SEWOO LK-B40 User Manual

B40 Rev. C 11/16

J. STEPHEN Lab., Ltd.

374-2, Gajang-dong, Osan-si, Gyeonggi-do, 447-210, Korea

TEL : +82-31-459-8200 FAX : +82-31-459-8880

www.miniprinter.com

All specifications are subject to change without notice

4” DESKTOP LABEL PRINTER

MODEL : LK-B40

1

Table of Contents

1. Safety Caution 2

2. Unpacking 4

3. Inspecting the Printer 5

4. Hooking Up the Printer and Computer 7

5. Load Label Paper 8

6. Load Pen folder Paper 10

7. Load Ribbon 12

8. Replace HEAD 13

9. Replace Platen Roller 15

10. Control HEAD Pressure 16

11. Maintenance Manual 18

12. Interface 21

13. Media Roll Size 23

14. Labels 24

15. Tags and Strip with Slots 25

16. Tags and Strip with Black Marks 26

17. Plain Continuous Stock 27

18. Using the Display and Buttons 28

19. Specications 55

20. Command List 57

3

2

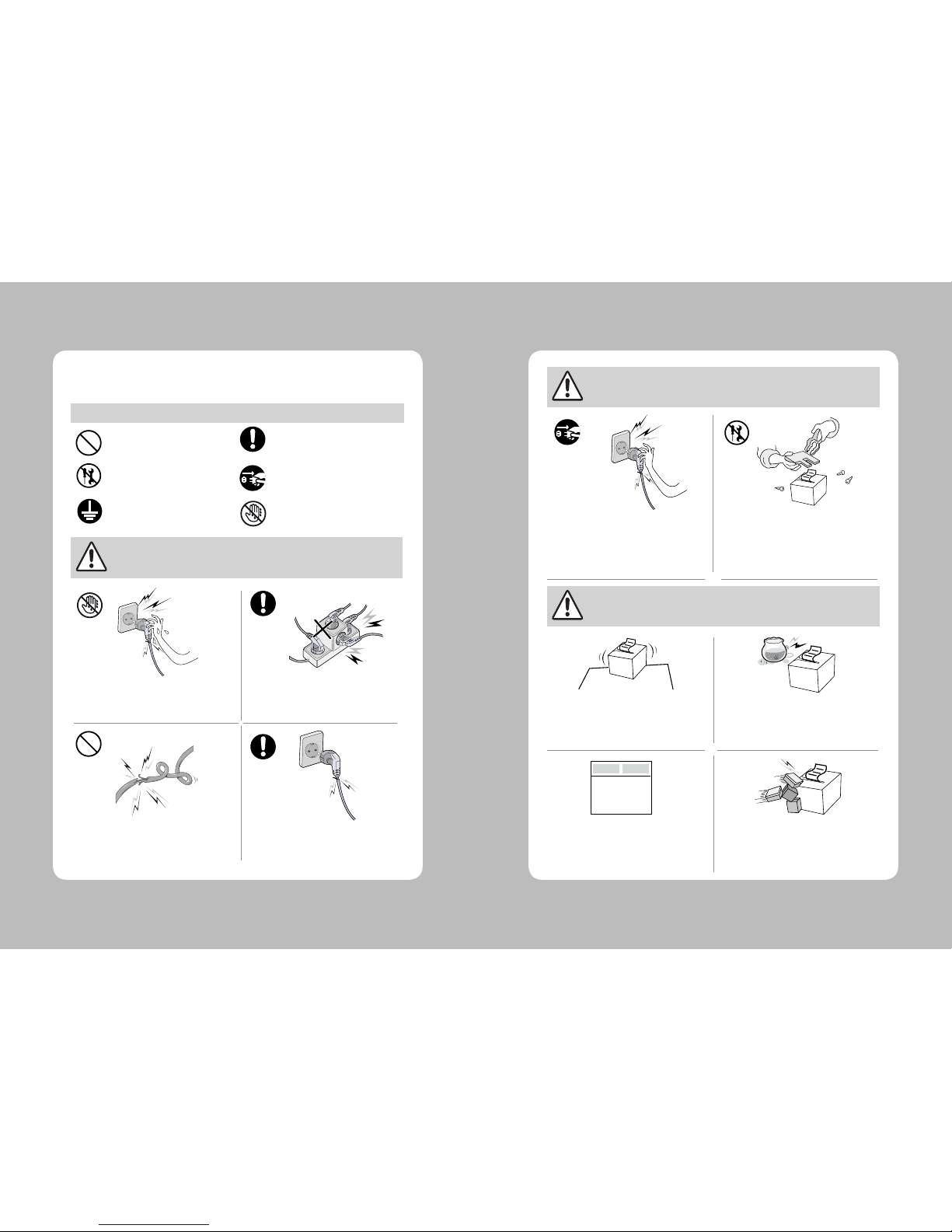

For higher reliability and safety, consider the following precautionary measures.

