SGB VL 330 Installation Advice

Leak detection technology

UK Distributor

t: +44 (0)1388 813433

f: +44 (0)1388 813307

sales@orangecounty.co.uk

www.orangecounty.co.uk

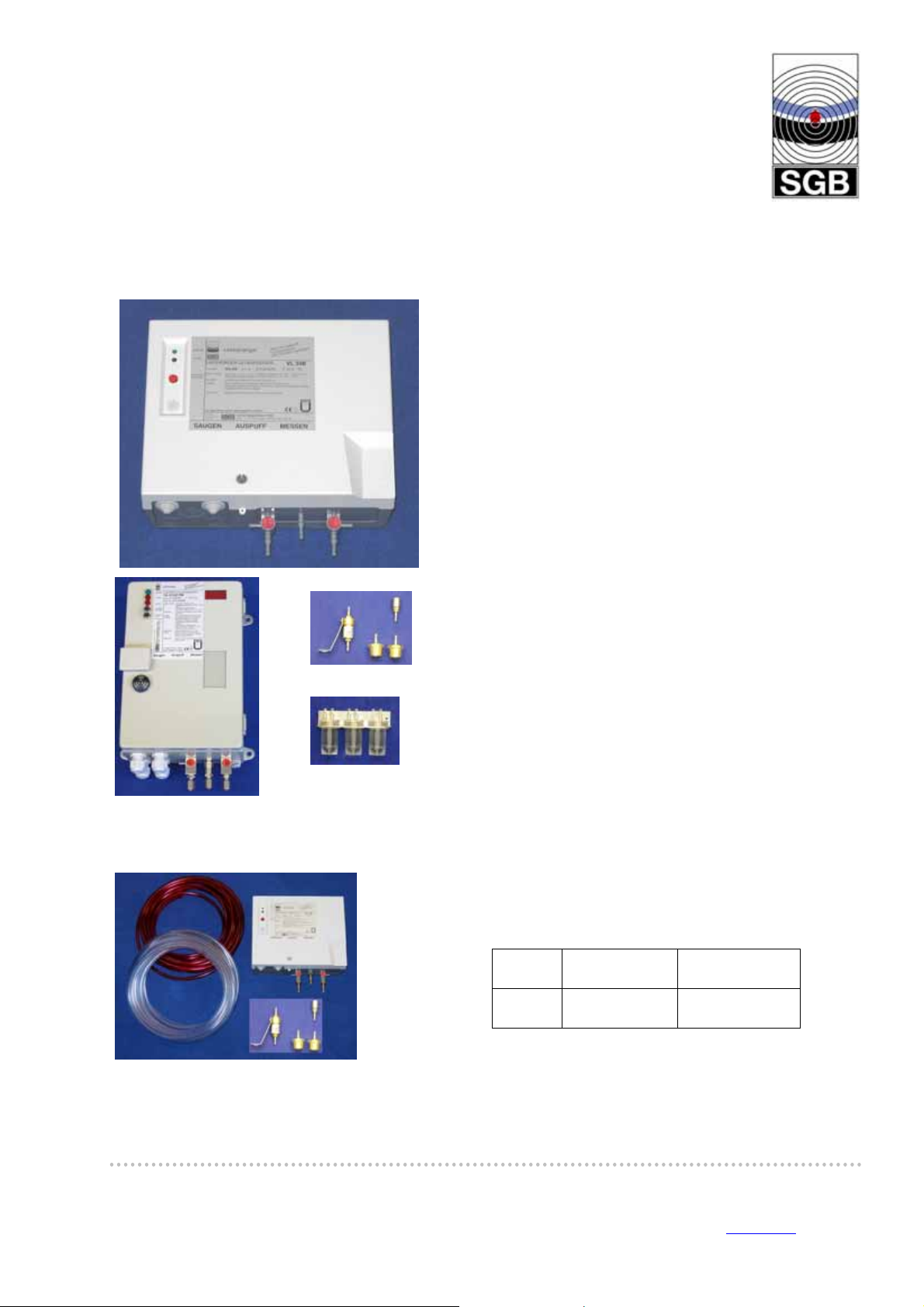

Underpressure leak detector VL 330

For a clean and protected environment

Leak detection system to detect and indicate

leaks in double-walled tanks.

