FEATURES

■ 0.5 micron triple layer metal HCMOS5S pro-

cess featuring retrograde well technology,

low resistance salicided active areas, polysilicide gates and thin metal oxide.

■ 3.3 V optimized transistor with 5 V I/O inter-

face capability

■ 2 - input NAND delay of 210 ps (typ) with

fanout = 2.

■ Broad I/O functionality including LVCMOS,

LVTTL, GTL, PECL, and LVDS.

■ High drive I/O; capability of sinking up to 48

mA with slew rate control, current spike suppression and impedance matching.

■ Generators to support SPRAM, DPRAM,

ROM and MULT with BIST options.

■ Extensive embedded function library includ-

ing DSP and ST micros, popular third party

micros and Synopsys synthetic libraries.

CB35000 SERIES

HCMOS STANDARD CELLS

PRELIMINARY DATA

■ Fully independent power and ground config-

urations for inputs, core and outputs.

■ I/O ring capability up to 800 pads.

■ Output buffers capable of driving ISA, EISA,

PCI, MCA, and SCSI interface levels.

■ Active pull up and pull down devices.

■ Buskeeper I/O functions.

■ Oscillators for wide frequency spectrum.

■ Broad range of 300 SSI cells.

■ Low Power / Low Drive library subset.

■ Design For Test includes IEEE 1149.1 JTAG

Boundary Scan architecture built in.

■ Cadence and Mentor based design system

with interfaces from multiple workstations.

■ Broad ceramic and plastic package range.

■ Latchup trigger current > +/- 500 mA.

ESD protection > +/- 4000 volts.

Table 1 Module Generator Library

Cell Description

256K bits max

SPRAM

16K word max 64 bit max

Zero static current

Tristate outputs

128K bits max

DPRAM

8K word max 64 bit max

Zero static current

Tristate outputs

2M bits max

ROM

32K word max 64 bit max

Diffusion programmable

Tristate outputs

Parallel asynchronous operation

MULT

2’s complement product

6 to 64 bits for both inputs

Ripple Carry or Fast Carry Look Ahead

July 1995 1/16

CB35000 SERIES

GENERAL DISCRIPTION

The CB35000 standard cell series uses a high

performance, low voltage, triple level metal,

HCMOS5S 0.5 micron process to achieve subnanosecond internal speeds while offering very

low power dissipation and high noise immunity.

With an average gate density of 5500 gates/mm2,

the CB35000 family allows the design of highly

complex devices. The potential available gate

count ranges above 1.5 Million equivalent gates.

Devices can operate over a Vdd voltage range of

2.7 to 3.6 volts.

