isoweld

®

3000 &

isoweld

®

Backpack

Operating Instructions

Installation Instructions

Version 2.0

North America - English

2

Table of contents

Operating Instructions

isoweld® induction welding tool 3

Symbols used 4

Rating plate 5

Safety instructions 5

Special safety instructions 8

Danger areas 10

System components isoweld®3000, isoweld®3000 Backpack 11

Overview isoweld®3000, isoweld® Backpack, Standard items supplied 13

Description of function 15

Transport 15

Power requirements 16

Start-up isoweld

®

3000, isoweld® Backpack 17

Calibration 21

Additional setting options 22

Test welding 22

Operation: welding 23

Checking the welding 25

Optional operation isoweld

®

3000, isoweld® Backpack:

working with the hand inductor 25

Technical data 26

Error messages 27

Disposal 28

Maintenance, service and warranty 28

Declaration of conformity 32

System components 35

Deciding on installation strategy 36

Preparing the roof for fastening 36

Measuring and marking fastening points 36

Fixing the stress plates 37

Rolling out the waterproof membrane 38

Marking the fastening points 38

Preparing the induction tool 39

Welding the membrane at the fastening points 40

Installation Instructions

3

Identification

Type: isoweld

®

3000, isoweld ® Backpack

Manufacturer: SFS

Division Construction

Rosenbergsaustrasse 10

CH-9435 Heerbrugg

Switzerland

www.sfsintec.biz

Rating: see type plate

The induction welding tool of the isoweld ® series has been designed in

Switzerland. The isoweld

®

3000 is assembled in Switzerland and the isoweld ®

Backpack is assembled in the US.

Responsible for documentation:

Daniel Gasser,

Reserach and Technology

Preface

Purpose of the document

This document is written for skilled building operatives working in the field of

flat roofs. It is intended to instruct skilled operatives in how to work safely and

efficiently with the units (see the section on "Safety instructions").

Structure of the documentation

The documentation describes all the phases in the life of the tool from transport,

installation, operation, maintenance and servicing up to disposal.

This manual was drawn up taking into account the provisions of the EU

Machinery Directive 2006/42/EC, Annex I, Clause 1.7.4 "Instructions".

The original operating instructions were prepared in German and modified in

English.

Keep this document safe

These operating instructions are part of the product and must be kept with the

unit at all times. They must be available to the operator at all times.

isoweld ® induction welding tool

4

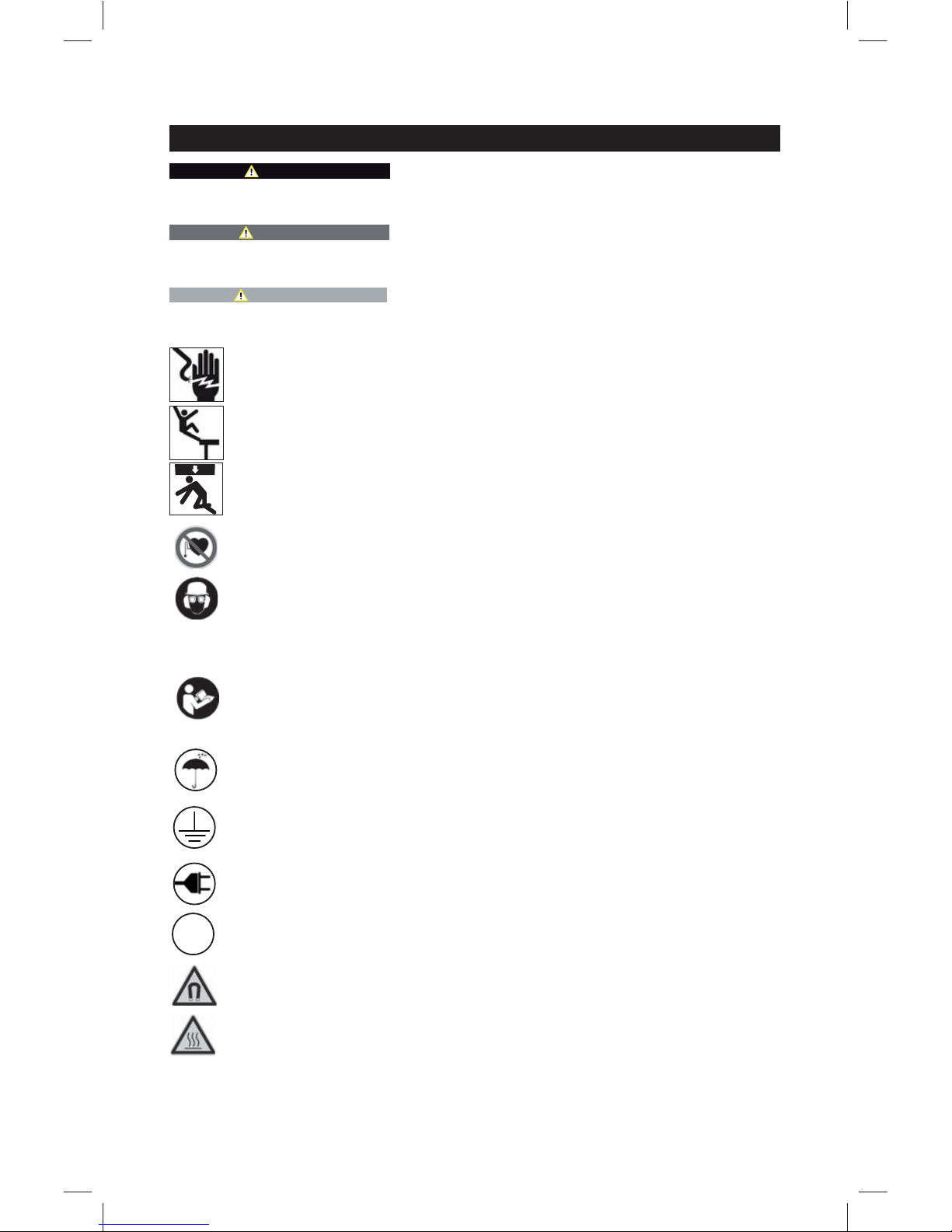

Indicates a hazardous situation. Death or severe permanent injury could result if

the situation is not avoided.

Indicates a potentially hazardous situation. Death or severe permanent injury

could result if the situation is not avoided.

Indicates a potentially hazardous situation. Slight or minor permanent injury could

result if the situation is not avoided.

DANGER!

WARNING!

CAUTION!

Symbols used

This symbol highlights hazard instructions that must be observed when

dealing with electrical equipment.

This symbol signals hazards that must be taken account of when

working on roofs.

This symbol signals hazards associated with crane transport.

This symbol signals risks for people who have a cardiac pacemaker.

This symbol makes clear the requirement to wear personal protective

equipment. Personal protective equipment always includes: safety

glasses, safety gloves, safety shoes, closely fitting working clothes

as well as a belt and safety rope. In every case the internal accident

prevention requirements must be observed.

The operating instructions must be read and understood before setting

up or using the tool. The instructions must be observed. Ask the

responsible department if the operating instructions are missing or if you

do not understand sections of the operating instructions.

This symbol signals hazards associated with magnetic fields.

FI

This symbol alerts operators to use the mandatory protective ground

conductor.

This symbol alerts operators to use the mandatory RCD switch.

This symbol alerts operators to use the mandatory protection against

moisture.

This symbol alerts operators to use the required network voltage.

This symbol highlights instructions that point out a fire hazard.

Instructions regarding additional important information.

5

Safety instructions

Rating plate

1 Machine type

2 Year of manufacture, serial number

3 Technical data

4 CE, FCC marking,Protection rating

Meaning of general safety instructions

The general safety instructions in this section provide information on possible

residual hazards that are always present or that could occur unexpectedly,

despite the correct usage of the unit.

The safety instructions must be observed by all persons who work on or with

the tool to prevent physical injury, damage or harm to the environment. These

persons are therefore obliged to read, understand and observe the provisions of

this section.

