Page 1

Operating

Instructions

Page 2

Measurable success by Sewerin equipment

Congratulations.

You have chosen a quality instrument manufactured by Hermann Sewerin

GmbH.

Our equipment will provide you with the highest standards of performance,

safety and efciency. They correspond with the national and international

guide-lines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice and

assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

SEWERIN SARL

17, rue Ampère – BP 211

67727 Hoerdt Cedex, France

Tél. : +33 3 88 68 15 15

Fax : +33 3 88 68 11 77

www.sewerin.fr

sewerin@sewerin.fr

SEWERIN IBERIA S.L.

Centro de Negocios “Eisenhower”

Avenida Sur del Aeropuerto

de Barajas 28, Of. 2.1 y 2.2

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.es

info@sewerin.es

Sewerin Ltd

Hertfordshire

UK

Phone: +44 1462-634363

www.sewerin.co.uk

info@sewerin.co.uk

Sewerin Sp.z o.o.

ul. Twórcza 79L/1

03-289 Warszawa, Polska

Tel.: +48 22 675 09 69

Faks: +48 22 486 93 44

Tel. kom. +48 501 879 444

www.sewerin.pl

info@sewerin.pl

Page 3

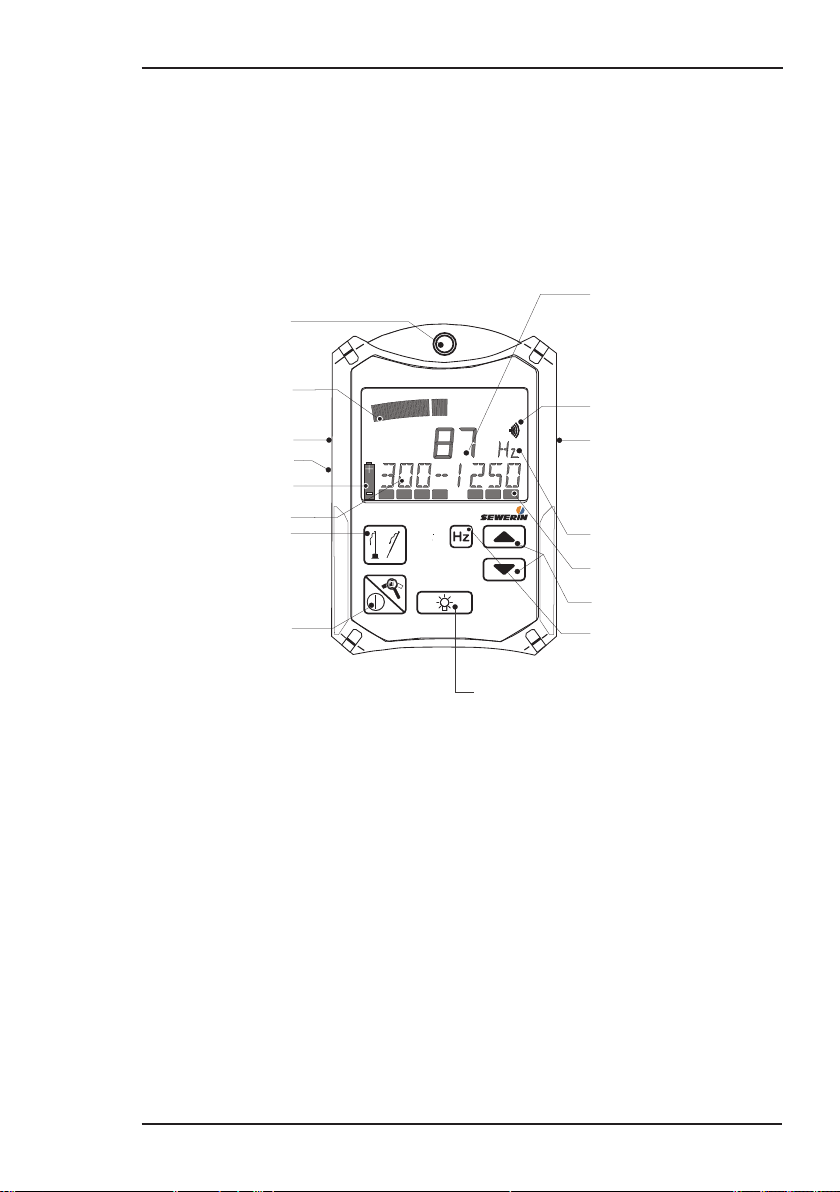

Illustration AQUAPHON A 100

Digital display

Speaker symbol

Socket for probes

Small digital display

Charging status display /

Volume display

Cusor keys

Hz key

Light key

Gaunlet key

Analog isplayd

Headphone socket

Loudspeaker

Battery symbol

Comment line

Mikrophone key

Magnifying-glass

and on/off key

AQUAPHON®A100

Page 4

Operating Instructions

AQUAPHON® A 100

20.04.2016 a – V8.X – 104194 – en

Page 5

Symbol explanation

CAUTION!

