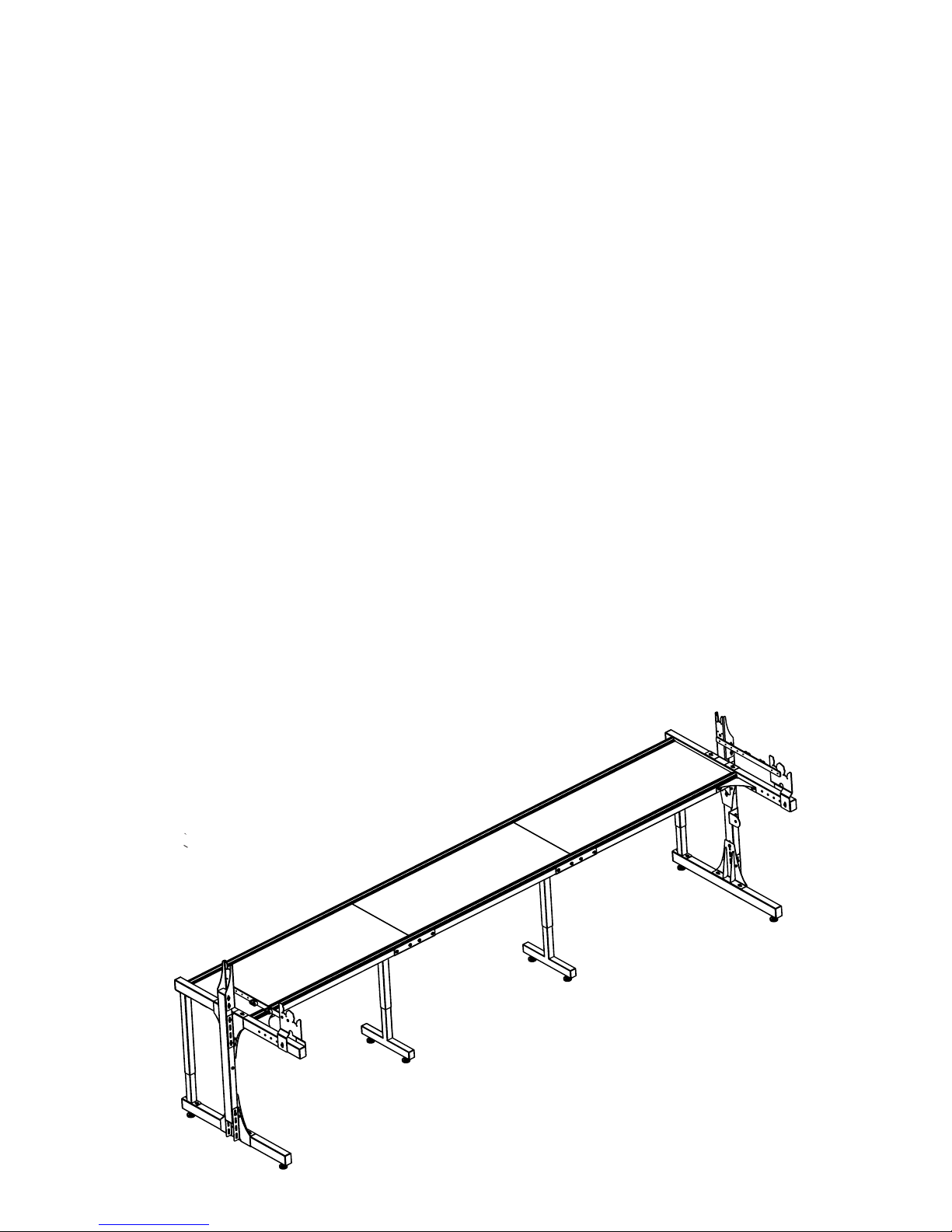

SewingMachinesPlus QF00007-12, QF00007-10 Assembly Instructions Manual

King Quilter Frame

#QF00007-12 and QF00007-10

Assembly Instructions

Table of Contents

Parts List ..........................................page 2

Preparation: Batting Bar Bracket Assembly, Do this First! ....page 7

Step 1: End Leg Assembly ..............................page 8

Step 2: Table Assembly ...............................page 14

Step 3: Center Leg Assembly ...........................page 15

Step 4: End Leg to Table Assembly ......................page 17

Step 5: Precision-Glide Track Assembly .................. page 22

Step 6: Front Pole Carrier / Rear Pole Carrier Arm Assembly . page 25

Step 7: Bungee Cleat Assembly .........................page 26

Step 8: Leveling the Frame .............................page 27

Step 9: Pole Assembly ................................page 28

Step 10: Adding Pole Ends .............................page 29

Step 11: Pole to Frame Assembly ....................... page 31

Step 12: Rubber End Cap Assembly ......................page 32

Step 13: Bungee Clamp Assembly .......................page 33