Read and follow the instructions carefully before running of the product.

1. Safety Caution

Indication

Prohibition

Must follow

Do not disassemble

Unplug the power from

the outlet

Grounding to prevent

electric shock

Do not handle the product

with wet hands

WARNING

WARNING

WARNING

Failure to follow these instructions could result in re, electric shock,

or other injuries, or property damage

Failure to follow these instructions could result in re, electric shock,

or other injuries, or property damage

Failure to follow these instructions could result in re, electric shock,

or other injuries, or property damage

(Potential risk of electric shock or re)

(Potential risk of electric shock or re)

(Potential risk of electric shock or re)(Potential risk of electric shock or re)

Do not pull or touch the power plug with

wet hands.

Do not bend the wire and do not allow the

wire to be pressed by heavy object.

If a power plug is broken or a plug is cut or

worn, do not use it.

Do not overload the power plug into

one outlet.

(Turn o the power at installation,

transportation, wiring and inspection.)

(Potential risk unit malfunction, electric

shock or re. When the product needs

to be repaired, please contact in place

where you ordered.inspection.)

Do not pull out the power plug to turn o

the product.

Do not disassemble, repair or modify the

product.

Dealer

(You may get hurt and it can be broken

when it falls)

(Potential risk of re or unit malfunction)

(Potential risk of re or unit malfunction)

(Potential risk of discoloration or

electric shock)

Do not install the product in uneven or

inclined surface.

If the product that needs to be repaired,

please contact in place where you ordered.

Please do not give excessive shock.

Keep product away from the water and

other material.

