Sewha SI 4200 Instruction Manual

Digital Weighing Controller

SI 4200

Instruction Manual

Ver. 3.15 May 2011

Digital Weighing Indicator

- 2 -

1. Before Installation

---------------

3 page

2. Introduction

---------------

4 page

3. Specification

---------------

5 page

4. Installation

4-1. External Dimension & Cutting Size

4-2. Load Cell Installation

4-3. Installation Components

---------------

---------------

---------------

---------------

11 page

11 page

11 page

12 page

5. Set-up

5-1. Calibration

5-2. TEST Weight Calibration Mode

5-3. Simulation Calibration Mode(Without Test Weight)

5-4 Unit Calibration Mode

5-5. F-Function Setting

5-6. F-Function List

---------------

---------------

---------------

---------------

---------------

---------------

---------------

14 page

14 page

14 page

17 page

20 page

22 page

23 page

6. Interface

6-1. Serial Interface (RS-232C)

6-2. Current Loop Interface

6-3. Print Interface (Option 01 : Centronics Parallel Interface)

6-4. Analog Output Interface (Option 02 : 0~10V)

6-5. Analog Output Interface (Option 03 : 4~20mA)

6-6. Serial Interface (Option 04 : RS-232C / 422 / 485)

6-7. BCD INPUT (Option 05)

6-8. BCD OUTPUT (Option 06)

6-9. Command Mode

---------------

---------------

---------------

---------------

---------------

---------------

---------------

---------------

---------------

---------------

35 page

35 page

39 page

40 page

42 page

43 page

44 page

45 page

46 page

47 page

7. Error & Treatment

7-1. Load Cell Installation

7-2. Calibration Process

7-3. Indicator Error & Treatment

7-4. Indicator Test Mode

---------------

---------------

---------------

---------------

---------------

49 page

49 page

49 page

50 page

51 page

Warrantee Certification

---------------

52 page

SI 4200

CONTENTS

- 3 -

This mark warns the possibility to arrive death or serious injury in

case of wrongly used.

This mark cautions the possibility to arrive serious human body

injury or product lose in case of wrongly used.

Warning for Electric Shock or Damage.

Please do not touch by hand

Protective Ground(Earth) terminal

Prohibition of Operation process

Warning

Caution

1. BEFORE INSTALLATION

1-1. Caution / Warning Marks

1-2. Other Marks

Digital Weighing Indicator

SI 4200

1-3. Copy Rights

1).All Right and Authority for this Manual is belonged to Sewhacnm Co.,Ltd.

2).Any kinds of copy or distribution without Sewhacnm Co.,Ltd’s permission will be prohibited.

1-4. Inquiries

If you have any kinds of inquiries for this model, please contact with your local agent or Head Office.

Head Office : Sewhacnm Co.,Ltd.

Website : http://www.sewhacnm.co.kr

Email : info@sewhacnm.co.kr , sales@sewhacnm.co.kr

Digital Weighing Indicator

- 4 -

2. INTRODUCTION

2-1. Introduction

Thank you for purchasing, this “SI 4200” Industrial Digital Weighing Controller.

This “SI 4200” model is advanced model for “Quantity Control application”, with 2ports serial port

interfaces and precise weighing control system, you can upgrade your weighing process.

This “SI 4200” Weighing Controller is suitable for any kinds of Weight Capacity with Counting by “Unit

Weight Calibration”.

Enjoy your process with “SI 4200” Weighing Controller.

2-2. Cautions

1) Don’t drop on the ground or avoid serious external damage on item.

2) Don’t install under sunshine or heavy vibrated condition.

SI 4200

3) Don’t install place where high voltage or heavy electric noise condition.

4) When you connect with other devices, please turn off the power of item.

5) Avoid from water damage.

6) For the improvement of function or performance, we can change item specification without prior notice

or permission.

7) Item’s performance will be up-dated continuously base on previous version’s performance.

2-3. Features

1) All Modules and Option Cards are isolated to maximize accuracy and performance.

2) External input terminal inside.(4pcs:Can be set by F11 mode)

3) By using “Photo-Coupler” on each module(Option, Analog board, In/Out), we improved “Impedance

problem”, “Isolation ability among inputs”, “Leading power problem”, and “Noise covering function”.

4) Data back-up function, when the sudden power off.

5) “Set value Error” check function added. – Check “Set values for each weighing mode”.

- If there is any wrong set value, “E” will be display and will not start weighing process

6) Polycarbonate film panel, strong for dust and water.

7) Weight Unit selection Function added. (“g”, “kg”, “t” selectable – F40)

8) Variable options(Order in advance, Refer Chapter 6. Interface) – “RS-232C” Standard installed.

9)2port Serial Interface available – various applications are available.

10) Simulation Calibrate mode added (Can calibrate without Test weight)