The I/O count for this array family ranges to over

600 signals and 800 pins dependent upon the

package technology utilized. A Sea of I/O

approach has been followed to give a solution to

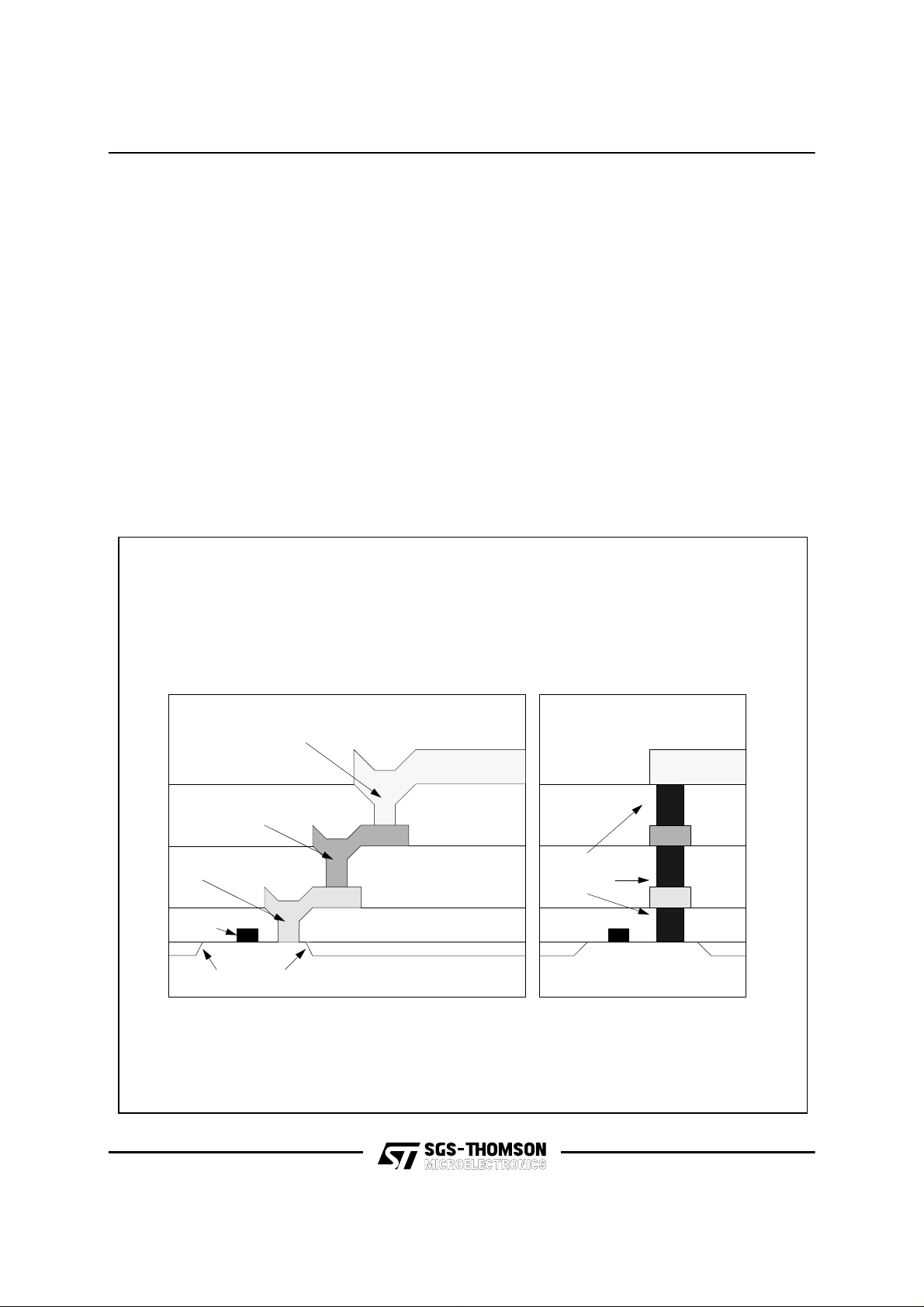

Figure 1

Advantages of stacked contacts and vias

today’s problems of drive levels and specialized

interface standards. The technology does not

utilize a set bond pad spacing but allows for pad

spacings from 80 microns upwards. The I/O is

fully compatible with that of the ISB35000

Structured Array family.

The I/O can be configured for circuits ranging

from low voltage CMOS and TTL to 350 mHz

plus low swing differential circuits. Standards like

GTL, SCSI-2, 3.3 Volt PCI, CTI, and a limited set

of 5.0 Volt interfaces are currently being

addressed. A specialized set of impedance

matched transmission line driver LVTTL type

circuits are also available with 25, 35, 45, and 55

Ohm output impedance. These buffers sacrifice

direct current capabilities for matching positive

and negative voltage and current waveforms.

CONVENTIONAL VIA LAYOUT

2nd VIA

METAL 3

1st VIA

METAL 2

CONTACT

METAL 1

GATE

ISOLATION

SUBSTRATE

AREA SAVINGS UP TO 20% FOR RANDO M LOGIC

SIMPLIFIED ROUTING AND DESIGN RULE CHECKING

3rd DIELECTRIC

2nd DIELECTRIC

1st DIELECTRIC

STACKED VIA LAYOUT

CONTACT / VIA

PLUGS

2/16

CB35000 SERIES

LIBRARY OVERVIEW

The design of the CB35000 family has been

optimized to allow extremely high density, high

speed and low power designs. For these reasons

a wide range of cells with different ranges of

driving capability are available in the library.

The library cells have been optimized in term of

functional and electrical parameters in order to

have:

■ Good balancing

■ Maximum speed

■ Optimum Threshold voltage

■ Symmetric Vdd/Vss Noise margin

■ Minimum Power-Speed figure

Surrounding the core are configurational

specialized transistors forming a Sea of I/O giving

a high degree of flexibility to the system designer .

