Page 1

Installation Manual

Page 2

Contents Page

Introducing the Skyroute UT ................................................................................................................2

1.1 Specifications................................................................................................................................... 2

1.2 Out of the Box ..................................................................................................................................4

Getting Started ................................................................................................................4

2.1 Installation Steps .................................................................................................................................4

2.2 Terminal Descriptions .......................................................................................................................5

Diagram of Positive and Negative Trigger ..............................................................................................6

Diagram of Relay Trigger/Dry Contact Trigger........................................................................................ 6

Diagram of Siren Trigger........................................................................................................................ 7

Secure Installation.......................................................................................................................... 8

Relocating the Antenna.......................................................................................................................... 8

How to Program........................................................................................................... 8

3.1 Installer's Programming ...................................................................................................................8

3.2 Programming Decimal Data............................................................................................................. 9

3.3 Programming Hex Data ...................................................................................................................9

3.4 Programming Toggle Option Sections ............................................................................................10

3.5 Viewing Programming .....................................................................................................................10

Program Descriptions .....................................................................................................................10

4.1 Zone Programming Sections [001] ..................................................................................................10

4.2 Telephone Line Monitor (TLM) .............................................................................................. ..........10

4.3 Swinger Shutdown ..........................................................................................................................10

4.4 Skyroute Programming Sections [803] ............................................................................................11

Activating the Skyroute Transceiver .....................................................................................................12

Calling Connect 24 ...............................................................................................................................12

Skyroute Transceiver Trouble Supervision ............................................................................................12

Skyroute Transceiver Trouble Shooting ............................................................................................12

4.5 PGM Output Options [009] ..............................................................................................................13

PGM Output Attributes ..............................................................................................................14

4.6 Event Buffers ..................................................................................................................................14

4.7 Resetting Factory Defaults ..............................................................................................................14

4.8 Installe's Lockout [Installer's Code] ................................................................................................15

Programming Work Sheets .....................................................................................................................16

Antenna Relocation Diagram ................................................................................................................20

PC16OUT with Skyroute UT Transceiver Diagram ................................................................................21

Skyroute UT with Low V oltage Output from Alarm Panel Diagram .........................................................22

Existing Alarm Control Panel with Skyroute UT (Switched Positive Bell) Diagram ................................23

Existing Alarm Control Panel with Skyroute UT (Switched Negative Bell) Diagram ...............................24

Summary Diagram of the Skyroute UT .................................................................................................25

Appendix A ...........................................................................................................................................26

1

Page 3

Introducing the Skyroute UT

The Skyroute UT offers a new wireless method of communication for the transmission of event information using the

Cellemetry service. Events are transmitted from the Skyroute transceiver via the Cellemetry network to the Clearing

House and then to the Central Station in a fast and reliable manner. Skyroute has been designed for simple and

straightforward installation.

1.1 Specifications

Communication Method

• AMPS Control Channel

Downloading Software Support

• PC580 v2.3 uses DLS-1 v6.7 and up.

Flexible Zone Configuration

• Four fully programmable zones

• 27 zone types; 8 programmable zone attributes

• Normally closed, single EOL

Audible Alarm Output

• 700mA Supervised Bell Output (current limited at 3 amps), 12VDC

• Steady or Pulsed Output

EEPROM Memory

• Does not lose programming or system status on complete AC and Battery failure

Programmable Outputs

• Two programmable outputs; 18 programmable options

• PGM1 = 50mA; PGM2 = 50mA

Powerful 1.5 Amp Regulated Power Supply

• 550 mA Auxiliary Supply, 12 VDC

• Positive Temperature Coefficient (PTC) components replace fuses

• Supervision for loss of AC power, low battery

• Internal clock locked to AC power frequency

Power Requirements

• Transformer = 16.5 VAC, 40VA

• Battery = 12 volt 7 Ah minimum rechargeable sealed lead acid battery

Programmer

• The Skyroute ut can be programmed using any Power keypad

PC5500, PC5508, PC5516, PC5532, PC1555RK and the PC580RK

2

Page 4

System Supervision Features

The system continuously monitors a number of possible trouble conditions including:

• AC power failure

• Low battery condition

• AUX Power Supply Trouble

• Bell output trouble

• Fault by zone

• Tamper by zone

Additional Features

• An event buffer which records the past 128 events with both the time and date at which they occurred;

buffer can be printed using PC5400 serial interface module, or viewed with the LCD5500Z keypad and

DLS-1 software

• Uploading and downloading capability

Antenna

• 3 – 5 dB gain, TNC connector

• Extension Kits available:

- LAE – 3 The 3 Foot Antenna Kit for Skyroute Transceiver

- LAE – 15 The 15 Foot Antenna Kit for Skyroute Transceiver

- LAE – 25 The 25 Foot Antenna Kit for Skyroute Transceiver

RF Power Output

• 3.0 Watts

Power Consumption (Skyroute)

• 12 VDC @30mA, from Panel Keybus

DC, from Bell Circuit

• 12 V

Current in Standby 90mA

Current when Receiving 135mA

Current when Transmitting 1.3A

Dimension

211mm x 234mm x 77mm

3

Page 5

1.2 Out of the Box

Please verify that the following components are included in your system:

• one Skyroute module

• one PC1-OUT module

• one antenna

• one PC5003C main control cabinet

• one PC580 main control circuit board

• one Installation Manual with programming worksheets

• one hardware pack consisting of:

- four plastic circuit board standoffs

- ten 5600Ω (5.6KΩ) resistors

- one 2200Ω (2.2KΩ) resistors

- one 1000Ω (1KΩ) resistors

-

ground connection assembly

- one cabinet door plug

Getting Started

Read this section completely before you begin. Once you have an overall understanding of the installation

process, carefully work through each step.

2.1 Installation Steps

Step 1: Mounting the Unit

Mount the panel in a dry area close to an unswitched AC power source. Before attaching the cabinet to the wall,

be sure to press the four circuit board mounting studs into the cabinet from the back.

NOTE: You must complete all wiring before connecting the battery, or applying AC to the panel.

Step 2: Mounting the Skyroute Transceiver

The Skyroute Transceiver can be mounted in the upper right hand corner of the panel cabinet through

the knock out.The Skyroute Transceiver case attaches to the panel cabinet through the use of clips.

Step 3: Mounting the Antenna

NOTE: The antenna should always be attached to the Skyroute Transceiver for proper operation. The

unit will not function properly if the antenna is not installed.

The antenna attaches to the TNC connector of the Skyroute Transceiver.The antenna should be mounted

as high above ground level as possible while at the same time taking care not to place the antenna

under a Radio frequency shield of any kind. For example do not mount the antenna directly below a

metal roofing over-hang. The Skyroute Transceiver functions best when installed in an unobstructed

“line of sight” to the cellular antenna site.

Step 4: Panel Wiring

Install the 1kΩ resistor (brown, black, red) across the Bell+ and Bell- terminals. Connect all the

zone inputs using the 5.6kΩ resistors (violet, blue, red). Follow connection diagram on page 20

for different configurations.

4

Page 6

Step 5: Skyroute Wiring

• Keybus Connection

The Skyroute transmitter has 4 terminals marked red, black, yellow and green. Connect these four

terminals to the 4 terminals on the main control panel marked KEYBUS (aux+, aux-, yellow and

green).