Step 14: Hook and Loop Strips on Poles Assembly ..........page 34

Step 15: Attach Leaders ..............................page 35

NOVEMBER 2018

King Quilter Frame Assembly 1

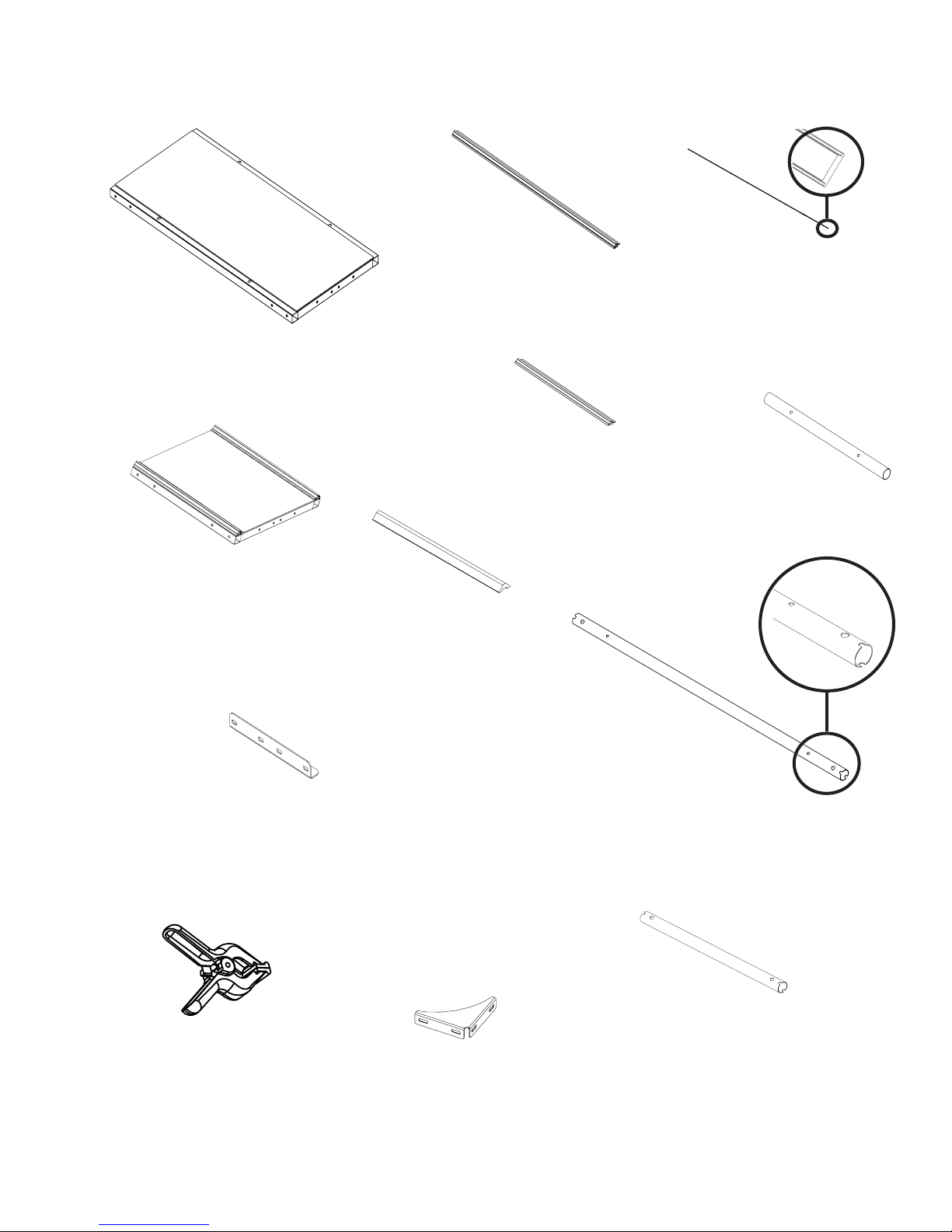

SMP QF00007-12 and QF00007-10 Frame Parts List

12-foot Black Plastic Track (4)

4 Foot Track Support Section

(6) For 12’ frame, (4) for 10’ frame

Part# QF09318-04

Four Foot Table Section

(3) For 12’ frame,

(2) for 10’ Frame

Part# QF00007-301

BOX 1 & 4

Two Foot Table Section (1) with

10’ Frame Only

Part# QF00007-302

BOX 4

Part# QF09318-02

BOX 1 & 4

(2) For 10’ frame only, (0) come with 12’ Frame

2 Foot Track Support Section

Part# QF09318-02

BOX 4

Track Support Coupler (4)

Part# QF09318-03

BOX 3

Fifteen come with 12’ frame and ten come with

BOX 3

2-Foot Coupler (10)

Part# QF09318-702

BOX 2

Table Splice Brace (4)

Part# QF09318-05

BOX3

Bungee Clamp (4)

Part# QF09318-110

BOX 3

Leaders - No Image

11’ Leaders for 12’ Frame (1)

9.5’ Leaders for 10’ Frame (1)

Part# QF09580

Part# QF09851

or

BOX 4

Front Gusset Bracket (2)

Part# QF00007-413

BOX 3

4-foot Pole Section

10’ frame.

