The documentation and process

INCH-POUND

conversion measures necessary to

comply with this revision shall be

completed by 31 November 2000.

MIL-PRF-19500/376E

31 August 2000

SUPERSEDING

MIL-PRF-19500/376D

21 August 1998

PERFORMANCE SPECIFICATION

SEMICONDUCTOR DEVICE, TRANSISTOR, NPN, SILICON, LOW-POWER

TYPES 2N2484, 2N2484UA, 2N2484UB, JAN, JANTX, JANTXV, JANS, JANHC, AND JANKC

This specification is approved for use by all Departments

and Agencies of the Department of Defense.

1. SCOPE

1.1 Scope. This specification covers the performance requirements for NPN, silicon, low-power transistors.

Four levels of product assurance is provided for each device type as specified in MIL-PRF-19500. Two levels of

product assurance are provided for die.

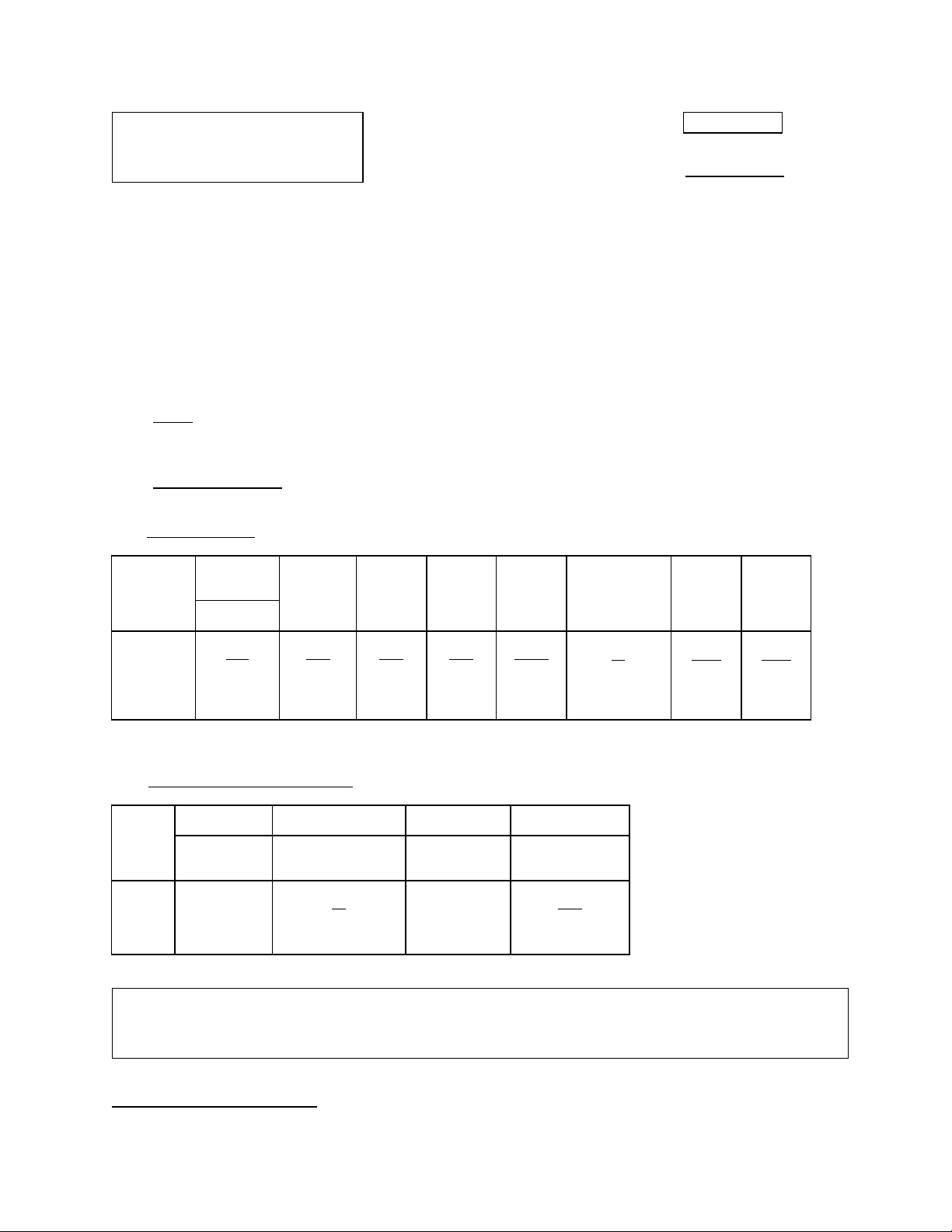

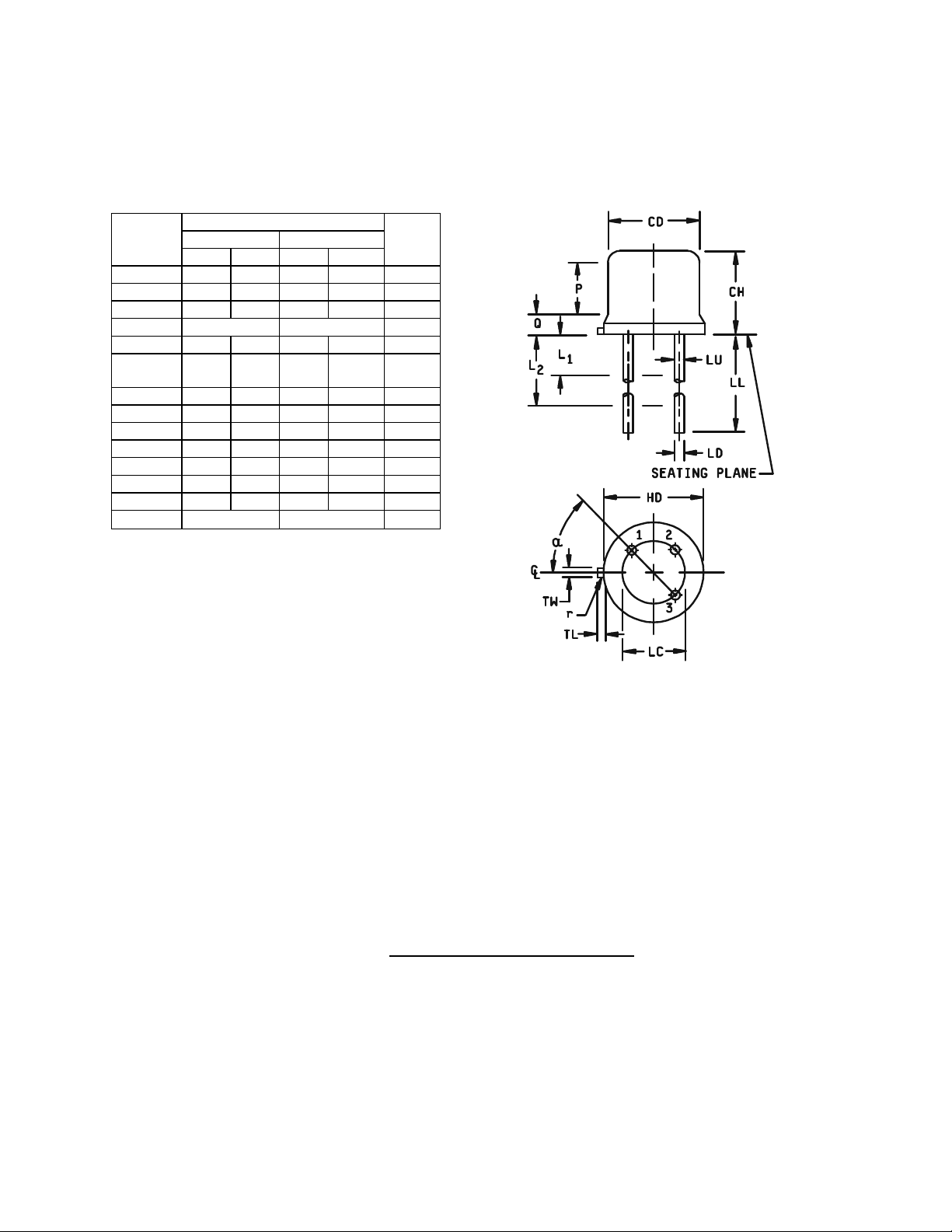