• Bell IN Terminal

This terminal is used to power the cellemetry modem.This connects to the BELL + on the control

panel. No other wire should be connected to the Bell+ of the control panel or to this terminal.

Step 6: Power up the Control

Once all zone and Keybus wiring is complete, power up the control panel. First, connect the red battery lead to the positive

terminal and the black lead to negative. Then, connect the AC.

NOTE: Connect the battery before connecting the AC. You must apply AC power to the panel for at least 10

seconds, or the panel will not function. The panel will not power up on the battery connection alone.

Step 7: Programming the System

Utilize any Power keypad to program the system. Simply connect the keypad (R , B, Y, G,) terminals to the keybus

(Aux+, Aux-, Yel, Green) on the control panel.

Fill out the Programming Worksheets completely before attempting to program the system.

Step 8: Testing the System

Test the panel thoroughly to ensure that all features and functions are operating as programmed.

2.2 Terminal Descriptions

Battery Connection

A 12V 7Ah rechargeable battery is used as a backup source of power in the event of an AC power failure. The battery

also provides additional current when the panel’s demands exceed the power output of the transformer, such as when

the Skyroute module is transmitting.

NOTE: Do not connect the battery until all other wiring is complete. Connect the battery before connecting the AC.

Connect the RED battery lead to the positive battery terminal; connect the BLACK lead to negative.

AC Terminals – AC

The panel requires a 16.5VAC, 40VA transformer. Connect the transformer to an unswitched AC source and connect the

transformer to these terminals.

NOTE: Do not connect the transformer until all other wiring is complete.

Auxiliary Power Terminals – AUX+ and AUX-

These terminals provide up to 550 mA of additional current at 12 VDC for devices requiring power. Connect the positive

side of any device requiring power to the AUX+ terminal, the negative side to AUX- (ground). The AUX output is protected.

This means that if too much current is drawn from these terminals (such as wiring short), the panel will temporarily shut

off the output until the problem is corrected.

Keybus Terminals – AUX+, AUX-, YEL, GRN

The Keybus is used by the panel to communicate with the Skyroute transceiver, the programming keypad and other

modules. Each module has four Keybus terminals that must be connected to the four Keybus terminals on the panel.

5

Page 7

Programmable Output Terminals – PGM1 and PGM2

Each PGM output is designed so that when activated by the panel, the terminal will switch to ground.

PGM1 can sink up to 50mA of current. Connect the positive side of the LED or buzzer to AUX+, the negative side to PGM1.

PGM2 operates similarly to PGM1. If more than 50 mA of current are required, a relay must be used.

For a list of the programmable output options, please see section the “PGM Output Options” Section.

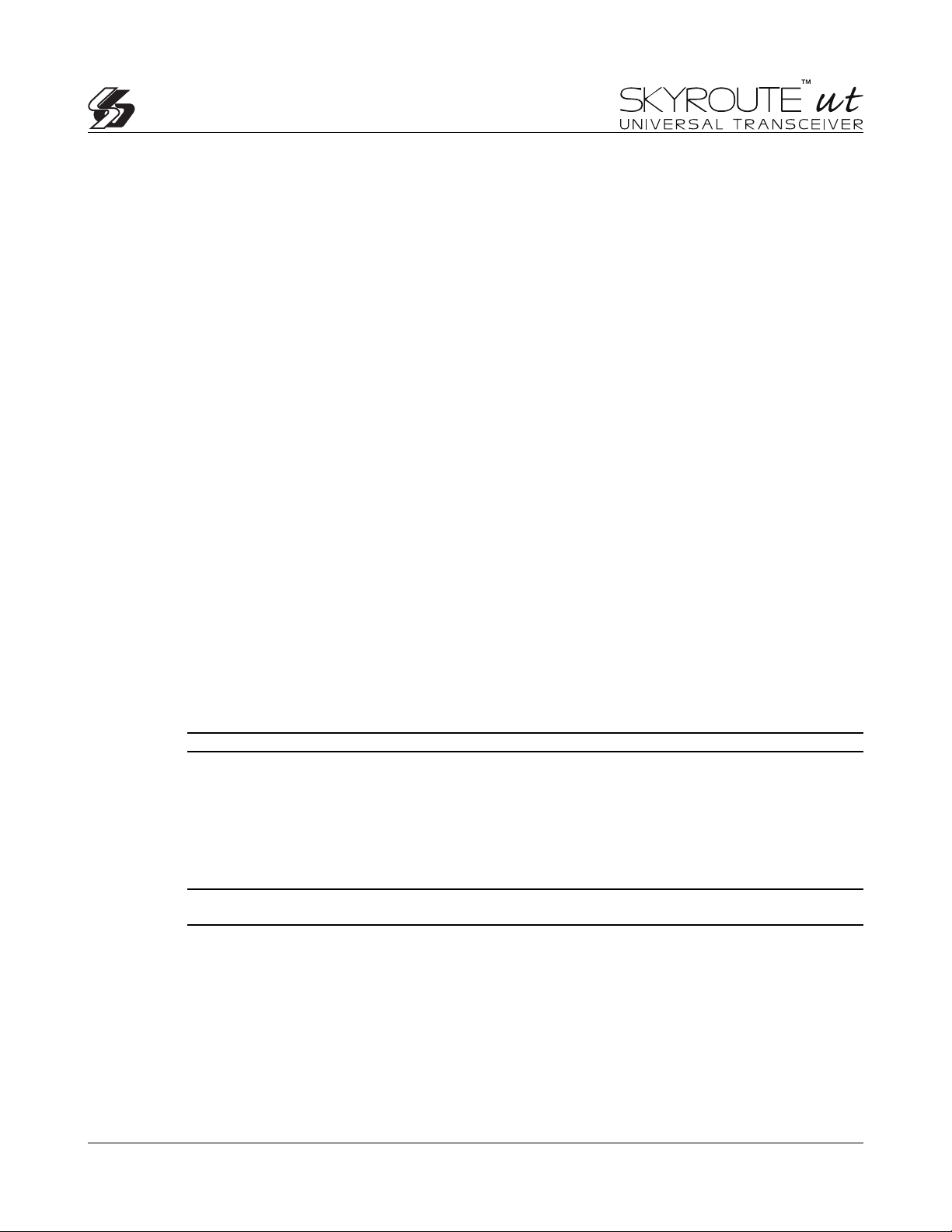

Zone Input Terminals – Z1 to Z4

Positive Trigger

5.6K

Z COM Z

Relay Trigger or Dry Contact Trigger

Normally Open Contact

-+

Negative Trigger

5.6K

Z COM Z

Normally Closed Contact

-+

-+

CN.O.

5.6K

Z COM Z

-+

CN.C.