5

4

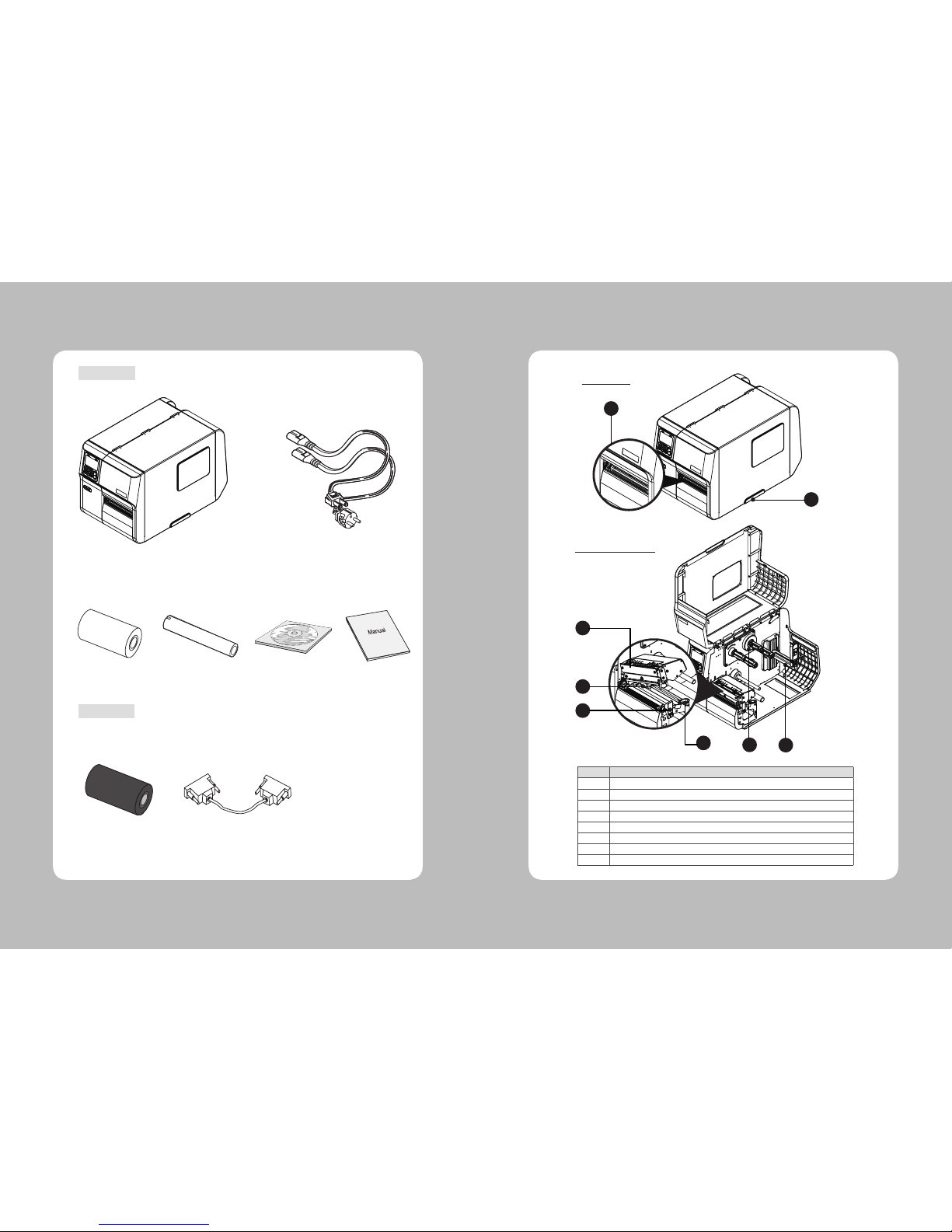

2. Unpacking

Printer

Power Cord(1EA)

Label

Ribbon

Ribbon Core

CD

(User’s Manual)

Quick Manual

3. Inspecting the printer

Interface cable

No.

Designation

1

Paper Exit

2

Door Handle

3

Head ASS’