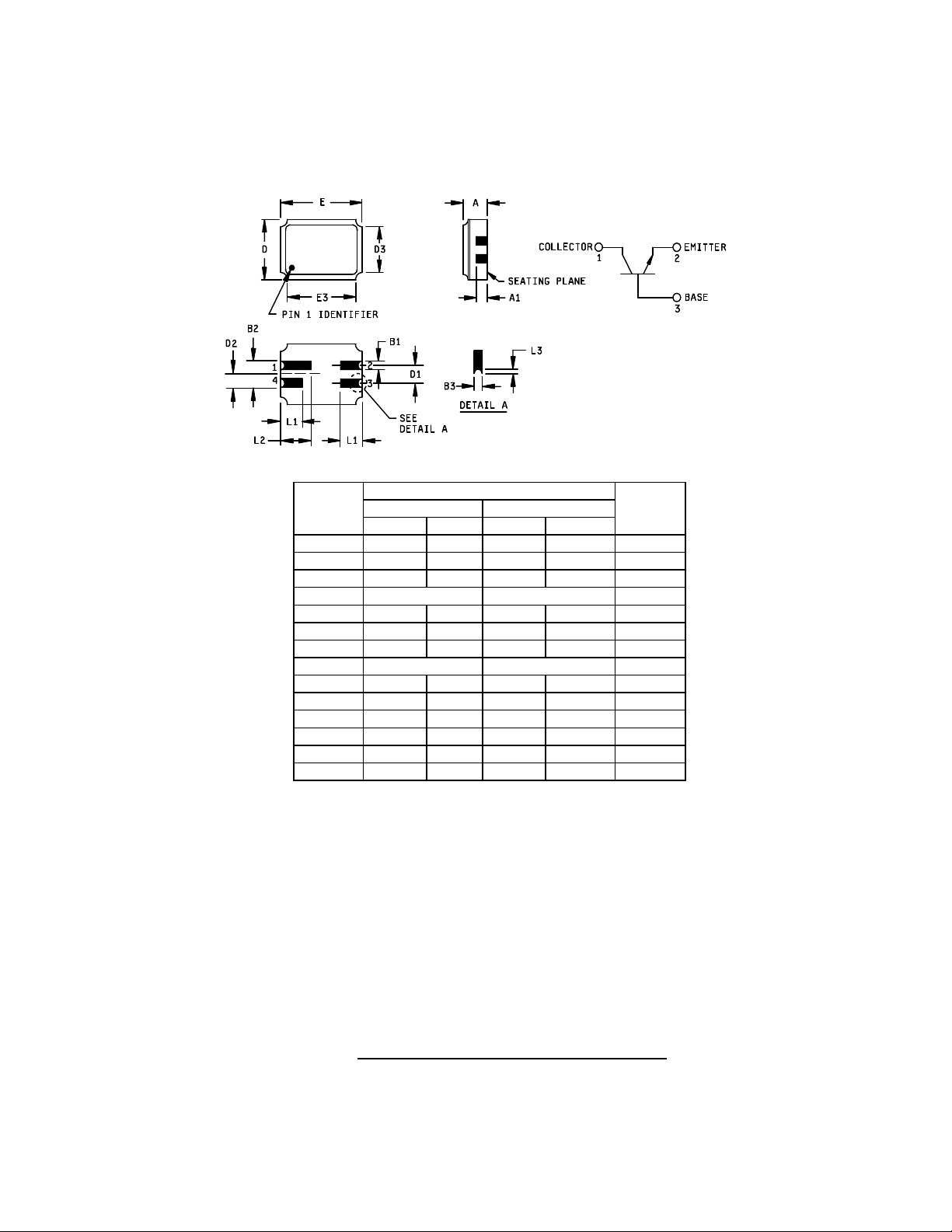

1.2 Physical dimensions. See figure 1 (similar to T0-18), figures 2 and 3 (surface mount case outlines UA and

UB), and figures 4 and 5 (die).

1.3 Maximum ratings.

Types

2N2484 500 (1) 60 6 60 50 -65 to +200 325 146

2N2484UA 650 (2) 60 6 60 50 -65 to +200 210 160

2N2484UB 500 (1) 60 6 60 50 -65 to +200 325 146

P

T

TA = +25°C

mW V dc V dc V dc mA dc

V

CBO

V

EBO

V

CEO

I

C

TJ and T

STG

°C °C/W °C/W

R

θJA

R

θJC

(1) Derate linearly at 3.08 mW/°C above TA = +37.5°C

(2) Derate linearly at 4.76 mW/°C above TA = +63.5°C.

1.4 Primary electrical characteristics.

Limits

Min

Max

h

fe

VCE = 5 V dc

IC = 1 mA dc

f = 1 kHz

250

900

C

obo

IE = 0

VCB = 5 V dc

100 kHz ≤ f ≤ 1 MHz

pF

5.0

|hfe|2 V

IC = 500 µA dc

VCE = 5 V dc

f = 30 MHz