5.6K

Z COM Z

6

Page 8

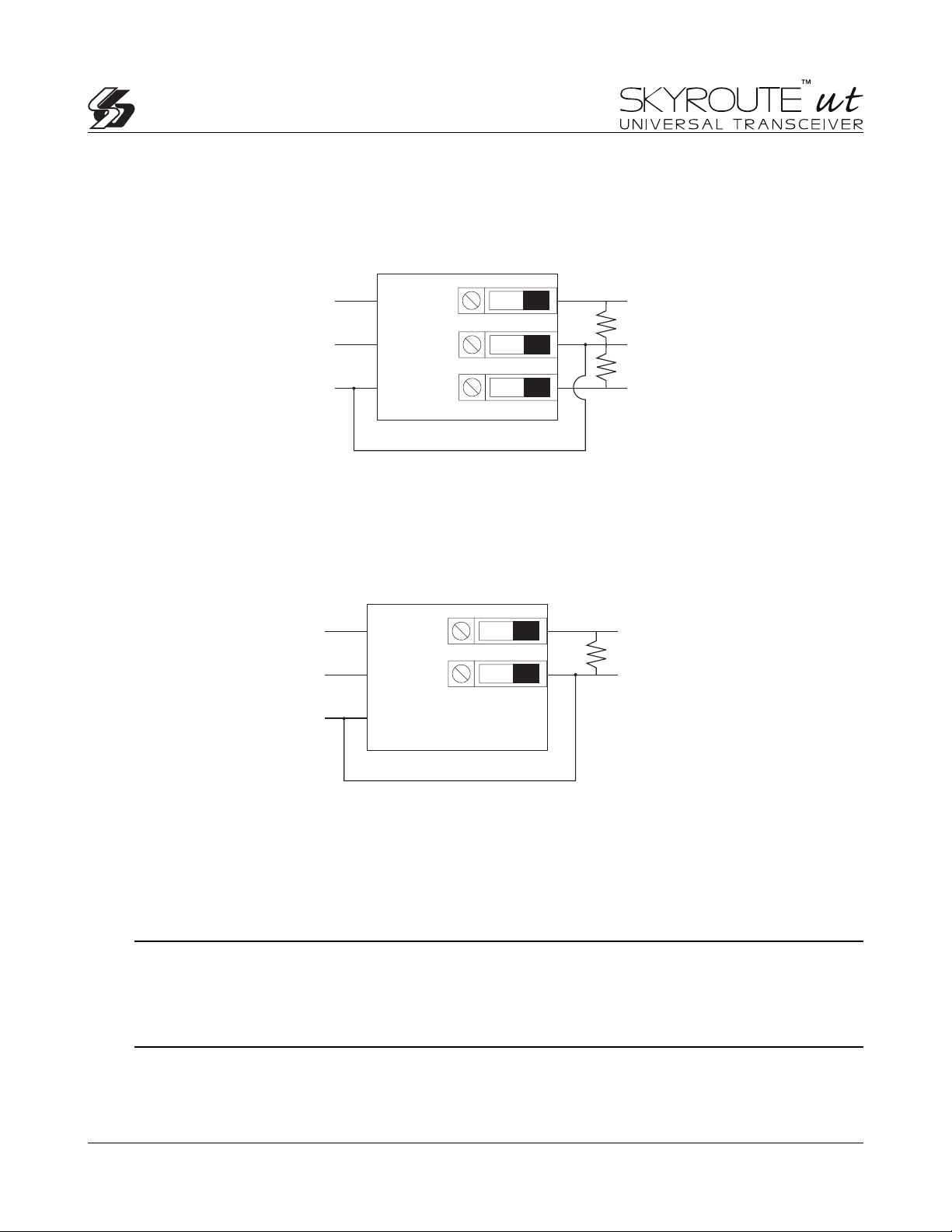

Siren Trigger

Use PC1OUT Module Included

Bell -

+ 12 volt

GND

Bell -

Bell +

(Bell + always active and Bell - switch to ground on alarm)

With this configuration, Zx1 will be trigger on

steady Bell and Zx2 will be trigger on pulsed Bell

(Bell - always to ground and Bell + switch to + on alarm)

Negative Siren Trigger

ORG

RED

BLK

Positive Siren Trigger

ORG

RED

BRG

GND

EMR

BRG

GND

Zx1

COM

Zx2

Zx

COM

GND

BLK

With this configuration, Zx1 will be trigger

every time the Bell is activated

Telephone Connection Terminals – TIP, RING, T-1, R-1

If a telephone line is required for central station communication or downloading, connect an RJ-31X telephone jack in

the following manner:

NOTE: Please ensure that all plugs and jacks meet the dimension, tolerance and metallic plating requirements

of 47 C.F.R. Part 68, SubPart F. For proper operation, no other telephone equipment should be connected

between the control panel and the telephone company facilities. Do not connect the alarm panel communicator

to telephone lines intended for use with a fax machine. These lines may incorporate a voice filter, which

disconnects the line if anything other than fax signals are detected, resulting in incomplete transmissions.

7

Page 9

Secure Installation

For a secure installation, the Skyroute UT must be in a secure, locked, and protected area via

sensors. All entry points must be protected. An instant trip IR sensor would be the most

appropriate for supervision of the panel. A cabinet tamper switch connected to the TMP

terminal of the Skyroute Transceiver is also required.

Relocating the Antenna

If a suitable location is not available for proper Cellemetry coverage, obtain an Antenna Extension

Bracket kit from your DSC/Sur-Gard supplier. Each kit contains an extension cable, a mounting bracket,

instructions, and all required hardware. Three lengths of extension cable are available:

Extension Kit Length of cable

LAE-3 3 feet (0.91 m)

LAE-15 15 feet (4.57 m)

LAE-25 25 feet (7.62 m)

Only use the Extension Kits to extend the mounting range of the antenna. Do not cut or splice

the extension cable. The maximum distance between the Skyroute transceiver and the antenna

is 25 feet (7.62 m) as obtained by using the LAE-25 Extension Kit. Make sure the antenna is

in a physically secured location to avoid tampering.

Secure the TNC connector from the Extension Kit to the mounting bracket, ensuring that the

star washers make solid electrical contact with the mounting bracket.

Remove the antenna from the Skyroute module and connect the extension cable to the TNC

connector on the module. Secure the antenna to the TNC connector mounted on the Extension

Kit Mounting Bracket. Locate the mounting bracket and antenna away from possible sources

of electrical interference. Moving the antenna just a short distance will likely be adequate.

Temporarily secure the mounting bracket in the new location and proceed with testing. If the

test is successful, permanently secure the mounting bracket and antenna at the new location.

How to Program

The following section of the manual describes the Installer’s Programming function and how to program the

various sections.

NOTE: Read the following section of the manual very carefully before you begin programming. We also

recommend filling out the Programming Worksheets section before you program the panel.

3.1 Installer’s Programming

Installer’s Programming is used to program all communicator and panel options. The Installer’s Code is [0580]

by default but should be changed to prevent unauthorized access to programming.

Installer’s Code ........ Section [006]

From an LED Keypad:

1. Enter [*][8][Installer’s Code].

The Program light (or System light on the PC1555RKZ) will flash to indicate that you are in programming

mode. The Armed light will turn on to indicate that the panel is waiting for the three-digit programming section

number.

8

Page 10

2. Enter the three-digit section number corresponding to the section you wish to program.

The Armed light will turn off. The Ready light will turn on to indicate that the panel is waiting for the information required

to complete programming the selected section.

3. Enter the information required to complete section programming (i.e.: numbers, HEX data, or ON/OFF options).

NOTE: If the three-digit section number entered is invalid, or if the module that pertains to the section is not

present, the keypad will sound a two second error tone.

