SG Rotarybolt Z03 Installation Instructions Manual

Rotarybolt™ Z03 Electronic Safe Lock

Installation Instructions

Mounting Considerations:

• Sargent & Greenleaf Rotarybolt Z03 electronic safe locks are designed to use the same mounting screw

locations as common S&G mechanical and electronic safe locks. In many instances it can easily be

mounted in place of these locks.

• The Rotarybolt Z

03

lock is available in left-hand and right-hand models. The illustrations on page 2 will

help you determine which one you need for your particular application.

•

The keypad diameter is approximately 3 ¾ inches (95.2 mm), which

allows mounting in applications where limited space is a consideration.

• The lock can be used with either a one-battery or two-battery style

keypad. To meet VdS requirements, the one-battery keypad must

be installed using the included one-way security screw. If the twobattery style of keypad is used, it must be the tamper resistant model

(61KP-201) to meed VdS requirements. Standard installations do

not require the security screw for one-battery keypads, or they can be

accomplished using the non-tamper two-battery keypad (61KP-101 or

61KP-105).

• A fresh Duracell

®

alkaline battery should be installed in the keypad, and

the keypad should be connected to the lock to check for proper operation

prior to installation. Follow the procedures outlined in the operating

instruction booklet.

• Modifications to the lock are not recommended and will void the manufacturer’s warranty.

• A minimum distance of .150 inch (3,8 mm) is recommended between the end of the lock case

containing the bolt and the safe’s blocking bar or cam plate (which is normally blocked by the extended

lock bolt). Maintaining this clearance will allow the lock to achieve optimum performance.

•

Personal data that can be directly related to a code holder, such as a birth date, street number, or phone

number, should not be used in creating a lock code. Avoid codes that can be easily guessed.

Note: This lock has been Listed by Underwriters Laboratories for use with the following S&G keypad(s):

6120-0XX, 6120-2XX, 6160-2XX (IP Series), 61KP-1XX, 61KP-2XX, 6130-4XX, 6130-5XX

Sargent & Greenleaf, Inc.

A Wholly Owned Subsidiary of Stanley Security Solutions, Inc.

PO Box 930, Nicholasville, Kentucky 40340-0930 USA

Phone (859) 885-9411

Phone (800) 826-7652

FAX (859) 887-2057

FAX (800) 634-4843

Copyright© 2006, Sargent & Greenleaf

page 1

Sargent & Greenleaf S.A.

