Page 1

Operating

Instructions

Page 2

Measurable success by Sewerin equipment

Congratulations.

You have chosen a quality instrument manufactured by Hermann

Sewerin GmbH.

Our equipment will provide you with the highest standards of performance, safety and efficiency. They correspond with the national and

international guide-lines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice

and assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

Sewerin Ltd.

8, Walsworth Road

Hitchin

Hertfordshire

SG4 9SP, UK

phone: +44 1462-634363

www.sewerin.co.uk

info@sewerin.co.uk

SEWERIN Sarl

17, rue Ampère - BP 211

67727 HOERDT CEDEX, France

Tél. : +33 3 88 68 15 15

Fax : +33 3 88 68 11 77

www.sewerin.com

sewerin@sewerin.fr

Sewerin USA, LLC

13551 W. 43rd Drive, Unit R

Golden, CO 80403-7272

phone: +1 303-424-3611

fax: +1 303-420-0033

www.sewerin.net

jerry.palmer@sewerin.net

SEWERIN IBERIA S.L.

c/ Cañada Real de Merinas, 17

Centro de Negocios „Eisenhower“

Edificio 5; Planta 2 - C

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.com

info@sewerin.es

Page 3

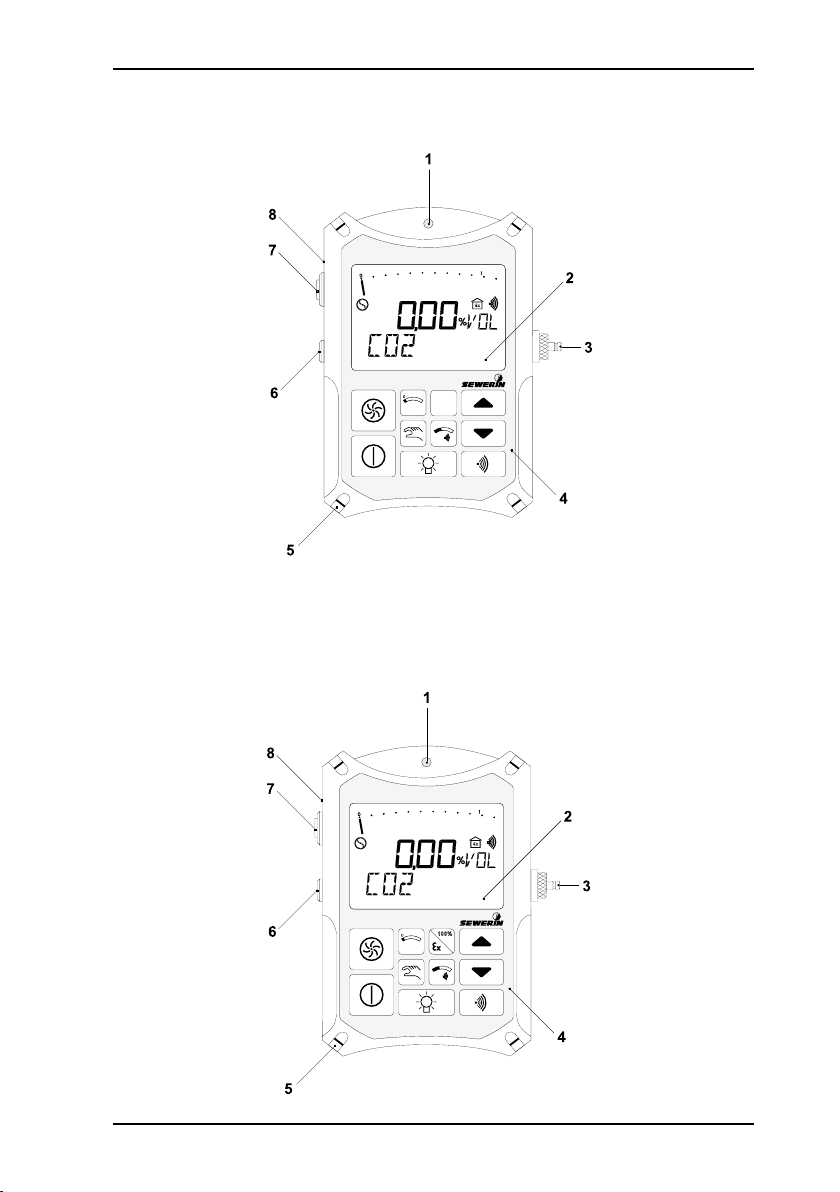

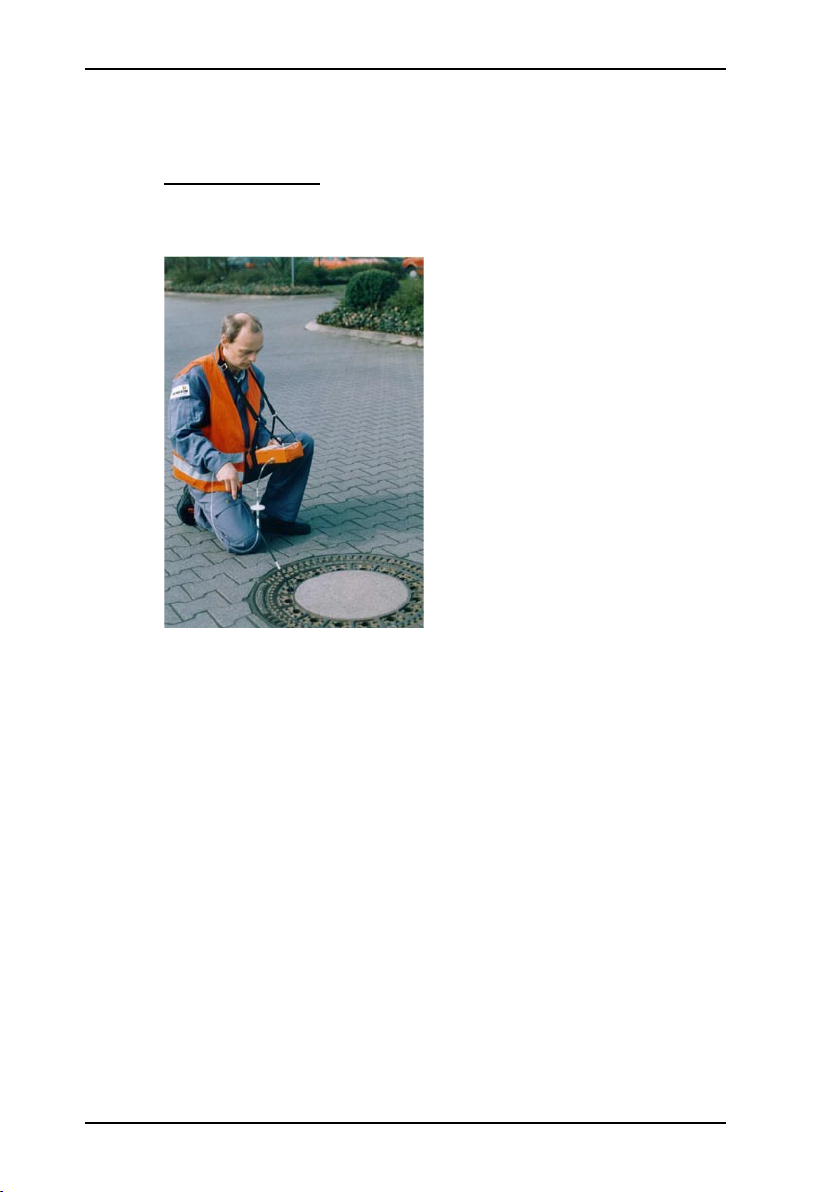

Illustration EX-TEC Combi

EX-TEC® Combi

EX-TEC® Combi

100%

Device variation 1

Device variation 2

Page 4

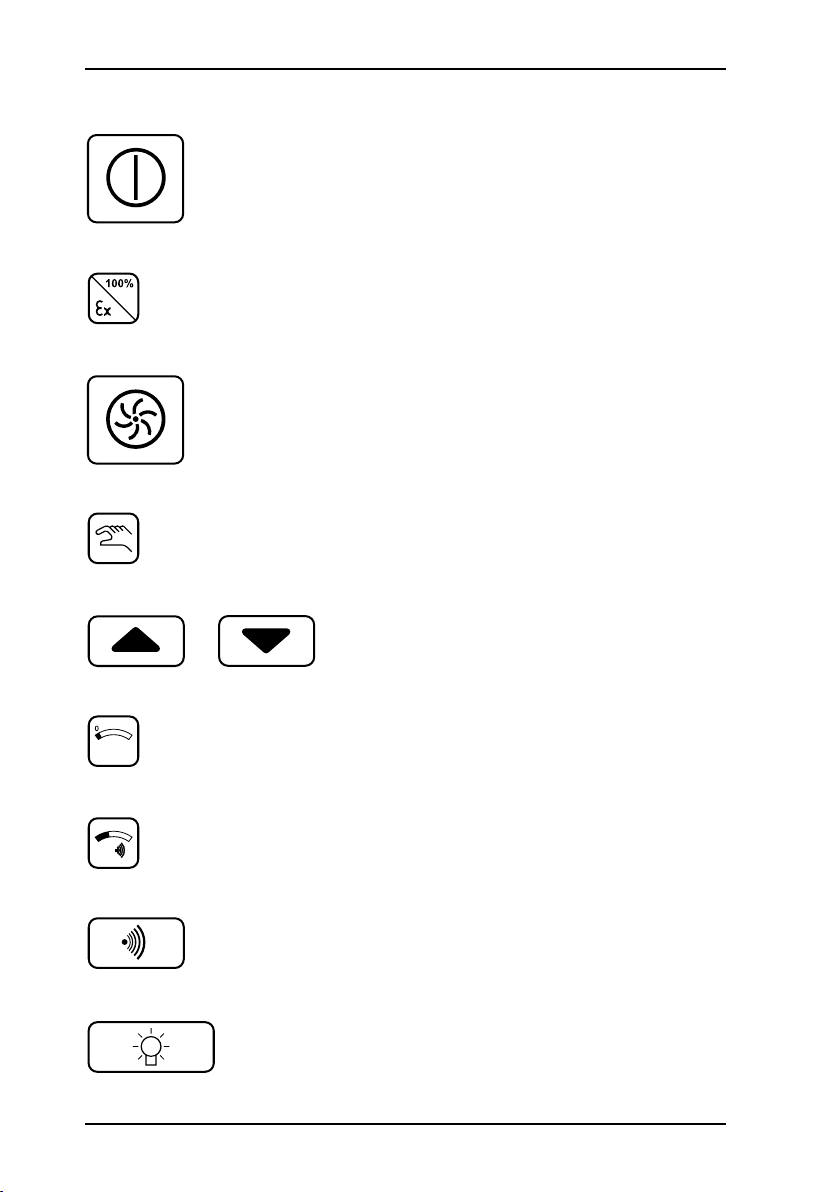

Brief operating instructions

EX-TEC Combi: brief operating instructions

Switch on/off

Toggle between GAS WARNING/GAS

MEASUR E M ENT op e rat i n g mo d es

(Device variation 2)

Device variation 1: Toggle between

GA S WAR NING/GAS MEASURE MENT operating modes

Switch pump on/off

(in GAS MEASUREMENT mode)

Toggle between automatic/manual gas

switching

Change the gas displayed (in manual

operation)

Zero-point correction for the gas displayed

Display gas alarm thresholds AL1 and

AL2

Acoustic clearance of the AL1 alarm

Switch LCD illumination on/off (switches

off automatically after about 4

Page 5

Operating Instructions

EX-TEC® Combi

15.06.2005 – V2.X – 103401 – en

Page 6

For your safety

This product may only be operated by appropriately-trained persons who

are familiar with the relevant operating manual.

It may only be used for its designated purpose, i.e. for industrial and commercial use.

Repair work may only be carried out by specialists or by persons who have

undergone appropriate training.

Any alterations or modifications to the product require the prior approval of

Hermann Sewerin GmbH. In the event of unauthorised alterations to the

product the manufacturer accepts no liability for damage.

Only Hermann Sewerin GmbH accessories may be used with the product.

Only spare parts approved by us may be used for repairs.

Hermann Sewerin GmbH accepts no liability for damage resulting from

non-compliance with the foregoing. The guarantee and liability provisions

in the Hermann Sewerin GmbH terms of sale and supply are not extended

by the foregoing.

We reserve the right to make changes in the context of continued technical development.

In addition to these instructions, please comply with generally applicable

safety and accident-prevention regulations!

Symbols used:

(⊗)

CAUTION!

This symbol warns of dangers that may threaten

the safety of the user or maty damage or destroy

the product.

Note:

This symbol flags information and hints extending

beyond the actual operation of the product .

This symbol will hereinafter identify all operating

modes and measuring techniques not tested by

DMT!