From an LCD Keypad:

1. From any keypad, enter [*][8][Installer’s Code]. The Keypad will display ‘Enter Section’ followed by three dashes.

2. Enter the three-digit number corresponding to the programming section number you wish to program. The keypad

will now display the information required to complete programming the selected section.

3. Enter the information required to complete section programming (i.e.: numbers, HEX data, or ON/OFF options).

If you enter information into a section and make a mistake, press the [#] key to exit the section. Select that section

again and re-enter the information correctly.

NOTE: There must be one digit in each box in the programming section in order for the change to be valid.

3.2 Programming Decimal Data

A set number of programming boxes are allotted for each section requiring decimal data (e.g.: codes, telephone

numbers). If a digit is entered for each program box, the panel will automatically exit from the selected programming

section. The Ready light will turn OFF and the Armed light will turn ON.

On the PC1555RKZ and PC5508Z keypads, you can also press the [#] key to exit a programming section without entering

data for every box. This is handy if you only need to change digits in the first few programming boxes. All other digits

in the programming section will remain unchanged.

3.3 Programming HEX Data

On occasion, hexadecimal (HEX) digits may be required. To program a HEX digit press the [*] key. The panel will enter

HEX programming and Ready light will begin to flash.

The following are the numbers that should be pressed to enter the appropriate HEX digit:

1 = A 2 = B 3 = C 4 = D 5 = E 6 = F

Once the correct HEX digit has been entered, the Ready light will continue to flash. If another HEX digit is required, press

the corresponding number. If a decimal digit is required, press the [*] key again. The Ready light will turn on and the panel

will return to regular decimal programming.

Example:

To enter 402C for your SID number, you would enter:[4][0][2][*][3]:

[4][0][2] to enter digit 4-0-2 (ready light is solid),

[*] to enter Hexadecimal mode (Ready light flashes)

[3] to enter C

NOTE: If Ready light is flashing, any number you enter will be programmed as the HEX equivalent.

9

Page 11

3.4 Programming Toggle Option Sections

Some programming sections contain several toggle options. The panel will use zone lights 1 through 8 to indicate if the

different options are enabled or disabled. Press the number corresponding to the option to turn it ON or OFF. Once all

the toggle options have been selected correctly, press the [#] key to exit the section and save the changes. The Ready

light will turn OFF and the Armed light will turn ON.

Refer to the Programming Worksheets in this manual to determine what each option represents and whether the light

should be ON or OFF for your application.

3.5 Viewing Programming

LED Keypads

Any programming section can be viewed from an LED keypad. When a programming section is entered, the keypad will

immediately display the first digit of information programmed in that section.

The keypad displays the information using a binary format, according to the following chart:

Press any of the Emergency Keys (Fire, Auxiliary or Panic) to advance to the next digit. When all the digits in a section

have been viewed, the panel will exit the section; the Ready Light will turn OFF and the Armed light will turn ON, waiting

for the next three-digit programming section number to be entered. Press the [#] key to exit the section.

LCD Keypad

When a programming section is entered, the keypad will immediately display all the information programmed in that

section. Use the arrow keys (< >) to scroll through the data being displayed. Scroll past the end of the data displayed

or press the [#] key to exit the section.

Program Descriptions

The following section explains the operation of all programmable features and options and provides a summary of all

corresponding programming locations.

4.1 Zone Programming Section [001]

The zone definitions describe how each of the zones you use will operate. Program a two-digit code describing the zone

definition in sections [001]. Enter either 00 if the zone is not used or 11 if the zone is used.

Zone Definitions

[00] Null Zone

The zone is vacant. Unused zones should be programmed as Null zones.

[11] 24hr Zone: If the zone is violated, the unit will report to the Central Station, and will log the event to the buffer. This

zone will follow the programmed number of alarms for swinger shutdown.

4.2 Telephone Line Monitor (TLM)

TLM Enable/Disable Section [015]: Toggle option [7]

4.3 Swinger Shutdown

The swinger shutdown feature is designed to prevent a “runaway” communicator from tying up the central station. After

the panel has communicated the programmed number of transmissions for an event, it will no longer report that event

until the swinger shutdown is reset. Different swinger shutdown levels can be set for zone alarms, zone tampers and

maintenance signals.

By default, each Swinger Shutdown limit is set to [003]. The panel will not send more than three signals for each zone

until the swinger shutdown is reset.

10

Page 12

There will be no communication on zones that have exceeded the limit of alarms set in the Swinger Shutdown counter.

Swinger shutdown will be reset every day at midnight or when the panel is armed. Once reset, the panel will again

communicate normally.

Swinger Shutdown ........ Section [370]

4.4 Skyroute Programming Sections....[803]

All programming on the Skyroute transceiver is done in the installer’s programming mode. Once in programming

mode, enter section [803] to access Skyroute programming.

Zone Definition……………………………………………Sub-Section [01]

This section will determine which "event code" will be sent to the Central Station for each zone.

Configuration Options……………………………………Sub-Section [06]

Channel B enable/disable…………..option[2]

This option must be selected when the Cellemetry provider is a “B” side carrier. Must be on in

Canada.

Home System only enable/disable…..option[3]

This option must be programmed to ensure that the Skyroute transceiver is communicating using the

proper carrier. When selected, the transceiver will only use towers with the same SID. (As programmed in

section [07]).

Skyroute Transceiver SID (System ID)…………………..Sub-Section [07]

The chart below lists the different System ID for each of the territories. For proper activation of the

Skyroute Transceiver the correct SID for the territory that you are in must be entered into section [07] in

Hex.

SID Table

System ID in Memco System ID in Memco

Decimal HEX Decimal HEX

16420 4024 Bell Mobility (Ont.) 16390 4006 MT & T Mobility

16418 4022 TB Tel Mobility 16408 4018 NBTel Mobility

16420 4024 Bell Mobility (Quebec) 16414 401E NewTel Mobility

16458 404A Quebec Tel Mobilité 16430 402E Island TelMobility

16422 4026 BCTEL Mobility 16410 401A SaskTel Mobility

16428 402C MTS Mobility 16384 4000 TELUS Mobility

Skyroute Test Time…………………………………………..Sub-Section [10]

Enter in this section the time of the day (Military Time) that you want the test transmission to be sent.

Test Transmission Day Mask…………………………………………..Sub-Section [11]

Select in this section the day of the week you want the test transmission to be sent.

Skyroute Transceiver Test Rates…………………………………………..Sub-Section [13]

Default Option ON Option OFF

OFF I_____I Option 1 Industrial Disabled

OFF I_____I Option 2 Commercial and Business Disabled

ON I_____I Option 3 Residential and Retail Disabled

OFF I_____I Option 4 Keybus Tests Enabled Keybus Tests Disabled

OFF I_____I Options 5 to 8 For Future Use

11

Page 13

Activating the Skyroute Transceiver

Before activating the Skyroute transceiver, ensure that the control panel is correctly wired and programmed and

operating properly. Make sure that the Skyroute transmitter is properly connected to the keybus and to the bell

positive circuit. When power is applied to the system, the Skyroute will go in initializing mode for few seconds and

then give a visual feedback by indicating signal strength on LED1, LED2 and LED3.