2.0

7.0

(1)

CE(sat)

IC = 1.0 mA dc

IB = 0.1 mA dc

V dc

0.3

(1) Pulsed (see 4.5.1).

Beneficial comments (recommendations, additions, deletions) and any pertinent data which may be of use in

improving this document should be addressed to: Defense Supply Center, Columbus, ATTN: DSCC/VAC,

Post Office Box 3990, Columbus, OH 43216-5000, by using the Standardization Document Improvement Proposal

(DD Form 1426) appearing at the end of this document or by letter.

AMSC N/A FSC 5961

DISTRIBUTION STATEMENT A. Approved for public release; distribution is unlimited.

MIL-PRF-19500/376E

Dimensions

Symbol Inches Millimeters Note

Min Max Min Max

CD .178 .195 4.52 4.95

CH .170 .210 4.32 5.33

HD .209 .230 5.31 5.84

LC .100 TP 2.54 TP 6

LD .016 .021 0.41 0.53 7,8

LL .500 .750 12.7019.05 7,8

LU .016 .019 0.41 0.48 7,8

L1 --- .050 --- 1.27 7,8

L2 .250 --- 6.35 --- 7,8

Q --- .040 --- 0.86 5

TL .028 .048 0.71 1.22 3,4

TW .036 .046 0.91 1.17 3

r --- .010 --- 0.25 10

α 45° TP 45° TP

6

NOTES:

1. Dimension are in inches.

2. Metric equivalents are given for general information only.

3. Beyond r (radius) maximum, TW shall be held for a minimum length of .011 (0.28 mm).

4. Dimension TL measured from maximum HD.

5. Body contour optional within zone defined by HD, CD, and Q.

6. Leads at gauge plane .054 +.001 -.000 inch (1.37 +0.03 -0.00 mm) below seating plane shall

be within .007 inch (0.18 mm) radius of true position (TP) at maximum material condition

(MMC) relative to tab at MMC.

7. Dimension LU applies between L1 and L2. Dimension LD applies between L2 and LL

minimum. Diameter is uncontrolled in L1 and beyond LL minimum.

