CLP270M

ApplicationSpecific Discretes

A.S.D.

OVERVOLTAGE AND OVERCURRENT

PROTECTION FOR TELECOM LINE

MAINAPPLICATIONS

Any telecom equipment submitted to transient

overvoltagesandlightningstrikes suchas:

Analogand ISDNline cards

PABX

MainDistribution Frames

Primaryprotection modules

DESCRIPTION

The CLP270M is designed to protect

telecommunicationequipment. It provides both a

transient overvoltage protection and an

overcurrentprotection.

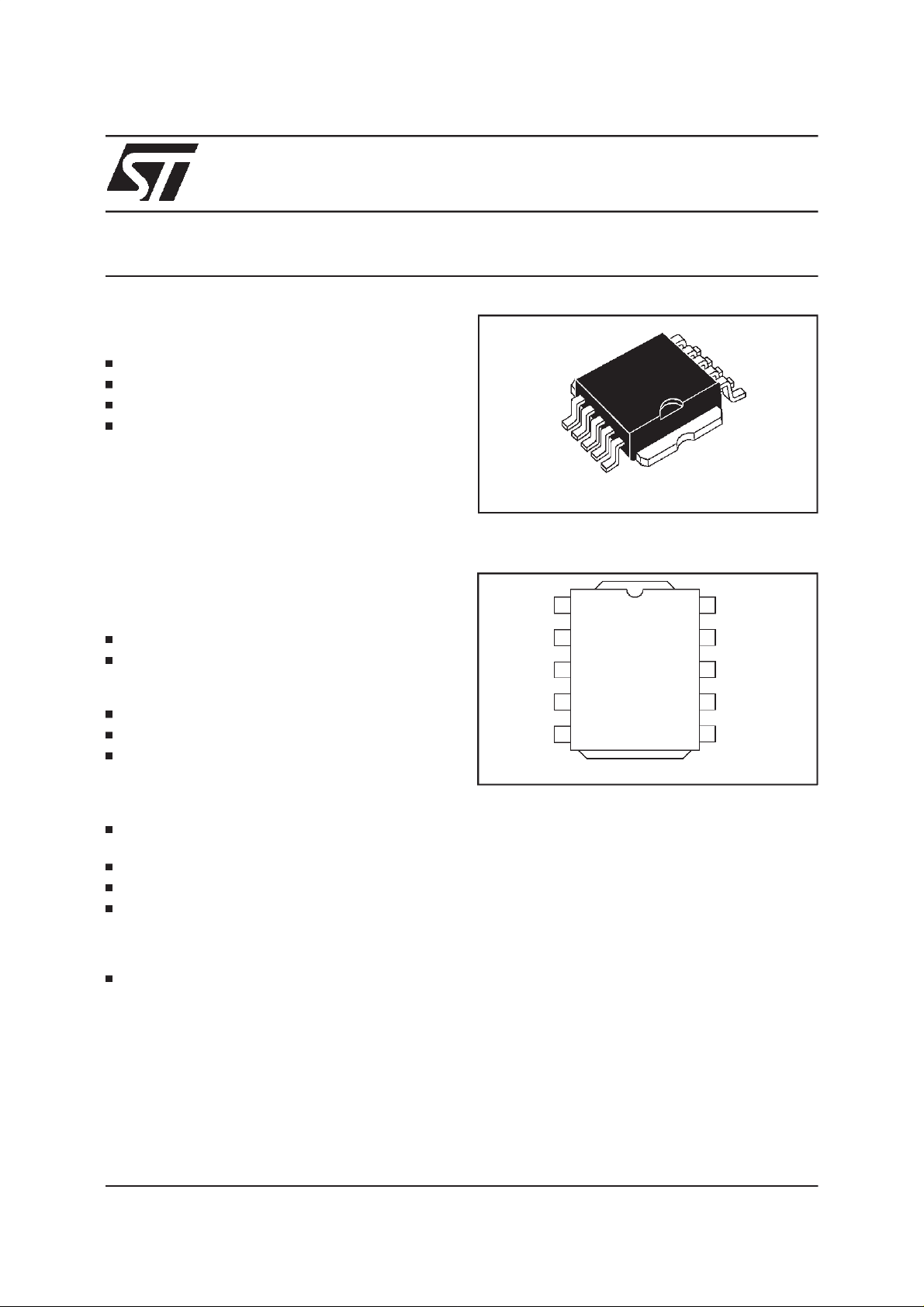

It is housedin a PowerSO-10

TM

package.

FEATURES

DUALBIDIRECTIONALPROTECTIONDEVICE.

HIGHPEAKPULSE CURRENT:

Ipp = 100A(10/1000µs SURGE)

Ipp = 500A(2/10µs SURGE)

MAX.VOLTAGEAT SWITCHING-ON: 380V

MIN.CURRENT AT SWITCHING-OFF : 150mA

FAILURESTATUSOUTPUTPIN

PowerSO-10

SCHEMATICDIAGRAM

1

TIP

S

TIP

L

TIP

L

TIP

L

TABis connected to GND

PRELIMINARY DATASHEET

TM

NCFS

RING

S

RING

L

RING

L

RING

L

BENEFITS

Both primary and secondaryprotectionlevelsin

onedevice.

Voltageand current controlledsuppression.

TM

SurfaceMountingwithPowerSO-10

package.

Line card cost reduction thanks to the very low

power rating of external components required :

balanced resistors, ring relay, low voltage SLIC

protection.

Falls into short circuit if destroyed,still ensuring

protection.