The geometrical aspect of the cells was

configured to allow extremely dense design, fully

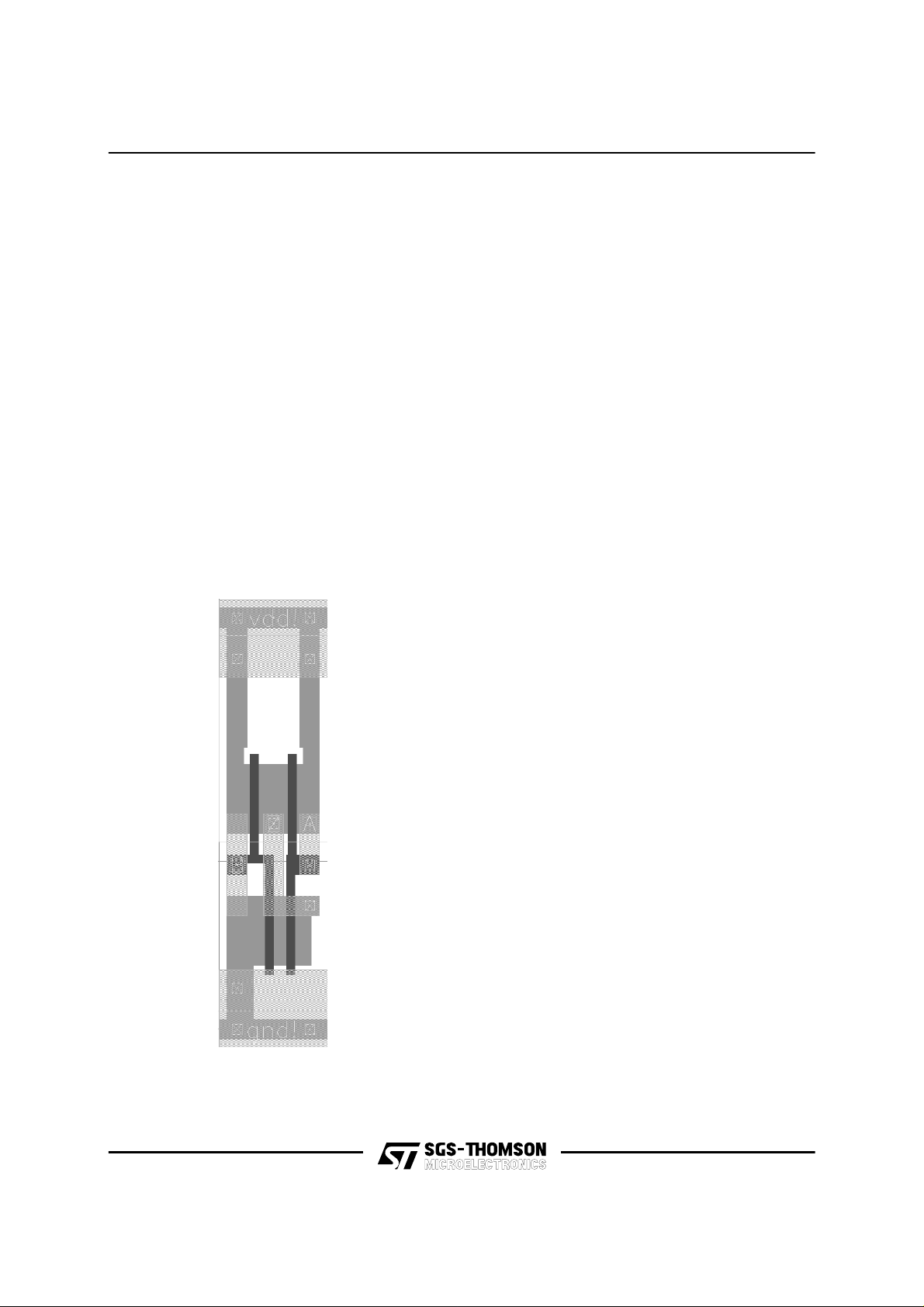

10 Êm

exploiting the features of the Place and Route

tool in terms of horizontal and vertical routing

grids. For Place and Route, three levels of metal

are utilized. Intracell and intercell wiring are

limited to first metal, with second and third metal

levels dedicated to interconnect wiring and power

distribution. Each cell gives the possibility to use

10 horizontal wiring channels using third metal.

With the horizontal grid unit being the same as

the Metal 2 minimum contacted pitch, the vertical

wiring can be done on every grid point, without

limitation.

TECHNOLOGY OVERVIEW

A major feature of the HCMOS5S process is

salicided active areas. This results in source

drain areas that are of one to two ohms

resistance as opposed to the hundreds or

thousands of ohms of source drain resistance in

previous technologies. This very low resistance is

one reason that very low transistor widths could

be utilized in the cell design since drive is not lost

due to source drain resistance. This use of low

width transistors results in lower capacitance

loading of the gates due to the smaller areas

utilized. Low resistance, low capacitance, and

small gates results in low power usage for

inverters as compared to previous technologies.

The reduction in power consumption allows the

usage of salicided active stripes to distribute

power internally to the simple cell, replacing, in

some cases, the usage of the first metal layer.

This saves silicon area by allowing greater

density, permeability and routability of the cells

resulting in greater overall circuit density.

Figure 2. ND2 Core Cell

The standard power distributions are Internal Vdd

and Vss, serving the internal cells and the

prebuffer sections of the I/O, External Vdd and

Vss serving the output transistors only, and

Receiver Vdd and Vss serving the first stages of

the receiver cells. Optional distributions for 5.0V

interface, GTL, CTL, and other standards can be

utilized as necessary.

3/16

CB35000 SERIES

LIBRARY

The following section details the elements which

make up the CB35000 Series library. The

elements are organized into three categories:

1. Macrocell library with Input, Output,

Bidirectional Buffers including JTAG

macrocells and Core cells.

2. Macrofunctions

3. Module generators.

I/O BUFFERS

CB35000 technology does not utilize a standard

type I/O cell but is a leader in the emerging Sea

of I/O approach to handling the chip interface

problem. This approach starts at the bond pad

area of the I/O where the pad size and pitch is not

determined until the customers choice of

packaging, signal interface standards and I/O

count is considered. Wire bond pad spacings for

80 micron centres are available where large

signal counts are most important.

Pad spacing can be increased incrementally. It is

expected that most designs will use 100 micron

spacings or above. It is also possible to use

different spacings for different width output

sections when needed within the same device.

Along with the variable bond pad spacing the I/O

output transistor section does not have a fixed

width. Previous technologies utilized a design

approach where the desired full function buffer

was designed for a maximum current taking one

pad location with the usual current in the range of

twenty four milliamps. The approach followed in

CB35000 is to have identical twenty five micron

wide output transistor slices stepped around the

die. Each slice contains one set of protection

diodes to the external power rails and eight P and

eight N transistors. The transistors are

specifically laid out and selectively non salicided

for ESD protection and latch up prevention.