8. All three leads.

9. The collector shall be internally connected to the case.

10. Dimension r (radius) applies to both inside corners of tab.

11. In accordance with ANSI Y14.5M, diameters are equivalent to φx symbology.

12. Lead 1 = emitter, lead 2 = base, lead 3 = collector.

FIGURE 1. Physical dimensions (similar to TO-18).

2

MIL-PRF-19500/376E

Dimensions

Symbol Inches Millimeters Note

Min Max Min Max

A .061 .075 1.55 1.90 3

A1 .029 .041 0.74 1.04

B1 .022 .028 0.56 0.71

B2 .075 REF 1.91 REF

B3 .006 .022 0.15 0.56 5

D .145 .155 3.68 3.93

D1 .045 .055 1.14 1.39

D2 .0375 BSC .952 BSC

D3 --- .155 --- 3.93

E .215 .225 5.46 5.71

E3 --- .225 --- 5.71

L1 .032 .048 0.81 1.22

L2 .072 .088 1.83 2.23

L3 .003 .007 0.08 0.18 5

NOTES:

1. Dimensions are in inches.

2. Metric equivalents are given for general information only.

3. Dimension "A" controls the overall package thickness. When a window lid is used, dimension "A" must

increase by a minimum of .010 inch (0.254 mm) and a maximum of .040 inch (1.020 mm).

4. The corner shape (square, notch, radius, etc.) may vary at the manufacturer's option, from that shown on

the drawing.

5. Dimensions "B3" minimum and "L3" minimum and the appropriately castellation length define an

unobstructed three-dimensional space traversing all of the ceramic layers in which a castellation was

designed. (Castellations are required on bottom two layers, optional on top ceramic layer.) Dimension

"B3" maximum and "L3" maximum define the maximum width and depth of the castellation at any point on

its surface. Measurement of these dimensions may be made prior to solder dipping.

6. Lead 4 = no connection.

FIGURE 2. Physical dimensions, surface mount (2N2484UA).

3

MIL-PRF-19500/376E

Dimensions

Inches Millimeters

Min. Max. Min. Max.

A .046 .056 0.97 1.42

A1 .017 .035 0.43 0.89

B1 .016 .024 0.41 0.61 3

D .085 .108 2.41 2.74

D1 .071 .079 1.81 2.01

D2 .035 .039 0.89 0.99

D3

E .115 .128 2.82 3.25

E3

L1 .022 .038 0.56 0.96 4

NOTES:

1. Dimensions are in inches.

2. Metric equivalents are given for general information only.

3. Dimensions B2 and B3 are identical to B1

4. Dimension L2 is identical to L1.

FIGURE 3. Physical dimensions, surface mount (2N2484UB).