- 5 -

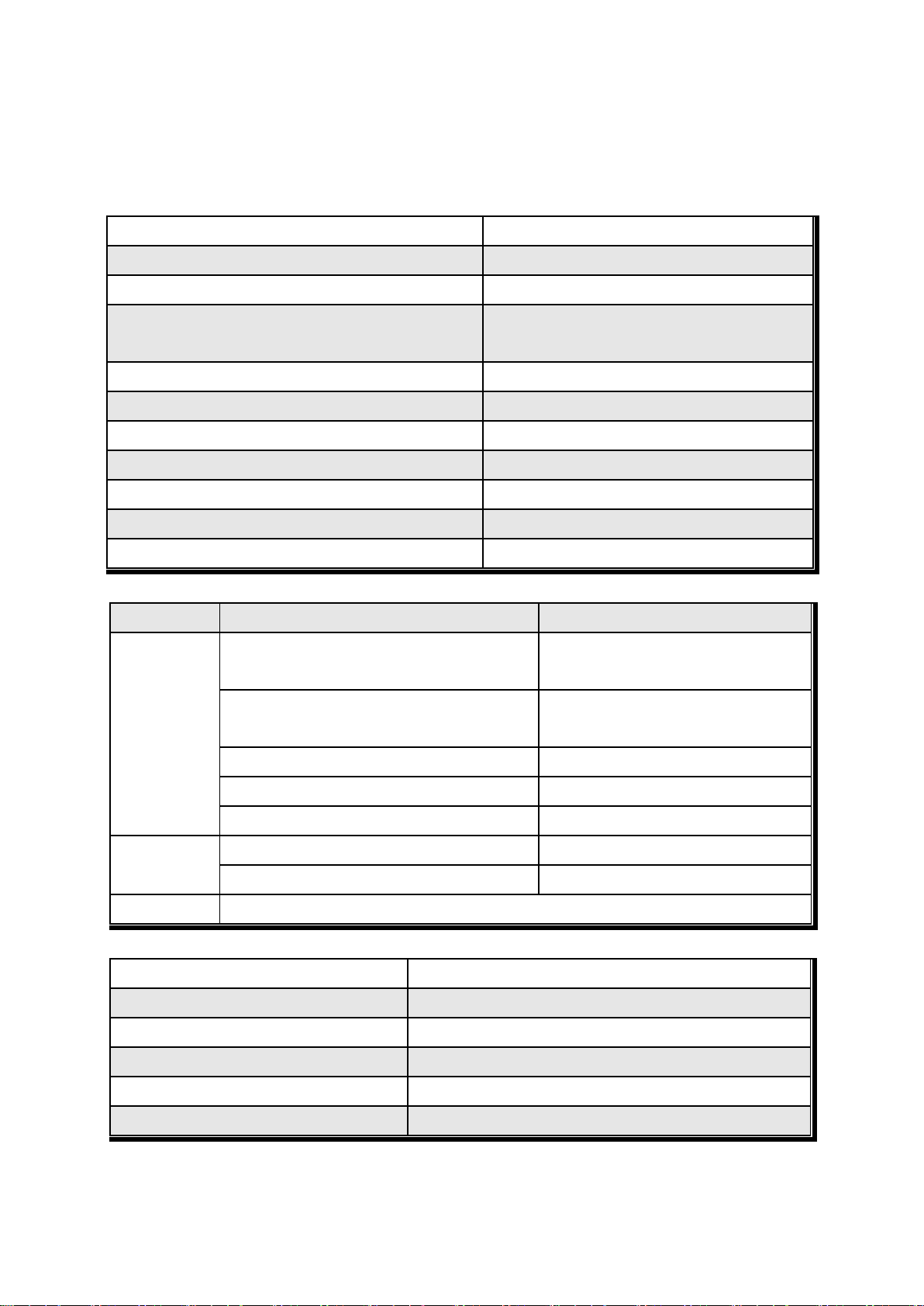

Input Sensitivity

0.2㎶ / Digit

Load Cell Excitation

DC 10V ( - 5V ~ + 5V )

Max. Input Signal

Max.3.2mV/V

Temperature Coefficient

[Zero] ±16PPM/℃

[Span] ±3.5PPM/℃

Input Noise

±0.3㎶ P.P

Input Impedance

Over 10㏁

A/D Conversion Method

Sigma-Delta

A/D Resolution(Internal)

520,000 Count(19bit)

A/D Sampling Rate

Max. 500times / Sec

Non-Linearity

0.005% FS

Display Resolution(External)

1/20,000

Display

Parts

Specification

Display

Main Display

7Segments, 7digits VFD green Color

Size :12.7(H) ×7.0(W)mm

Sub-Display

7Segments, 6digits FND, Red Color

Size : 9.2(H) ×4.8(W)mm × 3lines

Min. Division

×1, ×2, ×5, ×10, ×20, ×50

Max. display value

+999,950

Under Zero value

"-" (Minus display)

Status lamp

Steady, Zero, Tare, RUN, LIMIT, Print, Comm.

" ▼" Condition display Lamp

kg, g, t / SP1, SP2

Red / Yellow-Green LED Display(3Ø )

K e y

Number Key, Function, CAL. Lock key (14pcs)

Power Supply

AC110/220V(±10%), 50/60Hz, about 30VA

Operating Temperature Range

-10℃ ~ 40℃

Operating Humidity Range

Under 85% Rh (non-condensing)

External Dimension

200mm(W)x105mm(H)x165mm(L)

Net Weight(kg)

About 2.3kg

Gross Weight(kg)

About 3.0kg

3. SPECIFICATION

3-1. Analog Input & A/D Conversion

Digital Weighing Indicator

SI 4200

3-2. Digital Part

3-3. General Specification

※ AC 110V, Power supply is an optional before ex-factory.

- 6 -

Option No.1

Printer Interface : Centronics Parallel

Option No.2

Analog Output (0~10V or 0~5V)

Option No.3

Analog Output (4~20mA)

Option No.4

Serial Interface : RS-232C / 422 / 485

Option No.5

BCD INPUT (P/N change purpose)

Option No.6

BCD Output

Option No.7

Ethernet

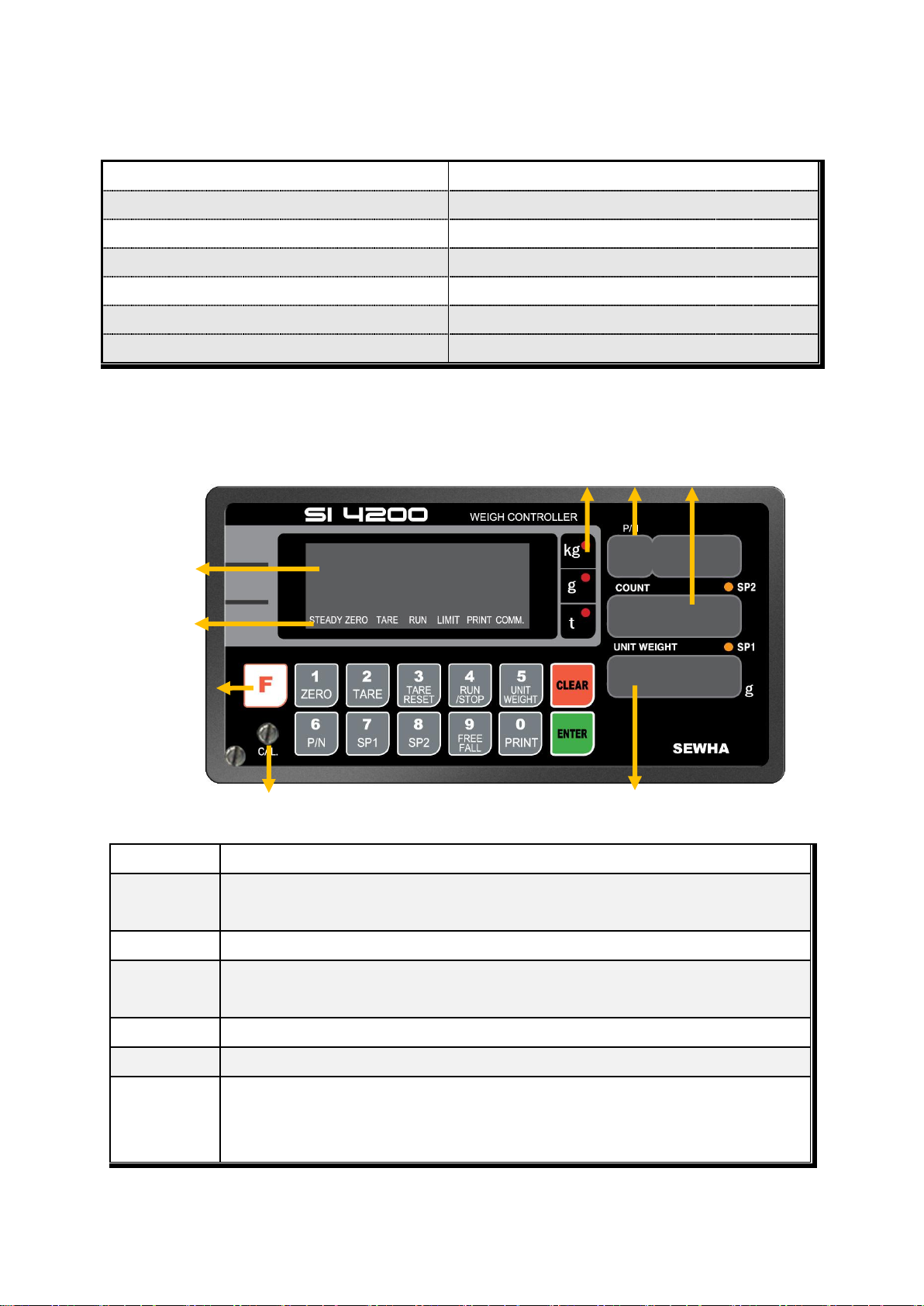

Steady

When the weight is Steady, “▼” Lamp is turn on.

