GS-C200S

The various signals that characterize the GS-C, their function and the active level are described in detail

in the following:

Pin Function

1-2-3

4-5-6

7

8

9

10

11

12

13

14

15

16

17 - 18

19

20 - 21

22

23

24

25, 29

26

27

The SEL0 (pin1), SEL1 (pin2) and SEL2 (pin3)inputs are used to select the communicationprotocol and

the module address. They have an internalpull-up and when unconnected they are at the 1 logic level.

The BR0 (pin4), BR1 (pin5) and BR2 (pin6)inputs are used to select the Baud rate of the

communication port. They have an internal pull-up and when unconnected they are at the 1 logic level.

The CHS checksum generationconditioning input enables the user to include or exclude the checksum

character from thedata exchange string. A ”zero” logic level appliedto this input disables the control and

the generation of the checksumcharacter thus allowing the GS-C to be connectedto a video terminal.

This pin is the common terminal for all logic signals and for the power supply return path.

The REC RecallProgram Enable input pin, when brought to ”zero”, enables the automatic recallof the

program stored inthe EEPROM and itsimmediate execution.

This pin is for testingpurpose only and itmust be grounded for normaloperation.

The RxD inputof the serial communication port is used by the module to receive commands from the

Host Computer. The input logic levels are compatible with the RS232 and V24 standards.

The TxD output of the serial communicationport is used by the moduleto send data to the Host

Computer. The logic levels of this output are compatiblewith the RS232 and V24 standards.

The TxPD Transmitted data pull-down resistorpin must always be connectedto the TxDoutput (pin 12)

when the Point-to-Point protocol is used. Whenthe Multipoint protocol is selected, this pin mustbe left

open on all modules except the chainterminator unit, in orderto avoid the TxD output overload.

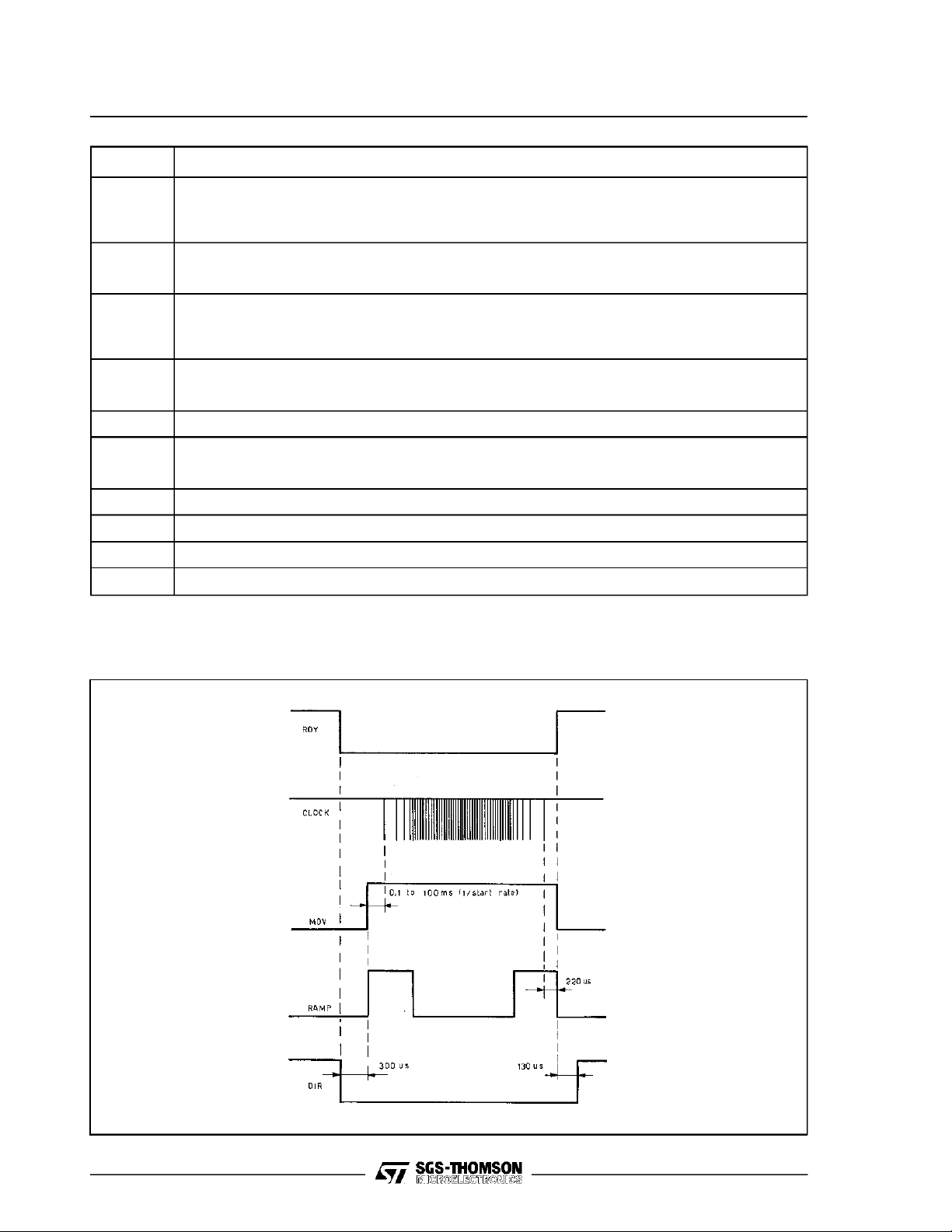

The RDY hardware statusoutput (opencollector) signal pin is used as the controllerstatus flag. RDY

assumes a ”zero” logic level when a command or a program is in execution

–12V unregulatedoutput. A maximum of 10mAcan be sinked from this pin.

+12V unregulatedoutput. A maximum of 10mA can be sinked from this pin.

Module supply input. For correctoperations a supply voltage ranging from 12 to 40 Volt is required.

See pin 8.

5 Voltregulated output, available either for the Sequencer-Driver logic section or for a custom interface

logic supply. The maximum current that can be sinked from this pin is 100mA.

The MOV Motor moving output becomes the logic level ”one” when the GS-C is executing a movement.

This output can be used to program the phase current level when the motion is runningat a levelhigher

than for the rest condition.

The RAMP Ramp in execution output is rised to the logic level ”one” when the GS-Cis executing an

acceleration or a decelerationramp. Thisoutput can be used to program the phase current level when

the motion is ramping at a level higherthan for the rest or slewing condition.

The ENABLE input pin allowsthe user to control the Step clock logic output to avoid the motorbeing

stepped if the previous step was not correctly executed. A ”zero” logic level appliedto this pin stops the

generation of the step pulses. Thisinput canbe used to stop the system when an emergency occurs,to

execute the motion according to externally generated timing, or to implementa closed loop control

system.

Not connected.

The DIR Direction selectionoutput isused to inform the Sequencer-Driveron the directionof rotation.

The logic level ”one” determines a clockwise rotation, but of course the rotationdepends on the motor

phases connectionto the Sequencer-Driver.

The RESET Power driver Reset output is brought to the ”zero” logic state for 400µs when the unit is

powered-on, or when the GS-C receivesthe ”Initialize position counter” command. Thisoutput is

normally used to assurethe correctstart-up of the Sequencer-Driver or any other external custom logic.

5/31

Page 6

GS-C200/ GS-C200S

Pin Function

The CLOCK Step clock output is used to informthe Sequencer-Driver to perform a step. The direction

28

30

31

32

33

34

35

36

37

38

(clockwise or counterclockwise) is defined by the logic status of the DIR output. In steady conditions, the

CLOCK is at the ”one” logic level, and the step is represented by a negative going pulsewith a 1.7µs

duration.

The HOME Home position input allowsthe systemto find itsreference point. This input can be driven by

a mechanically activated contact indicating the ”zero” position. It is normally used togetherwith the EOT

End-of-travel signal.

The UO1 User output 1 is intended for user purposes. Thestatus of this output can be set and cleared

under program control and it can be used forvarious functions. It is normally used for the control of

externaldevices, the selectionof the Sequencer-Driveroperating mode, or the synchronization of

complex movements.

The EOT End-of-travel inputallows, in combination with the HOME input, the correct mechanical

initialization of the system. For this purpose it must be brought to the ”zero” logic level when the system

reaches the run end position.

The U02 User output 2 is intended for user purposes. See pin 31 description.

The UI1 User input is intended for user purposes. The status of this input can be readby the Host

Computer or tested duringthe program execution, and used to condition the start of a movement,the

execution of a specific portion of a program (GS-C200S only), or any other similar operation.

The UO3 User output 3 is intended for user purposes. See pin 31 description.

The UI2 User input 2 input is intended for user purposes. See pin 34 description.

The UI3 User input 3 input is intended for user purposes. See pin 3 and pin4 description.

See pin 8.

Figure 2. GS-C Timing Diagram

6/31

Page 7

GS-C200/ GS-C200S

S.I.M.P.L.E. Interpreter Command and Functions

(SGS-THOMSONInteractive Stepper Motor Programming Language and Executor)

Command

Ax

Cx

Dxxx

E

F

f+/–xxxxxxx

G+/–xxxxxxx

g(+/–)

g(+/–)x

H(+/–)

Ix

jx

jcy,x

K

Lx

M

P

Po

Px

Q

Rxxx

Sxxx

Txxx

Ux

Vx

X

Wx

Z

+/–xxxxxx

Byte

Length

2

2

2

–

–

4

4

4

4

–

2

2

2

–

2

–

–

–

–

–

4

4

4

2

–

–

2

–

4

Function

Activate the specified(x) Useroutput.