January1998 - Ed: 5B 1/24

CLP270M

COMPLIESWITHTHE

FOLLOWING STANDARDS:

Peak Surge

Voltage

(V)

Voltage

Waveform

(µs)

Current

Waveform

(µs)

Admissible

Ipp

(A)

Necessary

ITUK20 4000 10/700 5/310 100 VDE0433 4000 10/700 5/310 100 VDE0878 4000 1.2/50 1/20 100 IEC-1000-4-5 level4

level4

FCCPart68,lightning surge

type A

FCCPart68,lightning surge

1500

800

100 9/720 5/320 25 -

10/700

1.2/50

10/160

10/560

5/310

8/20

10/160

10/560

100

100

200

100

type B

BELLCORETR-NWT-001089

Firstlevel

BELLCORETR-NWT-001089

2500

1000

2/10

10/1000

2/10

10/1000

500

100

5000 2/10 2/10 500 -

Secondlevel

CNETl31-24 4000 0.5/700 0.8/310 100 -

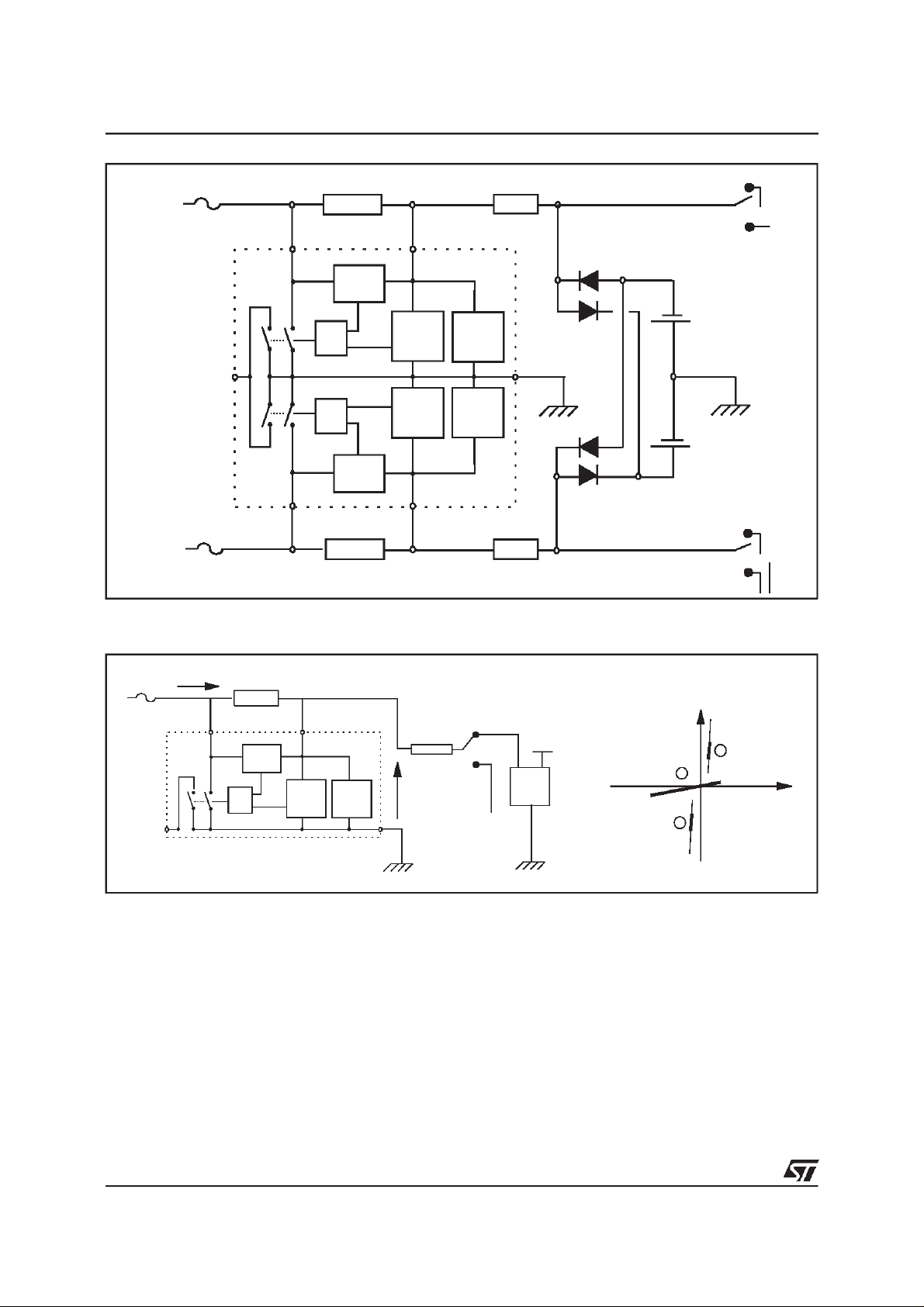

BLOCKDIAGRAM

Resistor

(Ω)

-

-

-

-

-

-

270

270

Pin Symbol Description

1 FS FailureStatus

2 TIPS TIP (SLICside)

3 / 4/ 5 TIPL TIP (Lineside)

6 / 7/ 8 RINGL

9 RINGS

RING(Lineside)

RING(SLICside)

10 NC Not connected

TAB GND Ground

2/24

CLP270M

APPLICATION NOTE

1.INTRODUCTION

This deviceincludesa primaryprotection level and is suitablefor main distribution frames and line cards.