Zero

When the current weight is Zero, “▼” Lamp is turn on.

(Displayed weight is Zero, “▼” Lamp is turn on.)

Tare

Tare function is set, “▼” Lamp is turn on. (Tare Reset “▼” Lamp is turn off.)

RUN

Under Packer Mode(F21-02) setting.

Start Packer Mode “▼” Lamp is ON

LIMIT

Under Limit Mode(F21-01) setting. “▼” Lamp is ON.

Print

When print key input or Auto print, “▼” Lamp is turn on.

Comm.

When indicator transfers or receives data from other devices, “▼” Lamp is turn on.

(If the “▼” is off although there is some data transference, please check communication

settings).

Weight Display

Status Lamp

Function Key

Unit Weight

Count

Weight Unit

P/N

Calibration Lock-Key

3-4. Option Card

※ Serial Interface (RS-232C) or Current Loop is Standard installed.

In the Optional Serial port, there is no Current Loop function

3-5. Front Panel (Display / Key Pad)

Digital Weighing Indicator

SI 4200

3-5-1. Status Lamp (ANNUNCIATORS) : “▼” Lamp is “ON”.

- 7 -

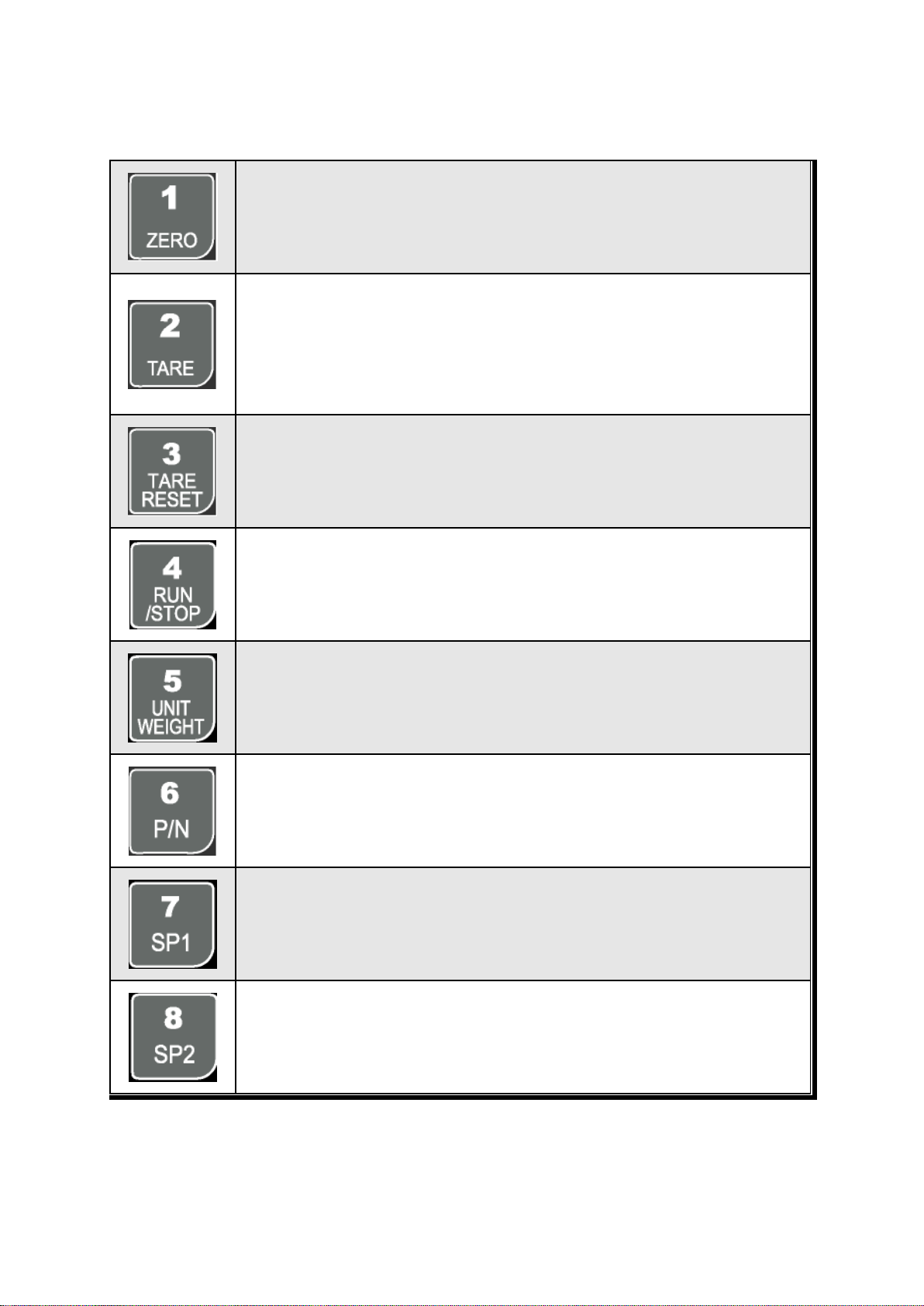

Make Weight value as Zero.

Under F08, you can set the Zero key operation range, as 2%, or 5%, or 10%, or 20% of

Max. Capacity.

※ Under “Tare” key input, Zero key will not be activated.

Make Weight value as Zero, including Tare Weight.

Under F09, you can set the Tare key operation range, as 10%, 20%, 50%, or 100% of

Max. Capacity.

Tare setting : Under F10-00 setting, “TARE” key input

Under F10-01 setting, “Tare”+ No. key + “Enter”

Remove set TARE value.

Under Packer Mode(F21-02), Start the packer mode process.

First input is “START”, Second input is “STOP”

Manual “Unit Weight” input Key.

If you already knew the “Unit Weight”, you can input “Unit weight” without calibration.

You can set each weighing process as a certain P/N.

Each weighing process will be saved with FINAL, PRE1, PRE2, and Free Fall set

value.(Max. 50 kinds of P/N you can set)

And you can call certain P/N with each set value.

You can set SP1 value through this key.

You can set SP2 value through this key.