Clear the specified (x) User output.

Delay for the specfied number (xxx) of tenth of second.

Startexecutingthe program currently stored into RAM memory.

Feedback the GS-C status (i.e.Ready orBusy).

Preset the position counter to the specifiedabsolute value (C200S).

Go to the specified target position(C200S).

Move the motor indefinitelyin the specified direction.

Move the motor in the specified directionuntil the specified(x) input is brought to zero.

Find Home position moving clockwise (+), or moving counterclockwise (–).

Initialize the position counter (x=1), the user outputs (x=2), or both (x=3).

Jump to memory location (x). Location (x)ranges between 0 and 118(C200S).

Jumpto memorylocation (x) if thebinaryvalue of the user inputs matches (y) value (C200S).

Kill the program inexecution.

Loop for the specified(x) number of times.

Transfer the RAM memory content to EEPROM.

Enter the programming mode (C200).

Enter the programming mode (C200S).

Exit the programming mode (C200S).

List to the host the program currently in RAM memory.

Set the Ramp length to the specified (xxx) value.

Set the start-stopspeed to the specified (xxx) value.

Set the slewrate speedto the specified (xxx) value.

Execute the program until the specified (x) user input isbrought to a low level.

Read back the current position (x=1) or the userI/O status (x=2).

Transferthe programfrom EEPROM to RAM.

Wait until the specified(x) user inputis raised to a logicone level.

Stop through a deceleration ramp.

Move clockwise (+) or counter-clockwise (–) for the specified (xxxxxx) number of steps.

7/31

Page 8

GS-C200/ GS-C200S

GS-C200 AND GS-C200SDESCRIPTION

The increasing popularity of microprocessors and

theirvery lowcost,havecontributed to afast growth

of stepper motors usage in a large numbers of

application previously covered by more complex,

bulk and expensive DC motors servo loops. The

GS-C200 and the GS-C200S modules have been

conceived to help the industrial designer in designing the stepper motor applications based on microprocessor control.

Thesemodules are programmable intelligentstepper motor controllers that coordinate highly complex movements and sequential operations. This

capability is performed through the integration of

sophisticated hardware and an easy to learn and

very functional and powerful programming language.

Thanks to this high level programming language,

the power of the instruction set and the ability to

condition an d cont r ol the program executi on

throughtheUSERinputsandoutputs,the GS-C200

and GS-C200S drastically reduce the design time

and start-up manufacturing phase of very complex

systems. The GS-C200S offers an advanced and

powerful instruction set that includes also the conditional jump which allows for more efficient program-ming. TheGS-C200,the GS-C200Sand their

companion modules, the GS-D200 and the GSD200S, can be used to drive in chopped mode of

bipolar stepper motor with a 2/2.5A maximum

phase current rating.

The two modules (GS-C and GS-D) are available

also on a single Eurocard board named respectively GS-DC200, GS-DC200S and GS-DC200SS

according to the variousmodules combination (see

the relevant data sheet). In the following the modules will be generically named GS-C. The specific

module part number will be used when the feature

is unique to that module.

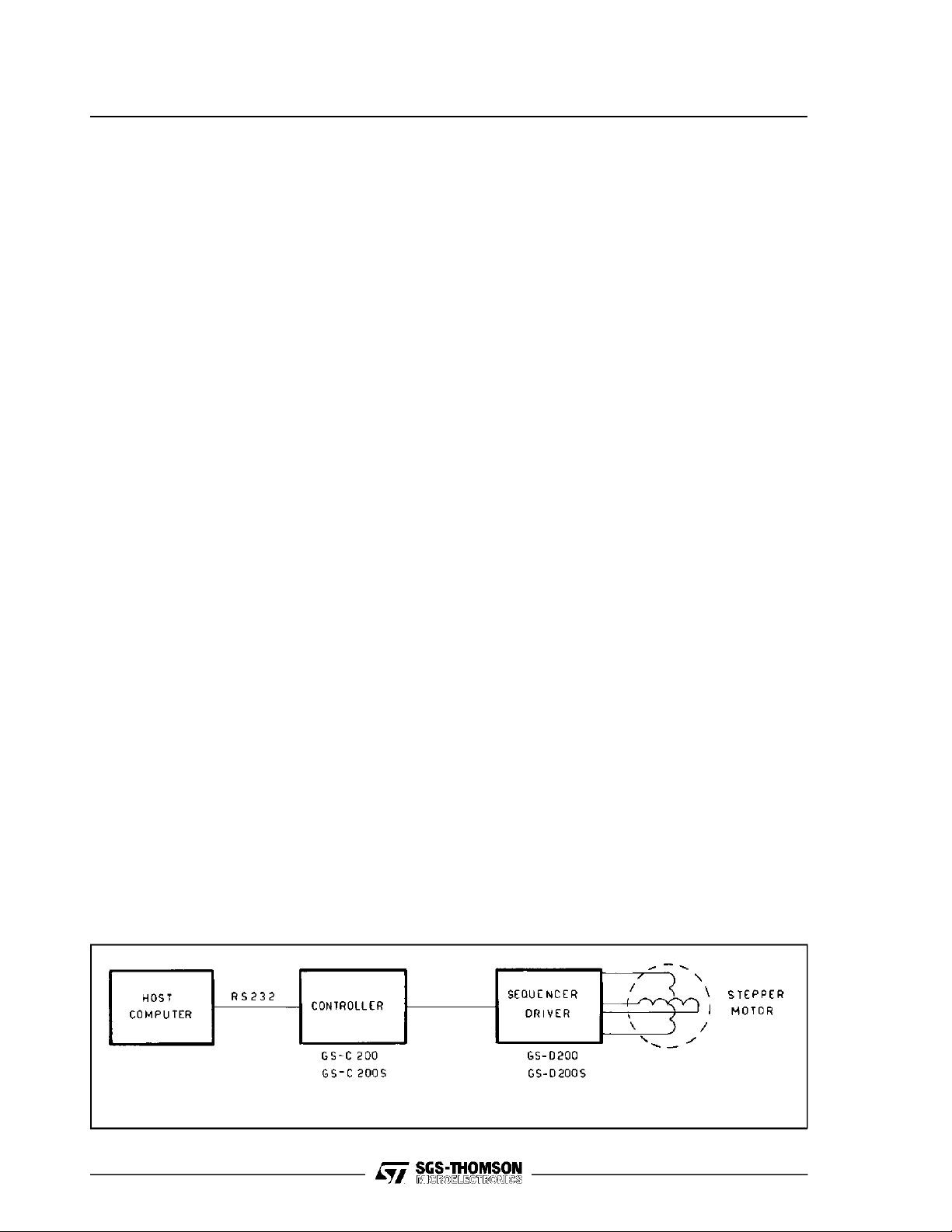

A MOTION SYSTEMARCHITECTURE

A complete motion system controlled by a host

computer is normally configuredas per fig. 3.

The GS-C logical and functional architecture is

shown in fig. 1 and it includes the following basic

blocks:

– Interface to the Host Computer via an RS232

communication port.

– Addressand baudrate selection.

– Interface to the Sequencer-Driver (in particular

but not exclusively, to the GS-D200 or GS-

D200S)via 5 outputand 3 input lines

– Command Interpreter and Executor.

– Program storage area

– Power Supply.

The above mentioned functions are performed by

the GS-Cwithout the addition of anyexternal component, and the module flexibility is further enhanced by the use of only one unregulated supply

voltage that can be the same used to supply the

Sequencer-Driver (from 12V up to 40V).

Commands are sent to the module bya Host Computer or by a simple video terminal during the

programming/debugging phase through an RS232

serial port. They are interpreted and validated by

the command interpreter and executed through the

Sequencer-Driver interface.

Command execution can be conditioned and controlled by the statusof the USER IN-OUTinterface.

Aprogram storagearea has been added to permanently store a program in an on-board EEPROM;

this is particulary beneficial to obtain a low cost

stand-alone controller that doesnot need any connection to an external computer or to store programs f requ ent ly used in complex motion

sequencies thus reducing the host computer burdenand speeding up the systemprocessing.

Particular attention hasbeen given to the simplicity

of the instruction setto allowan easydesign of the

system to those designers that are notvery familiar

with microprocessor software and programming.

In thefollowing a detailed description ofthe various

functional blocks is given.

Figure 3. A Motion System Block Diagram

8/31

Page 9

GS-C200/ GS-C200S

INTERFACE TO THE HOST COMPUTER AND

DATAPROTOCOL

The interface to the Host Computer is through an

RS232or V24 serial communication port.

Baud Rate Programming

The Baud rate is programmed between 110 and

9600 bit/secby using the BR0,BR1and BR2inputs

according to the following table:

BR0 (p4) BR1 (p5) BR2 (p6) Baud Rate

0 0 0 9600

1 0 0 4800

0 1 0 2400

1 1 0 1200

0 0 1 600

1 0 1 300

0 1 1 150

1 1 1 110

This settingis obtained byconnecting the pins 4,5,

and 6to ground (0 status) or by leaving themopen

(1 status). The communication port does not use

any control line but just the transmit and receive

signals. The host computer must handle the data

excange in the proper way.