These slices are paralleled to meet the current

needs of the user, for example, to construct a

24mA sink and 12mA source LVTTL buffer, a

number of slices would be used. The next group

of devices that makes up the I/O circuits is again

a 25u wide slice of specialized transistors that are

utilized to form the slew rate control sections of

the I/O. Each of these slices has circuits to

control the switching of up two sections of P and

N output transistors. These sections are of

course created from the output transistor slice

above the slew rate section and can be

connected as desired by the designer. Many

configurations of circuits can be created to supply

the desired results with slew rate slices paralleled

with multiple output sections. A further function of

the I/O circuits is current spike suppression

during switching of the I/O transistors. The logic

utilized causes the conducting transistors to turn

off before the opposing set of transistors turn on.

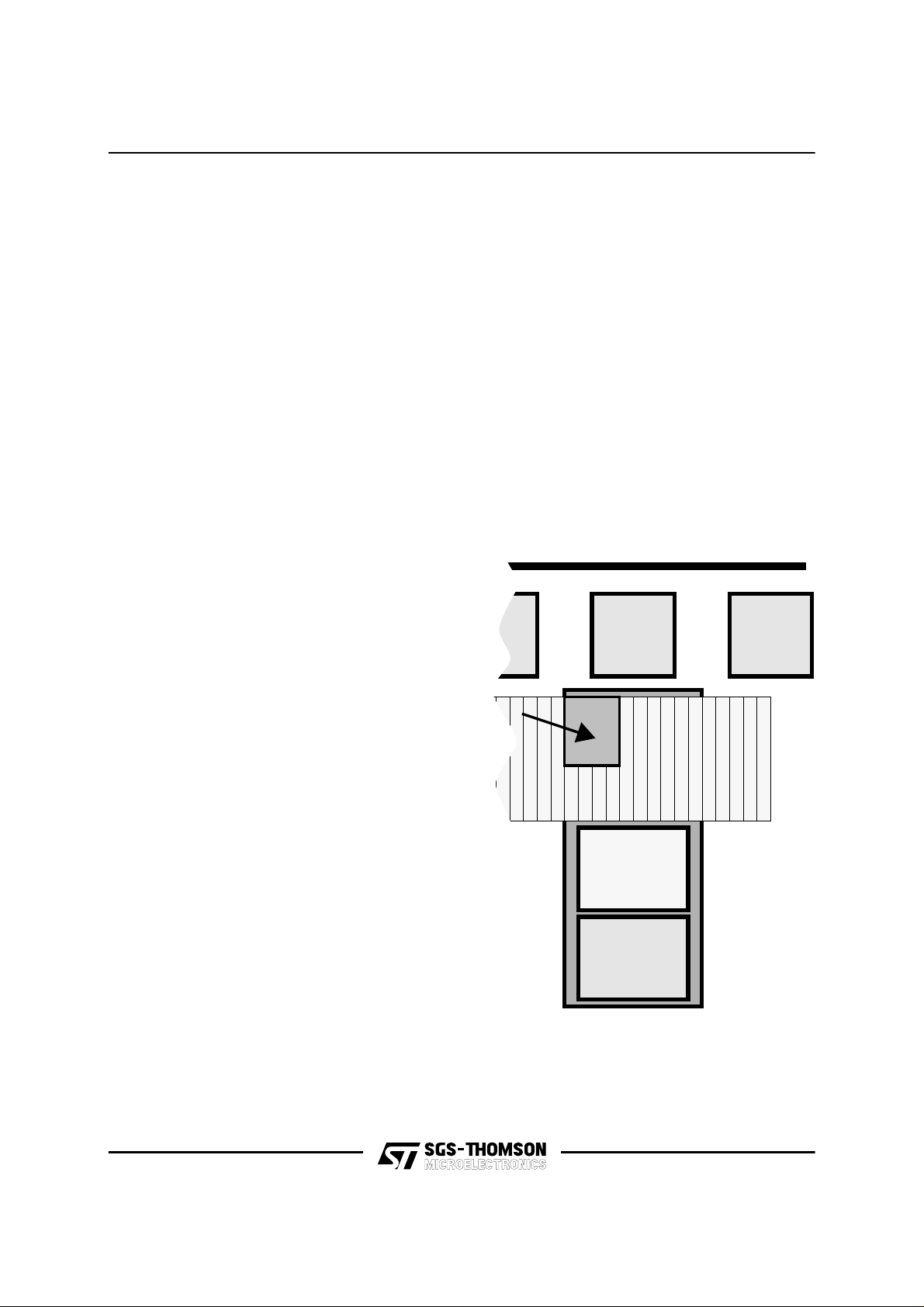

Figure 3

IO Buffer Technology

EDGE OF DIE

GUARDRING

PROGRAMMABLE

PITCH BOND PADS

4mA

Selected

SEGMENTED

OUTPUT

RIVER OF DRIVE

TRANSISTORS

INPUT

CONTROL

SLEW RATE

TRISTATE

BUSKEEPER

LEVEL SHIFTER

DIE CORE

4/16

CB35000 SERIES

MPUL

LPUL

Trip Level = 0.5 * Vdd

Figure 4a

D.C. Specifications for

LVCMOS Input Receivers

MPUL

LPUL

Trip Level = 1.4 Volts

(nominal)

