Page 1

Operating

Instructions

Page 2

Measurable success by Sewerin equipment

Congratulations. You have chosen a quality instrument manufactured

by Hermann Sewerin GmbH.

Our equipment will provide you with the highest standards of perfor-

mance, safety and efciency. They correspond with the national and

international guide-lines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice

and assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

SEWERIN SARL

17, rue Ampère – BP 211

67727 HOERDT CEDEX, France

Tél. :+33 3 88 68 15 15

Fax :+33 3 88 68 11 77

www.sewerin.fr

sewerin@sewerin.fr

SEWERIN IBERIA S.L.

Centro de Negocios “Eisenhower”

Avenida Sur del Aeropuerto

de Barajas 28, Of. 2.1 y 2.2

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.es

info@sewerin.es

Sewerin Ltd

Hertfordshire

UK

Phone: +44 1462-634363

www.sewerin.co.uk

info@sewerin.co.uk

Sewerin Sp.z o.o.

ul. Twórcza 79L/1

03-289 Warszawa, Polska

Tel.: +48 22 675 09 69

Faks: +48 22 486 93 44

Tel. kom. +48 501 879 444

www.sewerin.pl

info@sewerin.pl

Page 3

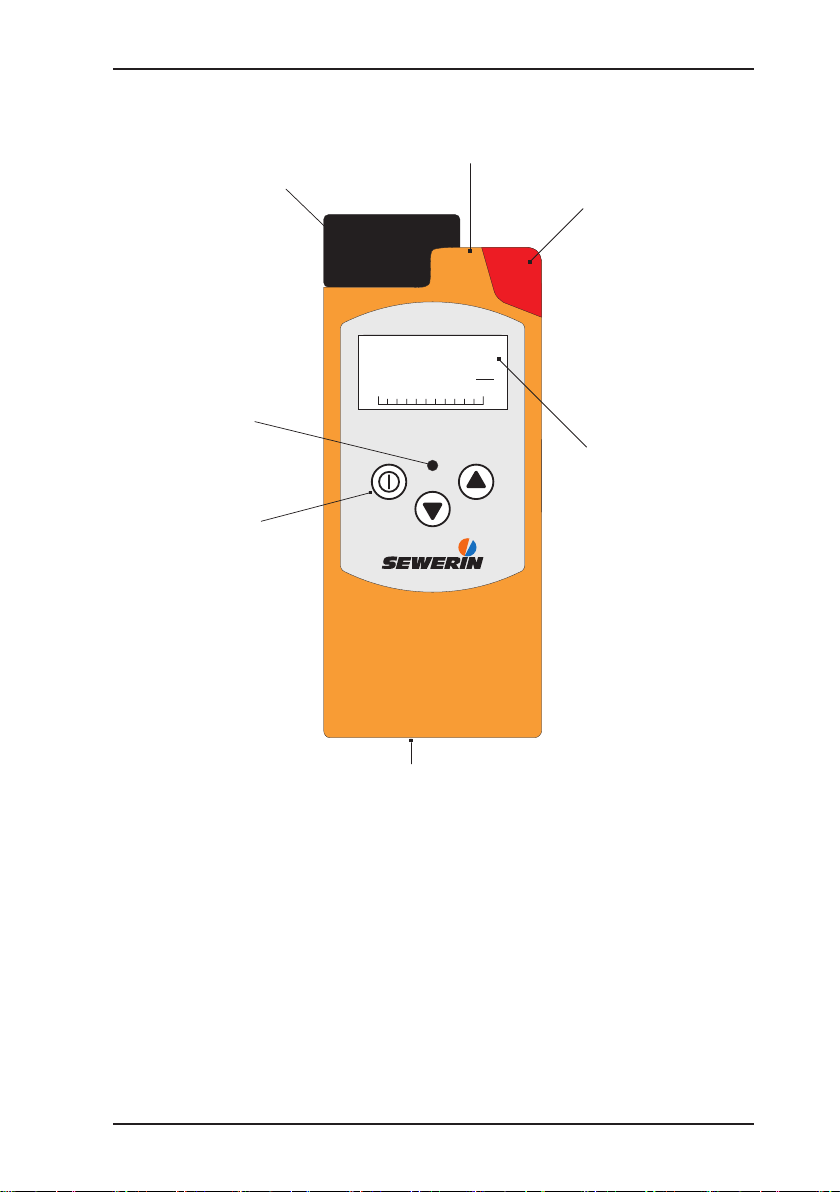

EX-TEC OD 4

®

0.0

THT

mg

m3

Sensor head

Attachment

Alarm lamp

LCD

Buzzer

Keypad

Charging contacts

Illustration EX-TEC OD 4

Page 4

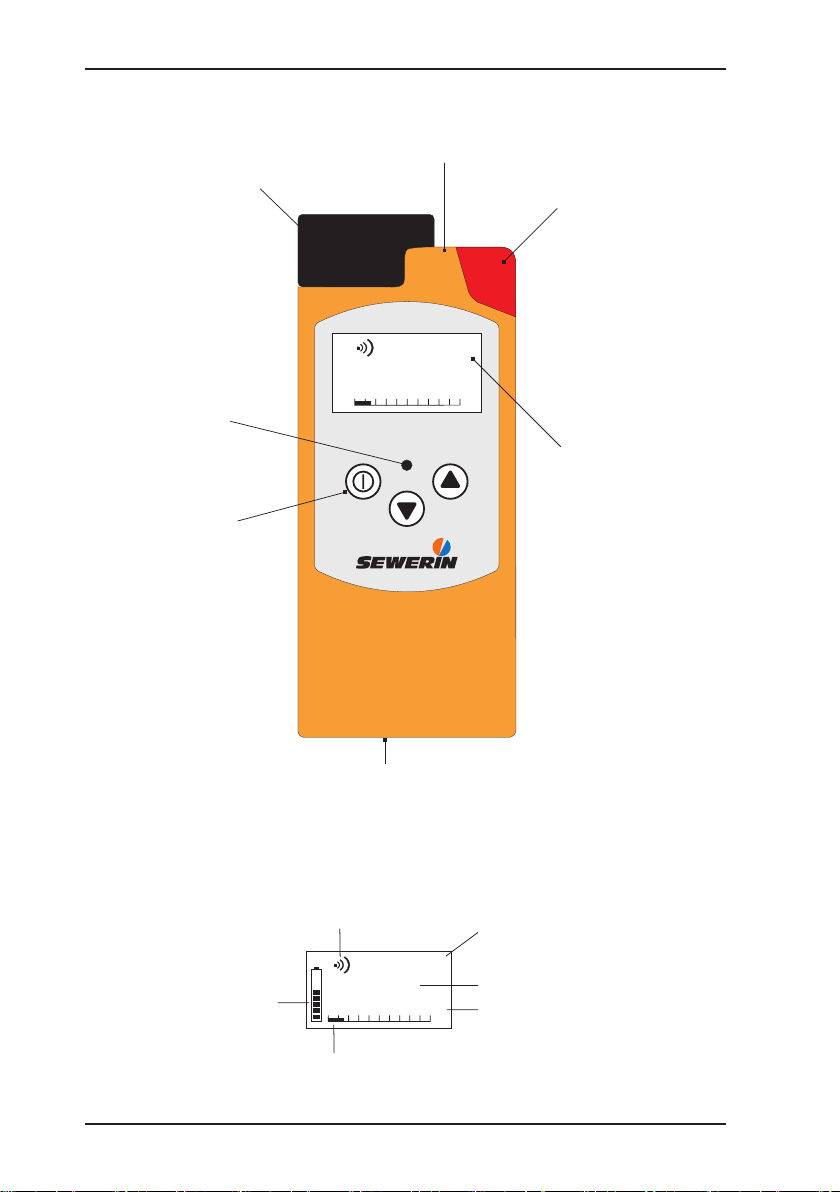

Illustration EX-TEC GM 4

Sensor head

Attachment

Alarm lamp

LCD

Buzzer

Keypad

Charging contacts

H2

Battery state

1500

EX-TEC GM 4

Activation

Alarm thresholds

1500

PPM

®

H2

PPM

Type of gas

Gas concentration

Unit

Trend bar

Page 5

Operating Instructions

EX-TEC® OD 4/GM 4

20.04.2016 a – V1.XXX – 103955 – en

Page 6

For your safety

This product may only be operated by appropriately-trained persons who

are familiar with the relevant operating manual.

It may only be used for its designated purpose, i.e. for industrial and commercial use.

Repair work may only be carried out by specialists or by persons who have

undergone appropriate training.

Any alterations or modications to the product require the prior approval of

Hermann Sewerin GmbH. In the event of unauthorised alterations to the

product the manufacturer accepts no liability for damage.

Only Hermann Sewerin GmbH accessories may be used with the product.

Only spare parts approved by us may be used for repairs.

Hermann Sewerin GmbH accepts no liability for damage resulting from

non-compliance with the foregoing. The guarantee and liability provisions

in the Hermann Sewerin GmbH terms of sale and supply are not extended

by the foregoing.

We reserve the right to make changes in the context of continued technical development.

In addition to these instructions, please comply with generally applicable

safety and accident-prevention regulations.

Symbols used:

CAUTION:

Note:

This symbol warns of dangers that may threaten

the safety of the user or maty damage or destroy

the product.

This symbol ags information and hints extending

beyond the actual operation of the product .