NotesLtr

4

MIL-PRF-19500/376E

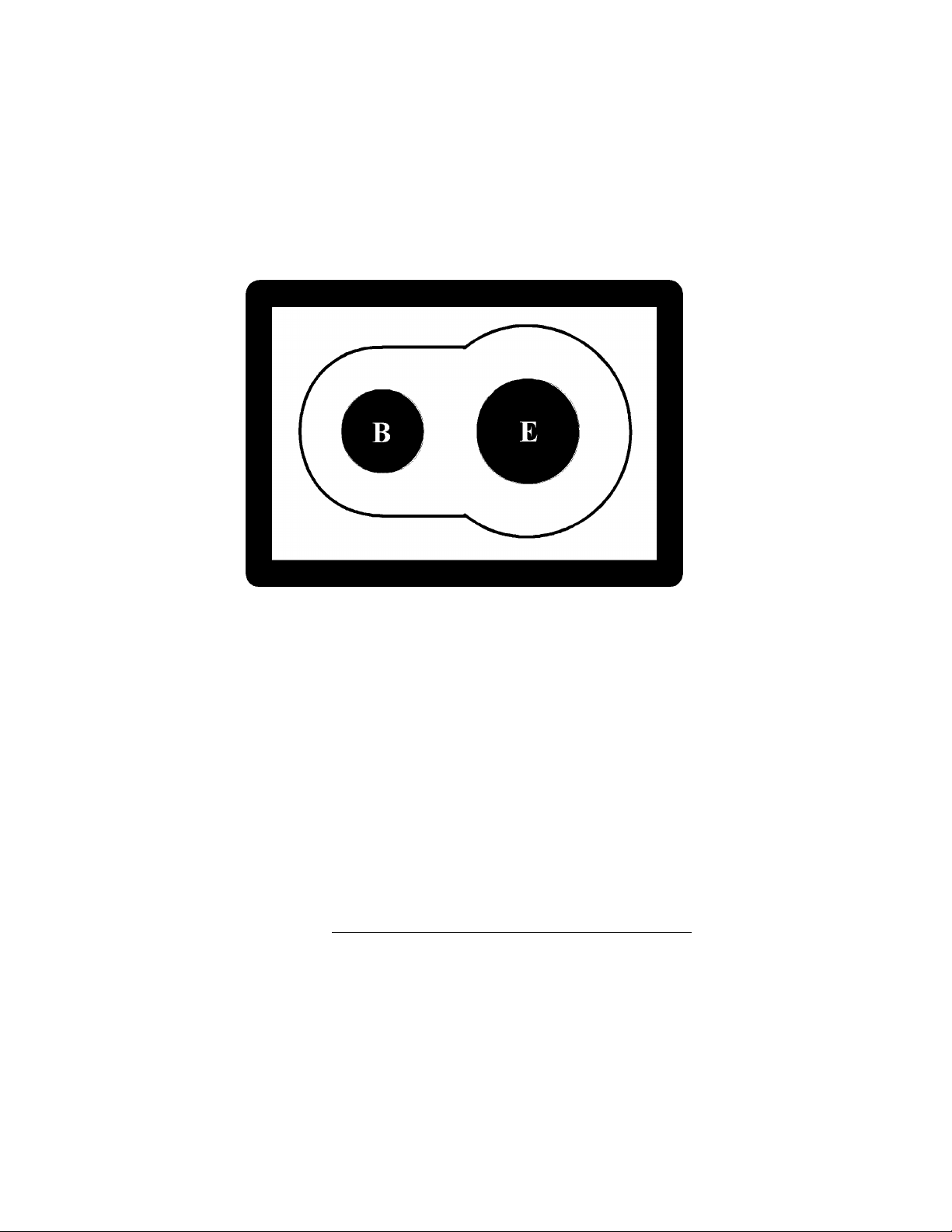

A- version

NOTES:

1. Die size...............................................0.015 x 0.019 inches ± 0.001 inch

2. Die thickness.......................................0.010 ± 0.0015 inches

3. Top metal............................................Aluminum 15,000Å minimum, 18,000Å nominal

4. Back metal ..........................................A. Gold 2,500Å minimum, 3,000Å nominal

B. Eutectic Mount – No Gold

5. Backside.............................................Collector

6. Bonding pad........................................ B = 0.003 inches, E = 0.004 inches diameter

7. Passivation.........................................Si3N4 (Silicon Nitride) 2kÅ min, 2.2kÅ nom.

FIGURE 4. Physical dimensions, JANHC and JANKC die, A - version.