Page 7

Contents Page

1 EX-TEC Combi system ...........................................................1

1.1 Excess-gas warning and measuring instrument .......................1

1.2 Fields of application ..................................................................2

1.3 Test certificates .........................................................................4

1.4 Carrying equipment ...................................................................5

2 Safety .......................................................................................6

2.1 Safety notes .............................................................................. 6

3 Measuring operation ...............................................................8

3.1 Instrument description ...............................................................8

3.2 Switching on ..............................................................................9

3.3 Modes .....................................................................................13

3.4 Switching gases ...................................................................... 15

3.5 Alarms .....................................................................................16

3.6 Instantaneous value alarms (AL1, AL2, AL3) ..........................17

3.7 Short-term value alarm (KZW), long-term value alarm (LZW),

minimum and maximum values (MIN/MAX) ............................23

3.8 Zero point adjustment .............................................................26

3.9 Illumination and contrast ......................................................... 26

3.10 Operating hours display and battery alarm ............................. 27

3.11 Switching off ............................................................................28

4 Charging ................................................................................29

4.1 Charging and charge maintenance .........................................29

4.2 Self-discharge ......................................................................... 30

5 Testing/maintenance .............................................................31

5.1 Function testing, testing display accuracy, maintenance ........32

5.2 Test set ....................................................................................34

5.3 Test gases ...............................................................................35

5.4 Testing the pump power, zero point and sensitivity .................37

I

Page 8

Contents Page

6 Info menu ...............................................................................39

6.1 Menu structure ........................................................................ 39

6.2 Overview ................................................................................. 40

7 Adjustment menu ..................................................................43

7.1 Menu structure ........................................................................ 43

7.2 Setting the H2S sensor ............................................................44

7.3 Setting the CO sensor .............................................................45

7.4 Setting the O2 sensor ..............................................................46

7.5 Setting the CO2 sensor ............................................................47

7.6 Setting the CH4 sensor ............................................................48

7.7 Setting the measurement quantity ..........................................50

7.8 Setting the test gas concentration ...........................................51

7.9 Inspection confirmation ........................................................... 54

7.10 Leaving the adjustment menu .................................................55

8 Memory menu ........................................................................56

8.1 Menu structure ........................................................................ 56

8.2 Clearing memory .....................................................................57

8.3 Setting the memory interval ....................................................58

8.4 Setting the memory mode .......................................................60

8.5 Setting the short-term value interval .......................................61

8.6 Leaving the memory menu ......................................................62

9 System menu .........................................................................63

9.1 Menu structure ........................................................................ 63

9.2 Setting the date/time ............................................................... 64

9.3 Setting the inspection interval ................................................. 66

9.4 Setting the inspection block ....................................................69

9.5 Setting the 100 vol.% range ....................................................70

9.6 Setting the PIN code ............................................................... 71

9.7 Setting the alarm thresholds ..................................................73

9.8 Checking the LCD ...................................................................77

9.9 Leaving the system menu ....................................................... 77

II

Page 9

Contents Page

10 Application hints ...................................................................78

10.1 Application hints from report of suitability examination

PFG-No. 41300401P ...............................................................78

11 Technical aspects ................................................................. 80

11.1 Technical notices ..................................................................... 80

11.2 Technical data .........................................................................82

11.3 Error messages .......................................................................93

11.4 Error and Alarm properties ......................................................97

11.5 Wearing Parts .........................................................................98

11.6 Spare parts ..............................................................................98

11.7 EC-Sensor Disposal ................................................................98

12 Hints on Disposal ..................................................................99

13 Delivery variants and accessories ....................................100

13.1 Delivery variants ....................................................................100

13.2 Accessories ...........................................................................101

Appendix ............................................................................................108

EC-type-examination certificates .........................................................108

Declaration of Conformity .................................................................... 118

Inspection protocols ............................................................................ 119

III

Page 10

1

1 EX-TEC Combi system

1 EX-TEC Combi system

1.1 Excess-gas warning and measuring instrument

The EX-TEC Combi is a combined warning and measuring

instrument for a number of different gases. It consists of:

the basic instrument, incorpora ting a pum p and a dat a

memory for documentation

purposes

4 sensor sockets for the measurement of up to 5 different

gases

The following sensors are available:

methane CH

4

or

propane C3H8

or nonane C9H20 (*)

carbon dioxide CO

2

oxygen O

2

hydrogen sulphide H2S

carbon monoxide CO

combined H2S/CO sensor

(*) This operating manual only describes methane mea-

surement!

Page 11

2

1 EX-TEC Combi system

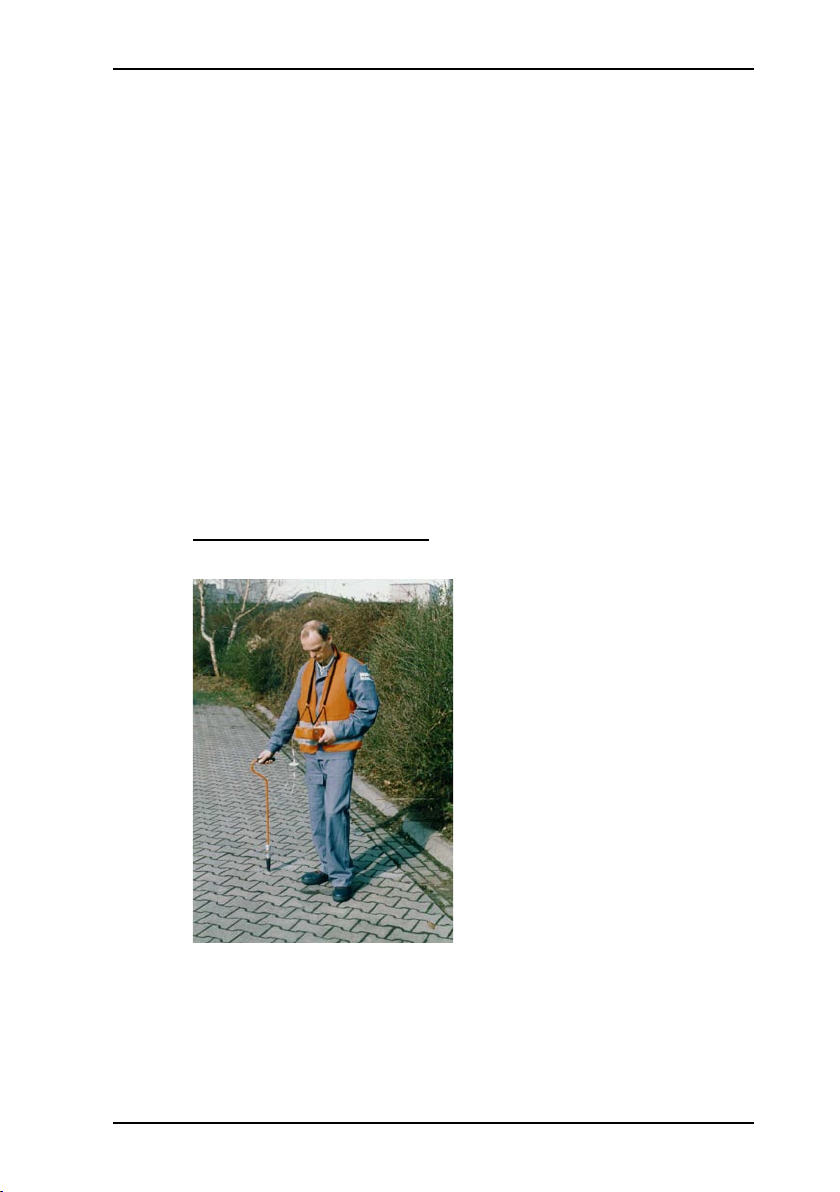

1.2 Fields of application

The EX-TEC Combi is suitable for use in the following fields:

WARNING mode

Workplace (atmospheric) monitoring in shafts and chambers in

these fields:

drinking-water supply (metering

and transfer shafts)

district-heating systems

telecommunications shafts

effluent-treatment systems

(sewage works, pump sumps,

digestion-tank areas, rainoverflow basins)

traffic areas

accessible culverts

Warning of explosive*) mixtures

- due to leaking gas pipes near the shaft

- due to the proximity of oil, coal, natural-gas or LPG storage

facilities

- due to the proximity of landfill sites, marshland, chemical

works, filling stations or refineries

- due to cleaning or coating work with substances containing

solvents

- due to the prohibited introduction of combustible substances

into the canal network (e.g. petrol leaks)

*) the EC prototype test certificate DMT01ATEX G 002 includes measurement functions

of the LEL methane/propane range

Warning of an oxygen defect /oxygen excess

- due to an increase in other gas components

- due to the decomposition of organic waste in shafts (e.g. wet

leaves)

Page 12

1 EX-TEC Combi system

- due to welding and heating processes with naked flames

- due to air depletion

Warning of toxic gases

- due to the formation of carbon dioxide by bacterial conversion

processes

- due to the formation of carbon dioxide in areas where there

is mineral water

- due to the formation of carbon dioxide in exhaled air

- due to the formation of hydrogen sulphide in effluent

- due to the formation of carbon monoxide from incomplete

combustion (e.g. poorly-adjusted gas-heating systems)

- due to the formation of carbon monoxide near highways or

car-parks

GAS-MEASURING mode *)

Determining gas concentrations

Localisation

- measuring gas concentration in probe holes

- determining which probe

hole has the maximum concentration

Gas injection

- monitoring filling with natural

gas and oxygen extraction

- measuring the methane and

oxygen concentration

Inertisation

- monito r ing flus h ing with

nitrogen and natural-gas

extraction

- measuring the methane and

oxygen concentration

*) No measuring function for explosion protection in accordance with guideline 94/4/EG.

3

Page 13

4

1 EX-TEC Combi system

1.3 Test certificates

Passive explosion protection

The EX-TEC Combi has been tested for explosion protection in

accordance with the European norm (CENELEC):

EC prototype test certificate:

Identification: II 2 G EEx ib d IIB T3

Testing institution: Physikalisch-Technische Bundesan-

Active explosion protection (measuring function)

The EX-TEC Combi has also been undergone a measurementfunction test in gas-warning mode:

EG prototype test certificate:

Test report: PFG n° 41300401

Testing institution: Deutsche Montan-Technologie GmbH

PTB 96 ATEX 2166, supplements 1

and 3

stalt, Braunschweig

DMT 01 ATEX G002, supplement 1

(measurement range 0 – 100 %LEL

methane/propane)

measurement range 0 – 25 vol.%

oxygen, measurement of oxygen

defect and excess,

measurement range 0 – 5 vol.% of

carbon dioxide,

measurement range 0 – 500 ppm of

carbon monoxide

measurement range 0 – 100 ppm of

hydrogen sulphide

(DMT), Essen

The test certificates can be found in the appendix.

Page 14

front view side view back view

front view side view back view

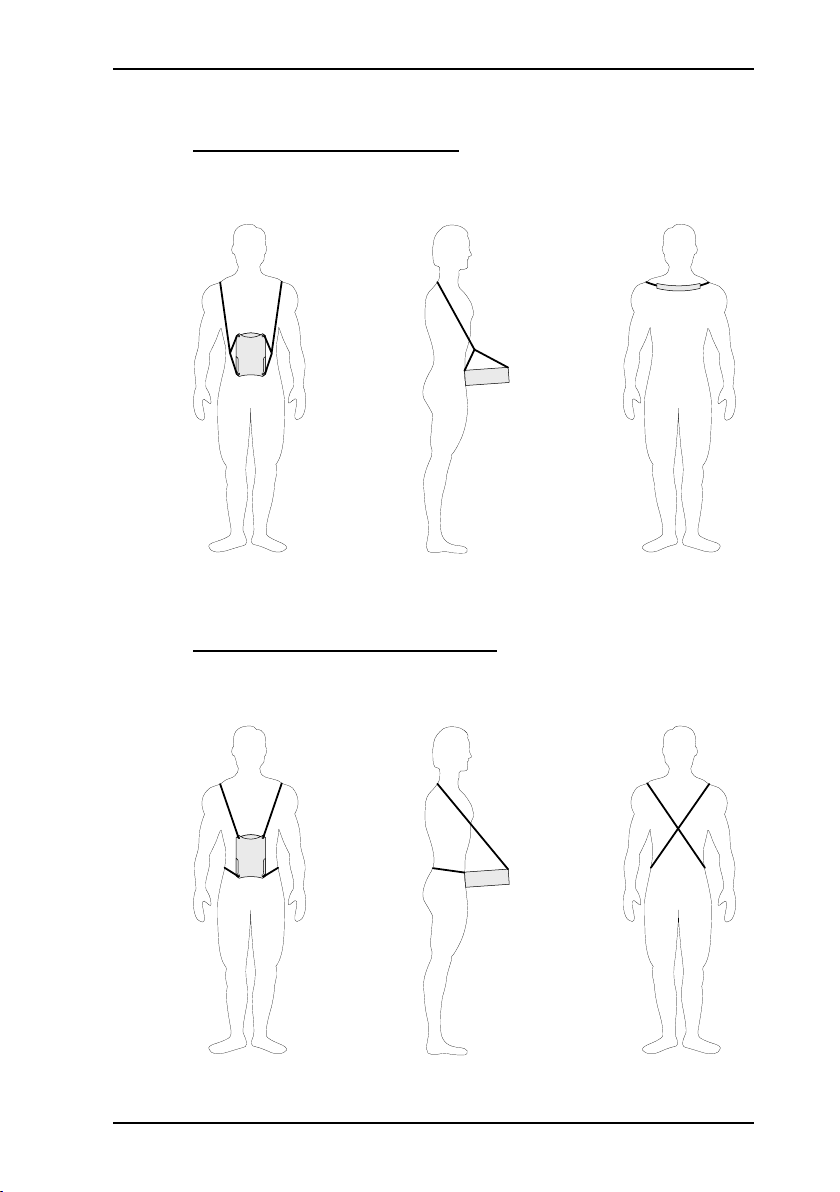

1.4 Carrying equipment

TRIANGEL carrying system

a quick and easy way of carrying the instrument, consisting of a

carrying strap and neck-pad

1 EX-TEC Combi system

CROSS-STRAP carrying system

a comfortable way to carry the instrument for longer periods,

consisting of 2 carrying straps crossed at the back

5

Page 15

6

2 Safety

2 Safety

2.1 Safety notes

CAUTION!

Always use original SEWERIN accessories with the

EX-TEC Combi.

CAUTION!

Always use a probe hose with a hydrophobic filter.

CAUTION!

Do not use other than the original SEWERIN fine

dust filters with the EX-TEC Combi. Never use ac-

tivated carbon filters, as these will collect H2S gas

particles, thus causing the warning feature to stop

working properly.

CAUTION!

Observe the permissible operating temperature of

-10 °C to +40 °C.

CAUTION!

The EX-TEC Combi may only be recharged in an

area not exposed to the danger of explosion.

Page 16

2 Safety

CAUTION!

Use the test gases only in well-ventilated areas,

as some concentrations exceed the pertinent MAK

values.

CAUTION!

The EX-TEC Combi satisfies the limits of the EMV

regulation. When using it near mobile radio equipment please also observe the instructions in their

manuals.

