®

ACST8-8C

ASD™

AC Switch Family

MAIN APPLICATIONS

AC static switching in appliance & industrial

■

control systems

Washing machine with bi-rotational induction

■

motor drive

Induction motor drive for:

■

- refrigerator / freezer compressor

- air conditioning compressor

FEATURES

V

■

DRM/VRRM

Avalanche controlled device

■

■ I

T(RMS)

High noise immunity: static dV/dt > 750 V/µs

■

Gate triggering current : IGT<30mA

■

■ Snubberless turn off commutation:

(dI/dt)c > 4.5A/ms

■ TO-220FPAB package

= +/- 800V

= 8A with T

CASE

=90°C

OVER VOLTAGE PROTECTED

AC POWER SWITCH

G

OUT

COM

TO-220FPAB

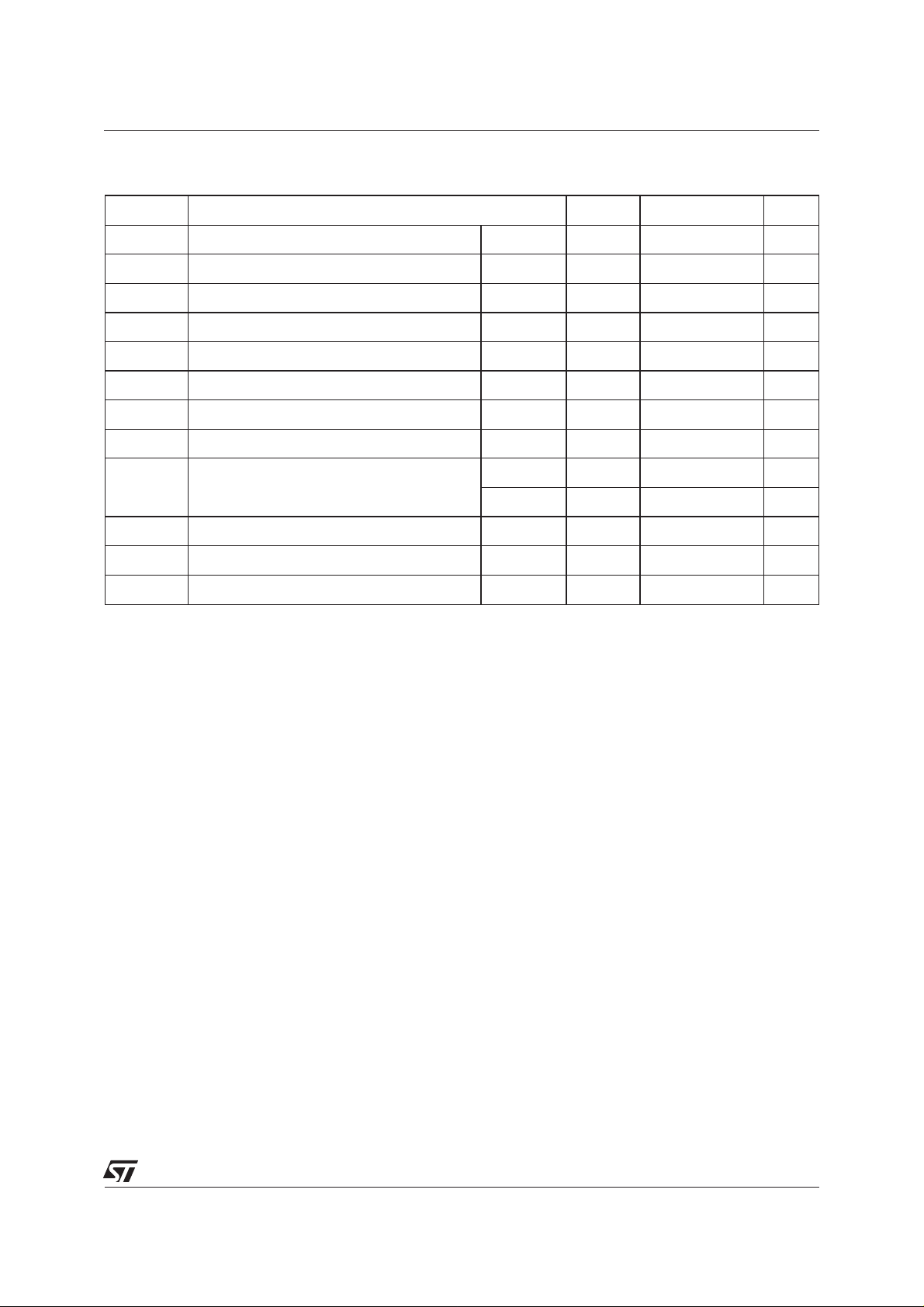

FUNCTIONAL DIAGRAM:

OUT

BENEFITS

■

Enables equipment to meet EN61000-4-5

standard

■

High off-state reliability with planar technology

■

Need no external overvoltage protection

■

Reduces the power component count

DESCRIPTION

The ACST8-8C belongs to the AC power switch

family built around the ASD technology. This high

performance device is adapted to home appliances

or industrial systems and drives an induction motor

up to 8A.

This ACST switch embeds a triac structure with a

high voltage clamping device to absorb the inductive

turn off energy and withstand line transients such as

those described in the IEC61000-4-5 standards.

G

COM

January 2002 - Ed: 4B

1/8

ACST8-8C

ABSOLUTE RATINGS (limiting values)

Symbol Parameter Value Unit

V

DRM /

V

RRM

I

T(RMS)

I

TSM

2

I

t Thermal constraint for fuse selection tp = 10ms 35 A2s

dI/dt Non repetitive on-state current critical rate of rise

V

PP

Tstg Storage temperature range - 40 to + 150 °C

Tj Operating junction temperature range - 40 to + 125 °C

Tl Maximum lead soldering temperature during 10s 260 °C

Note 1:accordingto test described by IEC61000-4-5 standard & Figure A.

GATE CHARACTERISTICS (maximum values)

Symbol Parameter Value Unit

P

G (AV)

P

GM

I

GM

Repetitive peak off-state voltage 800 V

RMS on-state current full cycle sine wave 50 to 60 Hz Tcase = 90°C 8 A

Non repetitive surge peak on-state current

Tj initial = 25°C, full cycle sine wave

tp = 20ms 80 A

tp = 16.7ms 85 A

Rate period > 1mn 100 A/µs

I

= 10mA (tr < 100ns)

G

Non repetitive line peak pulse voltage

note 1

2kV

Average gate power dissipation 0.1 W

Peak gate power dissipation (tp = 20µs) 10 W

Peak gate current (tp = 20µs) 1 A

THERMAL RESISTANCE

Symbol Parameter Value Unit

Rth (j-a) Junction to ambient 60 °C/W

Rth (j-c) Junction to case for full cycle sine wave conduction 3.5 °C/W

PARAMETER DESCRIPTION

Parameter Symbol Parameter description

I

GT

V

GT

V

GD

I

H

I

L

V

TM

V

TO

R

D

I

DRM/IRRM

dV/dt Static pin OUT voltage rise

Gate triggering current

Gate triggering voltage

Non triggering voltage

Holding current

Latching current

On state voltage

On state characteristic threshold voltage

On state characteristic dynamic resistance

Forward or reverse leakage current

(dI/dt)c Turn off current rate of decay

V

CL

Avalanche voltage at turn off

2/8

ACST8-8C

ELECTRICAL CHARACTERISTICS PER SWITCH

For either positive or negative polary of pin OUT voltage respect to pin COM voltage

Symbol Test conditions Values Unit

I

V

V

V

V

R

I

DRM

I

RRM

GT

GT

GD

I

H

I

L

TM

TO

D

V

= 12V (DC) RL=33Ω Tj = 25°C MAX. 30 mA

OUT

V

= 12V (DC) RL=33Ω Tj = 25°C MAX. 1.5 V

OUT

V

OUT=VDRM

I

= 100mA Gate open Tj = 25°C MAX. 40 mA

OUT

RL= 3.3kΩ Tj =125°C MIN. 0.2 V

IG= 20mA Tj = 25°C MAX. 70 mA

I

= 11A tp = 380µs Tj = 25°C MAX. 1.5 V

OUT

Tj = 125°C MAX. 0.95 V

Tj = 125°C MAX. 50 mΩ

V

OUT=VDRM

V

OUT=VRRM

Tj = 25°C MAX. 10 µA

Tj = 125°C MAX. 1 mA

dV/dt V

= 550V gate open Tj = 125°C MIN. 750 V/µs

OUT

(dI/dt)c Withoutsnubber Tj = 125°C MIN. 4.5 A/ms

V

CL

ICL= 1mA tp = 1ms Tj = 25°C TYP. 1200 V

AC LINE SWITCH BASIC APPLICATION

The ACST8-8C device is especially designed to drive medium power induction motors in washing machines, refrigerators, dish washers, and tumble dryers.