Calling Connect24

O

nce the Skyroute transceiver is indicating the signal strength of the network and that the status indicator (LED5) is

blinking 6 times (not connected to the clearing house) you are ready to call the Voice Response Unit of Connect 24.

Follow the voice prompt and when asked to perform a test, press on SW1 on the Skyroute transceiver to transmit a

test signal. When transmitting, LED4 blink once. If the test is successful, the VRU will give you a confirmation and

LED5 will then blink steady every half-second. Refer to Connect24 information package for more information on the

activation process.

NOTE: The confirmation of a successful test from Connect24 does not guarantee proper transmission of

event activity to your central station.

activation with Connect 24.

You must perform normal test with your monitoring station after

Skyroute Transceiver Trouble Supervision

The Skyroute Transceiver automatically monitors its operation and indicates trouble conditions by flashing LED5 on

the circuit board. LED5 normally flashes once every second when the Skyroute Transceiver is on stand-by (ready to

transmit) mode. Troubles are indicated when LED5 flashes more than once every second. Shown below is the

number of flashes used to indicate each trouble condition in order of importance.

(2) Radio not connected/Radio not responding: Skyroute Transceiver initialization of Cellemetry modem has failed.

(4) Service not available: The Cellemetry modem has failed to register with the cellular network.

(6) Not connected to Clearinghouse: The Skyroute Transceiver has not been activated.

(5) Failure to communicate: A signal has not been successfully communicated to the central station.

(3) Failed self-test: A self-test of the Cellemetry module has failed.

(1) Radio is operating normally: Skyroute Transceiver is ready to transmit.

Skyroute Transceiver Trouble Shooting

If Skyroute Transceiver will not communicate to the clearinghouse, check the following before calling Sur-Gard

technical support.

1.Check all wiring

A. Make sure all the keybus connections are correct.

B. B. Make sure Bell + is connected.

C. Make sure the GND of the Skyroute Transceiver is connected to a zone common or AUX – of the control

panel2. Check the LED5

A. Check number of flashes on LED5. If LED flashes more than once every half a second refer to table 2

B. 6 flashes means not connected to the Clearinghouse. A failed activation attempt. Re-activate.

3. If intermittent failure to communicate is seen (5 flashes), number of attempts (option 23) should be increased to

10 and/or response wait time should be increased to 60 (option 24 = 60).

4. If LED5 flashes once every half a second, yet Skyroute Transceiver does not communicate to clearinghouse call

Sur-Gard Technical support at 1-800-503-5869 ext.1 or 416-665-4494 ext.1.

12

Page 14

4.5 PGM Output Options....[009]

Program the programmable outputs PGM1 and PGM2 on the main board by selecting one of the output options listed

below (exceptions noted).

Main Board PGM OutputsSection [009]

NOTE: PGM outputs cannot be completely disabled in installer’s programming. To disable a PGM output

completely, you must remove all wiring from the output.

[01] Alarm Output

The output will activate when the alarm output is active and will deactivate when the alarm output is silenced. If the alarm

output is pulsing, the PGM output will pulse as well. This output will follow the activation of the alarm output (pre-alert).

[09] System Trouble Output

The PGM output will activate when any of the selected trouble conditions are present. It will deactivate when all the

selected trouble conditions are cleared.

The PGM attributes for this option, programmed in Sections [141] and [142], differ from the standard selection of

attributes.

Program which trouble conditions will activate the output by selecting some or all of the following attributes:

Attribute

[1] Service Required (battery, bell, general trouble, general tamper, general supervisory)

[2] AC Failure

[3] Telephone Line Trouble

[4] Failure to Communicate

[5] Fire Trouble / Zone Fault

[6] Zone Tamper

[7] Zone Low Battery

[8] Loss of Clock

[11] System Tamper (All Sources)

The PGM output will activate when any tamper condition is present and will deactivate when all tampers are restored.

[21]-[24] For future use

13

Page 15

PGM Output Attributes

In addition to programming the output type, you must also program the PGM output attributes for each output.

PGM output options [09] “System Trouble” and [10] “System Event” have their own unique set of attributes listed below

the description of each output type.

PGM output options [01], [03], [05]-[08], [11]-[20] have the following attributes:

Attribute ON OFF

[1] PGM Enable PGM Disable

[3] True Output Inverted Output

AttributeON: the output energizes when activated

Attribute OFF: the output de-energizes when activated

[4] Output Pulsed Output ON/OFF

Attribute ON: the output will activate once for the amount of time programmed in section [164]

when initiated by the user

Attribute OFF: the output will toggle ON or OFF when initiated by the user.

(Only applicable to options [19]-[20].)

PGM attributes return to their default settings when you change PGM output options. Please see the programming

worksheets for a list of the default settings for each PGM output type.

Be careful when selecting the normal and active states of each PGM output to ensure that an undesirable output state

does not occur after a loss and restore of AC power.

NOTE: If you program more than one PGM output as the same output type (e.g. if PGM1 and PGM2 are both

programmed as [19] Command Output 1), the settings for output attributes [1], [2] and [5] must be the same.

This does not apply to outputs programmed as types [09] and [10].

PGM Output AttributesSection [141]-[142]

4.6 Event Buffer

The panel will store the last 128 events which occurred on the system. The Event Buffer will contain the name, time

and date of each event, along with the zone number, access code number or any other information pertaining to the event.

If the Event Buffer Follows Swinger Shutdown option is enabled, the event buffer will not store events after the Swinger

Shutdown level has been reached. This will prevent the panel from overwriting the entire buffer if a problem exists.

The event buffer can be viewed in three different ways: from an LCD keypad printed on-site using the PC5400 printer

module, or it can be uploaded using DLS software.

Event Buffer Follows

Swinger Shutdown .. Section [013]: [7]

4.7 Resetting Factory Defaults

On occasion, it may be necessary to default the main control panel.

To default the main control panel (hardware), perform the following:

1. Remove AC and battery from the panel.

2. Remove all wires from the Zone 1 and PGM1 terminals.

3. With a piece of wire short the Zone 1 terminal to the PGM1 terminal.

14

Page 16

4. Apply AC power to the main panel.

5. When Zone Light 1 is lit on the keypad the default is complete.

6. Remove AC power from the control .

7. Reconnect all original wiring and power up the control.

NOTE: AC power must be used to power the panel. The panel will not default if only the battery is used.

To default the main control panel software and other modules, perform the following:

1. Enter the Installer’s Programming mode.

2. Enter the appropriate programming section [999].

3. Enter the Installer’s Code.

4. Re-enter the appropriate programming section [999].

The panel will take a few seconds to perform the default. When the keypad is again operational the default is complete.

Restore Panel to Default Programming Section [999]

4.8 Installer’s Lockout *[Installer code]

If Installer’s Lockout is selected, a hardware default cannot be performed. If a software default is performed, all

programming will restore to factory default.

If Installer’s Lockout Disable is selected, the panel will restore all programming to factory defaults when a

hardware or software default is performed on the main control panel.