This protection concept is explained and, in addition, the CLP270M performances are analysed when

facingdifferentsurgesasdescribedin the BELLCOREGR 1089 recommendations.

Fig. 1:

Subscriberline protectiontopology

Telecommunication

line

Telecommunication

line

“PRIMARYPROTECTION”

CLP270M

MDF

EXCHANGE

CLP270M

MDF

EXCHANGE

“SECONDARYPROTECTION”

SLIC

LINE CARD

“SECONDARYPROTECTION”

THDTxx

or

LCP1511D

or

LCDP1511D

LINE CARD

SLIC

Figure1is a simplifiedblock diagramof a subscriberline protectionthatiscommonlyused.

Thisshows two differenttopologies:

A ”primaryprotection”locatedon the Main DistributionFrame(MDF)eliminates coarselythe highenergy

environmentaldisturbances(lightningtransientsand AC power mainsdisturbances)

A ”secondary protection” located on the line card includes a primaryprotectionlevel (first stage) and a

residualprotection(secondstage)which eliminatesfinelytheremainingtransientsthathavenotbeentotally

suppressedbythefirststage.

2. STMicroelectronicsCLP270MCONCEPT

2.1.Evolutionof the SLICprotection

Over the years, t he silicon protect ion pe rformances ha v e co nsiderab ly cha nge d.

The first generation of products like SMTHBTxx and SMTHDTxx offered fixed overvoltage protection

againstsurges on eitherTIPor RINGlinein fourpackages.

The following generation like THBTxx and

THDTxx still offered fixed overvoltage protection

againstsurges on both TIP and RING lines in two

packages.

The next step was the introduction of the

LCP1511D which brought the advantage of full

programmablevoltage.

Today, the CLP270Mcombinesthe features of all

thepreviousgenerations.In additiontothat,itoffers

Fig. 2:

Linecard protection

Programmable

thanks to any

external voltage

reference

+I

SWON

I

Programmable

thanks to an

externalresistor

V

an overcurrentdetection when operatingin speech

modeandalso aFailureStatus output signal.

The figure 2 summarizes the firing modes of the

CLP270M which basically hold the SLIC inside its

correctvoltageand currentvalues.

-I

SWON

Line card

operating

conditions

3/24

CLP270M

2.2Application circuit:CLP270M in line card.

Fig.3 :

TIP

RING

CLP270Min linecard

Fuse

Rsense

TIPL TIPS

Overcurrent

detector

Ov v

RINGS

er oltage

ref

erence

(+/- 270V)

Overvoltage

reference

(+/- 270 V)

Overvoltage

OR

SW3 SW1

FS GND

Fuse

SW4 SW2

RINGL

OR

Overcurrent

Rsense

detector

detector

Overvoltage

detector

I

-Vbat

TIP

-Vbat

(*)

SLIC

RING

Rp

Rp

1

2

1

2

External

voltage

reference

Ring

Generator

(*) LCP1511D orTHDT seriesor LCDP1511D

Figure 3 above shows the topology of a protected analog subscriber line at the exchange side. The

CLP270Misconnectedto theringrelay viatwo balancedRp resistors,and totheSubscriberLine Interface

Circuit. A second device is located near the SLIC : it can be either a LCP1511D, a THDT series or a

LCDP1511D.

Thesetwo devicesare complementaryand their functionsare explainedbelow :

The first stage based on CLP270Mmanages the high powerissued from the external surges. When

used in ringing mode, the CLP270M operates in voltage mode and provides a symmetrical and

bidirectional overvoltage protection at +/- 270 V on both TIP and RING lines. When used in speech

mode, the CLP270Moperates in current modeandthe activationcurrent of the CLP270M is adjusted

sense

.

by R

The second stage is the external voltage reference device which defines the firing threshold voltage

during the speech mode and also assumes a residualpowerovervoltagesuppression. This protection

stage can be either a fixed or programmable breakover device. The THDTxx family acts as a fixed

breakoverdevice whiletheLCP1511Dor the LCDP1511Doperatesas a programmableprotection.

Thankstothistopology, thesurgecurrentinthelineisreducedafterthe CLP270M.Becausetheremaining

surge energy is low, the power ratings of Rp, the ring relay contactsand the external voltage reference

circuitcan bedownsized.Thisresultsin asignificantcost reduction.

4/24

CLP270M

Fig.4:

Switchingby voltageduringringingmode.

ILG

Fuse

TIP

FS

Rsense

TIPL TIPS

Overcurrent

detector

OR

SW3 SW1

Overvoltage

detector

1/2 CLP270M

Overvoltage

reference

(+/- 270V)

GND

ILG

1

Rp

VLG

2

-270

3

A1

2

1

V

+270

2.3.Ringingmode

Inringingmode(Ring relay in position2),the onlyprotectiondeviceinvolvedis theCLP270M.

Innormalconditions, theCLP270M operatesin region1ofA1curve,and is idle.

If an overvoltage occuring between TIP(or RING)andGND reaches the internalovervoltagereference

(+/- 270 V), the CLP270M acts and the line is short-circuited to GND. At this time the operating point

moves to region 2 for positive surges(region 3 fornegativesurges). Once thesurge currentfalls below

the switch offcurrent I

, the devicereturns to its initial state (region 1).

SWOFF

For surges occuring between TIP and RING, the CLP270Macts in the same way. This means that the

CLP270Mensures a tripolarprotection.