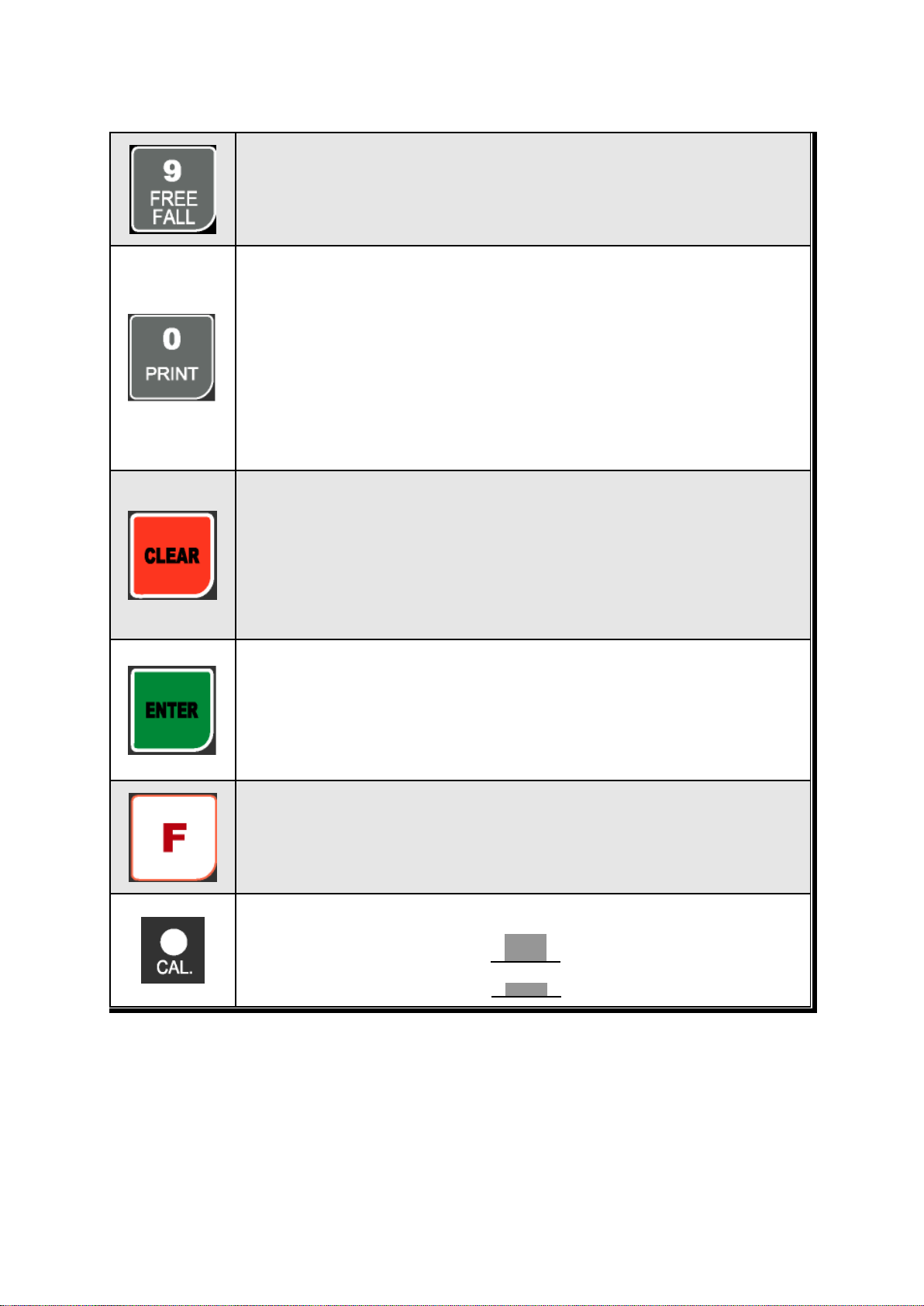

3-5-2. Key Operation

Digital Weighing Indicator

SI 4200

Digital Weighing Indicator

- 8 -

You can set FREE FALL value through this key.

1. Manual Print (F38-00 setting, under F35-01)

2. Manual weighing Data save for accumulated weighing count and weight.

(F01-00 / 02 setting)

3. Calibration mode

- Digit setting

Whenever pressing “0”key, digit will be change 1, 2, 5, 10, and 50.

- Decimal point position

Whenever pressing “0”key, decimal point will be change.

1. Modify the set value during setting process.

2. Calibration mode

- Move back to previous step.

F-function Mode.

- F-function Exit : Press “Clear” key, once.

- F-Test Mode Exit : Press “Clear” key, twice.

1. Save set value during setting process.

2. Calibration mode

- Save current setting and move to next step.

3. F-Function mode

- Save current F-function setting, and move to next F-function

1. “F-TEST” Mode Entrance : Press “F” key for 5sec.

2. Under “F-function Mode”, Move to next Function or move to certain function

No.(Press function No. and press “F” key)

3. Function key (Refer “Function keys”)

Enter/Exit to “Calibration” mode.

“ON” : Enter to Calibration Mode.

“OFF” : Exit from Calibration Mode.

SI 4200

- 9 -

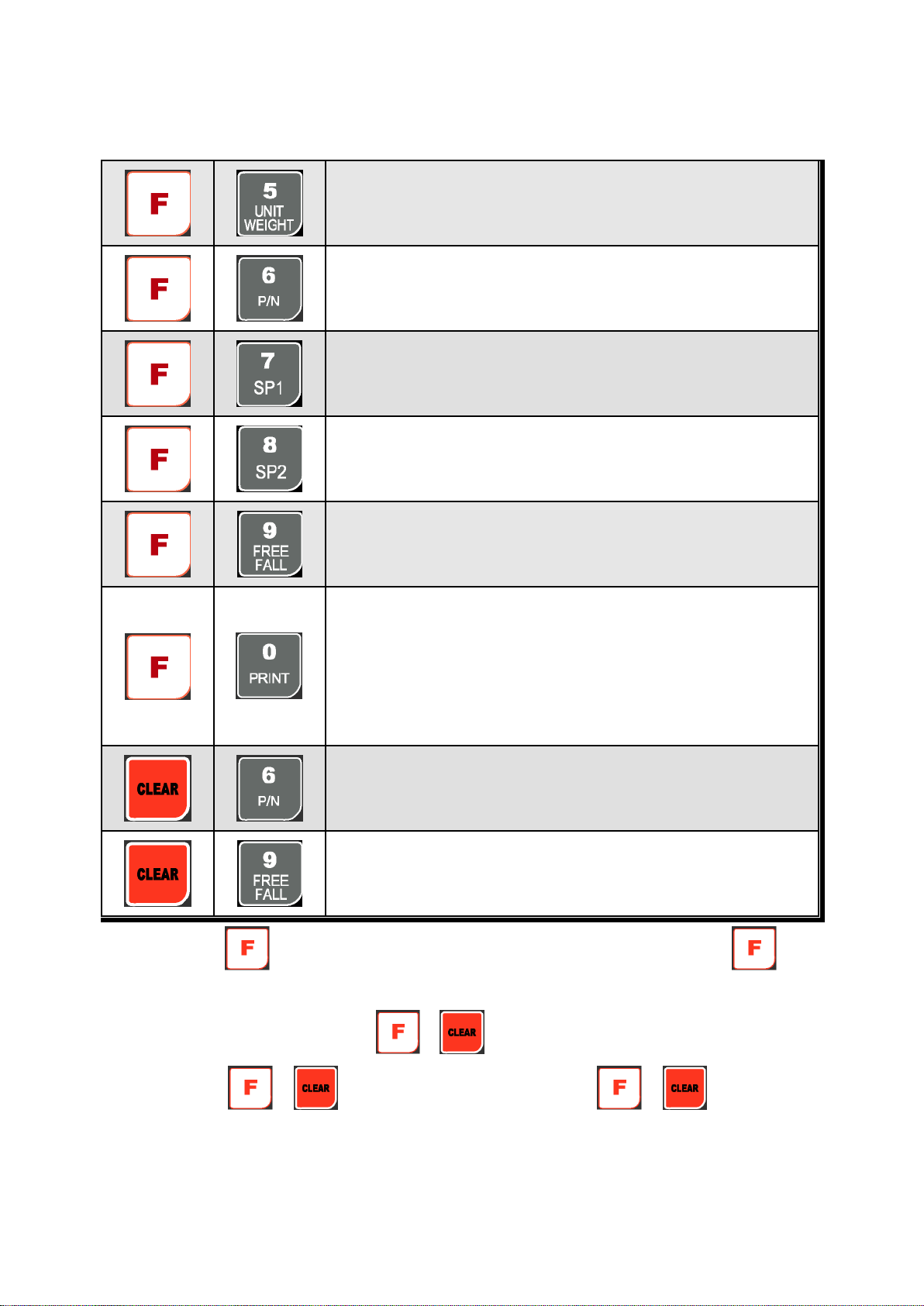

Enter “Unit Weight Calibration” mode.