7

Page 17

8

3 Measuring operation

3 Measuring operation

3.1 Instrument description

Note:

Fold out the illustration inside the front cover!

Item description function

1 alarm lamp optical warning on:

2 LCD display of:

3 probe connection connection for:

4 keypad instrument operation

5 attachment for carrying systems:

6 outlet for the gas sample

7 buzzer acoustic warning on:

8 interface serial RS-232-interface for con-

breaching alarm thresholds

display of error messages

gas concentrations

menu items

operating conditions

error messages

probe hose

test set

Triangel

cross-strap

breaching alarm thresholds

display of error messages

nection to a PC

(⊗)

Page 18

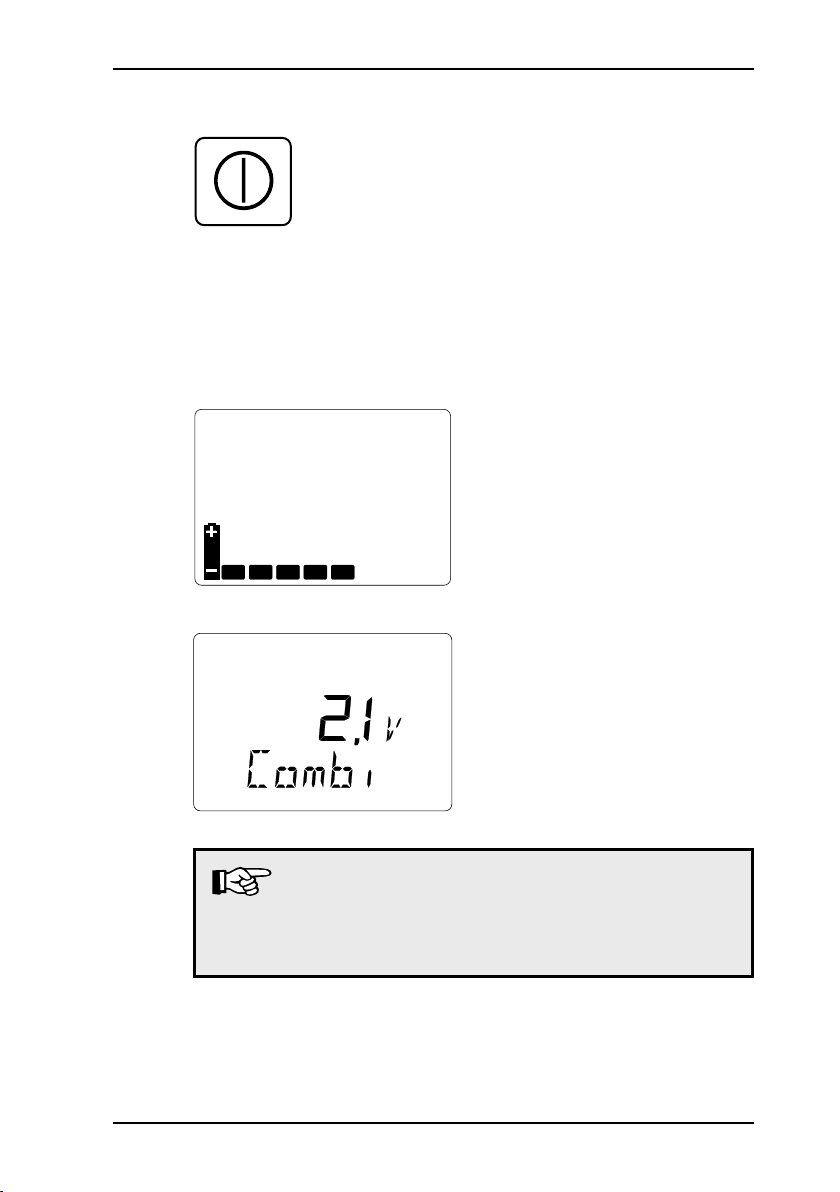

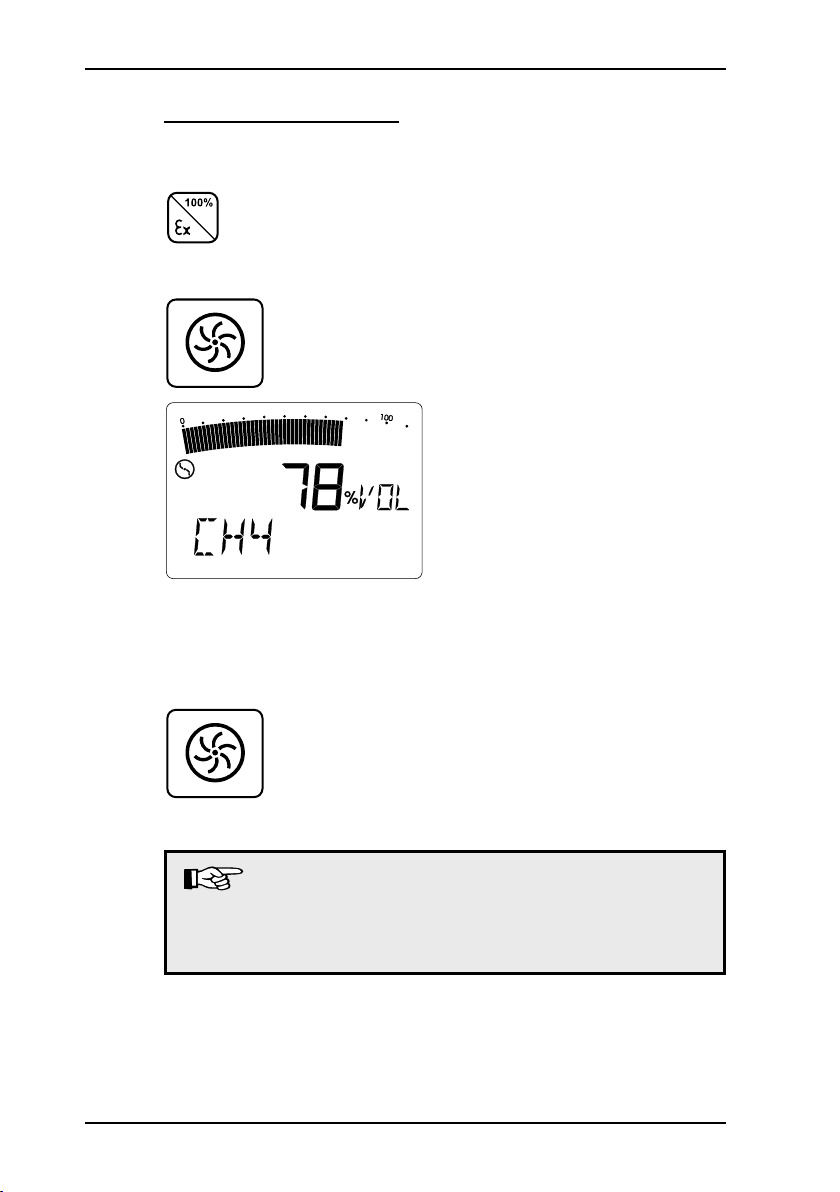

3.2 Switching on

3 Measuring operation

always switch the instrument

on in “fresh air”

press the on/off key for about

3 seconds

the optical and acoustic control

signals (items 1 and 7) operate

for about 3 seconds

the LCD illumination automati-

cally switches on for about 4

minutes

available operating hours are

displayed in the form of the

battery symbol and bars (e.g.:

5 hours = 5 bars)

the built-in pump runs at con-

stant power

the software version number

(e.g. 2.1) and instrument type

(Combi) are displayed

Note:

All the following instrument displays assume that

the EX-TEC Combi is fully equipped for the measurement of 5 gases (CH4 - CO2 - O2 - H2S - CO).

9

Page 19

10

3 Measuring operation

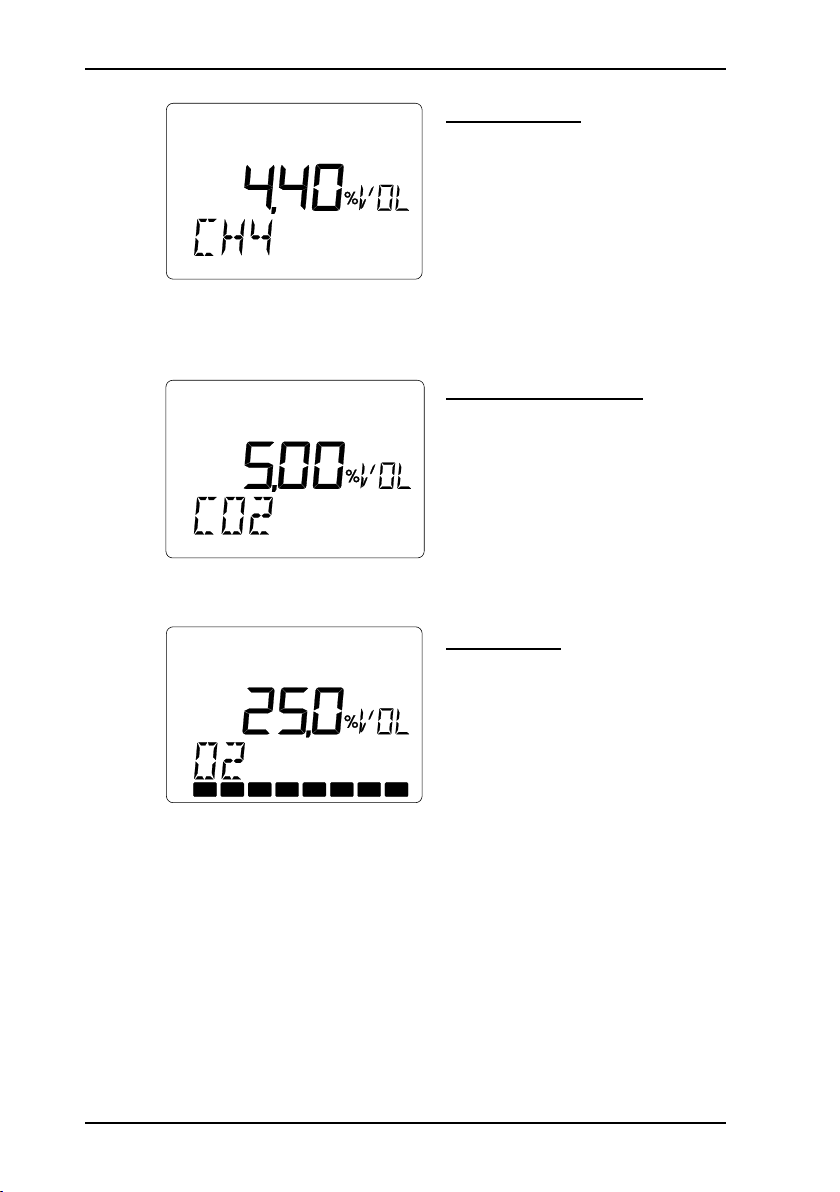

CH4 - methane

the measurement range for

methane is displayed:

0.00 – 4.40 %VOL

depending on your last setting

a display in the %UEG, %LEL,

%LIE, %VOL, %GAZ quanti-

ties may also be possible (cf.

section 7.6: Adjusting the CH4

sensor)

CO2 - carbon dioxide

the measurement range for

carbon dioxide is displayed:

0.00 – 5.00 %VOL

depending on your last setting

a display in the %VOL, %GAZ

quantities may be possible

(cf. section 7.7: Setting the

measurement quantity)

O2 - oxygen

the measurement range for

oxygen is displayed:

0.0 – 25.0 %VOL

depending on your last setting

a display in the %VOL, %GAZ

quantities may be possible

(cf. section 7.7: Setting the

measurement quantity)

display of the sensor lifetime

in the form of bars (cf. section

11.2: Technical data):

8 bars = 100 %

Page 20

3 Measuring operation

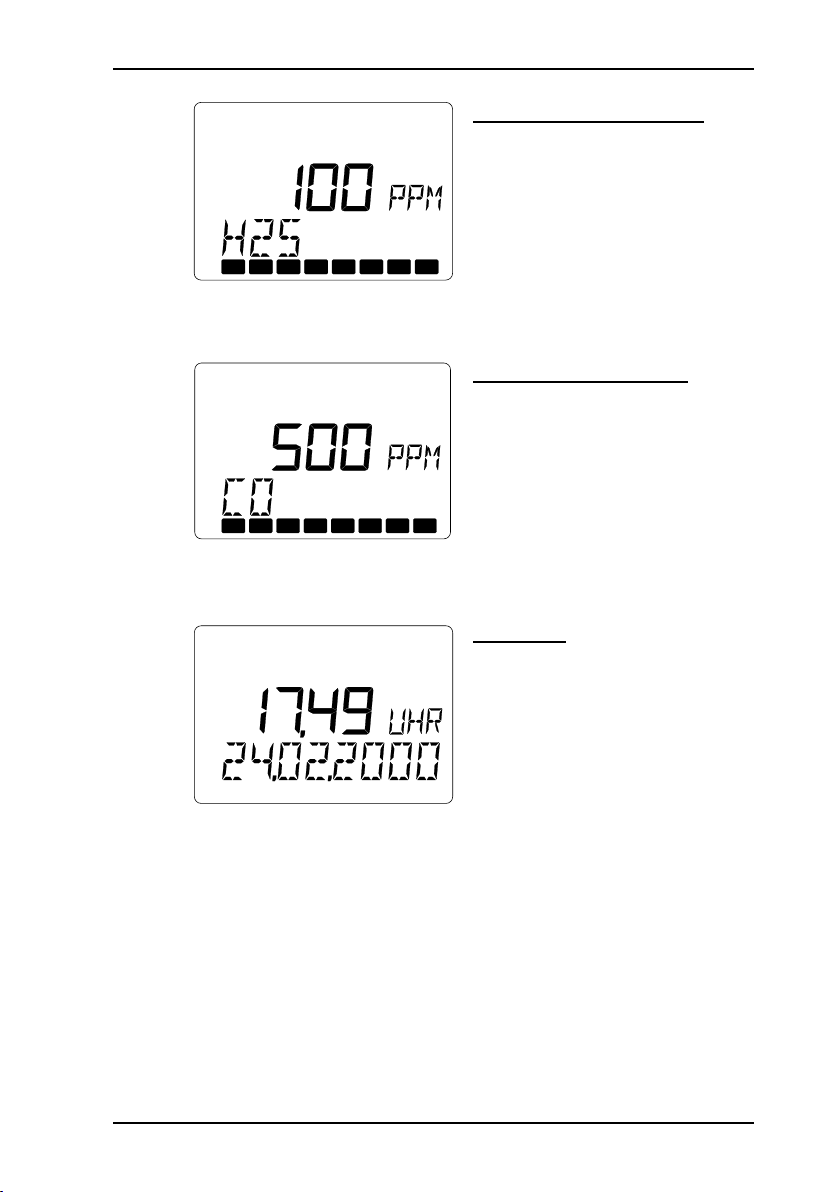

H2S - hydrogen sulphide

the measurement range for

hydrogen sulphide is displayed:

0 – 100 PPM

display of the sensor lifetime

in the form of bars (cf. section

11.2: Technical data):

8 bars = 100 %

CO - carbon monoxide

the measurement range for

carbon monoxide is displayed:

0 – 500 PPM

display of the sensor lifetime

in the form of bars (cf. section

11.2: Technical data):

8 bars = 100 %

Time/date

the current time (e.g.17:49)

and date (e.g. 24.02.2000) are

displayed

properly-set values are impor-

tant for the documentation of

your readings

you can correct any variances

(cf. section 9.2: Setting the

date/time)

11

Page 21

12

3 Measuring operation

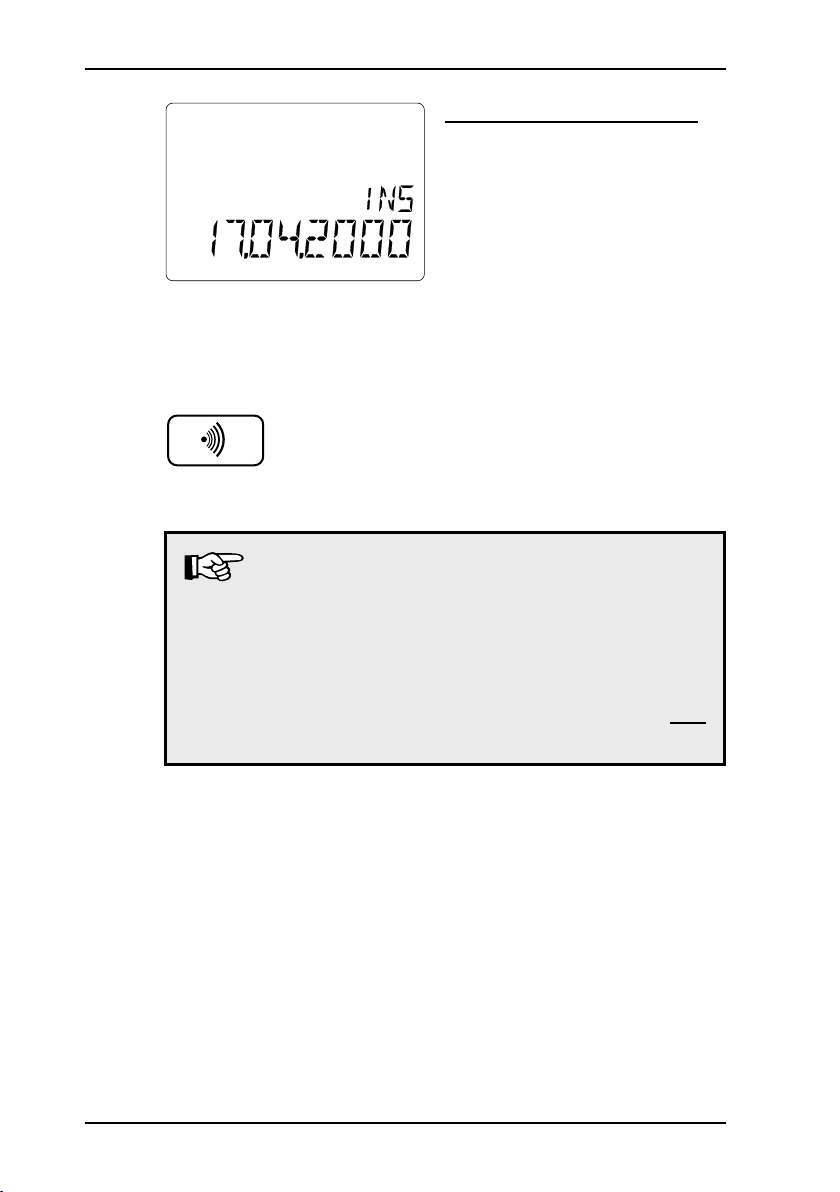

Next scheduled inspection

(display optional)

if you have set an inspection

interval, the next scheduled

inspection (e.g. 17.04.2000) is

displayed for about 3 seconds

(cf. section 9.3: Setting the

inspection interval)

depending on the date and

set schedule, the interval or

continuous alarm may also be

triggered (items 1 and 7)

clearing the alarm with the

buzzer key or waiting for 15

seconds switches to measuring

operation

Note:

If the EX-TEC Combi now automatically switches

off, the inspection date has passed with the inspection block switched on (cf. section 9.4: Setting the

inspection block).

The instrument does not revert to measuring operation until an inspection has been carried out and

confirmed.

Page 22

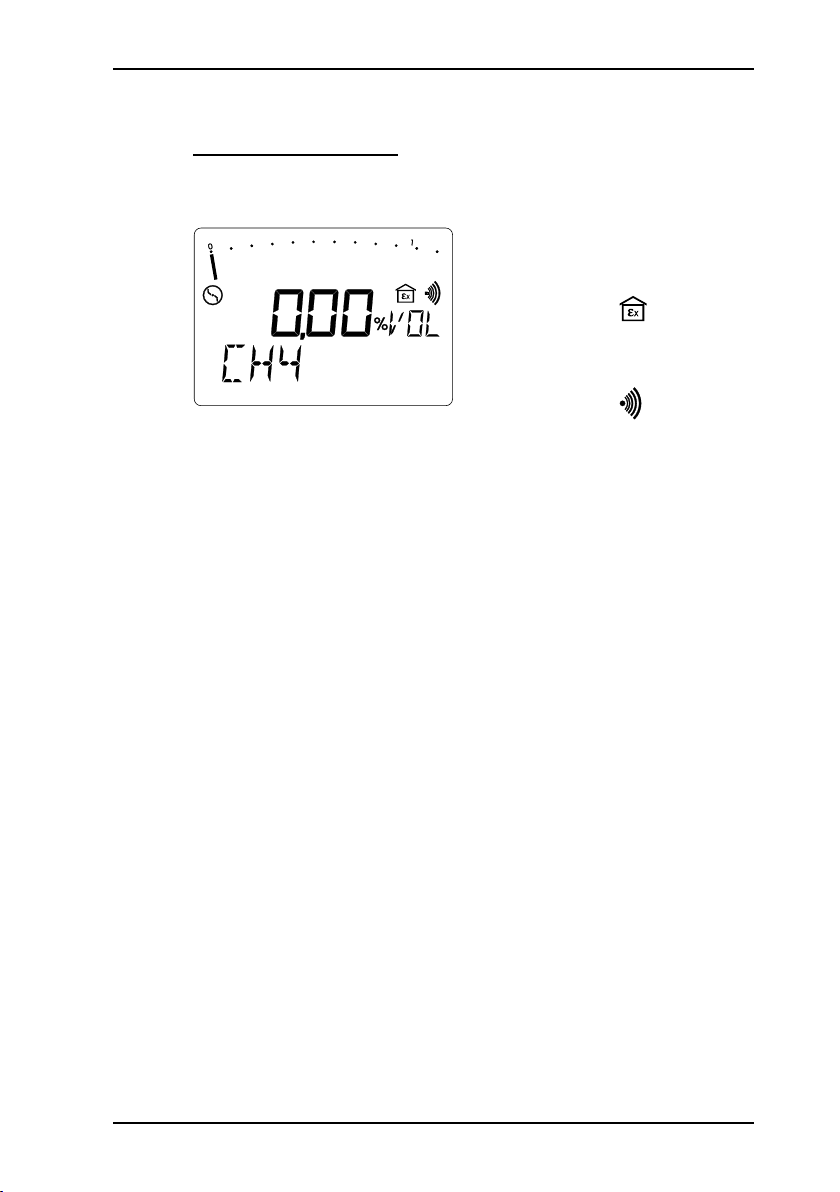

3.3 Modes

GAS-WARNING mode

Monitoring the atmosphere in shafts and chambers (cf. section 1.2: Fields of application)

CH4 - CO2 - O2 - H2S - CO

3 Measuring operation

im m edi at ely af t er bei ng

switched on the EX-TEC Combi

is always in warning mode

Indication:

all a la r m t hr es h ol ds ar e

activated

Indication:

each avail able gas is dis-

played for about 3 seconds

before switching to the next

Sequence:

Every 5 seconds an operating

signal is activated as a marker.

It is both, acoustic (item 7) and

optical (item 1). The optical

signal acts as a control that

the instrument is functioning

in gas-warning mode.

If the op e r a ting si g n al is

switched off, the monitoring

of the ga s conc e n t ra t i on

is no long er insur ed. The

endangered area must be left

immediately.

13

Page 23

14

3 Measuring operation

GAS-MEASURING mode (⊗)

Determining gas concentrations (cf. section 1.2: Fields of

application)

pressing the operating-mode

key (instruments variant 2)

for about 3 seconds switches

between the two modes

on instruments variant 1, the

switching is carried out by

pressing the pump-key for

about 3 seconds

in this mode all alarm thresholds

and the operating signal are

switched off

the pump now runs at maxi-

mum power

NB: (no symbols)

each avail able gas is dis-

played for about 3 seconds

before switching to the next

Sequence:

CH4 - CO2 - O2 - H2S - CO

in this mode, depending on

the task at hand, you can also

switch the instrument‘s pump

on and off by briefly pressing

the pump-key

Note:

If you wish to use the EX-TEC Combi purely as a warn-

ing device, you can deactivate GAS-MEASURING

mode (cf. section 9.5: Setting the 100 vol.% range)!

Page 24

3.4 Switching gases

3 Measuring operation

repeatedly pressing the hand

key toggles between automatic and manual gas-type

switching

Automatic switching

each avail able gas is dis-

played for about 3 seconds

before switching to the next:

Sequence:

CH4 - CO2 - O2 - H2S - CO

Manual switching

each gas is displayed until a

arrow key is pressed

pressing a arrow key then

switches to the next gas:

Sequence (cursor up):

CH4 - CO2 - O2 - H2S - CO

Note:

In WARNING mode automatic switching always

has priority!

If the instrument is in manual switching mode and

no key has been pressed for about 10 seconds, it

shifts back to automatic switching!

15

Page 25

16

3 Measuring operation

3.5 Alarms

The „Technical Rules for Hazardous Substances (TRGS 402 and

900)“ require certain limit values to be monitored and adhered to

in the air in the workplace.

In WARNING mode only the EX-TEC Combi thus has three

different types of alarm: one optical (item 1), one acoustic (item

7) and one that takes the form of the LCD illumination (item 2)

switching on:

AL1, AL2, AL3 The instantaneous value alarm appears with

KZW The short-term value alarm appears with toxic

LZW The long-term value alarm appears with

all gases:

CH4 - CO2 - O2 - H2S - CO

when the measured gas concentration

exceeds or falls below a fixed threshold

value.

gases:

CO2 - H2S - CO

when the gas concentration averaged over an

adjustable time period (e.g. 15 minutes) has

exceeded an assessed limit value.

toxic gases:

CO2 - H2S - CO

when the gas concentration averaged over

an 8-hour working shift has exceeded a fixed

limit value.