Whenused alone, theCLP270Macts at the internalovervoltagereferencelevel (+/- 270 V). Furthermore,

it ispossibleto adjust this thresholdlevel toa lowervoltageby using:

up to 4 fixedexternal voltage reference(V

externalreferencesupplies,V

andVb2(seefig.5b,onnextpage).

b1

toVZ4) (see fig. 5a, here-below).

Z1

Fig.5a: Methodtoadjustthe referencevoltage.

1

2

1

2

TIP

RING

Fuse

Rsense

TIPL TIPS

Overcurrent

detector

detector

RINGS

Overvoltage

reference

(+/- 270 V)

Overvoltage

reference

(+/- 270 V)

detector

Overvoltage

Overvoltage

detector

OR

SW3 SW1

FS GND

SW4 SW2

OR

Overcurrent

RINGL

Rsense

Fuse

Rp

VZ1

VZ2

VZ3

VZ4

Rp

5/24

CLP270M

Fig. 5b:

Methodto adjustthe referencevoltage

TIP

Fuse

Rsense

.

1

Rp

TIPL TIPS

Overcurrent

detector

Overvoltage

detector

Overvoltage

detector

RINGS

RING

OR

SW3 SW1

FS GND

SW4 SW2

RINGL

OR

Overcurrent

detector

Rsense

Fuse

Fig. 6: Switchingby currentduring speechmode.

Fuse

TIP

ILG

Rsense

TIPL TIPS

Overcurrent

detector

Overvoltage

Overvoltage

detector

OR

SW3 SW1

FS

reference

(+/- 270 V)

Rp

VLG

GND

Overvoltage

reference

(+/- 270 V)

Overvoltage

reference

(+/- 270 V)

1

2

Rp

External

voltage

reference

-Vbat

-VREF2

2

VB1

VB2

1

2

ILG

A2

5

4

VREF1

6

V

LG

2.4. Speechmode

Inspeechmode (Ring relay in position 1), the protectionis providedbythe combinationof bothCLP270M

andthe externalvoltagereferencedevice.

Innormalconditions,theworkingpointof thiscircuitis locatedinregion4 ofA2 curve: theCLP270Mis idle.

Whena surgeoccursonthe line,theexternalvoltagereferencedeviceclampsatGND or-V

respectively

bat

forpositiveand negativesurges.

This generates a current which is detected by R

and causes the protection to act : the line is

sense

short-circuitedto GND.

Theoperating point movesto region5 forpositivesurges or region6 for negativesurges.

Oncethe surge currentfalls below the switching-offcurrentI

, the CLP270Mreturnsto its initial state

SWOFF

(region4).

6/24

CLP270M

Fig.7a and7b: Switching-oncurrentversus R

sense

.

ISWON(T,Rsense) / ISWON(25°C,4 )Ω

2

@-20°C @25°C @75°C

1

Iswon @ 25°C (mA)

500

300

Iswonmin

negative

Iswonmax

negative

Iswonmin

positive

Iswonmax

positive

200

0.5

100

0.3

50

0.2

3 5 7 9 11 13

357911

Rsense ( )Ω

Rsense ( )Ω

Thechoice of the switching-oncurrents is functionof theR

sense

resistors.

In normal operating condition the current (typically below -100 mA) should not activate the protection

deviceCLP270M.Thereforethe level ofactivationis tobechosenjustabovethislimit(-200mA).Thislevel

isadjustedthrough R

Figures7a and 7b enable the designerstochoosethe right R

sense

.

value.

sense

EXAMPLE :

ThechoiceofR

=4Ωensuresa negativetriggeringof-190mA minand-320 mAmax.Inthiscase,the

sense

positivetriggeringwillbe 150mAminand280 mA max.

2.5.FailureStatus

TheCLP270Mhasan internalfeaturethat allowsthe usertoget a FailureStatus (FS)indication.Whenthe

CLP270Mis short-circuitingthe line to GND, a signal can be managed through pin 1. This signal can be

used to turn a LED on in order to provide a surge indication.It may also be used with a logic circuitry to

countthenumberof disturbancesappearingon thelines.

If a surge exceeding the maximum ratings of the CLP270M occurs on the line, the device will fail in a

short-circuit state.

Fig.8: FailureStatus circuitand diagnostic.

Fig.9: Operationlimitsanddestructionzoneof the

CLP270M.

FAILURE

STATUS

Rsense

1

CLP270M

1k

Rsense

+12V

5 000

2 000

1 000

500

200

100

50

20

10

0.01 0.02 0.05 0.1 0.2 0.5 1 2 5 10

t (ms)

Thefigure9 showstwo differentcurves:

The loweroneindicates the maximumguarantedworkinglimitsoftheCLP270M.

The upper curve shows the limit above which the CLP270M is completelydestructed. In thiscase, the

FailDiagnosticpin is on.

7/24

CLP270M

3. CLP270MTESTRESULTSACCORDING TO BELLCORE 1089 REQUIREMENTS.

3.1. BELLCOREGR-1089-CORE requirements:

Table 1: Firstlevel lightningsurge.

Surge Minimum

1 +/-600 100 10/1000 25 A

2 +/-1000 100 10/360 25 A

3 +/-1000 100 10/1000 25 A

4 +/-2500 500 2/10 10 B

5 +/-1000 25 10/360 5 B

Table2:

Secondlevel lightningsurge.

