EFS

Application Specific Discretes

A.S.D.

FEATURES

n VERY WIDE TEMPERATURE RANGE:

tube ignition from -30to+85°C

n SINGLE SHOT IGNITION FROM -30 to 0°C:

350mA, 1350V striking pulse

n VERY WIDE POWER RANGE:

Fluorescent tube lamp ignition from 18 to 70W

n EFS2B driver compatible with 50/60Hz

operation

n SELECTABLE PREHEAT TIME:

EFS2A driver: 1.5s or 2.56s (50Hz)

EFS2B driver: 0.74s or 1.24s (50Hz)

EFS2B driver: 0.62s or 1.03s (60Hz)

n 8 STRIKING PULSES CAPABILITY:

for very cold environment or ageing lamp

n STARTER SHUTDOWN WITH FAILED LAMP

BENEFITS

2-CHIPS SET FOR FLUORESCENT LAMP STARTER

STARLIGHT-KIT

S014

EFS2A-CD

EFS2B-CD

n Very low component count: 2 chips + 7 passive

components

n Meet EN55015 standards WITHOUT EMI

capacitor

n Extendedlife time of the fluorescent lamp due to

smooth and single shot ignition

n High inherent reliability and extended life time

of the starter

DESCRIPTION

The EFS Kit is a 2 chips set used with 7 additional

passive components, for Glow switch Starter.

The ASD (Application Specific Discretes)

includes a bi-directional Power Switch and a

Power Supply for the driver.

The driver provides a program to ensure a fully

optimised linear fluorescent lamp ignition.

TM : ASDis trademark ofSTMicroelectronics.