Vdd + 0.3 Volts

0.8 * Vdd

Typical Current from all Vdd

supplies at LPUL or MPDL

0.2 * Vdd

Vss - 0.3 Volts

Vdd + 0.3 Volts

Vss + 2.0 Volts

25 µA per receiver

MPDL

LPDL

Typical Current from all Vdd

supplies at LPUL or MPDL

25 µA per receiver

Figure 4b

Vss + 0.8 Volts

D.C. Specifications for

LVTTL Input Receivers

Table 2 I/O Drive Capacity for LVCMOS and

LVTTL Slew Rate Buffers

Current Drive

(mA)

2.0 50

4.0 100

8.0 200

12.0 300

16.0 400

24.0 800

Maximum

Capacitance (pF)

Vss - 0.3 Volts

MPDL

LPDL

Table 3 I/O Drive Capacity for LVCMOS and

LVTTL Non Slew Rate Buffers

Current Drive

(mA)

2.0 50

4.0 100

8.0 200

12.0 300

16.0 400

24.0 800

Maximum

Capacitance (pF)

5/16

CB35000 SERIES

Table 4 Temperature (Junction) and Voltage

Multipliers

T emperatureoCK

T

-55 0.77

-40 0.83

25 1.00

70 1.13

85 1.17

125 1.27

V

DD

K

V

2.7 1.20

3.0 1.11

3.3 1.00

3.6 0.94

Inside the slew rate sections the next slices of

specialized designed components step on a 50

micron wide pattern. The first of these 50 micron

wide sections is utilized for predriver circuits;

these include specialized built in test functions for

the I/O. The predriver of course interfaces the

core signals controlling tristate and switching

functions with the slew rate and output transistor

sections but it also allows all Output Buffers to be

driven high, low or put into tristate regardless of

the state of the internal logic greatly simplifying

parametric testing of the part and also assisting

customers who wish to use this feature during

board testing. Note that all output buffers can be

tristated by this function including buffers that

normally do not tristate. This test function also

turns off all pull up or down devices and shuts

down all differential receivers and converts them

into standard CMOS receivers. Inside the

predriver is a section of specialized transistors

used to create the receiver functions. This

section includes specialized non salicide

protection resistor diodes to further protect the

gates of the receiver devices from ESD and latch

up. Also present in this section are devices that

can be utilized to form various parameteriseable

pull up, pull down and buskeeper functions. A full

set of standard receivers with pull up and pull

6/16

down devices is present in the library. The

technologies supported match the output buffer

capabilities and include, LVCMOS, LVTTL, GTL,

CTL, Differential, etc. and a five volt interface

capability.

All pads except the sixteen corner pads can be

configured as power or I/O pads. The configured

power pads are known as placeable pads and

have an associated current handling capability.

Their placement is dependent on the types of

output buffers used in the design. For rules

governing the placement of pads, please contact

your local SGS-THOMSON design centre.

CORE LOGIC

The propagation delays shown in the CB35000

data book are given for nominal processing, 3.3V

operation, and 25 C temperature conditions.

However there are additional factors that affect

the delay characteristics of the macrocells. These

include loading due to fanout and interconnect

routing, voltage supply, junction temperature of

the device, processing tolerance and input signal

transition time. Prior to physical layout, the

design system can estimate the delays

associated with any critical path. The impact of

the placement and routing can be accurately RC

back annotated from the layout for final

simulations of critical timing. The effects of

junction temperature, (K

(K

) on the delay numbers are summarized in

V

) and voltage supply

T

Table 4. A third factor, is associated with process

variation. This multiplier has a minimum of 0.8

and a maximum of 1.2.

MACROCELLS AND MACROFUNCTIONS

The CB35000 series has internal macrocells that

are robust in variety and performance. The cell

selection has been driven by the need of

Synthesis and HDL based design techniques.

This offering is rich in buffers, complex

combinatorial cells and multi power drive cells,

which allow the Synthesis tool to create a netlist

compatible with the requirements of Place and

Route tools.

Macrofunctions are a series of soft-macros

facilitating quick capture of large functional blocks

and are available for such functions as counters,

Table 5 Module Generator Library

Cell Description

SPRAM

Zero static current, Tristate outputs

DPRAM

Zero static current, Tristate outputs

ROM

Diffusion programmable, Tristate outputs

Parallel asynchronous operation

MULT

Ripple Carry or Fast Carry Look Ahead

shift register and adders. Macrofunctions are

implemented at layout by utilizing macrocells and

interconnecting to create the logic function.

MODULE GENERATORS

A series of module generators using compiled

cell generation techniques, are available to

support a range of megacells. These modules

enable the designer to choose individual

parameters in order to create a compiled cell,

which meets the specific application

requirements. These include single port RAM,

dual port RAM, ROM and MULT. The compiled

cell generators construct custom cells, which are

implemented using a special leaf cell technique,

ensuring predictable layout and accurate module

characteristics. In choosing megacells the

designer can consider the trade-offs between

speed and area to generate a fully customized

cell which meets their specific device

requirements. These megacell generators are

complemented by a group of application specific

embedded megacells. These allow access to

technologies that have been hitherto the domain

of standard products. Examples include mixed

mode cells for graphics, DAC/ADC’s (4-9 bit),

PLL applications, and Digital Signal Processor

functions for cellular comms, fax and high-speed

modem.which initially consist of a Triple 8-bit

DAC, Graphics RAM, Clock Multiplier PLL and

Frequency Synthesis PLL.