This symbol warns of dangers that may threaten

the safety of the user or maty damage or destroy

the product.

Note:

This symbol ags information and hints extending

beyond the actual operation of the product .

Page 6

Contents Page

1 General .....................................................................................1

1.1 Warranty ....................................................................................1

1.2 Intended use .............................................................................2

1.3 General notes ............................................................................ 2

2 Function description ............................................................... 3

2.1 Water leak detection ..................................................................3

2.2 Acoustic pipeline location .......................................................... 3

3 Use ............................................................................................4

3.1 Switching on and off ..................................................................4

3.1.1 Manual probe selection .......................................................... 5

3.2 Adjusting the display contrast ...................................................5

3.3 Charging equipment .................................................................. 6

3.4 Charging ....................................................................................6

3.4.1 Self-discharge ........................................................................7

3.5 Connecting the headphones .....................................................8

4 Water leak detection ...............................................................9

4.1 Displays .....................................................................................9

4.1.1 Analog display ........................................................................ 9

4.1.2 Digital display ......................................................................... 9

4.1.3 Small digital display ................................................................9

4.1.4 Speaker symbol ...................................................................10

4.1.5 Volume display .....................................................................10

4.1.6 Battery symbol .....................................................................10

4.1.7 Comment line ....................................................................... 11

4.1.8 Basic amplication ............................................................... 11

4.2 Key functions ........................................................................... 11

4.2.1 Microphone key .................................................................... 11

4.2.2 Gauntlet key ......................................................................... 12

4.2.3 Hz key ..................................................................................12

4.2.4 Cursor keys .......................................................................... 14

4.2.5 Light key ............................................................................... 14

4.2.6 Magnifying-glass and on/off key ........................................... 15

4.3 Probe overview .......................................................................16

4.3.1 Ground microphone BO-4 .................................................... 16

4.3.2 Ground microphone 3P-4 ..................................................... 16

I

Page 7

Contents Page

4.3.3 Carrying rod H-4 ...................................................................16

4.3.4 Test rod T-4 ..........................................................................17

4.4 Switching on and off ................................................................18

4.5 Sound-protection function .......................................................19

4.6 Preliminary location ................................................................. 19

4.7 Pin pointing .............................................................................23

4.8 Individual settings .................................................................... 25

4.9 Factory settings (reset) ...........................................................27

5 Brief instruction ....................................................................28

5.1 Brief instruction on water leak detection .................................28

6 Malfunctions ..........................................................................31

7 Specications ........................................................................ 33

8 Accessories ...........................................................................34

8.1 Accessories for water leak detection ....................................... 34

8.2 General accessories ...............................................................34

9 Annexe ...................................................................................35

9.1 EU declaration of conformity ...................................................35

9.2 Hints on Disposal ....................................................................36

9.3 Record of changes ..................................................................37

10 Index .......................................................................................38

II

Page 8

1 General

1.1 Warranty

Hermann Sewerin GmbH bears no liability for damage attributable to non-compliance with these instructions.

The terms of warranty and liability of the conditions of sale and delivery of Hermann Sewerin GmbH are not extended by the above.

z This product may only be used after the operating instructions

have been read and understood.

z This product was developed for qualied skilled personnel in

public utility companies. The device must only be commissioned

after respective introduction.

z This product may only be used for its designated purpose.

z This product is destined for industrial and commercial applica-

tions.

z Repair work may only be carried out by appropriately trained

persons.

z Changes and modications to the product may only be carried

out with the consent of Hermann Sewerin GmbH. Unauthor-

ised modications to the product render the warranty of the

producer null and void.

z Only accessories from Hermann Sewerin GmbH may be used

with this product

z Only replacement parts approved by Hermann Sewerin GmbH

must be used for repairs.

z We reserve the right to make technical modications in the

interests of further development.

Please comply with general safety rules in addition to these instructions!