Page 7

Contents Page

1 EX-TEC OD 4/EX-TEC GM 4 system ......................................1

1.1 The EX-TEC OD 4 system ........................................................1

1.1.1 Before starting work ...............................................................1

1.1.2 The need for gas odorisation .................................................1

1.1.3 Measurement principle ........................................................... 1

1.1.4 Boundary conditions for measurement and sampling .............. 2

1.1.5 EX-TEC OD 4 ............................................................................3

1.1.6 Test certicates ......................................................................4

1.2 EX-TEC GM 4 system ............................................................... 5

1.2.1 Test certicates ......................................................................5

2 Safety .......................................................................................6

2.1 Safety instructions ..................................................................... 6

3 Measuring operation ............................................................... 8

3.1 Switching on .............................................................................. 8

3.2 Operating modes ..................................................................... 11

3.3 Alarms .....................................................................................16

3.4 Illumination and operating-hours display ................................. 18

3.5 Battery alarm ........................................................................... 18

3.6 Switching off ............................................................................19

4 Charging and battery operation ........................................... 20

4.1 Charging and charge maintenance when using NiMH batteries ... 20

4.2 Self-dischargeand battery care ...............................................22

4.3 Battery operation ..................................................................... 23

4.4 Instruments showing serial number 062 00 ............................24

5 Testing the instrument .......................................................... 25

5.1 Testing/upkeep ........................................................................25

5.2 Test set ....................................................................................27

5.2.1 EX-TEC GM 4 ......................................................................27

5.2.2 EX-TEC OD 4 ....................................................................... 28

5.3 Test gases ...............................................................................29

5.4 Testing the pump, zero point and display accuracy ................30

I

Page 8

Contents Page

6 Info menu ...............................................................................33

6.1 Menu structure ........................................................................33

6.2 Overview .................................................................................34

7 Adjustment menu .................................................................. 36

7.1 Menu structure ........................................................................36

7.2 Sensor adjustment ..................................................................36

7.2.1 Setting the H2-sensor ...........................................................36

7.2.2 Setting the O2 sensor ...........................................................37

7.3 Setting the test gas concentration ........................................... 38

7.4 Inspection conrmation ...........................................................40

7.5 Leaving the adjustment menu ................................................. 40

8 System menu ......................................................................... 41

8.1 Menu structure ........................................................................41

8.2 Setting the date and time ........................................................42

8.3 Setting the inspection intervall ................................................43

8.4 Setting the inspection block ....................................................46

8.5 Setting the PIN ........................................................................47

8.6 Setting the alarm thresholds ...................................................48

8.7 Setting the user name .............................................................51

8.8 Setting the language ...............................................................53

8.9 Leaving the system menu .......................................................53

9 Hardware menu .....................................................................54

9.1 Menu structure ........................................................................54

9.1.1 EX-TEC GM 4 ......................................................................54

9.1.2 EX-TEC OD 4 .......................................................................55

9.2 Setting the battery type ...........................................................56

9.3 Setting the illumination time and contrast ...............................57

9.4 Autostart ..................................................................................58

9.5 Range .....................................................................................59

9.6 Changing the sensor ...............................................................59

9.6.1 Gas ....................................................................................... 60

9.6.2 Sensor installation ................................................................ 60

9.7 Setting pump operation ...........................................................61

9.8 Carrying out an LCD test ......................................................... 61

II

Page 9

Contents Page

9.9 Restoring the factory settings .................................................. 62

9.10 Leaving the hardware menu ....................................................63

10 Memory menu ........................................................................ 64

10.1 Menu structure ........................................................................64

10.2 Clearing memory .....................................................................64

10.3 Setting the memory interval ....................................................65

10.4 Leaving the memory menu ......................................................65

11 Technical aspects..................................................................66

11.1 Technical notes .......................................................................66

11.2 Technical data .........................................................................68

11.3 Error messages ....................................................................... 79

11.4 Consumables .......................................................................... 80

11.5 Hints on Disposal .................................................................... 81

12 Delivery variants and accessories ......................................82

12.1 Delivery variants ......................................................................82

12.2 Accessories .............................................................................84

13 Appendix ................................................................................90

13.1 EU-declaration of conformity ...................................................90

13.2 Inspection protocol ..................................................................91

13.3 EX-TEC OD 4/GM 4 operating instructions in brief ................. 92

III

Page 10

1 EX-TEC OD 4/EX-TEC GM 4 system

1 EX-TEC OD 4/EX-TEC GM 4 system

The EX-TEC OD 4 is a combined warning and measuring instru-

ment for determining odorant concentration. It is available with

either a THT or a TBM sensor.

The EX-TEC GM 4 is a warning and measuring instrument that

detects oxygen and various toxic gases.

1.1 The EX-TEC OD 4 system

1.1.1 Before starting work

Adequate gas odorisation is an important criterion for safe network

operation. Please take careful note of the following information.

1.1.2 The need for gas odorisation

Natural gas is odourless. So that even the smallest leaks in indoor

installations or elsewhere in a gas-distribution network can be

immediately detected, the gas is odorised: a strong-smelling substance is added to it. The substances used are organic sulphur

compounds and acrylates. The most widespread currently being

tetrahydrothiophene (THT) and tertiary butyl mercaptan (TBM).

DVGW worksheet G 280 sets the minimum values for odorant

concentration at 10 mg of THT / m3 and 3.8 mg of TBM / m3. This

worksheet also requires the operator of a distribution network to

check and document the odorant concentration at least once a

year.

1.1.3 Measurement principle

The EX-TEC OD 4 contains an electrochemical sensor that reacts

to the smallest traces of sulphur compounds. This produces elec-

trical signals, which are then processed by the integral electronic

system. The intensity of the signal varies directly with the strength

of the concentration.

1

Page 11

1 EX-TEC OD 4/EX-TEC GM 4 system

The sensor is lled with a liquid (electrolyte), which makes it very

sensitive to high temperatures. The maximum storage temperature of 40 °C must therefore not be exceeded. Electrochemical

processes constantly take place inside the measurement cell,

requiring the EX-TEC OD 4 to be permanently supplied with battery power at an adequate voltage. For this reason the integral

batteries must not be permitted to reach a state of deep discharge.

When the instrument is not in use it should therefore be stored

in charge-maintenance operation (see section 4.1: Charging and

charge maintenance when using NiMH batteries).

1.1.4 Boundary conditions for measurement and sampling

As well as all sulphur compounds, the electrochemical measurement cell also reacts very strongly to moisture. Even though this

is rarely important when carrying out measurements in a gasdistribution network, operators should not blow through sampling

hoses to clear them.

When sampling it is essential to ensure that there are no connecting pieces made of rubber or synthetic substances between the

EX-TEC OD 4 and the connection to the gas main unless these

consist of inert materials (e.g. Viton or nylon).

A further factor that affects the measurement of sulphur com-

pounds with the EX-TEC OD 4 is the ow rate through the mea-

surement chamber, which must always exceed 20 l/h. Only the

connection hoses supplied with the instrument should therefore

be used for sampling.

2

Page 12

1.1.5 EX-TEC OD 4

The following sensors are available:

1 EX-TEC OD 4/EX-TEC GM 4 system

The EX-TEC OD 4 is a hand-held

instrument for the measurement

of tetrahydrothiophene (THT) or

tertiary butyl mercaptan (TBM). It

is available in pump and diffusion

versions.

Sensor

THT

TBM

range principle

0 –100 mg/m

0 –100 mg/m

3

3

electrochemical

electrochemical

3

Page 13

1 EX-TEC OD 4/EX-TEC GM 4 system

1.1.6 Testcerticates

Passive explosion protection

The EX-TEC OD 4 has been tested for explosion protection in

accordance with European norms (CENELEC):

EC prototype test certicate: TÜV 01 ATEX 1657

Identication: II2G Ex e ib IIB T4 Gb

Testing institution: TÜV NORD CERT GmbH,

Hannover

4

Page 14

1.2 EX-TEC GM 4 system

The EX-TEC GM 4 is a gas-measurement and warning instru-

ment. It is available in pump and diffusion versions. A different

sensor is used for each gas.

The following electrochemical sensors are available:

Sensor range

Carbon monoxide CO 0 – 500 ppm

Hydrogen H2 0 – 1.0 vol.%

Hydrogen sulphide H2S 0 – 100 ppm

Hydrogen sulphide H2S 0 – 2000 ppm

Ammonia NH3 0 – 100 ppm

Oxygen O2 0 – 25 vol.%

Hydrogen chloride HCI

1.2.1 Testcerticates

Passive explosion protection

The EX-TEC GM 4 has been tested for explosion protection in

accordance with European norms (CENELEC):

1 EX-TEC OD 4/EX-TEC GM 4 system

0 – 30 ppm

EC prototype test certicate: TÜV 01 ATEX 1657

Identication 1: II2G Ex e ib IIB T4 Gb

basic instrument without

leather case for all gases

except hydrogen H

2

Identication 2: II2G Ex e ib IIC T4 Gb

basic instrument with leather

case for all gases including

hydrogen H

2

Testing institution: TÜV NORD CERT GmbH,

Hannover

5

Page 15

2 Safety

2 Safety

2.1 Safety instructions

CAUTION!

Always use original SEWERIN accessories with the

EX-TEC OD 4/GM 4!

CAUTION!

Observe the permissible operating temperature

range of minus 10 °C to plus 40 °C!

(with some sensors the temperature range may be

wider - see section 11.2: Technical data)!

CAUTION!

The EX-TEC OD 4/GM 4 must not be recharged or

its battery compartment opened in areas exposed

to the danger of explosion!

CAUTION!

Test gases may only be used in well-ventilated

spaces!

CAUTION!

The EX-TEC OD 4/GM 4 satises the limits of the

EMV regulation. When using it near (mobile) radio

equipment please also observe the instructions in

the manuals for that equipment!

6

Page 16

CAUTION!

Please note that when the EX-TEC OD 4/GM 4 is

in measuring operation the gas sample is released

into the ambient air through its outlet.

Special care must be taken to ensure that this does

not produce an explosive or toxic gas mixture, espe-

cially during use in conned spaces. It may therefore

be necessary to use a gas-warning device to monitor

the ambient air.

CAUTION!

The EX-TEC GM 4 with the hydrogen sulphide H2S

sensor (0 – 2000 ppm) is a pure measuring instru-

ment: the „warning“ operating mode is not available.

Please note that the human sense of smell fails at

concentrations of 100 ppm of H2S and above. Concentrations of over 500 ppm of H2S lead to very seri-

ous damage to health, uncoordinated movements,

unconsciousness, respiratory failure and death. It is

thus essential to ensure that the lower toxic limit of

10 ppm in the ambient air is not exceeded!