- Please refer “5-4. Unit Calibration”.

Print all P/Ns’ accumulated weighing count and weight.

(Grand-Total Print)

High Range value setting (N.G Relay).

Under Range value setting(N.G Relay)

Print current P/N’s accumulated weighing count and weight.

(Sub-Total Print)

Display accumulated weighing count and weight

Max. accumulated weight display : 21,474,839,647(g, kg, ton)

Max. accumulated weighing count : 999,999times

※ Under F15, you can set what kinds of accumulated count and weight.

- F15-00 : Display current P/N’s accumulated count and weight.

- F15-01 : Display all P/Ns’ accumulated count and weight

Delete all P/Ns’ accumulated weighing count and weight

(If you set F44-01, the data will be automatically deleted after “Grand-Total

Print).

Delete current P/N’s accumulated weighing count and weight

(If you set F44-01, the data will be automatically deleted after “Sub-Total

Print).

※ “Function Keys”(Combined Key Function)

Digital Weighing Indicator

SI 4200

※ After Pressing key, you have to input above function keys within 5sec. - After 5sec, the key

activation is loose

※ If you set “F51-01” you can check the / key activation through Main display.

※ After Pressing “ ”, “ ” key, non-function keys are input, the “ ”, “ ” key

activation will be loose.

- 10 -

Warning

③ OPTION CARD

②

○3

○6

○5

○4

○7

○

1

3-6. Rear Panel

Digital Weighing Indicator

SI 4200

○1 POWER AC IN

- Power switch : Power on/off switch.

- Fuse : AC250V / 0.5A , φ5.25 , 20mm.

- AC IN : Available Input AC 110V / 220V.

※ The standard power supply is AC 220V(Fixed when ex-warehouse), if you want to have AC 110V,

please inform in advance.

② Option Card 1

③ Option Card 2

※Option Card Connector installed for Optional Interface or Output.

(Printer I/F, Analog out, RS-422/485, or RS-232C(two port)

④ LOAD CELL Connector (N16-05)

⑤ SERIAL I/F

“RS-232C” or “CURRENT LOOP”(9Pin, D-Type Female) are built-in as standard

⑥ External Input : External control input for wired remote control.

Refer to F-Function F11 to select desired function mode.

Input signal …………………………… Optical-Isolator

⑦ Relay Output Terminal : Set point(SP1, SP2, SP3, SP4) and Finish, Empty relay output.

(Refer “F21” setting.)

- 11 -

Power Cable

Communication Connector(D-SUB 9P)

Load-cell Cable

94

188

165

105

200

162.0

92

186

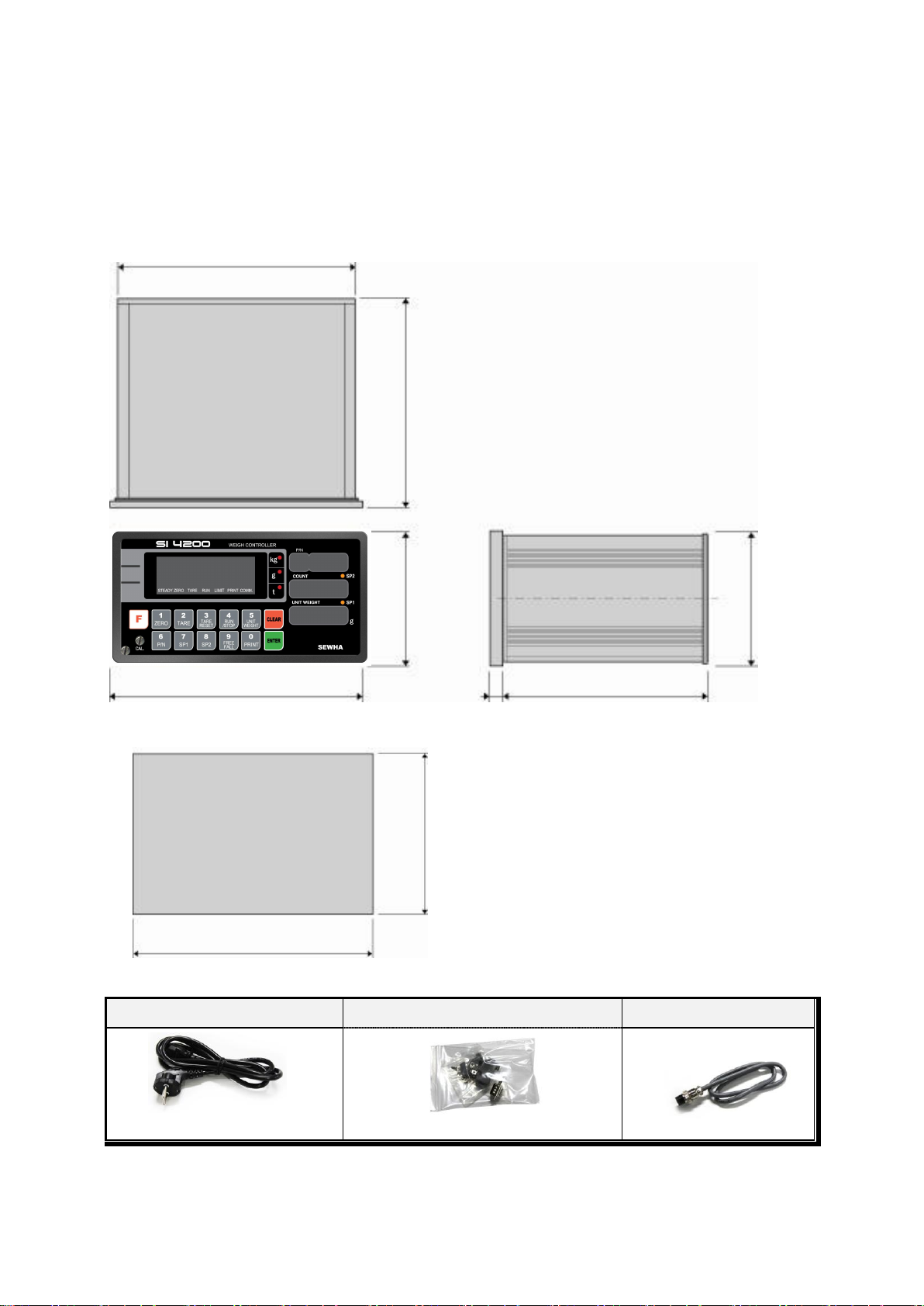

4. INSTALLATION

4-1. External Dimension & Cutting Size

(External Dimension) (unit : mm)