Surge Minimum

peak voltage

(volts)

peakvoltage

(volts)

Minimum

peakcurrent

per conductor

(Amps)

Minimum

peak current

per conductor

(Amps)

Maximumrise

/ Minimum

decay time for

voltageand

current

(µs)

Maximumrise

/ Minimum

decaytimefor

voltageand

current

(µs)

Repetitions,

eachpolarity

Repetitions,

eachpolarity

Test

connections

per

table4.1

Test

connections

per

table4.1

1 +/- 5000 500 2/10 1 B

Tables1 and2 summarizethe lighting surgesrequired by the bellcore 1089.

8/24

Table3: First level ACpower fault (table 4-7 of GR-1089-COREissue 2, december1997).

CLP270M

Test Voltage

(V

RMS

)

Shortcircuit

currentper

Duration Primary

protection

connections

conductor

(Amps)

table4.1

1 50 0.33 15 minutes Removed A

2 100 0.17 15 minutes Removed A

3 200,400

and 600

1 (at 600V) 601s

applicationof

Removed A

each voltage

4 1000 1 60 1s

applications

Operative

protectorin

place

5 see figure 4-3 see figure 4-3 60 5s

Removed seefigure4-3

applications

6 600 0.5 30s Removed A

7 600 2.2 2s Removed A

8 600 3 1s Removed A

9 1000 5 0.5s Operative

protectorin

place

Test

per

B

B

Table4:

Secondlevel AC power fault (table4-8 of GR-1089-COREissue 2, december1997).

Test Test for Voltage

1 Secondary

contact

2 Primary

contact

3 Short-term

fault induction

4 Long-term

fault induction

5 Highimpedance

induction

Test

connections

per

table4.1

(V

RMS

Shortcircuit

)

currentper

Duration

conductor

(Amps)

120,277 25 15minutes A

600 60 5 seconds A

600 7 5 seconds A

100-600 2.2

15minutes A

(at600V)

15minutes

9/24

CLP270M

Table5:

Test connection(table4-1 of GR-1089-CORE).

Test Two-wireinterface Four-wire interface

A 1. Tipto generator,Ring to ground

1. Eachlead(T, R, T1, R1)to generatorwith

other threeleads grounded

2. Ringto generator,Tipto ground

2. Tipand Ringto generatorsimultaneously,

T1 andR1 to ground

3. Tipto generator,Ring to generator

simultaneously

B Tip to generator,Ring to generator

3. T1and R1 to generatorsimultaneously,

Tip and Ring to ground

T, R, T1, R1 to generatorsimultaneously

simultaneously

S1

Switch

unit

under

test

Voltage

Source

Limiting

resistance

(IF specified)

S2

S3

S4

T

E

R

M

T

E

R

M

Test

Table6:

Applicationof lightning and AC power faulttest voltages (table 4-2 of GR-1089-CORE).

Test S1 S2 S3 S4

T to generator,Rto ground

Closed Open Open Closed

(conditionA1 of table4-1)

R to generator,T toground

Open Closed Closed Open

(conditionA2 of table4-1)

T to generator,Rto generator

Closed Open Closed Open

simultaneously

(conditionA3 of table4-1)

Tables1 to 6 summarizethesurgeneedsdefinedbyBellcoreregarding both lightningand ACpowerfault.

Incase of first leveltest, the equipmentundertestshallbe operatingafter thesurge. For the second level

tests,the equipment undertest maybedamaged,but no fire or electricalsafety hazard mayoccur.

10/24

CLP270M

3.2.Firstlevel lightningsurge:

3.2.1.ringingmode

Lightningphenomenaarethe mostcommonsurgecauses.Thepurposeof thistestis tocheckthe behavior

oftheCLP270Magainsttheselightning strikes.

Fig.10:

Lightningsimulationtest.

2/10 µs

GENERATOR

I1

4

Rsense

TIPL TIPS

Rp

+/- 2.5 kV

(500 A)

1/2 CLP270M

GND

V1

Figures11and 12showthatthe remainingovervoltagedoesnotexceed+/- 500V. TheCLP270Mswitches

onwithin250ns and withstandsthe500Agiven by the BELLCORE2/10µs generator.

Fig.11:

CLP270Mresponseto a positivesurge.

Fig.12 :

CLP270Mresponsetoa negativesurge.

3.2.2.Speechmode

Fig.13:

Lightningtest in speech mode.

2/10 µs

GENERATOR

+/- 5 kV

(500 A)

I

1

TIPL

1/2 CLP270M

4

Rsense

TIPS

GND

50

Rp

V1

I2

-48V

LCP1511D

SLIC

V2

11/24

CLP270M

Fig.14: CLP270Mresponsetoa positivesurge. Fig.15:CLP270Mreponsetoa negativesurge.

Figures14 and15 givethe voltageandcurrentbehaviorduring positiveandnegative2.5kV,2/10µs,500A

surge tests using a LCP1511D as second stage protection device. The firing threshold values are now

adjustedto GNDand to -Vbat(-48V) by theactionof thesecond stageprotectionwhichactsasan external

voltagereference.

Asshown onthesefigures,the maximumremainingvoltagedoesnot exceed+8.5Vfor positivesurgesand

-65Vfor negative surges.

12/24

3.3.Secondlevel lightningsurge

3.3.1.Lightningtest in ringing mode

Fig.16: Lightningtest in Ringing mode.

CLP270M

2/10 µs

GENERATOR

+/- 5 kV

(500 A)

Fig.17:

CLP270Mresponseto a positivesurge.

IV11

Rsense

TIPL

1/2 CLP270M

GND

4

Rp

TIPS

Fig.18:CLP270Mresponseto a negativesurge.