1

2

3

4

isoweld

®

6

Safety instructions

Meaning of specific safety instructions

For certain situations the applicable safety instructions are given at the relevant

place in the operating instructions. These instructions must be observed in order

to prevent physical injury, damage or harm to the environment.

Statutory requirements

In addition to the safety instructions in this operating manual, the statutory

accident prevention and environmental protection regulations applicable in the

country of use must be observed. Likewise the generally accepted rules for

safety and working in a technically correct manner must be observed.

Consequences of failure to observe the safety instructions

Failure to observe the safety instructions can lead to accidents with resultant

physical injury, damage or harm to the environment.

The manufacturer accepts no liability for injury or damage resulting from failure

to observe the safety instructions.

Intended use

The induction welding tool has been designed exclusively for the installation of

roofing membranes recommended by SFS on roofs.

Only fasteners, stress plates and sleeves approved for the tool and provided by

SFS may be used. The tool must be used within the limits defined in the

"Technical data" section.

Foreseeable misuse

• Starting to use the tool without instruction.

• Rendering the safety features inoperative and removing the warning labels.

• Working on roofs with a slope of more than 10°.

• Working backwards on roofs.

• Unsafeguarded or reckless working on roofs.

• Modifying the tool without the permission of the manufacturer.

• Using accessories or spare parts from another manufacturer without the

permission of SFS.

• Using or wearing isoweld

®

Backpack on an unstable support, steep incline or

ladder.

• In the case of misuse there is a risk of death or injury, damage to the tool

and damage to the material processed.

• It is not permitted to open the isoweld

®

induction generator under any

circumstances. Non-observance involves the risk of death or injury,

damage to the tool and damage to the processed material.

DANGER!

NOTICE

Welding with plates without an SFS

stamp may result in roof assembly failure.

USE ONLY SFS MARKED PLATES

7

• It is not permitted to use the isoweld

®

Backpack as a safety harness or wear

the isoweld® Backpack over a safety harness, under any circumstances.

Non-observance involves the risk of dealth or injury, damage to the tool and

damage to the processed material.

Safety instructions

• Keep your workplace tidy. An untidy workplace increases the risk

of accident.

• Keep children at a safe distance. Do not allow third parties to touch

the machine or the cable.

• It is imperative to comply with the safety regulations in the

respective country.

• Always wear the correct personal protective equipment when

working. Personal protective equipment includes: safety goggles,

safety gloves, safety shoes, closely fitting working clothes.

• When working on a roof it is possible for the tool or the operator to

accumulate a static charge. For this reason, we recommend that

anti-static clothing and anti-static shoes be worn and/or the use of

anti-static sprays.

• The induction welding tool and the magnets may have an effect on

the function of cardiac pacemakers and implanted defibrillators. It

is possible that cardiac pacemakers switch to test mode and cause

discomfort. It is possible that defibrillators cease to function. If you

are fitted with any such instruments, you must keep a minimum

distance of 20 inches (50 cm) from the inductor (also hand

inductor) and the magnets. You must warn persons fitted with such

instruments against coming too close to the magnets and inductors.

• Do not hold any objects containing metal in the direct proximity of

the inductor (e.g. watches, jewelry, keys, mobile phones, hearing

equipment, implants etc.).

• The

isoweld® stress plates become very hot due to the induction

process. There is a risk of burns when touching the stress plates

immediately following the welding process.

• Take account of environmental influences. Do not expose the

induction welding tool to rain. Do not use the induction welding

tool in damp or wet conditions. Ensure that you have good lighting.

Do not use the induction welding tool in the proximity of flammable

liquids or gases.

• Connect the tool to a socket with protective ground conductor. Any

breakage/disconnection of the protective conductor inside or

outside of the tool is potentially dangerous! Only use extension

cables with an earth conductor!

• The mains voltage must be as stated on the generator type plate.

• When the tool is used on building sites, the RCD switch is a

mandatory requirement for personal protection.

• Place the electric cable (supply cable) in a suitable location. Ensure

that it does not constitute a trip hazard and does not wear through.

Regularly check the electric cable, inductor cable and temperature

cable for damage.

• In the open, only use extension cables approved and marked for

this purpose.

General safety instructions – Part 1

FI

8

• Always switch the tool off and remove the mains connector during breaks or

maintenance work. Do not leave the tool unattended.

• When carrying out maintenance and service work, the power connection to

the tool must be disconnected.

• Regularly check the tool for damage, and that it is functioning properly. Use

the tool only if it is functioning properly.

• Repairs may only be carried out by a specialist.

• Only use system components from SFS or approved by SFS. Do not use any

accessories or spare parts from other manufacturers without approval by SFS.

•

The functionality of this system is guaranteed when original fastener, stress

plate, spare parts from SFS are used, and the unit is operated in accordance

with the operating instructions.

• Do not use or wear isoweld

®

Backpack on an unstable support, steep incline

or ladder.

• Always inspect isoweld

®

Backpack straps and connection points before use.

• Using an isoweld

®

Backpack tool with damaged straps or connection points

may result in a strap or connection breaking while in use and the machine

may fall causing personal injury.