Part# QF0007-701

BOX 2 & 4

Five come with 10’ frame only,

2-foot Pole Section

None come with 12’ frame

Part# QF0007-703

BOX 4

2 King Quilter Frame Assembly

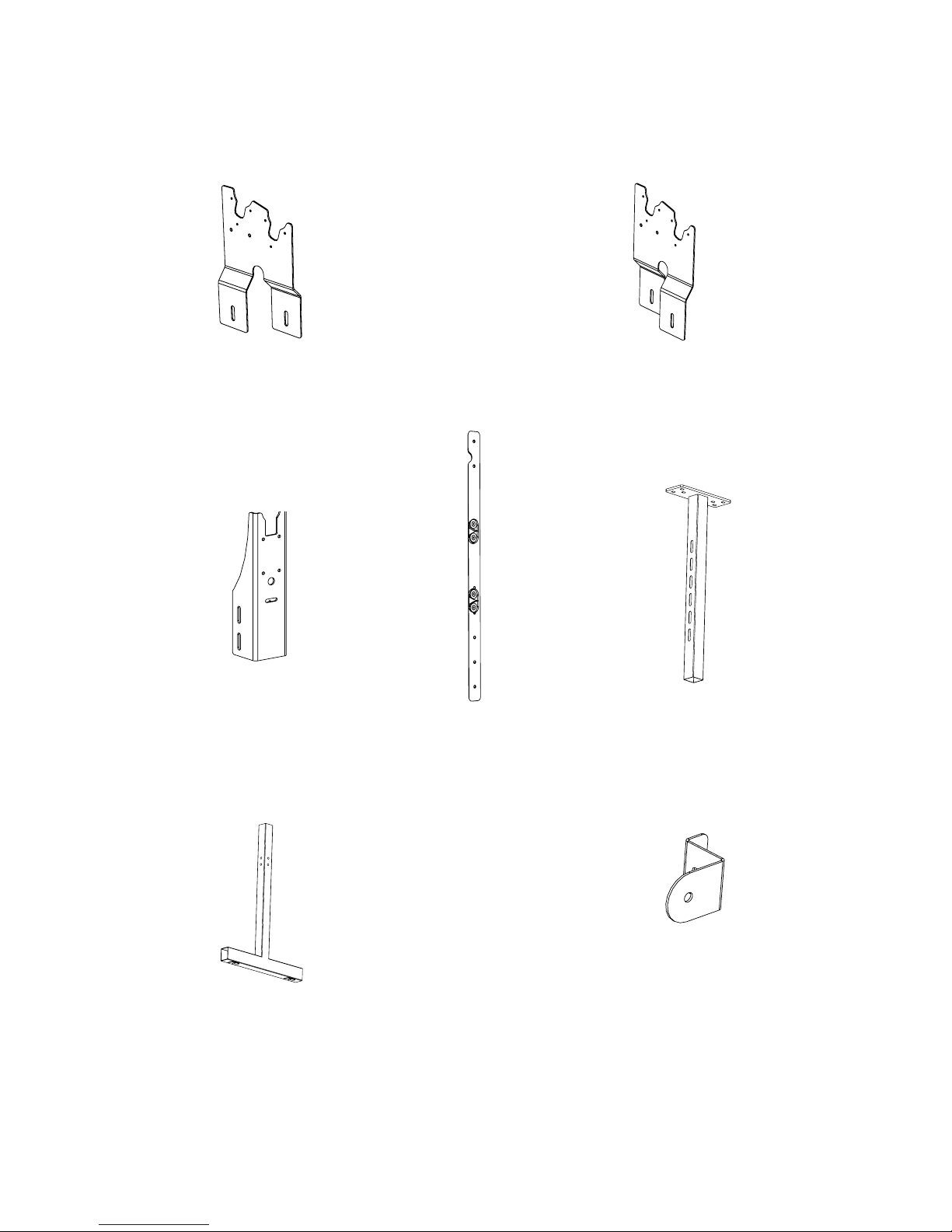

SMP QF00007-12 and QF00007-10 Frame Parts List

Inside Left

Upper Beam Left Hand Side Leg (1)

QF00007-503

BOX 1

Inside Right

Upper Beam Right Hand Side Leg (1)

QF00007-403

BOX 1

Lower Beam (Both Sides) (2)

QF00007-401

BOX 1

Inside Left Inside Right

Rear Leg Upper Left (1)