Pin COM : Common drive reference, to be connected to the power line neutral

Pin G :Switch Gate input to be connected to the controller

Pin OUT : Switch Output to be connected to the load

When driven from a low voltage controller, the ACST switch is triggered with a negative gate current flowing out of the gate pin G. It can be driven by the controller through a resistor as shown on the typical application diagram. In appliance systems, the ACST8-8C switch intends to drive medium power load in ON /

OFF full cycle or phase angle control mode.

Thanks to its thermal and turn-off commutation characteristics, the ACST8-8C switch is able to drive

an inductive load up to 8A without a turn-off aid snubber circuit.

In washing machine or drier appliances, the tumble rotates in both directions. When using bidirectional

phase shift induction motor, two switches are connected on each side of the phase shift capacitor: in

steady-state operation, one switch only conducts energising the coils and defining the tumble direction.

3/8

ACST8-8C

TYPICAL APPLICATION DIAGRAM

OUT

G

COM

CONTROL

UNIT

ROBUSTNESS AGAINST FAST CAPACITOR DISCHARGE

When parasitic transients or controller mis-operation occur, the blocked switch may turn on by spurious

switch firing. Since the phase shift capacitor is charged, its energy is instantaneously dissipated through

the two ACSTs whichcanbedestroyed.Topreventsuchafailure,aresistiveinductivecircuit R-L is added

in series with the phase shift capacitor.

The dI/dt depends on the maximal voltage V

tions), and on the inductance L:

dIdtV

max

=

L

The total switch turn on di/dt isthe sum of the di/dt created by any RC noise suppressor discharge and the

dI/dt created by the motor capacitor discharge.

Sincethemaximaldi/dtcapability at turn-on of the ACST8 is 100A/µs,themotorcapacitor di/dt is assumed

to be less than 50A/µs; therefore, the inductance should be 14µH.

The resistor R limits the surge current through the ACST8 during the capacitor discharge according to the

specifiedcurveI

=f(tp)asshown in Figure 6

TSM

dissipation (usually less than 1 W).

Finally both the 14µH inductance and the 1.2Ω resistance provide a safety margin of two onthe surge cur-

rent I

described in Figure 6.

TSM

of the phase shift capacitor (700V on 240V mainsapplica-

max

(tobeissued)

,and1.2Ωis low enough to limit the resistor

4/8

M

V

AC

C

L

R

Fast capacitor discharge when

one ACST switch turns on (T2)

and the motor runs (T1 ON).

700V

T1

ON

T2

ACST8-8C

AC LINE TRANSIENT VOLTAGE RUGGEDNESS

The ACST8-8C switch is able to safely withstand the AC line transient voltages either by clamping the low

energy spikes or by breaking over under high energy shocks.

The test circuit in Figure A is representative of the ACST application and is used to test the ACST switch

according to the IEC61000-4-5 standard conditions.Thankstotheloadimpedance,theACSTswitchwithstands voltage spikes up to 2 kV above the peak line voltage by breaking over safely. Such non repetitive

testing can be done 10 times on each AC line voltage polarity.

Fig. A: Overvoltage ruggedness test circuit for resistive and inductive loads

according to IEC61000-4-5 standardR=47Ω,L=10µH&V

PP

= 2kV

SURGE VOLTAGE

AC LINE & GENERATOR

Fig. 1: Maximum power dissipation versus RMS

on-state current.

P(W)

11

α=180°

10

9

8

7

6

5

4

3

2

1

0

012345678

IT(RMS)(A)

180°

α

α

R

L

OUT

V

+V

AC

PP

G

COM

Fig. 2-1: RMS on-state current versus case

temperature.

IT(RMS)(A)

9

8

7

6

5

4

3

2

1

0

0 25 50 75 100 125

Tc(°C)

α=180°

5/8

ACST8-8C

Fig. 2-2: RMS on-state current versus ambient

temperature.