Digital Weighing Indicator

SI 4200

(Cutting Size) (unit : mm)

4-2. Installation Components

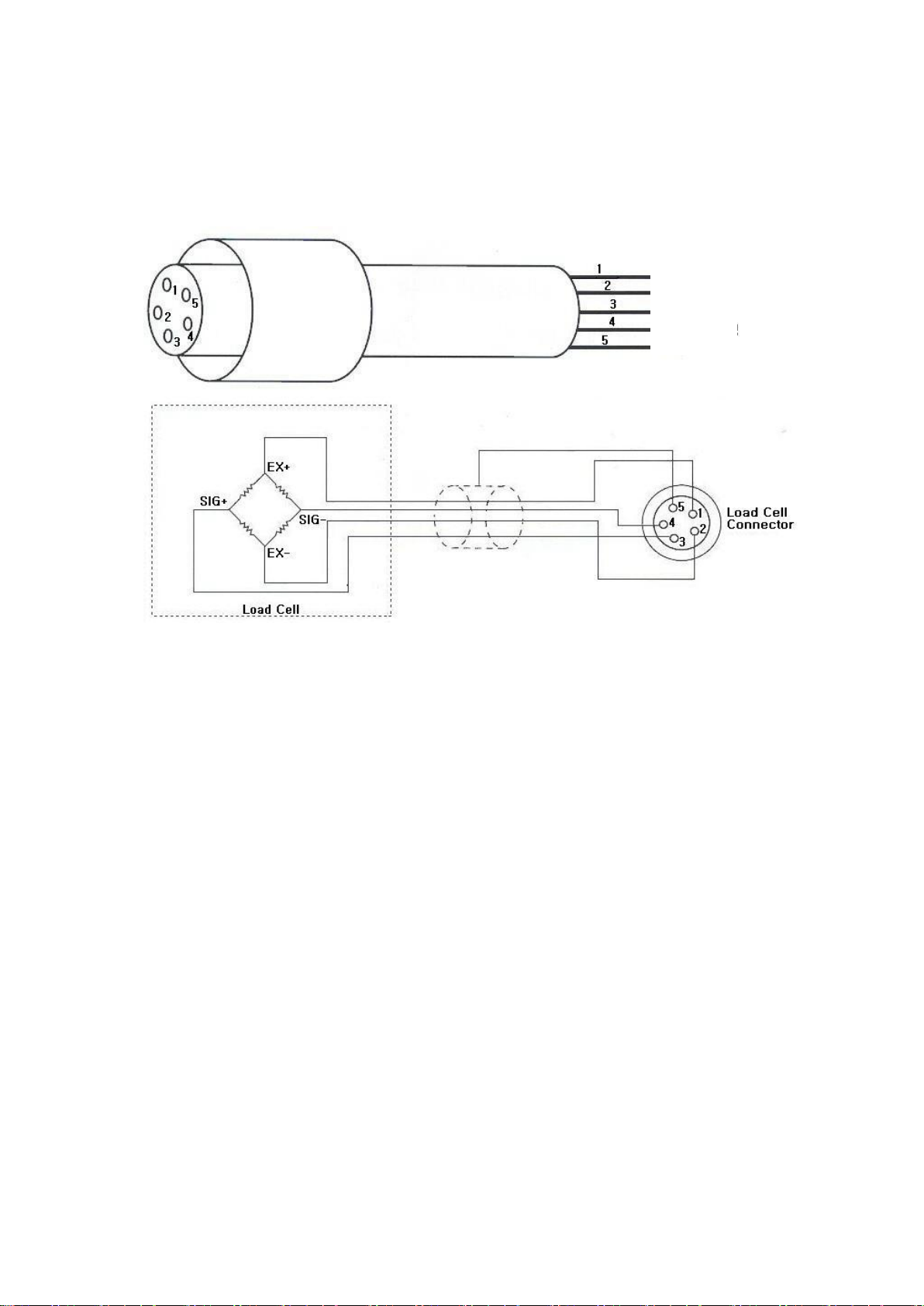

- 12 -

Red

White

Green

Blue

Shield

4-3. Load Cell Connector Specification

4-3-1. Load Cell Connector Specification

Digital Weighing Indicator

SI 4200

4-3-2. Load Cell Installation

1) You can connect Max. 8pcs of same capacity Load cells at once. (350Ω)

2) You have to make horizontal balance on the ground.

3) If you install more than 2pcs of Load cells, use Summing box and adjust output signal difference as

minimum. It can make wrong weighing process caused by each load cell’s variation.

4) If there is some temperature difference around Load cell, it can cause wrong weight measurement.

5) Don’t do Welding job or Arc discharge around installation place. But, there is no choice, please

disconnect power cable and Load cell cable.

6) If you measure static electricity material, please make earth between down part and up part of Load

cell.

- 13 -

Single Load cell use

0.2㎶ ≤

EⅹBⅹD

A : Load cell capacity(kg)

B : Load cell Voltage(mV)

D : Digit

E : affirmation Voltage of Load cell

N : Number of Load cell

A

Plural Load cells use

0.2㎶ ≤

EⅹBⅹD

AⅹN

5000ⅹ2ⅹ0.05

= 1 ≥ 0.2㎶

The calculated value is larger than 0.2㎶,

so this system has no problem.

500

5000ⅹ2ⅹ0.10

= 0.5 ≥ 0.2㎶

The calculated value is larger than 0.2㎶,

so this system has no problem.

500ⅹ4

Caution

!

4-2-4. Formula to plan the precise weighing system

This “SI 4200” weighing controller’s Max. input sensitivity is 0.1㎶ / Digit.

And for precise weighing system, the following formula must be satisfied.

Caution : “Input sensitivity” means Min. output voltage variation of weighing part to change 1digit. So,

please do not make large input voltage to make reliable weighing system.

Example1.)

The number of Load cell : 1pcs

Load cell capacity : 500kg

Digital Weighing Indicator

SI 4200

Load cell Rated output : 2mV/V

Division : 0.05kg

Affirmation Voltage of Load cell : 5,000mV

Max. Capacity of Weighing System : 300kg

Then, estimation result for this weighing system with formula,

Example2.)

The number of Load cell : 4pcs

Load cell capacity : 500kg

Load cell Rated output : 2mV/V

Division : 0.10kg

Affirmation Voltage of Load cell : 5,000mV

Max. Capacity of Weighing System : 1,000kg

Then, estimation result for this weighing system with formula,

※ According to “Resolution” or “Capacity”, it might not be calibrated like calculation.

Digital Weighing Indicator

- 14 -

1. At normal mode, remove “CAL-BOLT” on the Front panel

123

2. And press “CAL - LOCK S/W” inside.

Check the “SET-CAL. Massage on display.