QF00007-508

BOX 3

Rear Leg Upper Right (1)

QF00007-408

BOX 3

Upright Beam Both Sides (2)

QF00007-402

BOX 1

Rear Leg Lower (Both Sides) (2)

QF00007-409

BOX 3

King Quilter Frame Assembly 3

SMP QF00007-12 and QF00007-10 Frame Parts List

Lower Gusset Bracket (1 per side=2 total)

QF00007-406

BOX 3

Outer Side Bracket Left (2 per side= 4 total)

QF00007-405

BOX 3

Upper Gusset Bracket (1 per side=2 total)

QF00007-407

BOX 3

Outer Side Bracket Right (2 per side=4 total)

QF00007-404

BOX 3

Pole Cradle (3)

QF11038

BOX 3

4 King Quilter Frame Assembly

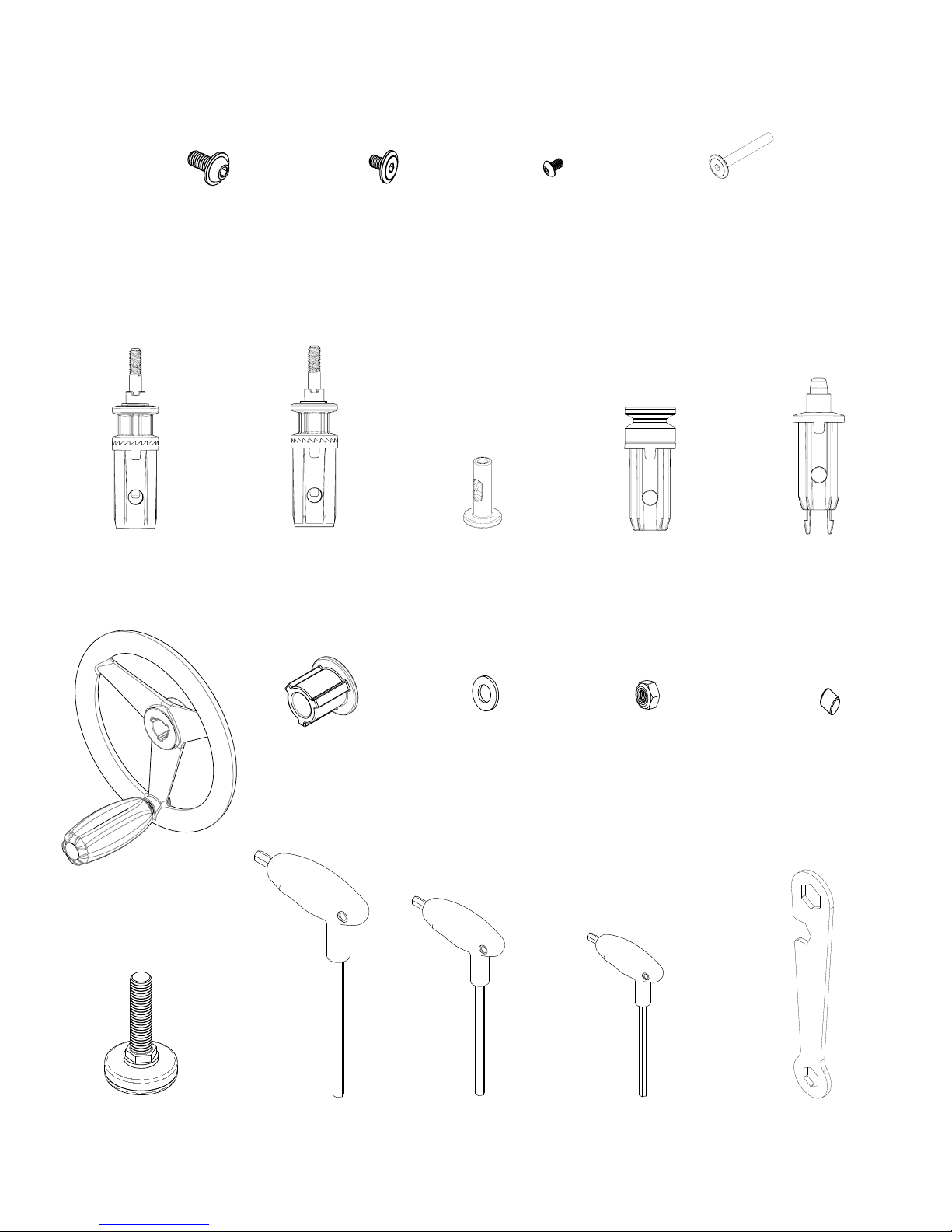

Screw, M4x18SKC ZN (9)

QF10870

BOX 3

Washer, M4x10 Flat ZN (9)