2 Safety

CAUTION!

When using the H2 sensor the HG4 must be in its

leather case (to provide explosion protection)!

7

Page 17

3 Measuring operation

V1.001

EX-TEC GM4

H2

3 Measuring operation

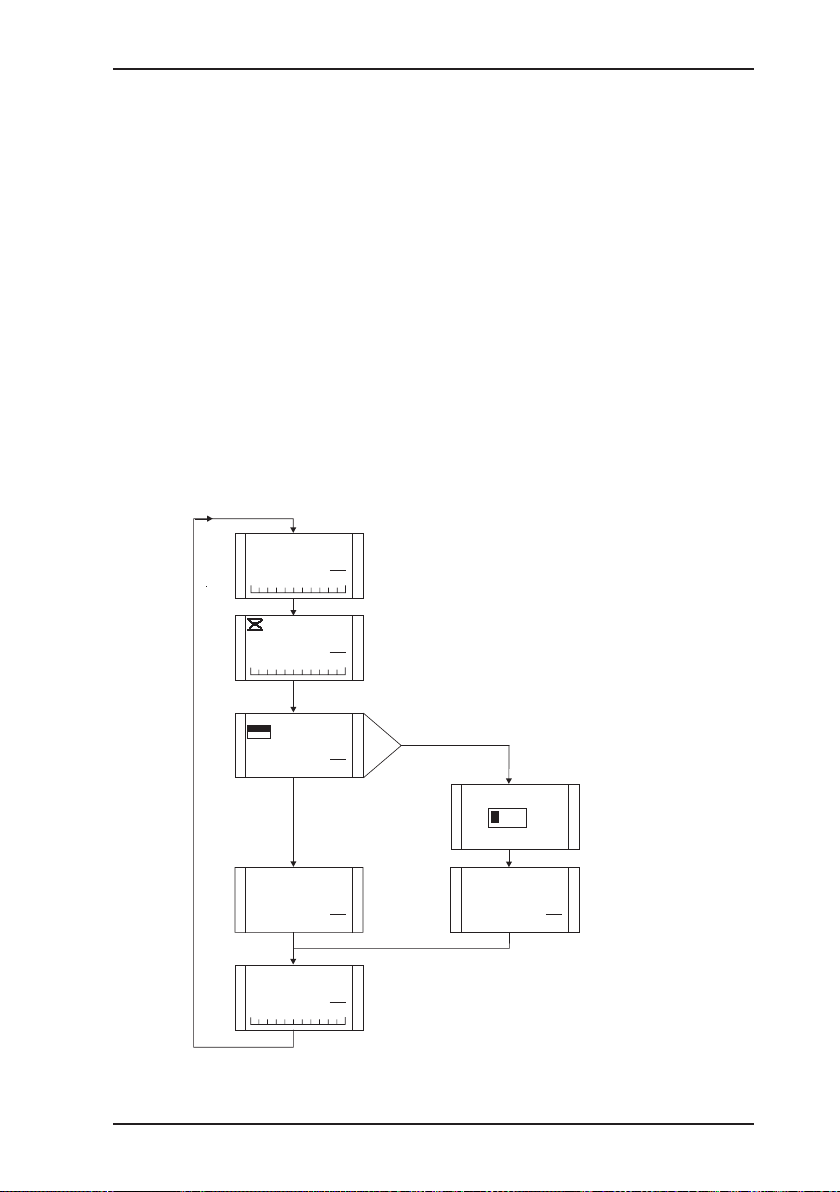

3.1 Switching on

Note:

This operating manual describes the functions

of software version 1.XXX. Other versions may

involve changes.In this event please consult any

page insertions.

z always switch the instrument

on in „fresh air“

z hold the on/off key down for

about 3 seconds

z the optical and acoustic control

signals (items 1 and 7) operate

for about 3 seconds

z the LC display illumination

automatically switches on

z pump instruments: the inte-

gral pump runs at constant

power

Opening screen

z display of:

- version number (V1.001)

- instrument type (GM 4)

- sensor type (H2)

8

27.11.2000

12:37

Stadtwerke GT

Heinz Muster

Abt. TDLL 24.4

Date/time

z display of:

- date (27.11.2000)

- time (12:37)

- user name

z properly-set values are impor-

tant for the documentation of

your readings

Page 18

3 Measuring operation

Sensor install.

12.06.2002

durability

24 Monate

H2

0...1,00 Vol%

z you can correct any variances

(cf. section 8.2: Setting the

date/time)

Instrument settings

The EX-TEC OD 4/GM 4 defaults

to a set operating mode at switchon, which you can change (cf.

section 9.4: Autostart). The

operating mode is factory-set to

„Measurement“:

z display of:

- battery-charge level

- gas (here: H2)

- operating mode

(here: measurement)

- range

(here: 0 – 1.00 vol.%)

Other possible settings can be

found in section 9.4: Autostart.

z display of the day the sensor

was tted

z display of expected sensor

life

Symbols

z available operating hours are

displayed (5 hours = 5 bars)

symbol: battery

z measurement is under way

(symbol eggtimer)

z all alarm thresholds are acti-

vated

symbol: alarm threshold

9

Page 19

3 Measuring operation

Next scheduled inspection

(display optional)

z if you have set an inspec-

tion interval, the next scheduled inspection date (e.g.

11.03.2004) is displayed for

about 3 seconds (cf. section

8.3: Setting the inspection

interval))

z depending on the current and

inspection dates, the intermittent or continuous alarm may

also be triggered (items 1

and 7)

z clearing the alarm with the

on/off key or waiting for 15

seconds switches to measuring operation

Note:

If the EX-TEC OD 4/GM 4 now automatically

switches off, the inspection date has passed with

the inspection block switched on (cf. section 8.0:

System menu).

The instrument does not revert to measuring opera-

tion until an inspection has been carried out and

conrmed.

10

Page 20

3.2 Operating modes

WARNING

z Warning of high gas concentration in buildings and the work-

ing environment

z Testing enclosed spaces

H2

1500

PPM

3 Measuring operation

z all alarm thresholds are acti-

vated

NB:

z the current gas concentration

is displayed:

- as a gure

(e.g.: 1500 PPM H2)

- as a trend bar

z every 5 seconds an operating

signal - both acoustic (item 7)

and optical (item 1) - is emitted

to conrm that the instrument

in functioning in the warning

operating mode. If this operating signal is not emitted,

you cannot be sure that the

gas concentration is being

properly monitored and must

leave the endangered area

without delay.

11

Page 21

3 Measuring operation

H2

PPM

1500

MEASUREMENT

EX-TEC GM 4:

z Testing the gas concentration in buildings

z Measuring gas concentrations in pipes and elsewhere

z Searching for leaks in pipes in buildings

z Checking joints, e.g. weld seams

z Carrying out building tests

z Checking enclosed spaces

EX-TEC OD 4:

z Determining the odorant concentration in natural gas

z Measuring the odorant concentration in the air in odorising

plants

z Before sampling observe the sufcient ush of intake

z the current gas concentration

is displayed:

- as a gure

(e.g.: 1500 PPM H2)

- as a trend bar

12

Sampling hoses

To ensure that the sample always passes through the

EX-TEC OD 4 at an adequate rate, there are different sampling

hoses for each of the possible pressure ranges. These are colourcoded as follows:

Colour Pressure range Part-Nr.

black 20 – 50 mbar OD04-Z0100

blue 50 – 125 mbar OD04-Z0200

green 125 – 400 mbar OD04-Z0300

yellow 400 – 1000 mbar OD04-Z0400

red 1 – 2 bar OD04-Z0500

(further on request)

Measurements are only reliable if the original Sewerin-supplied

hoses are used.

Page 22

Switching operating modet

H2

0...1,00 Vol%

H2

0...1,00 VOL%

AL1 0,4 VOL%

AL2 0,8 VOL%

pin point:

0001

pin point: 0001

02.07.02 13:58

1500 PPM

3 Measuring operation

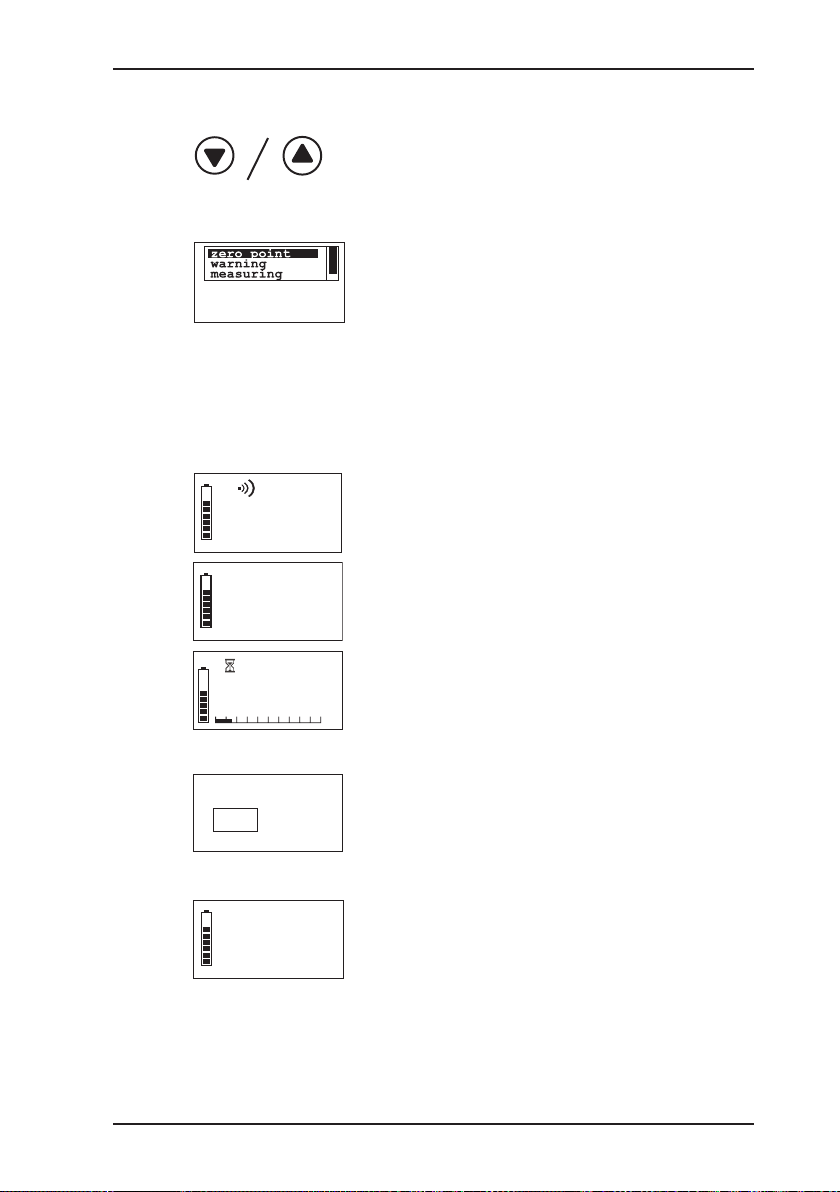

z holding down one of the cursor

keys for about 2 seconds

brings you to operating mode

selection

z use the cursor keys to select

one of the items:

Zero point

in the currently selected mea-

surement range zero-point

correction can be carried out

if necessary (temporary zero-

point adjustment within certain

limits)

Warning

selects the WARNING operating mode

Measurement

selects the MEASUREMENT

operating mode

1500

â

â

H2

PPM

Saving

The gas concentration measured can be saved and

assigned to a measurement

location. After the number of

the measurement location

has been entered, the measurement location, date, time

and reading are displayed

together once again. These

data can subsequently be read

out and analysed with the PC

analysis software (available

separately).

13

Page 23

3 Measuring operation

z then press the on/off key to

conrm your selection

Note:

If the selection is not conrmed with the on/off key,

the instrument reverts to its previous operating mode

after about 10 seconds!

14

Page 24

3 Measuring operation

Starting measurement (only possible on the EX-TEC OD 4 in

the „Measurement“ operating mode)

z A measurement can also be started by briey pressing the

on/off key.

z Indication when measurement is under way: eggtimer

symbol.

z Measurement is halted on the expiry of the measurement dura-

tion (about 3.5 minutes) or when the reading has stabilised.

z When measurement is complete the reading can be assigned

to a measurement location and saved.

z These data can subsequently be read out and analysed with

the PC analysis software (available separately).

z If no measurement location is entered within 10 seconds, the

measurement is lost.

0.0

0.0

store

Yes

No

16.5

pin point: ----

5.4.2002 8:50

16.5

14.5

THT

mg

m3

THT

mg

m3

mg

m3

mg

m3

THT

mg

m3

Possibilities to start measuring:

1) choose menu and start measuring

2) press on-key shortly

Cancel measuring:

1) press on-key shortly

2) choose menu and stop measuring

pin point:

0

012

pin point: 0012

5.4.2002 8:50

mg

16.5

m3

Time-out: 60 seconds

Time-out: 10 seconds

Measuring value remains

for 20 seconds

15

Page 25

3 Measuring operation

H2

AL1

VOL%

0,4

3.3 Alarms

In the WARNING operating mode the EX-TEC OD4/GM 4 has

various alarm thresholds:

EX-TEC OD 4

Example: TBM

AL1 alarm threshold 1 = 10 mg/m

AL2 alarm threshold 2 = 20 mg/m3

EX-TEC GM 4

Example: H2 (factory setting)

AL1 alarm threshold 1 = 4000 ppm

AL2 alarm threshold 2 = 8000 ppm

3

AL1 alarm (example: H2)

z if this alarm threshold is

exceeded, the result is:

- optical alarm (item 1)

- acoustic alarm (item 7) at

2 Hz

- LCD (item 2) lights up

- AL1 appears in the LCD

z the 2 Hz intermittent tone is

quite different from the operating signal

z the acoustic AL1 alarm can

be cleared by briey pressing

the on/off key, but the optical

alarm (item 1) continues

z if the concentration falls below

this alarm threshold, the optical and acoustic alarms (items

1 and 7) switch off

16

Page 26

3 Measuring operation

H2

AL2

VOL%

0,8

AL2-alarm (example: H2)

z if this alarm threshold is

exceeded, the result is:

- optical alarm (item 1)

- acoustic alarm (item 7) at

5 Hz

- LCD (item 2) lights up

- AL2 appears in the LCD

z the rapid intermittent tone at

5 Hz is quite different from the

operating signal

z the AL2 alarm cannot be

cleared

z if the concentration falls below

this alarm threshold, the alarm

becomes an AL1 alarm, which

can be cleared

17

Page 27

3 Measuring operation

0

3.4 Illumination and operating-hours display

z pressing any key switches the

LCD illumination on

z ou can also adjust the illumina-

tion time individually (cf. sec-

tion 9: Hardware menu)

z when the illumination comes

on the remaining operating

hours (e.g. 5 hours) are displayed

z this display (battery symbol

and bars) and the illumination

switch off automatically after

about 10 seconds

z the battery symbol appears in

the LC display and the operating signal sounds at twice

its normal rate

z you now have at least another

15 minutes' operating time

available

z after that the instrument must

be charged (cf. section 4:

Charging and battery opera-

tion)

1500

3.5 Battery alarm

H2

PPM

H2

PPM

18

Page 28

3.6 Switching off

3 Measuring operation

z hold down the on/off key for

about 3 seconds

z the optical and acoustical

control signals (items 1 and

7) are activated for about 3

seconds

z remaining operating hours are

displayed in the form of the

battery symbol and bars (e.g.

5 hours = 5 bars)

19

Page 29

4 Charging and battery operation

4 Charging and battery operation

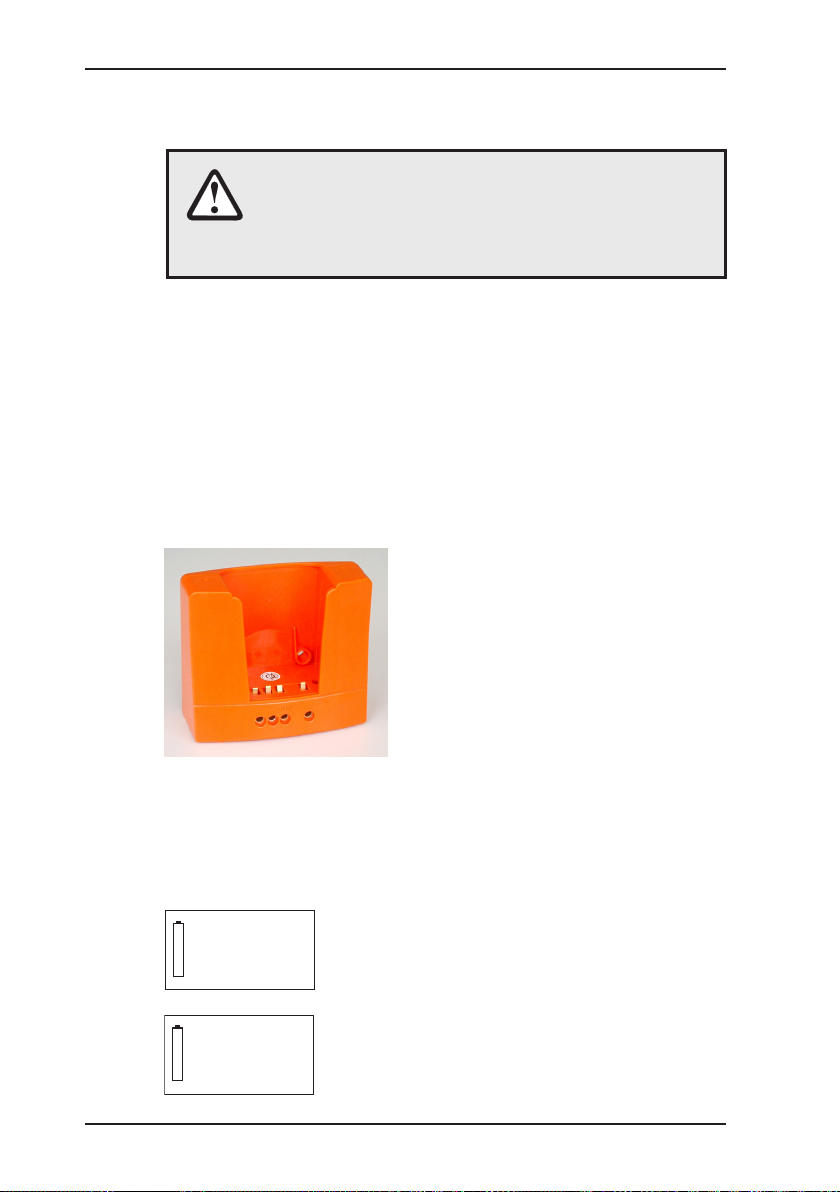

CAUTION!

The EX-TEC OD 4/GM 4 must not be recharged or

its battery compartment opened in an area exposed

to the danger of explosion

4.1 Charging and charge maintenance when using NiMH batteries

Batteries should be approximately at room temperature for charging.

Charging

After 12 hours‘ charging the instrument has about 20 hours of oper-

ation with the pump running or about 50 hours of operation in diffusion operation.

The docking station HG4 is required for charging. It can be used

either in the workshop or in the emergency vehicle.

The docking station has the following connections on its side:

z AC/DC adapter M4 for

100 – 240 V~

z Vehicle cable M4 12 V= mount-

ing

z Vehicle cable M4 12 V=

mobile

z Vehicle cable M4 24 V= mount-

ing

z You can operate up to 5 dock-

ing stations with one 100 – 240

V~ AC/DC adapter M4

z With more than 5 stations the

charg. volt.

too low

charg. volt.

too high

charging voltage is insufcient.