5et-Cal

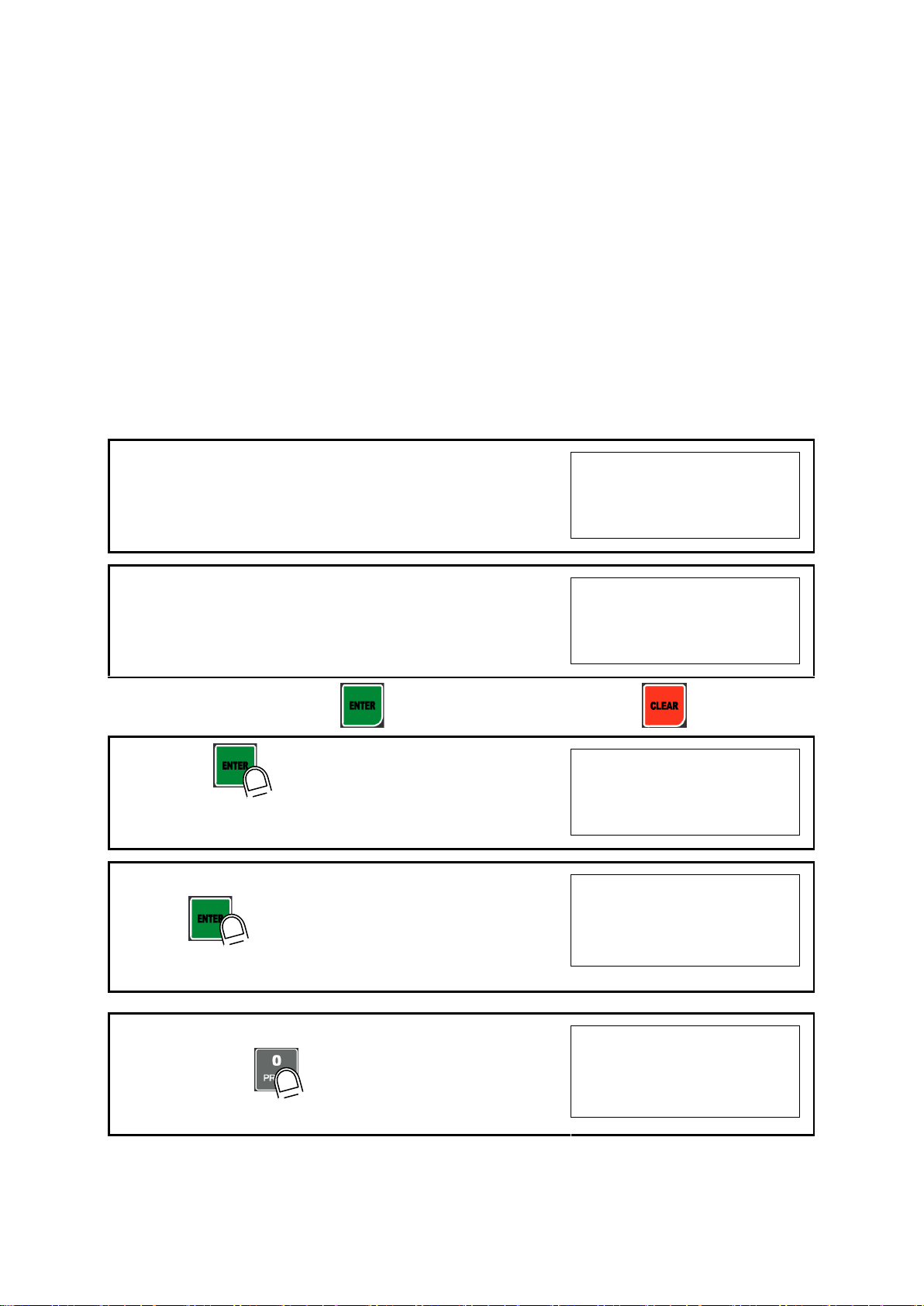

※ For the save the each step, press key, for the cancel or move back, press key.

3. If you press key, Calibration Mode starts.

After displaying “CAPA”,

C999999

4. Please input Max capacity of your weighing scale,

And press key.

Ex) Load cell CAPA : 20kg, division : 0.001 Input 20000

C 20000

5. define the optimal position or Decimal point

Whenever pressing key, Decimal point will be changed.

Ex) Load Cell CAPA : 20kg, division : 0.001kg input 20.000

p 20.000

5. SET-UP

5-1. Calibration

Adjust weight balance between “Real weight” on the load cell(Weight Part) and “Displayed weight of

Indicator”. When you replace LOAD CELL or Indicator, you have to do Calibration process once again

5-2. Test Weight Calibration Mode (Using Test weight)

※remarks : In case that “P-W” is displayed, you have to check the pass word.

Prepare At least 10% of Max. capacity of your weighing scale, and remove “CAL-BOLT” on the Front

panel and press “CAL - LOCK S/W” inside.

※remarks : In case that “P-W” is displayed, you have input the pass word to start

calibration mode.