4

Ribbon Spindle

5

Paper Holder

6

Paper Sensor

7

Print Head Release Lever

8

Paper width Guide

1

2

MAIN VIEW

COVER OPEN VIEW

Optional

Standard

8

7

6

3

4 5

7

6

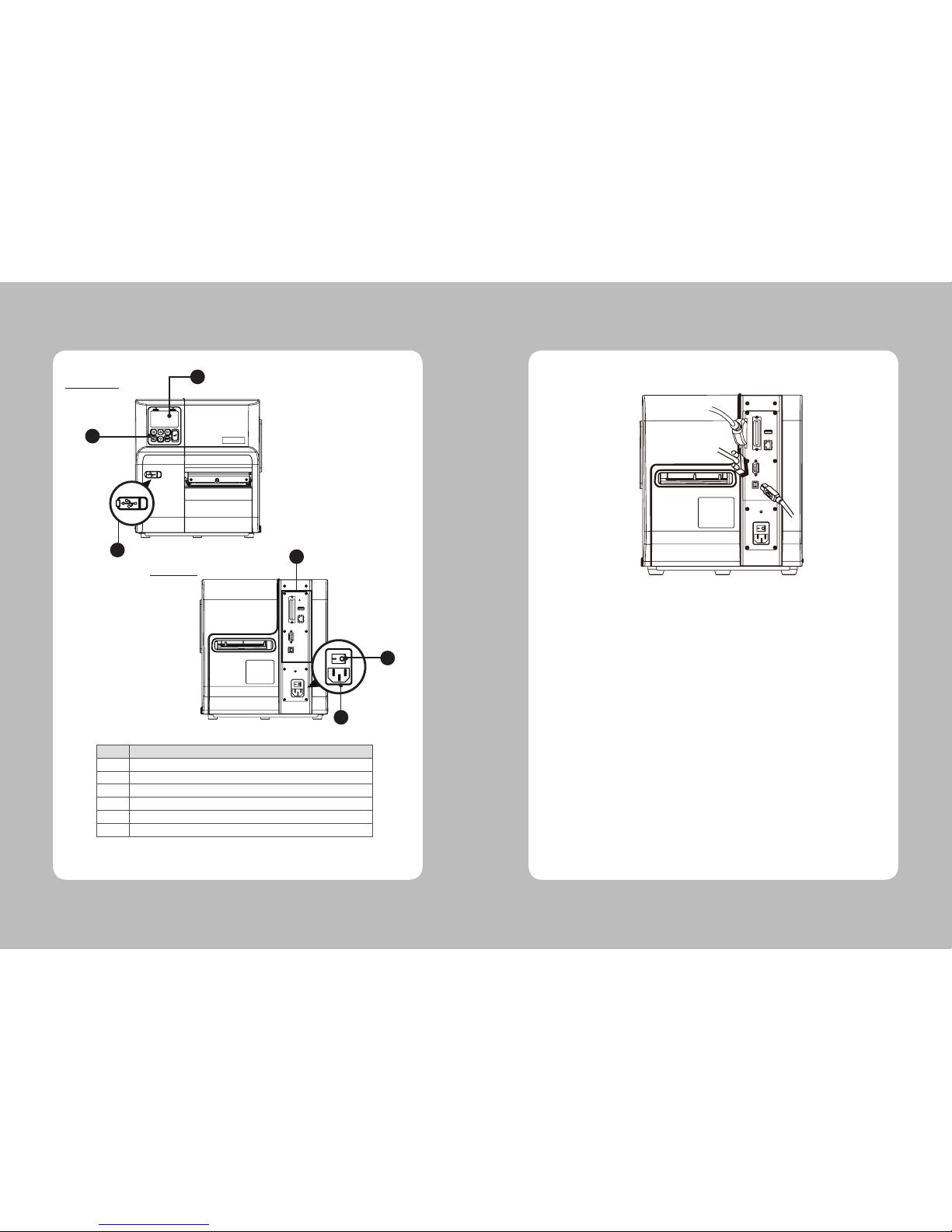

Make sure the printer is turned off then connect the printer to the PC

4. Hooking Up the printer and computer

USB

Serial

Parallel

-PRINTER REAR VIEW-

No.

Designation

9

Control Button

10

Display LCD

11

USB Host

12

Interface Connectors

13

Power Cord Connectors

14

Power Switch

9

10

11

12

FRONT VIEW

REAR VIEW

14

13

9

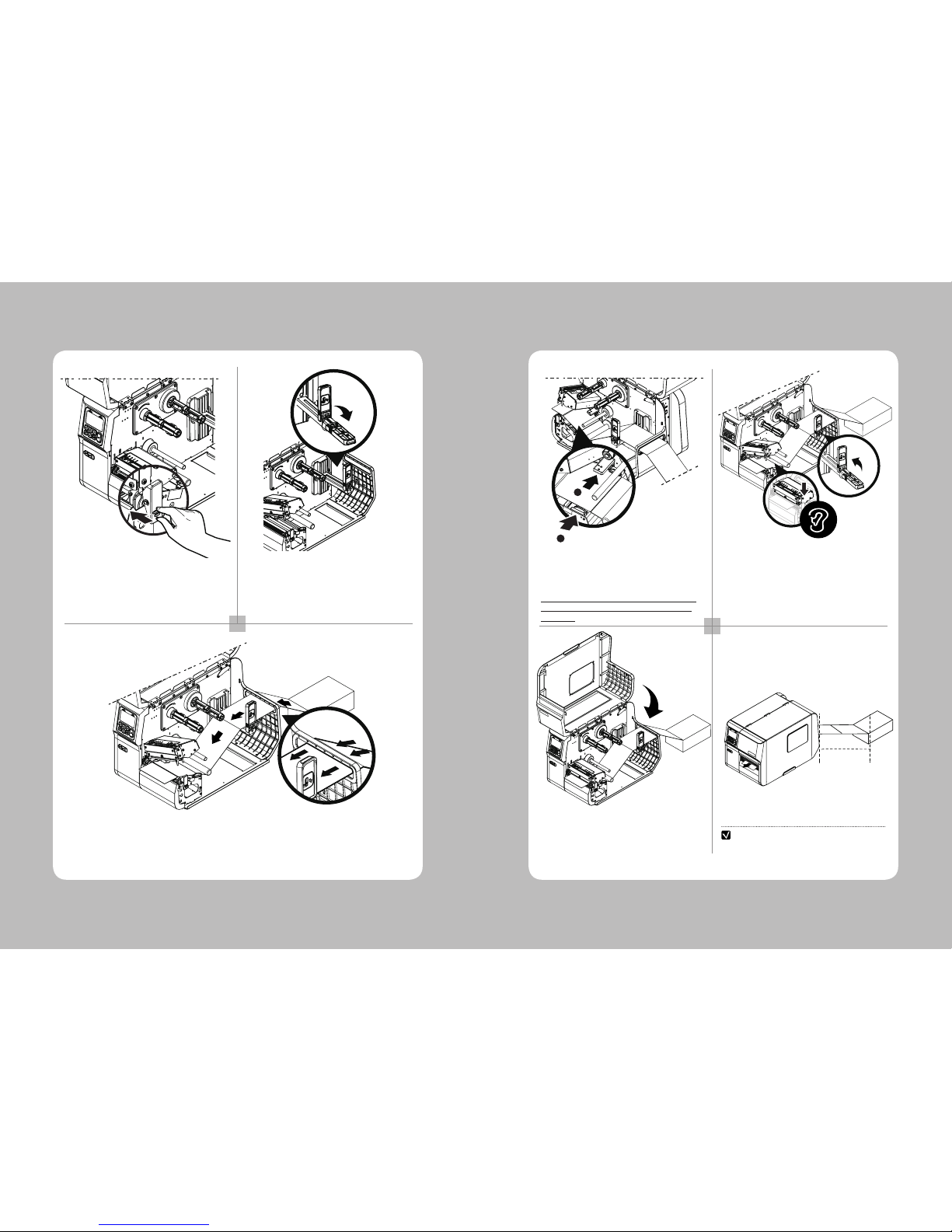

8

1 2

3

4

OPEN THE HEAD ASS’Y BY PUSHING THE LEVER.