To enable or disable Installer’s Lockout, perform the following:

1. Enter the Installer’s Programming mode.

2. Enter the appropriate programming section: [990] or [991].

3. Enter the Installer’s Code.

4. Re-enter the appropriate programming section: [990] or [991].

Installer Lockout EnableSection [990]

Installer Lockout DisableSection [991]

15

Page 17

Programming Work Sheets

Basic Interface Programming

Zone Definitions

00 Null Zone (Not Used)

11 24 Hour

[001] Zone 1-8 Definitions

Default Default

01 I_______I_______I Zone 1 00 I_______I_______I Zone 5

03 I_______I_______I Zone 2 00 I_______I_______I Zone 6

04 I_______I_______I Zone 3 00 I_______I_______I Zone 7

04 I_______I_______I Zone 4 00 I_______I_______I Zone 8

[006] Installer’s Code

Default

0580 [___][___][___][___]

[009] PGM Output Programming (PGM 1 and 2)

Programmable Output Options

01 Burglary and Fire Bell Output

09 System Trouble Output (with Trouble options)

10 System Event [Strobe (with Event options)]

11 System Tamper (all sources: zones, kpd, modules)

12 TLM and Alarm

13 Kissoff Output

14 Ground Start Pulse

15 Remote Operation (DLS-1 Support)

Default

19

I_______I_______I PGM 1

I_______I_______I PGM 2

10

[015] Third System Option Code

Default Option ON OFF Section

ON

I________I 7 TLM Enabled TLM Disabled

[370] Communication Variables

Default Section

003

I_______I_______I_______I Swinger Shutdown (Alarms and Rest) (001-014 Transmissions, 000=disabled)

003

I_______I_______I_______I Swinger Shutdown (Tampers and Rest) (001-014 Transmissions, 000=disabled)

003

I_______I_______I_______I Swinger Shutdown (Maint and Rest) (001-014 Transmissions, 000=disabled)

I_______I_______I_______I Transmission Delay (001-255 seconds)

000

030

I_______I_______I_______I AC Failure Communication Delay (001-255 minutes)

I_______I_______I_______I TLM Trouble Delay (No. of checks required - valid entries 003 - 255)

003

030

I_______I_______I_______I Test Transmission Cycle (land line) (001-255 minutes/days) (not used)

030

I_______I_______I_______I Test Transmission Cycle (001-255 days) (not used)

I_______I_______I_______I Zone Low Battery Transmission Delay (000-255 days)

007

030

I_______I_______I_______I Delinquency Transmission Cycle (001-255 days / hours)

16

Page 18

Downloading Options

[499] [Installer’s Code] [499] Initiate PC-Link (Local Downloading)

[803] Skyroute Programming

08 Fire

09 Supervisory

11 Burglary

12 Hold-up

13 Gas

14 Heat

15 Medical

16 Panic

17 Emergency

[01] Zone 1-4 Reporting Codes

Default Default

00 I_____I_____I Zone 1 00 I_____I_____I Zone 5 (not used)

00 I_____I_____I Zone 2 00 I_____I_____I Zone 6 (not used)

00 I_____I_____I Zone 3 00 I_____I_____I Zone 7 (not used)

00 I_____I_____I Zone 4 00 I_____I_____I Zone 8 (not used)

[06] Skyroute Configuration Options (1-8)

Default Option ON Option OFF

OFF I_____I Option 1 A Channel Selected A Channel Not Selected

ON I_____I Option 2 B Channel Selected B Channel Not Selected

OFF I_____I Option 3 Home System Only Not in Home System Operation

OFF I_____I Options 4 to 8 For Future Use

[07] Home SID Number

0000 I_____I_____I_____I_____I

This is the SID (in Hex) of the cellular service that is available on the current channel.

[10] Skyroute Test Time

9999 I_____I_____I_____I_____I 0000-2359 (in Military Time)

[11] Test Transmission Day Mask

Default Option ON Option OFF

OFF I_____I Option 1 Test on Sunday Disabled

OFF I_____I Option 2 Test on Monday Disabled

OFF I_____I Option 3 Test on Tuesday Disabled

OFF I_____I Option 4 Test on Wednesday Disabled

OFF I_____I Option 5 Test on Thursday Disabled

OFF I_____I Option 6 Test on Friday Disabled

OFF I_____I Option 7 Test on Saturday Disabled

OFF I_____I Option 8 For Future Use

17

Page 19

[13] Skyroute Test Rates

OFF I_____I Option 1 Industrial Disabled

OFF I_____I Option 2 Commercial and Business Disabled

ON I_____I Option 3 Residential and Retail Disabled

OFF I_____I Option 4 Keybus Tests Enabled Disabled

OFF I_____I Options 5 to 8 For Future Use

[22] Transmission Options

ON I_____I Option 1 Alarms/Restores Disabled

ON I_____I Option 2 Tamper Restoral/Restores Disabled

ON I_____I Option 3 Supervisory/Restores Disabled

ON I_____I Option 4 Low Battery/Restores Disabled

OFF I_____I Option 5 Opening/ Closing Disabled

ON I_____I Option 6 Maintenance Disabled

OFF I_____I Options 7 & 8 For Future Use

[23] Number of attempts

03 I_____I_____I 00 – FF (in HEX)

[24] Response Wait Time

19 I_____I_____I 00 – FF (in HEX) x10 seconds

Sections [30] to [78], if ’00’ is entered, then that reporting code is disabled. If ‘FF’ is in the section, then the

reporting code is enabled. ‘FF’ is the default value.

[30] Alarm Reporting Codes, Zones 1-8

Default Default

FF I_____I_____I Zone 1 Alarm FF I_____I_____I Zone 5 Alarm

FF I_____I_____I Zone 2 Alarm FF I_____I_____I Zone 6 Alarm

FF I_____I_____I Zone 3 Alarm FF I_____I_____I Zone 7 Alarm

FF I_____I_____I Zone 4 Alarm FF I_____I_____I Zone 8 Alarm

[34] Alarm RestoralReporting Codes, Zones 1-8

FF I_____I_____I Zone 1 Alarm Restoral FF I_____I_____I Zone 5 Alarm Restoral

FF I_____I_____I Zone 2 Alarm Restoral FF I_____I_____I Zone 6 Alarm Restoral

FF I_____I_____I Zone 3 Alarm Restoral FF I_____I_____I Zone 7 Alarm Restoral

FF I_____I_____I Zone 4 Alarm Restoral FF I_____I_____I Zone 8 Alarm Restoral

[48] Miscellaneous Tamper Reporting Codes

FF I_____I_____I General System Tamper FF I_____I_____I Keypad Lockout

FF I_____I_____I General System Tamper Rest.

18

Page 20

[75] Maintenance Alarm Reporting Codes

Default Default

FF I_____I_____I Battery Trouble Alarm FF I_____I_____I Aux Power Supply Trouble Alarm

FF I_____I_____I AC Failure Trouble Alarm FF I_____I_____I TLM Trouble Code

FF I_____I_____I Bell Circuit Trouble Alarm FF I_____I_____I General System Trouble

FF I_____I_____I Fire Trouble Alarm FF I_____I_____I General System Supervisory

[76] Maintenance Restoral Reporting Codes

FF I_____I_____I Battery Trouble Restoral FF I_____I_____I Aux Power Supply Trouble Restoral

FF I_____I_____I AC Failure Trouble Restoral FF I_____I_____I TLM Restoral

FF I_____I_____I Bell Circuit Trouble Restoral FF I_____I_____I General System Trouble Restore

FF I_____I_____I Fire Trouble Restoral FF I_____I_____I General System Supervisory

Restore

[77] Miscellaneous Maintenance Restoral Reporting Codes

FF I_____I_____I Phone #1 FTC FF I_____I_____I Event Buffer 75% Full

FF I_____I_____I Phone #2 FTC FF I_____I_____I DLS Lead IN

FF I_____I_____I Phone #1 FTC Restore FF I_____I_____I DLS Lead OUT

FF I_____I_____I Phone #2 FTC Restore FF I_____I_____I Delinquency Reporting Code

[78] Test Transmission Reporting Codes

FF I_____I_____I Periodic Test Transmission FF I_____I_____I Skyroute Test TX Code

FF I_____I_____I System Test

[99] Section [99] is for software defaulting of the Skyroute

10 I_____I_____I

Entering 00 will cause software default of the Skyroute. Entering FF will cause restart of the Skyroute Transceiver.