Thefigures17and18givethevoltageandcurrent behaviorduringpositiveand negative5kV,2/10µs,500A

surgewith the CLP270Macting in Ringingmode.

13/24

CLP270M

3.3.2.Speechmode

Fig.19:

Fig.20:

Lightningtestin Speech mode.

2/10 µs

GENERATOR

+/- 5 kV

(500 A)

CLP270Mresponseto a positivesurge.

I

1

TIPL

1/2 CLP270M

4

Rsense

TIPS

GND

50

Rp

V1

I2

-48V

LCP1511D

SLIC

V2

Fig.21:CLP270Mresponseto a negativesurge.

Thefigures20and22givethevoltageandcurrent behaviorduringpositiveand negative5kV,2/10µs,500A

surgewith the CLP270Macting in speechmode.

TheCLP270M withstandsthe second level lightningsurgetest without trouble.

14/24

3.4.FIRSTAND SECOND LEVELACPOWERFAULT

3.4.1.Ringingmode

CLP270M

Fig.22:

AC powerfaulttestin Ringingmode.

I1

Rs

V(RMS)

50Hz

4

Rsense

TIPL TIPS

1/2 CLP270M

GND

Rp

V1

Fig.24: ACpowerfaulttest in Speech mode.

Fig. 23:

Example of behavior when facing test 3

(400V,600Ω).

Fig. 25:

Example of behavior when facing test 3

(400V,600Ω).

V(RMS)

50 Hz

I1

Rs

4Ω

Rsense

TIPL TIPS

1/2 CLP270M

GND

50

Ω

Rp

-48V

LCP1511D

SLIC

V2

Thefigures 23and 25 givethe voltageand currentatthe CLP270Mterminalsin Ringingmodeand Speech

mode.The CLP270Mis able to withstandallthefirstlevel AC power fault testsas requiredin thetable 4-7

ofGR-1089-COREstandard.

Forthe secondlevel AC power faulttestsserialprotectionas PTCor fuseareneeded.

Allthesecurves, lightningand AC powerfaultrepresentthe behaviorof theCLP270Min worst case tests,

anyhow the CLP270Mwithstandsall the otherssurges of the BellcoreGR1098 standard. For the second

levelACpowerfault test, the use of seriesprotectionelements(PTC or fuses)are needed.

15/24

CLP270M

ABSOLUTEMAXIMUMRATINGS (R

Symbol Parameter TestConditions Value Unit

SENSE

=4Ω, and T

amb

=25°C)

I

PP

Line to GNDpeak surge

current

10/1000µs (opencircuit voltage

wave shape10/1000µs)

5/310µs(opencircuit voltage

wave shape10/700µs)

2/10µs (opencircuit voltage

wave shape)

I

TSM

Non repetitivesurge peak

tp = 20 ms 60 A

on-statecurrent(TIPor

RINGversusGround)

F = 50 Hz

T

stg

T

j

T

L

Storagetemperature range

Maximumjunctiontemperature

Maximumleadtemperatureforsolderingduring10 s 260 °C

ELECTRICAL CHARACTERISTICS(R

SENSE

tp = 200 ms 30 A

tp = 2 s 15 A

=4Ω, andT

amb

Symbol Parameter Test Conditions

I

LGL

Line to GNDleakage

current

. VLG=240V

. MeasuredbetweenTIP

(or RING)and GND

V

ref

Overvoltageinternal

reference

. ILG=1mA

.MeasuredbetweenTIP

(or RING)and GND

V

SWON

I

SWOFF

Line to GNDvoltageat

SW1or SW2switching-on

Line to GNDcurrentat

. Measuredat50 Hzbetween

TIPL(orRINGL)and GND

. Refer to testcircuit page 17

SW1or SW2switching-off

(negativecurrent)

I

SWON

Line currentat SW1 or

SW2switching-on

C RINGto GNDcapacitance

TIP to GND capacitance

TIP to RINGcapacitance

. Positivepulse

Negativepulse

.

. V

V

.

.V

RINGL

TIPL

GND

=-1V

=-48V

=0V

.F = 1 MHz V

RMS

=25°C)

=1V

100 A

130

500

- 40 to + 150

°C

150

Value

Min. Typ. Max.

Unit

10 µA

270 V

380 V

150 mA

150

190

180

280

320

mA

pF

62

57

16/24

CLP270M

TEST CIRCUITFORI

SWOFF

PARAMETER: GO-NOGO TEST

R

D.U.T.

V

BAT

This is a GO-NOGOtest whichallows to confirmthe switch-off(I

TESTPROCEDURE:

- Adjust the currentlevel at the I

- Firethe D.U.T.witha surgecurrent : I

- The D.U.T.will comebacktotheOFF-statewithin a durationof 50msmax.

Fig. 26: Typi calrelativ evariationofswi t chi ng-oncurrent(positiv eor negati v e)versusR

junctiontemperature(seetestconditionFig.28).

ISWON (T, Rsense) / ISWON (25°C,4 )Ω

2

1

=

-48V

@-20°C @25°C @75°C

SWOFF

SENSE

SWOFF

valueby shortcircuitingthe D.U.T.

=10A, 10/1000µs.

PP

Fig. 27: Variation of switching-on current versus

resistorand

R

500

300

200

at 25°C.

SENSE

Iswon@ 25°C (mA)

) levelina functionaltest circuit.