CB35000 SERIES

256K bits max

16K word max 64 bit max

128K bits max

8K word max 64 bit max

2M bits max

32K word max 64 bit max

2’s complement product

6 to 64 bits for both inputs

100 Mbps serial transputer links coupled with

large and fast memory can be used for pipelining,

caching and synchro circuits in modern RISC

computing architectures. Viterbi and Reed

Solomon cores aim at the HDTV and satellite

transmission markets. To support telecom needs

for CCITT standard applications, ADPCM cells

supporting CT2 protocol have been developed.

DESIGN FOR TESTABILITY

The time and cost for ASIC testing increases

exponentially as the complexity and size of the

ASIC grows. Using a design for testability

methodology allows large, more complex ASICs

to be efficiently and economically tested.

CB35000 supports the JTAG boundary Scan and

both edge and level sensitive scan design

techniques by providing the necessary

macrocells. Scan testing aids device testability by

permitting access to internal nodes without

requiring a separate external connection for each

node accessed. Testability is assured at device

level with the close coupling of LSSD latch

elements, Automatic Test Pattern Generation

(ATPG) and high pattern depth tester

architecture. BIST options for memory generators

are also available.

At system level, SGS-THOMSON fully supports

IEEE 1149.1, and the I/O structure utilized in this

family is completely compatible. Several types of

7/16

CB35000 SERIES

core scan cells are provided in the CB35000

Series library. Examples include FDxS/FJKxS

cells which are edge sensitive and LSxx cells

which are true LSSD cells. Non-overlapping clock

generator macros are also available.

EVALUATION DEVICE

An evaluation device is used to demonstrate the

performance of the CB35000 series as well as

verify the effectiveness of the design system. The

device has path delays, latches, a host of

macrocells and memory functions which were

Figure 5

Evaluation Device

used to verify the simulated characteristics that

are supplied in the data book. Characterization of

the path delays including interconnect shows

typical delays of 210 ps for a 2 input NAND with

receivers/drivers operating at frequencies of 200

MHz. The evaluation device is available in a 208

pin plastic quad flat pack.

8/16

CB35000 SERIES

PACKAGE AVAILABILITY

The CB35000 Series is designed to be

compatible with QFP, BGA and SBC package

types, in addition to the more traditional types

found.

The options include Plastic Leaded Chip Carriers

(PLCC) from 28 to 84 pins, while the Metric Quad

Flat Pack (xQFP) offering ranges up to 208 pins.

Both high performance and high power variants

are available as well as the TQFP thin types.

Figure 6

Packaging Capability

NUMBER

OF LEADS

PQFP TQFP BGA PLCC CPGA POWER PQFP

(Pins)

20

28

44

64

❍❍

❍❍

68

80

❍❍

84

100

120

128

144

160

176

❍❍ ❍

❍❍❍

❍❍

❍❍ ❍ ❍

❍❍

❍

180

208

❍❍❍

224

225

256

257

304

313

400

480

Ball Grid Array (BGA) packages are available

from 160 to 500 pins and SBC types allow the pin

count to reach the area of 1000 pins. Pin counts

for through board mounting (PGA) range up to

480.

The diversity in pin count and package style gives

the designer the opportunity to find the best

compromise for system size, cost and

performance requirements.

All packages for the military market are

hermetically sealed to meet MIL-STD-883

Method. Prototypes are developed in ceramic

packages for fast turnaround evaluation.

PACKAGE NAME

Slug/Spreader

❍

❍

❍❍

❍❍

❍

❍

❍

❍

❍

✮✮

✮✮

✮✮

❍ Packages in Production

✮ Packages in Development

9/16

CB35000 SERIES

DESIGN ENVIRONMENT

Several interface levels are possible between

SGS-THOMSON and the customer in the

undertaking of an ASIC design. The four levels of

interface are shown in Figure 7. Level 1 is

characterized by SGS-THOMSON receiving the

system specification and taking the design

through to validation and fabrication. At level 2

interface the designer supplies a complete logic

design implemented in a standard generic logic

family. SGS-THOMSON then takes the design

through to layout, validation and fabrication.

Level 3 is the most common and preferred

interface level. Logic capture and pre-layout

Figure 7

Customer/SGS-THOMSON Interface Levels

simulation are performed by the designer using

an SGS-THOMSON supported design kit. The

design is then taken through layout, validation

and fabrication by SGS-THOMSON.

The SGS-THOMSON design system validates all

designs before fabrication. Design kits are

provided that allow schematic capture entry via

Mentor Graphics and Cadence products.

Simulation is supported for Cadence and Mentor

Graphics. Full support is also provided for

Cadence Verilog, Synopsys VSS and System

Hilo simulators. Figure 8 shows the SGSTHOMSON Design Flow.

Test vector development uses TSSI software

from Summit and Currentest from CrossCheck.