Module Address Programming

The communication protocol can be either Point to

Point or Multipoint. In the first case a single communication line is required for each module, while

in the latter more than one module (up to seven)

can share the same communication line.

The Multipoint protocol as well as the peripheral

device address are selected through SEL0, SEL1

and SEL2 inputs. The Point-to-Point protocol is

selectedby connecting all the SELinputs to the 5V

outputpin (pin 20) or by leaving themopen.

The following table defines the protocol and the

address setting:

When the multipoint connection is chosen, the address ofeach module isobtained by connecting the

various SEL pin (1, 2, 3) to ground (0 status)or by

leaving them open (1 status).

The basic difference between the two protocols is

represented by the sytemwiring complexityandthe

data throughput. The Point-to-Point offers the

higher throughput data rate but it requires a connecting cable for each unit, while the Multipoint

minimizes the connecting cables but at reduced

throughput rate.When thislatterprotocolis chosen,

the command must always be preceeded by the

address of the unit.

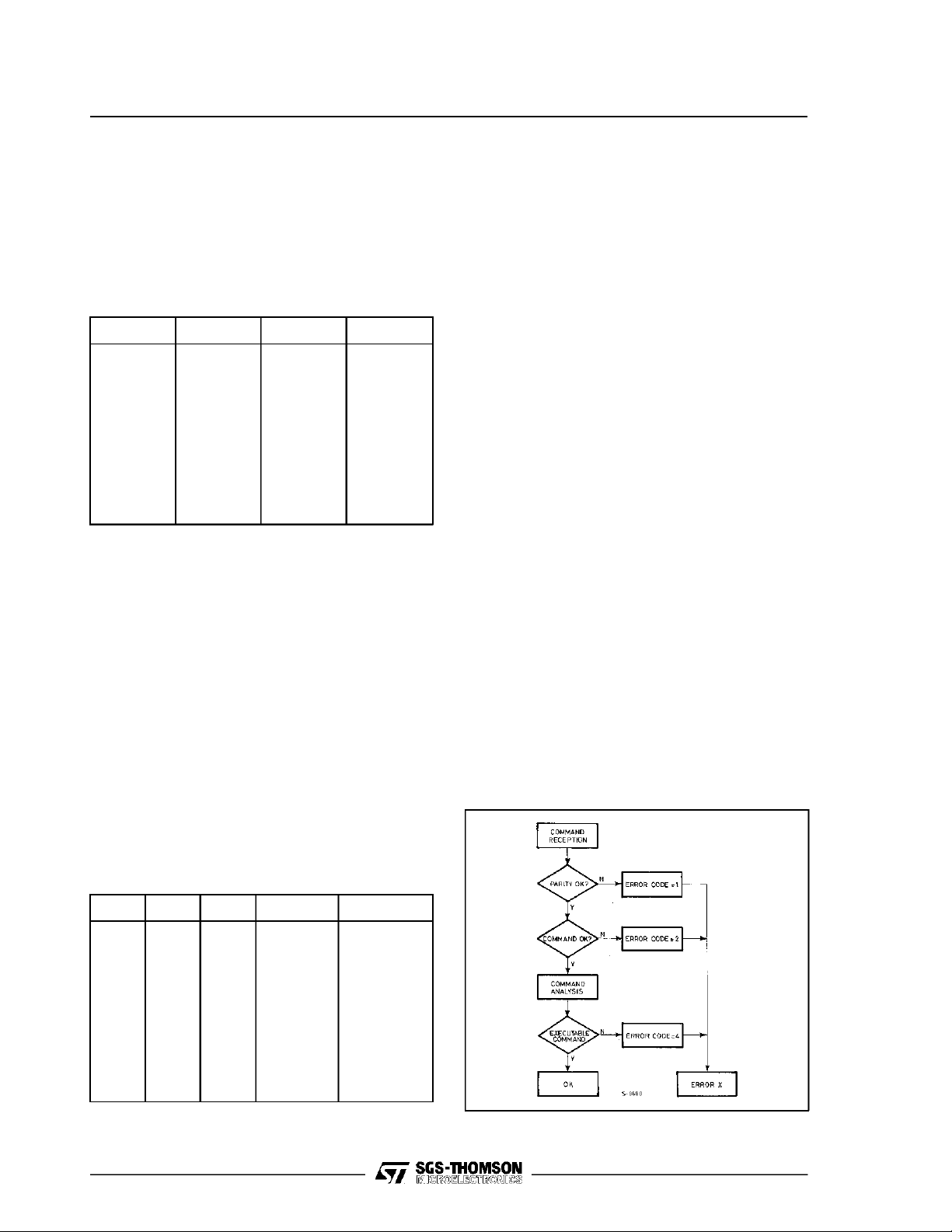

Data Exchange Protocol

The dialogue is always driven by the Host Computer which sends the string containing the command or the request to be implemented. The GS-C

module stores the instruction sent by the Host and

then it checks if the string has been correctly received by analyzing the parity bit. It then analyzes

the consistencyof the receivedinstructions by verifying the presence and correctness of the argument, andfinally,it checkswhether therequest can

be processed or not (for example, an attempt to

move outside the system limits, etc.) reporting to

the Host the analisysresult. If no error is detected,

the GS-C replies to the Host by a ”Y” message. In

case oferror, the messagewill be ”Error X” requesting the Hostto send themessage again orto modify

some parameters ofthepreviousmessageto fix the

error detected by the GS-C. The actual value of X

(see fig. 4 and error code table) gives the Host the

information on the type of detected error. The procedure implemented for the dialogue with the Host

is shownon the flowchart of fig. 4.

Figure4. Controller-Host Dialogue Flowchart.

SEL2 SEL1 SEL0 Address Protocol

0 0 0 7 Multipoint

1 0 0 6 Multipoint

0 1 0 5 Multipoint

1 1 0 4 Multipoint

0 0 1 3 Multipoint

1 0 1 2 Multipoint

0 1 1 1 Multipoint

1 1 1 – Point-to-Point

9/31

Page 10

GS-C200/ GS-C200S

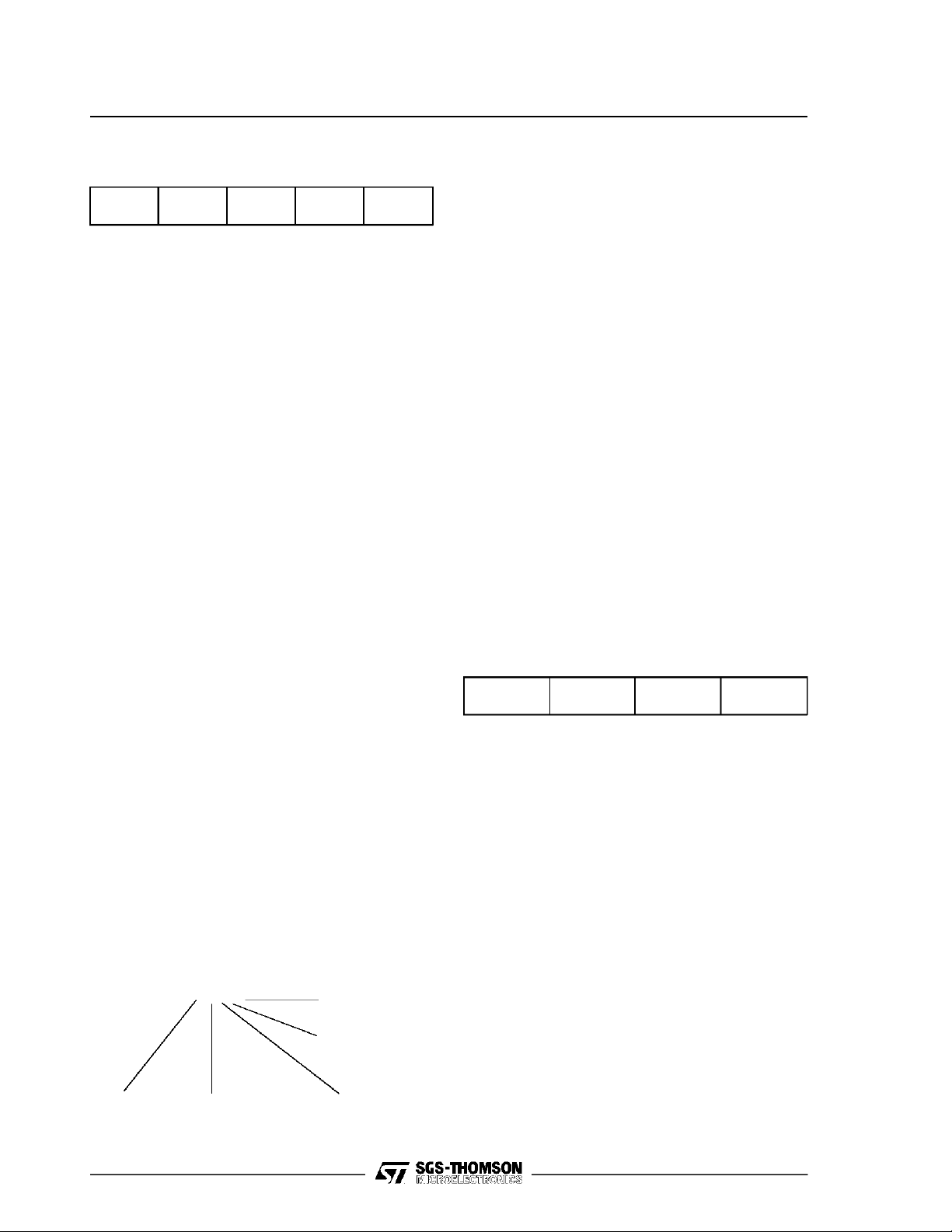

The general format of a command string is the

following:

ADDRE SS CO MMAND ARGU MENT CHEC KSU M CAR.RETURN

The Address must be the firsttransmitted characterand it is present only ifthe Multipoint protocol is

used (at least oneof SEL0, SEL1, SEL2 is different

from zero).