QF00007-417

BOX 3

SMP QF00007-12 and QF00007-10 Frame Parts List

Front Left Pole Carrier (1)

QF00007-511

BOX 3

Rear Pole Carrier Arm (2)

QF00007-410

BOX 3

Bungee Cleat Bar (2)

QF00007-412

BOX 3

Front Right Pole Carrier (1)

QF00007-411

BOX 3

Upper Middle Leg

(2) for 12’ frame, (1) for 10’ frame

QF005300-602

BOX 3

Lower Middle Leg

(2) for 12’ frame, (1) for 10’ frame

QF05300-601

BOX 3

Batting Bar Bracket (2)

QF00007-414

BOX 3

King Quilter Frame Assembly 5

SMP QF00007-12 and QF00007-10 Frame Parts List

SHORT BOLT RATCHET WHEEL

QF09318-730

QF09318-730

LONG BOLT RATCHET WHEEL

QF09318-730

LONG BOLT RATCHET WHEEL

RATCHET STOP HOLDER

QF09318-205

Fig. 10-2

QF09318-105

BUNGEE HOLDER SPACER

QF09318-103

RATCHET STOP

QF09318-203

RATCHET STOP HOLDER

QF09318-205

CONNECTOR BOLT

QF09318-204

RAIL BEARING SNAP

QF09318-105

RAIL BEARING SNAP COVER

QF09318-106

Fig. 10-2

QF09318-105

Screw M8 x 1.25 x 16 SBHCS (98)

Part# QF09318-07

BOX 3

Ratchet Left Hand (1)

Part# QF11035

BOX 3

Large washer head

screw M6 x 12mm

(26 total)

Part# QF09318-303

BOX 3

Ratchet Right Hand (2)

Part# QF11034

BOX 3

Button Head Cap

Screw M5 x 8mm

(SBHCS) (24 total)

Part# QF09318-304

BOX 3

Ratchet Thumb Shifter

(3)

Part# QF11023

BOX 3

Large washer head

screw M6 x 50mm

(SBHCS) (4 total)

Part# QF00007-200

BOX 3

Ratchet Idler End Cap (3)

Part# QF11036

BOX 3

Spg Lded Idler End Cap (4)

Part# QF11037

BOX 3

Hand Wheel Insert (1)

May be pre-assembled

with Hand Wheel.

Part# QF09318-713

BOX 3

Hand Wheel Assembly (1)

Part# QF09325

BOX 3

Leveling Foot (8)

Part# QF09318-108

BOX 3

6 King Quilter Frame Assembly

5mm Allen Wrench (1)

Part# QF09318-113

BOX 3

M8 Flat Washer (1)

Part# QF09318-702

BOX 3

4mm Allen Wrench (1)

Part# QF09318-112

BOX 3

M8 Lock Nut (1)

Part# QF09318-08

3mm Allen Wrench (1)

Part# QF09318-111

BOX 3

BOX 3

Rubber End Cap (2)

Part# QF09318-716

BOX 3

17/13/16mm Wrench (1)