IT(RMS)(A)

2.5

2.0

1.5

1.0

0.5

α=180°

Printed circuit boardFR4

Natural convection

Tamb(°C)

0.0

0 25 50 75 100 125

Fig. 4: On-state characteristics (maximum val-

ues).

Iout(A)

100

Tj=25°C

10

VTM(V)

1

0123456

Tj=125°C

Tj max. :

Vto = 0.95V

Rd = 50 mΩ

Fig. 3: Relative variation of thermal impedance

versus pulse duration.

K = [Zth/Rth]

1.E+00

Zth(j-c)

1.E-01

1.E-02

Zth(j-a)

tp(s)

1.E-03

1.E-03 1.E-02 1.E-01 1.E+00 1.E+01 1.E+02 1.E+03

Fig.5:Surge peak on-statecurrentversus number

of cycles.

ITSM(A)

90

80

t=20ms

Repetitive

Tc=90°C

Non repetitive

Tj initial=25°C

Number of cycles

70

60

50

40

30

20

10

0

1 10 100 1000

Fig. 6: Non repetitive surge peak on-state current

for a sinusoidal pulse with width tp < 10ms, and

corresponding value of I

22

ITSM(A), I t(A s)

1000

dI/dt limitation:

100A/µs

100

10

0.01 0.10 1.00 10.00

6/8

2

t.

tp(ms)

Tj initial=25°C

ITSM

I²t

Fig. 7: Relative variation of gate trigger current,

holding current and latching current versus junction temperature (typical values).

IGT,IH, IL[Tj]/IGT,IH, IL[Tj=25°C]

3.0

2.5

2.0

1.5

1.0

0.5

0.0

IGT & IH

IL

Tj(°C)

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

ACST8-8C

Fig.8:Relative variation ofcriticalrate of decrease

ofmaincurrent versusreapplied dV/dt (typical values).

(dI/dt)c[(dV/dt)c] / Specified (dI/dt)c

5

4

3

2

1

dV/dt (V/µs)

0

0.1 1.0 10.0 100.0

Fig. 10: Relative variation of static dV/dt versus

junction temperature

dV/dt[Tj] / dV/dt[Tj = 125°C]

3.5

3.0

Vout=550V

Fig.9:Relative variation ofcriticalrate of decrease

of main current versus junction temperature.

(dI/dt)c[Tj] / (dI/dt)c[Tj=125°C]

6

5

4

3

2

1

0

0 25 50 75 100 125

Tj(°C)

2.5

2.0

1.5

1.0

0.5

Tj(°C)

0.0

0 25 50 75 100 125

ORDERING INFORMATION

ACS T 8 - 8 C FP

I8AT(RMS):

AC Switch

Topology:Triac

V 800VDRM:

I

GT

C = 30mA

Package

FP:TO-220FPAB

7/8

ACST8-8C

PACKAGE MECHANICAL DATA

TO-220FPAB (Plastic)

H

Dia

L6

L2

L3

L5

D

L4

G1

G

F1

F2

F

DIMENSIONS

REF.

A

B

A 4.4 4.6 0.173 0.181

Millimeters Inches

Min. Max. Min. Max.

B 2.5 2.7 0.098 0.106

D 2.5 2.75 0.098 0.108

E 0.45 0.70 0.018 0.027

F 0.75 1 0.030 0.039

L7

F1 1.15 1.70 0.045 0.067

F2 1.15 1.70 0.045 0.067

G 4.95 5.20 0.195 0.205

G1 2.4 2.7 0.094 0.106

H 10 10.4 0.393 0.409

L2 16 Typ. 0.63 Typ.

L3 28.6 30.6 1.126 1.205

L4 9.8 10.6 0.386 0.417

E

L5 2.9 3.6 0.114 0.142

L6 15.9 16.4 0.626 0.646

L7 9.00 9.30 0.354 0.366

Dia. 3.00 3.20 0.118 0.126

OTHER INFORMATION

Ordering type Marking Package Weight Base qty Delivery mode

ACST8-8CFP ACST88C TO-220FPAB 2.4 g 50 Tube

■

Epoxy meets UL94,V0

Informationfurnished is believedto be accurateandreliable. However, STMicroelectronicsassumes no responsibilityforthe consequences of

useof such informationnor for anyinfringement of patentsor other rightsof third partieswhichmay result fromits use. Nolicense is grantedby

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2002 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany

Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore

Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

8/8

Loading...

Loading...