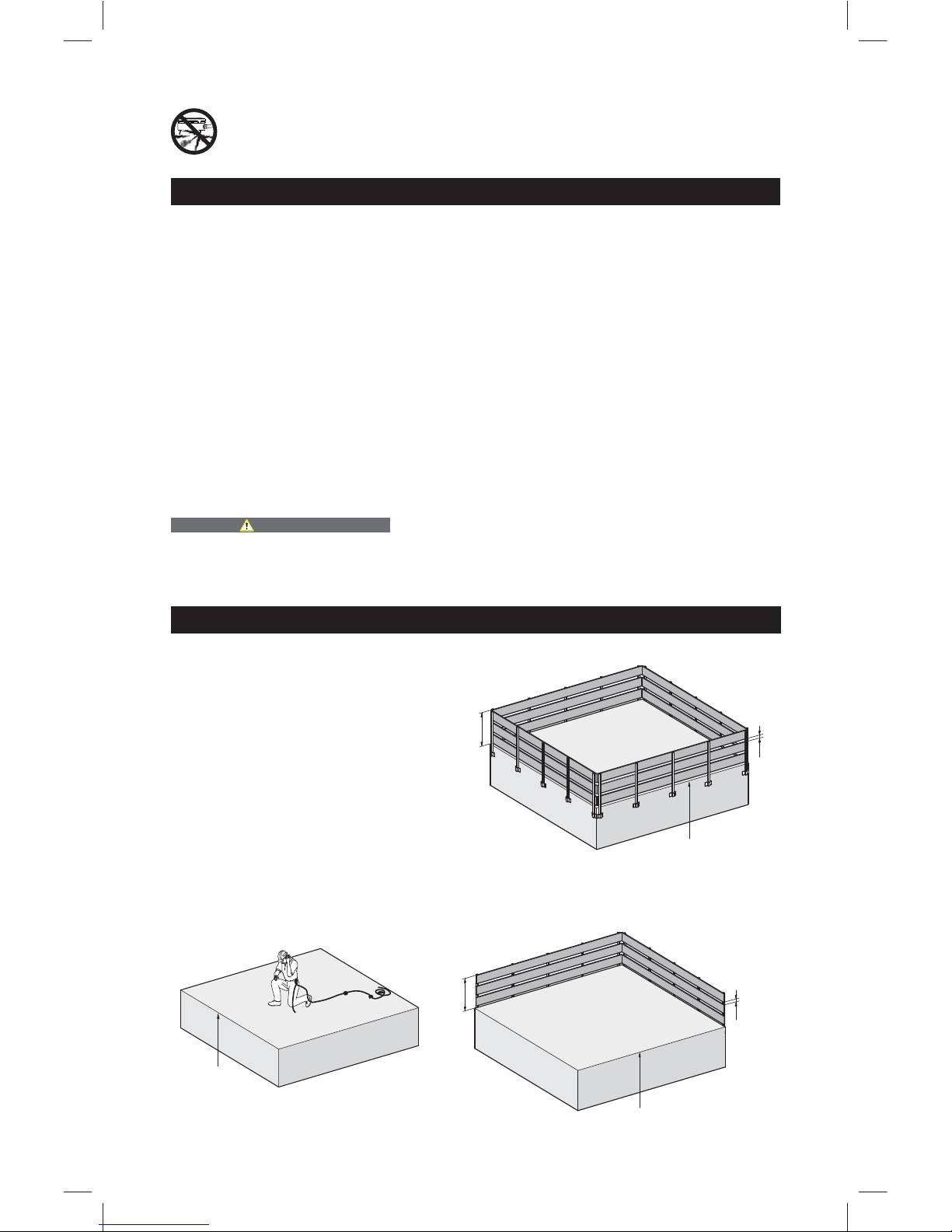

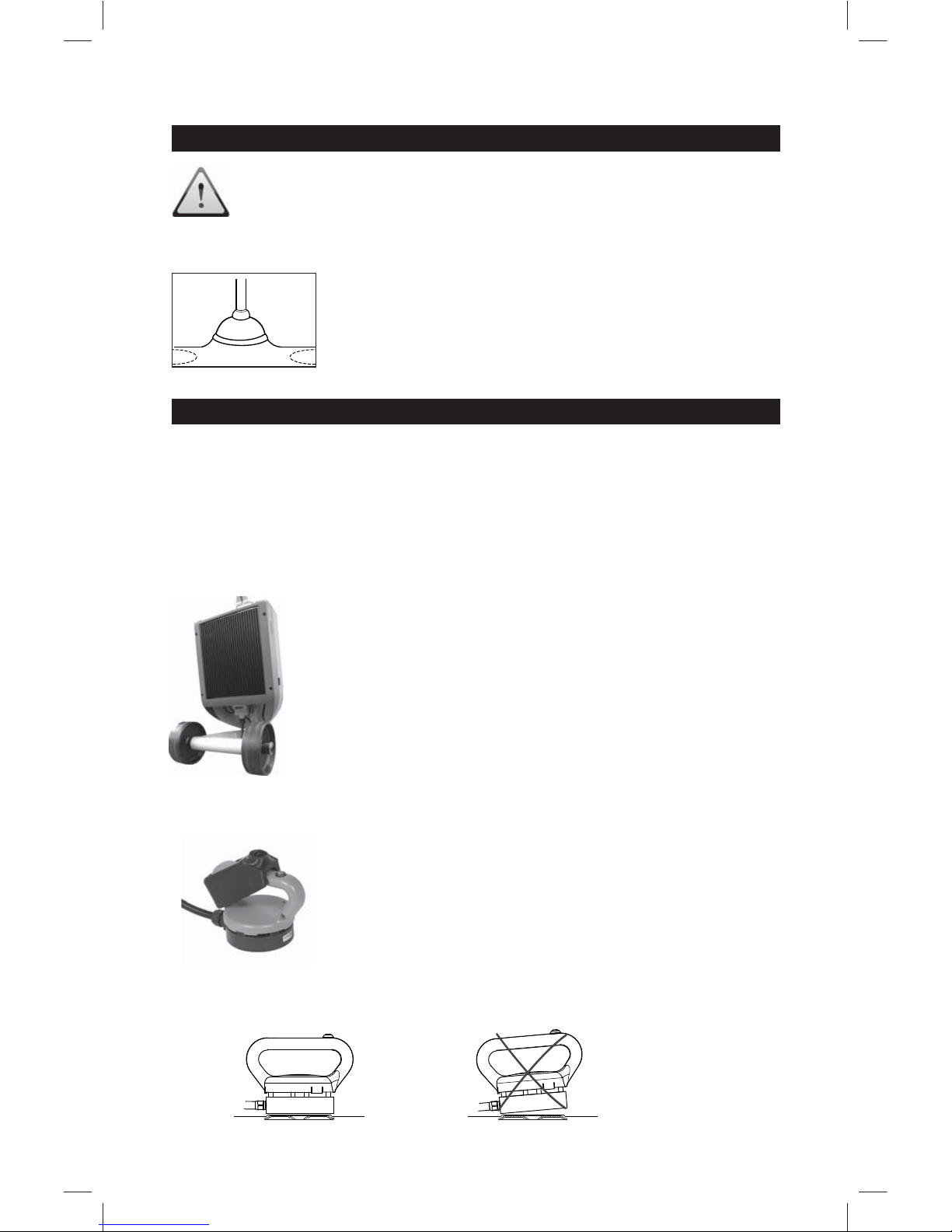

Special safety instructions

• When working on roofs with a

slope of between 0 and 10° a

guard rail must be fixed at the

edge of the roof.

• When the roof slope is more than

10° special safety devices must be

employed.

• When the working height is more

than 10 ft. (3 m) above ground,

appropriate fall prevention

measures must be employed

(see below).

• Fall prevention measures for work lasting less than 2 working days. In the case

of work that takes longer, proceed as described above (see below).

>5 m

>3 m

max. 47 cm

100 cm

max. 47 cm

100 cm

>5 m

Safety instructions

General safety instructions – Part 2

• Never start the welding process while the supply cable is under

the tool. Ensure that the cable is far enough away from the

inductor during the work process.

WARNING!

9

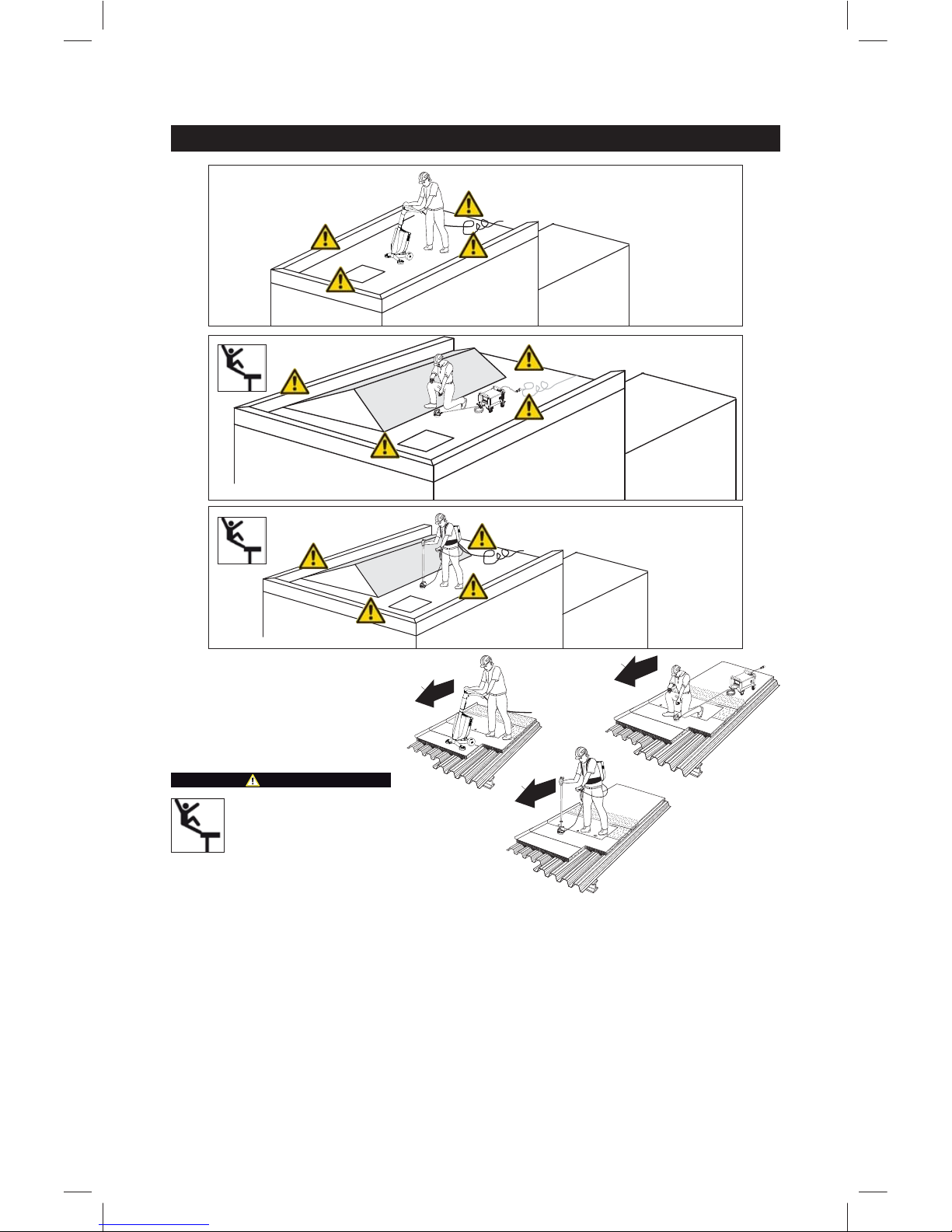

• Risk of falling through: beware of areas

in the roof that are not structurally safe,

e.g. rooflights, tarpaulins etc. These

areas must be appropriately marked and/

or secured with gangways.