Part# QF09318-114

BOX 3

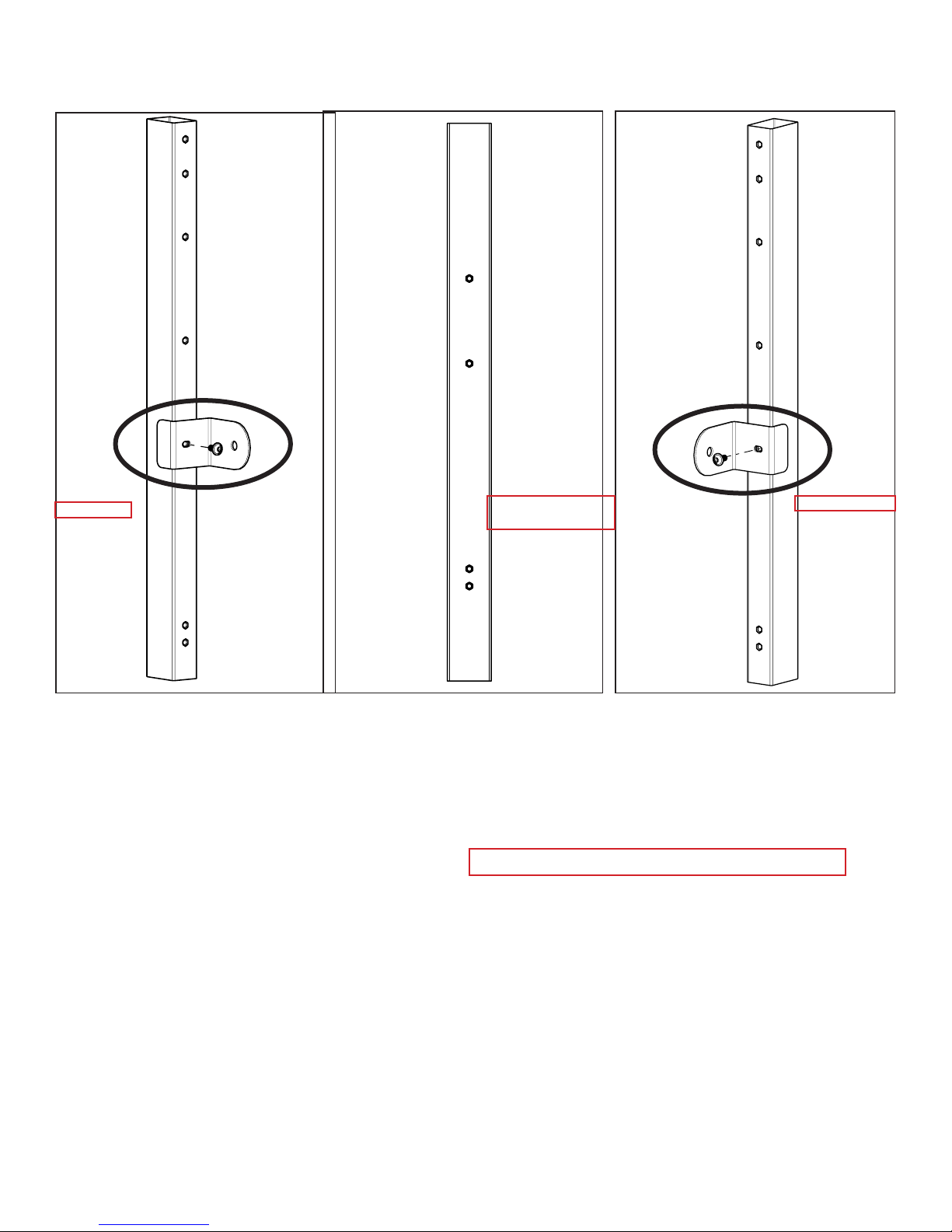

Preparation: Batting Bar Brackets

left side

Parts Needed

2 - upright beams

2 - batting bar brackets

2 - screws, M8 x 16mm SBHCS

Tools Required

5mm Allen wrench (provided)

Prep-1: Insert an M8 x 16mm SBCHS

into the batting bar bracket on the left

side of the frame.

right sideinside view of

upright beam

Do this Preparation rst!

Prep-2: Slide the bracket towards the

center of the frame until it touches the

leg and there is no gap. Fully tighten

the screw with the M5 Allen tool

provided.

Prep-3: Repeat the process for the

batting bar bracket on the right side of

the frame.

