Page 1

Overpressure leak detector

DL and DLG

Z – 65.23 - 409

Art. No.: 603 002

Documentation DL

SICHERUNGSGERÄTEBAU GMBH

Hofstraße 10

57076 Siegen

Issue: 07/2006

Page 2

2 von 49

OVERPRESSURE LEAK DETECTOR DL..

Content

1 Overview of the various designs 1 page

2 Technical description for the overpressure leak detector DL 15 pages

3 Drawings to the technical description 8 pages

4 Appendix to the technical description 6 pages

3.1 Appendix B: Switch and pressure values 2 page

3.2 Appendix TD: Technical Data 1 page

3.3 Appendix FC: Dry Filter monitoring 1 page

3.4 Appendix TF: Dry filter – Size of dry filters 1 page

3.5 Appendix DP: Evaluating the display for the function "Tightness test" 1 page

5 Dimension and Drilling, Plastic-housing 1 page

6 Dimension and Drilling, Steel-housing, weather protected 1 page

7 Working sheet AB-820 500 pneumatic connections 2 pages

8 Approval Certificate of the TÜV-Nord 5 pages

9 Approval of the DIBT 5 pages

10 Declaration of conformity 1 page

22/08/2006

- 1 -

Page 3

Overview of the various designs for

3 von 49

OVERPRESSURE LEAK DETECTORS DL..

GI 1

Overview of the various designs

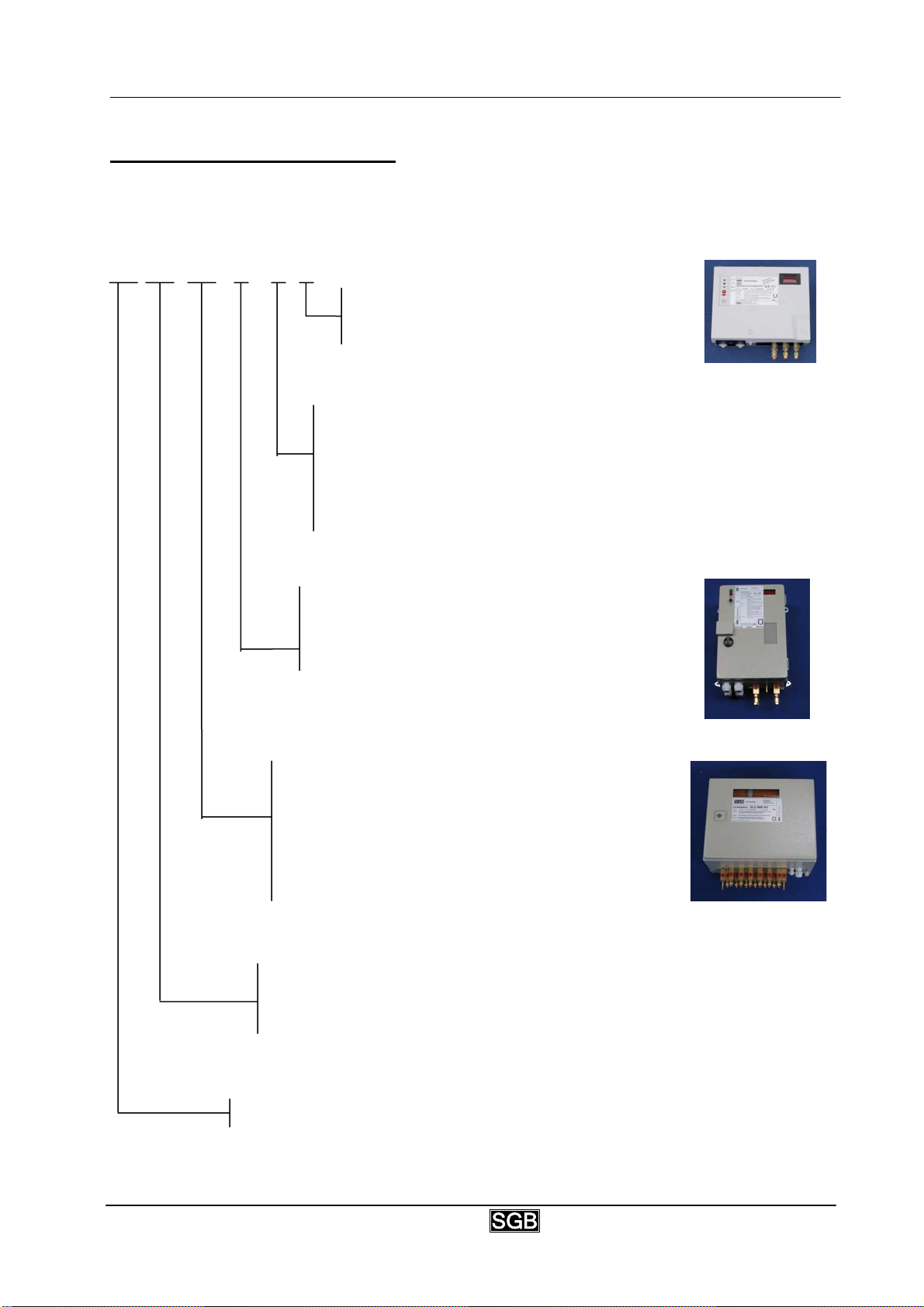

The different designs of overpressure leak detectors in the DL series are described more

precisely by means of the attached letters.

DL …. ELC (P) FC M

The leak detector’s ‘manometer’ design is

equipped with a digital pressure reading in

the housing’s lid.

The leak detector’s ‘filter control’ design is

equipped with a monitoring device for the dry

filter, which emits a separate status signal

when the dry material has been consumed.

It is only available for alarm pressures of up to

450 mbars.

The leak detector’s ‘protected’ design is located

in a weatherproof housing.

Leak detectors for alarm pressures of 590 mbars

and higher are only available in this design.

The leak detector’s 'economic leak control’ design

functions as both a leak detector and a leak reading

device: whereby the leak detector is equipped with

an integrated distribution for connecting up to 6

tanks.

This design is always weatherproof and the ’P’ is

therefore inapplicable.

‘Numerical values’ for the leak detector’s alarm

pressure.

The alarm pressures range from 50 mbars to 3,000

mbars.

The leak detector’s ‘pressure leak detector’ design works

at overpressure in relation to the atmospheric pressure.

01/09/2005. Your partner for leak detector equipment Sicherungsgerätebau GmbH, Siegen

Page 4

4 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

Contents Page

1 Subject

2 Field of application

2.1 Requirements for interstitial space 2

2.2 Tanks / interstitial space 2

2.3 Stored products 2

2.4 Exclusion 3

3 Description of functions 3

3.1 Switching and pressure values 3

3.2 Normal operation 3

3.3 Air or liquid leak 4

3.4 Air drying / Dry filter (DL.. ONLY) 4

3.5 Overpressure valve 4

3.6 Description of the display and control elements 4

4 Installation instructions 6

4.1 General 6

4.2 Personal protective equipment 7

4.3 Installation of the leak detector 7

4.4 Installation of the connection lines 7

4.5 Installation of the dry filter (DL.. ONLY) 8

4.6 Choice of pressure reducer (DLG.. ONLY) 8

4.7 Pressure cylinder and pressure reducer (DLG.. ONLY) 8

4.8 Electrical connection 9

4.9 Installation examples 9

5 Start up/servicing 9

6 Operating instructions 10

6.1 General 10

6.2 Maintenance 11

6.3 Intended use 11

6.4 Function test 11

6.5 Alarms 14

7 Removal 14

8 Marking 15

9 Abbreviations 15

DRAWINGS

Setting three-way valves P – 060 000

Installation example DL .. M1 + M2 – 060 000

Installation example DLG .. M3 + M4 – 065 000

Wiring diagram DL .. SL - 853 600

Wiring diagram DLG .. SL – 853 700

Test device P - 115 392

ANNEX:

B Switching and pressure values B – 1

TD Technical data TD – 1

26/01/2006

1

Page 5

5 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

1 Subject

Overpressure leak detector for double-walled tanks with pressure provided either by a pump or

by a compressed gas supply.

DL .. Overpressure leak detector with integrated pump. Dots stand for alarm pressure.

DLG .. Overpressure leak detector with compressed gas supply. Dots stand for alarm pressure

2 Field of application

2.1 Requirements for interstitial space

• Evidence of the pressure resistance of the interstitial space (see Annex B, column "p

TEST

"

minimum test pressure of the interstitial space)

• Evidence of the suitability of the interstitial space (for Germany: Building Inspectorate

Suitability Serification)

• Tightness of the interstitial space (see chap. 6.4.4)

• The number of interstitial spaces for monitoring in underground tanks depends on the total

interstitial space volume. According to prEN 13160, 8 m

3

must not be exceeded. It is

recommended not to exceed 4 m³ with regard to the feasibility of monitoring the tightness of

the interstitial space.

2.2 Tanks/interstitial space (see chapter 2.4)

• Under- and above ground double-walled steel or plastic tanks, without leak detection liquid

in the interstitial space, manufactured in the factory or on site, whose interstitial space is

suitable for the connection of a DL .. as per Annex B.

• Under- and above ground single-walled steel or plastic tanks with pressure-resistant leak

detection lining or leak detection jacketing, whose interstitial space is suitable for the

connection of a DL .. as per Annex B.

• Double-walled sumps or containments with interstitial space suitable for the connection of a

DL .. as per Annex B.

2.3 Stored products

Liquids hazardous to water with regard to the following points:

• The leak detection medium must not react with the stored products.

• Vapour/air mixtures resulting from the

- stored liquid

- stored liquid in combination with air / humidity or condensation

- stored liquid in combination with parts (materials) in contact with the liquid

must be classified in gas group IIA and II B and in temperature code T1 to T3.

26/01/2006

2

Page 6

6 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

2.4 Exclusion

If permeation occurs in the interstitial space as a result of the stored product and the material

structure of the inner tank wall (e.g. in double-walled GRP tanks) which can result in an

explosive atmosphere in the interstitial space under normal operating condition, ONLY leak

detector DLG .. must be used in combination with an inert leak detection medium (pressure

cylinder or operational network).

3 Description of functions

The overpressure leak detector DL .. resp. DLG .. monitors both walls of a tank for leaks. The

monitoring pressure is high so that any leaks above or below the liquid level (stored product and

ground water) are detected as a fall in pressure.

Pressure is built in up in:

DL .. by sucking in the outside air through the

integrated pump via a dry filter and forwarding it

to the interstitial space.