Page 26

3 Measuring operation

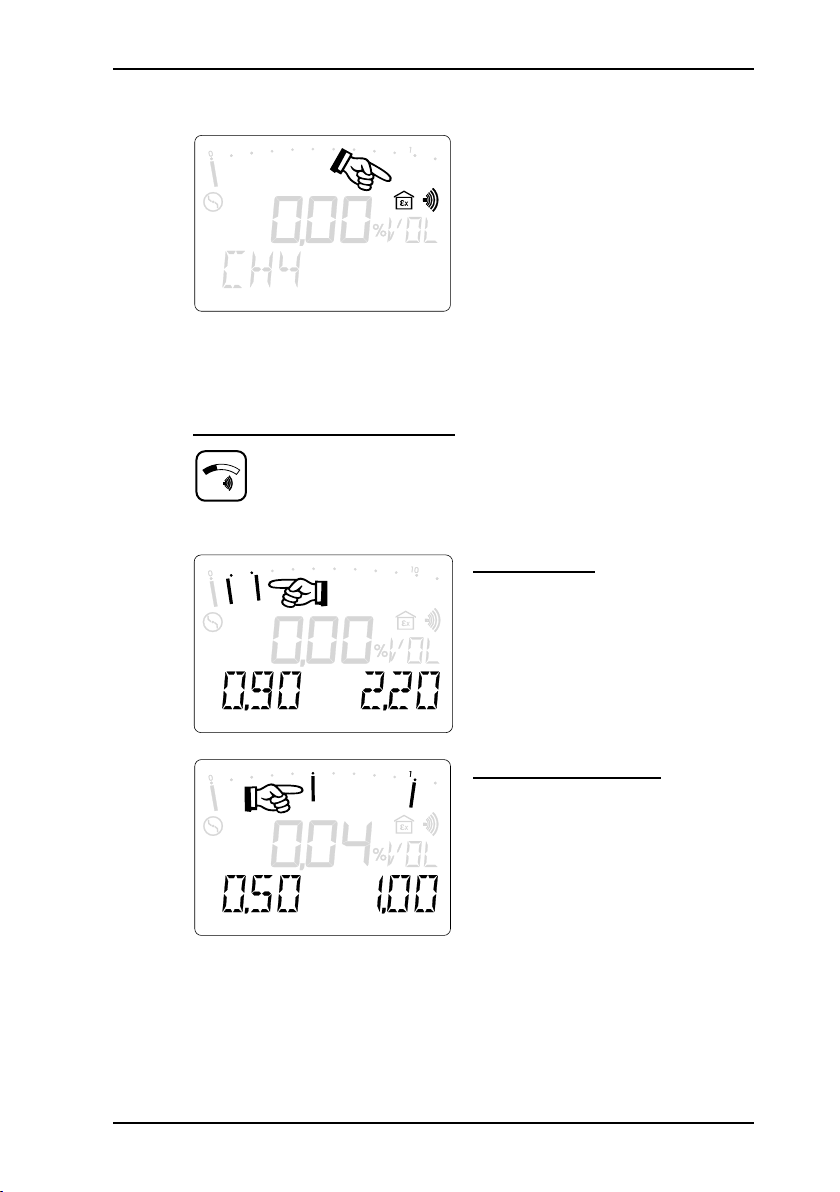

3.6 Instantaneous value alarms (AL1, AL2, AL3)

when in gas-warning mode

the EX-TEC Combi is constantly in alarm readiness

this is displayed in the LCD

by two symbols: Ex-area and

alarm threshold

the alarm is triggered as soon

as a threshold is breached

Display of alarm thresholds

holding down the threshold

value key displays the set

alarm thresholds for the pertinent gas

Methane CH

alarm thresholds (factory set-

4

tings):

AL1 = 0.90 %VOL = 20 %LEL

AL2 = 2.20 %VOL = 50 %LEL

Carbon dioxide CO

alarm thresholds (factory set-

4

tings):

AL1 = 0.50 %VOL (MAK value)

AL2 = 1.00 %VOL

17

Page 27

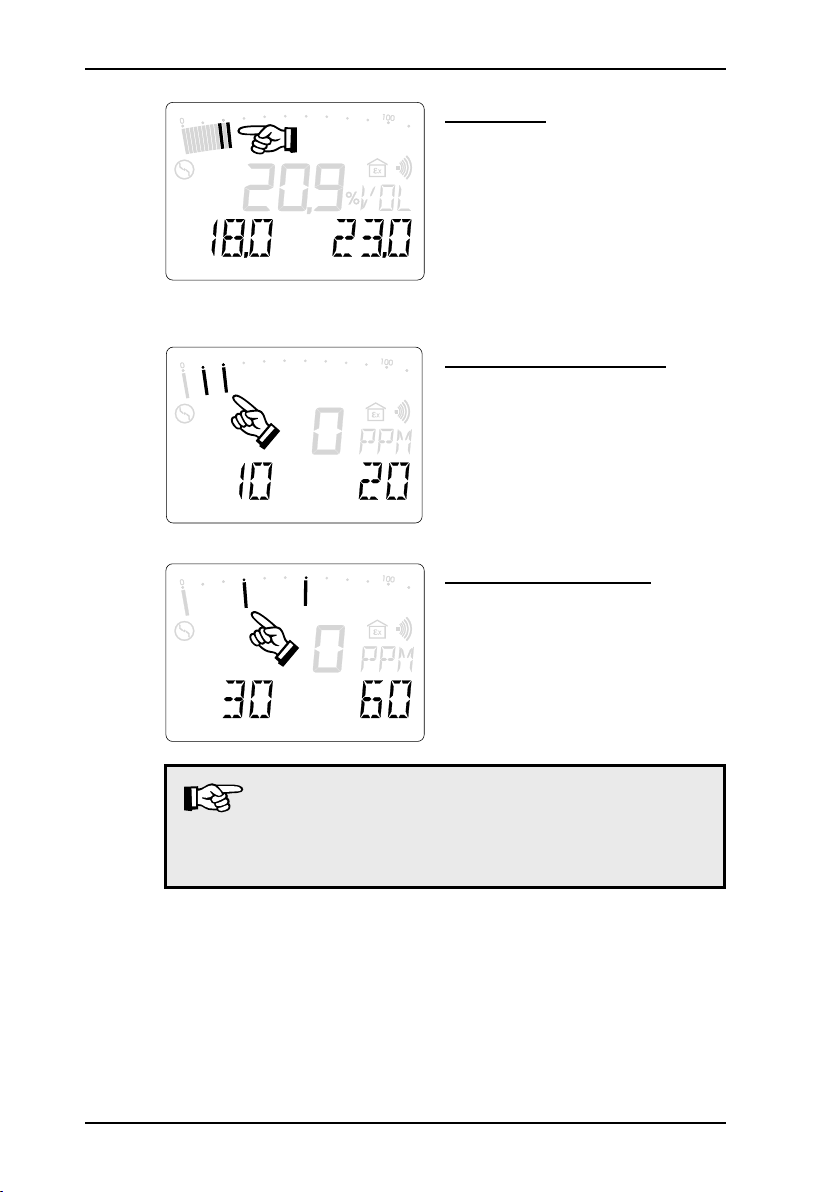

18

3 Measuring operation

Oxygen O

alarm thresholds (factory set-

2

tings):

AL1 = 18.0 %VOL

AL2 = 23.0 %VOL

the AL1 alarm threshold is

triggered when the value falls

below the threshold

Hydrogen sulphide H2S

alarm thresholds (factory set-

tings):

AL1 = 10 PPM (MAK value)

AL2 = 20 PPM

Carbon monoxide CO

alarm thresholds (factory set-

tings):

AL1 = 30 PPM (MAK value)

AL2 = 60 PPM

Note:

You can alter the factory-set thresholds to your own

individual limits (cf. section 9.7: Setting the alarm

thresholds)!

Page 28

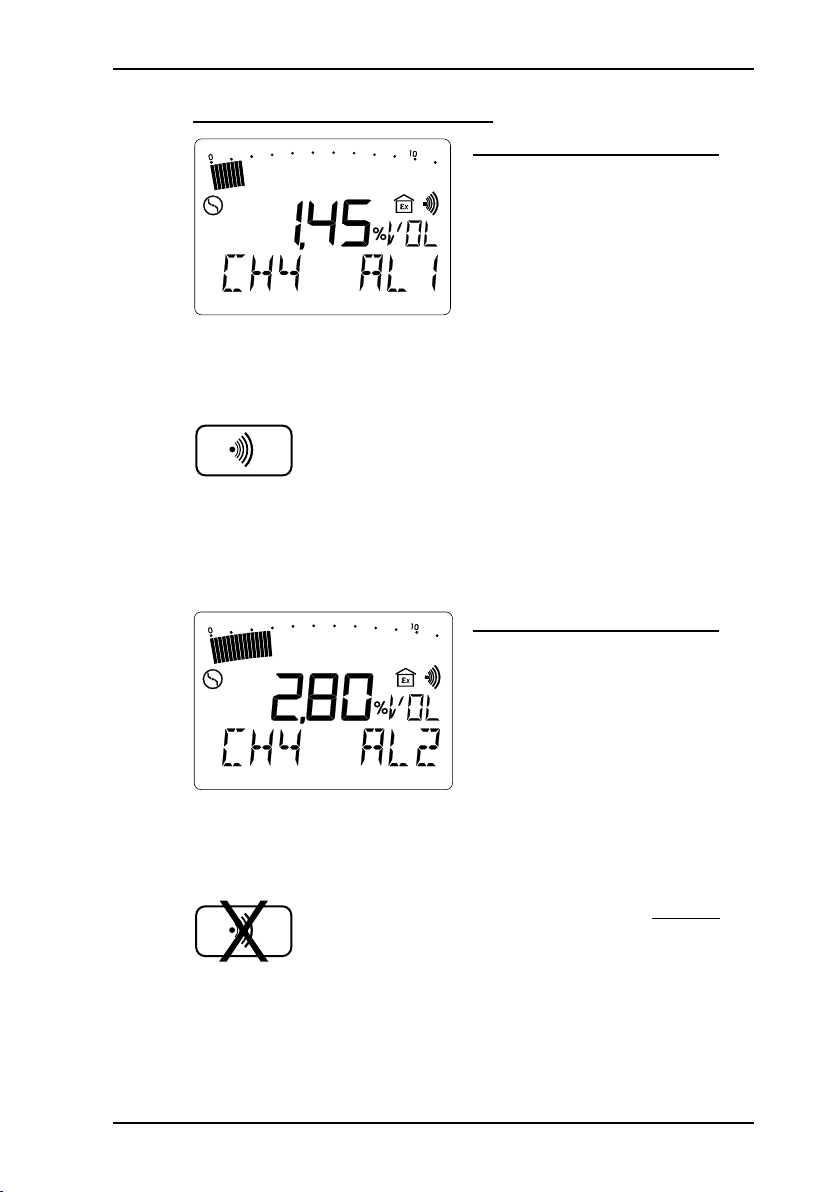

Triggering the alarm thresholds

AL1 alarm (Example: CH4)

AL2 alarm (Example: CH4)

3 Measuring operation

exceeding this alarm threshold

triggers:

- the optical alarm (item 1)

- the acoustic alarm (item 7)

- the appearance of AL1 in

the LCD

the interval tone is clearly dis-

tinguishable from the operating

signal

the AL1 alarm can be cleared,

th e optical ala rm (it em 1)

persists

if the concentration falls below

this alarm threshold, the optical and acoustic alarms (items

1 and 7) switch off

exceeding this alarm threshold

triggers:

- the optical alarm (item 1)

- the acoustic alarm (item 7)

- the appearance of AL2 in

the LCD

the continuous tone is clearly

distinguishable from the operating signal

the AL 2 alarm cannot be

cleared

if the concentration falls below this alarm threshold, the

alarm that sounds (AL1) can

be cleared

19

Page 29

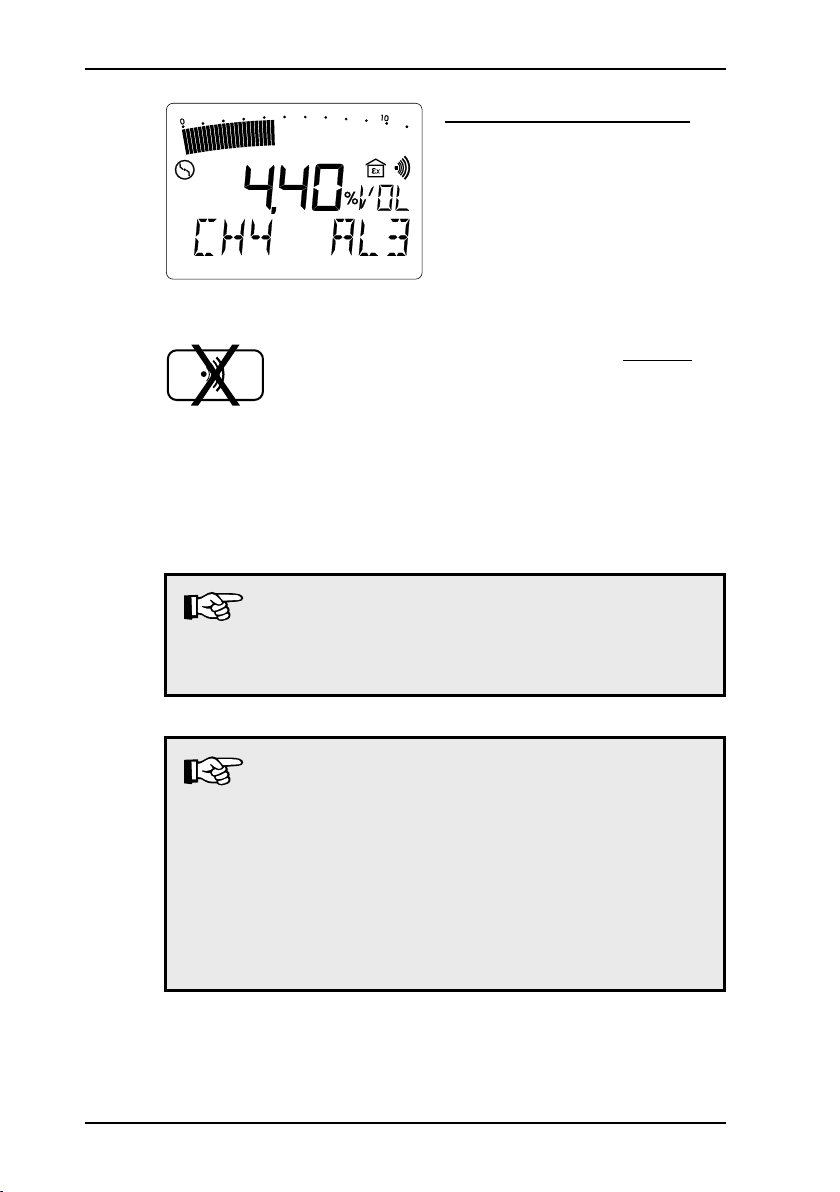

20

3 Measuring operation

AL3 alarm (Example: CH4)

if the end of the measurement

range is exceeded, the optical

and acoustic alarms (items 1

and 7) are triggered and AL3

appears in the LCD

the continuous tone is clearly

distinguishable from the operating signal

the AL 3 alarm cannot be

cleared either

if the gas concetration falls be-

low the end of measurement

range, the AL3 alarm is reset

and the AL2 alarm activated

Note:

The AL3 alarm can be suppressed by switching

to GAS-MEASURING mode or switching off the

instrument!

Note:

In the GAS-WARNING mode, 0 – 100 %LEL methane

concetrations exceeding the upper measuring range

value can influence the accuracy of measurement.

After triggering the AL3 alarm in this measuring

range, the instrument must be inspected before any

further use (cf. section 5.1: Function testing, testing

display accuracy, maintenance). It is necessary to

repeat this operation the following days.