5

MIL-PRF-19500/376E

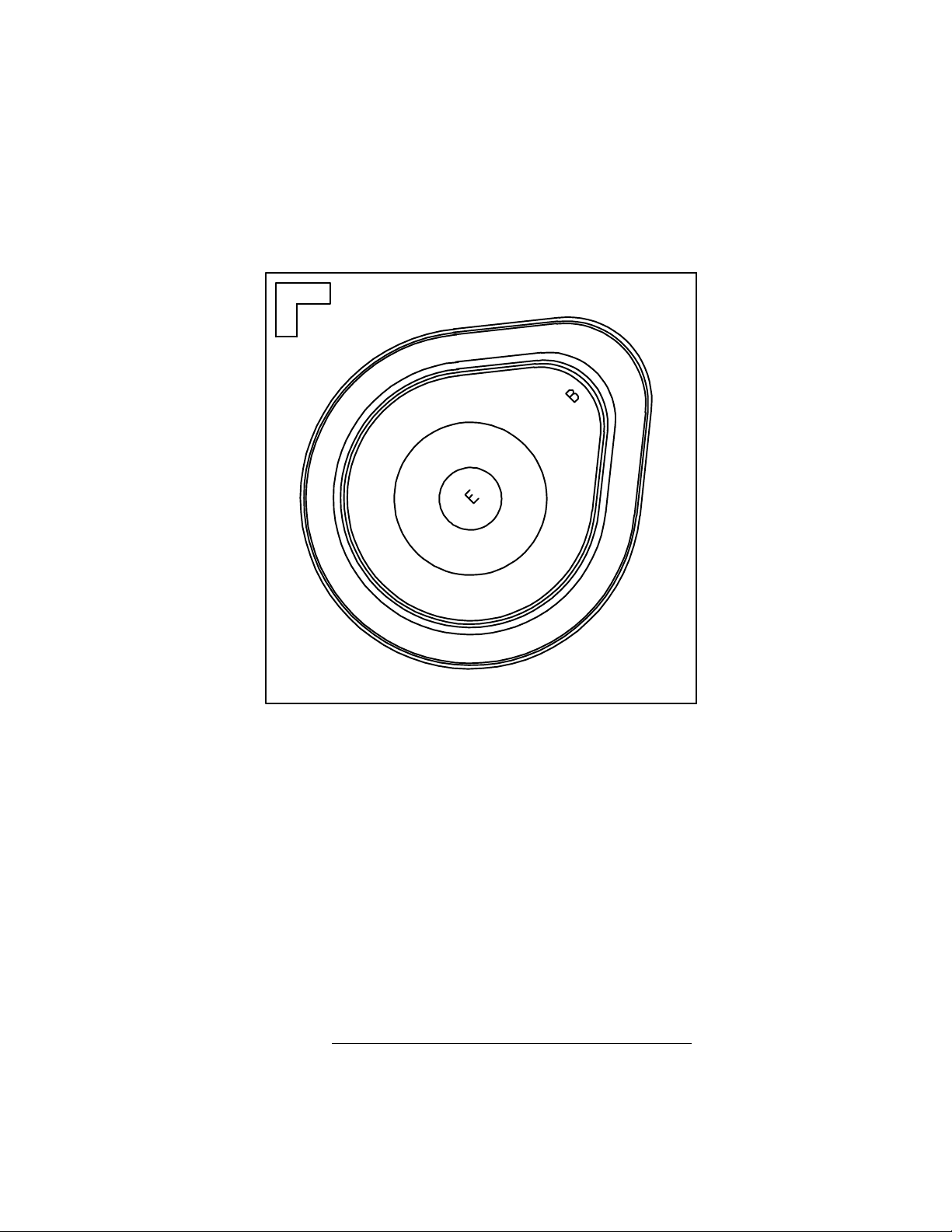

B - version

Die size:.....................................................0.018 x 0.018 inches

Die thickness: ............................................ 0.008 ± 0.0016 inches

Base pad: .................................................. 0.0025 inches diameter

Emitter pad:............................................... 0.003 inches diameter

Back metal:................................................ Gold, 6500 ± 1950 Å

Top metal: ................................................. Aluminum, 19500 ± 2500 Å

Back side:..................................................Collector

Glassivation:..............................................SiO2, 7500 ± 1500 Å

FIGURE 5. Physical dimensions, JANHC and JANKC die, B - version.

6

Loading...

Loading...