An error message is displayed

to that effect

z if you connect the docking sta-

tion directly to a 24-V network in

the vehicle, the voltage will be

too high for proper charging

20

Page 30

4 Charging and battery operation

04

Place the EX-TEC OD 4/GM 4 in the docking station and a display

on the following lines appears:

z the instrument now has 5

operating hours left (= 5 bars)

and needs another 4 hours to

reach full charge

z if it is fully charged, all the bars

appear and the digital display

disappears

Charge maintenance

Once the instrument is fully charged, it switches automatically to

charge maintenance. It can be left in the docking station until the

next time it is needed.

21

Page 31

4 Charging and battery operation

4.2 Self-dischargeand battery care

If the instrument is not placed in the charging adapter when it is

switched off, this will cause the nickel/metal-hydride battery to

self-discharge, reducing the remaining operating time.

After a maximum of 30 days the instrument indicates no remain-

ing operating hours and it must be recharged.

Note:

Brief periods of use and protracted disuse may in

the long term lead to the so-called „memory effect“,

which means that the actual battery capacity available is less than what is shown in the display.

You can counteract this by fully discharging the

EX-TEC OD 4/GM 4 regularly (e.g. once a month)

and then recharging it.

Switch the instrument on and place it in the docking

station. When it is fully discharged, charging begins

automatically. The entire process takes:

22

20 h (typical discharge, pump instrument)

+ 12 h (full charge)

= 32 h

Page 32

4.3 Battery operation

charge aborted

Alcalinebattery

With new non-rechargeable alkaline batteries the EX-TEC OD 4/

GM 4 will operate for 20 hours with the pump running or 50 hours

in diffusion operation.

Changing the batteries

When the batteries need to be changed, the battery compartment

can be opened with the screwdriver supplied (the two lower screws

on the back of the instrument). Insert the new cells the right way

round (as marked) and close the battery compartment again.

Once the old batteries are removed the date and time are preserved in the instrument for about 120 seconds. If the battery

change takes longer than this, you will have to re-enter both values

next time it is switched on. No other data will be lost.

The value for the operating-hours display for nickel/metal-hydride

batteries is lost if these are replaced by alkaline batteries, so if

nickel/metal-hydride batteries are inserted again they must rst

be fully discharged and then recharged. This ensures that the

available operating hours will be correctly displayed.

4 Charging and battery operation

z An EX-TEC OD 4/GM 4 tted

with non-rechargeable alkaline

batteries cannot be charged.

If you try to do so a warning

message is displayed and the

instrument must be removed

from the docking station.

23

Page 33

4 Charging and battery operation

4.4 Instruments showing serial number 062 00

WARNING!

To ensure that the device remains explosion-proof

as per ATEX 100a, only the following disposable/

rechargeable batteries may be used:

– Those supplied by SEWERIN,

– Others offered by SEWERIN, provided that

compliance with standard EN 60079-7:2003 (especially chapter 5.7.2.1.17; explanation stated

below) is guaranteed.

The types used in a battery compartment must

always be identical in terms of sort (disposable/rechargeable), capacity and manufacturer.

Disposable battery requirements

z Battery size: Mignon AA

z The creepage distance and air gap between the poles must

not be less than 0.5 mm in accordance with (EN 60079-7:2003;

Kap. 5.7.2.1.17).

z Alkaline batteries must comply with EN 60086-1 type LR6.

24

Rechargeable battery requirements

z Battery size: Mignon AA

z The creepage distance and air gap between the poles must

not be less than 0.5 mm in accordance with (EN 60079-7:2003;

Kap. 5.7.2.1.17).

z The accumulators must comply with DIN EN 61951-2 type HR6

and adhere to the temperature range.

CAUTION!

A device operated with disposable alkaline batteries

cannot be charged. A notice to this effect is shown

on the display.

The device comes with nickel metal hydride rechargeable batteries. The corresponding settings are saved.

Page 34

5 Testing the instrument

5.1 Testing/upkeep

The required and prescribed instrument tests must be carried out

in accordance with the following norms:

z EN 50073 (Guidelines for the selection, installation, operation

and maintenance of instruments for the detection and mea-

surement of combustible gases and oxygen)

z EN 45544-4 (Electrical workplace-atmosphere instruments for

the direct detection and direct concentration measurement of

toxic gases and vapours, part 4: Guidelines for selection, installation, operation and upkeep)

z BGI 518 (T023)

z DVGW worksheet G 465-4

The instrument tests prescribed by DVGW worksheet G 465-4

(Technical information, note) are divided into the following sections. Testing also covers accessories used with the instru-

ments.

What ? Who ? When ?

function test user before use

display-accuracy

test (adjustment)

upkeep

(maintenance, re-

pair if necessary)

expert or special-

ist rm

SEWERIN, expert,

authorised special-

ist rm

5 Testing the instrument

daily to half-yearly

annually or whenever a defect occurs

Function test

This is the simplest form of instrument test. Carried out by the

user before use, it comprises the following points:

z external condition including probe systems

z function of the operating controls

z function of the operating controls

z inspection of the pump and the intake channel

z pump function

z zero-point check

25

Page 35

5 Testing the instrument

Checking display sensitivity (adjustment)

Testing frequency must be specied as a function of the sensors

tted and the use of the instrument. It can be anywhere between

daily and half-yearly.

Testing must be carried out by an expert on the operator‘s own

staff, by a specialist rm or by Sewerin itself.

The function test should be carried out at the same time.

Upkeep - maintenance and repair

The instrument must be maintained at least once a year by

SEWERIN Service, a specialist rm authorised by SEWERIN or

a SEWERIN-authorised expert.

Certicates must be issued accordingly.

The test disc on the instrument

conrms when maintenance was

last carried out and indicates the

next scheduled date.

26

Annual maintenance and repair must cover at least the specialist

care and adjustment of the instrument and the replacement of

components with a limited useful life.

Note:

Where instruments have explosion protection the

applicable regulations must be be observed!

Note:

Technicians responsible for upkeep must have been

trained and instructed by Sewerin!

Page 36

5.2 Test set

The EX-TEC GM 4 and EX-TEC OD 4 each have their own test

sets.

5.2.1 EX-TEC GM 4

The test set SPE HG and SPE-Y check display accuracy:

C

B

E

5 Testing the instrument

D

A

Fig.: Test set SPE HG

Item. Description Function

A instrument hose

connection with:

z probe connection

z test heads

B test gas connection connection for:

z test gas cans

z pressure-hose adapter (in

conjunction with pressure

reducer

C pressure indication Display of actual pressure inside

the test gas can

D release key release of test gas

E connection hose connection with:

z instrument hose

27

Page 37

5 Testing the instrument

5.2.2 EX-TEC OD 4

The test set SPE OD checks display accuracy:

E D

C

A

B

Fig.: Test set SPE OD

Item. Description Function

A instrument hose

connection with:

z probe connection

z test heads

B test gas connection connection for:

z test gas cans

z pressure-hose adapter (in

conjunction with pressure

cylinder and pressure reducer

reducer

C pressure indication Display of actual pressure inside

the test gas can

D release key release of test gas

E connection hose connection with:

z instrument hose

28

Page 38

5.3 Test gases

The following test gases are used in conjunction with the test set

SPE HG/SPE OD to check the zero point and display accuracy

in the factory. Test gas concentrations other than those listed

here can also be used - see section 7.3: Setting the test gas

concentration.

Gas test gases

THT

-zero point

-sensitivity

TBM

-zero point

-sensitivity

Carbon monoxide CO

-zero point

-sensitivity

Hydrogen H2

-zero point

-sensitivity

Hydrogen sulphide H2S

-zero point

-sensitivity

Ammonia NH3

-zero point

-sensitivity

Oxygen O2

-zero point

-sensitivity

Hydrogen chloride HCI

-zero point

-sensitivity

5 Testing the instrument

fresh air

e. g. 15 mg/m3 in synthetic air

fresh air

z. B. 10 mg/m3 in synthetic air

fresh airt

z. B. 30 ppm in synthetic air

fresh air

1 % vol. in synthetic air

(0 – 100 ppm and 0 – 2000 ppm)

fresh airt

40 ppm in N

2

fresh air

50 ppm in N

100 % vol. CH4 or CO

2

2

fresh air

fresh air

5 ppm in synthetic air

29

Page 39

5 Testing the instrument

5.4 Testing the pump, zero point and display accuracy

Pump (pump instruments only)

The power of the instrument‘s integral pump is 5 – 15 l/h. You

can function-test it by carrying out a simple impermeability test

as follows:

z swith the instrument on in fresh air

z place the test head on the EX-TEC OD 4/GM 4 and cover its

nipple with a nger

if the pump is working properly, error message F100 (cf. section

11.3: Error messages) appears after about 10 seconds

This error message is triggered if the volume ow falls below

half its nominal level.

The error message can be cleared by holding down any key.

z we recommend, replacing the pump lter of pump instruments

on a regular basis (cf. section 11.4: Consumables).

Changing the pump lter with the EX-TEC OD 4/GM 4

switched off:

Undo and remove the sensor cap and extract the sensor from

its holder. Now remove the pump lter (the white disc 4 mm in

diameter) and replace it with a new one. The sensor (with rubber

seal) and sensor cap can now be replaced. Do not overtighten

the sensor cap screws.

30

For further testing proceed as follows:

z screw the selected test gas can by hand onto the test set you

are using as far as it will go

z EX-TEC GM 4: connect the test head HG4 to the hose of the

SPE HG or SPE-Y

z EX-TEC OD 4: connect the test and probe head OD4 (plug

connection) to the hose of the SPE OD

z enter your results in the test record (cf. appendix)

Page 40

5 Testing the instrument

Zero point

wait for the instrument to warm up and reach a stable zero

point:

Gas tolerance

THT -1.0 mg/m3 – +1.0 mg/m

TBM -1.0 mg/m3 – +1.0 mg/m

3

3

Carbon monoxide CO -3 ppm – +3 pppm

Hydrogen H

2

-40 ppm – +40 ppm

Hydrogen sulphide H2S (0 –100 ppm or. 0 – 2000 ppm)

-3 ppm – +3 ppm or

-20 ppm – +20 ppm

Ammonia NH3 -3 ppm – +3 ppm

Oxygen O2 -0.5 % vol. – +0.5 % vol.