Page 30

3 Measuring operation

Note:

In the GAS-WARNING mode the following remarks

should be observed during operation at degrees below zero, high temperatures and high humidity:

Degrees below zero lead to a diminished display

(up to 4 % LEL at -10 °C) at the zero-point of the

methane and propane sensor. This can be compensated by a correspondingly lower adjustment

of the alarm thresholds.

When adjusting the methane sensor with dry gas,

high temperatures and high relative humidity (> 90 %)

could lead to a diminished display (up to 30 % of

measuring value). This can be compensated by

a correspondingly lower adjustment of the alarm

thresholds.

Note:

After triggering the AL3 alarm in the CO- or H2Smeasuring range, the instrument must be inspected

before any further use (cf. section 5.1: Function

testing, testing display accuracy, maintenance).

21

Page 31

22

3 Measuring operation

CH

C H

C H

4

3 8

9 20

Confirmation

CO

2

O *

2

H S

2

CO

End

of range

AL3

Main alarm

AL2

Pre-alarm

Al1

Alarm display

0.90 %VOL

20 %LEL

0.34 %VOL

2.20 %VOL

50 %LEL

0.86 %VOL

4,40 %VOL

100 %LEL

1.7 %VOL

0.50 %VOL 1.00 %VOL 5.00 %VOL

18.0 %VOL 23.0 %VOL 25.0 %VOL

10 PPM 20 PPM 100 PPM

30 PPM 60 PPM 500 PPM

X

X

NH

3

50 PPM 75 PPM 100 PPM

0.15 %VOL 0.35 %VOL 0.7 %VOL

Summary

All alarm thresholds (factory settings) and clearance facilities in

brief:

* Exception:

With oxygen O2 both thresholds take the form of a main alarm.

The AL1 alarm is triggered if the value falls below the threshold

of 18.0 vol.%.

Page 32

3 Measuring operation

3.7 Short-term value alarm (KZW), long-term value alarm (LZW), minimum and maximum values (MIN/MAX)

briefly press the on/off key in

gas-warning mode

MIN/MAX - minimum and maximum values

Often it is only the display of the minimum or maximum concentrations encountered so far that is of interest. These can be

displayed for all gases since the last time the instrument was

switched on.

MIN value (Example: CO2)

the minimum concentration

value (e.g. 0.25 %VOL) since

the last time the instrument

was switched on is displayed

MIN appears in the LCD

pressing the arrow-up key

brings you to the next display

MAX value (Example: CO2)

the maximum concentration

value (e.g. 0.75 %VOL) since

the last time the instrument

was switched on is displayed

MAX appears in the LCD

pressing the arrow-up key

brings you to the next display

23

Page 33

24

3 Measuring operation

KZW - short-term value alarm

This monitoring mode is based on an averaging period, usually 15 minutes (cf. section 8.5: Setting the short-term value

interval).

The total concentrations of the pertinent toxic gas over the averaging

period must not exceed the product of the MAK value and the

overshoot factor.

Gas MAK value Factor

carbon dioxide CO

hydrogen sulphide H2S 10 ppm 1

carbon monoxide CO 30 ppm 2

Example: a constant reading > 2.00 vol.% (= 4 x 0.50 vol.%) over

2

0.50 vol.% 4

15 minutes triggers the KZW alarm (main alarm),

which cannot be cleared.

KZW (Example: CO2)

the current short-term value

(e.g. 0.30 %VOL) since the

last time the instrument was

switched on is displayed

KZW appears in the LCD

pressing the arrow-up key

brings you to the next display

Page 34

3 Measuring operation

LZW - long-term value alarm

This monitoring mode is based on a shift length of 8 hours.

The total concentrations of the pertinent toxic gas over the length

of the shift must not exceed the MAK value.

Example: a constant reading > 0.50 vol.% over 8 hours trig-

gers the LZW alarm (main alarm), which cannot be

cleared

LZW (Example: CO2)

the current long-term value

(e.g. 0.10 %VOL) since the

last time the instrument was

switched on is displayed

LZW ap p ears in the LCD

(item 2)

the display of these values

disappears:

- if the on/off key is briefly

pressed

- if no key is pressed for about

10 seconds

Note:

Both alarms (KZW and LZW) can be suppressed

by switching to GAS-MEASURING mode or turning

the instrument off.

25

Page 35

26

3 Measuring operation

3.8 Zero point adjustment

if the EX-TEC Combi deviates

from its zero point after flushing with „fresh air“ (observe

tolerances), this can be corrected manually

pressing the zero point key

sets the zero point for the

gas displayed (max. 5% from

the end of the measurement

range)

if the zero point cannot be set,

the sensor must be adjusted

(cf. section 7: Adjustment

menu)

CO2 zero point

the zero point for carbon di-

oxide is 0.04 %VOL, as this

is the concentration found in

normal fresh air

3.9 Illumination and contrast

Illumination

repeatedly pressing the light

key switches the LCD illumination on and off

after about 4 minutes the illu-

mination automatically switches off again

Page 36

3 Measuring operation

Contrast

simultaneously pressing the

light key and a arrow key

increases or reduces the contrast of the LCD

your last setting is preserved

even when the instrument is

switched off

3.10 Operating hours display and battery alarm

Operating hours display

simultaneously pressing both

arrow keys during measuring

operation displays the number

of operating hours remaining

(e.g. 5 hours)

this display (battery symbol and

bars) disappears automatically

after about 10 seconds

Battery alarm

when the charge falls below

a threshold value the battery

symbol appears, the alarm

lamp flashes and an acoustic

signal sounds.

the battery alarm ca n be

cleared

when the battery symbol is

triggered, there is at least

another 15 minutes‘ operating

time remaining.

27

Page 37

28

3 Measuring operation

3.11 Switching off

this period of time is empha-

sized acoustically by a double

beep tone

after that the instrument must

be recharged (cf. section 4:

Charging)

press the on/off key for about

3 seconds

the optical and acoustic control

signals (items 1 and 7) operate

for about 3 seconds

remaining operating hours are

displayed in the form of the

battery symbol and bars (e.g.

5 hours = 5 bars)

Page 38

4 Charging

4.1 Charging and charge maintenance

Charging

When fully charged the instrument has a maximum of 9.5 hours‘

operating time with the pump running.

To charge the instrument you will need the docking station HS

1.2 A (see illustration), which can be used in the workshop or the

emergency vehicle.

The following connection sockets

can be found on the side of the

docking station HS 1.2 A:

AC/DC adapter M4 100 – 240 V~,

Car cable M4 12 V= mounting,

Car cable M4 12 V= mobile,

Car cable M4 24 V= mounting.

Switch the EX-TEC Combi off and place it in the charger. A display on the following lines appears:

the instrument still has 5 ope-

rating hours left (= 5 bars) and

will take another 3 hours to be

fully recharged

if it is fully charged, all the bars

appear and the numerical display disappears

4 Charging

Charge maintenance

As soon as the instrument is fully charged it automatically switches

to charge maintenance. It an be left in the charging adapter until

the next time it is needed.

29

Page 39

30

4 Charging

4.2 Self-discharge

If the instrument is not placed in the charging adapter when it is

switched off, this will cause the nickel-cadmium battery to selfdischarge, reducing the remaining operating time.

After a maximum of 30 days the instrument indicates no remaining

operating hours and it must be recharged.

Note:

Brief periods of use and protracted disuse may in

the long term lead to the co-called „memory effect“,

which means that the actual battery capacity available is less than what is shown in the display!

You can counteract this by fully discharging the

EX-TEC Combi regularly (e.g. once a month):

leave it switched on until it switches itself off, then

recharge it!

Page 40

5 Testing/maintenance

Note:

Gas warning instruments must always be tested by

the user before use or before each shift.

But at a minimum all 4 month. The test must

cover:

the battery charge

the display with environmental gas conditions

and test gases

(Technical bulletin BGI 518)

Note:

DIN EN 50073 and EN 45544-4 provides that portable gas warning instruments (of which the EX-TEC

Combi is one) must be tested as stipulated in their

operating instructions and immediately before use.

Items that the test is required to cover include the

zero point and display sensitivity with a field calibration instrument and test gas.

5 Testing / maintenance

Note:

In case of calibration data to multiple gas types are

stored, tests of display accuracy must be carried out

for all existing calibrations using corresponding test

gases (see section 5.3).

31

Page 41

32

5 Testing / maintenance

5.1 Function testing, testing display accuracy, maintenance

Please consider the necessary and prescribed instruments control according to:

EN 50073

EN 45544-4

BGI 518 (T023)

BGI 836 (T021)/Applicable only in Germany

DVGW worksheet G 465-4/Applicable only in Germany

Testing must also cover accessories used. Tests carried out and

other activities must be documented and the documentation retained for at least one year. The instrument tests required and

prescribed by DVGW G 465-4 (Technical Communications, reference) are divided into the following sections:

What ? Who ? When ?

function testing user prior to start working

testing display accuracy (adjustment)

servicing

(maintenance, any

repairs required)

specialist or specialist company

SEWERIN,

specialist or authorised company

daily to half-yearly

annual;

on defective instruments

Function testing

This is the simplest form of instrument test, which must be carried out by the user before starting work. It covers the following

items:

external condition including probe systems

function-testing the controls

battery charge

inspecting the pump and suction inlet

pump function

zero point

display of test gas feeding

Page 42

5 Testing / maintenance

Testing display accuracy (adjustment)

The frequency of the tests must be fixed depending on the sensors built-in and intensity of use.

The test must be carried out by a gas-supply company specialist,

a specialist company or by SEWERIN itself.

The test gas described (see section 5.3: Test gases) must be

used. The guidelines on the selection, installation, application

and maintenance of appliances for the detection and measuring

of flammable gases, oxygen or toxic gases (EN 50073 and

EN 45544-4) need to be observed

Moreover, national regulations BGI 518 and BGI 836 must be

complied with!

A full function test must also be carried out.

Servicing - maintenance and repair

Instruments must be serviced (and any necessary repairs carried out) at least once a year, by SEWERIN Service, a specialist

company authorised by SEWERIN or an authorised specialist of

the gas-supply company.

These activities must be documented in writing.

The test plaque on the instrument gives the date of the last

service and the scheduled date

of the next (e.g. 5/00 = May

2002).

Annual maintenance and repair must include at least the specialist care of the instrument, its settings and the replacement of

components with a limited lifetime.

Note:

Where instruments feature explosion protection

the applicable regulations must be observed!

Servicing operatives must be SEWERIN-

trained!

33

Page 43

34

5 Testing / maintenance

5.2 Test set

The test set SPE VOL is available to test the pump power, zero

point and sensitivity:

E

C

D

A

G

F

B

(Fig. 1)

Item description function

A device connection connection with:

probe connection

test heads

B test gas connection connection for:

test gas cans

pressure hose adapter

(in conjunction with pressure cylinder and pressure reducer)

C manometer Display of remaining pressure

inside the test gas container

D release button release of test gas

E fresh air supply opening for:

aspirating fresh air

fresh air hose

F needle valve with

flowmeter

reading the pump power in litres

per hour (l/h)

G connection hose connected to:

device

Page 44

5.3 Test gases

The following test gases are used in conjunction with the test set

SPE VOL tester to test zero point and sensitivity:

Gas Test gas

Methane CH

zero point: - fresh air

sensitivity 1:- 2.2 vol.% (50 %LEL) CH4 in synth. air

sensitivity 2: - 100 vol.% CH

Propane C3H

zero point:- fresh air

sensitivity- 1.0 vol.% (59 %LEL) propane (C3H8)

Nonane C9H

zero point:- fresh air

sensitivity- repla cement test gas 0.30 vol .%

Carbon dioxide CO

zero point:- fresh air

sensitivity- 2.0 vol.% (CO2) in synth. air

Oxygen O

zero point:- 100 vol.% methane (CH4)

sensitivity- fresh air

Hydrogen sulphide H2S

zero point:- fresh air

sensitivity- 40 ppm hydrogen sulphide (H2S) in

Carbon monoxide CO

zero point:- fresh air

sensitivity- 40 ppm carbon monoxide (CO) in

Ammonia NH

zero point:- fresh air

sensitivity- 50 ppm Ammonia (NH3) in Nitrogen

5 Testing / maintenance

4

4

8

in synth. air

(⊗)

20

propane (C3H8) in synth. air (reading to

be a returned when replacement test

gas: 0.35 vol.%)

2

2

synth. air

synth. air

(⊗)

3

35

Page 45

36

5 Testing / maintenance

These gases are supplied in 6 test gas cans:

2.2 vol.% CH4, 2.0 vol.% CO2, 17.5 vol.% O2, 40 ppm CO

1.0 vol.% C3H

0.3 vol.% C3H

40 ppm H2S

50 ppm NH

100 vol.% CH

8

8

3

4

Page 46

5 Testing / maintenance

5.4 Testing the pump power, zero point and sensitivity

Proceed as follows:

screw the selected test gas can onto the test set SPE VOL as

far as it will go (fig. 1, item B)

connect the instrument‘s probe connection (item 3) with the

hose of the test set SPE VOL (fig. 1, item A)

switch the instrument on; the pump aspirates fresh air through

the test set SPE VOL (fig. 1, item E)

enter your test results in the Inspection protocol

Pump power

use the needle valve (fig. 1, item F) to set the flow to maximum;

it must be greater than 30 l/h

Zero point

wait for the instrument to settle at a stable zero point; permis-

sible tolerances with fresh air are:

Gas

Methane CH

4

Tolerance

-0.15 – +0.15 vol.%

(-3 – +3 %LEL)

Propane C3H

8

-0.06 – +0.06 vol.%

(-3 – +3 %LEL)

Nonane C9H

20

(⊗)

-0.05 – +0.05 vol.% or

(-3 – +3 %LEL)

Carbon dioxide CO

2

+0.04 – +0.10 vol.%

Hydrogen sulphide H2S -3 – +3 ppm

Carbon monoxide CO -3 – +3 ppm

Ammonia NH

3

-3 – +3 ppm

(⊗)

In a fresh air environment, the display of the oxygen sensor will

indicate a nominal value of 20.9 vol.%.