SI 4200

Digital Weighing Indicator

- 15 -

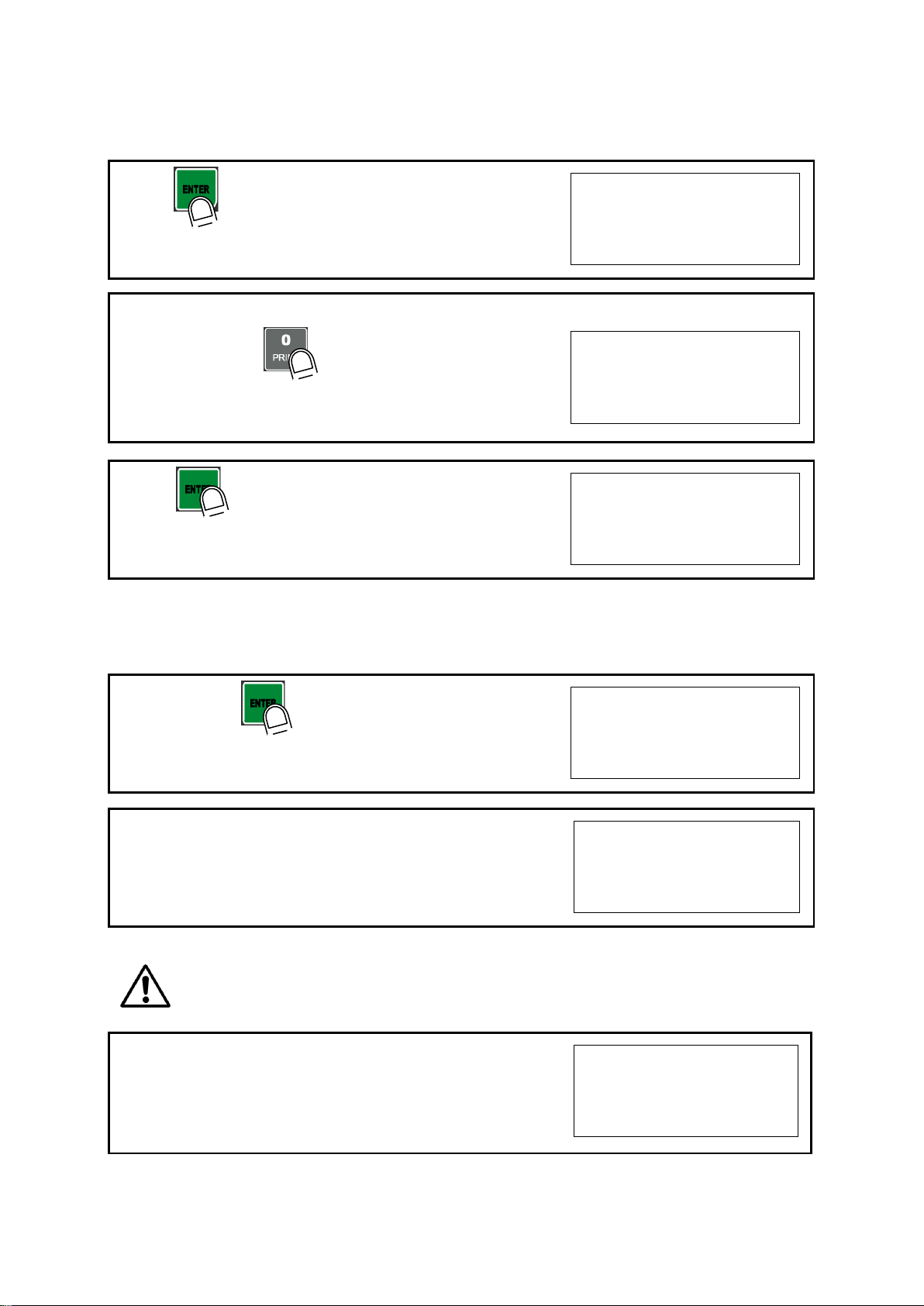

6. Press key to save and move to next step.

p 20.000

7. Define the optimal Digit/Division value of weighing measurement.

Whenever pressing key, the Digit/Division value will

be changed like 1->2->5->10->20->50.

Ex) Load cell CAPA : 20kg, division : 0.001 Input division “1”

d 1

8. press key to save the Digit/Division value and move

to next step

d 1

※ Caution : (Max. capacity value / division value) cannot be over 20,000.(as Indicator resolution is 1/20,000).

If the value is over 20,000, Error message “ Err 01 “ will be displayed and move back “CAPA” mode again.

9. When you press key, the indicator starts to find

“Zero” span..

dead

10. Indicator will search “DEAD weight” during 5sec, automatically.

After finding optimal “Zero” span , step is automatically

Moves to next.

Cal-1 0

※ Caution : At this step, if there some force or Vibration on Weighing scale, and unstable condition will be

continued, “ErrorA” will be display, and “DEAD value” will not be calculated.

Under this condition, please remove force or vibration and process it again.

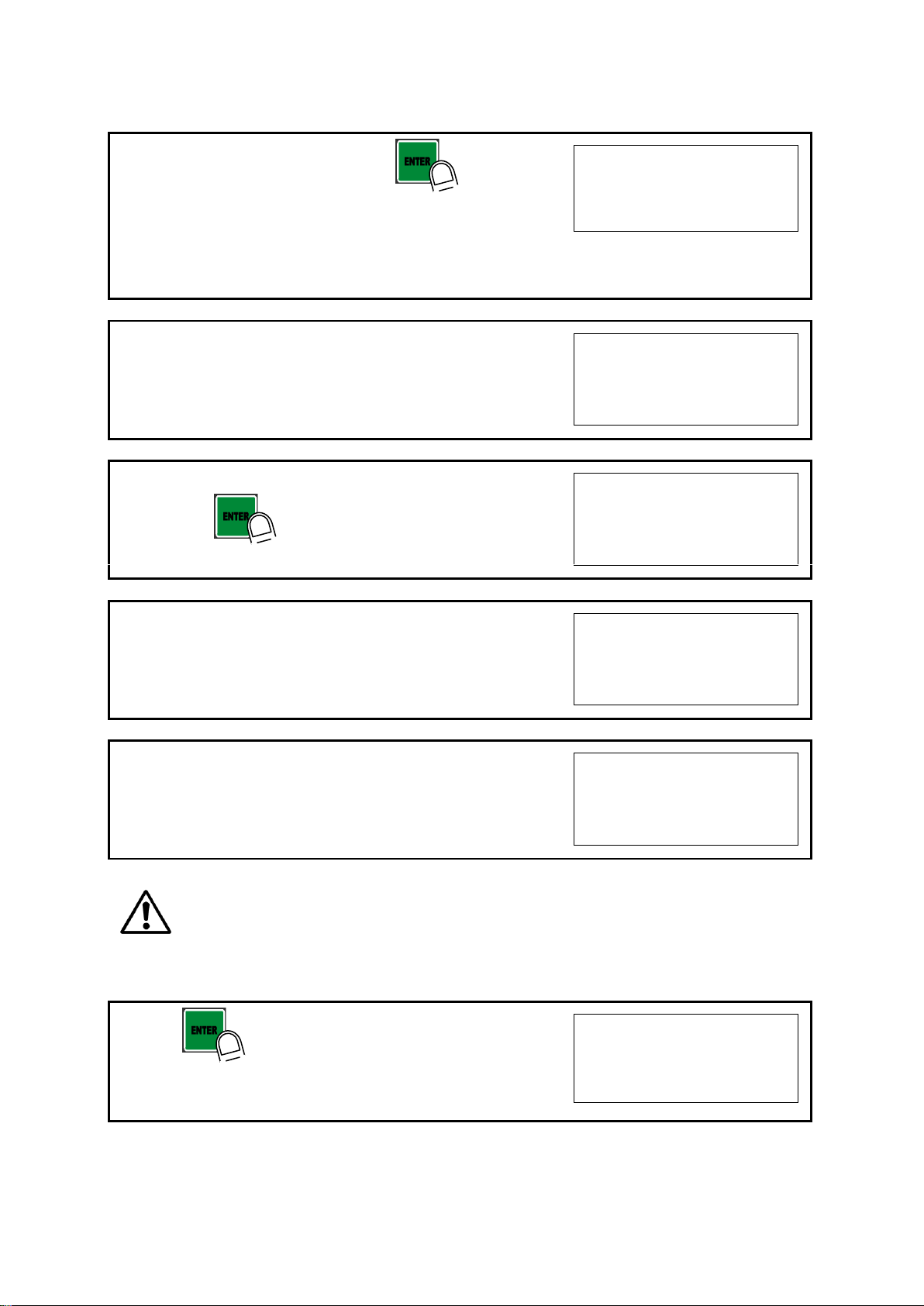

11. Span Calibration mode starts..

l 20.000

SI 4200

Digital Weighing Indicator

- 16 -

12. Input “Test weight” capacity. And press key.

Ex) Load Cell CAPA : 20kg, division 0.001

Use test weight(at least 2kg) which is 10% of max CAPA(20kg)

input test weight 2.000

l 2.000

13. After displaying “UP” ,please load “Test Weight” .

Ex) Load Cell CAPA : 20kg, division 0.001

Use test weight(at least 2kg) which is 10% of max CAPA(20kg)

Up

14. And press key.(Do not unload test weight)

Up

15. Indicator will calculate span value during 5sec, automatically

Cal-2 0

16. After calculation, span value displays on the display.

Please unload the test weight.

0.629238

※ Caution : The “Test Weight’s value” must be at least 10% max. capacity of weighing scale.

“at least 10%” means to guarantee precise weighing process you have to make standard with at least

10% of weight of Max. capacity.

We programmed the calibration will not be done, when you load less than 10% of max. capacity.

17. Press key to save all calibration process.

After then it resets automatically.

(Now, fasten the Calibration Bolt. )

end

SI 4200

Loading...

Loading...