9, chemin du Croset

1024 Ecublens, Switzerland

Phone +41-21 694 34 00

FAX +41-21 694 34 09

Document 630-689ENG

Revised 1/2/2007

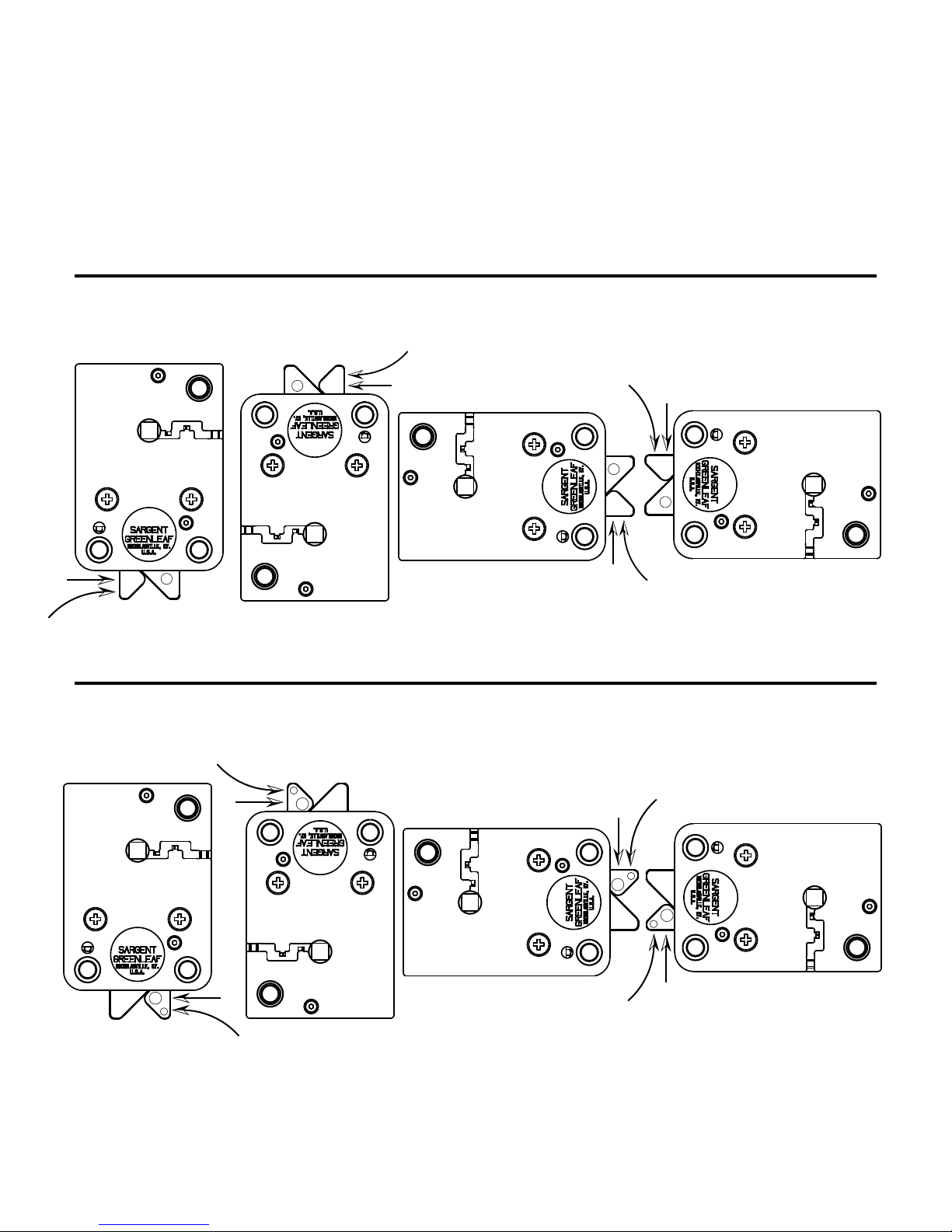

Left-hand or Right-hand?

The Rotarybolt Z03 lock uses a very efficient bolt design that allows it to “fold” into the lock case when the

correct code is entered and the safe’s boltwork presses against the side of the lock bolt. This provides for

smooth operation and long life. It also requires the lock to be handed, which means the direction from

which the safe’s boltwork presses against the Rotarybolt bolt determines which model must be used.

The illustrations below should make it easy for you to select the correct model for your safe. The arrows

represent the direction in which the safe’s blocking bar (straight arrow) or cam plate (curved arrow) moves

when the door’s handle is being turned to unlock the safe.

The four locks immediately below are all the same left-hand model (Model 2003-300 Rotarybolt Z03). Each is shown in one of the

four standard mounting positions. Each is depicted as it would be seen by looking at the back (inside) of the safe door.

LEFT-HAND MODEL 2003-300

MOUNTED VERTICAL-DOWN

LEFT-HAND MODEL 2003-300

MOUNTED RIGHT-HAND

LEFT-HAND MODEL 2003-300

MOUNTED VERTICAL-UP

LEFT-HAND MODEL 2003-300

MOUNTED LEFT-HAND

The four locks immediately below are all the same right-hand model (Model 2003-200 Rotarybolt Z03). Each is shown in one of the

four standard mounting positions. Each is depicted as it would be seen by looking at the back (inside) of the safe door.

RIGHT-HAND MODEL 2003-200

MOUNTED RIGHT-HAND

RIGHT-HAND MODEL 2003-200

MOUNTED LEFT-HAND

RIGHT-HAND MODEL 2003-200

MOUNTED VERTICAL-DOWN

RIGHT-HAND MODEL 2003-200

MOUNTED VERTICAL-UP

page 2

Installation Notes

Although the Rotarybolt Z03 lock is easy to install, we recommend the following procedures be performed

only by an experienced locksmith or safe technician. Your safe may incorporate relocking devices that are

attached to the lock body. Misalignment or detachment of these devices can result in a lockout; a condition

where the safe probably cannot be opened without damage.

The Rotarybolt Z03 lock requires a 9-volt alkaline battery. We recommend fresh Duracell® batteries. Do not

use an old or partially drained battery in your lock. A new battery will power your lock for approximately

8,000 openings when used without the time delay feature.

Installation . . .

Step 1

Remove the existing lock (if one is present). The

mounting plate should be smooth and flat, with

either 1/4 – 20 or M6 mounting screw holes. The

wire channel (spindle hole) must have a minimum

diameter of 5/16 inch.

Step 2

Use a reamer or file to remove any sharp edges

from the wire channel (spindle hole) that could

damage the wire cable.

Run the connector through the wire channel.

Gently pull the connector and all excess cable to

the outside of the safe. Make sure the cable is not

crimped or stressed at any point. It is also very

important make sure the cable is not crimped or

folded against itself under the lock body as you

prepare to fasten the lock to the mounting plate.

page 3

Step 3

Once you’ve double-checked to make sure the

wire cable is not crimped or in contact with

any sharp surface, attach the lock to the safe’s

mounting plate. Use the three 1/4 – 20 or M6

(metric) mounting screws provided. They should

be tightened to 30 - 40 inch-pounds (33.9 -

45.2. dNm)

The lock incorporates a bolt-though cover that

allows the mounting with the cover in place.

Removing the cover voids the product warranty.

Step 4

Once the lock is fastened into place, check

to make sure all three mounting screws are

tight. Avoid bottoming a screw in a mounting

plate hole. Although the screw will feel tight,

it will not be holding the lock firmly against

the plate.

Ensure a gap of at least .150 inch (3.8 mm)

between the end of the lock case and the

blocking bar of the safe’s boltwork. The gap

to be measured is indicated by the space

between the arrows.

Step 5

Pictured is an installation that requires attachment

of the safe manufacturer’s relock device plate to

the lock cover using the cover screws or a suitable

substitute. If your situation is similar, be sure the

thickness of the relock device plate is not great

enough to prevent the screws from engaging the

lock case by at least four threads. If necessary,

use longer 8-32 machine screws to insure proper

fit. The cover screw holes are only tapped as deep

as the original screws, so using other screws may

require tapping the screw holes slightly deeper into

the lock case. Cover screws must engage the lock

case by at least four threads.

If the relock device plate is not properly attached,

it may come loose. The safe will then have to be

forcibly opened.

page 4

Loading...

Loading...