• When working on roofs the entire risk

area on the ground must be cordoned

off and signed. It is important to ensure

that third parties are not endangered by

falling objects.

• Do not use or wear isoweld® Backpack on an unstable support, steep incline

or ladder.

• It is not permitted to use the isoweld

®

Backpack as a safety harness or wear

the isoweld

®

Backpack over a safety harness, under any circumstances.

Non-observance involves the risk of dealth or injury, damage to the tool and

damage to the processed material.

Special safety instructions

WARNING!

10

1 Fall hazard at roof edge

2 Fall hazard at step in roof

3 Break-through hazard, e.g.

glass windows

4 Trip hazard from cable

Always work in a forward

direction, never backwards.

Danger areas

1

DANGER!

3

4

1

1

2

3

3

4

4

1

1

1

2

2

11

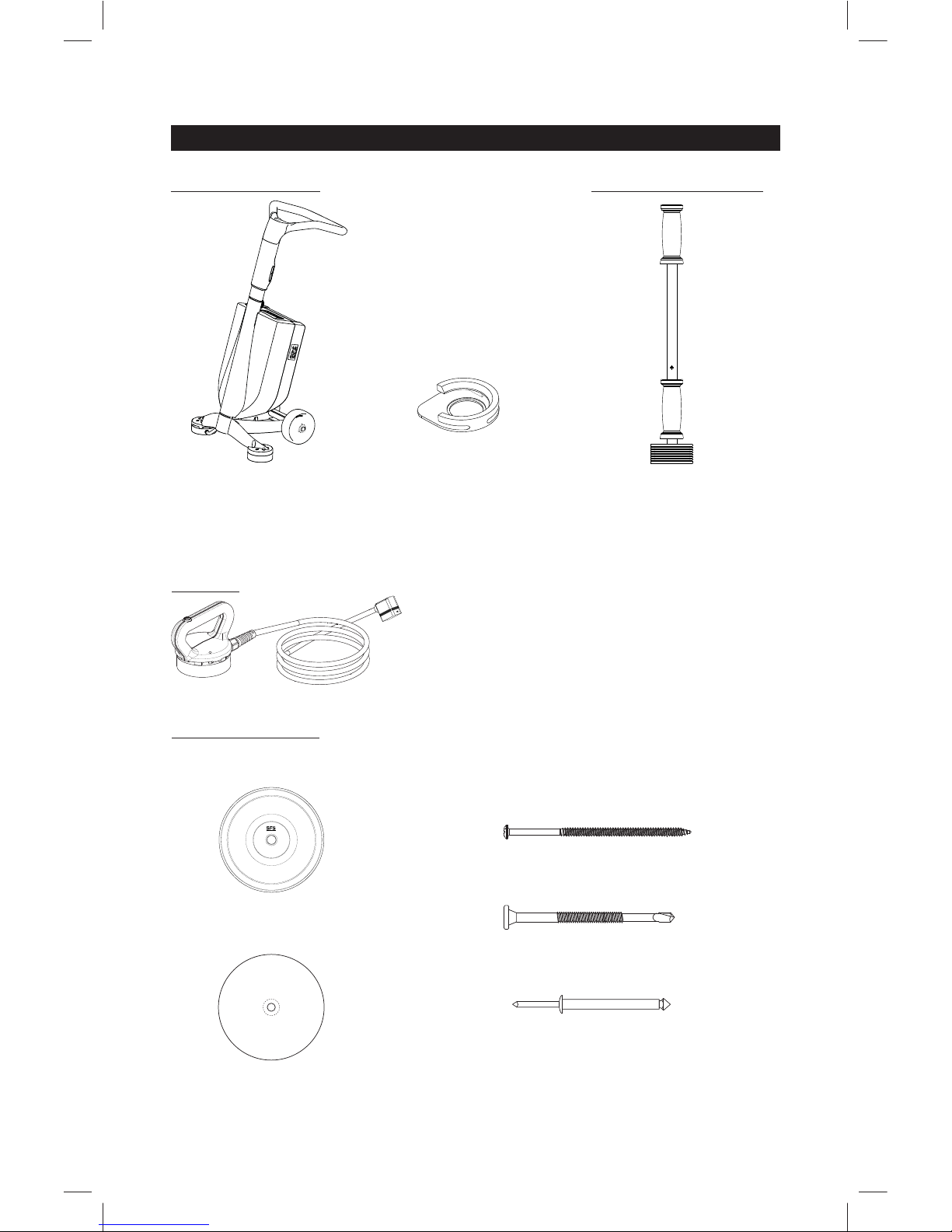

System components isoweld® 3000

Induction welding tool

isoweld® 3000

Magnet

FI Magnet

Calibration template

isoweld

®

Included in delivery:

Fixing components:

Additional accessories:

Hand inductor

FI-H

Optional:

Fastener:

DF-#15xL"

PUR-#12xL"

FI-P-6.8 isoweld

®

plate

for metallic systems

Stress plate:

TPR-L-6,3xL(mm)

FI-Pad

12

System components isoweld® Backpack

Magnet

FI Magnet

Fixing components:

Additional accessories:

Fastener:

DF-#15xL"

PUR-#12xL"

FI-P-6.8 isoweld® plate

for metallic systems

FI-Pad

Stress plate:

Calibration template

isoweld

®

Induction welding tool

isoweld® Backpack

Included in delivery:

TPR-L-6,3xL(mm)

13

Overview isoweld®3000

4

1

2

1 Inductor

2 Weld button

3 Cable holder

4 Handle

5 Clamping lever for height adjustment

6 Clamping lever for plug connection

7 Display

8 Generator

9 On/Off switch

10 Calibration template

11 Connector

1

2

11

Hand inductor FI-H (optional)

5

7

9

8

6

3

Calibration template

10

11

Standard items supplied isoweld®3000

Induction welding tool, complete

1 Induction welding tool isoweld® 3000

1 Calibration template

1 Set of instruction material

5 Protective foils for inductor

1 Transport box

14

1 Hand-held inductor

2 Flexible handle adaptor allows inductor to be placed on a slanted surface (+/- 5º)

3 Same as magnet pole

4 Turn lock clamp

5 Adjustable Handle

6 Wireless activation switch and handle

7 For thumb action

8 Index finger activation

9 Weld

10 x2

11 OK

12 Cord management

13 Integral waist strap

14 Closed cell foam padded straps

15 Carr y handle

16 Standard generator (same as stand-up tool)

17 4 T20 Screws to remove generator

18 Rubberized feet for impact resistance

19 OK

20 Wired activation switch

21 x2

22 Weld

23 Calibration

Tem plate

Overview isoweld® Backpack

9

10

11

8

7

6

15

14

16

17

18

21

19

20

22

2

3

4

5

12

13

1

Standard items supplied isoweld® Backpack

23

Induction welding tool, complete

1 Induction welding tool

isoweld® Backpack

1 Calibration template

1 Set of instruction material

5 Protective foils for inductor

1 Transport box

1 Hand-held inductor with

cord straps

1 Wired activation switch

1 Adjustable handle

1 Flexible handle adaptor

15

Description of function

Transport

The isoweld ® induction welding tool has been designed for efficient welding of

waterproof membranes with metal stress plates. It is possible to use PVC and

TPO waterproof membranes. The tool has been designed as an upright unit and

therefore allows ergonomic work without excessive fatigue. As soon as the

induction welding tool has been placed over a metal stress plate, the welding

process is triggered by pressing the start button. The welding process ensures

that the waterproof membrane is connected to the stress plate. It is important

that this connection is subsequently weighed down with a magnet.