PENTAWATT HV

EFS21-TL5

May 2000 - Ed: 5A

1/14

EFS

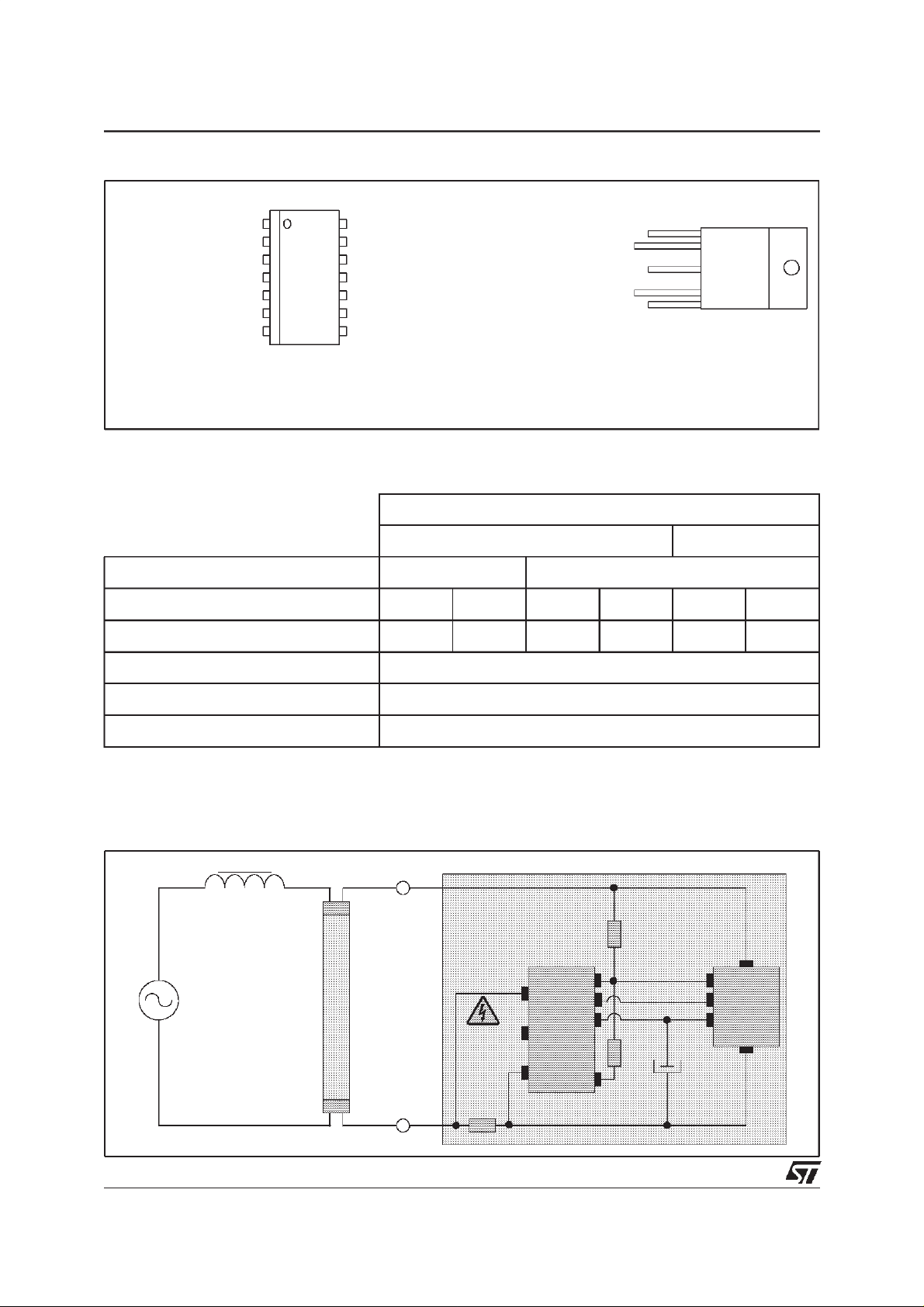

PIN CONNECTION (top view)

State tube detection 1

Preheat select 2

to be grounded 3

Shunt 4

to be grounded 5

to be grounded 6

to be grounded 7

DRIVER: EFS2A-CD

SO14

14 G1

13 G2

12 VCC

11 GND

10 to be grounded

9 DO NOT CONNECT

8 to be grounded

G1 1

Vcc 2

Tube 3

GND 4

G2 5

Pentawatt HV

ASD: EFS21-TL5

and :EFS2B-CD

EFS STARLIGHT-KIT PARTS SELECTION:

The EFS STARLIGHT-KIT answers effectively to linear fluorescent lamp ignition needs:

MAINS FREQUENCY

50Hz 60Hz

DRIVER VERSION EFS2A EFS2B

Pin 2 connection

PREHEAT DURATION

GND VCC GND VCC GND VCC

1.5s 2.56s 0.74s 1.24s 0.62s 1.03s

ASD EFS21

LAMP POWER RANGE

AMBIENT TEMPERATURE RANGE

Note 1: below-20°C, it isrecommended to limitthe lamp powerrange to 58W.

Note 2: theignition temperature rangeis given with startingaid, as requiredin the IEC 81and IEC926 (§6.3.1) standards.

18 to 70W (note 2)

-30 to 85°C (note1, note 2)