1 General

1

Page 9

1 General

1.2 Intended use

The A 100 is a instrument for electro-acoustic water leak detec-

tion and acoustic pipeline location

Note:

This operating instructions describes the functions

of software version 8.X. Future changes are subject

to modication!

1.3 General notes

z In order to ensure the correct functioning of the devices, the

following requirements must be complied with:

− Devices must not be dipped or immersed.

− Display and keyboard must not be scratched.

− Devices must not be dropped.

− Devices must not be used as supports.

z The allowed operating temperature range is -10 °C – +50 °C.

z The allowed storage temperature is -25 °C – +70 °C.

z If additional devices are used (e.g. generators), the correspond-

ing operating manuals must be complied with.

2

Page 10

2 Function description

2.1 Water leak detection

The A 100 is used in combination with various microphones (listed

in the „Accessories“ section) for the electro-acoustic detection of

water-leaks.

When a pressurised pipeline develops a leak, water ows through

it into the surrounding soil at high speed.

Consequence:

The pipeline material vibrates at the exit point. This vibration is

transmitted by the pipe, with the result that it can be picked up

even at remote contact points (valves and the like). This structure-

borne noise is rendered audible by the A 100.

The water jet - and the pipe, in the vicinity of the leak - also induce

vibration in the soil. This is transmitted to the surface, where it

can be picked up as ground-borne noise.

Even with electro-acoustic leak detection the human ear retains

its importance. Suitable practice enables noises of different types.

and tones to be compared, and leak noise distinguished from

extraneous, unrelated noise.

2 Function description

2.2 Acoustic pipeline location

Plastic lines cannot be located by the classical electromagnetic

method because they do not conduct electricity.

The acoustic method of pipeline location uses a different principle:

the lines transmit mechanical vibration better than the surrounding earth. If suitable vibrations are applied to the line, they are

transmitted along its length and through the earth to its surface,

and can then be located there with an ground microphone and

receiver with headsets according to the water leak detection

principle. As with water leak detection, the line is in the place

where the greatest intensity is found. Fibrous-cement and metallic

pipes can also be located in this way.

If you wish to detect the lines acoustically, follow the operating

instructions for the vibration emitter (eg, COMBIPHON). Proceed

as with for water leak detection. The A 100 also offers an additional

mode to assist in detecting lines (see section 4.2.1).

3

Page 11

3 Use

3 Use

3.1 Switching on and off

z Plug a probe into the appropri-

ate input .

Probe connection: input 1

z A brief signal tone sounds.

z The software version appears

in the display.

z The charge status of the re-

chargeable batteries appears

in the display.

z The type of probe plugged in

is automatically determined.

z The probe type briey appears

1

in the display. If the probe type

is not automatically identied it

can be selected manually (see

section 3.1.1).

z If a microphone has been

plugged in, the bandpass currently set for the frequency

lter is briey displayed.

4

Page 12

3.1.1 Manual probe selection

If the probe is not automatically identied (if it is an old model, for

example), it can be selected manually:

3 Use

z The layout of the display de-

pends on the used probe. The

measurement process may be

started.

z To switch off, unplug the probe

from the input.

z Hold down the microphone

key.

z Plug in the probe.The „>“

symbol appears on the left of

the bottom text line and the

name of the probe that can

be selected, e.g. „M01“ in the

middle.

z Pressing the cursor keys

switches between possible

probes.

z Pressing the magnifying-glass

key displays the selected

probe.

3.2 Adjusting the display contrast

The display contrast can be adjusted as follows:

z Hold down the light key.

z Press the cursor-down key to

reduce the contrast.

z Press the cursor-up key to

increase the contrast.