Hydrogen chloride HCI -1 ppm – +1 ppm

If display values are outside these tolerances the pertinent sensor

must be readjusted (cf. section 7: Adjustment menu).

31

Page 41

5 Testing the instrument

Display accuracy

z EX-TEC GM 4: place the test head HG4 (without screws) on

the instrument and hold down the release key of the SPE HG

until the displayed concentration has reached a stable value.

z EX-TEC OD 4: place the test and probe head OD4 (plug

connection) (without screws) on the instrument and turn the

knob of the SPE OD. Now begin a measurement.

The display values given in this table must be reached when

the test gases listed in section 5.3 are administered.

Gas Toleranz

THT 90 % – 110 % of the test gas

TBM 90 % – 110 % of the test gas

Carbon monoxide CO 27 – 33 ppm

Hydrogen H

Hydrogen sulphide H2S (0 – 100 ppm or 0 – 2000 ppm)

Ammonia NH3 45 – 55 ppm

Oxygen O2 20.4 – 21.4 % vol.

Hydrogen chloride HCI 4.5 – 5.5 ppm

2

0.9 – 1.1 % vol.

36 ppm – 44 ppm or 20 – 60 ppm

32

If display values are outside these tolerances the pertinent sensor

must be readjusted (cf. section 7: Adjustment menu).

Page 42

6 Info menu

6.1 Menu structure

measuring operation Info V1.000

PIN code adjustment 0 PPM or mg/m3

measuring operation

6 Info menu

conc. in PPM or mg/m3

test gas

inspection OK

exit

system Date/time

date format

INS interval

INS block

PIN code

AL1 alarm

AL2 alarm

unit VOL%

user name

language

exit

hardware battery

accu capacity

back light

contrast

autostart

level PPM

range

type of gas

sensor install.

pump

LCD test

reset

exit

memory clear

interval

exit

exit

33

Page 43

6 Info menu

0

PPM

PIN 000

0

6.2 Overview

This is how to reach the Info menu during operation:

+

z simultaneously press both

cursor keys for about 2 sec-

onds

z NB: on pump instruments

the integral pump continues to

run at constant power

z you are now on the INFO menu

item (cf. menu structure)

z you must now enter your PIN

(cf. section 8.5: Setting the

PIN):

- factory setting = 0001

- pressing one of the cursor

keys changes the value of

the highlighted digit

- pressing the on/off key

saves this value

z only then do you have access

to all menu items

z you are now on the adjust-

ment menu item (cf. menu

structure)

34

Page 44

Adjustment

6 Info menu

z press one of the cursor keys

to navigate within the Info

menu

This applies to all menu and

submenu areas

z press the on/off key to select

the highlighted submenu

z if you select the menu item

Back, the instrument reverts

to measuring operation

35

Page 45

7 Adjustment menu

adjustment 0 PPM or mg/m3

adjustment

7 Adjustment menu

The adjustments described below relate to the H2 adjustment

on the EX-TEC GM 4. For other gases, use the test gases given

in section 5.3.

The O2 adjustment is covered explicitly in section 7.2.2. The

EX-TEC OD 4 is adjusted for THT or TBM as per the H2 adjustment, but the test set SPE OD is used with the test and probe

head OD4 (plug connection) and the connection hose supplied

with the test set has to used as well.

7.1 Menu structure

conc. in PPM or mg/m3

test gas

inspection OK

exit

7.2 Sensor adjustment

7.2.1 Setting the H2-sensor

0 ppm

This function resets the zero point:

z carry out the adjustment in fresh air

z wait for the displayed concentration to reach a stable value

z press the on/off key to conrm .

36

Page 46

100 ppm

This function resets the display accuracy of the sensor:

z use the test set SPE HG, the test head HG4 and 100 ppm H2

test gas (cf. section 5: Testing the instrument)

z place (but do not screw) the test head on the EX-TEC GM 4

and hold the release key down until the displayed concentration has reached a stable value.

z press the on/off key to conrm

7.2.2 Setting the O2 sensor

0 % vol.

z use the test set SPE HG, the test head HG4 and 100 % vol.

CH4 or CO2 test gas (cf. section 5: Testing the instrument)

z place (but do not screw) the test head on the EX-TEC GM 4

and hold the release key down until the displayed concentration has reached a stable value.

z press the on/off key to conrm

7 Adjustment menu

20.9 % vol.

z carry out the adjustment in „fresh air“

z wait for the displayed concentration to reach a stable value.

z press the on/off key to conrm .

37

Page 47

7 Adjustment menu

test gas

PPM 0100

0

7.3 Setting the test gas concentration

If you use test gases other than those supplied by SEWERIN

(cf. section 5.3: Test gases), the concentration must be set ac-

cordingly.

Test gas

z briey pressing the on/off key

brings you to the test gas adjustment for the ppm-range

z the current concentration is

displayed, e.g. the factory

setting:

100 PPM (... for hydrogen H2)

z you can enter the required

concentration digit by digit by

pressing one of the cursor

keys and pressing the on/off

key to conrm

38

Page 48

7 Adjustment menu

The adjustment ranges of the individual test gases are:

THT

-adjustment range 10 – 50 mg/m

-increment 0.5 mg/m

3

3

TBM

-adjustment range 5 – 50 mg/m

-increment 0.5 mg/m

3

3

Carbon monoxide CO

-adjustment range 10 – 50 ppm

-increment 1 ppm

Hydrogen H

2

-adjustment range 100 – 10,000 ppm

-increment 20 ppm

Hydrogen sulphide H2S (0 – 100 ppm)

-adjustment range 10 – 100 ppm

-increment 1 ppm

Hydrogen sulphide H2S (0 – 2,000 ppm)

-adjustment range 40 – 2,000 ppm

-increment 10 ppm

Ammonia NH3

-adjustment range 50 – 100 ppm

-increment 1 ppm

Oxygen O2

-adjustment range 17.0 – 22.0 % vol.

-increment 0.1 % vol.

Hydrogen chloride HCI

-adjustment range 10 – 25 ppm

-increment 0.5 ppm

39

Page 49

7 Adjustment menu

7.4 Inspectionconrmation

Inspection OK

In this function you conrm the inspection or adjustment you

have carried out by pressing the on/off key:

z this date is stored as a function of the set date (cf. section 8.2:

Setting the date/time)

z the next inspection or adjustment date is calculated in accord-

ance with the set inspection interval (cf. section 8.3: Setting

the inspection interval)

7.5 Leaving the adjustment menu

Back

This function switches you back to the Info menu:

z press the on/off key to conrm .

40

Page 50

system date/time 29.01.2001 11:10

system

8 System menu

8.1 Menu structure

8 System menu

date format DD.MM.YYYY

INS interval week 00

INS block no

PIN code PIN 0001

AL1 alarm conc. in PPM or mg/m3

AL2 alarm conc. in PPM or mg/m3

unit VOL% VOL%

user name Gasversorgung

language Deutsch

exit

YYYY-MM-DD

yes

%VOL

%GAZ

Musterstadt

Otto Mustermann

English

Français

Italiano

41

Page 51

date/time

3.07.2001 18:18

2

Nullpunkt

date format

DD.MM.YYYY

YYYY-MM-DD

8 System menu

8.2 Setting the date and time

This function sets the current date and the current time:

Date format

This function sets the date display format:

z the date and time are dis-

played

z press one of the cursor keys

to change the value of the

highlighted digit to the current

value

z press the on/off key to save

the value of the highlighted

digit

DD.MM.YYYY

(e.g.: 31.01.2001)

YYYY-MM-DD

(e.g.: 2001-01-31)

z press one of the cursor keys

to select one of the settings:

z press the on/off key to save

the selected setting

42

Page 52

8.3 Setting the inspection intervall

The EX-TEC OD 4/GM 4 can remind you of scheduled inspection

and adjustment dates. This reminder is based on the inspection

interval:

INS interval

weeks 0

0

8 System menu

z the last interval to be set is

displayed

z press one of the cursor keys

to change the interval in week-

ly increments (range: 0 – 52

weeks)

z press the on/off key to save

the set interval

43

Page 53

8 System menu

Example: inspection interval

How does the instrument indicate an inspection date?

1 week before (02. 03. 2004 - 08. 03. 2004)

Inspection

next week

During inspection period (09. 03. 2004 - 15. 03. 2004)

Inspection

necessary

selected inspection interval:

04 weeks

inspection routine started

(i.e. inspection conrmed, see chapter 7.4):

10.02.2004

from these settings follows:

the next inspection has to be effected between 09. - 15.03.2004.

LCD:

When switched-on a hint on the ap-

proaching inspection appears (as 4.

picture) for approx. 3 secs.

lamp/buzzer:

inactive

instrument:

the instrument then automatically switches to measuring operation

LCD:

When switched-on a hint on the due

inspection appears (as 4. picture) for approx. 10 secs.

lamp/buzzer:

interval light/sound

instrument:

the instrument then automatically switches to measuring operation

z by pressing ON/OFF key

OR

z automatically after 10 seconds

44

Page 54

8 System menu

after exceeding inspection period (ab 16. 03. 2004)

Inspection

overtime

LCD:

When switched-on a hint on the overdue

inspection appears (as 4. picture) for ap-

prox. 10 secs.

lamp/buzzer:

permanent light/sound

instrument:

type of reaction depends on function setting INS lock (see chapter 8.4)

Lock active (INS lock = yes)

instrument switches off

z by pressing the ON/OFF key or one

of the cursor keys

OR

z automatically after 10 seconds

Lock deactivated (INS lock = no)

instrument switches to measuring

operation

z by pressing ON/OFF key

OR

z automatically after 10 seconds

How does the instrument deteremine the next inspection

date?