The Command is the second character(s) of the

string, inthe Multipoint protocol, but it becomes the

transmission opening character when the Point-toPointprotocol is used (SEL0, SEL1 and SEL2 = 0).

TheArgument, ifrequired,isspecified immediately

after the command and its length depends on the

command type.

The Checksum character verifies the correctness

of the received string; itsvalue isdetermined bythe

sum of the binary values of the preceding characters. Theresultiscut atthe seventhleast significant

bit and ORed with exadecimal 10 (C200S/C200

from V2.2) to make the result compatible with the

transmission system. The last character, the string

endingcharacter, is always aCarriage Return that

will be identified in thefollowing by thesymbol (↓).

By connecting the pin CHS (pin 7) to ground, the

checksum character isnot anymore requested, and

the task of guaranteeing the correctness of the

message is left to the parity bit. It should be noted

that by using thisdialogue mode, the data integrity

confidence level is reduced. Because motion systems normally operate in manufacturing premises

subjected to heavy electro-magnetic noise, and

because any communication problem may have

catastrophic effects on the system actions, it is a

good practice to use the checksumcharacter whenever possible. Thechecksum character is normally

not used (pin CHS connected to ground)when the

GS-C is connected to a video-terminal, i.e. during

the initial programming and debugging phase. In

the following, three examples of command strings

sent to a GS-C module are given.

Example 1 - MULTIPOINTPROTOCOL. The Host

Computer wants to set the USER output 3 of the

module #2. The command will have the following

format:

2A36↓

Carriage return

Checksum

Address

Module #2

Command

Activate

Argument

USERout 3

The checksum character 6 results from the binary

sum of the character 2 (ASCII value = 32) + character A (ASCII value = 41) + character 3 (ASCII

value = 33) truncated at the seventh bit.

Example 2 - POINT-TO-POINTPROTOCOL.

The same instructionis given bythe Hostto aPoint

to Point connected module.

The command will have the following format:

A3t↓

The checksum character has an ASCII value t that

derivesfrom the sum ofthe ASCII code A+3=41+33

= 74 in binary weighted code or t inASCIIcode.

Example 3 - POINT-TO-POINT PROTOCO L

WITHOUT CHECKSUM.

For the same instruction, the command format will

be:

A3↓

The stringconsists ofcommand and argument only.

The GS-Cfeeds backinformation to the Host every

time it receives a command, therefore it has not to

identify itself to the Host when answering in a

Multipoint connection.

The formatof thestring answered backbythe GS-C

is the following:

ANSW .CODE ARG UMENT CHECK SUM CAR.RETUR N

The first character, which always identifies the answer type,may assume oneof thefollowing values:

Y The command string has been correctly

received.

B The controller is Busy and cannot process

commands.

R The controller is Ready to process commands.

E An error has been detected. The type of error

is specifiedby the number following the ”E”.

V A controller status (a position or an USER

input/output status) is sent back and its value

is specifiedby the characters following the ”V”.

The lengthofthe Argument, presentonly for”E” and

”V” answers, can range between 1 and 7 characters, and it is a function of the received command.

The number following the ”E” code, i.e. the error

argument, specifies the detectederror typeaccording to the followingtable:

10/31

Page 11

GS-C200/ GS-C200S

Error code Type of error

1

2

3

4

5

6

Parity error when receiving one or more

characters, checksum error, or too longa

command string.

Command argument out of limit or not

requested.

Storage capacity overflow.

Not allowedor not executable command.

Overflow errorduring program execution

(GS-C200only).

EEPROM programming error.

The number following the ”V” code depends onthe

type of the received command.

When the GS-C answers to a ”V1” request (feedback theactual absolute position against the Home

position), the answer willbe:

Vxxxxxxx↓

where the xxxxxxxrepresent the absolute position.

When the GS-C answers to a ”V2” request (feed-

backthe USERinput/output status),the answer will

be:

Vxy↓

where thex and y meaning is:

x = 1 User Input 1 = 1

x = 2 User Input 2 = 1

x = 4 User Input 3 = 1

y = 1 User Output1 = 1

y = 2 User Output 2 = 1

x = 4 User Output 3 = 1

The logic values of the inputs and outputs are

added together. Forexample theanswer:

V36↓

indicates the following USER I/O status:

UI1 = 1 UO1 = 0

UI2 = 1 UO2 = 1

UI3 = 0 UO1 = 1

36

THE SEQUENCER-DRIVER INTERFACE

The interfaceto theSequencer-Driver and,through

it, to the mechanical environment, consists of eight

logic signals (5 outputs and 3 inputs)which enable

the GS-C intelligent controller to interface the GSD200 or the GS-D200S modules as well as any

Sequencer Drivers currently available. The eight

signals can be divided into two groups, named

respectively:

PRIMARY SIGNALS

UTILITYSIGNALS

The primary signals are those necessary for the

correct system operation:

RESET Output to reset the Sequencer-

Driver.

CLOCK Step clock output.

DIR Direction output.

ENABLE Step enable input.

The functionof each signal is described indetail in

section PIN DESCRIPTION onpage 4/31; it will be

shown later that the Step Enable Input in conjunction withthe position sensorof the motor, allowsthe

implementation of closed loop systems (see paragraph Closed Loop Operation on pag. 27). The

Utility signals allow the optimization of the driving

system and theminimization ofthe hardware. They

are:

MOV Movementin execution output.

RAMP Ramp in execution output.

EOT Mechanical Endof Travel input.

HOME Electrical Home Position input.

By using these signals it is possible to correctly

define the system starting point or reference position, orto change the current in the motor windings

during the acceleration and deceleration phases in

order to optimize the motor performance.

Atypicalexample of theutility signalsimplementation is given here. Let’s suppose that the required

speed profile is as shown in fig. 5.

Figure 5. Speed-Time Profile.

Thepresence ofChecksum character,whose value

is calculated by using the method described in the

previous example, is conditioned by the CHS pin

status.

When CHS is grounded (either by a logic signal or

by a strap to ground) the checksum is deleted.

The string terminator is, as in the previous case, a

Carriage Return.

11/31

Page 12

GS-C200/ GS-C200S

To optimize the motor torque during the acceleration and deceleration (t1and t3) it is convenient to

use a phase current profile as shown in fig. 6.

Duringthe SLEWphase (t2) whenthe motor rotates

at constant speed, the current is reduced to the

minimum value necessary to compensate the system losses (friction)and theload inertia. During the

STALL phase (t0and t4) the current is further reduced to the bare value necessary to maintain the

load in the right mechanical position.By using this

current profile the power dissipation of the Sequencer-Driver and motor isoptimized.

This profile can easily be implementedby usingthe

utility signals:

MOV Movement in execution.

RAMP Ramp in execution.

Figure 6. Phase Current-Time Profile.

The statusof these two outputs can be used to set

the appropriate phase current value for the power

driver, by a simple but effectiveinterface circuitthat

is described in detail in fig.11of paragraph PHASE

CURRENTPROGRAMMING on page 24.

THEUSER INTERFACE

The USER interface consists of three inputs and

three outputs which are TTL compatible. They can

be read and/or activated during the execution of a

program under the complete usercontrol; therefore

they condition a program execution.

Thesesignals allow the implementation ofcomplex

movements,minimizingthe programlengthand the

useof external hardware. The start of amovement

or ofasequence can be conditioned by alogic level

applied to one or more inputs, thus performing the

”mechanical tree” function.

The USER outputs logic state is set by program

instructions and this information can be used by

other controllers to synchronize multiple movements or to controlexternal drivers.

By using only these signals, it is possible to build

up simple systems which implement cyclic movements and create a true stand-alone system. The

example reported in figure 7 shows one of the

possible utilization of USER output. The example

Figure 7. USER Output Applicative Example

refers to a complete motion control system implemented by using the GS-C200 controller and the

GS-D200 Sequencer-Driver. The USER output

UO1 is used to enable the GS-D200(UO1 High) or

to inhibit it (UO1 Low).

The USER output UO2 is used to select themotor

current decay inherent to the chop mode control of

GS-D200. When UO2 is high a slow decay is imposed to the phase current during recirculation;

when UO2is low a fast decay is selected.

The USERoutputUO3allowsthe selectionbetween

the half and full-step mode of operation of the

GS-D200. Half-step occurs when UO3 is high.