King Quilter Frame Assembly 7

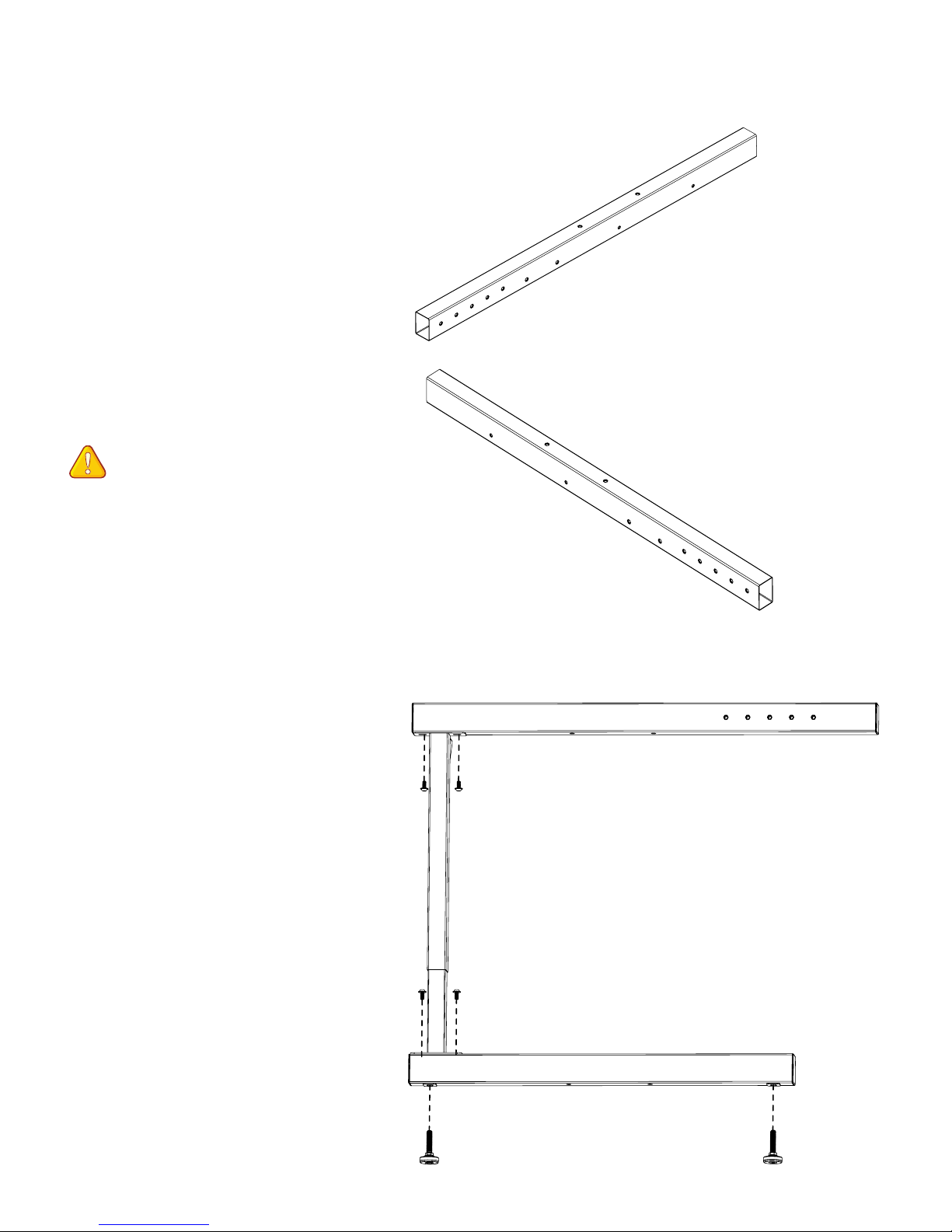

Step 1: End Leg Assembly

NOTE: Assembly is easiest if all

connections are nger-tightened rst,

as instructed, while assembling the

frame. Tighten with the wrench only

when instructed.

Why is this important? If you tighten

as you go, you may have trouble

getting all the parts to align properly.

NOTE: Protect your frame

and work surface. To avoid any

damage to your frame parts and

work surface, place a protective

material on the oor or work surface

to prevent scratches and other

damage

Parts Needed

1 - left rear leg upper

1 - right rear leg upper

2 - rear leg lower

2 - lower leg beam

1 - upper beam left hand side leg

1 - upper beam right hand side leg

2 - upright leg beam

4 - outer side bracket right

4 - outer side bracket left

2 - lower gusset bracket

2 - upper gusset bracket

4 - leveling feet

58 - screw M8 x 16mm SBHCS

8 - screw M6x12 SH ange

Tools Required

5mm Allen wrench (provided)

4mm Allen wrench (provided)

17/13/16 wrench (provided)

NOTE: Height Adjustment

Be aware that there are two rivnuts

inside the leg to facilitate continuous

graduated table top height

adjustment from approximately 28”

to 34”; set both center legs using the

same height rivnut to avoid leveling

problems later on.

Left Rear Leg Upper

The lower leg is

xed to upper leg

with one M8 X 16

SBHCS per leg

1-1: Determine how high you want your table

top. One way to estimate the desired height is to

measure the distance from your elbow to the oor

with your arms bent at the elbow at 90 degrees

and hands in front of you. Next subtract 16 to 18

inches. This will give you the approximate table

top height for comfortable quilting, depending if

you like your table a little higher or a little lower.

The machine’s needle plate is about six inches

higher than the table top. The handlebars will be

approximately six to nine inches higher than the

needle plate. Most are comfortable with their arms

bent at 90 degrees and forearms horizontal, parallel

to the oor when free-motion quilting.

Note: To determine the approximate table

top height: Add ve inches to the height of the

leg assembly to compensate for the bottom tube

height, the leveling foot height and the table top

tube height. The frame will be leveled later on,

which may alter the height slightly.

Right Rear Leg Upper

Rear Leg Lower

8 King Quilter Frame Assembly

Step 1: End Leg Assembly (continued)

1-2: Slide the left rear leg upper down

over the rear leg lower to the desired

height and insert the M8x16 screw

into one of the two holes that best

corresponds to your desired height.

Fully tighten this height screw now to

maintain the desired height.

1-3: Identify the top beam for the

left and right side legs, which have

different inside rivnut hole locations.

The side with the most rivnuts goes to

the inside of the frame.

NOTE: When a screw goes into a

slotted/elongated hole the normal rule

is for the slotted hole to be centered

on the screw if possible.

Inside view of upper beam

right hand side leg

Inside view of upper beam

left hand side leg

1-4: Place the left upper beam above

the vertical rear leg assembly and the

lower leg beam below and insert the

four M8x16 SBHCS screws. Align the

back edge of the bracket with the end

of the upper beam and lower beams.

Finger tighten the screws only for now.

1-5: Thread the levelers into the

bottom of the lower beam about half

way. This will facilitate leveling the

frame later. Use the 17/13/16 wrench

if needed to adjust the levelers.