DANGER!

38 Kg

©

Falling load

Note: NEVER lift or hang the isoweld

®

3000 transport box at the

handles.

38 Kg

NOTICE

Welding with plates without an SFS

stamp may result in roof assembly failure.

USE ONLY SFS MARKED PLATES

16

General

• The points below describe the power requirements for the use of the

isoweld

®

induction machine. These notes are recommendations.

Each job site and its power situation is individual and therefore no

performance guarantee can be given.

• In addition to the recommendations stated in this document, the local

safety and electrical regulations applicable in the country of use must be

observed.

• Consultation of a qualified electrician is advisable.

Electrical safety

• Connect the machine to a socket with a protective ground conductor

Any breakage/disconnection of the protective conductor inside or

outside the tool is potentially dangerous! Use only extension

cables with an ground conductor!

• When the tool is used on building sites, the use of an RCD switch is a

mandatory requirement for personal protection.

Power supply

• Stable power is essential for problem-free operation of the induction

machine.

• A minimum of

- 20 amps per electrical circuit required for countries with 110 volts /

120 volts nominal voltage

- 10 amps per electrical circuit required for countries with 230 volts

nominal voltage

• Maximum one induction machine per circuit, with a recommendation

not to use other devices on the same circuit as the isoweld

®

3000,

isoweld® Backpack.

• Off-load voltage shall not exceed:

- 160 volts for countries with 110 volts / 120 volts nominal voltage

- 240 volts for countries with 230 volts nominal voltage

• On-load voltage at the point of utilization at the machine terminals, with

the machine running, must be higher than:

- 110 volts for countries with 110 volts / 120 volts nominal voltage

- 200 volts for countries with 230 volts nominal voltage

• It is preferable for the induction machine to have its own dedicated

power supply so as to avoid power surges from other equipment, e.g.

drill machines.

Generator

• Use a minimum 5000 watt generator

• Requirements volts and amps see above

• With ground fault circuit interrupter (GFCI)

• Grounding / earthing required

Transformer

• Necessary for use in countries with a nominal voltage of 110 volts if the

voltage at the point of utilization, with the machine running, falls below

110 volts.

• The functionality of the system is only ensured if the transformer

provided by SFS is used.

Power requirements Part 1

17

Start-up isoweld®3000

After opening the container, the body of the unit

can be carefully lifted out. Then the handle of the

tool (see overview) is removed from the transport

box and carefully inserted into the tool.

1. Use fixing screw to secure the

push-fit connection.

2. Adjust the handle to an ergonomic

working height. For this purpose,

release the clamping lever at the

upright and adjust the height.

Re-tighten the clamping lever.

3. Connect the tool to a suitable

power source.

- the cable should not be too long

- suitable conductor cross section

- unroll extension cable

Ensure that the connection is

correctly made.

4. Operate mains switch to turn unit

on.

5. The display shows the input

screen.

The induction welding tool is delivered ready for operation ex-works.

4.

5.

1.

2.

The country-specific regulations must be observed.

3.

Power requirements Part 2

Power cables

• The usable cable thickness and length depend on the power situation on

the job site.

• General rule: The shorter and thicker the cable, the better.

• Recommendations cable thickness:

- for countries with 230 volts nominal voltage: 3 x 1.5 mm

2

- for countries with 110 volts / 120 volts nominal voltage: 12 gauge

cable (3 x 2.5 mm

2

)

• Use only cables appropriate for this application. Check the

cables regularly for damage.

• Outdoors, use only extension cables approved and marked for

this purpose.

18

The induction welding tool is delivered ready for operation ex-works.

After opening the container, remove the poles and hand-held inductor, then the

backpack unit can be carefully lifted out. The inductor unit, pole and cords can be

carefully assembled and attached to the tool.

Start-up isoweld® Backpack

1. For use in stand-up mode, connect the handle

adaptor to the hand inductor.

2. Screw the adjustable handle into the top of

the handle adaptor.

3. Press the wireless activation switch/handle

grip on to top of adjustable handle.

4. Adjust the pole with the turning lock clamp to

an ergonomic working height.

5. Open the cover to the hand-held port and

connect the hand-held inductor.

5a. If desired, connect wired activation

switch.

6. Connect the tool to a suitable power source.

- the cable should not be too long

- suitable conductor cross section

- unroll extension cable (diagram page 19)

Ensure that the connection is correctly

made.

©

1

3

5

5a

4

2

19

7. Operate main switch to turn unit on.

8. The display shows the input screen.

9. Perform start-up calibration and test weld

procedures. (see pages 20 & 21)

These procedures must be performed prior

to putting the backpack on.

The country-specific regulations must be

observed.

First, inspect the shoulder straps to

ensure they are not damaged and that they

are firmly connected to the tool body with no

damage or wear at the connection points.

10. After inspection, place your arms through the

shoulder straps to support the backpack on

your back.

Using a tool with damaged straps or

connection points may result in a strap or

connection breaking while in use and the

machine may fall causing personal injury.

If there is any damage noted to the straps or

connections, follow the instructions noted in

the maintenance, service and warranty

section of this manual.

11. Adjust the straps

11a. Adjust the shoulder straps to a good

working fit by adjusting the strap

length at the clip

11b. Attach the chest strap and adjust to

length

11c. Attach the waist strap and adjust its

length so that the machine is

supported by your hips.

12. Use the cord management straps to organize

the power cord and inductor cord for safe,

efficient working.

11 a

11 b

11 c

WARNING!

8

6

7

20

Start-up

Before working with the induction welding tool, the project parameters must

be entered into the display. The parameters required are the waterproof

membrane material and thickness. The following options are available:

For changing the settings, proceed as follows:

The position display is on the choice of the waterproof membrane material

(4first line).

1. Press the button

OK

. ≥ appears and flashes.

2. Press the

L

button or press the M button until the required waterproof

membrane material is displayed.

3. Confirm the selection by pressing the

OK

button. 4 appears.

4. Press the

M

button to go to the waterproof membrane thickness selection.

5. Press the

OK

button. ≥ appears and flashes.

6. Press the

L

or M button to determine the waterproof membrane thickness.

7. Confirm the selection by pressing the

OK

button.

The parameters have now been set and stored.

Note: the settings (parameters) used last will be loaded. It is possible to

either adopt these settings or make new selections of the following settings.

Display examples

Waterproof

membrane

material

Waterproof membrane thickness (mm/mil)

PVC

TPO

0.9-1.1/35-44

1.2-1.4/45-59 1.5-1.7/60-69 1.8-2.0/70-79 2.1-2.3/80-90

21

1. Use the calibration template and place an isoweld® plate into the recess

provided for it (A).

2. Push the calibration template on to the corner of the waterproof membrane

(B).

3. Place the inductor into the calibration device and ensure that it is positioned

correctly (C): the arm (D) to the inductor must be resting in the recess (E)

provided.

4. Press the L or M button to move to CALIBRATION.

5. Press the OK button to open the calibration program.

6. You are now in the calibration program.

7. Press the start button (2).

8. The automatic calibration is completed when there is a beeping sound

for 1 second and the display returns to standard view.

The tool is now calibrated.

Calibration

Ensure that the project parameters are set correctly (waterproof

membrane material and thickness).

Only use material for calibration which has been defined for the current

project.

Calibration process

ABCC

When should the tool be calibrated?

• every morning before starting work

• when moving to another building site

• when working with a different material (PVC instead of TPO or vice-versa,

thinner or thicker waterproof membrane)

• change from 110V to 230V or vice-versa

• change of generator (USA, CAN) or transformer (UK)

D

E

isoweld® 3000 isoweld® Backpack

22

The tool is now ready for operation. (status display

M

lights up green).