The dry filter dries the air to approx. 10%

humidity. Drying is necessary to prevent

moisture/condensation from collecting in the

interstitial space. Spent dry filter fillings must

be regenerated or replaced.

DLG .. by conveying compressed gas (dried air or

intert gas) to the interstitial space. The leak

detector has a display in the housing lid which

shows the operating pressure in the interstitial

space.

• Values under 50 mbar or under 0.73 PSI are

not shown.

• Values between 50 and 999 mbar are shown

in mbar without decimals.

• Values from 1 bar are shown in bar with 2

decimal places and from 10 bar with 1 decimal

place.

• Values in PSI are shown with 1 or 2 decimal

places.

3.1 Switching and pressure values

Annex B contains a list of the switching values.

3.2 Normal operation

The overpressure leak detector is connected by pressure and measuring line with the interstitial

space(s). The overpressure created by the pressure generator (pump or pressure cylinder) is

measured and controlled by a pressure sensor.

On reaching the operating pressure (refill OFF), the pressure generator (pump or solenoid

valve) is switched off. The pressure slowly falls again due to unavoidable leaks in the leak

detection system. On reaching the switching value for "refill ON", the pressure generator is

switched on again and operating pressure restored.

In normal operation, the leak detector swings between these two pressure values with short

operational times and longer standstill periods, depending on the level of tightness and

temperature fluctuations in the system.

26/01/2006

3

Page 7

7 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

3.3 Air or liquid leak

If a leak occurs below or above the liquid level or ground water, leak detection medium escapes

from the interstitial space. Pressure falls until the pressure generator is switched on to restore

the operating pressure. If the volume flow escaping out of the leak is greater than the refill

intake from the pressure generator, then the pressure in the system falls although the pressure

generator is activated.

Enlargement of the leak causes a further loss in pressure until the alarm pressure is reached.

The visual and audible alarm is triggered.

3.4 Air drying / dry filter (DL . ONLY)

The air fed to the interstitial space passes through a dry filter in the suction line. The dry filter

dries the air to approx. 10% humidity to prevent corrosion and accumulation of condensation

1

the interstitial space.

The dry filter is rated for twelve months as long as the system is used for its intended use and

there are no additional fluctuations in temperature.

A dry filter is orange when new and turns colourless (or green) when spent. Spent dry filters

must be replaced or regenerated without delay.

3.5 Overpressure valve

The overpressure valve integrated in the pressure line protects the interstitial space from

intolerably high overpressure (exceeding the test pressure).

Intolerably high overpressure can be caused among others by:

• increase in ambient temperature (e.g. direct sunshine)

• increase in temperature from hot filling (possibly consult manufacturer)

3.6 Description of the display and control elements

3.6.1 Status of the display elements (LEDs) for type DL ..

LEDs Operating status Alarm status Alarm, audible alarm

Unit out of order

switched off

in

OPERATION:

ON ON ON ON

green

ALARM: red

OFF ON FLASHES ON

1

Accumulation of condensation in the interstitial space can cause an intolerable pressure increase.

26/01/2006

4

Page 8

8 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

3.6.2 Status of the display elements (LEDs) for type DLG ..

LEDs Operating

status

OPERATION:

ON ON ON ON ON ON

Refilling

activated

Filling

activated

Alarm

status

Alarm, audible

alarm switched off

Unit out

of order

green

ALARM: red

PRESSURE

FEED: yellow

OFF OFF

OFF ON FLASHES ON ON OFF

OFF

FLASHES

2

ON

ON FLASHES ON

3.6.3 Operating functions through keys

For DL .. and DLG ..

Switch audible alarm off:

Press the button "Audible alarm" once briefly, audible signal switches off, red LED flashes.

Press again to switch the audible signal on.

This function is not available in normal operation and during malfunctions.

Testing the visual and audible alarm

Press and hold the button "Audible alarm" (approx. 10 sec.), the alarm is triggered until the button

is released.

This is only possible if pressure in the system has exceeded the "Alarm OFF" pressure.

2

on or off depending on pressure and/or audible alarm

26/01/2006

5

Page 9

9 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

DL .. DLG ..

Zero point adjustment3:

Three-way valve 21 in setting II (alarm triggered,

pump running)

Press and hold the button "Audible alarm" until

the "Alarm" LED flashes quickly (approx. 5 sec.),

release button, then press again and release.

Zero point adjustment is confirmed by 3 visual

and audible signals.

Three-way valve 21 in setting I

The zero point adjustment can only be repeated

after operating pressure has been built up.

Checking the tightness of the monitored system

Press and hold the button "Audible alarm" until

the "Alarm" LED flashes quickly, then release. A

value for tightness is shown when the "Alarm"

LED lights up (see chapter 6.4.5)

For this check, the leak detector must have

completed at least 1 automatic refilling interval in

normal operation (i.e. without filling with an

installation pump) for a meaningful statement.

Filling the interstitial space with leak detection

medium

Press and hold the "Filling" button for approx. 5

sec. until the yellow LED flashes. Filling is

activated.

On reaching the operating pressure, the yellow

LED goes off and filling stops.

When pressure falls because of pressure

compensation processes, filling can be activated

again to ensure that the interstitial space is filled

completely.

If you hold the button for longer than 10 sec., this

triggers the alarm. It goes off again just after you

release the button.

Checking the tightness of the monitored system.

Press and hold the button "Audible alarm" until

the "Alarm" LED flashes quickly, then release. A

value for tightness is shown when the "Alarm"

LED lights up and is also shown in the display

(see chapter 6.4.5)

10 sec. after the value is displayed, the leak

detector goes back to normal operation.

For this check, the leak detector must have

completed at least 1 automatic refilling interval in

normal operation (i.e. without activating the filling

function) for a meaningful statement.

4 Installation instructions

4.1 General

(1) Installation only by qualified companies

(2) Comply with pertinent accident prevention regulations.

(3) Comply with the ex regulations (if necessary) such as BetrSichV [Operational Safety

Ordinance] or others.

(4) Before inspecting control shafts, check the oxygen level and scavenge the control shaft if

necessary.

DLG ONLY

(5) When transporting the pressure cylinder to and from the site, always comply with the

corresponding traffic regulations.

(6) Secure the pressure cylinder on site to prevent it from falling over.

3

Only applicable for DL 50 to DL 450.

4

For Germany: qualified companies as per § 19l WHG [Water Resources Act] with skills and know-how

when it comes to fire and explosion protection.

4

.

26/01/2006

6

Page 10

10 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

(7) If start up/operation takes place in enclosed rooms, ensure that there is adequate

ventilation. Affix a warning sign.

4.2 Personal Protective Equipment

The items listed here refer in particular to safety when working on systems which may be

subject to risk of explosion.

When working in potentially explosive areas, at least the following items of equipment are

required:

• Suitable clothing (risk of electrostatic charge)

• Suitable tools (as per EN 1127)

• Suitable gas detectors for the prevailing vapour/air mixtures (work should only be carried out

at concentrations 50% below the lower flammable limit

5

)

• Instruments for measuring the oxygen level in the air (Ex / O-meter)

4.3 Installing the leak detector

(1) Mounted to the wall usually with plugs and screws.

(2) In a dry room, or in the open air in a suitable protective box.

(3) Installation in protective box: additional external signal or alarm forwarding via dry relais

contacts to central control desk or similar device.

(4) NOT in potentially explosive areas.

(5) The distance between leak detector and interstitial space should be kept as short as

possible.

4.4 Installation of connection lines (between leak detector and tank)

(1) Metal (usually copper) or plastic tubes with pressure resistance at least equal to the test

pressure of the interstitial space, the same applies to fittings and screwed unions. (Note

temperature range, particularly when using plastic).

(2) Inside clearance min. 4 mm for inert gas as leak detection medium

min. 6 mm for air as leak detection medium

(3) Should not be much longer than 50 m. If longer than 50 m, use tube/hose with larger inside

clearance using corresponding adapters.

(4) Colour coding: Measuring line: red

Pressure line: white (or clear)

(5) The full cross section must be maintained. No squeezing or bending

6

.

(6) Metal or plastic tubes underground or plastic tubes installed outside above ground must be

routed in conduits.

5

Other percentages are possible based on national or company regulations.

6

If necessary, use commercially available moulded pieces (with stipulated bending radii) for plastic tubes.

26/01/2006

7

Page 11

11 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

(7) Seal conduits to be gas-tight with protection from penetration of liquids.

(8) Avoid build-up of static electricity (e.g. when inserting and routing tubes).

(9) Details for connecting systems, see worksheet AB-820 500

4.5 Installation of the dry filter (DL .. ONLY)

(1) As close as possible to the leak detector. If the leak detector is mounted in a protective

box, the dry filter can be installed in the protective box or in the open air.

(2) Vertical with intake opening at the bottom, using enclosed installation material.

(3) Connect the dry filter to the leak detector intake port with a PVC hose (or similar).

4.6 Choice of pressure reducer (DLG ..ONLY)

(1) The pressure reducer must have an integrated overpressure valve.

(2) The range for the pressure reducer must be selected according to the specific application

respectively adjusted pressure (see Annex B).

4.7 Pressure cylinder and pressure reducer (star up/function test) (DLG .. ONLY)

(1) After the pressure cylinder has been set up securely, remove the protective cover.

(2) Fit the pressure reducer to the cylinder.

(3) Close the shut-off cock on the pressure reducer.

(4) Install the connecting tube between leak detector and pressure reducer.

(5) Turn pressure control valve all the way back.

(6) Open bottle shut-off cock (poss. leak test between pressure reducer and bottle)

(7) Adjust pressure at pressure reducer as per Annex B using pressure control valve on

pressure reducer (poss. readjust during pressure build-up).

(8) To change the pressure cylinder:

- Close the shut-off cock on the pressure reducer.

- Close the bottle shut-off cock.

- Remove the pressure reducer from the cylinder (caution: gas escapes until pressure is

relieved in the pressure reducer)

- Put protection cover on the cylinder.

- Erect and secure new cylinder, remove protection cover.

- Fit the pressure reducer (poss. leak test between pressure reducer and cylinder)

- Open bottle shut-off cock.

- Open shut-off cock on pressure reducer, poss. readjust pressure using the pressure

control valve.

26/01/2006

8

Page 12

12 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

4.8 Electric connection

(1) Power supply: according to label

(2) Permanent installation, i.e. no plugged or switched connections.

(3) Comply with the regulations issued by the utility company.7

DL .. DLG ..

(4) Terminal configuration: (see also SL-853

600)

1 / 2 Mains connection

3 / 4 Occupied (internal pump)

5 / 6 External signal (in an alarm, a line

voltage present here, stopped

by pressing button "Audible

alarm").

