SGL SDR 63 Operating Instructions Manual

OPERATING INSTRUCTIONS

PLASTIC CENTRIFUGAL ROOF MOUNTED FANS

SDR 63.3 SIZES 355 – 710

Issued: PA S Operating manual No. 28.95.103 Valid from: Serial No. 29956

Date: 01.03.2001 Plastic Radial Roof Mounted Fans

SDR 63 Sizes 355-710

1. General notes

This operating manual is valid for all plastic centrifugal roof

fans of series

SDR 63 Sizes 355 - 710

manufactured and supplied by SGL ACOTEC GmbH in

56427 Siershahn, Berggarten 1, Germany.

The instructions must be handed to the user, who has to

inform the people responsible for operation, servicing and

repair. No liability is accepted for damage resulting from

non-observance of the instructions.

The fans supplied by SGL ACOTEC are designed with

reference to the order on the basis of flow rate, total

pressure differential, medium, operating temperature and

installation site. The actual parameters are shown on the

machine card or rating plate.

The product supplied must only be used for the application

specified in the contract and within the scope of the

conversion possibilities listed in this operating manual. Any

other use is regarded as not in accordance with the

intended purpose. SGL ACOTEC do not accept liability for

any damage arising from such a use.

CONTENTS

1. General notes 2

2. Construction and operating principle 2- 3

3. Realization of the safety requirements 4

4. Transport/Storage 4

5. Installation 4

6. Drive 5

7. Installation of the motors 5

8. Commissioning 5

9. Inspection/Maintenance 6

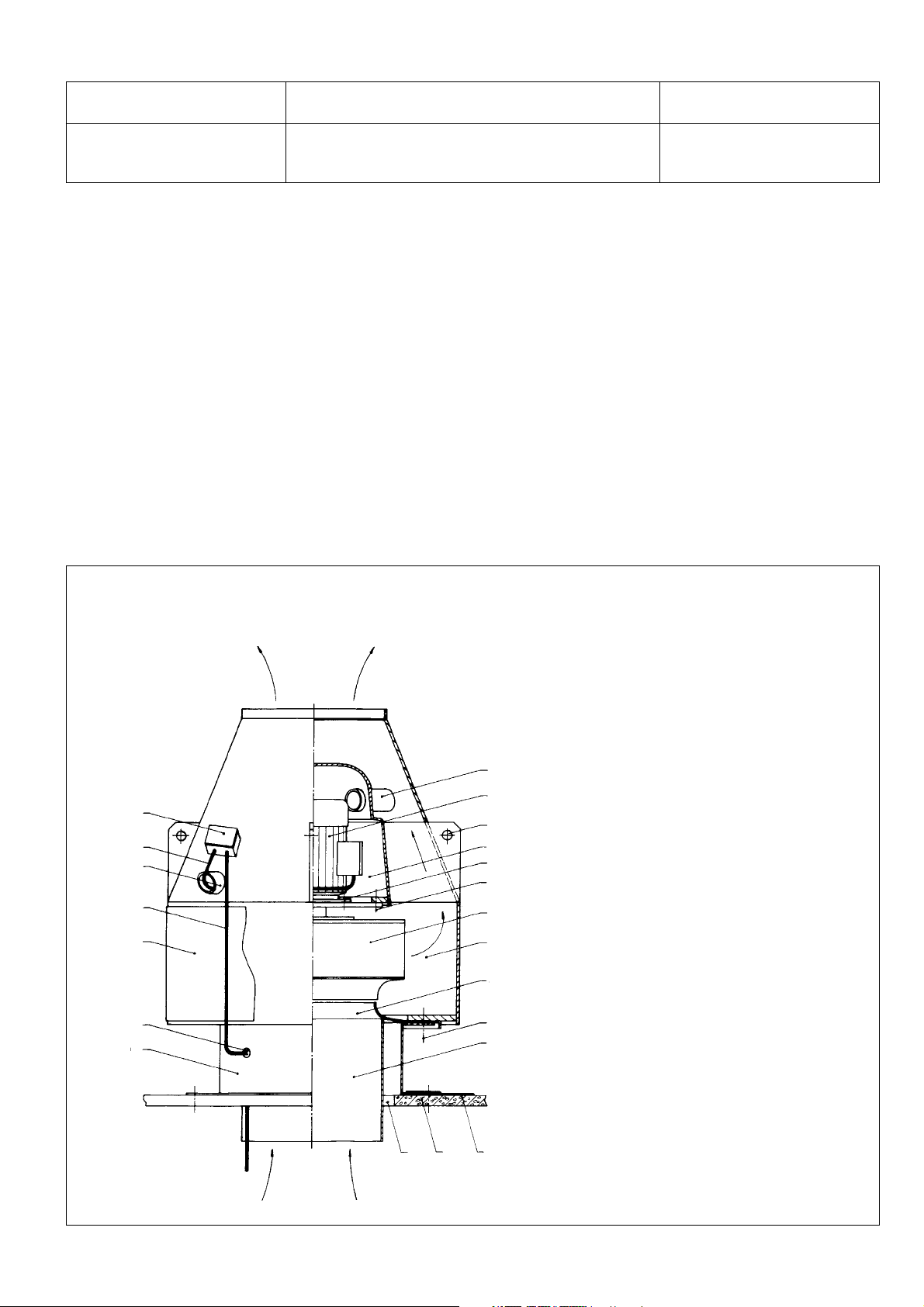

2. Construction and operating principle

SGL ACOTEC Centrifugal Roof Mounted Fans of Series

SDR 63 have been designed as vertically discharging,

direct-drive feed appliances for corrosive gases and

vapours. The medium handled is drawn in axially by the

rotating impeller and by deflection downstream of the

horizontal impeller outlet again passed axially around the

enclosed motor and to the outlet branch.

SDR fans of sizes 355 - 710 are of welded construction

and consist of the following sub-assemblies: enclosure,

motor support, impeller, air intake and tubular liner. Motor

support as well as the top and bottom section of the

enclosure are welded together. For Sizes 355 and 400, 450

and 500 as well as 560 and 630, identical enclosures are

used respectively. This makes it possible to convert the

fans also after delivery and installation by changing the

impeller and air intake to the other respective size.

The motor support is designed for the installation of six

motor sizes (71 - 132) in the design B5. The motors are

screened against the medium; cooling air supply is via

ventilation hoses (fig. 1). The impellers used have eight

backward curved blades and are balanced electrodynamically in two planes. Minimum balancing quality Q 6.3 to

ISO 1940.

10. Servicing/Conversion 6

Appendix: Characteristics diagrams 8-11

2

Issued: PA S Operating manual No. 28.95.103 Valid from: Serial No. 29956