Entering any other value will not cause default or a restart.

19

Page 21

Skyroute UT Antenna Cable Installation

20

Page 22

PC16-OUT* with a Skyroute UT Transceiver

DSC

CONTROL

PANEL

with PC16-OUT Support

COM

COM COMZ2 Z4 Z6 Z8 RING TIP R-1

GROUND

CONNECTION

Nut

Washer

Cabinet

Bolt

Ground

Rod

RED

BLK

YEL

GRN

T-1

EGNDPGM

BLU

YEL

RED

BLK

SKYROUTE CN

RED BLK

BATTERY

12V 7.0Ah

Typi cal

battery

charge current

is 360 mA.

120Vac

60Hz

PRIMARY

RED

BLK

-

–

SI

Connection for PC-Link

S0

+

AUX

AC

REDBELL

BLK YEL GRN Z1 Z3 Z5 Z7COM

12

PC580

Any Zone

-

+

AC

AUX

RED

12

YEL GRN

Z1 Z3COM

BELL

BLK

YEL

GRN

1K

Z2 Z4

PGM

RING TIP R-1

COM

EGND

T-1

BELL + BELL IN

*PC16-OUT

Any Output

LED 1

LED 2

LED 3

LED 4

SW1

LED 5

Test

Switch

SKYROUTE

YEL

RED

GRN

BLK

Max.

Signal Strength

Min.

Rx/Tx

Status

Indicator

COM

BELL

OUT

Indicator

BELL

IN

TAM

SKYROUTE UT

*Optional device not included with the Skyroute UT

21

Page 23

Skyroute UT Transceiver

(With low voltage output from Alarm Panel)

GENERIC

CONTROL

RED

BLK

-

–

+

BELL

AUX

AC

Programmable Output

Switched to ground

PANEL

RED BLK

BATTERY

12V 7.0Ah

Typi cal

battery

charge current

is 360 mA.

120Vac

60Hz

PRIMARY

S0

SI

Connection for PC-Link

SKYROUTE CN

PC580

YEL GRN

YEL

GRN

12

PGM

5K6

Z1 Z3COM

Z2 Z4

COM

RING TIP R-1

GROUND

CONNECTION

Nut

Washer

Cabinet

Bolt

Ground

EGND

T-1

Rod

RED

BLK

YEL

GRN

Any zone terminal

programmed

as a 24-Hour Zone.

-

+

AC

AUX

BELL

BLK

RED

1K

BELL + BELL IN

SKYROUTE UT

22

Max.

LED 1

Signal Strength

LED 2

Indicator

LED 3

Min.

LED 4

Rx/Tx

Status

SW1

LED 5

Indicator

Test

Switch

SKYROUTE

YEL

RED

BLK

TAM

GRN

COM

BELL

BELL

OUT

IN

Page 24

Existing Alarm Control with a Skyroute UT Transceiver

(Switched Positive Bell)

GENERIC

CONTROL

RED

BLK

-

–

+

BELL

AUX

AC

Parallel with

Siren or Bell

PANEL

RED BLK

BATTERY

12V 7.0Ah

Typi cal

battery

charge current

is 360 mA.

120Vac

60Hz

PRIMARY

50 FT MAX

ORG

RED

BLK

BRG

GND

SKYROUTE CN

S0

SI

20 FT MAX

Connection for PC-Link

PC580

5K6

-

+

AC

AUX

RED

12

YEL GRN

BELL

PGM

Z1 Z3COM

Z2 Z4

RING TIP R-1

BLK

YEL

GRN

1K

COM

EGND

T-1

BELL + BELL IN

RED

BLK

YEL

GRN

GROUND

CONNECTION

Nut

Washer

Cabinet

Bolt

Ground

Rod

SKYROUTE UT

PC1OUT

LED 1

LED 2

LED 3

LED 4

SW1

LED 5

Test

Switch

SKYROUTE

YEL

RED

GRN

BLK

Max.

Signal Strength

Min.

Rx/Tx

Status

Indicator

COM

BELL

OUT

Indicator

BELL

IN

TAM

23

Page 25

Existing Alarm Control with a Skyroute UT Transceiver

(Switched Negative Bell)

GENERIC

CONTROL

RED

BLK

-

–

+

BELL

AUX

AC

PANEL

RED BLK

BATTERY

12V 7.0Ah

Typi cal

battery

charge current

is 360 mA.

120Vac

60Hz

PRIMARY

S0

SI

50 FT MAX

20 FT MAX

Connection for PC-Link

ORG

RED

BLK

BRG

EMR

GND

SKYROUTE CN

PC580

5K6

-

+

AC

AUX

RED

12

YEL GRN

BELL

PGM

Z1 Z3COM

Z2 Z4

RING TIP R-1

BLK

YEL

GRN

1K

COM

EGND

T-1

BELL + BELL IN

RED

BLK

YEL

GRN

GROUND

CONNECTION

Nut

Washer

Cabinet

Bolt

Ground

Rod

SKYROUTE UT

PC1OUT

LED 1

LED 2

LED 3

LED 4

SW1

LED 5

Test

Switch

SKYROUTE

YEL

RED

GRN

BLK

Max.

Signal Strength

Min.

Rx/Tx

Status

Indicator

COM

BELL

OUT

Indicator

BELL

IN

TAM

24

Page 26

Skyroute UT Transceiver

Z COM Z

5.6K

Negative Trigger

Z COM Z

5.6K

Positive Trigger

Relay Trigger or Dry Contact Trigger

Z COM Z

5.6K

-+

CN.O.

-+

Normally Open Contact

Z COM Z

5.6K

-+

CN.C.

-+

Normally Closed Contact

Siren Trigger

Use PC1OUT Module Included

ORG

RED

BLK

Bell -

+ 12 volt

GND

Zx1

COM

Zx2

BRG

GND

EMR

Negative Siren Trigger

(Bell + always active and Bell - switch to ground on alarm)

With this configuration, Zx1 will be trigger on

steady Bell and Zx2 will be trigger on pulsed Bell

Positive Siren Trigger

(Bell - always to ground and Bell + switch to + on alarm)

With this configuration, Zx1 will be trigger

every time the Bell is activated

ORG

RED

BLK

Bell -

Bell +

GND

Zx

COM

BRG

GND

RED BLK

BATTERY

12V 7.0Ah

Typic al

battery

charge current

is 360 mA.