11 / 12 Dry relay contacts (opened on

alarm and power failure).

(4) Terminal configuration: (see also SL-853

700)

1 / 2 Mains connection

3 / 4 Occupied (internal solenoid)

5 / 6 External signal (in an alarm, a line

voltage here, stopped by pressing

button "Audible alarm".

11 / 12 Dry relay contacts (open

on alarm and power failure)

21 / 22 Occupied (internal sensor)

4.9 Installation examples

Installation examples are shown in the Annex

5 Start up/servicing

(1) Observe also the instructions in chapter 4.

(2) Special safety measures are required when commissioning a leak detector in an already

filled tank (e.g. check that there is no gas in leak detector and/or interstitial space). Other

measures can depend on local conditions at the discretion of the staff.

(3) After completing the pneumatic connection, proceed with the electrical connection.

(4) Check that the LEDs "Operation" and "Alarm" light up and that the audible alarm works.

Press the button "Audible alarm".

(5) Three-way valve 21 in position "III", connect test instrument.

DL ..

(6) Apply operating pressure to leak detection

system as per table on page 3 (use

installation pump with adequately

dimensioned dry filter or nitrogen pressure

cylinder).

(7) Pressure can be built up with the installation

pump directly using the pressure line or via

the three-way valve 20 (position IV).

Note: If pressure cannot be built up with the

7

For Germany: also VDE regulations

DLG ..

(6) Press and hold "Fill" button for approx. 5

secs. until yellow LED flashes. The solenoid

valve opens to fill the interstitial space

quickly. On reaching the operating

pressure, filling stops and the yellow LED

goes off.

For very large interstitial spaces, it may be

necessary to change the cylinder (see

chapter 4.6).

Note: If pressure cannot be built up in spite of

26/01/2006

9

Page 13

13 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

connected installation pump, find and

eliminate the leak (poss. check capacity of

installation pump, check correct setting of

pressure reducer).

the connected pressure cylinder, find and

eliminate the leak (poss. check correct setting of

pressure reducer). CAUTION: Leak detector

display begins at 150 mbar pressure.

(7) Filling can (should) be activated again to

ensure that the interstitial space is filled

completely.

(8) On reaching the leak detector operating pressure (pressure generator in leak detector

switches off), install pressure tube again or set both valves to setting "I". Remove pressure

instrument.

(9) Check functions as per chapter 6.4

6 Operating instructions

6.1 General

(1) Following impervious, correct connection of the leak detection system, the leak detector

can be presumed to work in the normal range.

(2) If the pressure generator switches on frequently or runs continuously, this indicates leaks

which must be eliminated in an appropriate period of time.

(3) An alarm always indicates a major leak or defect. Find and eliminate the cause quickly.

(4) The operator must regularly check that the "Operation" LED is working properly.

(5) Disconnect the leak detector from the power supply before performing and repair work.

(6) The operating lamp goes off when there is a circuit failure: the dry relay contacts open.

(7) (DL .. ONLY). When the filter filling changes colour from orange to colourless (or green),

it must be replaced or regenerated.

6.2 Maintenance

6.2.1 By the operator:

(1) Check the dry filter regularly

8

. When it changes colour from orange to colourless (or green),

replace or regenerate the filter filling.

(2) Check the filling in the pressure cylinder regularly. If the pressure is only just above the

pressure setting on the pressure reducer, refill or replace the cylinder.

6.2.2 Maintenance work and function check by qualified experts

8

Recommended: min. at 2 monthly intervals

9

For Germany: experts for installation/service of leak detectors or in the responsibility of an expert,

according to the currently valid regulations.

9

.

26/01/2006

10

Page 14

14 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

(1) Once a year to ensure functional and operational safety.

(2) Scope of inspection as per chapter 6.4

(3) Also check compliance with the conditions in chapter 4.5 and 6.2.

6.3 Intended use

• Groups of interstitial space only for underground interstitial spaces.

• Double-walled tanks, sumps or containments whose walls on the stored product side are

resistant to permeation from particles which can generate potentially explosive vapours.

EXCEPTION:

Inner walls not resistant to permeation when using an inert leak detection medium.

• The alarm pressure must be min. 30 mbar higher than any pressure occurring in the

interstitial space (from inside and/or outside).

• Grounding (where applicable) according to valid regulations

10

.

• Leak detection system is impermeable, according to chapter 6.4.6 of this documentation.

• Mount the leak detector outside potentially explosive area.

• Lead-throughs for the pneumatic hoses are sealed gas tight.

• Leak detector (electric) is connected so that it cannot be switched off.

6.4 Function test

Check functional and operational safety

• every time after start up

11

• on the basis of chapter 6.2 in the intervals stated there

• every time after troubleshooting

6.4.1 Test scope

(1) Poss. check the scope of work with the person responsible on site.

(2) Comply with the safety regulations for handling the specific stored product.

(3) (DL .. ONLY) Regeneration/replacement of the filter filling.

(4) Check the free passage of air (gas) in the interstitial space (chapter 6.4.2).

(5) Check the switching values with the test unit (chapter 6.4.3),

alternatively: check the switching values without test unit (chapter 6.4.4)

(6) Check the overpressure valve (chapter 6.4.5).

(7) Tightness test (chapter 6.4.6).

(8) Restore operating condition (chapter 6.4.7).

(9) Test report confirming functional and operational safety to be compiled by the qualified

person.

10

e.g. EN 1127

11

For Germany; otherwise comply with the national regulations (e.g. VAwS)

26/01/2006

11

Page 15

15 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

6.4.2 Check the free passage of air (gas) in the interstitial space

(1) If several interstitial spaces are manifolded together, check the free passage of each

interstitial space on its own:

(2) If several interstitial spaces are connected to a manifold with shut-off cocks in the pressure

and measuring lines, close all shut-off devices at the distribution units.

(3) Connect measuring gauge at three-way valve 21, setting "III".

(4) Three-way valve 20 in setting "IV". The (corresponding) interstitial space is vented.

CAUTION: maintenance work and function checks only by qualified persons. If inert gas is

used as leak detection medium, ensure there is adequate ventilation!

(5) Open shut-off cocks of the first (following) tank (measuring and pressure lines in pairs).

(6) Ascertain the pressure loss on the measuring gauge. If there is no pressure loss, find and

remedy the cause.

(7) Close the shut-off cocks opened under paragraph (4).

(8) Proceed with steps (5) to (7) with every other tank.

(9) Three-way valve 20 and 21 in setting "I", remove measuring gauge.

(10) Open all shut-off cocks on the manifold with connected tanks.

6.4.3 Checking the switching values with test unit.

(1) Connect the test unit to the test port of three-way valve 20 and 21. Both valves in setting

"II"“.

(2) Connect measuring gauge to the test unit.

(3) Close needle valve (test unit), pressure is built up to operating pressure.

(4) Vent using the needle valve, ascertain switching values for "Pump ON" and "Alarm ON"

(visual and audible), note values.

(5) Close needle valve and ascertain switching values for "Alarm OFF" and "Pump OFF". Note

values (possibly open needle valve slightly for slow increase in pressure)

(6) Three-way valve 20 and 21 in setting "I", remove measuring gauge.

6.4.4 Checking the switching values without test unit

(1) If several tanks are connected by a manifold, close all the shut-off cocks on the manifold

apart form the valves for the tank with the smallest interstitial space.

(2) Connect measuring gauge to three-way valve 21, setting "III".

(3) Vent via three-way valve 20 (setting "III"), ascertain switching values for "Pump ON" and

"Alarm ON" (with visual and audible alarm), note values.

(4) Three-way valve 20 in setting "I", ascertain switching values for "Alarm OFF" and "Pump

OFF", note values

(5) Three-way valve 21 in setting "I", remove measuring gauge.

(6) Open all shut-off cocks on the manifold with connected tanks.

26/01/2006

12

Page 16

16 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

6.4.5 Checking the overpressure valve

Operating pressure must have been built up in the leak detector for this test.

(1) Three-way valve 21 in setting "II" (pressure sensor is vented). The pump switches on and

the alarm is triggered.

(2) Connect measuring gauge to three-way valve 20, setting "II".

(3) Ascertain opening pressure of the overpressure valve (no further increase in pressure) and

note value. If the opening pressure of the overpressure valve exceeds the test pressure of

the tank, replace or adjust the valve.

(4) Three-way valve 21 in setting "I". The pump switches off, ascertain the closing pressure of

the overpressure valve (no further fall in pressure

12

), note the values.

(5) Three-way valve in setting "I", remove measuring gauge.

6.4.6 Tightness test

(1) Check that all shut-off cocks with connected tank are open.

(2) Connect measuring gauge to three-way valve 21, setting "III".

(3) Begin with the leak test after pressure has compensated. The tightness test is passed

when the values in the following table are achieved.

Interstitial space volume in litres Max. 1 mbar (0.015 psi) pressure loss in

250

500

1000

1500

2000

2500

3000

3500

4000

22 minutes

45 minutes

1.50 hours

2.25 hours

3.00 hours

3.75 hours

4.50 hours

5.25 hours

6.00 hours

(4) Three-way valve 21 in setting "I", remove measuring gauge.

6.4.7 Restore the operating condition

(1) Seal the housing

(2) The shut-off cocks for every connected tank must be in the "open" setting.

12

If the pump switches on before the closing pressure is reached, find out why and eliminate the cause.

26/01/2006

13

Page 17

17 von 49

6.5 Alarms

OVERPRESSURE – LEAK DETECTOR DL ..

DL ..

(1) Red LED lights up, the audible signal can

be heard.

(2) Stop the audible signal.

DLG ..

(1) Red and yellow LEDs light up, the audible

signal can be heard.

(2) Stop the audible signal.

(3) Inform the installation company

(3) Inform the installation company

immediately.

(4) Find and eliminate the cause of the alarm,

then check the functions of the leak

detection system according to section 6.4.

immediately.

(4) Find and eliminate the cause of the alarm,

then check the functions of the leak

detection system according to section 6.4.

(5) In the event of a malfunction, only the red

LED lights up (yellow is off). Inform the

manufacturer.

7 Removal

For the removal of units, which can cause a risk of explosion, always comply with the following

points:

• Check that no gas is present before and during work.

• Any openings which could allow for entrainment of a potentially explosive atmosphere must

be sealed gas-tight.

• Do not use spark-producing electrical tools (saws, abrasive cutters). If this is unavoidable,

comply with EN 1127.

• Avoid the build-up of electrostatic charges (e.g. through friction or wearing unsuitable

clothing).