The GS-C200S is capable of executing a jump

command either direct or conditioned by the logic

status of the USER inputs. This capability is very

useful because it allows complex programs to be

writtenby usinga limitednumber ofinstructions.This

feature makes also possible to have a segmented

program contained inthe internal memory; the selection and the subsequent execution of the needed

program segmentis started by aspecificlogic status

applied to the USERinputs.

THE S.I.M.P.L.E. COMMAND INTERPRETER

AND EXECUTOR AND THE PROGRAMMING

LANGUAGE

The GS-C modules contain an interpreter program

named S.I.M.P.L.E., acronym for SGS-THOMSON

Interactive Stepper Motor Program Language and

Executor, that recognizes simple mnemonic com-

mands, verifies thecorrectness of the received commandsandexecutes the instruction sequences ofeach

command or acomplete command sequence by translation into complex executable instructions. The interpreter recognizesthreedifferent types ofcommands:

DIRECT EXECUTION COMMAND

DELAYEDEXECUTION COMMAND

UTILITY COMMANDS

12/31

Page 13

GS-C200/ GS-C200S

Direct execution commands are immediately actuated. They include: start and stop the program

execution, set the programming mode, checkposition, check I/O,etc...

Delayed execution commands are run when requested by thesequence currently storedin memory. By using a combination of these commands, it

is possible to perform very complex movements

includingalso the conditioningby external stimulus,

the iteration of a specific sequence for a defined

number of times.

Utility commands allow the GS-C modules to performseveral additional functionssuch as the detection oftheposition, phase current optimization etc...

These commands, when properly used, speed up

the systemdebugging phase andthey increase the

system efficiency.

Note: To easily learn how to program the GS-C and to minimize

development time, a P.C.based self explaining and interactiveprogram named F.A.S.T. (First Advanced Stepper motor Training pro-

gram), abl e to comm unicate with the module by using the

Point-to-Pointprotocol, has been developed and itis availableto the

end user. (See GS-C200PROG datasheet).

Command strings can be easily implemented also

by using a high level language such as BASIC, or

they canbe generated by adedicated microcontroller programmed in machine language. The dialogue speed is limited by the time required to

construct the command string and to analyze the

GS-C data, andit results noticeabily reduced when

a ”machine language” program is used.

The program, after testing, can be stored in the

EEPROM included in the GS-C module and then

loaded and automatically executed at power-up,

resultingin a low cost stand-alone system.It is also

possible to save the program as a DOS file on a

floppy disk for future retrieval, or to ease the field

update of the program itself.

Every command is identified by one or two charactersandby a variable length argument (from 0to 7

characters). If the Multipoint communication protocol is used, the address is specified by the number

that preceeds the command. All the commands

sent by the Host, aswell as the data generated by

the GS-C, are terminated by a Carriage Return

(ASCII value = 0D).

In the following pagesall thecommandswhich may

be executed by the GS-C200 and the GS-C200S

are detailed, as well as their format. A practical

example of the command usage is also given. The

presence of anasterisk at the end of the command

denotes that the command is executable only by

the GC-C200, while two asterisk denote a command executed only by the GS-C200S.

Each command is shown in the same format used

during the programming phase, i.e. the command

identifier plus the argument:

Gsxxxxxxx

The argument can be single, double or missing

according to thevarious command types.

The various argument are identified by different

letters according to the particular type i.e.:

s = sign + or –

x = figure 1 to 3

y = figure 0 to 7

v = value 1to999depending oncommand

p = position 1to 999999 incremental or the

absolute position

Apart the different number of executable commands and functions, the GS-C200S and the GSC200 look very similar each other. The only

foundamental difference is the way they manage

the position counter.

The position counter is the reference ruler for the

microprocessor to move correctly from the actual

position to the targeted one, executing the proper

number of steps in the right direction.

The GS-C200 position counter allows a maximum

of ten million steps to be executed, and the home

position corresponds to the 0count position. When

a movement is larger than the position ruler limits

an Error 5 is reported to the Host.

The GS-C200Sposition counter allows amaximum

total count of 224step ranging from –8388608 to

+8388607 steps. When the maximum count is exceeded the counter wraps-around. For example if

the position counter is +8388606 and a +5 steps

movement is executed, the final position will be:

+8388606 Initial position

+8388607 After 1 step execution

–8388608 After 2 stepsexecution

–8388607 After 3 stepsexecution

–8388606 After 4 stepsexecution

–8388605 Final position

Of course no error isreported.

13/31

Page 14

GS-C200/ GS-C200S

Command Description

Ax

TheActivate command sets a User output to the active logic level ”one”.

The commandis always followedby an argument whose value ranges between 1 and 3, and that

specifies the User output to be activated. The commandstring:

A2↓

causes the UO2 output to be set to the logic level ”one”.

TheActivate command is of the delayed execution type and it occupies 2 memorylocations.

Cx TheClear command clears a User output, i.e it forces the logiclevel to ”zero”.

Dvvv The Delay command allows the execution of a delay.

E TheExecute command starts the execution of the program stored in memory.

F

The commandis always followedby an argument whose value ranges between 1 and 3, and that

specifies the User output to be cleared.

The commandstring:

C3↓

cleares the UO3 output by forcing it to the logic level ”zero”.

The three USER outputs are automatically cleared at power-up.

The Clear command is of the delayed execution type and it occupies 2 memory locations.

The instruction is always followed by an argumentwhose value ranges between 1 and 255, and that

specifies the duration in tenth of sec. of the delay to be executed.

The commandstring:

D15↓

causes a 1.5 seconds delay to be executed before the next instruction is considered.

TheDelay command is of the delayedexecution type and it occupies2 memory locations.

It is also used to terminate the GS-C200 programmingsession and no argument is required.

TheExecute command isof the immediateexecution type.

TheFeedback command allows the host computer to know whether the controlleris ready to

receive a command or not. Tocomply with this request, the GS-C repliesby:

B↓ (Busy)

in case it isexecuting a program, or:

R↓ (Ready)

if it is ready to receivea command, or:

E5↓ (Error)

This latter answer, used only by the GS-C200, indicates that duringthe program execution the

position counter has reachedthe overflow condition (i.e. > 9999999).

The feedback command is of the immediateexecution type.

fsxxxxxxx** Theforce command, executable only by the GS-C200S, allows the user to preset the position

Gxxxxxxx* TheGoto command forces the motor to reach the specified target position.

14/31

counter to the desiredvalue.

This command is always followed by the signand the value of the position that spans from

– 8388608 to + 8388607.

Theforce command isof the delayed/immediate execution type and itoccupies 4 memory

locations.

This command, executed exclusively by the GS-C200, is always followed by an argument whose

value ranges between 0 and 9999999, and it defines the position to be reached.

The 0 position coincides with the Home position or with the positionwhere an Initializecommand

has been sent.

TheGoto command isof the delayed execution type and it occupies 4 memory locations.

Page 15

Command Description

Gs *

The ”velocity mode” Goto command allows to move the motor continuously, i.e. the motor is

accelerated to the programmed speed and then it slews indefinitely inthe selected direction until a

”stop” command is received.

The commandis always followedby the direction information.

The commandstring:

G+↓

move the motor in the clockwise direction while:

G–↓

move the motor in the counterclockwise direction. Tostop the motoreither the Z or the K command

can be used.

The ”velocity mode” Goto command isof the delayedexecution type and itoccupies 4 memory

locations.

GS-C200/ GS-C200S

Gsx * A further possibility offeredby the Goto command, that greatly improves the GS-C200flexibility, is

Gsxxxxxxx** The Goto command forcesthe motor to reach the specified target position.

gs **

the ”controlledvelocity mode” operation.

This command is followedby the direction information and by the User input to be tested to stop the

operation.

This occurs when a ”zero” level is applied to the specifiedUser input. For example the command

string:

G+2↓

causes the motor to ramp to the programmed slew speed and to move at this speeduntil the UI2

input is brought to ”zero”.

The ”controlledvelocity mode” Goto command is of the delayed execution type and itoccupies 4

memory locations.

This command, executed exclusively by the GS-C200S,is always followed by an argument whose

value ranges from – 8388608 and + 8388607, and it defines the position to be reached.

The 0 position coincides with the Home position or with the positionwhere an Initializecommand

has been sent.

TheGoto command isof the delayed execution type and it occupies 4 memory locations.

The ”velocity mode” Goto command allows to move the motor continuously, i. e. the motoris

accelerated to the programmed speed and then it slews indefinitely inthe selected direction until a

”stop” command is received.

g+1↓

move the motor in the clockwise direction while:

g–↓

move the motor in the counterclockwise direction.

Tostop the motor either the Z orthe K command canbe used.

The ”velocity mode” Goto command is of the delayed execution type and it occupies 4 memory

locations.

gsx ** An additionalpossibility offered by the Gotocommand, further improving the GS-C200S flexibility, is

the ”controlledvelocity mode” operation.

This command is followedby the direction information and by the User input to be tested to stop the

operation.

This occurs when a ”zero” level is applied to the specifiedUser input. For example the command

string:

gt1↓

causes the motor to ramp to the programmed slew speed and to move at this speeduntil the UI1

input is brought to ”zero”.

The ”controlledvelocity mode” Goto command is of the delayed execution type and itoccupies 4

memory locations.