5

Page 13

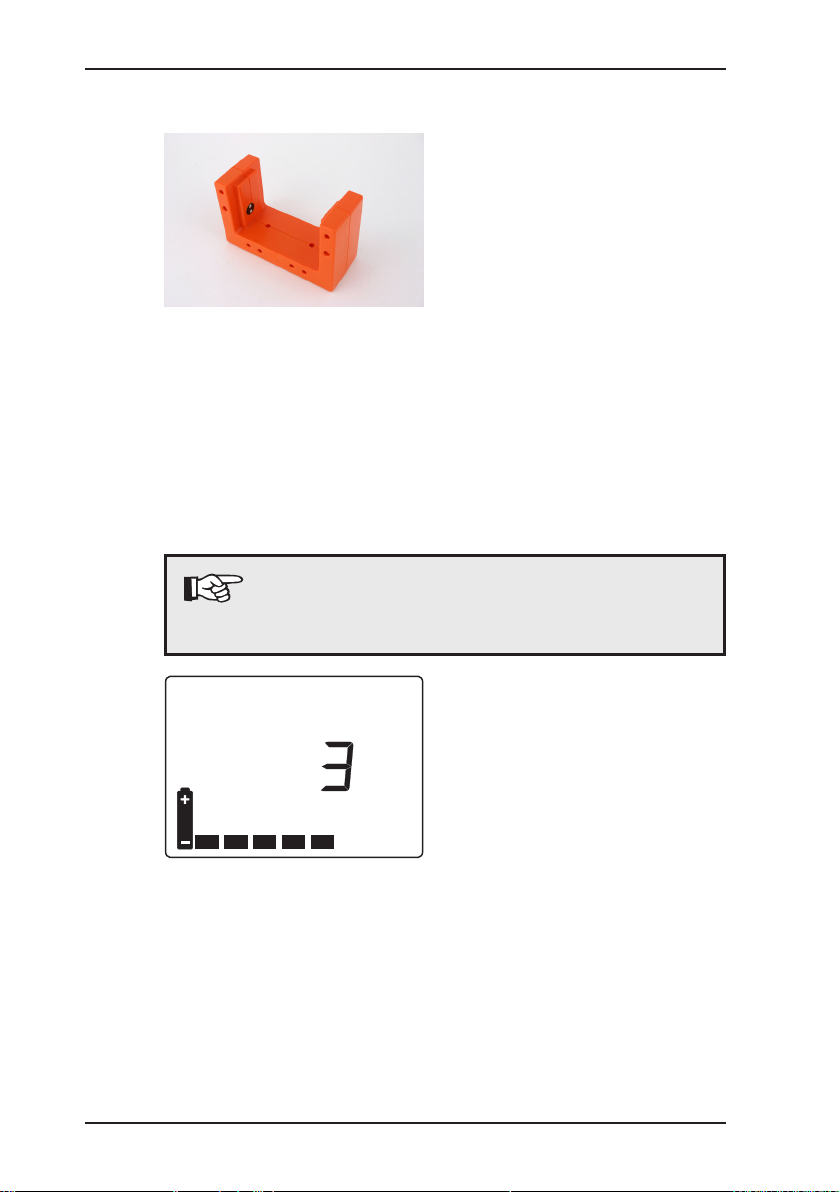

3 Use

3.3 Charging equipment

3.4 Charging

Note:

Charging the accumulator only within temperature

range 0 – 45 °C.

When fully charged the instru-

ments have a maximum ope-

rating time of approx. 12 hours.

To charge an instrument you need

the docking station HS 1,2 A (see

g.), which can be used either in

the workshop or in the emergency

vehicle .

The docking station has the following sockets on its side:

z AC/DC adapter M4,

100 – 240 V~

z Vehicle cable M4 for 12 V

z Switch off the instrument and

plug it into the docking station.

The following (or similar) appears in the display:

z The instrument now has 5 op-

erating hours (= 5 bars) left. It

will take another 3 hours to be

fully charged.

The actual operating time

depends on the accumulators’

condition (age ...) and operation (light, volume ...) charging

time takes max. 4 hours.

z When it is fully charged all the

bars appear and the number

display disappears.

6

Page 14

3 Use

z You can leave the instrument

in the docking station until you

need it again.

If you have a case for your

A 100, it can be charged inside.

z Connect cable to the docking

station inside the case.

z Connect the plug-in AC/DC

adapter M4 or vehicle cable

M4 to socket 2.

3.4.1 Self-discharge

If the instrument is not placed in the docking station HS 1,2 A when

switched off the NiMH-accumulator will self-discharge, which is

considered when displaying the remaining operating time.

After no more than 30 days the instrument will indicate zero operating hours, and it must be recharged.