SFS recommends that a test weld be carried out

after calibration and before starting installation. Position a stress plate on a level, heat-resistant base

and place a piece of the waterproof membrane to

be used on it. Carry out a test weld (see section on

welding operation). Allow the weld to cool down for

at least 10 minutes. Try to disengage the plate from

the waterproof membrane with the help of pliers.

If the membrane offers a lot of resistance or is destroyed in the process

(after tearing off the stress plate), the weld has been successful. Should

the welded waterproof membrane not have sufficient adhesion to the

stress plate, you need to check the settings (parameters) at the tool etc. For

technical assistance, please contact your service provider. You will find this at

1-800-DEKFAST (335-3278) or www.sfsintecusa.com (US) or

www.sfsintec.ca (CA)

Additional setting options

By pressing the

Menu

button you can set the volume and tone of the signal sound

and the unit of measure (mm/mil).

1. Press the OK button. ≥ appears and flashes.

2. Press the

L

or M button until the required volume is reached.

3. Confirm the selection by pressing the

OK

button.4appears.

4. Press the

M

button to move to the selection of tone or unit of measure.

5. If you want to change these too, repeat steps 1 to 3 accordingly.

6. Press the Menu button in order to return to the standard view.

The parameters have now been set and stored.

Test welding

To set one of these parameters, proceed as

follows:

For example, the position display is on selection

of volume (*first line).

23

Operation: welding

Before carrying out the welding, SFS recommends marking the position

of the stress plates on the top face of the waterproof membrane.

Danger of falling!

Careless working on the roof can lead to falls.

When working on a roof you must wear appropriate safety equipment.

Never use the tool backwards, but always in a forwards direction (see

sections on Hazards and Work position).

It is not permitted to use the isoweld

®

Backpack as a safety harness or

wear the isoweld

®

Backpack over a safety harness, under any

circumstances. Non-observance involves the risk of dealth or injury,

damage to the tool and damage to the processed material.

The induction welding tool and the magnets may have an effect on the

function of cardiac pacemakers and implanted defibrillators. It is possible

that cardiac pacemakers switch to test mode and cause discomfort. It

is possible that defibrillators cease to function. If you are fitted with any

such instruments, you must keep a minimum distance of 20 inches (50

cm) from the inductor (also hand inductor) and the magnets. You must

warn persons fitted with such instruments against coming too close to

the magnets and inductors.

DANGER!

Before installing the waterproof membrane, SFS recommends that the

position of the plates on top of the insulation be checked. Should the

height of any stress plate be incorrect, the height needs to be corrected.

underdriven correct

overdriven

min. 2 mm

W

W

NOTICE

Welding with plates without an SFS

stamp may result in roof assembly failure.

USE ONLY SFS MARKED PLATES

24

Overlaps of waterproof membrane in the area of the stress plate should be

avoided. However, should this situation arise the special function of the welding

tool can be used. Instead of proceeding with normal welding, the

x2

function key

can be pressed. Now proceed as steps 1 to 5.

Important: the

x2

function will only remain active for one weld.

4. The welding process takes approx. 3 to 4 seconds and is terminated

with a double signal sound.

Caution: moving the tool before the welding process has been

completed will always result in an error message and a faulty weld!

5. After completing the welding process, move the tool from the weld

and immediately place a magnet on the welded point. Allow the

magnet to remain for at least 1 minute. The magnet ensures the

necessary pressure and cooling of the stress plate. It is an essential

part of achieving a good weld!

The magnet must be placed within the first 3 seconds after

terminating the welding.

Check the underside of the magnet regularly and remove any metallic

particles.

The magnet must not be rotated during or after positioning if there is

contact with the waterproof membrane. If this instruction is not followed,

the waterproof membrane may be damaged.

6. Move to the next plate position and repeat the search and welding process as

described in steps 1 to 5.

7. At the end of the welding work, switch off the tool at the main switch and

then disconnect from the mains.

Operation: welding

Full overlap Partial overlap Partial overlap

1. Preparing the magnet.

2. Place inductor (1) on stress plate.

3. Press the start button on the handle (3).

a. If the unit has been placed correctly, which means that the cover is suffi-

cient, a continuous signal sound will be heard (1 second) and the status

display

M

changes to orange. The welding process will start automatically.

b. If the unit is not correctly placed, i.e. the cover is insufficient, the inductor

(1) has to be moved until the position is correct (see Fig.1). As soon as the

position is correct, the welding process starts automatically.

c. The tool is equipped with an acoustic search mode which helps the user

to position the inductor precisely on the stress plate. The search mode is

active for max. 15 seconds. When the time limit has

been exceeded, a failure signal sound can be heard

(2 seconds). In this case, acknowledge the signal

by pressing the

OK

button, allow the stress plate to

cool down and restart the welding process (step 1

and subsequent steps).

Fig. 1

25

Working with the hand inductor

Alternatively it is also possible to carry out welds with the hand inductor

(available as an option). This may be appropriate on roof upstands, around

rooflights, on shed roofs etc.

The hand inductor is controlled via the main tool and automatically adopts all

functions and settings from it!

isoweld

®

3000

Checking the welding

If the correct parameters have been selected for the

welding and the recommended test weld has been

successful with positive results, and the instructions in

the operating instructions have been followed, no further

checks of the operation are necessary.

If you are not sure whether certain joints have already

been welded, SFS recommends using the suction pad

provided or a commercially available suction device to carry

out a test. Try to lift the roofing membrane at the point

in question. If that is possible, the joint is still open and

requires welding.

Please note that the underside of the inductor must be positioned

parallel to the top face of the plate!

©

Fig. 2

©

1. Unplug the inductor from the main tool

2. Plug the hand inductor into the main tool (see Fig. 2).

3. Carry out calibration as described in the "Calibration"

section.

4. For further steps, see "Operation: welding" section.

1. Remove the handle adaptor (see Fig. 3) and the inductor

becomes a hand-held tool.

isoweld® Backpack

Fig. 3

©

remove

26

Technical Data isoweld® Backpack

Induction generator:

Workable temperature range: -5 °C to +50 °C

23 °F to 122 °F

Electrical connection: 110V / 230Vw

Power consumption: 1500 Watt

Frequency: 50 Hz / 60 Hz

Tool dimensions isoweld® Backpack:

Size: 457x317.5x203 mm (assembled)

18x12.5x8 in (assembled)

Weight: 10.9 Kg (complete)

24 lbs (complete)

Dimensions of transport box:

Size: 635x508x355.6 mm

25x20x14 in

Weight: 10.4 Kg

23 lbs

Technical data isoweld®3000

Induction generator:

Workable temperature range: -5 °C to +50 °C

23 °F to 122 °F

Electrical connection: 110V / 230V

Power consumption: 1500 Watt

Frequency: 50 Hz / 60 Hz

Tool dimensions isoweld®3000:

Size: 550x520x1100 mm (assembled)

21.6x20.5x43.3 in (assembled)

Weight: 18.5 Kg (complete)

40.8 lbs (complete)

Dimensions of transport box:

L/W/H: 940 x 584 x 610 mm

37 x 23 x 24 in

Weight:15.4 kg

34.0 lbs

27

Error messages

Error message Cause Action

Error 01

voltage problem

Voltage supply is too low for

the tool

Press the

OK

button.

• Choose an electricity circuit

with less load

• Reduce the length of the

supply cable

• Change the supply voltage to

230V (GB, USA, CAN).

Error 02

overload

Max. permitted inductor current

exceeded

Press the

OK

button.

• Restart the welding process

• Should this error message be

displayed repeatedly, please

contact your SFS service

provider.

Error 03

system error

System error

Press the OK button.

• Restart the welding process

• Should this error message be

displayed repeatedly, please

contact your SFS service

provider.

Error 04

system too hot

Tool has heated up too much

Press the OK button.

Turn off the tool at the main switch

and allow to cool down.

Error 05

welding not

complete

Required welding temperature

not reached

Press the OK button.