• Dispose of contaminated parts appropriately (risk of outgassing).

8 Marking

• Electrical data

• Serial number

• Type designation

• Manufacturing date (month / year)

• Manufacturer's symbol

• Statutory symbols

• Pressure and shut-off cock line for leak detection medium air can be connected to zone 2

interstitial space; there are no restrictions for nitrogen as leak detection medium.

9 Abbreviations

01 LED "Alarm", red

02 Shut-off cock

05 Shut-off cock (pressure regulator)

26/01/2006

44 Solenoid valve

45 LED "Refill", yellow"

59 Relay

14

Page 18

18 von 49

OVERPRESSURE – LEAK DETECTOR DL ..

09 LED "Operation", green

13 Pressure line

14 Pressure reducer

17 Overpressure pump

19 Pressure cylinder

20 Three-way valve in pressure line

21 Three-way valve in measuring line

24.1 Fine-wire fuse

24.2 Fine-wire fuse

24.3 Fine-wire fuse

25 Pressure cylinder shut-off cock

29 Key "Fill"

30 Housing

43 Measuring line

61 Check valve with filter

69 Buzzer

70 Overpressure valve

71 Key "Audible alarm"

72 Dry filter

73 Interstitial space

76 Main PCB

77 Pressure control valve

102 Pressure sensor

103 Display

104 Operational pressure network (air / nitrogen)

105 Control unit

106 Contacts for serial data transfer

26/01/2006

15

Page 19

II

19 von 49

20

20

21

IIII

21

20

20

IIIIII

21

IVIV

21

Druckleitung Messleitung

27-11-2002

P - 060 000

Page 20

76

20 von 49

30

17102

Ex

72

ExEx

13

212070

43

73

27-11-2002

M1 - 060 000

Page 21

09

21 von 49

01

71

69

230 V / 50 Hz

20

72

Ex

21

02

13

Ex

43

Ex

/

73 73 73

27-11-2002

M2 - 060 000

Page 22

09

22 von 49

01

45

71

29

69

230 V / 50 Hz

20

13

21

43

103

104

14

Ex

02

Ex

73 73 73

Ex

/

27-11-2002

M3 - 065 000

Page 23

76

23 von 49

25

0

0

2

0

0

1

0

0

3

r

a

b

0

1

0

0

b

a

r

1

6

14

30

70

102

05

44

19

77

2120

Ex

13

43

ExEx

73

27-11-2002

M4 - 065 000

Page 24

Rp

24 von 49

~

17/60

102

24.1

26

AC

DC

09

453

69

59

11 121

105

106

27-11-2002

76

71 01

SL - 853 600

Page 25

44

25 von 49

24.3

24.2

26511121

AC

DC

09

4

3

24.1

69

59

103

106

102

21

22

105

71 29 01 45 76

27-11-2002

SL - 853 700

Page 26

98

26 von 49

20

90°90°

21

85

22

84

20

21

85

22

98

0

Kl. 1,0

52

17-12-2002

P - 115 392

Page 27

OVERPRESSURE LEAK DETECTOR DL ..

27 von 49

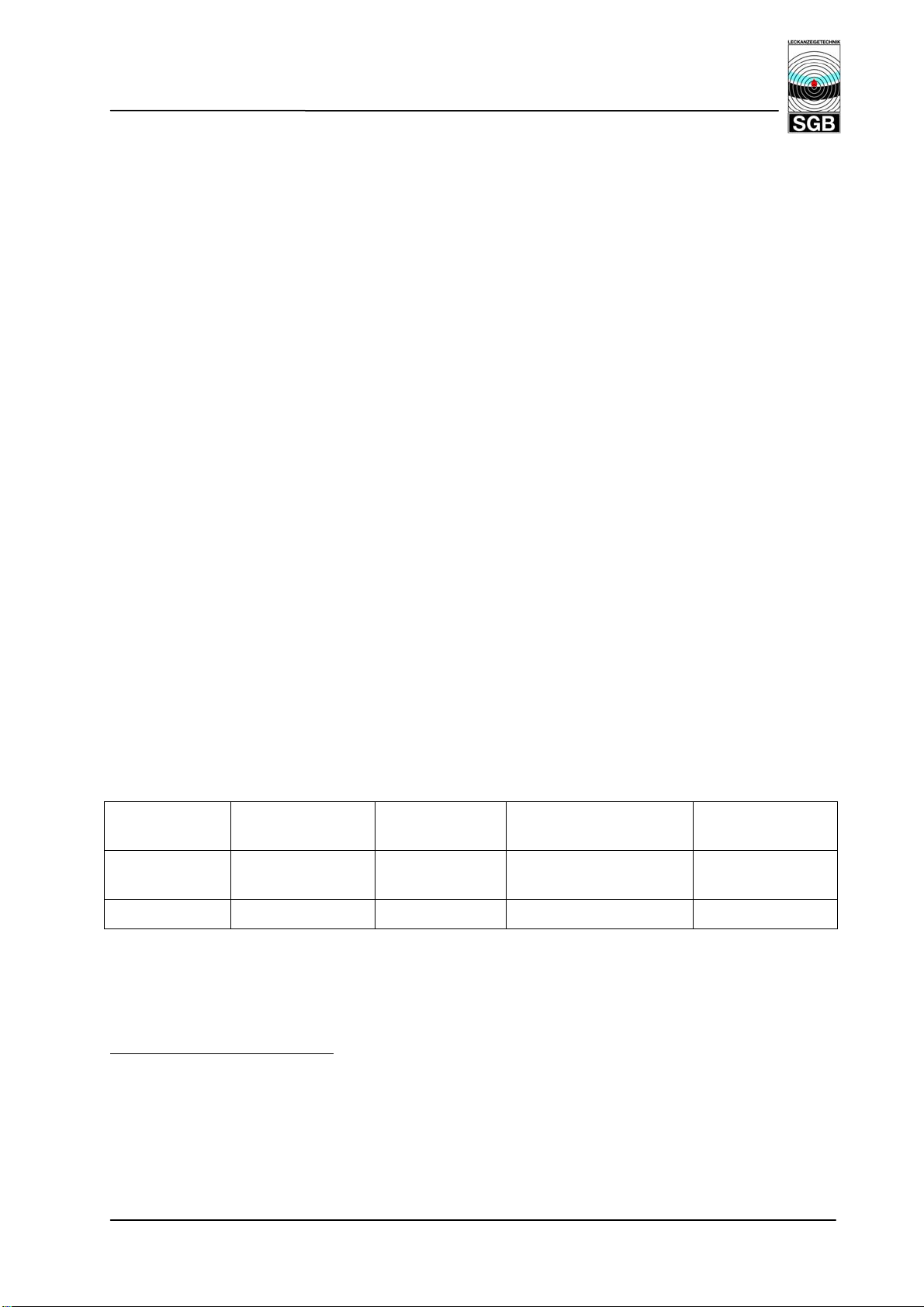

B Switching and pressure values

ANNEX B

Type

DL

pTS

[mbar]

p

AE

[mbar]

p

PA

[mbar]

50 20 > 50 < 100

100 70 > 100 < 150

290 260 > 290 < 350

330 300 > 330 < 410

400 370 > 400 < 500

450 420 > 450 < 510

590 560 > 590 < 700

750 720 > 750 < 850

1000 970 > 1000 < 1400

1100 1070 > 1100 < 1450

1500 1450 > 1500 < 1900

2000 1950 > 2000 < 2400

2300 2250 > 2300 < 2770

2500 2450 > 2500 < 2900

1

P

ÜDV1

[mbar]

p

PRÜF

[mbar]

170 ± 20 ≥ 200

220 ± 20 ≥ 250

420 ± 20 ≥ 450

465 ± 20 ≥ 500

565 ± 20 ≥ 600

565 ± 20 ≥ 600

750 ± 30 ≥ 850

940 ± 30 ≥ 1000

1550 ± 50 ≥ 1750

1580 ± 70 ≥ 1820

2100 ± 50 ≥ 2350

2650 ± 50 ≥ 2950

3100 ± 100 ≥ 3500

3200 ± 50 ≥ 3550

3000 2950 > 3000 < 3400

_

Special switching values agreed between SGB and customer

3750 ± 50 ≥ 4150

The following abbreviations are used in the table:

maximum pressure at the low point of the tank, including overlay pressure

P

TS

switch value "Alarm ON", the alarm is triggered at the latest at this pressure

p

AE

p

switch value "Alarm OFF", the alarm goes off on passing this value.

AA

The switching value "Alarm OFF" is approx. 15 mbar higher than the switch value

"Alarm ON" for pressure stages < 1000 and approx. 100 mbar higher for pressure stages

> 1000

(p

= pAE + ~15 mbar (pressure stages < 1000) ~ 100 mbar (pressure stages > 1000))

AA

p

Switch value "Pump OFF" (=nominal pressure)

PA

p

Switch value "Pump ON“

PE

The switch value "Refill ON" is approx. 15 mbar lower than the switch value "Refill OFF"

for pressure stages < 1000 and approx. 100 mbar lower for pressure stages > 1000

(p

= pPA - ~15 mbar (pressure stages < 1000) ~ 100 mbar (pressure stages > 1000))

PE

Opening pressure overpressure valve 1 (interstitial space side)

p

ÜDV1

p

Minimum test pressure of the interstitial space

PRÜF

1

The table states the opening pressure for the overpressure valve at which the volume flow of the pump is blown off.

The triggering pressure (first opening) is lower.