PLACE THE ROLL OF PAPER ON THE PAPER

HOLDER.

5. Load Label Paper

FLIP DOWN THE PAPER HOLDER GUIDE.

5 6

2

7 8

LOWER THE PRINTER COVER TO THE DIRECTION

OF THE ARROW AS SHOWN IN THE PICTURE.

CLOSE THE PRINTER COVER TO THE END SLOWLY.

1

1. SLIDE THE PAPER UNDER THE PAPER SHAFT.

1. SLIDE THE PAPER INTO THE PAPER SENSOR.

2. ADJUST THE PAPER GUIDE PROPERLY TO FIT

THE PAPER WIDTH.

CAUTION: IF YOU ADJUST PAPER GUIDE NARROWER

THAN THE PAPER WIDTH, IT MAY CAUSE PRINTING

PROBLEMS

AFTER ADJUSTING THE PAPER GUIDE, FLIP UP

PAPER HOLDER GUIDE.

PULL THE PAPER TO THE HEAD ASS’Y AND

CLOSE THE HEAD ASS’Y.

(MAKE SURE TO CHECK THE CLOSING SOUND)

1

2

11

10

1 2

3

OPEN THE HEAD ASS’Y BY PUSHING THE LEVER.

6. Pen folder Paper

FLIP DOWN THE PAPER HOLDER GUIDE.

INSERT THE PAPER INTO THE PAPER ACCESS SLOT AT THE REAR OF THE

PRINTER. SLIDE THE PAPER UNDER THE PAPER SHAFT.

4 5

6 7

1. SLIDE THE PAPER THROUGH THE PAPER

SENSOR.

2. ADJUST THE PAPER GUIDE PROPERLY TO FIT

THE PAPER WIDTH.

CAUTION: IF YOU ADJUST PAPER GUIDE NARROWER

THAN THE PAPER WIDTH, IT MAY CAUSE PRINTING

PROBLEMS.

AFTER ADJUSTING THE PAPER GUIDE, PUT THE

PAPER HOLDER GUIDE UP. PULL THE PAPER TO THE

HEAD ASS’Y AND CLOSE THE HEAD ASS’Y.

(MAKE SURE TO CHECK THE CLOSING SOUND)

2

1

PLACE THE PAPER AT LEAST

THE DOUBLE OF THE PAPER

LENGTH(300MM) DISTANCE AWAY

FROM THE PRINTER.

NOTE

300mm

LOWER THE PRINTER COVER TO THE

DIRECTION OF THE ARROW AS SHOWN IN

THE PICTURE.

CLOSE THE PRINTER COVER TO THE END SLOWLY.