Every leak in one of the walls will be indicated by

an optical and audible alarm before liquid enters

the environment.

(Class I-system in accordance to the European

standard EN 13 160)

Liquids to be monitored:

Water polluting liquids :

• with a flash point > 55° Celsius; e.g. Diesel,

heating oil)

• specific chemicals in accordance to chemical

resistance of the leak detector. Different materials

to realise chemical resistance are available.

Installation kit

for the tank

triple condensate

VL 330 P in a protection box

trap

Complete set including for all necessary

installation equipment

Approved for the use together with:

• double-walled horizontal tanks (e.g. EN 12285)

• single-walled horizontal or rectangular tanks

equipped with a lining (e.g. DIN 6625 or similar)

• double-walled ball shaped tanks

• upright standing tanks (e.g. DIN 6618/2)

Approvals:

Germany: Z -65.22 - 389

•

Technical data:

type alarm

underpressure

VL 330

>330 mbar

(> 4.79 psi)

operational

underpressure

450 mbar

(6.53 psi)

Sold by: SGB Sicherungsgerätebau GmbH Tel.: + 49 / (0) 271 / 48964-0

Hofstr. 10 D-57076 Siegen Fax: + 49 / (0) 271 / 48964-6

Postfach: 21 07 41 D-57031 Siegen http//www.sgb.de

E-mail: sgb@sgb.de

Leak detection technology

Underpressure leak detector VL 330

For a clean and protected environment

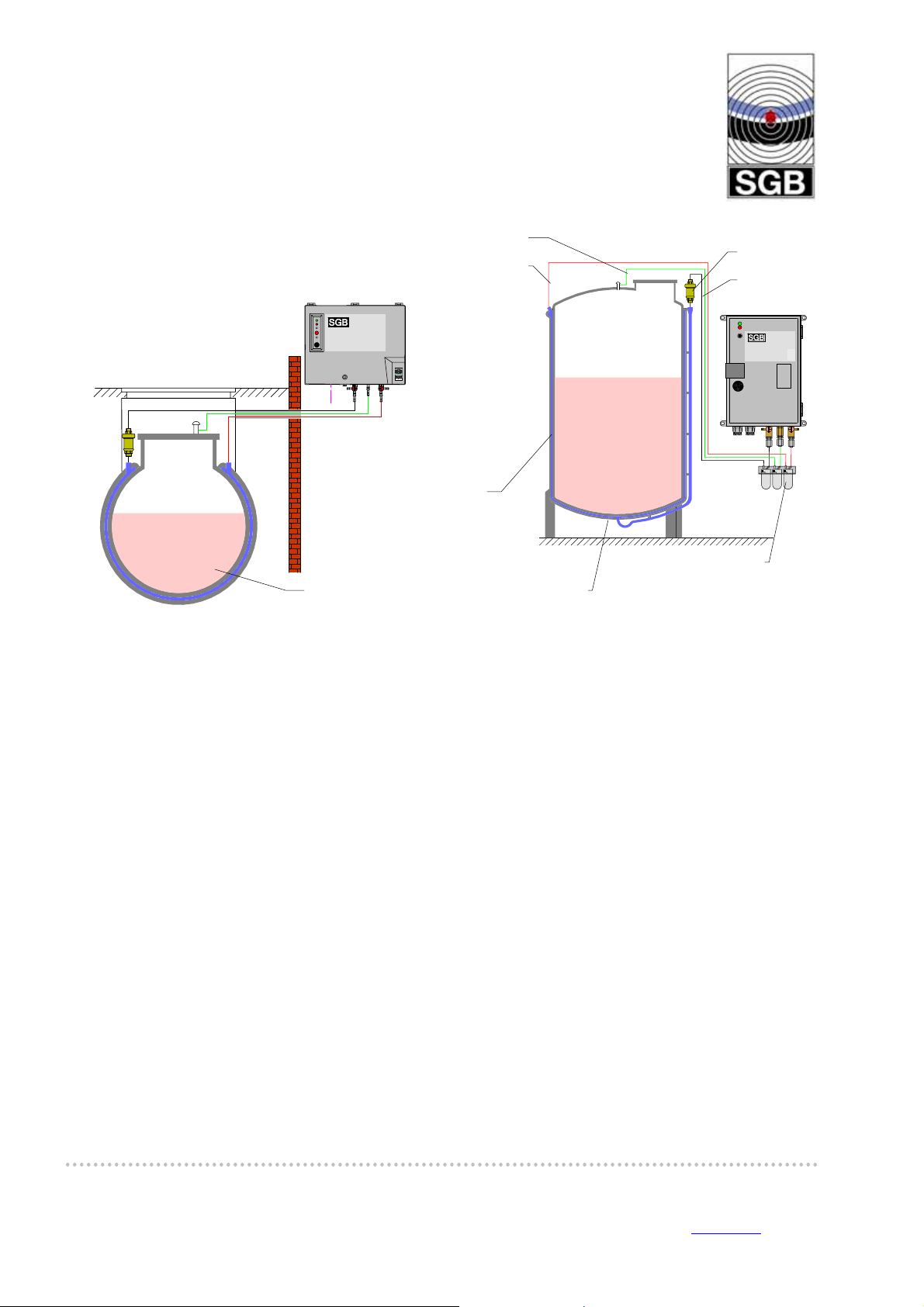

VL 330

P

Interstitial space with

Double-walled steel tank

underground

Monitoring principle:

The pump in the leak detector creates a

operational underpressure in the interstitial space.

Any minor unavoidable untightness is

compensated by the system automatically.

In case of a leak, air, groundwater or product is

sucked into the interstitial space.

If the volume flow of air entering the interstitial