15/31

Page 16

GS-C200/ GS-C200S

Command Description

Hs

TheHome command allows the GS-C to find the mechanical reference position.

The commandis followedby the argument that specifies the searching directionof the End Of

Travel switch.

The argument can be omitted and in such a casethe GS-C willexecute the command:

H+↓

As soon as the GS-Creceives the Home command, it moves the motorin the selected direction at

the Start-Stop speed (definedas the first instruction at the beginning of the program) until the End

Of Travel input is brought to ”zero”. When thiscondition is reached the direction is reversed and the

movement continues until the Homeinput reaches the ”zero” logical level. The position counter is

then cleared as well as the program contained inthe RAM memory, and the controller is ready to

process a new command.In the GS-C200S, the position is also cleared, but the previousprogram,

present in the RAM is saved. Whenthe Home and the End Of Travel inputs are tied toghether the

system reference point will correspondto the End Of Travel position.

Toallow the system homing also in a standalone application, an Home command is automatically

executed at start-up after the program recall. The Home direction isdefined by the logic state of the

RxD input(pin 11)that when unconnected is equivalent to a H+ command, while when connectedto

the +5V pin it forces a H– command. In a stand-alone environment, when the Home command is

not needed, it is mandatory to ground the End od Travel and the Home inputs (pins 32and 30). The

Home command is of the immediateexecution type.

Ix The Initialize commandforces the GS-C module to be selectively inizialized.

jv **

jcv,y**

The commandis followedby an argument whosevalue ranges between 1 and 3, and that specifies

where the action is addressed according to the following table:

1 = Position counter is cleared

2 = User outputs are cleared

3 = Position counter and User outputs are cleared.

TheInitialize command is used to create a logic Home positionfor the GS-C200if the 9999999

steps are not enough for the specificapplication. This function is better performed by the force

command in the GS-C200S, for whichit isalso possible to insert this command into the program.

TheInitialize command is of the immediateexecution type for the GS-C200, while it results of the

delayed/immediate execution type for the GS-C200S and it occupies 2 memory locations.

Thejump command, executed only by the GS-C200S, allows the user to move insidethe program

and to repeat indefinitelya portion of the program itself.

The argument specifies the memory locationto be reachedand it rangesfrom 0 (that is the program

starting point) to 118.

Thejump command is of the delayed execution type and it occupies 2 memory locations.

Theconditional jump command, executed only by the GS-C200S module, allowsthe user to move

inside the program as a function of the logicstate of the Userinputs.

The argument specifies both the memory location to be reached (v), that must range between 0 and

118,and the User input condition to be matched (y) in orderto execute the conditional jump.

The followingexample shows how powerful this command is:

jc0,40↓

jc1,52↓

jc2,74↓

When the first command is encountered the moduletests the status of the User input pins and if

theirvalue is 0 a jump to the memory location 40 isexecuted. If the condition is not met the jump is

not executed and the following instruction is examined, and soon.

Theconditional jump command is of the delayedexecution type and it occupies 2 memory

locations.

K TheKill command aborts the programexecution.

16/31

The program can be restarted just by issuing the Execute instruction which will startthe sequence

from the first program instructionand not from the interrupt point; it istherefore advisable to always

send a Home instruction after a Kill instruction inorder to allowthe system to start from a known

position.

TheKill command is of the immediateexecution type.

Page 17

Command Description

Lo

Lxxx

TheLoop start command marksthe memory location wherethe portion of a repeatedlyexecuted

command sequence begins.

This command is normally used togetherwith the Loop repetition number command.

TheLoop start command is of the delayed execution type and it occupies 2 memory locations.

TheLoop repetition number command allows an instruction,a sequence or a whole program to

be repeated for the specified numberof times.

The command must be followedby an argument ranging from 1 to 255, that specifies how many

timesthe portion of the programcontained between the Loop start commandand the Loop

repetition number has to be executed.

The sequence:

L0↓

•

•

•

L10↓

forces the command sequence included between L0 and L10 to be repeated ten times.

This command in normally used togheter with the Loop start command. If the loop starting point is

not specified, the interpreter repeats the sequence starting from the beginningof the program.

TheLoop repetition number command is of the delayedexecution type and it occupies 2 memory

locations.

GS-C200/ GS-C200S

M The Memory save command allows the programcurrently stored in the RAM memory to be

P* TheProgram enter command sets the GS-C200 in the programming mode and it allows a new

Po ** The Program enter command sets the GS-C200Sin the programmingmode and it allows a new

Px ** TheProgram exit command sets the GS-C200Sin the execution mode and it allowsthe unitto

Q TheQuery command instructsthe GS-Cto send to the Host computer the program currentlystored

permanently saved in the EEPROM.

The program can then be reloaded both automatically or under command.In the first case, it is

executed automatically at power on, while in the latterthe X command mustbe issued.

TheMemory save command is of the immediateexecution type.

program to be entered in the memory.

The instruction doesn’t requireany argument and it causes the cancellationof the program

contained inthe RAM memory

The programming session isterminated by theExecute command. The Program enter command

is of the immediateexecution type.

program to be entered in the memory.The instruction doesn’t require any argument and it causes

the cancellation of the programcontained in the RAM memory.

The programming session isterminated either by theprogram exit or the Execute command.

TheProgram enter command isof the immediateexecution type.

wait for a command. The instruction doesn’t require any argument. TheProgram exit command is

of the immediate execution type.

in the RAM memory.

Every program instruction isseparated by a carriage return(ASCII 13), and the program end is

evidenced by the transmission of a message”END” that is the sequence terminatorand it must be

recognized by the Host. The instruction does not requireany argument. The Query command is of

the immediateexecution type.

17/31

Page 18

GS-C200/ GS-C200S

Command Description

Rvvv

Svvv

TheRamp command allowsthe user to define the length of the acceleration and deceleration

ramps that are always identical.

The commandis followedby an argument whosevalue ranges from 1 to 999 and it determines the

number of steps necessary to pass from the Start-Stop speed to Slew speed. The instruction:

R50↓

specifies an acceleration or deceleration ramp 50 steps long. When the number of stepsto be

executed is lower than the length of the two ramps(acceleration and deceleration),the ramping is

reversed before the maximum speed is reachedto guaranteethe correctness of the final position.

More than one ramp length can be used during the program execution just by introducingan R

command in the proper sequence place.

R25↓

3000↓

•

•

R85↓

–800↓

•

This program executes a 25 steps ramplength forthe movements until the R85 command is

encountered; from that moment all the movements are executed with a 85 steps ramp length.

This feature allows the user to optimize the motionsystem to adapt for different friction and load

conditions. TheRamp command isof the delayed execution type and it occupies 4 memory

locations.

TheStart-Stop command allows the user to choose the step rateat which the motion isstarted.

The commandis always followedby an argument whose value ranges between 1 and 1000 and it

corresponds to a Start-Stop step rate of 10 to 10,000 steps/second (a by 10 multiplier is used).

The range normallyused is from1 to 50 corresponding to a 10 to 500 steps/second rate.

The command:

S30↓

indicates a 300 step/secor 300Hz Start-Stop frequency.

A Start-Stop command must initiate any programto beexecuted in standalone environment.

More than one Start-Stop rate canbe used duringthe program execution justby introducinga new

Start-Stop command when needed, asshown in the following program sequence:

S20↓

•

•

•

•

TheStart-Stop command is of the delayed execution type and it occupies 4 memory locations.

Tvvv TheTop-speed command allows the user to choose the motion system Slew speed.

The commandis always followedby an argument whose value ranges between 1 and 1000 that

correspond to a Top-speed step rate of 10 to 10000 steps/second (aby 10 multiplieris used).

The range normallyused is from30 to 500, corresponding to a 300 to 5000 steps/second rate.

The command:

indicates a 3000 steps/sec or 3kHz rate (equivalent to 900 turns/minute for a motor with200

steps/turn).

More than one Top-speedrate can be used during the programexecution just by introducinga new

Top-speed command inthe proper sequence place as per the example reported in the Start-stop

speed command description.

TheTop-speed command is of the delayed execution type and it occupies 4 memory locations.

T200↓

S35↓

T300↓

T300

18/31

Page 19

Command Description

Ux

The Until command allows the program currently stored inRAM memory to be continuously executed until a specificUSER input is brought to ”zero”.

The command is always followed by an argumentwhosevalue ranges between 1 and 3, and it

specifies the User input to be tested. Thecommand:

U2↓

states that the program, once started,will be continuously executed as long as the User inputUI2 is

at the logic level ”one”.

Just after User InputUI2 is set to ”zero”, the program processesthe next command after U2. The

Until command is of the delayed execution type and itoccupies 2 memory locations.

GS-C200/ GS-C200S

Vx The Verify command allows the Hostto know the current absoluteposition of the motorversusthe

Home position or the statusof the USER inputsand outputs.

The instruction is always followed by an argument whose value, 1 or 2, specifiesthe type of

requested information. The requestfor thecurrent absolute positionis obtained by issuing the

instruction:

V1↓

the GC-C200 answer can be

1234567↓

while the GS-C200S answer can be:

+1234↓

The request of the USER outputs status is obtained by using the instruction:

V2↓

the GS-C answer can be:

25↓

that denotes the followingInput/Output status:

UI1 = 0 UO1 = 1

UI2 = 1 UO2 = 0

UI3 = 0 UO1 = 1

25

The Verify command is of the immediate execution type.