7

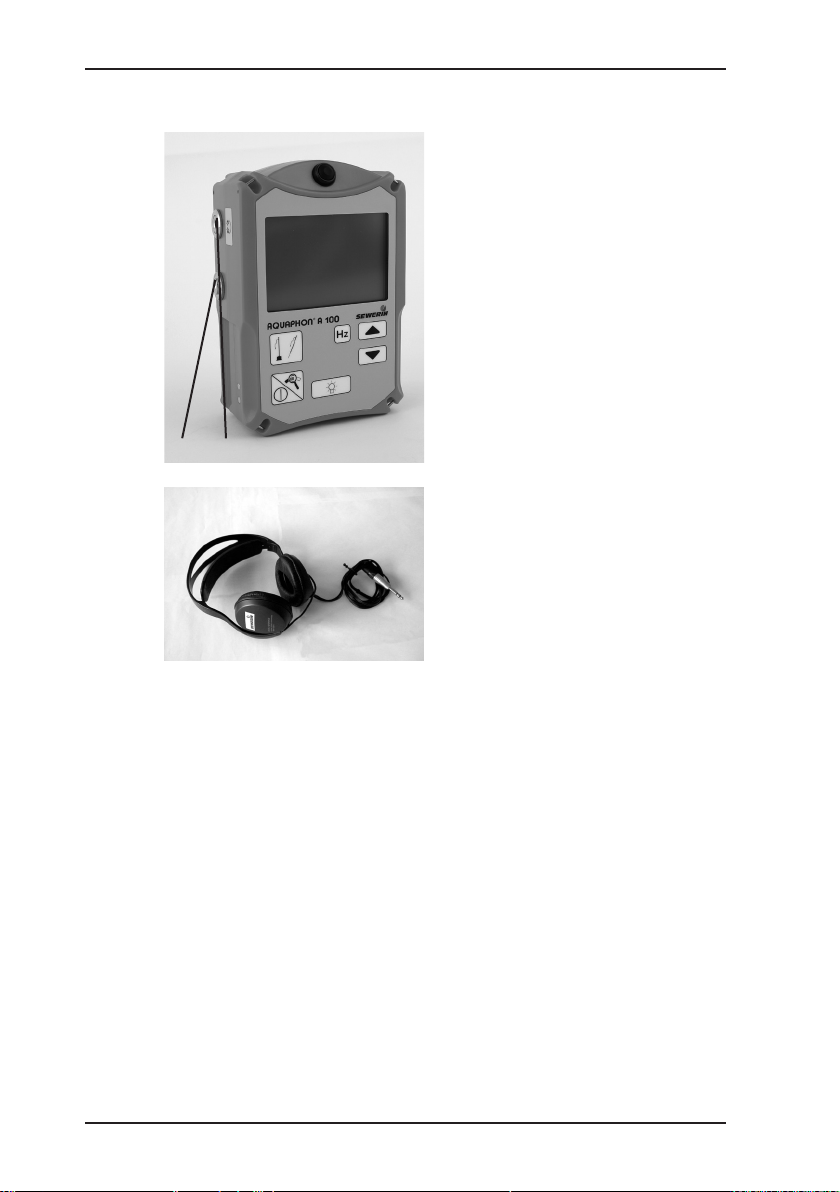

Page 15

3 Use

3.5 Connecting the headphones

1 2

A 100 are tted with a speaker

(1).

Such produces the conrmation

and alarm signals. There is,

furthermore, a specic tone for

pipeline location.

During water leak detection no

leak noise is emitted over the

speaker: headphones must be

used. Switching from speakers

to headphones:

z Plug the headphones jack-

plug into socket 2.

The speaker is switched off

automatically; sound is output

to the headphones.

z When the headphones are

unplugged the sound is once

more output to the speaker.

8

Page 16

4 Water leak detection

4.1 Displays

4.1.1 Analog display

4.1.2 Digital display

4 Water leak detection

The analog display indicates the

current reading.

The digital display indicates the

smallest value measured during

a single measurement.

In the „MAX“ mode, the digital

display always shows the great-

est measured value. In „MAX“

mode you can switch by holding the micro key for 3 seconds

(only with microphones with

cable connection, not with radio

microphones).

4.1.3 Small digital display

For the purposes of comparison

the small digital display always

indicates the precedent value

measured.

9

Page 17

4 Water leak detection

4.1.4 Speaker symbol

4.1.5 Volume display

The speaker symbol indicates

that the A 100 headphones are

activated.

The volume display indicates

the volume set. If the bar on the

extreme left is shown in reverse

video, the volume is low; if the

bar on the extreme right is shown

in reverse video, the volume is

maximum.

The volume can be adjusted with

the cursor keys.

4.1.6 Battery symbol

10

The battery symbol appears

about 15 minutes before the

battery runs out. In case the accumulator volume drops further,

the instrument automatically

switches off to protect the accumulator.

Page 18

4.1.7 Comment line

4.1.8 Basicamplication

4 Water leak detection

Various possible settings and

parameters are displayed in the

comment line. The lter setting is

shown here, for example.

Basic amplication is useful for

adapting to extreme situations.