BASIC APPLICATION DIAGRAM

BALLAST

150KΩ

ASD

22µF - 16V

MAINS

FLUORESCENT

LAMP

18W TO 70W

DO NOT

CONNECT

0.39Ω

DRIVER

4

U2

9

7/8/10/11

2/3/5/6

14

13

12 2

R

1

3

1

5

U1

4

2/14

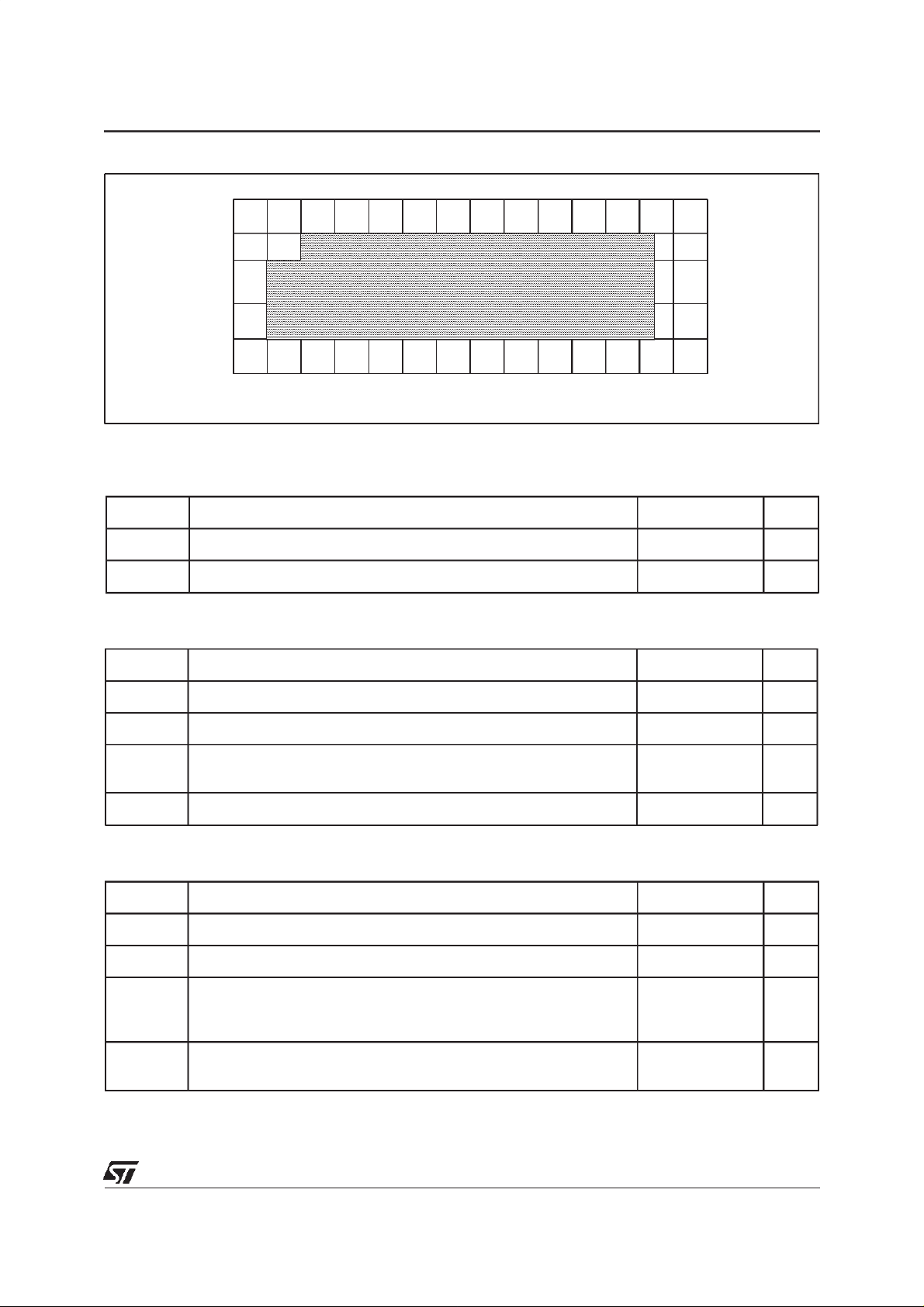

RECOMMENDED LAMP POWER RANGE APPLICATION

LAMP POWER(W)

70 W

58 W

EFS

36 W

18 W

-30 -100 1020304050607080-20 90

Note 2: the ignition temperature range is given with starting aid, as required in the IEC 81 and IEC926 (§6.3.1) standards.