X The eXchange command allowsthe user to transferthe program currently stored in the EEPROM

Wx The Wait-for command allowsthe programstart or a portion of programexecution to be

into the RAM.

This command is used either during the programdebugging phase when the F.A.S.T.program is

utilized, or when the fast execution of a frequently used program isneeded.

In this latter case the Host recalls the program from the EEPROM by simply issuing the following

command string:

E↓

X↓

The eXchange command isof the immediateexecution type.

conditioned by the risingedge of an external signal applied to the a USER input. Thecommand is

always followedby an argumentwhose value ranges between 1 and 3, and it specifies the User

input to be tested in order to conditionsthe next commandexecution. The instruction:

W2↓

states that the programexecution is conditionedby the presence of a ”one” logic level at the User

Input UI2. TheWait-for command is of the delayed execution type and it occupies 2 memorylocations.

19/31

Page 20

GS-C200/ GS-C200S

Command Description

Z

TheZero the speed command allowsa smoothstop of the motionsystem.

When the GS-C receivesthis command it reduces the stepping rate to ”zero” through a deceleration

ramp and it stops the programexecution. If there is no motion when activated, the program

execution is immediately stopped. By usingthis command it is possible to stop the motor still

maintaining traceof thesystem position.

The program can be subsequentely restartedthrough an E command.

±xxxxxx The incremental positioning command allows the user to performa movement referenced to the

During the program execution, the GS-C accepts

only theF,Z and Kcommands.Any othercommand

sentto the GS-C during the program execution has

no effect, and the module will respond to the Host

Computer by sending the answerB (Busy).

The GS-C200S programming requires a specific

attentionbecause,whena program includesajump

command, it is mandatory to address the proper

memory positiontocorrectly execute the sequence.

For this purpose it is mandatory to define the jump

memory location by adding, for each program instruction, the proper bytes length that is specified

in the command description. The program starts

from memory address 0.

THEPROGRAM STORAGEAREA

The GS-C contains two storage areas reserved to

the User. The first is the microprocessor Random

AccessMemory from where the motion program is

executed, the second is an EEPROM where the

programs are saved. The EEPROM contains a

program or a command sequence programmed by

the user that can be transferred into the RAM

memory by using the X command.

The RAM contains either a programor a command

sequence sentby the Host computer ortransferred

from the EEPROM. In anycase the programthat is

executed when an E or Goto command is issued.

is the one contained in the RAM.

If the program is sent by the Host, it ischecked to

verify if the logical and physical correctness has

been respected and if the storage capability is not

exceeded.In case an error isdetected, it is notified

to theHost throughan appropriated error message.

The number of instructions that can be stored depends on the type of instruction, and typically it

ranges between 30 and 60, fora total of 119memory locations.

actual position. The command can be issued either with a + or – sign that defines the directionof

the motion, and it is followed by an argument ranging from 1 and 999999 that defines the numberof

steps to beexecuted.

TheIncremental position command can be mixed to the Goto absolute positioning command in a

program, and it is normallyused in a subroutine.

TheIncremental positioncommand is of the delayedexecution type and it occupies 4 memory

locations.

THE POWER SUPPLY

The GS-Cmodule containsa high efficiency switch

mode power supply. It generates thevarious regulated voltages required for the proper operation of

the internallogic and thecommunication port, starting from an unregulated input voltage that can

range from12 to 40 Volt. The module also features

a 5V output capable of delivering up to 100mA,

which can beused to supplyexternal devices orthe

logic port of a GS-D module. This output is protected against short circuit to ground. Two outputs

at ±12V are available with a current capacity of

10mA.

PROGRAM EXAMPLES

After the descriptionof thecommunication protocol,

of the various commands and of the various messages, some simpleprograms examples are given

in the following.

Example 1

The required action is to run a motor at 1000

steps/sec. rate, with a start-stop rate of 100

steps/sec., and a ramp length of 50 steps. The

target position tobe reached is the step 500000.

The operative sequence is the following:

1) Connect the GS-C200 to an Host Computer

equipped with theadvanced Basic program.

2) Power-on the GS-C200.

3) Enter the DOS operating system and then run

the F.A.S.T. program (see the GS-C200PROG

datasheet).

4) Start the programming session by typing the

following command sequence:

F↓ Read the controller status.

AReady isansweredby the GS-C.

I3↓ Clear theposition counter and the

USERoutputs.

20/31

Page 21

GS-C200/ GS-C200S

P↓ Enter the programming mode

S10↓ Set the Start-stop rate to 100

steps/sec.

T100↓ Set the Slew speed rate to 1000

steps/sec.

R50↓ Set the Ramp length to 50 steps.

G500000↓ Goto the target position

E↓ Endof the programming session.

The GS-Cstarts theprogram exe-

cution.

The G500000 command can be substituted by the

+500000 command. The program can also be

stored in the GS-C EEPROM by typing an M↓

command before the E↓ command.

Example 2

The program chosen for thisexample drills5 equidistant holes on a metal bar. A GS-C and GS-D

motion system is used to control the vertical position of the drill, while a second GS-C and GS-D

motion system is used for the proper bar loading

and positioning. To better clarify the operations to

be executedand to showthe program simplicity, the

two command sequencesand the relative process

flowcharts are also reported.

The programming session is entered following the

points 1 to 4 of the previous example. The first

command sequence, used to correctly position the

metal bar, is the following:

S10↓ Set theStart-stop speedto100steps/sec

T100↓ Setthe Slew speed to 1000 steps/sec

R40↓ Set the ramp length to 40 steps

W1↓ Wait for the external Start

+250↓ Reachthe first drilling position

L0↓ Loop starting point

A2↓ Activate the unit 2 forcing UO2 = 1

D1↓ Wait0.1 sec

C2↓ Then reset UO2

W2↓ Waituntil drilling completion

+120↓ Reachthe drillingposition 120 steps CW

L4↓ Repeat the loop 4 times

A2↓ Activatethe unit 2 forcingUO2 = 1

C2↓ Then reset UO2

W2↓ Waituntil drilling completion

+250↓ Reach thecuttingposition 250 stepsCW

A1↓ Activatethe cutting blade forcing UO1 =1

D5↓ Wait0.5 sec

C1↓ Clear cutting command resetting UO1

The second command sequence, used to drill the

metal bar, is the following:

S15↓ Set the Start-stop rate to 150 steps/sec

T200↓ Setthe Slew rate to 200 steps/sec

R25↓ Set the Ramp length to 25 steps

W1↓ Wait for start

W2↓ Wait fora drilling command from unit 1

A2↓ Activate the drill motor forcingUO2 = 1

+150↓ Pulldown the drill

D1↓ Wait0.1 sec

G0↓ Lift the drill up

C2↓ Stop the drillmotor

A1↓ Notify drilling completion to unit 1forcing

UO1 = 1

D1↓ Wait0.1 sec

C1↓ Then clear UO1

The combination of these two programs operates

only on one bar, then the two GS-C become available again to the Host both forthe repetition of the

program or for the entering of a new command

sequence.

If the operation has to be repeated till the exhaustion of bars, it will be sufficient to add, at the

beginning of the first sequence, the command;

U3↓ execute until UI3 = 1

which allows the drilling cycle to continue until the

controller which takes care ofthe bar positioning, is

notified to stop the operations.

This notification is accomplished by clearing the

User input UI3 of GS-C devoted to the positioning.

Todemonstrate the efficiencyoftheGS-C programming language it is worth to mention that the program for the bar positioning uses 50 memory

locations, while the program for the drill control

needsonly 36memory locations.The twoprograms

can becontained in theGS-C memory thus making

the system simplerand easier to maintain.

21/31

Page 22

GS-C200/ GS-C200S

Figure 8. Automatic Drilling And Positioning System Block Diagram.

22/31

Page 23

Figure 9. Programs Flow-charts.

GS-C200/ GS-C200S

23/31

Page 24

GS-C200/ GS-C200S

GS-C200AND GS-C200S APPLICATION

THE SEQUENCER-DRIVER INTERFACE

The GS-C is a general purpose stepper motor

controller capable to drive any type of motor, i.e.

two, three and five phases motors, by just interfacing it to the rightSequencer-Driver.

Sometime the available Sequencer-Driver requires

two separate Clock lines, one for each direction,

and thisrequirement is easily fulfilled by thecircuit

of figure 10.

Figure 10. Alternative Sequencer-Driver driving.

PHASECURRENT PROGRAMMING

As already explained, the possibility to modify the

phase current of a stepper motor according to

differentoperating conditions, gives substantial improvements intermofefficiencyandsystemreliability because it minimizes the resonance effectsand

the dissipated power.

The phase current programming can be implemented in various modes, either via a software

command by changing the status of the USER

output lines, or by hardware. Of course, the Sequencer-Driver musthavethecurrentprogramming

capability. An example of a hardware solution, implemented around a GS-C and GS-D200/200S

module, is shown in fig.11.

The application utilizes the two outputs:

MOV Movement in execution output

(pin 22)

RAMP Ramp in execution (pin 23)

of the GS-Cmodule and the

I

oset

of the GS-Dmodule.

The phase current has theshape showninfig.6,i.e.

it is minimized whenthe motor is stopped, it has its

maximum value during the acceleration/deceleration ramps, and an intermediate value during the

slew phase.