Iswonmin

negative

Surge

generator

Iswonmax

Iswonmin

negative

positive

-V

P

Iswonmax

positive

0.5

0.3

0.2

3 5 7 9 11 13

Rsense ( )Ω

Fig. 28:I

MEASUREMENT

SWON

- Iswon = I1 when the CLP270M switches on (I1 is

progressivelyincreasedusing R)

- Both TIP and RING sides of the CLP270M are

checked

=10

48 V

.

Ω

RL

R sense

TIPL TIPS

DUT

RINGL RINGS

I1

GND

-R

L

±

100

50

357911

Rsense ( )Ω

Fig. 29: Relative variationof switching-offcurrent

versusjunctiontemperatureforR

SENSE

and 10Ω.

ISWOFF [Tj°C] / ISWOFF [25°C]

2.0

1.8

1.6

1.4

1.2

1.0

R

0.8

0.6

0.4

-40 -20 0 20 40 60 80

Tj(°C)

between3

17/24

CLP270M

Fig. 30:

versusR

Relativevariation of switching-off current

(between3 and10Ω).

SENSE

ISWOFF[Rsense] / ISWOFF[4 Ω]

1.6

1.4

1.2

1.0

0.8

0.6

0.4

46810

Rsense ( )Ω

Fig.31:

Residualcurrentl1 after theCLP270M.

The residualcurrent l1 is definedbyits peakvalue

(I

) and its duration (τ)@IP/2 (see below circuit

P

test).

Currentsurge input

waveform(µs)

I

(A)

PP

5/310

130A

SURGE

GENERATOR

positivesurge

negativesurge

TIPL TIPS

DUT

RINGLRING

R sense

Residualcurrent

afterthe CLP270M

Peak

waveform

current

(A)

I

P

4.2

1.1

R = 50 Ohms

I1

GND

S

t(µs)

1

0.5

-48V

Fig. 32: Relative variation of switching-onvoltage

versusdV/dt with an externalresistor of 4 Ω.

VSWON / REFV

1.12

1.10

1.08

1.06

1.04

1.02

1.00

0.98

0.1 0.3 1 3 10 30 100 300 1000

dV/dt (V/µs)

Fig. 33: Relative variation of internal reference

voltageversusjunctiontemperature(I

REF [Tj°C] /V [25°C]REF

V

1.10

1.05

1.00

0.95

0.90

0.85

-40 -20 0 20 40 60

Tj (°C)

=1mA).

LG

18/24

CLP270M

Fig. 34:

Typical junction capacitance (TIPL/GND)

versusapplied voltage.

C (pF)

220

200

180

160

140

120

100

80

60

40

0 102030405060

(V)

V

R

Fig. 35: Maximum non repetitive surge RMS on

statecurrentversusoverloadduration .

ITSM(A)

100

90

80

70

60

50

40

30

20

10

0

0.01 0.1 1 10 100 1000

TIP or RING

vs GND

t(s)

F=50Hz

Tj initial=25°C

19/24

CLP270M

SOLDERINGRECOMMENDATION

The soldering process causes considerable

thermal stress to a semiconductor component.

This has to be minimized to assure a reliable and

extended lifetime of the device. The

PowerSO-10

TM

package can be exposed to a

maximum temperature of 260°C for 10 seconds.

However a proper soldering of the package could

be done at 215°C for 3 seconds. Any solder

temperature profile should be within these limits.

As reflow techniques are most commonin surface

mounting, typical heating profiles are given in

Figure 36, either for mounting on FR4 or on

metal-backed boards. For each particular board,

the appropriate heat profile has to be adjusted

experimentally. The present proposal is just a

starting point. In any case, the following

precautionshaveto be considered:

- alwayspreheat the device

- peaktemperatureshouldbeat least30 °C

higherthan the meltingpointof the solder

alloychosen

- thermalcapacityof the basesubstrate

Fig36 :

Typical reflowsoldering heat profile

Temperature ( C)

250

o

o

245 C

Voids pose a difficult reliability problem for large

surface mount devices. Such voids under the

packageresultin poorthermalcontactandthehigh

thermal resistance leads to component failures.

The PowerSO-10 is designed from scratch to be

solely a surfacemount package,hencesymmetry

in the x- and y-axis gives the package excellent

weightbalance.Moreover, the PowerSO-10offers

the unique possibility to control easily the flatness

and quality of the soldering process. Both the top

and the bottomsolderededges of the packageare

accessible for visual inspection (soldering

meniscus).

Coplanarity between the substrate and the

package can be easily verified. The quality of the

solder joints is very important for two reasons : (I)

poor quality solder joints result directly in poor

reliability and (II) solder thickness affects the

thermal resistance significantly. Thus a tight

control of this parameter results in thermally

efficientand reliablesolder joints.

o

215 C

200

Soldering

Cooli ng

150

Epoxy FR4

board

Preheating

100

Metal-backed

50

board

0

0 40 80 120 160 200 2 40 280 320 360

Time (s )

20/24

CLP270M

SUBSTRATES ANDMOUNTINGINFORMATION

The use of epoxy FR4 boardsis quite commonfor

surface mounting techniques, however, their poor

thermal conduction compromises the otherwise

outstanding thermal performance of the

PowerSO-10. Some methods to overcome this

limitationarediscussedbelow.

One possibility to improvethe thermal conduction

is the use of large heat spreader areas at the

copper layer of the PC board. This leads to a

reductionof thermalresistanceto 35 °Cfor 6 cm

of theboardheatsink(see fig. 37).

Use ofcopper-filledthroughholesonconventional

decrease thermal resistance accordingly. Using

a configurationwith 16holesunderthe spreaderof

thepackage with a pitchof1.8mmanda diameter

of 0.7 mm, the thermal resistance (junction heatsink) can be reduced to 12°C/W(see fig. 38).