13

12

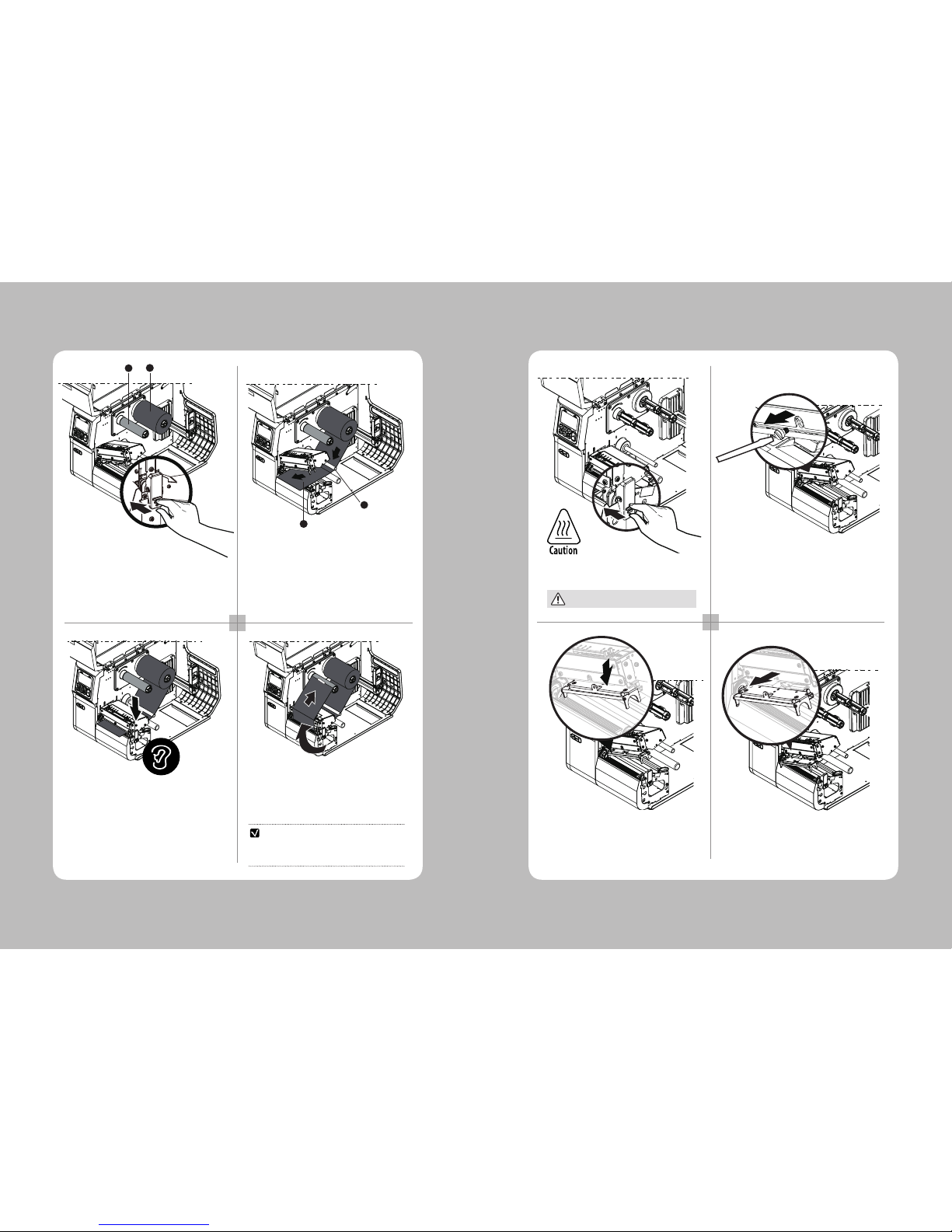

1 2

3

4

OPEN THE HEAD ASS’Y

BY PUSHING THE LEVER.

1. PLACE RIBBON CORE ON THE HOLDER(1)

2. PLACE THE RIBBON ON THE RIBBON SUPPLY

SPINDLE(2)

Ribbon

Guide Shaft

7. Load Ribbon

1 2

3

OPEN THE HEAD ASS’Y BY PUSHING THE

BUTTON.

The printhead may be hot

REMOVE HEAD SET SCREW(1) WITH (-) SCREW

DRIVER (YOU MAY USE A COIN).

8. Replace HEAD

PULL THE DETACHED HEAD ASS’Y(1) TO

THE HEAD ASS’Y.

DETACH HEAD ASS’Y TO THE DOWNWARD.

4

1

2

PRESS THE FEED BUTTON TO REMOVE RIBBON

WRINKLE

CHECK

1

2

1. SLIDE THE RIBBON UNDER THE RIBBON

GUIDE SHAFT.

2. PULL THE RIBBON TO THE FRONT OF THE

HEAD ASS’Y.

PRESS THE PUSH BUTTON ON TOP OF THE HEAD

ASS’Y AND LOWER THE HEAD ASS’Y UNTIL IT

LOCKS. MAKE SURE TO CHECK THE CLOSING

SOUND.

PLACE THE RIBBON AS SHOWN IN THE PICTURE

AND FIX ON THE RIBBON CORE BY TAPING.