After an inspection has been effected, it has to be conrmed (see

chapter 7.4). Thereby the internal inspection routine is started

again.

Example:

Inspection effected 11. 03.2004

Inspection conrmed 11. 03.2004

Inspection interval 4 weeks (see previous page)

Next

inspection period 08. 04. 2004 – 14. 04. 2004

45

Page 55

8 System menu

INS block

No

Yes

8.4 Setting the inspection block

You can activate an inspection block to make sure your EX-TEC

OD 4/GM 4 is regularly checked. This block does not become

active until the next inspection date has passed (cf. section 8.3:

Setting the inspection interval)..

After that the instrument cannot be operated until the inspection

has been carriedoutandconrmed (cf. section 7.4: Inspection

conrmation):

z briey pressing the on/off key

brings you to the inspectionblock routine

z the last setting is displayed,

e.g.:

No = block inactive

Yes = block active

z you can set the desired con-

dition by pressing one of the

cursor keys and conrming

with the on/off key

46

Page 56

PIN 001

0

PIN code

8.5 Setting the PIN

You can set up your EX-TEC OD 4/GM 4 so that only authorised

persons, e.g. instrument technicians and experts, have access

to the information menu with all its subfunctions. This involves

setting a PIN that must be entered every time the information

menu is called.

When an incorrect PIN is entered the instrument reverts to its

switch-on routine:

PIN = 0000

the function is inactive, every user has access to the Info menu

PIN = 0001 – 9999

the function is active, only persons who know the set PIN have

access to the Info menu

8 System menu

z briey pressing the on/off key

brings you to the PIN-setting

routine

z the last PIN to be set (0001 =

factory setting) appears in the

LC display

z we recommend you to use a

different PIN

z by pressing or holding down

one of the cursor keys and

and conrming with the on/off

key you can set each of the 4

digits from left to right to the

desired PIN

Note:

Make a note of your PIN and only give it to authorised

persons!

If you forget your PIN, please contact SEWERIN

service!

47

Page 57

8 System menu

AL1 alarm

PPM 4000

0

AL2 alarm

PPM 8000

0

8.6 Setting the alarm thresholds

Alarm thresholds other than those pre-set by SEWERIN can be

set as follows.

AL1-alarm

AL2-alarm

z briey pressing the on/off key

brings you to the AL1 alarm

threshold routine

z the current alarm threshold is

displayed, e.g. the factory setting for H2: 4000 PPM

z press one of the cursor keys

to set the desired threshold

and the on/off key to conrm

z briey pressing the on/off key

brings you to the AL2 alarm

threshold routine

z the current alarm threshold is

displayed, e.g. the factory setting for H2: 8000 PPM

48

z press one of the cursor keys

to set the desired threshold

and the on/off key to conrm

Page 58

8 System menu

The AL1 threshold is always lower than the AL2 threshold. The

adjustment ranges of the individual alarm thresholds (factory

settings in bold) are as follows:

Gas AL1 threshold AL2 threshold

THT/TBM

-adjustment range

-increment

CO

-adjustment range

-increment

H

2

-adjustment range

-increment

H2S (0 – 100 ppm)

-adjustment range

-increment

NH

3

-adjustment range

-increment

O

2

-adjustment range

-increment

HCI

-adjustment range

-increment

0.1 – 20.0 mg/m

0.1 mg/m

3

30 ppm

5 – 199 ppm

1 ppm

0.4 % vol.

40 – 9.980 ppm

1 ppm

10 ppm

5 – 99 ppm

1 ppm

20 ppm

1 – 99 ppm

1 ppm

18.0 % vol.

15.0 – 24.9 % vol.

0.1% vol.

5 ppm

9.5 ppm

0.5 ppm

3

20.1 – 100.0 mg/m

0,1 mg/m

60 ppm

6 – 200 ppm

1 ppm

0.8 % vol.

60 – 10.000 ppm

1 ppm

20 ppm

6 – 100 ppm

1 ppm

150 ppm

2 – 100 ppm

1 ppm

23.0 % vol.

15.1 – 25.0 % vol.

0,1 % vol.

10 ppm

1.0 – 10 ppm

0.5 ppm

3

3

49

Page 59

8 System menu

unit VOL%

%GAZ

%Vol

VOL%

% vol. unit

z briey pressing the on/off key

brings you to the volume-unit

setting routine

z he current setting is displayed,

e.g.:

VOL% - display in VOL% (D/GB)

%VOL - display in VOL% (I)

%GAZ - display in %GAZ (F)

z press one of the cursor keys

to set the required unit and the

on/off key to conrm

50

Page 60

8.7 Setting the user name

You can also enter your name, your department or other personal

information in the EX-TEC OD 4/GM 4. These will then be dis-

played every time the instrument is switched on to avoid doubt

about who it is assigned to.

Three lines of 16 characters each are available for entries, e.g.:

Gassupply - line 1

Anytown - line 2

Otto Mustermann - line 3

User name

The user name is entered with buttons and . All existing

signs must be conrmed.

There are two possibilities of entering:

1. possibility: new entry, no existing sign to be overwritten.

Entry starts with a blanc „ „.

Letters A - Z can be chosen in alphabetical order with button

.

After reaching letter Z the menu starts again with letter A.

Letters Z - A can be chosen downwards with button .

After letter A the additional characters

@>=<;:9876543210/.-,+*)(‚&%$#“ are displayed!

8 System menu

Note:

The additional characters can only be chosen with

button .

The chosen letter is conrmed with button .

The instrument automatically goes to the next letter.

After conrming the last letter of the user name, the instrument

returns to the system menu.

51

Page 61

8 System menu

2. possibility: an existing letter has to be overwritten.

When switching to the letter, the already existing letter is displayed.

The blanc appears when pressing button , thereafter letters

A - Z can be chosen as described on the previous page.

After reaching letter Z the menu starts again with letter A.

When pressing button the previous letter of the alphabet ap-

pears, all others appear in descending order.

After letter A the additional characters @>=<;:9876543210/.-,+*)

(‚&%$#“ are displayed!

The chosen letter is conrmed with the button.

The instrument automatically goes to the next letter.

After conrming the last letter of the user name, the instrument

returns to the system menu.

Note:

It could occur that during entry blancs a displayed

by a black block. This only happens in entry mode.

The actual display shows the correct blancs.

52

Page 62

language

Englisch

Fran ais

Italiano

ç

Deutsch

system

exit

AL1 alarm

AL2 alarm

unit VOL%

user name

language

8.8 Setting the language

You can set the language of the individual menu items:

8.9 Leaving the system menu

8 System menu

z briey pressing the on/off key

brings you to the languagesetting routine

z the available settings are

displayed

z press one of the cursor keys

to set the required language

and the on/off key to conrm

z this function switches back to

the Info menu

z press the on/off key to con-

rm

53

Page 63

9 Hardware menu

hardware battery accu NiMH

hardware

9 Hardware menu

9.1 Menu structure

9.1.1 EX-TEC GM 4

Alkaline

accu capacity mAh 1100...2300

back light sec. 010

contrast 55%

autostart warning

range PPM

type of gas CO 300 PPM

sensor install. 12.06.2002

pump yes

LCD test

reset no

exit

measuring

mg/m3

10000 PPM

H

2

S 100 PPM

H

2

S 2000 PPM

H

2

100 PPM

NH

3

25.0 Vol%

O

2

no

yes

54

Page 64

9.1.2 EX-TEC OD 4

hardware battery accu NiMH

hardware

9 Hardware menu

Alkaline

accu capacity mAh 1100...2300

back light sec. 010

contrast 55%

autostart warning

range PPM

type of gas THT 0...100 mg/m3

sensor install. 12.06.2002

pump yes

LCD test

reset no

exit

measuring

mg/m3

TBM 0...100 mg/m3

no

yes

55

Page 65

9 Hardware menu

0..10000 PPM

battery

Accu NiMH

Alcaline

NullpunktNullpunkt

Accu capacity

mAh 1600

1

9.2 Setting the battery type

The EX-TEC OD 4/GM 4 can be operated with both rechargeable

and non-rechargeable batteries (primary cells).

For the correct display of operating hours it is important for the

current battery type to be properly set:

If you have selected NiMH as the battery type, you can enter the

capacity (see the information on the battery itself):

z the last battery type set is dis-

played

z press one of the cursor keys

to select between settings:

NiMH batteries

(rechargeable)

alkaline batteries

(non-rechargeable)

z press the on/off key to save

the battery type set

z the last value set is displayed

56

z press the cursor keys to

change the value

(range: 1100 – 2300 mAh)

z press the on/off key to save

the set value

Page 66

contrast

22 %

back light

sec. 10

0

9.3 Setting the illumination time and contrast

During measuring operation the LCD illumination can be switched

on by pressing any key (cf. section 3.4: Illumination and operating-hours display).

The period for which the illumination stays on can be set individually:

z the last period set is dis-

played

z press the cursor keys to

change the value in seconds

(range: 10 – 240 seconds)

z press the on/off key to save

the set value

The contrast of the LCD can be set individually:

z the last contrast set is dis-

played

9 Hardware menu

z press one of the cursor keys

to change the value in percent

(range: 0 – 100 %); 55 % is a

good working value

z press the on/off key to save

the set value

57

Page 67

9 Hardware menu

autostart

warning

measuring

9.4 Autostart

The EX-TEC OD 4/GM 4 enables you to set the default operating

mode after switch-on. This function is preserved even when the

instrument is switched off.

z briey pressing the on/off key

brings you to the Autostart

routine

z the last set operating mode

is highlighted, e.g. the factory

setting „Measurement“

z press one of the cursor keys

to select one of the Autostart

functions

z briey press the on/off key to

conrm the selected Autostart

function

58

Page 68

range

PPM

mg/m3

9.5 Range

The EX-TEC OD 4/GM 4 enables you to dene the measurement

units for some gases.

With THT/TBM sensors, for example, you can switch between a

display in ppm and mg/m3.