The higher the basic amplication, the louder the noise in the

headphones. The values 10, 100

or 1000 appear in the display.

Basic amplication can be al-

tered with the magnifying-glass

key (see section 4.2.6).

4.2 Key functions

4.2.1 Microphone key

10 = high noise amplica-

tion

100 = medium noise ampli-

cation

1000 = low noise amplica-

tion

Pressing the microphone key

activates the A 100. Pressing it

again deactivates it.

11

Page 19

4 Water leak detection

Modus „MAX“

4.2.2 Gauntlet key

If you hold down the micro key

for 3 seconds, you can switch to

„MAX“mode. This mode helps

with acoustic line detection. Instead of minimum values, only

max values are shown in this

mode (only with microphones

with cable connection, not with

radio microphones).

Pressing the gauntlet key activates the A 100. Depending on

the options selected in the set-up

menu it is deactivated either by

releasing the gauntlet key or by

pressing it again.

4.2.3 Hz key

12

The Hz key is used to alter the

frequency-lter setting. The l-

ter bandpass - which is a least

300 Hz wide - can be set anywhere between 1 Hz and 10 kHz.

Pressing both cursor keys at

once resets the bandpass to its

default setting, which depends

on the probe.

Page 20

Different leak noises can be

heard best in different frequency

ranges, and two people may

hear the same noise differently.

To optimise acoustic perception

a bandpass can be set.In this

case only a particular frequency

range is fed to the headphones.

The best setting can be found

by experiment, or alternatively

the A 100 can search for it automatically.

Setting the frequency range manually

z Press the Hz key.

The most recently set limits

are displayed; the lower lter

limit ashes.

z The cursor keys change the

lower lter limit step by step.

z Press the Hz key again.

The upper lter limit ashes.

z The cursor keys change the

upper lter limit step by step.

z Press the Hz key again.

The lter limits are saved.

4 Water leak detection

13

Page 21

4 Water leak detection

Automatic search for the best frequency range

The A 100 has a lter-optimisation function that automatically

searches for the best frequency range. It should not be activated

if there is any signicant extraneous noise, and the leak noise -

particularly ground-borne noise - should already be audible.

4.2.4 Cursor keys

z Press the Hz key until a clear-

ance tone sounds.

z The A 100 takes a „noise sam-

ple“ and analyses it.

While analysis is under way

the display indicates various

frequency ranges. The noise

produced by the lter values

displayed can be heard over

the headphones.

z The A 100 selects the fre-

quency range in which the leak

noise is especially clear.

The cursor keys are used to adjust the volume of the speaker or

headphones. The volume setting

is shown in the display by a bar

in reverse video.

4.2.5 Light key

14

The light key switches the dis-

play illumination on and off.

It switches off automatically after

about 2 minutes.

Page 22

4.2.6 Magnifying-glass and on/off key

The analog display indicates

the relative noise level. The

display can be adapted to prevailing conditions to make a

change in the display from one

measurement point to another

easier to detect. This adaptation switches the analog display

(instantaneous value) between

scale values 10, 100 and 1000

and alters basic amplication for

the headphones.

10 = high sensitivity, high

100 = medium sensitivity,

1000 = low sensitivity, low

Automatic adjustment takes

place to maintain the ratio between the current delayed-action

value and the instantaneous

value.

4 Water leak detection

noise amplication

medium noise ampli-

cation

noise amplication

z Press the microphone key.

The A 100 is activated.

z Press the magnifying-glass

key.

The sensitivity of the analog

display is altered.

z The current sensitivity setting

is shown above and to the right

of the display.

15

Page 23

4 Water leak detection

4.3 Probe overview

4.3.1 Ground microphone BO-4

4.3.2 Ground microphone 3P-4

The ground microphone BO-4

is used to locate leaks beneath

stabilised surfaces.

The ground microphone 3P-4

is used to locate leaks beneath

unstabilised surfaces. An earth

spike can be screwed onto it

for use in soft ground. Its 3 feet

guarantee stability at all times.

4.3.3 Carrying rod H-4

16

The carrying rod can be used

with both ground microphones.

The BO-4 or 3P-4 microphone

is screwed onto its lower end.

Page 24

4.3.4 Test rod T-4

4 Water leak detection

The test rod is used for preliminary leak location. The test rod

is placed in contact with valves

on the line under investigation.

17

Page 25

4 Water leak detection

4.4 Switching on and off

z Put the microphone jack-plug

into socket 1 on the A 100.

z The A 100 switches on.