01/02/2006

- B-1 -

Page 28

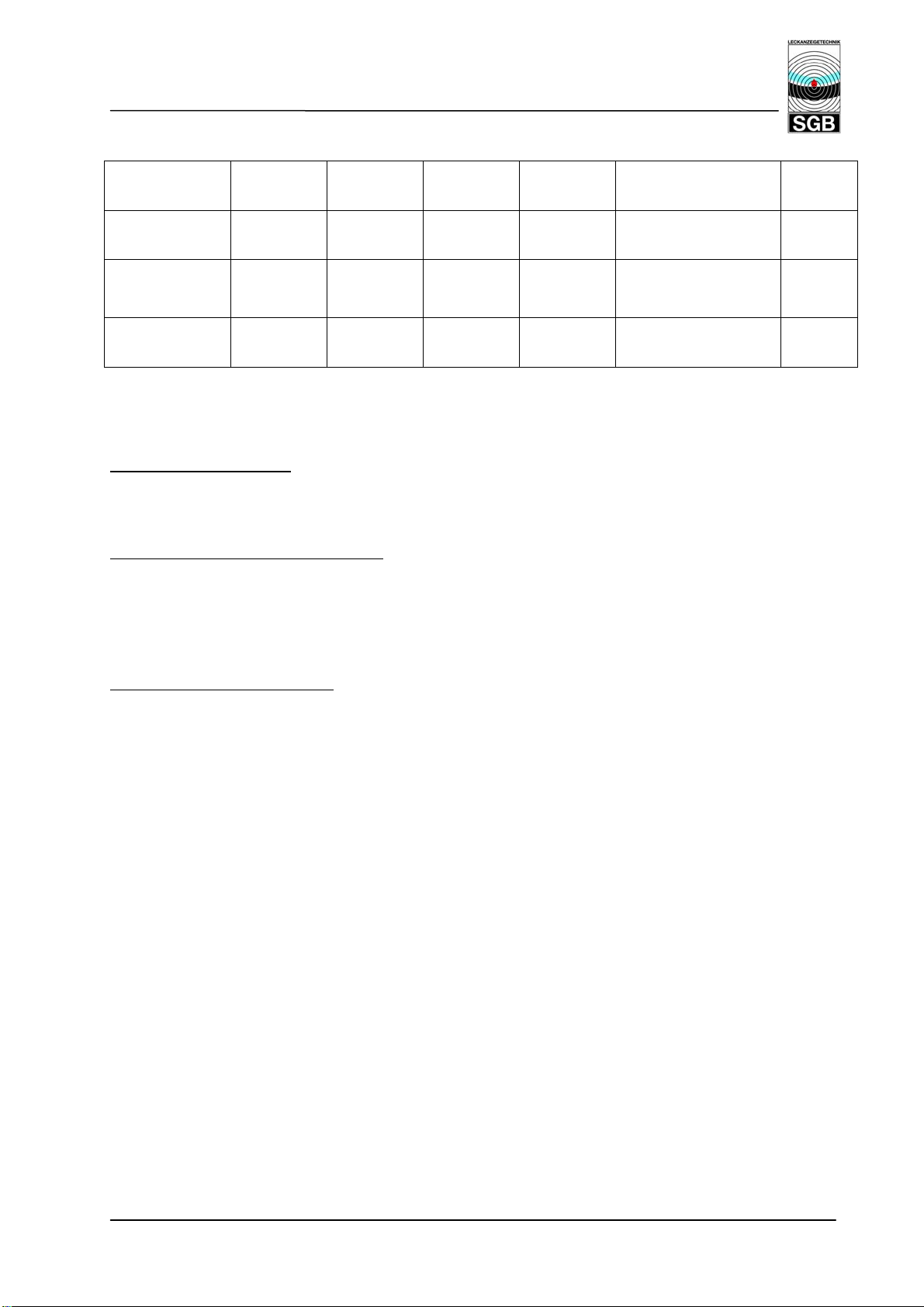

ANNEX B

28 von 49

OVERPRESSURE LEAK DETECTOR DL ..

Type

DLG

pTS

[mbar]

p

AE

[mbar]

p

PA

[mbar]

50 20 > 50 < 100

100 70 > 100 < 150

290 260 > 290 < 350

330 300 > 330 < 410

400 370 > 400 < 500

450 420 > 450 < 510

590 560 > 590 < 700

750 720 > 750 < 850

1000 970 > 1000 < 1400

1100 1070 > 1100 < 1450

1500 1450 > 1500 < 1900

2000 1950 > 2000 < 2400

2300 2250 > 2300 < 2770

2500 2450 > 2500 < 2900

2

P

[mbar]

ÜDV1

p

3

ÜDV2

[mbar]

p

PRÜF

[mbar]

170 ± 20 600 ± 50 ≥ 200

220 ± 20 650 ± 50 ≥ 250

420 ± 20 850 ± 50 ≥ 450

465 ± 20 900 ± 50 ≥ 500

565 ± 20 1000 ± 50 ≥ 600

565 ± 20 1000 ± 50 ≥ 600

740 ± 30 1250 ± 100 ≥ 850

940 ± 30 1500 ± 100 ≥ 1000

1550 ± 50 2700 ± 100 ≥ 1750

1580 ± 70 2400 ± 100 ≥ 1820

2100 ± 50 3400 ± 100 ≥ 2350

2650 ± 50 4200 ± 100 ≥ 2950

3100 ± 100 4800 ± 200 ≥ 3500

3200 ± 50 5000 ± 100 ≥ 3550

p

DM

[mbar]

200

250

450

500

600

600

850

1000

1800

1850

2400

3000

3500

3600

3000 2950 > 3000 < 3400

_

Special switching values agreed between SGB and customer

3750 ± 50 6000 ± 100 ≥ 4150

The following abbreviations are used in the table:

maximum pressure at the low point of the tank, including overlay pressure

P

TS

switch value "Alarm ON", the alarm is triggered at the latest at this pressure

p

AE

p

switch value "Alarm OFF", the alarm goes off on passing this value.

AA

The switch value "Alarm OFF" is approx. 15 mbar higher than the switch value "Alarm

ON" for pressure stages < 1000 and approx. 100 mbar higher for pressure stages >

1000

(p

= pAE + ~15 mbar (pressure stages < 1000) ~ 100 mbar (pressure stages > 1000))

AA

Switch value "Pump OFF" (=nominal pressure)

p

PA

p

Switch value "Pump ON“

PE

The switch value "Refill ON" is approx. 15 mbar lower than the switch value "Refill OFF"

for pressure stages < 1000 and approx. 100 mbar lower for pressure stages > 1000

(p

= pPA - ~15 mbar (pressure stages < 1000) ~ 100 mbar (pressure stages > 1000))

PE

Opening pressure overpressure valve 1 (interstitial space side)

p

ÜDV1

p

Opening pressure overpressure valve 2 (supply side)

ÜDV2

p

Minimum test pressure of the interstitial space

PRÜF

p

Set pressure at the pressure reducer

DM

4200

2

The table states the opening pressure for the overpressure valve at which the volume flow of the pump is blown off.

The triggering pressure (first opening) is lower.

3

Overpressure valve 2 ÜDV2 can be omitted if the test pressure in the interstitial space is higher than the triggering

pressure of the overpressure valve integrated in the pressure reducer.

01/02/2006

- B-2 -

Page 29

ANNEX TD

29 von 49

OVERPRESSURE LEAK DETECTOR DL ..

Technical data

1. Electrical data

Power supply (without external signal) 230∼ V - 50 Hz - 50 W

Switch contact load, terminals AS (5 and 6) 230∼ V - 50 Hz - 200 VA

Switch contact load, potential-free contacts, max: 230∼ V - 50 Hz - 3 A

(Terminals 11 and 12) min: 6 V / 10 mA

External fuse of the leak detector max. 10 A

Overvoltage category 2

2. Pneumatic data (requirements for the test measuring gauge)

Nominal size mind. 100

Class accuracy mind. 1.6

Scale end value suitable

21/07/2005

- TD-1 -

Page 30

ANNEX FC

30 von 49

OVERPRESSURE LEAK DETECTOR DL..

Dry filter monitoring (FC)

1 Function

A sensor is integrated in the suction line of the pump between pump and dry filter to measure

the moisture of the air intake.

The sensor registers the increase in relative humidity when the desiccant is spent. The optical

and audible alarm is triggered together with the potential-free message when the drying capacity is insufficient.

The visual indication consists of alternate flashing of the two red alarm LEDs. The potential-free

indication is present at terminals 31 to 34:

31/32 Contact opens on receiving a message

31/34 Contact closes on receiving a message

2 Changing the drying material

When getting the indication "dry filter spent", the drying material should be replaced after an

appropriate period of time.

The audible signal can be acknowledged by pressing briefly once. The visual and potential-free

indication remains.

The entire indication can be acknowledged by pressing and holding the button "Acknowledge

dry filter message" (until the lower LED flashes). Next time the pump starts up (or if this function

is carried out while the pump is running, after approx. 30 s), the indication is triggered again if

the residual moisture is too high.

After replacing the drying material, quit the indication by pressing and holding the button as

described above.

3 Limits of use

The following limits of use must be observed for the dry filter monitoring function:

1. The pump must run min. 30. sec to obtain a meaningful statement.

During or after start up of the leak detector, the time between pump ON and OFF should be

measured to check whether this minimum operating time is achieved.

2. No meaningful measuring results are obtained at low temperatures (below -5°C) so that the

measurement is deactivated below -5°C.

21/07/2005

- 1 -

Page 31

ANNEX TF

31 von 49

OVERPRESSURE LEAK DETECTOR DL..