WORKING AREA

Tamb(°C)

(see note 2)

ABSOLUTE RATINGS (limiting values)

Symbol Parameter Value Unit

Top Operating Junction temperature range -30 to +125 °C

Tstg

Storage temperature range

-55 to +150 °C

DRIVER: EFS2 A & EFS2B

Symbol Parameter Value Unit

Vcc Maximum supply voltage 14 V

Ptot Power dissipation 500 mW

ESD Electrostatic discharge between any pins

1kV

Standard: MIL STD 883C Human Body Model

V

SENSE

Input operating range

±10 V

ASD: EFS21

Symbol Parameter Value Unit

I

T(RMS)

Tcase

I

TSM

RMS on-state current Tcase = 90°C1A

I

Surge peak on-state current

T(RMS)

=1A t

= 0.16s tON= 0.75s

OFF

+ 120 °C

15 A

Tjinitial = 25°C, tp = 10ms

Minimum repetitive rate periode : 1min.

V

V

DRM

RRM

Repetitive peak off-state voltage

600 V

3/14

EFS

ELECTRICAL CHARACTERISTICS (Tj=25°C, unless otherwise specified)

DRIVER

Symbol Parameter Min. Typ. Max. Unit

Vcc

V

UVLO

V

CCH

V

CCL

I

CC

I

SO

LAMP OFF STATE DETECTION

tc

V

REF

ASD

Supply voltage in preheat mode

Under voltagelock-out threshold

Supply limitation high in standbymode

Supply limitation low in standby mode

Supply current in standby mode

Ignition current level Rsense= 0.39Ω

712V

5V

6.8 7.7 8.7 V

6.77 7.57 8.41 V

440 450 475 µA

280 350 420 mA

Checking delayafter zero crossing lampvoltage

EFS2A version

EFS2B version

2.9 5.9 ms

2.5 7.5 ms

Internal referencevoltage 1.12 1.26 V

Symbol Parameter Min. Typ. Max. Unit

VT + Positive on-state voltage IT= 1.5A tp = 500µs 2.1 3.15 V

VT - Negative on-state voltage IT= 1.5A tp = 500µs 0.89 1.2 V

V

V

V

I

I

BR

DCM

RCM

DRM

RRM

I

H

Breakdown positive voltage I

= 5mA tp= 10ms 1200 1350 1500 V

DRM

Non repetitive peak off-state voltage

Pin 1 = Pin 2 = Pin 4 = Pin 5 Repetitive rate : 3Hz

Leakage current, at V

DRM/VRRM

rated

Pin 1 = Pin 2 = Pin 4 = Pin 5

Holding current dI/dt = 9 A/ms

800 V

20 µA

350 mA

Pin1 = Pin 2 = Pin4 = Pin5

ORDERING INFORMATION

DRIVER

ASD

TM

EFS 2 A/B CD- EFS 2 1 TL5-

Electronic

Fluorescent

Switch

Digit

A: 50Hz

B: 50/60Hz

SO14

Package

Electronic

Fluorescent

Switch

KitKit Version

Version

Digit

TL5:

PentawattHV Package

with lead forming

4/14

DEMONSTRATION BOARD DIAGRAM

EFS

THERMAL

FUSE

R2R1

DRIVER

R5

R4

4

4

U2

9

7/8/10/11

3/5/6

D1

R3

14

13

12

Vcc

2

GND

OPEN

one of the tracks

R6

C1

ASD

3

1

5

U1

2

4

When the starter has to be protected against over-temperature, over-current or short circuit, it is

recommended to implement a thermal fuse in series with the starter.

Tomeet (IEC 926)standards,a capacitor (f.i.5nF) can beconnected betweenpin 3and pin 4 ofthe ASD.

BOARD ASSEMBLY

PCB with Pentawatt HV and SO14

DRILL and CUT the track

for SHORT preheat -->

for LONG preheat -->

Pin 2 is the preheat time select pin. To select a shortpreheat time, drill to cut the Vcc to pin 2 track at the

metallic hole. To select a long preheat time, drill to cut the GND to pin 2 track. The layout must be

configured for either choice to avoid supply short circuit.