For zero calibration, the sensor is exposed to a pure CH4 environment (100 % by volume).

Tolerances:

Oxygen O2 -0.5 – +0.5 vol.%

37

Page 47

38

5 Testing / maintenance

If display values are outside these tolerances the pertinent sensor

must be readjusted (cf. section 7: Adjustment menu).

Sensitivity

press the release key (fig. 1, item D) on the test set SPE VOL

and adjust the flow to the fresh air value (fig. 1, item F)

hold down the release key until the displayed concentration

has settled at a stable value; permissible tolerances with test

gases:

Gas

Methane CH

Propane C3H

Nonane C9H

4

20

8

(⊗)

Carbon dioxide CO

2

Tolerance

2.0 – 2.4 vol.% (45 – 55 %LEL)

0.90 – 1.10 vol.% (54 – 64 %LEL)

0.35 – 0.40 vol.% (50 – 57 %LEL)

1.8 – 2.2 vol.%

Hydrogen sulphide H2S 37 – 43 ppm

Carbon monoxide CO 37 – 43 ppm

Ammonia NH

3

47 – 53 ppm

(⊗)

The oxygen sensor is tested for its sensitivity in a fresh air environment.

Tolerances:

Oxygen O2 20.4 – 21.4 vol.%

If display values are outside these tolerances the pertinent sensor

must be readjusted (cf. section 7: Adjustment menu).

Page 48

INFO V2.1

JUSTAGE

H2S 0 PPM

H2S 40 PPM

CO 0 PPM

CO 30 PPM

O2 0 VOL.%

O2 20,9 VOL.%

CO2 0 VOL.%

CO2 2,00 VOL.%

CH4 0 %UEG

CH4 50 %UEG

CH4 100 %VOL

CH4 %UEG %LEL %LIE %VOL %GAZ

%VOL %GAZ

PRÜFGAS

INS-OK

EXIT >

MEM-CLR

MEM-INT

MEM-STOP

KZW-INT

EXIT >

DAT/UHR

INS-INT

INS-STOP

100

%VOL

PIN-CODE

ALARM

LCD

EXIT

>

MEMORY

SYSTEM

EXIT

6 Info menu

6.1 Menu structure

6 Info menu

39

Page 49

40

6 Info menu

6.2 Overview

The info menu is accessible only when the EX-TEC Combi is

switched off.

now simultaneously press the

following 3 keys

you are now in the INFO menu

item (cf. menu structure)

the software version number

(e.g. V2.1) is displayed and

the LCD illumination automatically switches on for about 4

minutes

you must now enter your PIN

code (cf. section 9.6: Setting

the PIN code)

0001 = factory settings

only now do you have access

to all menu items

the pump runs at constant

power; it can be switched on

or off with the pump key at

any time

the arrow-up key returns you

to the menu structure

Page 50

6 Info menu

you are now in the ADJUST-

MENT menu item (cf. section

7: Adjustment menu)

the arrow-up key brings you

to the next display

you are now in the MEMORY

me n u item (cf. secti o n 8:

Memory menu)

the arrow-up key brings you

to the next display

you are now in the menu item

SYSTEM (cf. section 9: System menu)

the arrow-up key brings you

to the next display

41

Page 51

42

6 Info menu

... or

you are now in the EXIT menu

item

there are now 2 ways of con-

tinuing to navigate through the

menu structure

pressing the arrow-up key

returns you to the ADJUSTMENT menu item (cf. menu

structure)

briefly pressing the on/off key

leaves the menu structure and

the instrument switches to

measuring operation

Page 52

JUSTAGE

H2S 0 PPM

H2S 40 PPM

CO 0 PPM

CO 30 PPM

O2 0 VOL.%

O2 20,9 VOL.%

CO2 0 VOL.%

CO2 2,00 VOL.%

CH4 0 %UEG

CH4 50 %UEG

CH4 100 %VOL

CH4 %UEG %LEL %LIE %VOL %GAZ

%VOL %GAZ

PRÜFGAS

INS-OK

EXIT >

7 Adjustment menu

7.1 Menu structure

7 Adjustment menu

you are in the ADJUSTMENT

menu item

briefly pressing the on/off key

brings you to the adjustment

menu

43

Page 53

44

7 Adjustment menu

7.2 Setting the H2S sensor

H2S - zero point 0 PPM

release fresh air from the

SPE VOL

wait for the display to settle at

a stable value and confirm the

adjustment with the on/off key

(OK appears in the LCD)

pressing the arrow-up key

brings you to the next display

H2S - sensitivity 40 PPM

now release test gas 40 PPM

H2S from the SPE VOL (cf.

section 7.8: Setting the test

gas concentration)

wait for the display to settle at

a stable value and confirm the

adjustment with the on/off key

(OK appears in the LCD)

once this has happened, turn

off the test gas feed

pressing the arrow-up key

brings you to the CO-sensor

setting facility

Page 54

7.3 Setting the CO sensor

7 Adjustment menu

CO - zero point 0 PPM

now release fresh air from the

SPE VOL

wait for the display to settle at

a stable value and confirm the

adjustment with the on/off key

(OK appears in the LCD)

pressing the arrow-up key

brings you to the next display

CO - sensitivity 40 PPM

now release test gas 40 PPM

CO from the SPE VOL (cf. section 7.8: Setting the test gas

concentration)

wait for the display to settle at

a stable value and confirm the

adjustment with the on/off key

(OK appears in the LCD)

once this has happened, turn

off the test gas feed

pressing the arrow-up key

brings you to the O2-sensor

setting facility

45

Page 55

46

7 Adjustment menu

7.4 Setting the O2 sensor

O2 - zero point 0 %VOL

now release test gas 100 vol.%

CH4 from the SPE VOL

wait for the display to settle at

a stable value and confirm the

adjustment with the on/off key

(OK appears in the LCD)

once this has happened, turn

off the test gas feed

pressing the arrow-up key

brings you to the next display

O2 - sensitivity 20.9 %VOL

now release fresh air from

the SPE VOL (cf. section 7.8:

Setting the test gas concentration)

wait for the display to settle at

a stable value and confirm the

adjustment with the on/off key

(OK appears in the LCD)

pressing the arrow-up key

brings you to the CO2-sensor

setting facility

Page 56

7.5 Setting the CO2 sensor

7 Adjustment menu

CO2 - zero point 0 %VOL

now release fresh air from the

SPE VOL through a carbon

dioxide filter (Sewerin accessory, see section 13.2)

wait for the display to settle at

a stable value and confirm the

adjustment with the on/off key

(OK appears in the LCD)

pressing the arrow-up key

brings you to the next display

CO2 - sensitivity 2.00 %VOL

now release test gas 2.00

%VOL CO2 from the SPE VOL

(cf. section 7.8: Setting the test

gas concentration)

wait for the display to settle at

a stable value and confirm the

adjustment with the on/off key

(OK appears in the LCD)

once this has happened, turn

off the test gas feed

pressing the arrow-up key

brings you to the CH4-sensor

setting facility

47

Page 57

48

7 Adjustment menu

7.6 Setting the CH4 sensor

CH4 - zero point 0 %VOL

now release fresh air from the

SPE VOL

wait for the display to settle at

a stable value and confirm the

adjustment with the on/off key

(OK appears in the LCD)

pressing the arrow-up key

brings you to the next display

CH4 - sensitivity 2.20 %VOL

now release test gas 2.20 %VOL

(50 %UEG) CH4 from the SPE

VOL (cf. section 7.8: Setting

the test gas concentration)

wait for the display to settle at

a stable value and confirm the

adjustment with the on/off key

(OK appears in the LCD)

once this has happened, turn

off the test gas feed

pressing the arrow-up key

brings you to the next display

Page 58

7 Adjustment menu

CH4 - sensitivity 100 %VOL

now release test gas 100 %VOL

CH4 from the SPE VOL

alternatively you can dispense

with the SPE VOL and use

natural gas from the local

supply instead

wait for the display to settle at

a stable value and confirm the

adjustment with the on/off key

(OK appears in the LCD)

once this has happened, turn

off the test gas feed

Note:

Before switching to the next step, please wait until

the displayed concentration has reached the value

of 0 vol.%!

pressing the arrow-up key

brings you to the next display

CH4 - %UEG-range language

repeatedly pressing the on/off

key switches between the following displays in the %UEG

range:

%UEG - display in Untere Explosionsgrenze (D)

%LEL - display in Lower Explosive Limit (GB)

%LIE - display in Limite Inférieure d´Explosion (F)

%VOL - display in %VOL (D/GB)

%GAZ - display in %GAZ (F)

49

Page 59

50

7 Adjustment menu

conf i r m th e d i s pl a y, e. g .

%VOL, with the on/off key

(OK appears in the LCD)

this se t t in g is pre s er v e d

even when the instrument is

switched off

pressing the arrow-up key

brings you to the measurement-quantity setting facility

7.7 Setting the measurement quantity

CH4, CO2, O2 %VOL-range language

repeatedly pressing the on/off

key switches between the following displays in the vol.%

range:

%VOL - display in %VOL (D/GB)

%GAZ - display in %GAZ (F)

conf i r m th e d i s pl a y, e. g .

%VOL, with the on/off key

(OK appears in the LCD)

this se t t in g is pre s er v e d

even when the instrument is

switched off

pressing the arrow-up key

brings you to the test gas concentration setting facility

Page 60

CH4 GAS

CO2 GAS

O2 GAS

H2S GAS

CO GAS

EXIT >>

PRÜFGAS

7.8 Setting the test gas concentration

if you use use test gases

other than those supplied by

SEWERIN, the concentration

must be set accordingly

you are in the TEST GAS

menu item

7 Adjustment menu

briefly pressing the on/off

key brings you to the test gas

menu

Example: CH

you are now in the CH4 GAS

menu item

4

51

Page 61

52

7 Adjustment menu

briefly pressing the on/off key

brings you to the CH4 test gas

concentration setting facility

the current concentration is

displayed (e.g.: 50 %UEG =

2.20 %VOL)

you can set the desired con-

cen t r at i on by re p ea t ed ly

pressing or holding down a

arrow key

the selected concentration is

displayed (e.g.: 45 %UEG =

2.00 %VOL)

confirm the concentration with

the on/off key

this se t t in g is pre s er v e d

even when the instrument is

switched off

the adjustment ranges of the

individual test gas concentrations are:

Page 62

7 Adjustment menu

test gas 2.20 vol.% (50%LEL) methane CH

adjustment range:- 1.75 – 3.50 vol.% (40 – 80 %LEL)

step size- 0.05 vol.% (1 %LEL)

test gas 1.0 vol.% (59 %LEL) propane C3H

adjustment range- 0.68 – 1.36 vol.% (40 – 88 %LEL)

step size- 0.02 vol.% (1 %LEL)

test gas

for nonane C9H

20

(⊗)

replacement test gas 0.3 vol.%

propane (C3H8)

adjustment range- 0.30 – 0.50 vol.% (40 – 80 %LEL)

step size- 0.05 vol.% (1 %LEL)

test gas 2.00 vol.% carbon dioxide CO

2

adjustment range- 0.90 – 4.10 vol.%

tep size- 0.02 vol.%

test gas 20.9 vol.% oxygen O

2

adjustment range- 17.0 – 22.0 vol.%

tep size- 0.1 vol.%

test gas 40 ppm hydrogen sulphide H2S

adjustment range- 10 – 100 ppm

step size- 1 ppm

test gas 40 ppm carbon monoxide CO

adjustment range- 10 – 150 ppm

step size- 1 ppm

test gas

50 ppm Ammoniak NH

(⊗)

3

adjustment range- 10 – 100 ppm

step size- 1 ppm

4

8

repeatedly pressing a arrow

key brings you to the exit from

the test gas menu

53

Page 63

54

7 Adjustment menu

7.9 Inspection confirmation

EXIT >>

signpost (>>) to menu level 2

pressing the on/off key leaves

the test gas menu

pressing the arrow-up key

brings you to the inspection

INSPECTION OK

the EX-TEC Combi can re-

mind you of scheduled inspection and adjustment dates

this requires the inspection

interval and the inspection

block to be set in the system

menu (cf. sections 9.3 „Setting the inspection interval“

and 9.4 „Setting the inspection

block“)

confirm the inspection or ad-

justment you have carried

out with the on/off key (OK

appears in the LCD):

this date is stored as a function

of the set date (cf. section 9.2

„Setting the date/time“)

Page 64

7.10 Leaving the adjustment menu

7 Adjustment menu

the next inspection or adjust-

ment date is calculated in accordance with the set inspection interval

pressing the arrow-up key

brings you to the exit from the

adjustment menu

EXIT >

signpost (>) to menu level 1

pressing the on/off key leaves

the adjustment menu

you are now back at the top

ma i n -menu level an d can

switch between the following

menu items:

- JUSTAGE

- MEMORY

- SYSTEM

- EXIT

55

Page 65

56

8 Memory menu

MEM-CLR

MEM-INT

MEM-STOP

KZW-INT

EXIT >

MEMORY

8 Memory menu

8.1 Menu structure

the EX-TEC Combi continu-

ously stores readings from the

sensors that are present

these can later be read out

with the appropriate evaluation software (separate user

manual) via the RS-232-interface (item 8)

you are in the MEMORY menu

item

briefly pressing the on/off

key brings you to the memory

menu

Page 66

8 Memory menu

8.2 Clearing memory

(⊗)

MEMORY CLEAR

if you have set the memory

mode = stack memory (cf.

section 8.4: Setting memory

mode), this function enables

you to clear the entire readings

memory

confirm the clearance with

the on/off key (OK appears

in the LCD)

pressing the arrow-up key

brings you to the memory-interval setting facility

57

Page 67

58

8 Memory menu

8.3 Setting the memory interval

(⊗)

MEMORY INTERVAL

briefly pressing the on/off key

brings you to the memory-interval setting facility

by repe atedly pres sing or

holding down a arrow key

you can select the following

memory intervals:

Seconds range:

- 1 second

- 10 seconds

- 20 seconds

- 30 seconds

Minutes range:

- 1 minute

- 2 minutes

- 3 minutes

- 5 minutes

- 10 minutes

- 20 minutes

- 30 minutes

Page 68

8 Memory menu

Data-memory capacity

the EX-TEC Combi stores the following values in its data

memory:

- readings for each gas (instantaneous values at the moment

of scanning)

- event values for each gas (MIN, MAX, KZW, LZW values and

alarm overshoots)

- special error displays, alarms

depending on the set memory interval and the number of gases,

data memory can continuously record the following periods

(times in hh:mm):

M e m o r y

3 gases 4 gases 5 gases

interval

1 sec 01:02 00:41 00:29

10 sec 10:28 06:58 04:51

20 sec 20:56 13:56 09:43

30 sec 31:25 20:54 14:35

1 min 62:50 41:48 29:11

2 min 125:40 83:37 58:23

3 min 188:30 125:25 87:34

5 min 314:10 209:02 145:58

10 min 628:20 418:05 291:56

20 min 1256:40 836:10 583:52

30 min 1885:00 1254:15 875:48

Example: when the instrument is set to warn for 4 gases and with

the memory interval set to 1 minute you can record

event values over a period of 41 hours 48 minutes.