Outside view of

left hand leg assembly

King Quilter Frame Assembly 9

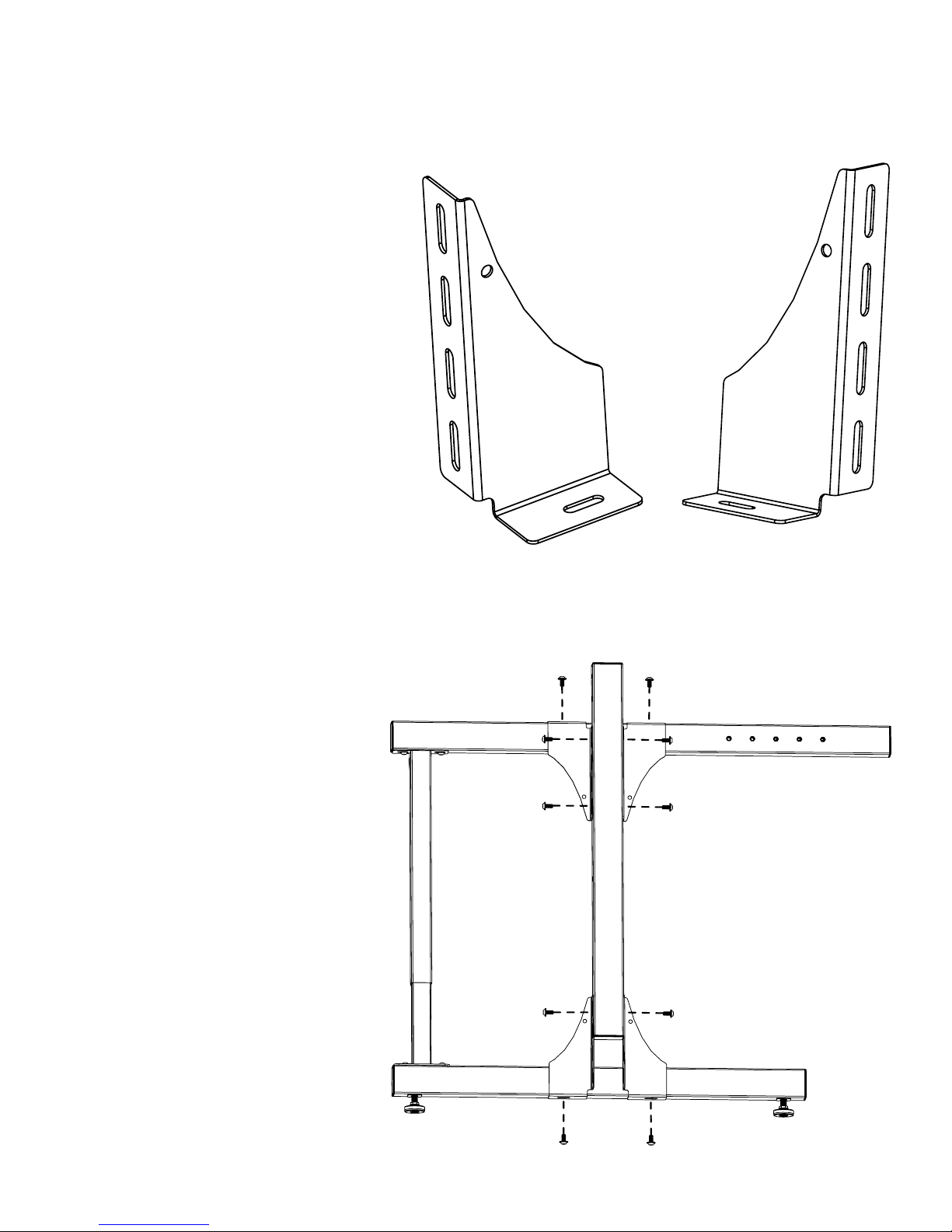

Step 1: End Leg Assembly (continued)

1-6: Identify the outer side bracket

right and outer side bracket left.

Two of each bracket are used on the

outside of the leg assembly. On the left

leg assembly the left bracket is used

on the top right and bottom left and

the right bracket is used on the top left

and bottom right.

1-7: Place the brackets into place

and align three M8 x16 SBHCS screws

into each of the top brackets and

two screws into each of the bottom

brackets.

Outer side bracket left Outer side bracket right

10 King Quilter Frame Assembly

Step 1: End Leg Assembly (continued)

1-8: A left and right bracket are used

on the top with three screws in each.

Finger tighten the screws only for now.

1-9: A left and right bracket are used

on the bottom with two screws in

each. Finger tighten the screws only

for now.

Note:

Upright beam

shown in its

highest position.

The frame height

is adjusted at

these lower

brackets with

three screws.

King Quilter Frame Assembly 11

Loading...

Loading...