9.6 Changing the sensor

The sensor in the EX-TEC GM 4 can be changed. The following

sensors are available: CO, H2, H2S (100 ppm), H2S (2000 ppm),

NH3, O2 and HCl.

Sensors not in use have to be stored in a special storage box.

9 Hardware menu

z briey pressing the on/off key

brings you to the Autostart

routine

z the last set unit is highlighted

z press one of the cursor keys

to select one of the measurement units

Note:

The sensor in the EX-TEC OD 4 cannot be changed,

and if an EX-TEC GM 4 is tted with an HCl sensor

that cannot be changed either.

When you have changed the sensor you must enter the gas type

and then the date on which the sensor was tted.

CAUTION!

Whenever you change a sensor, you must readjust

the instrument following a suitable test routine (see

section 7).

59

Page 69

9 Hardware menu

sensor install.

12.06.2002

type of gas

CO 300 PPM

H2 10000 PPM

9.6.1 Gas

9.6.2 Sensor installation

The sensor installation date can be entered.

z briey pressing the on/off key

brings you to the gas-setting

routine

z the possible sensors are dis-

played

z press one of the cursor keys to

select one of the sensors

z briefly pressing the on/off

key brings you to the sensor

installation-date routine

z the date when the sensor was

installed is displayed

60

z press one of the cursor keys

to enter the date and the on/

off key to conrm

Page 70

pump

No

Yes

9.7 Setting pump operation

This function only applies to pump instruments. Pump instruments

have the letter P on the identication sticker on the back.

If the pump of an EX-TEC OD 4/GM 4 (pump) fails, you can switch

it off and continue to use it as a diffusion instrument (though the

probes cannot be used):

9.8 Carrying out an LCD test

The LCD of your EX-TEC OD 4/GM 4 has a matrix display. This

test checks whether it is fully functional.

The test pattern that it generates enables the failure of individual

pixels to be rapidly detected.

9 Hardware menu

z the last set condition is dis-

played

z press one of the cursor keys

to select one of the condi-

tions:

Yes (pump active)

No (pump inactive)

z press the on/off key to save

the set condition

z briey pressing the on/off key

starts the LCD test

61

Page 71

9 Hardware menu

9.9 Restoring the factory settings

If all instrument settings (e.g. gas, sensor type, pump condition,

contrast, illumination time etc.) have become totally disordered,

the EX-TEC OD 4/GM 4 can be restored to a dened initial state

(factory setting):

CAUTION!

„After the instrument has been restored to its original

settings, the adjustment must be checked!“

z the date of the last restora-

tion to factory settings is displayed

z press one of the cursor keys

to select one of the options:

No leave settings as they

are

Yes restore factory settings

z press the on/off key to conrm

the selected option

62

Page 72

9.10 Leaving the hardware menu

This function switches back to the Info menu:

9 Hardware menu

z press the on/off key to con-

rm

63

Page 73

10 Memory menu

memory clear

memory

10 Memory menu

10.1 Menu structure

10.2 Clearing memory

interval

exit

z this function clears all saved

readings

z press one of the cursor keys

to select one of the options:

No leave the memory con-

tent as it is

Yes clear all saved read-

ings

64

z press the on/off key to conrm

the selected option.

Page 74

interval

5 sec.

10.3 Setting the memory interval

Data-memory capacity

Interval capacity

1 s typ. 7 h

2 s typ. 15 h

5 s typ. 39 h

10 s typ. 78 h

20 s typ. 156 h

30 s typ. 234 h

60 s typ. 470 h

10 Memory menu

z you can set the frequency at

which readings are saved,

e.g.:

5 sec (factory setting)

readings are saved every 5

seconds

z press one of the cursor keys

to change the value

z press the on/off key to save

the new value

10.4 Leaving the memory menu

This function switches back to the Info menu:

z press the on/off key to con-

rm

65

Page 75

11 Technical aspects

11 Technical aspects

11.1 Technical notes

Identicationsticker

The identication sticker on the back of the instrument includes

a pictogram of a crossed-out screwdriver. This means that the

battery compartment may not be opened in an area exposed to

the danger of explosion.

Notes

If the EX-TEX OD 4 is not left in the docking station after

charging, it will have to be fully recharged again after 4 weeks

at the most.

If the instrument will not switch on because of lack of power, charge it up and recalibrate it after a 3-day recovery period.

66

Accessories

The instrument accessories fall into three main groups: charging

equipment, test equipment and sampling hoses (see section 12.2

„Accessories“).

Cleaning

The instrument should only be cleaned with a damp cloth: use

no solvents, benzene, silcon-containing Cockpit-Spray or similar

substances.

Page 76

11 Technical aspects

Static charge

Electrostatic charges should generally be avoided. Electrostatically oating objects (like metallic housings with no earth connection,

for example) are unprotected against charges transferred from

dust, aerosols and the like.

Battery change

After a change of batteries the EX-TEC OD 4 and the EX-TEC GM 4

with an HCl sensor require a minimum warm-up period of 15 mi-

nutes for a stable zero point to be reached.

67

Page 77

11 Technical aspects

11.2 Technical data

Instrument data

- Dimensions (W x H x D) 60 x 144 x 35 mm

- Weight: about 300 g

EX-TEC GM 4 (Serial number)

- diffusion instrument: 062 00 (type - version - number)

- pump instrument: 062 01 (type - version - number)

EX-TEC OD 4 (Serial number THT)

- diffusion instrument: 062 02 (type - version - number)

- pump instrument: 062 03 (type - version - number)

EX-TEC OD 4 (Serial number TBM)

- diffusion instrument: 062 04 (type - version - number)

- pump instrument: 062 05 ((type - version - number)

Explosion protection (CENELEC)

- Testing institution: TÜV NORD CERT GmbH, Hannover

- Test number: TÜV 01 ATEX 1657

- Identication 1:

- Identication 2:

II2G Ex e ib IIB T4 Gb

basic instrument without leather case

for all gases except hydrogen H

2

II2G Ex e ib IIC T4 Gb

basic instrument with leather case for

all gases including hydrogen H

2

68

Pump power

- negative pressure: > 150 mbar

- volume ow: typically 5 – 15 l/h

Page 78

11 Technical aspects

Power supply

- Batteries: 3 rechargeable NiMH batteries or

3 alkaline primary cells

(cf. section 4.3: Battery operation)

- Charging voltage: 12 V=

- Charging current: 360 mA (pulsed)

- Charging period: about 12 hours (depending on battery

capacity)

Measurement

principle:

electrochemical measurement cell,

temperature compensation,

zero-point correction

Sensor life: see sensor data!

Operating time: 20 h (pump operation)

50 h (diffusion operation)

alarms and illumination reduce the operating time

Connection pressure

(EX-TEC OD 4)

20 mbar - 2 bar

(through different hoses: see page 12)

Operating and

storage temperature: see sensor data!

69

Page 79

11 Technical aspects

THT sensor data

Measurement principle: electrochemical

Range: 0 – 100 mg/m

3

Response times (pump instruments):

t90< 210 sec

The use of probes increases response times!

Warm-up period: about 1 minute

Lifetime (depending on the ambient temperature):

- expected 18 months

Cross-sensitivity at 20 °C:

Gas Concentration Display

Carbon Dioxide CO2 5,000 ppm 0 mg/m3

Carbon Monoxide CO 100 ppm 2 mg/m3

Carbon Oxide Sulde

1 % vol. 10 mg/m3

(COS)

Ethylene C2H4 1 % vol. yes, not dened

Hydrocarbons 100 % vol. 0 mg/m3

Hydrogen H2 1 % vol. > 200 mg/m3

Hydrogen Sulde H2S 20 ppm 0 mg/3

Isopropanol C3H8O 200 ppm 400 mg/m3

Methane CH4 100 % vol. 0 mg/m3

Nitrogen N2 100 % vol. 0 mg/m3

Tert.-Butylmercaptane 10 mg/m3 10 mg/m3

Triethyleneglycol

ppm scale yes, not dened

C6H14O4

70

Operating temperature: -10 °C – +40 °C

Humidity: 10 – 95 % r.h., non-condensing

Page 80

TBM sensor data

Measurement principle: electrochemical

11 Technical aspects

Range: 0 – 100 mg/m

3

Response times (pump instruments):

t90< 270 sec

The use of probes increases response times:

Warm-up period: about 1 minute

Lifetime:

expected 12 months

Cross-sensitivity at 20 °C:

Gas Concentration Display

Alcohols 1,000 ppm 0 ppm

Carbon Dioxide CO2 5,000 ppm 0 ppm

Carbon Monoxide CO 300 ppm 0 ppm

Hydrocarbons 100 % vol. 0 ppm

unsat. Hydrocarbons 1,000 ppm 0 ppm

Hydrochloric Acid HCI 10 ppm 0 ppm

Hydrogen H2 1,000 ppm 0 ppm

Hydrogen Sulde H2S 1 ppm 0 ppm

Nitrogen N2 100 % vol. 0 ppm

Nitrogen Dioxide NO2 1 ppm yes, not dened

Nitrogen Monoxide NO 10 ppm 0 ppm

Operating temperature: -10 °C – +40 °C

Humidity: 10 – 95 % r.h., non-condensing

71

Page 81

11 Technical aspects

Carbon monoxide CO sensor data

Measurement principle: electrochemical

Range: 0 – 500 ppm

Response times (pump instruments):

The use of probes increases response times!

Warm-up period: about 1 minute

Lifetime (depending on ambient temperature):

- garanteed 24 months

- expected 36 months

Cross-sensitivity at 20 °C:

Gas Concentration Display

Alcohol 1,025 ppm 0 ppm

Ammonia 100 ppm 0 ppm

Carbon dioxide 10 % vol. 0 ppm

Chlorine or bromine 5 ppm 0 ppm

Benzene vapour 1 % vol. 0 ppm

Hydrogen 1,000 ppm 250 ppm

Hydrogen sulphide 20 ppm 0 ppm

Nitrogen dioxide 10 ppm 0 ppm

Nitrogen oxide 100 ppm 25 ppm