SYSTEM SYSTEM

INTERFACE LEVELS

SPECIFICATION

CUSTOMER

LEVEL 1

CUSTOMER

LEVEL 2

LEVEL 3

LEVEL 4

LOGIC

DESIGN

CUSTOMER

SCHEMATIC

CAPTURE

DESIGN

VERIFICATION

CUSTOMER

PRE-LAYOUT

SIMULATION

SGS-THOMSON

SGS-THOMSON

LAYOUT POST-LAYOUT

SIMULATION

SGS-THOMSON

MANUFACTURE

AND TEST

SGS-THOMSON

ECR1 ECR2

10/16

Figure 8

SGS-THOMSON Design Flow

CB35000 SERIES

HARDWARE DESCRIPTION

LANGUAGE

VHDL / HDL

LOGIC SYNTHESIS

SYNOPSYS

GATE LEVEL SIMULATION

VERILOG-XL

MENTOR

SYSTEM HILO

VSS

TSSI

CURRENTEST

FUNCTIONAL

SIMULATION

VHDL / HDL

SCHEMATIC CAPTURE

CADENCE

MENTOR

FLOORPLANNING

DELAY EVALUATION

RC BACK ANNOTATION

CLOCK TREE SYNTHESIS

SIGN OFF SIMULATION

SGS-THOMSON

LAYOUT

SILICON

11/16

CB35000 SERIES

Table 6 Absolute Maximum Ratings (note1)

Supply Voltage, Vdd -0.5 V to +6.0 V

Input or Output Voltage -0.5 V to (Vdd + 0.5V)

DC Forward Bias Current, Input or Output -24mA source, +24mA sink

Storage Temperature Ceramic -65 to 150 degrees Centigrade

Storage Temperature Plastic -40 to 125 degrees Centigrade

Note 1. Referenced to Vss. Stresses above those listed under “absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only and functional operation of the device at these or any other conditions above those indicated

in the operation sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect the device reliability.

Table 7 Recommended DC Operating Conditions

Normal Operating Supply Voltage Vdd (note 1) 3.3 V +/- 10% (3.0 V to 3.6 V)

Extended Operating Supply Voltage Vdd (notes 1,2) 3.3 V + 0.3V/-0.6V (2.7V to 3.6V)

Operating Ambient Temperature

Commercial (note 3)

Industrial (note 3)

Military (note 4)

Note 1. Commercial, Industrial, and Military Conditions

Note 2. Low Voltage TTL Circuits are NOT functional to specifications below 3.0 Volts

Note 3. All circuits will operate to full specifications with a Vdd of 3.0V to 3.6V and a junction temperature of -40 to +125 degrees centi-

grade. These junction temperatures are compatible with the Commercial and Industrial Temperature Ranges.

Note 4. All circuits will be functional from -55 to +150 degrees centigrade junction temperature (military Ambient Temperature Range)

but will not necessary operate to published specifications. Only circuits specified as operational to extended temperature range

may be used when operating to Military temperature conditions.

0 to 70 degrees Centigrade

-40 to +85 degrees Centigrade

-55 to +125 degrees Centigrade

Table 8 Special Voltages (Vcc) Operating Conditions

FVI (Five Volt Interface) Supply Voltage (notes 1,2) 5.0V +/- 10% (4.5 V to 5.5 V)

GTL (Gunning Transistor Logic) Supply Voltage (notes 1, 3) 1.2V +/- 5% (1.14 V to 1.26 V)

CTT (Center Tap Terminated) Supply Voltage (notes 1,4) 1.5V +/- 10% (1.35 V to 1.65 V)

Note 1. Commercial, and Industrial Use Only -40 +85 degrees Centigrade

Note 2. I/O Circuits Only takes Special External Power Distribution and May NOT be mixed with GTL or CTL circuits on any one side of

Note 3. I/O Circuits Only takes Special External Power Distribution and May NOT be mixed with FVI or CTL circuits on any one side of

Note 4. I /O Circuits Only takes Special External Power Distribution and May NOT be mixed with FVI or GTL circuits on any one side of

the die. Only a very limited buffer set is available.

the die. Only a very limited buffer set is available.

the die. Only a very limited buffer set is available.

12/16

CB35000 SERIES

Table 9 LVTTL Interface DC Electrical Characteristics (Note 1)

Symbol Parameter Conditions Min Typ Max Unit Notes

Vil Low Level Input Voltage 0.8 Volts 2,3

Vih High Level Input Voltage 2.0 Volts 2,3

Vol Low Level Output Voltage Iol = Rated Buffer

Current

Voh High Level Output Voltage Ioh = Rated Buffer

2.4 3.0 Volts 2,3,4

Current

Vt + Schmitt Trigger +Ve

Threshold

Vt - Schmitt Trigger -Ve

0.9 1.1 Volts 2,3

Threshold

Note 1. These are normal Voltage and extended temperature specifications

Note 2. Adherence to rules in Power Pin / Pad Specifications Required

Note 3. Refer to the CB35000 Standard Cell Specification for full Testing Levels and Conditions

Note 4. Buffers offered in 2, 4, 8, 12, 16, and 24 mA TTL options

Vdd from 3.0 V to 3.6 V

Temperature Ambient from -55 to 125 degrees Centigrade

Table 10 LVCMOS Interface DC Electrical Characteristics (Note 1)