Allow the weld point to cool down

and restart welding process.

Error 06

no plate

Max. search time exceeded

Press the OK button.

• Check that there is a stress

plate

• Allow the weld point to cool

down and restart welding

process.

• Should this error message

be displayed several times,

recalibrate the tool.

Error 07

plate lost

Inductor has been accidentally moved during the welding

process

Press the

OK

button.

Allow the weld point to cool down

and restart welding process.

Error 08

temperature

sensor

Temperature sensor defective

Press the

OK

button.

Contact your SFS service provider.

Error 09

no calibration

The program used has not been

calibrated

Press the

OK

button.

Calibrate the tool in accordance

with the "Calibration" section.

Error 10

mains voltage

Permissible input voltage too

low

Press the OK button.

• Choose an electricity circuit with

less load

• Reduce the length of the supply

cable

• Change the supply voltage to

230V (GB, USA, CAN).

28

• Regularly clean the tool using a soft cloth and mild cleansing solution.

• Protect the tool from moisture and dirt.

Avoid contact between any plastic components of this equipment and

solvents, oils, gasoline, petro-based products, acids or other harsh

chemicals; they can damage the plastic components, which could result in

personal injury.

Electrical maintenance

On principle, electrical equipment may only be serviced and repaired by qualified

technicians.

Backpack Straps

If there is damage or wear to the straps or connection points, the strap or

connection may break during use and the machine may fall causing personal

injury.

If the straps are determined to be worn but the connection points show no signs

of wear or damage, remove the straps by removing the eight (8) T25 attachment

screws and loosening the upper tie straps. Replace the straps by reinserting the

eight (8) T25 screws through a new strap and re-attaching the upper tie straps to

the equipment. Use only straps intended for use with this equipment.

Maintenance, service and warranty

Disposal

The tool must not be disposed of with household refuse.

Dispose of the tool at the disposal points provided for this type of

equipment in accordance with the national or local regulations.

The tool must be disposed of in accordance with the European

Directive 2012/19/EU (WEEE). This directive regulates the return and

recycling of waste equipment within the EU.

NOTICE

Welding with plates without an SFS

stamp may result in roof assembly failure.

USE ONLY SFS MARKED PLATES

WARNING!

(4) T25

(4) T25

Upper tie

straps

29

Replacing the Battery in the Wireless Activation Switch:

1. Remove the two (2) T10 screws from

the base of the switch and remove the

lower cap

2. Reach in and slide out the wireless

switch module

3. Slide the switch board out slightly from

its housing in order to access the

battery

4. Replace the 3V CR2032 Lithium Cell

Battery with a new one and recycle the

old battery

Reprogramming the Wireless Activation Switch:

1. Remove the four (4) T20 screws

from the gray plastic housing in

order to access the generator

1

2

3

If there is damage or wear to any of the connection points, contact SFS tool

service or an authorized repair shop.

Using a tool with damaged straps or connection points may result in a

strap or connection breaking while in use and the machine may fall causing

personal injury.

WARNING!

1

4 screws

to remove

generator

30

2. Remove the elastic strap that runs

across the top of the generator so

that you can access the side of the

generator adjacent to the Backpack

harness

3. Rock the generator forward from the

Backpack harness in order to access

the reprogramming switches

4. Press the “Start” button of the

reprogramming switches and hold

for three (3) seconds

5. 5 While still holding the “Start”

button on reprogramming switch

panel, single click the “Weld” (i.e.

“Start”) button on the wireless

activation switch

6. Release the “Start” button on

the reprogramming switch panel.

The “Weld” button on the wireless is

now programmed to work with this

generator

7. Press the “OK” button of the

reprogramming switches and hold

for three (3) seconds

8. While still holding the “OK” button

on reprogramming switch panel,

single click the “OK” button on the

wireless activation switch

Release the “OK” button on

the reprogramming switch panel.

The “OK” button on the wireless is

now programmed to work with this

generator

2

©

3

©

4

©

7

©

5

©

8

©

Weld

OK

31

9. Press the “x2” button of the

reprogramming switches and hold

for three (3) seconds

10. While still holding the “x2” button

on reprogramming switch panel,

single click the “x2” button on the

wireless activation switch

Release the “x2” button on

the reprogramming switch panel.

The “x2” button on the wireless is

now programmed to work with this

generator

Service

For technical information, please contact SFS tool service.

Warranty

The isoweld® 3000 and isoweld® Backpack must be registered

within 30 days of purchase. To protect your investment and

register the tool, go online at:

www.sfsconstructionna.com/toolregistration/

1. This induction welding tool has been carefully checked, tested and subjected

to strict quality control.

2. We warrant the rectification, free of charge, of defects on the induction

welding tool that occur within 24 months of the date of sale or 200,000 welds

to the end user and that are due to a material or manufacturing fault. Individual

special regulations apply to the conditions of the warranty in some countries.

We reserve the right to rework defective parts or replace them with new ones.

The ownership of the replaced parts is transferred to us.

3. Improper usage or handling, as well as the opening of the tool by unauthorised

repair centers, will render void any claims under the warranty. The warranty

excludes the following: damage caused by penetration of water or other

liquids, a cut or damaged cable, damage to the electronics and mechanical

damage caused by overloading. Likewise excluded are wear parts such as the

induction coil, gliding foil etc.

4. Claims under the warranty can only be accepted if defects (as well as

transport damage) are notified without delay. The statute of limitations is not

automatically extended by the provision of service under the warranty.

5. In order to make a claim under the warranty, the took registration must be on

record, as noted above. To make the claim, contact SFS at:

US: 1-800-DEKFAST (335-3278)

6. Any further claims by the purchaser – in particular the right to rescission,

price reduction or claims for damages – are excluded due to the warranty

obligations undertaken by us, as far as permitted by the law.

9

©

10

©

x2

32

We SFS intec AG

Division Construction

Rosenbergsaustr. 10

CH-9435 Heerbrugg

hereby declare that the products in the series

Type: isoweld® 3000, isoweld® Backpack

comply with all the essential requirements of the following directives:

2014/35/EU EU Low Voltage Directive

2014/30/EU EU EMC Directive

Person authorised to compile the technical documentation as per Annex VII A of

the directive 2006/42/EC:

Daniel Gasser

SFS intec AG

Rosenbergsaustr. 10

CH-9435 Heerbrugg

Daniel Gasser

Head of Research and Technology

SFS intec AG

In the case of modification of the tool this declaration and the warranty will be

rendered void.

We reserve the right to make modifications!

Declaration of conformity

7. The purchaser is entitled, at the purchaser’s choice, to a price reduction

(reduction of the purchase price) or rescission (annulment of the contract of

purchase), if we are unable to rectify within a reasonable period any defects

that may occur.