Current programminginput (pin9)

Figure 11. Phase Current Programming of the GS-D200/200S

24/31

Page 25

GS-C200/ GS-C200S

Let’sassume the followingvaluesare needed:

I

= 0.25A

rest

I

= 1.5A

ramp

I

= 0.5A

slew

The logic condition ofthe RAMPand MOV outputs

in the various states is:

During the ramping phase both pins 22 and

23 are high: Tr1 is ON and Tr2 is OFF.

During the slew phase pin 23 is low and pin

22 is high: Tr1and Tr2are OFF.

In stall condition Tr1is OFF and Tr2 is ON.

The value of R1, R2, R3 is determined as follows

(for further details please see the GS-D200/200S

data sheet). The value of R3, that fixes the I

slew

= 0.5A (Tr1 and Tr2 OFF), is easily calculated by

referring to the GS-D data sheet:

I

R3 =

slew

1 − 0.933 ⋅I

slew

R3 = 937 Ω

The value ofthe R2resistor,when paralleled toR3,

fixes the value of I

R2 // R3=

=0.25A(Tr1 OFF, Tr2ON).

rest

I

rest

1 − 0.933⋅ I

rest

R2 // R3 = 326Ω

R2 = 500Ω

The value of R1, that depends on the value of R3

and the resistors contained in the GS-D200/200S

module, fixes I

= 1.5A(Tr1 ON, Tr2OFF).

ramp

The valuesof the internal resistors are:

1.2kΩ to ground and 10kΩ to VSSfor the

GS-D200

750Ω to ground and 10kΩ to VSSfor the

GS-D200S

Assuming the GS-D200S is used, after some

straightforward calculations, it results:

R1 = 4245Ω

of course all these values do not take into account the

transistorssaturation losses and insomecases, when

a veryprecise current is needed, atrimming isrequired.

GALVANICISOLATION

=

The industrial environment, where normally a stepper motor and its driving system operate, is very

noisy andforthisreason itisoften advisable tohave

a galvanicisolation betweenthe Host computerand

the motion system. Because the connection between the Host and the GS-Cmodule requires only

three wires (TxD, RxD and ground), the galvanic

isolation can be implemented as per fig. 12 that

uses only two optocouplers and two resistors, one

protection diode and a +12 or +15V source.

A +12 or +15V source is normally available on the

pin 6 and 8 of any RS232 connector. The source

impedance is quite high (in the range of 220 to

600Ω) and for this reason thevalue of R2 must be

greater than 1000Ω to avoid the source overload.

Figure 12. GS-C200 to Host galvanic isolation.

25/31

Page 26

GS-C200/ GS-C200S

COMPLEX MOVEMENTS SYNCHRONIZATION

In manyapplications thesynchronization ofseveral

movements is quite often required and the GS-C

allowsthis function to beeasily implemented either

by using the Step Enable input or the User input/output pins. In fig.13A and fig.13B the block

diagrams relative to the twosolutions are reported.

The solution A is the simplest but it has some

limitations, i.e. it can be used only when the whole

system has to move synchronously. The solution B

is more complex but also more flexibleand it allows

the program to control where and when the synchronization must be implemented.

THE START-STOP SPEED ( S command)

SELECTION

A typical Start-Stop curve (as shown on Fig. 14),

shows that for a given driving voltage and phase

current, the highest drive frequency allowed at the

start (Pull-In Rate) is much lower than the one

allowed for the stop (Pull-Out Rate) and that both

are influenced by the load value. Of course the

higher the current level the higher is the available

torque, and the system canbe startedat a greater

speed.Asignificant increaseofthe start-stop speed

is obtained when the supply voltage is increased

but in both cases the problem related to the mechanical resonance mustbe considered. Itis advisable to maintaina significant safety margin against

the system torque limit in order to avoid any problem due to the friction variation. A commonly accepted rule fixes the Start-Stop speed equal to the

50% of the maximumtheoretical value reported on

the motor data sheet; this takes into account friction, load inertia variations as well as motor parameter differencesand power supply fluctuations.

Figure14. Start-Stop Characteristic.

SLEW SPEED (T command) SELECTION

The Slew speed is roughly determined by the load

and it can be evaluated by using the following

relation:

F ⋅L

6000⋅t

where

F = Strength in Pounds

T = Torquein Ounce/Inch

L = Length in Inches

N = Speed in turn/min.

t = Time inseconds

=

T ⋅N

10

Figure13. Complex Movements Synchronization

A

B

26/31

Page 27

GS-C200/ GS-C200S

The Slew speed is also limited by the motor electrical and physical characteristics, as shown on Fig.

15 where the behaviour of the minimum available

torque versus the driving frequency is reported.

It can be noted that the torque decreases almost

linearly starting from a certain frequency, and this

frequency depends on the motor windings impedance andthe rotor inertia.

Figure15. Torque/Frequency Characteristic.

RAMP LENGHT (R command) SELECTION

The acceleration and deceleration ramps are not

likely to be calculated and they shall be optimized

during the system debugging and testing phase.

The testing may start with very conservative ramp

gradients, i.e. verylong ramps,that willbegradually

shorteneduntilthe firstpositioningerror isdetected.

The acceleration and deceleration ramps generated by the GS-C have the trend shown in fig. 16.

Figure16. The GS-C200 Acceleration Ramp.

It is important to note that, when the number of

steps to be executed does not allow to reach the

Slew speed,the GS-C moves to the target position

performing a partial acceleration ramp linked to a

shortened deceleration ramp. This represents the

minimum time consuming way to reach the specified position.

CLOSED LOOP OPERATION

The stepper motor isa device normally driveninan

open loop mode and there is no direct control

between the cause and the effect. In adverse conditions an issued step may not be performed mechanically because the driving conditions do not

match the required torque and speed. In addition,

the resonance phenomenon, common to all the

stepper motors,can also affectthe correct positioning.

In some particular applications, when the load has

a very large spreadof values andthe torque margin

is limited, it is sometimes necessary to implement

an external electronic circuitry to guarantee the

correct system positioning

To this purpose three different methods can be

adopted:

a) Digitalencoding of the absoluteposition.

b) Recognition that a step has been executed by

the usage of a slotted disk, two optocouplers

and some logic.

c) Thesameas aboveby the usageofvelocitycoils

and some logic.

The first solution is very expensive andthe digitalized position value must be read by the computer

through aparallel port by using aspecifically written

program. A further limitation arises from the fact

that every shaftencoder provides justthe information relative to the position but itdoes not take care

if more than one turn has been performed by the

motor shaft, and an external logic is also required

to detect and save this condition.

The secondsolutionislessexpensive butitrequires

a tedious trimming of the mechanical positioningof

the optical sources and detectors to be effective.

The major drawback ofthis solution is its sensitivity

to dust, and the whole position sensing system

must be contained in a dust free box.

The last solution is probably the best under every

point of view because it does not require any mechanical positioning adjustement that has been

previously madeby the motor manufacturer; moreover it is dust insensitive beeing based on flux

variation across an air gap and finally no mechanical hardware must be added to the system.

27/31

Page 28

GS-C200/ GS-C200S

Infig. 17 the blockdiagram ofa closedloop system

is reported.

If the step execution is recognized by a movement

detector thatuses either a slotted disk orthe motor

velocity coils, two logic signals (x,y) like those reported in fig. 18 are available.

Figure 17. Closed Loop System.

Figure 18. Signal Output of the MovementDetector.

It is possible, by using these two signals as inputs

(x, y)of the very simple andinexpensive logic circuit

reported infig. 19, to detect the direction of rotation

and the step execution. The output of the circuit is

then used to condition the step enable inputof the

GS-C module allowing the step clock pulse to be

issued only if theprevious stephas been executed.

Figure 19. Suggested Logic to Close the Loop.

28/31

Page 29

GS-C200/ GS-C200S

ELECTRONICDAMPING

Any stepper motor system when driven atvery low

stepping rates, has an oscillatory stepresponse as

shown in fig. 20.

This oscillatory behaviour is due to fact that the

motor reaches the stall position after each excitation change through an acceleration and a successive deceleration. This causes the motor shaft to

rotate with jumps instead of uniform motion.

Another consequence of this oscillatory single step

response is that the long system settling time can

cause mechanical stresses to the driven load.

A second tedious effect is the enhancement of the

rotor oscillation when the driving step rate approaches the natural resonance frequency of the

motor. If the step rate is lower than this frequency,

the motor is behind the equilibrium position and the

velocity is near to zero when the next excitation

change occurs.

When the step rate is increased to a value close to

the natural resonance frequency, an increase ofthe

oscillations also occurs,and as soon asthe oscillation amplitude exceeds the step amplitude, the

corrispondence between the rotor position and the

excitation sequence is lost and any subsequent

rotor movement is erratic as shown in fig. 21.

Asimple method to reduce the oscillationsproblem

is to usethe halfstep driving,but this also limits the

maximum speedof the system.

When this limitation is not acceptable, other two

basic techniques may be adopted to damp the

system oscillations:

1. A mechanical damper

2. An electronic damping circuit.

Figure 21. Slow Speed Step Response.

Figure 20. Typical Single Step Response.

29/31

Page 30

GS-C200/ GS-C200S