0.2 0.4 Volts 2,3,4

1.7 1.9 Volts 2,3

Symbol Parameter Conditions Min Typ Max Unit Notes

Vil Low Level Input Voltage 0.2xVdd Volts 2,3,4

Vih High Level Input Voltage 0.8 x

Volts 2,3,4

Vdd

Vol Low Level Output Voltage Iol = Rated

0.2 0.4 Volts 2,3,4,5,6

Buffer

Current

Voh High Level Output Voltage Ioh = Rated

Buffer

Current

Vt + Schmitt Trigger +Ve

0.85

x

Vdd

0.9

Volts 2,3,4,5,6

x

Vdd

1.7 1.9 Volts 2,3

Threshold

Vt - Schmitt Trigger -Ve

0.9 1.1 Volts 2,3

Threshold

Note 1. These are extended voltage and temperature specifications

Note 2. Adherence to rules in Power Pin / Pad Specifications Required

Note 3. Refer to the CB35000 Standard Cell Specification for full Testing Levels and Conditions

Note 4. Buffers offered in 2, 4, and 8 mA CMOS options

Note 5. Note only one CMOS buffer may sink or source DC current when parametric measurements are taken due to the reason that the

Note 6. If no buffers are sinking or sourcing current and all internal pull up or pull down resistors in bidi buffers have been disabled by

Vdd from 2.7 V to 3.6 V

Temperature Ambient from -55 to 125 degrees Centigrade

power supply specifications for CMOS product are not written to support DC current. If more than one buffer is active voltage

drops in the supply may cause false failure readings.

having the T2 Test Pin positive Vol (max) = 0.05 Volts and Voh (min)=Vdd-0.05 Volts

13/16

CB35000 SERIES

Table 11 General Interface DC Electrical Characteristics (Note 1)

Symbol Parameter Conditions Min Typ Max Unit Notes

Iil Low Level Input Current Vi =Vss +/-10 uA 2

Iih High Level Input Current Vi = Vdd +/-10 uA 2

Ioz Tri-State Output Leakage Vo=0V or Vdd +/-10 uA 2

Cin Input Capacitance Freq=1MHz 2.0 4.0 pF 3,4

Co Output Capacitance Freq=1MHz 4.0 pF 3,4

Cio Bidi, I/O Capacitance Freq=1MHz 0.9 1.1 pF 3,4

Iklu I/O Latch Up Current V<Vss, V>Vdd 200 500 mA

Vesd Electrostatic Protection HBM 2000 4000 V 5

Note 1. These are extended voltage and temperature specifications

Note 2. Adherence to rules in Power Pin / Pad Specifications Required

Note 3. Excluding Package

Note 4. At 0.0 Volts

Note 5. Human Body Model

Vdd from 2.7 V to 3.6 V

Temperature Ambient from -55 to 125 degrees Centigrade

14/16

CB35000 SERIES

15/16

DESIGN CENTRES

USA

Carrollton, TX 75006-5039

1310 Electronics Drive

MS 2337

Tel.: (1) 214/466-8844

Lincoln, MA 01773

55 Old Bedford Rd.

Tel.: (1) 617/258-0300

San Jose, CA 95110

2055 Gateway Place

Suite 300

Tel.: (1) 408/452-8585

EUROPE

FRANCE

94253 Gentilly Cedex

7, avenue Gallieni - BP 93

Tel.: (33-1) 47407575

GERMANY

8011 Grasbrunn

Bretonischer Ring 4

Neukeferloh Technopark

Tel.: (49-89) 460060

ITALY

20090 Assago (MI)

Viale Milanofiori

Strade 4 - Palazzo A/4/A

Tel.: (39-2) 89213215

40033 Casalecchio di Reno (BO)

Via R. Fucini, 12

Tel.: (39-51) 591914

SWEDEN

S-16421 Kista

Borgarfjordsgatan, 13

Box 1094

Tel.: (46-8) 7939220

UNITED KINGDOM and EIRE

Marlow, Bucks SL7 1YL

Planar House, Parkway

Globe Park

Tel.: (44-1628) 890800

ASIA/PACIFIC

HONG KONG

Wanchai

22nd Floor

Hopewell Centre

183 Queen’s Road East

Tel.: (852-5) 8615788

KOREA

Seoul 121

8th floor Shinwon Building

823-14, Kuksman-Dong

Kang-Nam-Gu

Tel.: (82-2) 553-0399

SINGAPORE

Singapore 2056

28 Ang Mo Kio

Industrial Park 2

Tel.: (65) 482-1411

TAIWAN

Taipei

11th Floor

105 Section 2,

Tun Hua South Road

Tel.: (886-2) 755-4111

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no

responsibility for the consequences of use of such information nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights

of SGS-THOMSON Microelectronics. Specifications mentioned in this publication are subject to change without notice.

This publication supersedes and replaces all information previously supplied. SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems without express written approval

of SGS-THOMSON Microelectronics.

1995 SGS-THOMSON Microelectronics - All rights reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands

- Singapore - Spain - Sweden - Switzerland - Taiwan - United Kingdom - U.S.A.

Loading...

Loading...