RECOMMENDED COMPONENTS ACCORDING TO APPLICATION CONDITIONS

Application Conditions

AC mains Single

230V - 50Hz

Lamp Power Range

Ambient Temperature Range

18 to 70W 18 to 36W

Single

Twin series 230V / 50Hz or

120V - 60Hz

-30 to + 85°C (note 3)

single 115V / 50Hz

Recommended Components

ASD version EFS21

Driver version EFS2A or EFS2B EFS2B EFS2A or EFS2B

R1, R2 30kΩ - 0.125W - 5% 15kΩ - 0.125W - 5%

R3 130kΩ - 0.125W - 5%

R4 2.2kΩ - 0.25W- 5% 3.3kΩ- 0.25W -5%

R5 0.39Ω - 0.25W - 5% (note 4)

R6 0.39kΩ - 0.25W- 5%

C1 22µF - 16V - 20%

C2 BYD17K (800V)

Note 3: below -20°C, it is recommended to limit the lamp power range to 58W.

Note 4: R5(Rsense) should have a 8 A, 10 ms surge capability.

5/14

EFS

EFS STARLIGHT-KIT APPLICATION NOTE

1/ THE AC POWER SWITCH: FUNCTIONAL DESCRIPTION

he Starter is a bi-directional switch which performs two functions:

n the preheat ofthe tube,

n the ignition of the tube.

BALLAST

PREHEAT

FLUORESCENT

1

TUBE

2

V strike

220V / 50HZ

The mains voltage is applied Preheating of the tube Striking of the tube

During the preheat period, the ASD is fully

conducting. The tube lamp is shortcircuited by the

starter, and the current flows through its filaments.

In these conditions, the lamp can not light up, but

the temperature of the lamp electrodesincreases.

At the end of the preheat period, lamp filaments

are warm enough to emit electrons in the gas and

to permit the lamp ignition in good conditions. The

ASD switches off the preheating current . Atthis

moment, the ballast is equivalent to a current

generator (I=I

SO,ISO

= Switched Off current). As

the ASD switches off, the starter voltage

increases. Theamplitude ofthis high voltage spike

is then clamped by the ASD (V

1350 V). As

BR′

the starter and the lamp are in parallel, the striking

pulse is directly applied to the lamp. The

electromagnetic energy of the ballast is then

discharged through the lamp and the ASD.

2/ WHAT’S NEW IN THIS SWITCH?

3

Striking pulse

NEW EFS ASD

The AC SWITCH merges an auxiliary power

supply for the driver, a power clamping device

(1350V) and a bi-directional switch with his

execution pilot block.

6/14

Vcc

TUBE

CLAMPING

AC SWITCH

G1

G2

ON / OFF

DRIVER

Powersupply

GND

VOLTAGE

HIGH

EFS

Present solutions work with a unidirectional

Conventional discrete circuit (minimal version)

switch, like MOS transistors or GTO (Gate Turn

Off thyristor). As a starter is a bi-directional switch,

it is necessary to use a rectifier bridge (4 diodesof

1500V ). More, 2 or 3 diodes in series with the

GTO are required to get the necessary switch off

1500V

GTO

effect, and the whole is controlled with an analog

timer built around a small SCR.

The interest of a bi-directional switch arises itself:

a drastic reduction of the number of components,

SCR

and of course, a reduction of power losses (only 1

forward voltageinstead of 5).

3/ LAMP IGNITION FEATURE:

A lamp requires a minimum energy level to be ignited, but this energy depends especially on the lamp

temperature. The lower the temperature is, the more energetic the lamp strike is.

This energy stored in the ballast is directly proportional to the Switched Off current

IE

(

SO

In other words, the required energy and of course the ISOlevel, are maximum for the minimum

LI

.

SO

2

)=

.

2

temperature. Results based on experiments show that it is necessary to switch off a current of 350 mA to

strike a 58W tube at -30°C (with a voltage amplitude clamped at 1200V and starting aid).

Therefore,the best way to strike a tube independentlyof the temperature is to keep the maximum ISOlevel

for allthe temperature range. Unfortunately, thesolution is not so simple to implement because theenergy

level at ambient or warm temperature would be much important: the lamp would be ignited, but the lamp

lifetime would be shortened. This is why one of the innovations of the ASD is to modulate the striking

energy versus temperature (see feature hereafter).