1

z If the A 100 does not switch

on, press the on/off key.

z One of the following displays

briey appears in the display:

for test rod or

18

for ground microphone or

for other microphone types.

z To switch off, unplug the probe

from socket 1.

Page 26

4.5 Sound-protection function

Caution!

Only Sewerin headphones should be used, as these

are adjusted to the A 100. The threshold at which

the sound-protection function is triggered can be

adjusted: see section 4.8 „Individual adjustments“.

4 Water leak detection

The A 100 incorporates a sound-

protection function. With a sud-

den loud noise the sound in

the headphones is immediately

mufed. If the sound gets even

louder the headphones are

switched off. Once this noise

source has ceased the A 100

reverts to normal operation.

The sound-protection function

ensures that no excessive sound

pressure reaches the ears.

This headphones symbol appears in the comment line when

the sound-protection function is

activated.

4.6 Preliminary location

Structure-borne sound is transmitted a very long way by metallic pipes, which makes the test

rod very effective for preliminary

location.

z Connect the headphones to

the A 100.

z Connect the test rod to the

A 100.

z Place test rod on the rst mea-

surement point.

19

Page 27

4 Water leak detection

z Activate the A 100 with the

gauntlet key or the microphone key.

A speaker symbol appears

in the display during measurement.

The analog display indicates

the current measurement

volume.

The noise can be heard by the

headphones.

During this measurement the

digital display indicates the

smallest value measured.

The small digital display indicates the smallest value

measured during the previous

measurement. (This value is 0

after rst measuring.)

The smallest measured value

is shown in the analog display

in reverse video during the

measurement.

z To deactivate the A 100 re-

lease the gauntlet key or press

the microphone key again.

If the A 100 is not deactivated when the gauntlet key

is released, the function of

the gauntlet key has been

changed (see section 4.8). In

this event press the gauntlet

key again.

z Place the test rod on the

next measurement point and

proceed exactly as described

above.

The previously measured

value now appears in the small

digital display for the purposes

of comparison.

20

Page 28

4 Water leak detection

In water leak detection the display will be similar to that shown

in the illustration above.

The noise is loudest near the leak and quieter further away.

On the left: the analog display indicates about 30%: this is the

instantaneous noise value.

However, the analog display often uctuates substantially because

of changing ambient noise. Even a trend can be hard to recog-

nise. This is why the large digital display (gure 16) indicates the

smallest noise value measured at this point so far (the current

delayed-action value). Even if ambient noise grows louder, this

display is unaffected - while if it grows quieter the display falls

further.

The gure 16 is also shown in the analog display as a segment

in reverse video.

The small digital display indicates “0”: as yet there is no value

in memory.

Centre: the analog display indicates about 60%. The large digital

display (gure 38) indicates a value greater than the left-hand

measurement point. This is an indication that the leak is closer.

The small digital display now indicates “16”: it reminds you of

the result from the last measurement point (last delayed-action

value). This makes it easier to decide whether you have not yet

reached the leak or have already gone past it.

21

Page 29

4 Water leak detection

Right: the current delayed-action value has fallen because the

leak is further away. The last delayed-action value, “38”, provides

us a further comparison.

The following illustration shows how a leak noise overlaid by

uctuating extraneous noise is shown in the display.

22

Page 30

4.7 Pin pointing

Non-metallic pipe materials do not transmit structure-borne sound

as well. Therefore checking at the valves is not enough. The

sections between valves must also be checked with a ground

microphone.

Listening to the surface of the ground at short intervals enables the

leak to be located without digging. Here, too, the A 100 provides

a precise optical comparison of the noise intensities.

The above illustration, for example, shows how the display

changes when passing a leak.

4 Water leak detection

z Connect the ground micro-

phone to the A 100.

z Place the microphone on the

ground.

z Activate the A 100 with the

gauntlet key or the microphone key.

A speaker symbol appears

in the display during measurement.

The analog display indicates

the current measurement

volume.

23

Page 31

4 Water leak detection

The current noise can be heard

through the headphones.

The digital display indicates

the smallest value measured.

The small digital display indicates the previously-meas-

ured value. For the rst measurement this value is 0.

The smallest measured value

is shown in the analog display

in reverse video.

z To deactivate the A 100 re-

lease the gauntlet key or press

the microphone key again.

If the A 100 is not deactivated when the gauntlet key

is released, the function of

the gauntlet key has been

changed (see section 4.8). In

this event press the gauntlet

key again.

z Place the ground microphone

on the next measurement

point and proceed exactly as

described above.