33

System components 35

Deciding on installation strategy 36

Preparing the roof for fastening 36

Measuring and marking fastening points 36

Fixing the stress plates 37

Rolling out the waterproof membrane 38

Marking the fastening points 38

Preparing the induction tool 39

Welding the membrane at the fastening points 40

System isoweld

®

3000 and

isoweld

®

Backpack

Installation Instructions

35

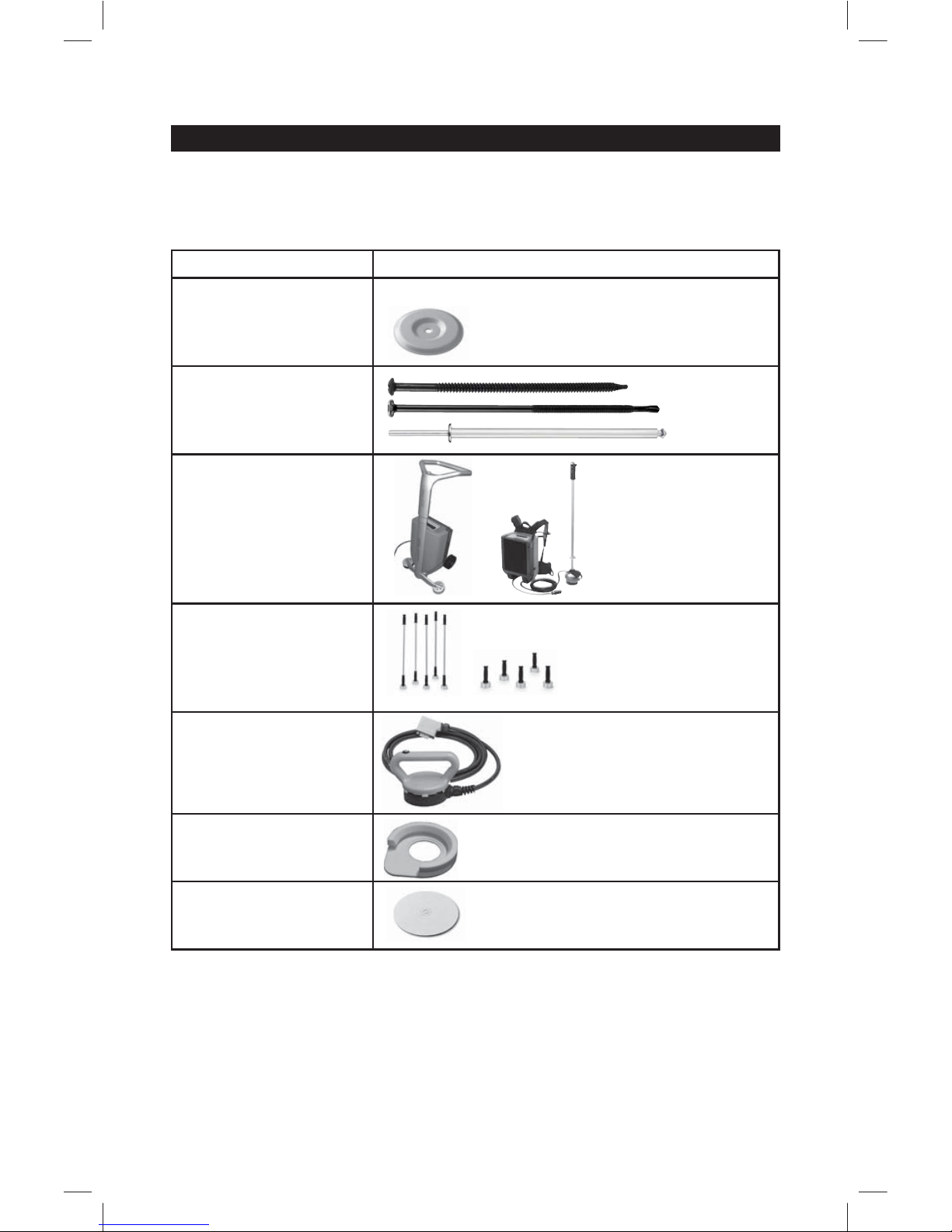

Ensure that you have all required system components at your disposal.

System components

System components Product identification

Stress plate

FI-P

Fastener

#15 Dekfast

#12 Purlin

TPR-L Peel Rivet

Induction tool

isoweld

®

3000

isoweld

®

Backpack

Magnets

FI-Magnet

Hand inductor

FI-H

Calibration template

Pad for EPS/XPS

application

FI-Pad

36

1. Deciding on installation strategy

2. Preparing the roof for fastening

3. Measuring and marking fastening points

• Familiarize yourself with the results of the wind load calculation and decide

on the procedure for the installation.

• Consider how best to deploy personnel, materials and equipment. In this

way you will achieve a fast, correct and efficient installation.

• Prepare the roof for laying out the waterproof membrane (e.g. prepare

substrate, vapor barrier, thermal insulation, fleece etc.).

• It is important to observe local regulations and manufacturers’ instructions.

We recommend that only so much roof area be prepared as can be

fastened and welded on the same day.

• Before rolling out the waterproof membrane, steps 3 and 4 have to be

carried out.

Measure the locations of the fastening points in accordance with the wind load

calculation and mark these on the prepared roof surface using e.g. a chalk line.

37

4. Fixing stress plates

underdriven

correct overdriven

min. 2 mm

W

W

• Fix the stress plates in accordance with the wind load calculation.

• Use the specified fastener.

Only set as many stress plates as can be welded on that day.

• Ensure that the stress plates are dry and clean, both in storage and during

and after installation.

• When installing on EPS/XPS thermal insulation, an FI-Pad must always be

used, even when a fleece is placed between the EPS/XPS thermal insulation

and the waterproof membrane.

• The FI-Pad must be placed directly under the stress plate.

FI-Pad

NOTICE

Welding with plates without an SFS

stamp may result in roof assembly failure.

USE ONLY SFS MARKED PLATES

• Check the setting depth of the stress

plates (see figure below).

• The stress plates must be set parallel to

the surface.

Incorrectly installed stress plates

adversely affect the quality of the weld.

38

6. Marking the fastening points

5. Rolling out the waterproof membrane

• Install the waterproof membrane in accordance with the membrane

manufacturer’s instructions.

Compared to seam fixing systems, the isoweld

®

system makes it

possible to reduce the overlap of the waterproof membrane.

• Overlaps of the waterproof membrane in the area of the stress plate should

be avoided. See also the isoweld

®

3000 / isoweld® Backpack operating

instructions.

• Ensure that the underside of the waterproof membrane is dry.

• Use the isoweld

®

magnets (turning clockwise) or other suitable aids to mark

the top of the waterproof membrane above the stress plate.

Careful marking contributes significantly to a fast welding process.

Clean magnets from debris on a regular basis to prevent membrane

damage.

39

7. Preparing the isoweld® 3000 / isoweld® Backpack induction tool

Prepare the isoweld

®

3000/ isoweld® Backpack induction tool for

welding in accordance with the separate operating instructions.

This includes in particular:

• unpacking and assembling the magnets

• unpacking and assembling the tool

• switching the tool on

• entering the waterproof membrane material

• entering the waterproof membrane thickness

• calibration

• test welding

40

11.

12.

13.

14.

15.

16.

19.

18.

17.

20.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

1.

2.

3.

4.

5.

6.

9.

8.

7.

10.

8. Welding the membrane at the fastening points

Proceed with the welding process in accordance with the isoweld

®

operating instructions.

For an efficient process, we recommend the following procedure:

1. Place at least 10 magnets to the right of the points to be welded (A).

2. Weld the first of these points (B).

3. Place the magnet on to this fastening point within 3 seconds of completing

the welding (C).

4. Proceed to weld the following points 2 to 10 as described in steps 2 and 3

(D).

5. Move the isoweld

®

induction tool to the starting point of the next line (point 11

(E).

6. Proceed to weld points 11 to 20 of the line on the left, as described in steps

2 to 4.

7. etc.

1.

2.

3.

4.

5.

6.

9.

8.

7.

10.

1.

2.

3.

4.

5.

6.

9.

8.

7.

10.

1.

2.

3.

4.

5.

6.

9.

8.

7.

10.

A

B

C

D

E

41

Fast and exact positioning of the magnet is a prerequisite for good

welds.

The magnet must not be rotated during or after positioning if there is

contact with the waterproof membrane. If this instruction is not followed,

the waterproof membrane may be damaged.

Clean magnets from debris on a regular basis to prevent membrane

damage.

• Ensure that all fastening points have been properly welded.

• Should you be uncertain about whether some welds have completed

properly, SFS recommends testing with a commercially available suction

pad.

See also isoweld

®

operating instructions.

© 2018 SFS, iFR, 902047, 03/18, 2.0 Mat. No. 1586027

Created in United States / Right of modifications reserved

SFS Group USA, Inc.

Division Construction

1045 Spring Street

PO Box 6326

US-Wyomissing, PA 19610

800 234 4533

T +1 610 376 5751

F +1 610 376 8551

us.construction@sfsintec.biz

www.sfsintecusa.com

SFS - Canada

40 Innovation Drive

Dundas, ON L9H 7P3

T +1 905 689 5401

ca.info@sfsintec.biz

www.sfsintec.ca

Loading...

Loading...