Date: 01.03.2001 Plastic Radial Roof Mounted Fans

SDR 63 Sizes 355-710

Housing, motor support and impellers are made from

thermoplastics. The permissible operating temperatures of

the fans are with construction in

PVC 50°C

PP 70°C

and must not be exceeded.

Fig. 1 SGL ACOTEC Centrifugal Roof Fan SDR, flat roof installation

12

10

8

11

6

13

14

7

9

18

2

19

20

3

1

4

21

5

1 – Housing

2 – Motor support

3 – Impeller

4 – Air intake

5 – Liner

6 – Splinter guard

7 – Upper ventilation hose

8 – Lower ventilation hose

9 – Motor

10 – Motor lead

11 – Fan supply cable

12 – Terminal box

13 – Moisture-proof union

14 – Roof mount

15 – Roof covering

16 – Roof penetration

17 – Roof liner

18 – Hitching point

19 – Fixing screw, motor

20 – Fixing screw, motor flange

21 – Fixing screw, fan

16

1715

3

Issued: PA S Operating manual No. 28.95.103 Valid from: Serial No. 29956

Date: 01.03.2001 Plastic Radial Roof Mounted Fans

SDR 63 Sizes 355-710

3. Realization of the safety requirements

SGL ACOTEC Centrifugal Roof Mounted Fans Type SDR

are manufactured to the latest technological standards and

conform to the legal requirements in design, construction

and safety measures. If used in accordance with their

purpose and in compliance with this operating manual,

they are safe and reliable.

• All rotating parts are covered so that they cannot be

touched (motor enclosed, impeller screened by a

housing).

• On open-inlet fans the air intake is covered by a protective grille.

• The enclosures are radially surrounded by a splinter

guard, which if the impeller and/or housing are

damaged, prevents flying fragments.

• The enclosures and plastic impellers are welded in

accordance with the valid regulations. Welding additives

for thermoplastics conform to DVS 22.11.

• All impellers are statically and dynamically balanced

in two planes. Balancing quality min. Q 6.3 to ISO 1940.

The user of centrifugal roof fans supplied by SGL ACOTEC

has the following obligations:

• The fans must only be operated, serviced, converted

and repaired by authorized persons. These must be

instructed by the user in accordance with the operating

instructions about the correct procedure during the

above work and about possible angers.

• The user is obliged to operate the supplied product

only in sound condition.

• Unauthorised modifications which affect the function

and/ or safety of the fan are not permitted.

• All servicing, inspection, conversion and maintenance

operations must only be carried out with the fan at rest

and the power supply shut off.

• The removal of information-, instruction- and prohibition

plates from the product is not permissible. In all cases,

the fan must also be operated in accordance with all

local safety and accident prevention regulations.

4. Transport and storage

• The fans must be transported carefully and safely to

prevent damage through excessive force. Any impact-,

traction- or pressure stress on the plastic housings

must be avoided.