350mA

I.S.O.

200mA

Switched off current

versusambient temperature

A.S.D. FEATURE

For freezing temperatures, the ISOlevel is maintained at 350 mA, and for positive temperatures, the I

level decreases slowly.

SO

7/14

EFS

4/ AUXILIARY POWER SUPPLY:

In order to reduce the number of components, an

auxiliary power supply is integrated in the ASD.

This active power supply works directly on the

mains and requires only a low voltage capacitor

16V - 22µF. The operating mode of this supply

varies with the starter operating phase:

POWER SUPPLY SCHEMATIC

D1

7.68

7.57

R6

G1

VCC

C SUPPLY

DRIVER

R1R2

ASD

TUBE

GND

Supply operation during preheat phase:

During preheat phase, the driver manages alone the supply function (neither the driver nor D1 and R6 are

involved). A part of the current flowing through theASD is used, at the beginning and at theend of each

positive mains half cycle, to charge the output capacitor.

Supply operation during standby phase:

When the lamp is lit, the monitors its supply voltage (Vcc). At the beginning of each positive mains half

cycle, when Vcc is lower than 7.57V, the driver closes the ASD supply switch. The capacitor is charged

to provide the standby current of the driver. During this phase the tube lamp is short circuited by the

ASD. When the supply voltage reaches 7.68V, the driver opens the ASD supply switch. Since this

current is also flowing in the ballast, the supply turn off provides across the lamp an additional voltage

spike. After running few minutes the lamp becomes warm and this spike voltage naturally decreases.

SUPPLY DURING PREHEAT PHASE

SUPPLY DURING STANDBY PHASE

(Without E.M.I. Capacitornor R6 nor D1)

Starter current

at the ignition

5min after

ignition

Starter voltage

To reduce dramatically this repetitive voltage spikes across the lamp, the R6 resistor with the diode D1

provide a part of the supply current. Thus, the ripple voltage of thesupply voltageis reduced,as wellas the

level of the switched off current. On the other hand, this increases the safety margin of the RF noise

(versus the IEC 55015 limits)

8/14

5/ THE DRIVER: FUNCTIONAL DESCRIPTION

EFS2A DRIVER Internal block diagram (50Hz operation)

EFS

State

tube

Shunt

Vcc

State tube detection

(Striked / Off)

ISO synchro

350mA

UVLO

Minimum

Powersupply

0 current synchro

8 attempts

Strikes counter

Clock 1/8

Current generator

Pre-heat

period

counter

30mA

1,5s

or

2.5s

Preheat

Select

G2

G1

GND

ALGORITHM

1. At switch on:

Atswitch on, an integratedUnder Voltage Lock Out function (UVLO)resets the driver as long as thesupply

voltage stays belowa safety level.

2. Preheat:

The ignition sequence begins with the preheat

phase.Two differentduration’s can be selected with

PIN 2 (see table EFS STARLIGHT-KIT PARTS

SELECTION page 2).

ACMAINS ON

UVLO RESET

Preheat *

1.5s or 2.5s

Duringthis phase, the driver maintains the ASD in

a full ON-state making the starter equivalent to a

bi-directional conducting switch.

3. Ignition of the fluorescent tube:

At the end of the preheat period, the starter strikes

the fluorescent lamp.

For that, the driver reads continuously the current

through the starter. When the current reaches the

Switch Off level (ISO= 350mA), the driver turns off

theASD. This inducesa highvoltage pulse across

the lamp. This pulse amplitude is limited by the

ASD (′1350V).

4. If the lamp fails to strike:

The driver detects the stateof the tube (lit or off). If it

Loop 2

Autosupply

Fail = 0

Attempt = 0

Strike

Attempt = Attempt + 1

Tube

YES

Ignited?

Fail = Fail + 1

Loop 1

Fail = 8

NO

YES

Fail = 0

Preheat *

0.75s or 1.25s

Loop 3

NO

YES

Attempt <8

NO

Autosupply

stays off during 8 mains cycles (loop 1), a new

preheat period, shorter than the first one, starts

again (loop 3), followed by a new ignition attempt.