59

Page 69

60

8 Memory menu

confirm the interval with the

on/off key

this se t t in g is pre s er v e d

even when the instrument is

switched off

pressing the arrow-up key

brings you to the memorymode setting facility

8.4 Setting the memory mode

(⊗)

MEMORY STOP

you have the possibility to

choose the memory mode

between the ring memory or

the stack memory

briefly pressing the on/off key

brings you to the memorymode setting facility

by repeatedly pr e s s i ng a

arrow key you can select the

following memory modes:

OFF (ring memory)

readings are continuously written

to memory; when memory is

full the oldest values are overwritten

Page 70

ON (stack memory)

readings ar e only written to

memory until it is full, thus writeprotecting the oldest values

confirm the memory mode with

the on/off key

this se t t in g is pre s er v e d

even when the instrument is

switched off

pressing the arrow-up key

brings you to the short-term

value-interval setting facility

8.5 Setting the short-term value interval

SHORT-TERM VALUE INTERVAL

for the meaning of the KZW

alarm (cf. section 3.7 Shortterm value alarm (KZW), longterm value alarm (LZW), minimum and maximum values

MIN / MAX)

8 Memory menu

briefly pressing the on/off key

brings you to the short-term

value-interval setting facility

by repeatedly pressing or hold-

ing down a arrow key you can

select the following short-term

value-interval settings:

Adjustment range:

- 1 – 30 minutes

- 1 minute step size

61

Page 71

62

8 Memory menu

8.6 Leaving the memory menu

the usual setting is for a 15

minutes averaging interval

confirm the interval with the

on/off key

this se t t in g is pre s er v e d

even when the instrument is

switched off

pressing the arrow-up key

brings you to the exit from the

memory menu

EXIT >

signpost (>) to menu level 1

pressing the on/off key leaves

the memory menu

you are now back at the top

ma i n -menu level an d can

switch between the following

menu items:

- JUSTAGE

- MEMORY

- SYSTEM

- EXIT

Page 72

DAT/UHR

INS-INT

INS-STOP

100 %VOL

PIN-CODE

ALARM

LCD

EXIT

>

SYSTEM

9 System menu

9.1 Menu structure

9 System menu

you are in the SYSTEM menu

item

briefly pressing the on/off

key brings you to the system

menu

63

Page 73

64

9 System menu

9.2 Setting the date/time

DATE/TIME

briefly pressing the on/off key

brings you to the date/time

setting

Date

the last day (24 - flashing)

and month (02) to be set are

displayed

by repe atedly pres sing or

holding down a arrow key ...

... and confirming with the

on/off key you can first set the

day and then the month to the

current date

Year

the last year (2000 - flashing)

to be set is displayed

Page 74

9 System menu

by repe atedly pres sing or

holding down a arrow key ...

... and confirming with the

on/off key you can set the

current year

Time

the last hours (17 - flashing)

and minutes (49) to be set are

displayed

by repe atedly pres sing or

holding down a arrow key ...

... and confirming with the

on/off key you can first set the

hours and then the minutes to

the current time

these settings are preserved

even when the instrument is

switched off

pressing the arrow-up key

brings you to the inspectioninterval setting facility

65

Page 75

66

9 System menu

9.3 Setting the inspection interval

INSPECTION INTERVAL

the EX-TEC Combi can re-

mind you of regular scheduled

tests (e.g. inspections, adjustments)

this reminder is based on the

inspection interval

briefly pressing the on/off key

brings you to the inspectioninterval setting facility

Inspection interval = 0 – 52 CW

the last interval to be set is

displayed in CW (calendar

weeks), e.g.:

- 0 CW = function inactive

- 4 CW = monthly

- 52 CW = annual

by repe atedly pres sing or

holding down a arrow key ...

... and confirming with the

on/off key you can set the

desired interval

this se t t in g is pre s er v e d

even when the instrument is

switched off

pressing the arrow-up key

brings you to the inspectionblock setting facility

Page 76

9 System menu

Example: inspection interval

selected inspection interval:

04 weeks

inspection routine started

(i.e. inspection confirmed, see section 7.9):

10.02.2004

from these settings follows:

the next inspection has to be effected

between 09. – 15.03.2004

During the next 3 weeks the EX-TEC Combi will display the following references to the inspection date:

24.02.2004 – 01.03.2004 (> 1 week before)

LCD: the coming inspection date is

displayed for about 3 seconds

on switch-on

lamp/buzzer: inactive

instrument: the instrument then automati-

ca lly swit ches to meas uring

operation

02.03.2004 – 08.03.2004 (1 week before)

LCD: the coming inspection date is

displayed for about 3 seconds

on switch-on

lamp/buzzer interval lamps / interval tone

instrument: the instrument then automati-

ca lly swit ches to meas uring

operation

67

Page 77

68

9 System menu

09.03.2004 – 15.03.2004 (scheduled)

LCD: the due inspection date is dis-

lamp/buzzer: interval light/sound

instrument: when the display is cleared with

16.03.2004 – ... (from 1 week later)

LCD: the overdue inspection date is

lamp/buzzer: interval light/sound

instrument: depending on the setting of the

played on switch-on

the buzzer key (item 4) or after

waiting for about 15 seconds the

instrument automatically switches

to measuring operation.

displayed on switch-on

INS-STOP function (cf. section

9.4: Setting the inspection block)

the following conditions are possible:

INS-STOP = OFF

when the display is cleared with

the buzzer key (item 4) or after

waiting for about 15 seconds the

instrument automatically switches

to measuring operation

INS-STOP = ON

when any key is pressed (item

4) or after waiting for about 15

seconds the instrument automatically switches off.

Page 78

9.4 Setting the inspection block

9 System menu

INSPECTION STOP

to make sure your EX-TEC

Combi is regularly checked

you can activate an inspection block

this block does not become

active until the next inspection

date has passed (cf. section

9.3: Setting the inspection

interval)

after that you cannot use the

instrument until the inspection

has been carried out and

confirmed (cf. section 7.9:

Inspection confirmation)

briefly pressing the on/off key

brings you to the inspectionblock setting facility

Inspection-block condition

the last setting is displayed,

e.g.:

- OFF = block inactive

- ON = block active

by repeatedly pr e s s i ng a

arrow key ...

... and confirming with the on/

off key you can set the desired

condition

69

Page 79

70

9 System menu

9.5 Setting the 100 vol.% range

this se t t in g is pre s er v e d

even when the instrument is

switched off

pressing the arrow-up key

brings you to the operatingsignal setting facility

100 %VOL (GAS-MEASURING)

th e EX- T EC Com b i has

two modes (cf. section 3.3:

Modes):

WARNING mode

monitoring the atmosphere

(w o r kplace moni t o ring) in

shafts and chambers

GAS-MEASURING mode

determining gas concentrations

if you wish to use the instrument

purely as a warning device, you

can switch off the 100 %VOL

(GAS-MEASURING) range

briefly pressing the on/off key

brings you to the 100 %VOL

range setting

100 %VOL range condition

the last setting is displayed:

- OFF = 100 %VOL inactive

- ON = 100 %VOL active

Page 80

9.6 Setting the PIN code

9 System menu

by repeatedly pr e s s i ng a

arrow key ...

... and confirming with the on/

off key you can set the desired

condition

this se t t in g is pre s er v e d

even when the instrument is

switched off

pressing the arrow-up key

brings you to the setting of the

PIN-code

PIN CODE

you can set your EX-TEC

Combi so that only authorised

persons, e.g.:

- instrument technicians

- experts

have access to the info menu

with all its subfunctions

this involves setting a PIN

code that must be entered

every time the info menu is

called

when an incorrect PIN code is

entered the instrument reverts

to its switch-on routine

briefly pressing the on/off key

brings you to the PIN-code

setting facility

71

Page 81

72

9 System menu

Setting the PIN CODE

the last PIN code to be set

(0001 = factory setting) appears in the LCD

we recommend you to use a

different PIN code

by repe atedly pres sing or

holding down a arrow key ...

... and confirming with the

on/off key you can set each

of the 4 digits from left to right

to the desired PIN code

PIN code = 0000

the function is inactive, every

user has access to the info

menu

PIN code = 0001 – 9999

the function is active, only

persons who know the set

PIN code have access to the

info menu

this se t t in g is pre s er v e d

even when the instrument is

switched off

pressing the arrow-up key

brings you to the alarm-threshold setting facility

Note:

Make a note of your PIN code and only give it to

authorised persons.

If you forget your PIN, please contact SEWERIN

Service.

Page 82

CH4 AL1

CH4 AL2

CO2 AL1

CO2 AL2

O2 AL1

O2 AL2

H2S AL1

H2S AL2

CO AL1

CO AL2

EXIT >>

ALARM

9.7 Setting the alarm thresholds

9 System menu

you can set your own alarm

thresholds if you do not wish to

use those pre-set by SEWERIN

you are in the ALARM menu

item

briefly pressing the on/off

key brings you to the alarmthresholds menu

73

Page 83

74

9 System menu

Example: CH4 alarm threshold 2

you are now in the CH4 AL2

menu item

briefly pressing the on/off key

brings you to the facility to set

alarm threshold 2 for methane

CH

4

the current alarm threshold is

displayed

(e.g.: 50 %UEG = 2.20 %VOL)

by repe atedly pres sing or

holding down a arrow key

you can set the desired alarm

threshold

the selected alarm threshold

is displayed (e.g. 40 %UEG =

1.75 %VOL)

the setting ranges for the in-

dividual alarm thresholds are:

(factory settings in bold):

Page 84

9 System menu

Gas AL1 threshold AL2 threshold

Methane CH4 (vol.%) 0.90 vol.% 2.20 vol.%

adjustment range:- 0.45 – 4.15 vol.% 0.50 – 4.20 vol.%

step size:- 0.05 Vol.% 0.05 Vol.%

Methane CH4 (%LEL) 20 %LEL 50 %LEL

adjustment range:- 10 – 94 %LEL 11 – 95 %LEL

step size:- 1 %LEL 1 %LEL

Propane C3H8 (vol.%) 0.34 vol.% 0.86 vol.%

adjustment range:- 0.18 – 1.60 vol.% 0.20 – 1.62 vol.%

step size:- 0.02 vol.% 0.02 vol.%

Propane C3H8 (%LEL) 20 %LEL 50 %LEL

adjustment range:- 10 – 94 %LEL 11 – 95 %LEL

step size:- 1 %LEL 1 %LEL

Nonane C9H20 (%LEL) (⊗) 0.15 vol.% 0.35 vol.%

adjustment range- 0.05 – 0.60 vol.% 0.10 – 0.65 vol.%

step size:- 0.05 vol.% 0.05 vol.%

Carbon dioxide CO

0.50 vol.% 1.00 vol.%

2

adjustment range:- 0.10 – 4.90 vol.% 0.20 – 5.00 vol.%

step size:- 0.10 vol.% 0.10 vol.%

Oxygen O

2

18.0 vol.% 23.0 vol.%

adjustment range:- 15.0 – 24.9 vol.% 15.1 – 25.0 vol.%

step size:- 0.1 vol.% 0.1 vol.%

Hydrogen sulphide H2S 10 ppm 20 ppm

adjustment range:- 5 – 99 ppm 6 – 100 ppm

step size:- 1 ppm 1 ppm

Carbon monoxide CO 30 ppm 60 ppm

adjustment range:- 5 – 199 ppm 6 – 200 ppm

step size:- 1 ppm 1 ppm

Ammonia NH3 (⊗) 50 ppm 75 ppm

adjustment range- 5 – 99 ppm 6 – 100 ppm

step size:- 1 ppm 1 ppm

75

Page 85

76

9 System menu

confirm the alarm threshold

with the on/off key

this setting is preserved even

when the instrument is switched

off

repeatedly pressing a arrow

key brings you to the exit from

the alarm-threshold menu

EXIT >>

signpost (>>) to menu level 2

pressing the on/off key leaves

the alarm thresholds menu

pressing the arrow-up key

brings you to the LCD-check

facility

Page 86

9.8 Checking the LCD

9.9 Leaving the system menu

9 System menu

with this function you can carry

out a visual check that all

segments of the LCD are in

working order

confirm the LCD check with

the on/off key

all the possible LCD characters

and symbols are activated

pressing the arrow-up key

brings you to the exit from the

menu

EXIT >

signpost (>) to menu level 1

pressing the on/off key leaves

the memory menu

you are now back at the top

ma i n -menu level an d can

switch between the following

menu items:

- JUSTAGE

- MEMORY

- SYSTEM

- EXIT

77

Page 87

78

10 Application hints

10 Application hints

10.1 Application hints from report of suitability examination PFG-No. 41300401P

On the basis of the measurement results and remarks contained

in the test report PFG-No 41300401P, the EX-TEC portable