Dry filter

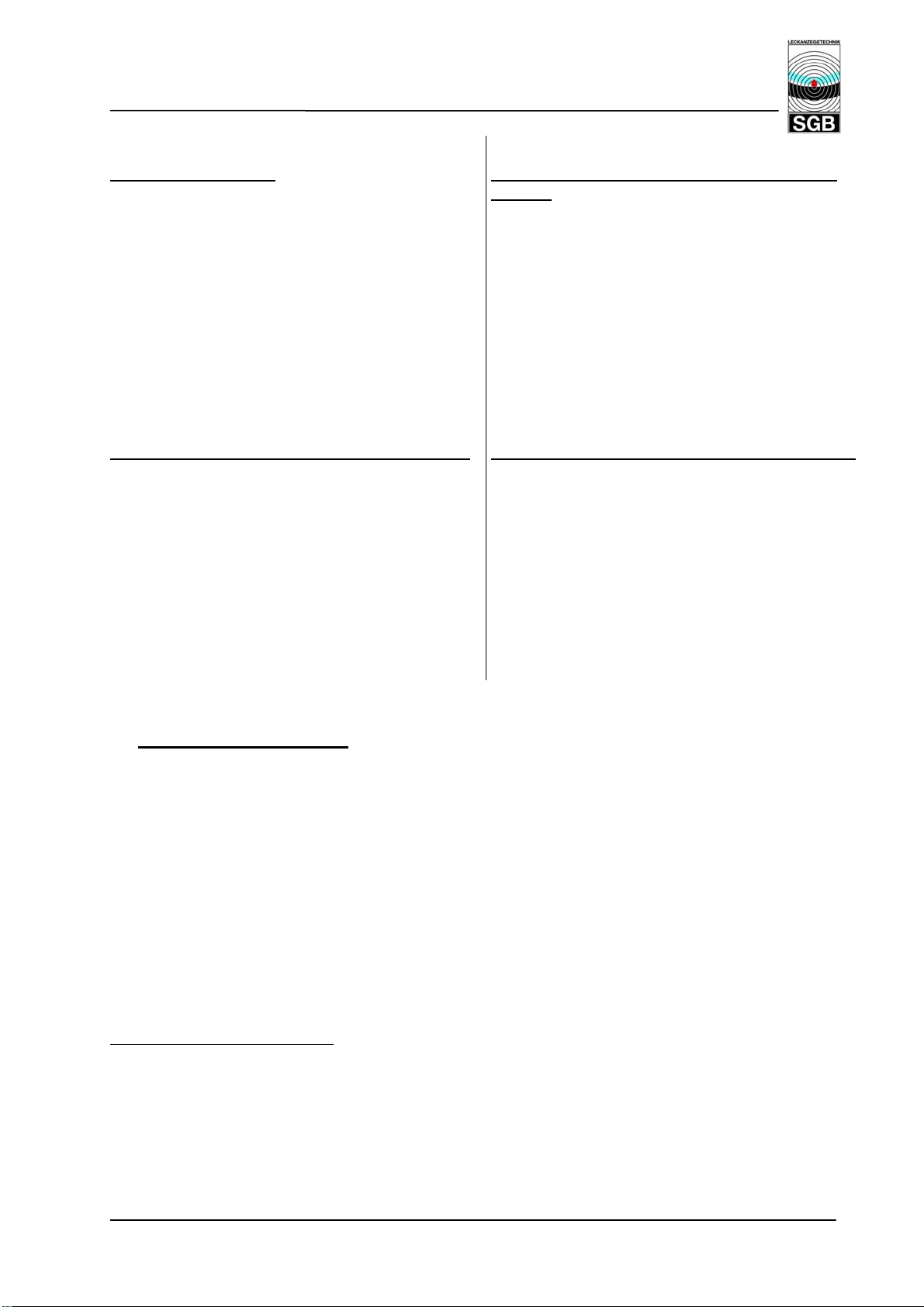

1 Size of dry filter for underground tanks:

TF 180 (the larger dry filters can also be used)

2 Size of dry filters for above ground tanks:

Max. volume of the interstitial space with

Type

DL 50

DL 100

DL 290

DL 330

DL 400

DL 450

DL 590

DL 750

DL 1000

DL 1100

DL 1500

DL 2000

DL 2300

DL 2500

DL 3000

TF 180 TF 1 TF 2 TF 6

350 750 2100 4800

300 600 1600 3700

250 520 1500 3500

240 500 1350 3000

210 400 1150 2600

150 300 800 1850

130 250 700 1600

110 230 600 1400

21/07/2005

- 1 -

Page 32

ANNEX DP

32 von 49

OVERPRESSURE LEAK DETECTOR DL..

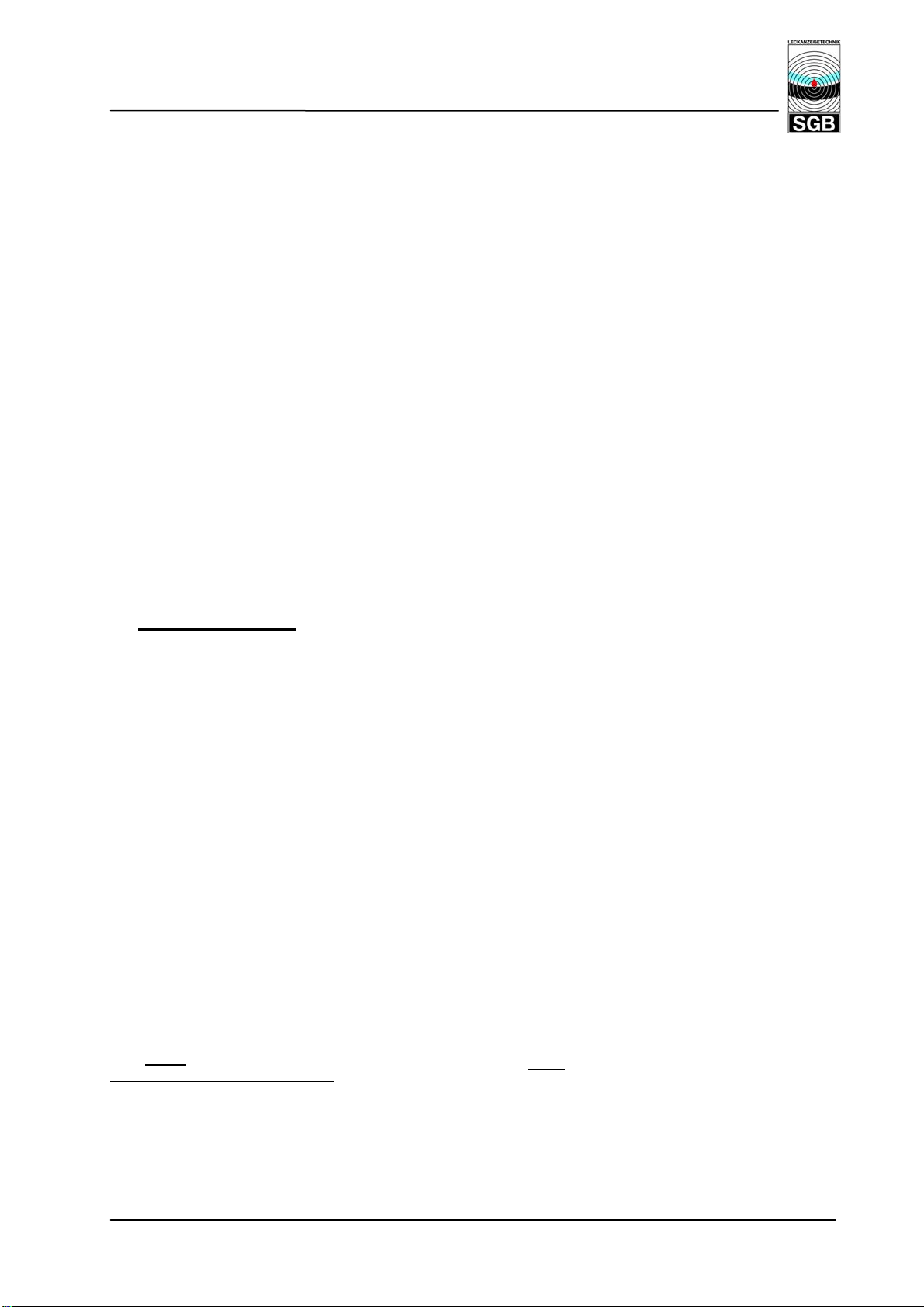

Evaluating the display for the function "Tightness test"

Chapter 3.6.3 described "Checking the tightness of the monitored system". This function can be

used to obtain an indication of the tightness of the monitored system.

This is only possible if the switching value "Alarm OFF" has been exceeded. It can be repeated

several times in succession.

This check is advisable before carrying out a recurrent function test on a leak detector, to see

directly whether there is any need to look for leaks.

After pressing the button, this is confirmed by a brief audible signal which can be heard once,

followed by a flashing signal, i.e. the Alarm LED flashes briefly to indicate the tightness as follows:

Number or flashes Evaluation of the tightness

0 Very tight

1 bis 3 Tight

4 bis 6 Sufficient tight

7 bis 8 Maintenace recommended

9 bis 10 Maintenace highly recommended

The smaller the above value, the more tight is the system. The meaningfulness of this value

naturally also depends on temperature fluctuations and should therefore be considered to be an

indicative value.

22/08/2006

- 1 -

Page 33

To remove th e cover

33 von 49

~350

30 100217

To open the cover

B x H x T = 266 x 217 x 110

~250

170

230

6

266

18-11-2003

Dimension / Drilling

Page 34

8

34 von 49

200

260

300

T = 140

220

28-06-2005

Drilling / Dimension

Page 35

Work Sheet: AB-820 500

35 von 49

Pneumatic connections

1 Flare type fitting for flare type pipes

1. Lubricate the O-rings

2. Place the intermediate ring loosely in the threaded connection piece

3. Push the union nut and the thrust collar over the pipe

4. Tighten the union nut manually

5. Tighten the union nut until clearly increased force is needed

6. Finished assembly: turn by a further ¼ of a revolution

2 Clamping ring threaded fitting for plastic and metal pipes

1. Insert the support sleeve into the end of the pipe

2. Insert the pipe with support sleeve as far as it will

go

3. Tighten the thread until strong resistance can be

clearly felt

4. Lightly loosen the nut

5. Tighten the nut until resistance can be felt (nut

must exactly match the thread of the basic body)

3 Olive threaded fitting for plastic and metal pipes

1. Insert the reinforcing sleeve into the end of

the pipe

2. Knock in the reinforcing sleeve

3. Push the union nut and the olive over the

end of the pipe

4. Screw the union nut by hand until you feel

a stop

5. Press the pipe against the stop in the inner

cone

6. Tighten the union nut by approx. 1.5 revolutions (pipe must not turn)

7. Loosen the union nut: check whether the pipe visibly projects from under

the cutting ring (it doesn’t matter if the clamping ring can be turned)

8. Retighten the union nut using normal force

4 Quick-action fitting for PA- and PUR-tubes

1. Make a right-angled cut in the PA pipe

2. Loosen the union nut and push it over the end of the pipe

3. Push the pipe onto the nipple up to where the thread begins

4. Tighten the union nut by hand

5. Further tighten the union nut using a wrench until clearly increased force

is needed (approx. 1 to 2 revolutions)

NOT suitable for PE-pipes

AB-820500.DOC

24. Jul. 03 Revision: 1.0 Page: 1

Page 36

Work Sheet: AB-820 500

36 von 49

Pneumatic connections

5 Tube connections (socket 4 and 6 mm for EXCESS PRESSURE)

1. Push wire or screw clip over the tube

2. Push the tube onto the Cu pipe or the tube socket (if necessary heat or dampen PVC tube),

tube must fit tightly all the way round

3. Wire clip: clamp tightly using pliers and push onto the joint

Screw clip: push the clip over the joint and tighten it using a screwdriver,

care must be taken that the clip is a smooth tight fit.

6 Tube connections (socket 4 and 6 mm for VACUUM)

For vacuum applications where there is no excess pressure on the connection lines even in the

case of a leakage proceed as in item 5, but without clips.

For vacuum applications where excess pressure could arise in the case of a leakage, proceed as

in Item 5.

AB-820500.DOC

24. Jul. 03 Revision: 1.0 Page: 2

Page 37

TÜV Nord / Systems

37 von 49

1 July 2005

2102Stb

File: 3237DV01040

Order No.: 8100586804

A p p r o v a l C e r t i f i c a t e

for the design of a leak detector

as part of a leak detection system

================================================================

1 Subject

Overpressure leak detector as part of a leak detection system function on the

basis of overpressure

2 Commissioned by

Sicherungsgerätebau GmbH

Hofstraße 10

57076 Siegen

3 Details about the leak detector

3.1 Manufacturer

See commissioned by

3.2 Type

DL .. / DLG ..