120Vac

60Hz

PRIMARY

SI

Connection for PC-Link

S0

PC580

5K6

-

+

AC

12

YEL GRN

AUX

BLK

RED

Z1 Z3COM

BELL

YEL

1K

BELL + BELL IN

Z2 Z4

PGM

GRN

RING TIP R-1

EGND

COM

T-1

SKYROUTE UT

GROUND

CONNECTION

Washer

Cabinet

Ground

RED

BLK

YEL

GRN

25

SKYROUTE CN

Nut

Bolt

Rod

Max.

LED 1

Signal Strength

LED 2

Indicator

LED 3

Min.

LED 4

Rx/Tx

Status

SW1

LED 5

Indicator

Test

Switch

SKYROUTE

YEL

RED

BLK

TAM

GRN

COM

BELL

BELL

OUT

IN

Page 27

Appendix A

SIA Communications For Skyroute

SIA Communication Format:

The SIA communication format used in this product follows the Level 2 specifications of

the SIA Digital Communication Standard - February 1993. This format will send the

Account Code along with a its data transmission. Below are the Zone Alarms & Alarm

Restores (Zones 01-32) as well as any additional codes that can be transmitted;

Terms:

Code Description

— Not used

zz Zone #

us User #

ln Line

ex Expander #

Alarms:

Event Description SIA Message Zone# Identified

Null Zone (Not used) ———————- ———

Delay 1 BAzz/BHzz Yes

Delay 2 BAzz/BHzz Yes

Instant BAzz/BHzz Yes

Interior BAzz/BHzz Yes

Delay H.A. BAzz/BHzz Yes

Interior H.A. BAzz/BHzz Yes

24 Hr Burglary BAzz/BHzz Yes

Standard Fire FAzz/FHzz Yes

Delayed Fire FAzz/FHzz Yes

24 Hour Supervisory (LINKS) UAzz/UHzz Yes

24 Hr Supervisory Buzzer UAzz/UHzz Yes

24 Hr Supervisory USzz/URzz Yes

24 Hr Medical MAzz/MHzz Yes

24 Hr Panic PAzz/PHzz Yes

24 Hr Hold-up HAzz/HHzz Yes

24 Hr Gas GAzz/GHzz Yes

24 Hr Heat KAzz/KHzz Yes

24 Hr Emergency QAzz/QHzz Yes

24 Hr Sprinkler SAzz/SHzz Yes

24 Hr Water WAzz/WHzz Yes

24 Hr Freeze ZAzz/ZHzz Yes

24 Hr Latching Tamper BAzz/BHzz Yes

Momentary Keyswitch Arm BAzz/BHzz Yes

Maintained Keyswitch Arm BAzz/BHzz Yes

26

Page 28

SIA Communications For Skyroute(continued)

Event Description SIA Message Zone# Identified

Duress Alarm HA00

Opening After Alarm OR00

Keypad [F]ire FAzz/FHzz Yes

Keypad [A]uxiliary MAzz/MHzz Yes

Keypad [P]anic PAzz/PHzz Yes

PGM2:

2 Wire Smoke FA99/FH99

Audible 24 Hour UA99/UH99

Silent 24 Hour UA99/UH99

Zone Tamper (1-32) TAzz Yes

Zone Tamper Restorals (1-32) TRzz Y es

General System Tamper / Restore TA00/TR00

Closing by Access Codes CLus Yes

(1-32,33,34,40,41,42)

Partial Closing CGus Yes (using UBzz)

Opening by Access Codes OPus Yes

(1-32,33,34,40,41,42)

Battery Trouble YT00/YR00

AC Failure Trouble AT00/AR00

Bell Circuit Trouble UT99/UJ99

Fire Trouble FT00/FJ00

Auxiliary Power Supply Trouble YP00/YQ00

TLM Trouble Code (via Skyroute) LT00

General System Supervisory / Restore ET00/ER00

General System Trouble / Restore YX00/YZ00

TLM Restoral LR00

FTC Fail / FTC Restoral YC00/YK00

Event Buffer 75% Full Since Last Upload JL00

Periodic Test Transmission RP00

System Test RX00

Skyroute Test Transmission Code TX00 Signal Strength

Zone Fault Alarm/Restoral UTzz/UJzz

Burglary Verified BV00

Delinquency Code CD00

Zone Low Battery XTzz/XRzz

Recent Closing CR00 User NOT Identified

Zone Expander Supervisory UA00/UH00

Keypad Lockout JA00

Special Closing (DLS, Keys, Maint, Quick) CLus Yes (User)

Special Opening (DLS, Keys, Maint) OPus Yes (User)

DLS Lead In RB00

DLS Lead Out (Successful) RS00

Auto-Arm Cancellation CE00

Late to Close CI00

Skyroute Tamper Cut TAzz/TRzz Yes

Keybus Cut USzz/URzz Yes

Telephone Line Cut LTln/LRln

Expansion Device ETex/ERex

1

2

Yes

Yes

27

Page 29

Page 30

Limited Warranty

Sur-Gard Ltd. warrants that for a period of sixty months from the date of purchase, the product shall be free of defects in materials

and workmanship under normal use and that in fulfillment of any breach of such warranty, Sur-Gard Ltd. shall, at its option,

repair or replace the defective equipment upon return of the equipment to its repair depot. This warranty applies only to defects

in parts and workmanship and not to damage incurred in shipping or handling, or damage due to causes beyond the control

of Sur-Gard Ltd., such as lightning, excessive voltage, mechanical shock, water damage, or damage arising out of abuse,

alteration or improper application of the equipment.

The foregoing warranty shall apply only to the original buyer, and is and shall be in lieu of any and all other warranties, whether

expressed or implied and of all other obligations or liabilities on the part of Sur-Gard Ltd. This warranty contains the entire

warranty. Sur-Gard neither assumes, nor authorizes any other person purporting to act on its behalf to modify or to change

this warranty, nor to assume for it any other warranty or liability concerning this product.

In no event shall Sur-Gard Ltd. be liable for any direct, indirect or consequential damages, loss of anticipated profits, loss of

time or any other losses incurred by the buyer in connection with the purchase, installation or operation or failure of this product.

Warning

Sur-Gard Ltd. recommends that the entire system be completely tested on a regular basis. However, despite frequent testing,

and due to, but not limited to, criminal tampering or electrical disruption, it is possible for this product to fail to perform as

expected.

How to contact us:

Sales

For information about additional products, please call our sales number: 1-800-418-7618, or e-mail us

at sales@sur-gard.com.

Technical Support

If you have questions or problems when using Sur-Gard products, you can call technical support. If you are within

the United States, Puerto Rico, the U.S. Virgin Islands or Canada, you can get support by dialing 1-800503-5869

ext.I. If you are outside these areas, please call (416) 665-4494 ext.1, or e-mail us at support@sur-gard.com.

Internet

Visit our Sur-Gard site. You will be able to search the Sur-Gard technical information database and read information about

new products. You will also be able to send us your questions. Our World Wide Web address is http://www.sur-gard.com.

© Sur-Gard Security Systems Ltd.

401 Magnetic Drive, Unit 24-28,

Downsview, Ontario, M3J-3H9

Phone: 416-665-4494

Sales:1-800-418-7618

Technical Support:1-800-503-5869

www.sur-gard.com

29003347 R0

Printed in Canada

Loading...

Loading...