15

14

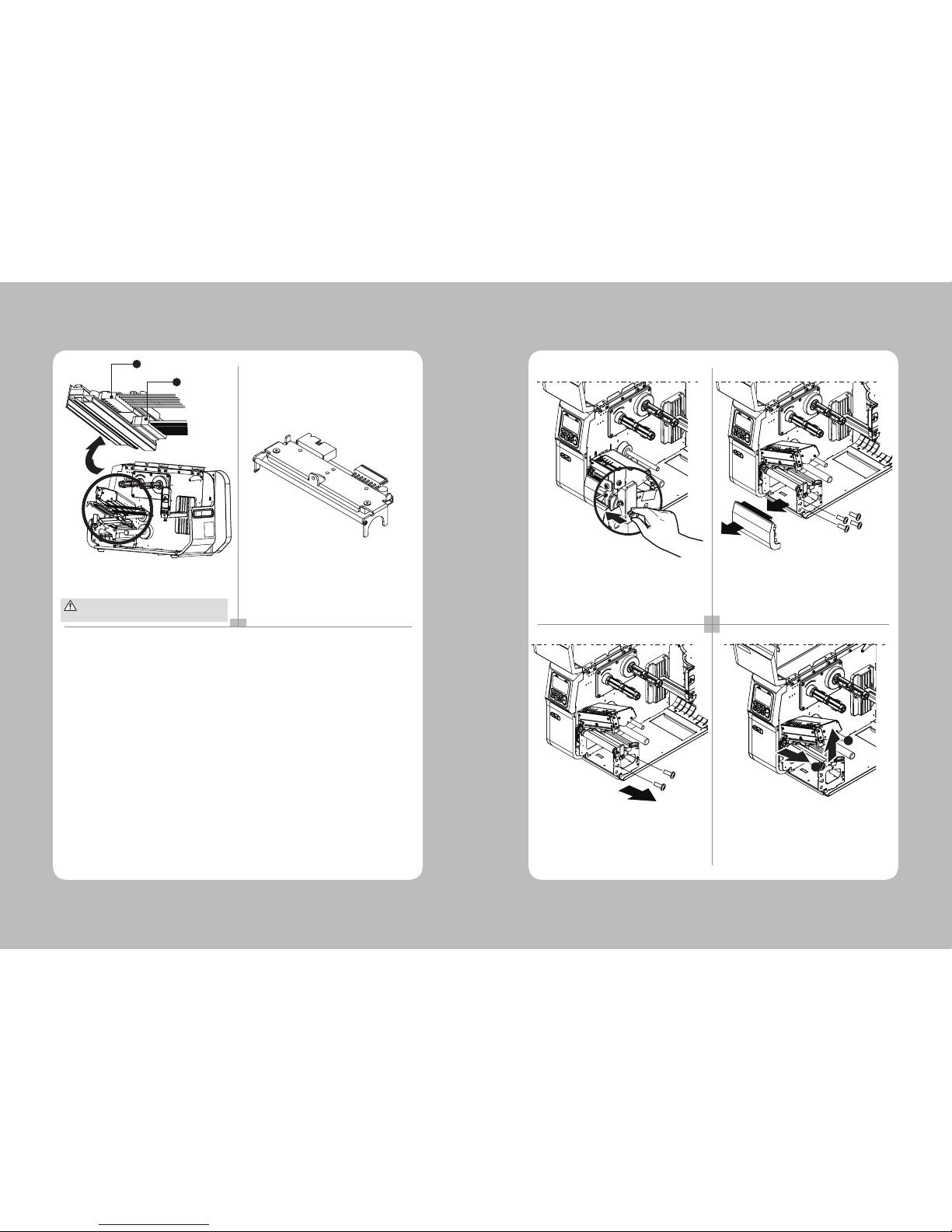

5 6

3

REMOVE POWER CABLE AND DATA CABLE.

DETACHED HEAD ASS’Y.

POWER CABLE

DATA CABLE

9. Replace Platen Roller

1 2

3

4

Take care not to allow the print head to become scratched and /or damaged in any way.

1

2

OPEN THE HEAD ASS’Y BY PUSHING THE LEVER. UNSCREW 4 SCREWS(2 INSIDE SCREWS,

2 OUTSIDE SCREWS) AND SEPARATE THE

COVER FRONT OUTPUT TRAY.

1. DETACH THE BEARING AND BUSH.

2. REMOVE THE PLATEN ASS’Y.

1

2

UNSCREW 2 SCREWS TO REMOVE THE HEAD

OPEN LEVER.