* see the preheat duration table § 6

The driver will try to fire the tube 8 times. If none of

the8 attempts succeeds in strikingthe lamp, the driver turns in standbymode, and the whole starteris fully

stopped until the next mains removal andpower supply reset.

5. If the lamp is ignited:

If the lamp is ignited, the driver stays in standby mode while monitoring the state of the lamp (loop 2).

During normal operation of the tube, this short pulse is masked by the lamp conduction. If the mains

interruptionis really longenough toturn offcompletely the lamp,a new ignition sequencestarts again (loop

3) with 8 other new possible attempts.

9/14

EFS

6/ PREHEAT PHASE DURATION 50-60Hz:

The driver determines the preheat duration by counting mains cycles. This numeric solution brings

naturally a good precision depending only on the mains frequency tolerance.

With the 2 driver versions, the EFS startlight-kit provides a choice of 4 preheat duration’s. The following

tablegives thepreheat duration before the firstignition attempt.The seven nextpreheat duration’s, incase

of unsuccessful ignition attempt, last the half of the first one

PREHEAT DURATION

MAINS FREQUENCY 50Hz 60Hz

DRIVER VERSION EFS2A EFS2B EFS2B

Pin 2 connection GND VCC GND VCC GND VCC

1.5s 2.56s 0.74s 1.24s 0.62s 1.03s

7/ TUBE STATE DETECTION:

During the ignition sequence or once the lamp is lit, the starter checks the state of the lamp (lit or off).

To determine this state, the driver reads the lamp voltage through the resistor bridge (R1+R2+R3, R4).

- If the lamp is off, its voltage equal the mains voltage.

- If the lamp is lit, its voltage is only 80 V (for a 58W lamp).

Thus the lamp state is determined by comparison of the lamp voltage with a programmed detection level.

CORRECT SETTING = NO WAVEFORM

ACROSS THE GREY AREATolerance effects:

Tolerances on resistors (R1, R2, R3 and R4) as

well as on the integrated comparator bring a

tolerance on the set detection level. Thus the

detection level is included in a range delimited by

the maximum and the minimum detection levels

(DL

MAXDLmin

).

DL

MAX

DL

min

OFF Lamp

Voltage

The driver checks the state of the lamp when

mains voltage is maximum, that isto say 5ms after

the zero crossing mains voltage (50Hz). Here

LIT Lamp

Voltage

again internal tolerances bring a tolerance on the

real checking moment (TC

minTCMAX

).

TC

min

TC

MAX

How to set the detection level?

Only the R4 resistor value can be set to adjust the detection level. Values of resitors R1 to R3 must match

values of the table RECOMMENDED COMPONENTS ACCORDING TO APPLICATION CONDITIONS of

the page 5. Practically the R4 resistor value has to be set so that neither the OFF lamp voltage nor the LIT

lamp voltage cross the grey area.

The DL

DL

MAX

and DL

MAX

xR R R R

.( )

=

limits can be calculated as follows:

min

MAX MAX MAX

+++1265 4 1 2 3

min

R

4

min

and

DL

.( )min min min

min

=

xR R R R

++ +1122 4 1 2 3

MAX

4

R

MAX

10/14

8/ E.M.I. CAPACITOR:

As required in the IEC 926 standard (§11.5),

“starters which are interchangeable with glow

starters in accordance with IEC 155 shall contain

means for radio interference suppression, the

effect of which is equivalent to that of the radio

interference suppression capacitor prescribed in

7.12 of IEC 155”.

The EFS starlight-kit is compatible with this 5nF

E.M.I. Capacitor which must be connected directly

across the ASD (between pin 3 “TUBE” and pin

4 “GND”).

On the other hand, this E.M.I. capacitor increases

DRIVER

Rsense

9

7/8/10/11

2/3/5/6

14

13

12

1

4

1

5

2

the striking pulse width of about 55% on positive

temperatures.