3.3 Application

Double walled tanks, single walled tanks with pressure-resistant jacketing and

double walled sumps and containments with sufficient pressure resistance

(see section No. 2 of the Technical Description dated 21 April 2004)

3.4 Design

The designation "overpressure leak detector type DL.. / DLG.." covers two

types which differ according to how pressure is generated and with regard to

the switching pressures. The units consist essentially of a pressure transducer

and a display/message unit, with electronic control and signal processing. Air

or inert gas can be used as leak detection medium, complying with the

maximum pressures on the bank bottom stated in Annex B of the Technical

Description.

Page 38

The following unit variants are used:

38 von 49

Overpressure leak detector DLG ..

The leak detector can be operated with air as well as with inert gas as leak

detection medium. The necessary operating pressure in the interstitial space is

generated by pressure-controlled refilling from a stationary pressure

accumulator connected to the interstitial space. If the operating pressure in the

interstitial space falls below the adjusted alarm value, then the visual and

audible alarm is triggered automatically.

Overpressure leak detector DL ..

In this version, pressure is generated in the interstitial space by an integrated

pump, using only dried ambient air as leak detection medium.

All unit variants are equipped with a test coupling for connecting an external

measuring gauge.

Overpressure valves to protect the interstitial space from excessive

overpressure are an integral part of the leak detectors and installed in the

pressure lines of the unit. Overpressure valves to protect the type DLG .. units

when connected to an external pressure accumulator must be connected

externally between the leak detector and pressure accumulator, as required.

Details of the design for leak detector DL.. / DLG .. are contained in the

Technical Description issued by Sicherungsgerätebau GmbH dated 21 April

2004.

4. Test principles

Approval principles for leak detection systems for double walled pipes (ZGLAGR)

EN 13160 Part 1 and 2

5. Test documents/Test samples

5.1 Technical Description of the overpressure leak detector DL.. dated 21 April

2004

5.2 Sample version of leak detector type DL 400

5.3 Approval certificate DLR-G dated 14 May 2002

5.4 Supplement with details of the dry filters for DL_4000

5.5 Parts list leak detector VL..

Page 39

6. Tests

39 von 49

The sample version of the leak detector in the variant DL 400 was tested with

reference to the Technical Description with design drawings and circuit

diagrams as well as installation and operating instructions and software

documentation, for compliance with the requirements of the approval

principles for leak detection systems.

The following tests were carried out:

1. Test of the electrical equipment (without taking account of explosion

protection).

2. Switching cycles at various limit temperatures (-25°C to +70°C)

3. Testing the visual and audible alarm

4. Pressure and leak tests of the installations

7 Test results

The Leak detector DL.. fulfilled the requirements stipulated in the approval

principles for leak detection systems. The parts of the sample unit conform

with the Technical Description and drawings. The function tests on sample unit

leak detector type DL400 showed that the unit withstands the loads and

remains fully functional. The parts of the electronic circuit integrated in the unit

remained fully functional even under the temperature loads.

The mechanical function tests and software test produced positive results.

Undefined measured values, incorrect calibrations and failure of the system

cycle triggered the alarm.

The function tests over 440 hours also produced positive test results. Leak

detector DL 400 fulfils the requirements made of it with regard to monitoring

the overpressure generated in the interstitial space with an automatic alarm on

reaching the alarm pressure. The leak detector pump is capable of

compensating for pressure fluctuations caused for example by changes in

temperature. The switching values of the pressure switch (alarm ON > 400

mbar, pump ON <500 mbar) are met as stated in the Technical Description.

The pressure switching values remain within the stated tolerances even at the

limit temperatures of -25°C and +70°C.

Evaluation of continuous operation of the unit as a whole – the unit was

subject to 10,000 load cycles – also produced no notable deviations in the

pressure switching values or restrictions in its functioning ability.

Measurement of the volume flow using a suspended particle flow meter

showed that the volume flow at the stated alarm switching value of 400 mbar

amounts to 85 +

adequately rated.

15 l/h (see curves). The flow rate of the pressure pump is

Page 40

Pump curve leak detector DL 400:

40 von 49

The switching processes were adjusted to the upper temperature limit of

+70°C and lower temperature limit of -25°C in such a way as to trigger an

alarm within 5 minutes.

Tests of the alarm signalling device also produced positive results. The

audible alarm produces a sound level of > 70 dB(A) at 1 m distance from the

closed housing after 24 h continuous operation. The visual alarm can be

considered adequate.

The overpressure valve triggered in the pressure range stated by the

manufacturer. The overpressure valve is capable of dissipating the entire flow

output of the overpressure pump so that the interstitial space of the tank is

protected with regard to an excessive increase in pressure after the tank has

heated up or following failure of the pressure switch.

The electrical installation in the switching box complies with the DIN VDE

regulations. An external alarm lead is protected by switching a potential-free

relay, with an additional fuse to protect the unit from the circuit of the outer

alarm.

The leak detector with type designation DLG.. is identical to the leak detector

DLR-G which was already certified with the approval certificate dated 14 May

2002 and approved with approval number Z-65.26-349, so that its suitability

for the intended application was already verified in the approval process.

Suitability of the adequate capacity of the dry cartridges was already verified in

the approval process for leak detector type DL-4000.

8 Assessment

Leak detector type DL../DLG.. is suitable as a component in a leak detection

system based on overpressure and fulfils the requirements of the approval

principles for leak detection systems. The leak detector as component in an

overpressure leak detection system constitutes a safety device in accordance

with §19h Water Resources Act for rapid, reliable detection of leaks in water

polluting liquids when the following conditions are met:

1. The leak detector variants are to be produced, adjusted and operated in

accordance with the Technical Description dated 22 April 2004.

2. The corresponding leak detector type must only be used for the

interstitial spaces stated in the section "Limits of operation" in the

Technical Description. The corresponding leak detector type must be

Page 41

selected so that the alarm switching pressure is always at least 30 mbar

41 von 49

above the static pressure of the stored liquid, taking account of possible

overlay pressure in the tank. In the case of a sump, the maximum liquid

hight of the liquid being collected must be taken into consideration. The

units are to be selected on the basis of the tables contained in Annex B

of the Technical Description dated 21 April 2004.

3. The details stated by the manufacturer in the operating instructions

must be heeded for producing and sustaining the operating pressure of

the leak detector. The leak detectors are to be operated so that the

tolerable operating pressure of the interstitial space is not exceeded.

For leak detector type DLG.., fundamentally only pressure reducers

should be used with a maximum setting range for the pressure reducing

valve 5% to 10% below the test pressure of the interstitial space.

Otherwise, overpressure valves must be provided to prevent the

pressure from exceeding the maximum tolerable operating pressure in

the interstitial space.

4. The supply pressure for the leak detector DLG.. stated in the Technical

Description for the pressure accumulator must be heeded because

otherwise, the re-fill quantity of leak detector medium deviates from the

tolerable value stated in the approval principles.

5. Every leak detector must be marked indelibly and legibly with at least

the following details:

Manufacturer or manufacturer's symbol

Year of production

Production number

Approval code

Type designation

Nominal operating data.

6. Every leak detector must undergo individual testing before delivery. The

requirements of ZG LAGR No. 7 must be observed in terms of

production monitoring.

7. Every leak detector must be accompanied by installation and operating

instructions together with a copy of the approval certificate and, in the

case of type DL.., corresponding documentation for the dry filters

(cartridges) to be used and the corresponding interstitial space sizes.

9 Note

Compliance with the requirements for explosion protection, electromagnetic

compatibility and the low voltage directive was not part of the tests.

/round stamp/signature/

Surveyor of the Technischer Überwachungs-Verein Nord e.V.

Test department for leak detection systems.

Page 42

GERMAN INSTITUTE FOR BUILDING TECHNOLOG

42 von 49

Public Law Institution

10829 Berlin, 5 April 2005

Kolonnenstraße 30 L

Phone: +49(0) 30 78730-364

Fax: +49(0) 30 78730-320

Ref: III 14-1.65.23-9/05

General Building Inspectorate Approval

Approval number: Z-65.23-409

Applicant: Sicherungsgerätebau GmbH

Hofstraße 10

57076 Siegen

Approval item: Overpressure leak detector type DL.. and type

DLG.. as part of a leak detection system for double

walled tanks, tanks with leak detection lining or

leak detection jacketing, interstitial space of sumps

and containments for the storage of water polluting

liquids

Validity period: until 30 April 2010

The above approval item is herewith granted general building inspectorate approval.

This general building inspectorate approval consists of six pages and two annexes.

/round stamp/

German Institute

for Building Technology

Page 43

Page 3 of the General Building Inspectorate Approval No. Z-65.23-409 d ated 5 April 2005

43 von 49

II. SPECIAL REGULATIONS

1. Approval item and scope of application

1.1 The subject of this general building inspectorate approval is an overpressure

leak detector type designations DL.. (with integrated pump) and DLG.. (with

integrated compressed gas supply) with the design variants for alarm pressure

switching values of >

mbar, >

1500 mbar, >

450 mbar, > 590 mbar, > 750 mbar, > 1000 mbar, > 1100 mbar, >

2000 mbar, > 2300 mbar, > 2500 mbar and > 3000 mbar

50 mbar, > 100 mbar, > 290 mbar, > 330 mbar, > 400

overpressure.

1.2 The leak detectors may be connected to suitable interstitial spac es of double

walled tanks, tanks with leak detection lining or leak detection jacketing,

sumps and containments for plant for the storage, filling and transhipment of

water polluting liquids (structure of the leak detection system see Annex 1).

1.3 Suitable interstitial space refers to interstitial space with a volume of up to 8 m³

rated with an interstitial space test pressure corresponding to the specific

design variant of the particular leak detector.

1.4 The general building inspectorate approval is issued notwithstanding test or

permit reservations in other legal areas (e.g. 1

st

Ordinance on the Machine

Safety Law – Low Voltage Ordinance – Law on Electromagnetic Compatibility

of Machines – EMC - , 11

th

Ordinance on the Machine Safety Law – Explosion

Protection Ordinance).

1.5 With this general building inspectorate approval, the approval item is not

required to undergo specific water suitability testing and type approval as per §

Law 19 h of the Water Resources Act (WHG)

1

.