17

16

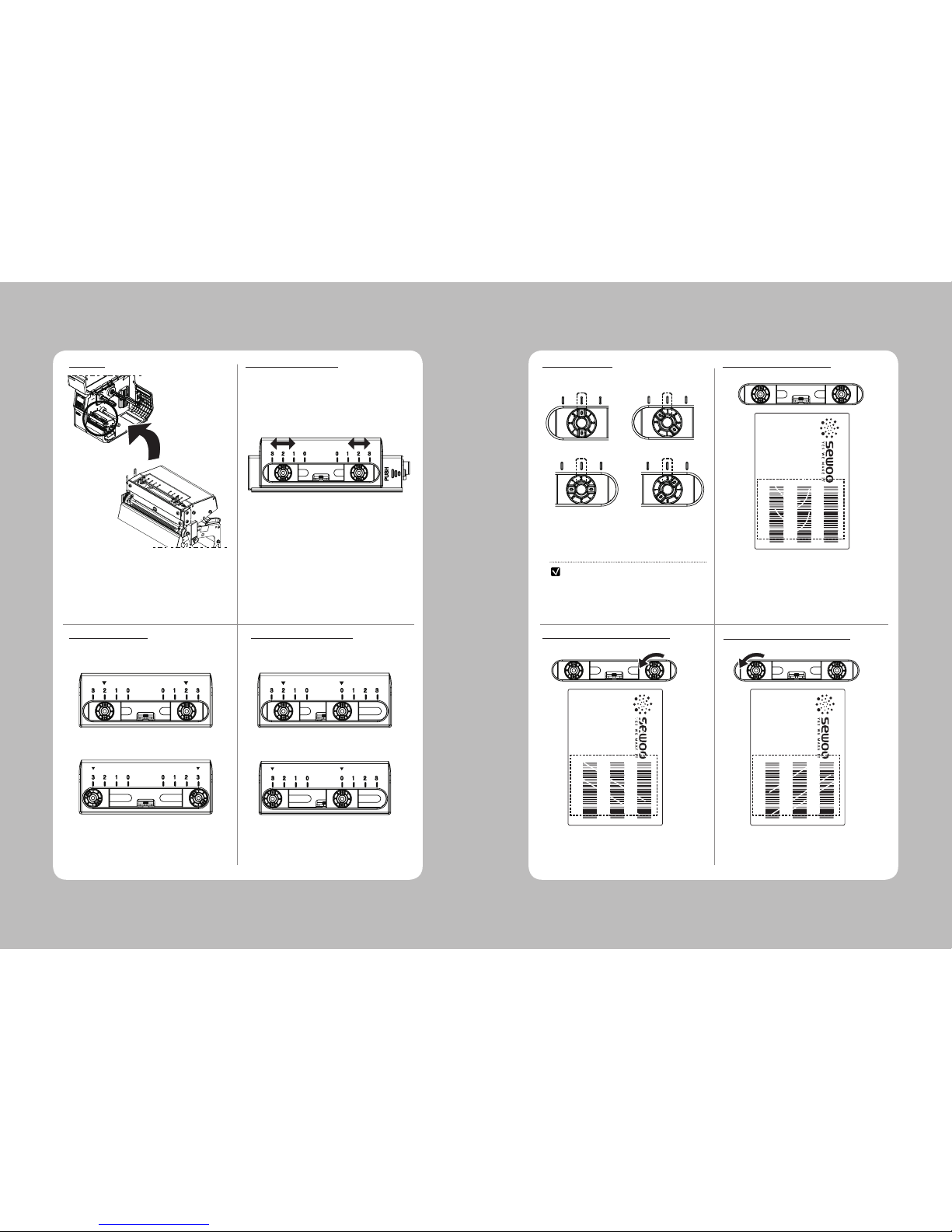

USE THE DIAL TO ADJUST A HEAD PRESSURE

FOR PAPER (0: LOW ~ 3: HIGH)

INCREASE THE RIGHT PRESSURE CONTROL

DIAL TO GET RID OF A DIAGONAL WRINKLE.

INCREASE THE LEFT PRESSURE CONTROL

DIAL TO GET RID OF A DIAGONAL WRINKLE.

LOWER THE PRINTING DENSITY LEVEL TO

GET RID OF A CRESCENT-SHAPED WRINKLE.

THE PRESSURE CONTROL CAN BE MOVED

DEPENDS ON PAPERS AND /OR SIZE.

10. Control HEAD Pressure

LOCATION

MOVE PRESSURE CONTROL

CONTROL PRESSURE CONTROL WRINKLE (CRESCENT)

CONTROL WRINKLE (DIAGONAL LINE)

CONTROL WRINKLE (DIAGONAL LINE)

THE PRESSURE CONTROL CAN BE POSITIONED

TO ACHIEVE THE BEST PRINT QUALITY.

(2-2, 3-3)

THE PRESSURE CONTROL CAN BE POSITIONED

TO ACHIEVE THE BEST PRINT QUALITY.

(2-0, 3-0)

FOR THE 4 INCH PAPER FOR LESS THAN 3 INCH PAPER

- THE LEVER IN CIRCLE IS THE HEAD PRESSURE

ADJUSTER.

- YOU CAN ADJUST THE PRINTING BALANCE BY

CONTROLLING THE HEAD PRESSURE AND

CHANGING THE POSITION OF THE HEAD

PRESSURE CONTROLLER.

NOTE

ROTATE THE DIAL CONTINUOUSLY TO GO

BACK TO ‘0’

(2-0)

(3-3)

(2-2)

(3-0)

MODEL: B40

LABEL PRINTER TEST

BARCODE : CODE39

Q’TY: 3PCS

SD820462

SD820462

SD820462

MODEL: B40

LABEL PRINTER TEST

BARCODE : CODE39

Q’TY: 3PCS

SD820462

SD820462

SD820462

MODEL: B40

LABEL PRINTER TEST

BARCODE : CODE39

Q’TY: 3PCS

SD820462

SD820462

SD820462

(0)

(2)

(1)

(3)

Loading...

Loading...