Besidethe thermaladvantage,thissolutionallows

multi-layer boards to be used. However, a

drawbackof thistraditionalmaterialpreventits use

in very high power, high current circuits. For

instance, it is not advisable to surface mount

devices with currents greater than 10 A on FR4

2

boards. A Power Mosfet or Schottky diode in a

surfacemount powerpackagecan handleup to

around50Aifbettersubstratesareused.

FR4 techniqueswill increase the metallizationand

Fig37 : Mountingon epoxyFR4 headdissipation by extendingthearea of the copperlayer

Copper foil

FR4 board

Fig38 : Mountingon epoxyFR4 byusingcopper-filled throughholes for heat transfer

Copperfoil

heattransferheatsink

FR4board

21/24

CLP270M

A new technology available today is IMS - an

Insulated Metallic Substrate. This offers greatly

enhanced thermal characteristics for surface

mount components.IMS is a substrate consisting

of threedifferentlayers,(I)thebasematerialwhich

is availableas an aluminiumor a copper plate, (II)

a thermal conductive dielectrical layer and (III) a

copper foil, which can be etched as a circuitlayer.

Using this material a thermal resistance of 8°C/W

with 40 cm

2

of board floating in air is achievable

(see fig. 39). If even higher power is to be

Fig 39 :

Mountingon metal backedboard

Copper foil

Aluminium

Insulation

dissipated an external heatsink could be applied

whichleadstoanR

assuming that R

(j-a)of 3.5°C/W(see Fig. 40),

th

(heatsink-air) is equal to R

th

(junction-heatsink). This is commonly applied in

practice, leading to reasonable heatsink

dimensions. Often power devices are defined by

considering the maximum junction temperatureof

the device. In practice , however, this is far from

being exploited. A summary of various power

managementcapabilitiesis made in table 1 based

on a reasonabledelta T of 70°Cjunctionto air.

Fig 40 : Mounting on metal backed board with an

externalheatsinkapplied

Copperfoil

Aluminium

heatsink

FR4boar d

th

The PowerSO-10 concept also represents an

attractive alternative to C.O.B. techniques.

PowerSO-10offers devicesfully tested at low and

high temperature. Mounting is simple - only

conventionalSMT is required- enablingthe users

controlthe high temperaturesoftsolderingas well.

An optimized thermal management is guaranteed

through PowerSO-10 as the power chips must in

any case be mounted on heat spreaders before

beingmounted onto the substrate.

to get ridof bondwire problemsandtheproblemto

TABLE7 : THERMALIMPEDANCEVERSUS SUBSTRATE

PowerSo-10packagemountedon Rth(j-a) P Diss (*)

1.FR4usingtherecommendedpad-layout 50°C/W 1.5 W

2

2.FR4withheatsink on board (6cm

3.FR4withcopper-filledthroughholes and externalheatsink applied

2

4. IMSfloatinginair (40cm

)8°C/W 8.8 W

)35°C/W 2.0 W

12°C/W 5.8 W

5. IMSwithexternalheatsinkapplied 3.5°C/W 20 W

(*)Basedon a delta Tof70 °Cjunction to air.

22/24

PACKAGEMECHANICALDATA

10

CLP270M

B

0.10 A B

6

A1

Q

E3 E1

SEATING

PLANE

A

C

a

SEATING

PLANE

A1

L

H

1

eB

0.25 M

h

A

F

E4

D

D1

E2E

5

DETAIL”A”

DETAIL”A”

DIMENSIONS

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 3.35 3.65 0.131 0.143

A1 0.00 0.10 0.00 0.0039

B 0.40 0.60 0.0157 0.0236

C 0.35 0.55 0.0137 0.0217

D 9.40 9.60 0.370 0.378

D1 7.40 7.60 0.291 0.299

E 9.30 9.50 0.366 0.374

E1 7.20 7.40 0.283 0.291

E2 7.20 7.60 0.283 0.299

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

E3 6.10 6.35 0.240 0.250

E4 5.90 6.10 0.232 0.240

e 1.27 0.05

F 1.25 1.35 0.0492 0.0531

H 13.80 14.40 0.543 0.567

h 0.50 0.019

L 1.20 1.80 0.0472 0.0708

Q 1.70 0.067

a0° 8°0° 8°

DIMENSIONS

MARKING

Package Type Marking Packing BaseQuantity

PowerSO-10

TM

CLP270M CLP270M Tube 50

Tape and reel 60

23/24

CLP270M

ORDERCODE

CurrentLimiting Protection

FOOTPRINT

MOUNTINGPAD LAYOUT

RECOMMENDED

CLP 270 M-TR

TR = tapeand reel

= tube

Package: PowerSO-10

Minimumoperation voltage

HEADERSHAPE

Dimensionsin millimeters Dimensions in millimeters

SHIPPINGTUBE

C

DIMENSIONS(mm)

TYP

B

A

B

C

Lengthtube

18

12

0,8

532

A

Informationfurnished is believed tobe accurateand reliable. However, STMicroelectronics assumesno responsIbility forthe consequences of

use of such information nor for any infringementof patentsor otherrightsof thirdparties which mayresult fromitsuse. No license isgranted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replacesall informationpreviously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademarkof STMicroelectronics

1998 STMicroelectronics - Printed inItaly - All rightsreserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Mexico - Morocco -

The Netherlands - Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

http://www.st.com

24/24

Loading...

Loading...