2 Stipulations for the product

2.1 Properties and composition

2.1.1 A leak in the walls of the interstitial space is indicated visually and audible

when pressure falls to the alarm switching value.

2.1.2 The leak detector consists of the display and control elements, the

overpressure pump with upstream dry filter or a permanently connected

pressure cylinder or operational pressure network with inert gas or dried air,

the pressure and measuring lines with shut-off and safety valves, the pressure

sensor and electrical control components. The parts and components are

stated in the Technical Description

2

. To protect the interstitial space from

intolerable overpressures, the overpressure valves are adjusted to the opening

pressures stated in Annex B to the Technical Description.

1

Act on the Management of Water Resources (Water Resources Actw – WHG) dated 19 August 2002

2

Technical Description verified by Tüv Nord dated 11 March 2005 for the overpressure leak detector

type DL..

Page 44

Page 4 of the General Building Inspectorate Approval No. Z-65.23-409 d ated 5 April 2005

44 von 49

2.1.4 Verification of safe functioning of the approval item was provided according to

the "Approval principles for leak detection systems for tanks (ZG-LAGB)" of

the German Institute for Building Technology dated August 1994.

2.2 Production and marking

2.2.1 Production

The leak detectors must only be produced in the applicant's factory. They must

comply with the documentation featured in Annex 2 of this general building

inspectorate approval with regard to design, dimensions and materials.

2.2.2 Marking

The leak detector, its packaging or delivery note must be marked by the

manufacturer with the compliance symbol (Ü-symbol) according to the

compliance symbol ordinances of the federal states. The marking may only be

applied if the prerequisites as per section 2.3 are fulfilled. In addition, the leak

detector must be marked with the following details:

- type designation

- approval number

2.3 Compliance verification

2.3.1 General

Confirmation that the leak detectors comply with the stipulations of this general

building inspectorate approval must be provided for every production factory

with the manufacturer's Declaration of Conformity on the basis of inhouse

production controls and type testing of the leak detector by an acknowledged

testing agency.

2.3.2 Inhouse production controls

Inhouse production controls are to be set up and implemented in the

production factory.

Inhouse production controls are too include individual testing of every leak

detector. The individual tests by the manufacturer are to warrant that the parts

of the leak detector function reliably and comply with the tested type.

The results of the inhouse production controls are to be recorded and

evaluated. The records must include at least the following details:

- leak detector designation

- type of control or test

- date of production and testing of the leak detector

- results of the controls or tests

- signature of the person responsible for inhouse production control

Page 45

Page 5 of the General Building Inspectorate Approval No. Z-65.23-409 d ated 5 April 2005

45 von 49

The records are to be kept for at least five years. They are to be submitted to

the German Institute for Building Technology and the highest building

supervisory authorities on demand.

In the case of unsatisfactory test results, the manufacturer must introduce

immediate measures to eliminate the defects. Leak detectors which fail to

comply with requirements must be handled in such a way so as to rule out any

risk of confusion with conforming approval items. After eliminating the fault, the

corresponding test must be repeated immediately insofar as technically

feasible and required as verification that the fault has been eliminated.

2.3.3 Type testing by acknowledged testing agency

Type testing includes the function tests stated in the "Approval principles for

leak detection systems for tanks". If verification according to the general

building inspectorate approval has been obtained in samples from on-going

production, the corresponding tests replace type testing.

3. Stipulations for the design

3.1 (1) Care must be taken to ensure that the leak detector is adequately resistant

to the liquid being stored and that the water polluting liquid does not react with

the leak detection medium.

3.2 The limits of operation of the leak detectors to ensure that the alarms are

given are stated in Annex B of the Technical Description with reference to the

maximum effective liquid pressure on the bottom of the tank (static pressure of

the stored liquid plus overlay pressure) depending on the alarm switching

value of the leak detector version.

3.3 The leak detector must only be connected to several interstitial spaces in the

case of underground tanks. The shut-off valves for every connected tank must

be set to "open" when the leak detector is operating.

3.4 Connection of the leak detectors to tanks as per section 1.2 for the storage of

liquids with flash points <

55°C is only permitted if the operating modes stated

in the Technical Description with safeguarded refilling or without safeguarded

refilling with the use of inert gas or dried air as leak detection medium, comply

with the requirements made in Annex B of DIN EN 1310-1

equipment categories as per EN 1127-1

4

.

3

regarding the

Refilling as per Annex B of DIN EN 13160-1 with air or inert gas as leak

detection medium (monitoring medium) is said to be safeguarded

- if the leak detector has an integrated pump

- if the leak detector is connected to a permanently operating

compressed air or gas network suitable for operation of the leak

detector

3

DIN EN 1310-1:09/2003, leak detection systems, Part 1 General principles

4

DIN EN 1127-1:10/1997, Explosion protection, Part 1 Principles and methods

Page 46

Page 6 of the General Building Inspectorate Approval No. Z-65.23-409 d ated 5 April 2005

46 von 49

- if residual pressure monitoring of the pressure cylinder with alarm

function is installed for operation with a permanently connected

pressure cylinder (stationary a pressure cylinder).

Refilling according to Annex B of DIN EN 13160-1 with air or inert gas as leak

detection medium (monitoring medium) is considered not to be safeguarded if

there is no residual pressure monitoring of the pressure cylinder with alarm

function for operation with the permanently connected pressure cylinder

(stationary pressure cylinder).

4. Stipulations for the execution

4.1 (1) The leak detector must be installed according to section 4 of the Technical

Description and started up according to section 5 of the Technical Description.

Installation, servicing, repairs and cleaning of the leak detector must only be

contracted to such companies which are specialist companies for these

activities in accordance with § 19 I Water Resouces Act (WHG).

(2) The activities as per (1) do not have to be carried out by specialist

companies if they are featured under the exceptions for mandatory specialist

companies according to the national regulations or the manufacturer of the

approval item carries out these activities with his own specially qualified staff.

This does not affect the occupational safety requirements.

4.2 The leak detectors must be installed outside potentially explosive areas in a

dry room, or in a protective box when installed in the open air.

5 Stipulations for use, servicing, maintenance and recurrent tests

The leak detection systems with leak detectors must be operated and

maintained according to section 6 of the Technical Description. The

manufacturer must include the Technical Description with the delivery.

/round stamp/

German Institute for

Building Technology

/signature/

Certified

Dr. Ing. Kanning

Page 47

EC DECLARATION OF CONFORMITY

47 von 49

We,

Sicherungsgerätebau GmbH

Hofstraße 10

D- 57076 Siegen

hereby declare in sole responsibility that the leakage probes

DL.., DLR-P..

comply with the essential requirements of the EC directives listed below.

This declaration shall lose its validity if the device is modified without consulting us.

Number / short title Satisfied regulations

2004/108/EC

EMC Directive

73/23 EEC

Low Voltage Directive

89/106/EEC

Construction Products

Directive

94/9 EEC

Equipment in Potentially

Explosive Atmospheres

EN 61 000-6-1: 2001

EN 61 000-6-2: 2000 + A2: 2005

EN 61 000-3-2: 2000 + A2: 2005

EN 61 000-3-3: 1995 + A1: 2001 + A2: 2005

EN 60 335-1: 2002

EN 61 010-1: 2001

EN 60 730-1: 2000

EN 13 160-1-2: Approved body: TÜV-Nord, Hamburg

The leak detector with its pneumatic parts may be connected to

spaces (interstitial spaces of tanks / pipelines / fittings) which are

required for category 3 devices. The following documents were

used:

EN 1127-1: 1997

EN 60 079-10: 1996

EN 13 160-1-2: 2003

EN 13463-1: 2001

The ignition hazard analysis did not result in any additional

hazards.

Compliance is declared by

Martin Hücking

(Technical Director)

L:\ÜBERSETZUNGEN\DOKUMENTATIONEN\ENGLISCH\DL\15-1-Declaration DL..-DLR-P...DOC Last updated: June 2006

Page 48

EC DECLARATION OF CONFORMITY

48 von 49

We,

Sicherungsgerätebau GmbH

Hofstraße 10

D- 57076 Siegen

hereby declare in sole responsibility that the leak detectors

DLG ..; DLR-G..

comply with the essential requirements of the EC directives listed below.

This declaration shall lose its validity if the device is modified without consulting us.

Number / short title Satisfied regulations

2004/108/EC

EMC Directive

73/23 EEC

Low Voltage Directive

89/106/EEC

Construction Products

Directive

94/9 EEC

Equipment in Potentially

Explosive Atmospheres

EN 61 000-6-1: 2001

EN 61 000-6-2: 2000 + A2: 2005

EN 61 000-3-2: 2000 + A2: 2005

EN 61 000-3-3: 1995 + A1: 2001 + A2: 2005

EN 60 335-1: 2002

EN 61 010-1: 2001

EN 60 730-1: 2000

EN 13 160-1-2: Approved body: TÜV-Nord, Hamburg

The leak detector with its pneumatic parts may be connected to

spaces (interstitial spaces of tanks / pipelines / fittings) which are

required for category 3 devices and also, under specific

conditions, to spaces which are required for category 1 device.

The following documents were used:

EN 1127-1: 1997

EN 60 079-10: 1996

EN 13 160-1-2: 2003

EN 13463-1: 2001

The ignition hazard analysis did not result in any additional

hazards.

Compliance is declared by

Martin Hücking

(Technical Director)

L:\ÜBERSETZUNGEN\DOKUMENTATIONEN\ENGLISCH\DL\15-2-Declaration DLG..-DLR-G...DOC Last updated: June 2006

Page 49

Warranty

49 von 49

Dear customer,

You have purchased a high-quality leak detector from our company.

All of our leak detectors undergo a 100% quality control examination.

The type plate with the serial number is only affixed after all test criteria have been complied with.

The warranty period for our leak detectors is 24 months, beginning on the date of installation on

site.

The maximum warranty period is 27 months from our date of sale.

Our warranty will be effective only if the customer submits to us the functional report or test report

on initial putting into service, prepared by a recognised company specialised in water and water

protection systems, including the serial number of the leak detector.

Our warranty shall not apply in the event of faulty or improper installation or improper operation, or

if modifications or repairs are carried out without the manufacturer's consent.

In case of malfunction, please contact your local specialist company:

Stamp of the specialist company

Yours sincerely

Sicherungsgerätebau GmbH

Hofstraße 10 - D - 57076 Siegen

+49 / 271 / 48964 - 0

Fax: +49 / 271 / 48964 - 6

L:\ÜBERSETZUNGEN\DOKUMENTATIONEN\ENGLISCH\GARANTIE-ERKLÄRUNG NEU-GB.DOC

Loading...

Loading...