space is higher than the limited volume flow of the

vacuum pump, the pressure will rise to the alarm

underpressure.

Groundwater or stored product is sucked into the

interstitial space. When the interstitial space is

filled up, the liquid enters the liquid stop valve,

which closes then. No further underpressure can

be produced. Some more liquid will be sucked

into the measuring line, causing a rise in pressure

to the alarm underpressure. The optical and

audible alarm is released.

Measuring line

underpressure

Exhaust line

Liquid stop valve

Suction line

VL 330 PM

Condenate trap

Double-walled

vertical steel tank

with suction line to

the low point

Installation advice:

The leak detector shall not be installed in

potentionally explosive atmosphere.

Outside closed and dry rooms, the leak detector

VL 330 P will realise the required weather

protection.

Coloured, chemical resistant, flexible or rigid tubes

are to be used as a connection between leak

detector and interstitial space.

Condensate traps are to be installed in all low

points of the connection lines, if applicable.

Three way cocks in the suction- and measuring

line on the leak detector guarantee a quick and

easy function check.

Dry relay contacts for alarm transmitting are

included as standard.

When operating, installing and commissioning the

leak detector VL 330, the conditions laid down in

the approvals for the leak detector, tanks and

linings are to be observed.

All works shall be carried out by a qualified person.

Subject to changes. Photos and SGB Sicherungsgerätebau GmbH Tel.: + 49 / (0) 271 / 48964-0

dimensions ar not binding for the Hofstr. 10 D-57076 Siegen Fax: + 49 / (0) 271 / 48964-6

extend of delivery. Postfach: 21 07 41 D-57031 Siegen http//www.sgb.de

Germany E-mail: sgb@sgb.de

Loading...

Loading...