• When transported by truck, rail or ship, the fans must

be loaded and secured so that slipping, tilting or

friction are avoided.

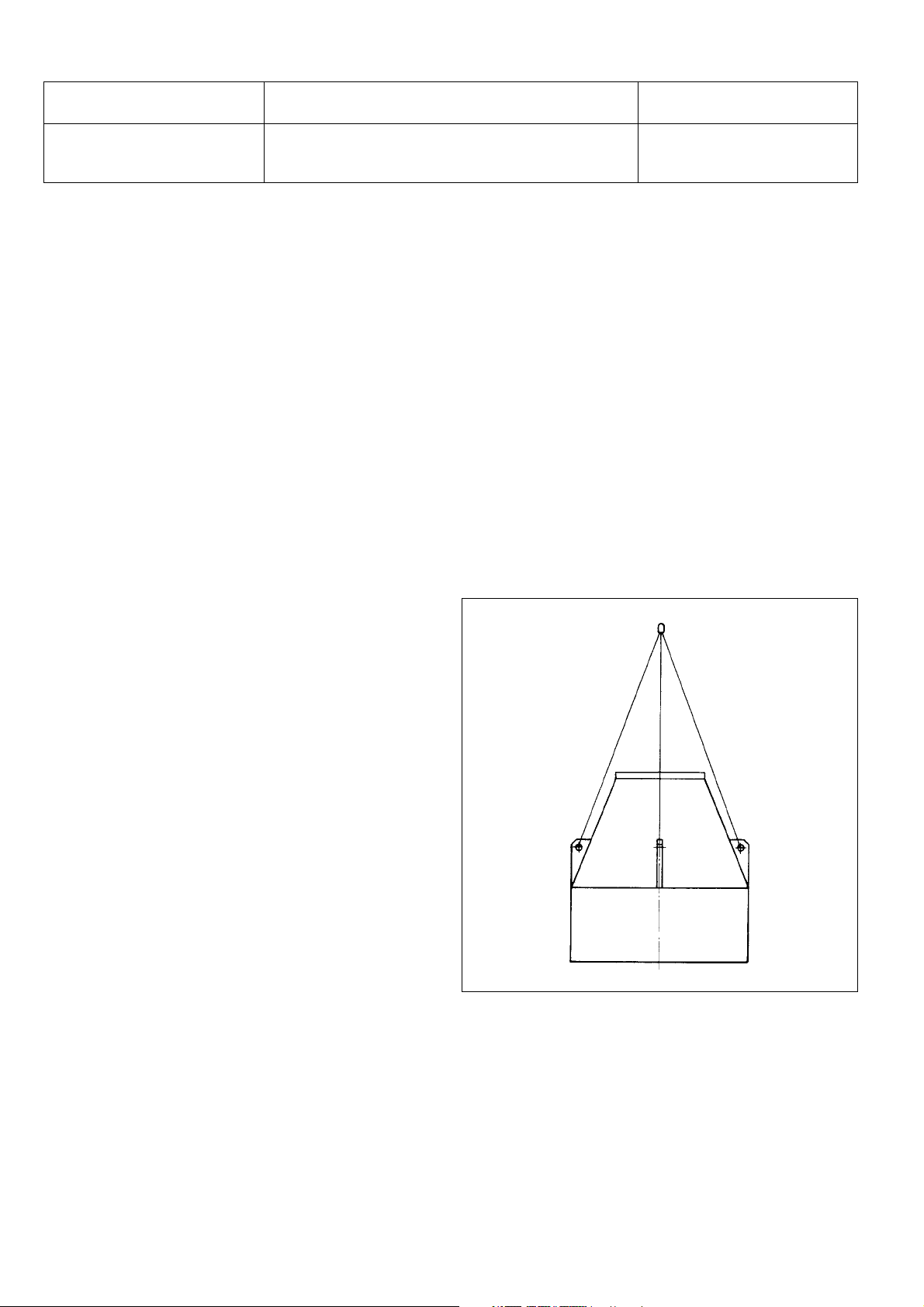

• The fans must be lifted and carried by means of fork-lift

truck or crane. When transported by crane, the fans

must be attached at the four plastic hitching eyes (fig. 2)

provided for that purpose.

To prevent damage of the eyes, shackles or fabric

attachments must be used.

The storage of the fans does not require any special

arrangements. They should be stored in rooms or on

roofed-over areas.

The discharge opening must be covered to prevent

objects from dropping into it. The fans must not be

stacked.

Fig. 2 SDR crane handling

5. Positioning

The SDR fans are placed on flat or sloping roofs by

installation on roof mounts, which are fixed onto the roof

covering and sealed with the roof liner (fig. 1).

• The intake-side duct must be connected to the liner

passing through the roof penetration and must only be

made with flexible connectors (bellows-type expansion

joints).

• Drive motor and terminal box at the top section of the

4

Loading...

Loading...