8.1. Operation in single lamp configuration

The EFS STARLIGHT-KIT is ideal in the following configurations:

- Single Starter / 230V / 50Hz - Single Starter / 230V / 60Hz - Single Starter / 120V / 60Hz

ASD

3

4

EFS

C

E.M.I.

T

U

B

E

Note 4: the different driver versions should be chosen according to the table “EFS STARLIGHT KITPARTS SELECTION” page 2.

Note 5: Components to choose are listed in the table “RECOMMENDED COMPONENTS ACCORDING TO APPLICATION CONDITIONS”

page 5.

AC

MAINS

8.2. Operation with capacitor for power factor correction:

The EFS STARLIGHT-KIT is also suitable for magnetic ballast including front end parallel capacitor.

The EFS STARLIGHT-KIT is NOT suitable for magnetic ballast including front end serial capacitor.

LEADING MAGNETIC BALLAST WITH

SERIAL CAPACITOR

T

U

B

E

MAGNETIC BALLAST WITH SHUNT

PARALLEL CAPACITOR

T

U

B

E

AC

MAINS

11/14

EFS

8.3. Operation on the 230V/50Hz AC mains in twin tubes configuration

The EFS STARLIGHT-KIT is also suitable for the configurations Twin tubes Starter

Note 5: Components to choose are listed in the table “RECOMMENDED COMPONENTS ACCORDING TO APPLICATION CONDITIONS”

page 5.

The only electrical diagram difference consists of the R4 resistor which needs to be changed from 1 to

2.2kΩ. Without this modification, the starter will generate only one ignition attempt instead of 8 in case of

defective lamp; the loop 3 is removed fromthe algorithm described in page 9.

AC

MAINS

230V

TWINTUBE

T

T

U

U

B

B

E

E

BALLAST

230V / 50HZ

FLUORESCENT

TUBE

STARTER

F

F

O

SOCKET

F

F

O

ALIGHT

ALIGHT

In the Twin Series 230V/50Hz configuration, the polarity of the two starters must be respected:

In case of no operation of starters, rotate one of the starters of 180° on its socket.

Rotate of 180°

only one starter

12/14

PACKAGE MECHANICAL DATA

SO14 (Driver)

EFS

L

a2

A

b

e3

D

14

17

e

M

8

S

F

Dim.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 1.75 0.069

G

c1

C

a1 0.1 0.2 0.004 0.008

a2 1.6 0.063

b 0.35 0.46 0.014 0.018

b1 0.19 0.25 0.007 0.010

b1

a1

E

C 0.5 0.020

c1 45o(typ.)

D 8.55 8.75 0.336 0.334

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 7.62 0.300

F 3.8 4.0 0.150 0.157

G 4.6 5.3 0.181 0.208

L 0.5 1.27 0.020 0.050

M 0.68 0.027

S8

o

(max.)

13/14

EFS

PACKAGE MECHANICAL DATA

Pentawatt HV with lead forming - TL5 (ASD)

DIMENSIONS

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 4.3 4.8 0.169 0.188

C 1.22 1.42 0.048 0.056

D 2.4 2.8 0.094 0.110

DIAM 3.65 3.85 0.144 0.152

E 0.35 0.45 0.014 0.018

F 0.65 0.75 0.026 0.030

G1 4.88 5.28 0.192 0.208

G2 7.42 7.82 0.292 0.308

H2 10.4 0.409

H3 10.05 10.4 0.396 0.409

L1 3.3 0.130

L2 14.24 14.64 0.560 0.576

L3 2.34 2.74 0.092 0.108

L5 2.6 3 0.102 0.118

L6 15.1 15.8 0.594 0.622

L7 6 6.6 0.236 0.260

R 0.5 0.020

Informationfurnished isbelieved to be accurate andreliable. However,STMicroelectronics assumesno responsibility for the consequencesof

use of such information nor for any infringement ofpatents orother rights of third parties which may result from its use. No licenseis granted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for useas critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan -Malaysia

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

14/14

Loading...

Loading...