The previously measured

value now appears in the small

digital display for the purposes

of comparison.

z Use the ground microphone

to check the area of the section where the leak is thought

to be.

The illustration on the previous

page shows an example of the

display when crossing a leak.

24

Page 32

4.8 Individual settings

On the A 100 various settings can be freely selected and perma-

nently saved. The set-up table on the next page highlights the

various possibilities.

This is a list of settings that you can alter and save. First of all

please switch-on the instrument.

4 Water leak detection

z Hold down the microphone

key.

z Press the on/off key.

„ELWset“ appears in the comment line.

z The microphone key calls the

menu items one after another.

z The cursor-up key alters the

status of the selected menu.

z After the last menu the „save“

message appears.

z The cursor-up key saves the

current settings and terminates the function.

Notes:

The ear protection function should be set to „low

level“ only with low surrounding noise so that is

already activated with moderate noise levels. In

situations with high noise, such level should be set

to option (1), factory settings. In special cases, the

setting option (2) may be used. The ear protection

function will then only be activated in case of very

loud noise levels. To avoid that the ear protection

function is activatet too often and impairs locat-

ing the leak, the headphones’ volume may not

be set too loud.

25

Page 33

4 Water leak detection

ELW - setup table

Menu

num-

Description Condition

(0)

Condition

(1)

Condition

(2)

ber

1 The gauntlet key

(item 1) is a key

which does or

does not stay

without* with /

down when

pressed

2 Quit tone on

pressing button

3 sound-protection

function operates at

4 Basic amplica-

tion

on* off /

low

threshold

middle

threshold*

low middle* high

high

threshold

5 headphones

switch off com-

yes* no /

pletely

( * = factory setting)

Example:

If the comment line contains „No 3 0“, the sound-protection

function operates at the low threshold.

Basic amplication is useful for adapting to extreme situations.

The higher the basic amplication, the louder the noise in the

headphones at a given volume setting. Pressing the magnifying-

glass key is a convenient way to alter basic amplication.

If you do not want the headphones to switch off completely when

the sound-protection function is triggered by loud noises, only

heavily mufed, select „switch off headphones completely: No“.

This means that the user will not lose all ambient noise while using

the hearing-protection headphones. An orientation, for example

in trafc, is limited possible.

26

Page 34

4.9 Factory settings (reset)

4 Water leak detection

The factory settings (e.g. lter

settings) can be restored as

follows.

z Plug in a microphone jack-

plug while holding down the

light key.

z „Reset“ appears in the bottom

text line for about 2 seconds.

27

Page 35

5 Brief instruction

5 Brief instruction

5.1 Brief instruction on water leak detection

Preliminary location

z Connect the headphones to the A 100.

z Connect the test rod to the A 100.

z Place test rod on the rst measurement point.

z Activate the A 100 with the gauntlet key or the microphone key.

A speaker symbol appears in the display during measurement.

The analog display indicates the current measurement volume.

The noise can be heard by the headphones.

During this measurement the big digital display indicates the

smallest value measured.

During this measurement the small digital display indicates the

smallest value of the precedent measurement. For the rst measurement this value is 0. During this measurement the smallest

measured value is shown in the analog display in reverse video.

z To deactivate the A 100 release the gauntlet key or press the

microphone key again.

If the A 100 is not deactivated when the gauntlet key is released,

the function of the gauntlet key has been changed (see section

4.8). In this event press the gauntlet key again.

28

Page 36

5 Brief instruction

z Place the test rod on the next measurement point and proceed

exactly as described above.

The previously measured value now appears in the small digital

display for the purposes of comparison.

29

Page 37

5 Brief instruction

Pin pointing

z Instead of a test rod connect a ground microphone to the A 100.

z Place the microphone on the ground.

z Activate the A 100 with the gauntlet key or the microphone key.

A speaker symbol appears in the display during measurement.

The analog display indicates the current measurement volume.

The current noise can be heard through the headphones.

The digital display indicates the smallest value measured.

The small digital display indicates the previously-measured

value. For the rst measurement this value is 0.

The smallest measured value is shown in the analog display

in reverse video.

z To deactivate the A 100 release the gauntlet key or press the

microphone key again.

If the A 100 is not deactivated when the gauntlet key is released,

the function of the gauntlet key has been changed (see section

4.8). In this event press the gauntlet key again.

z Place the ground microphone on the next measurement point

and proceed exactly as described above.

The previously measured value now appears in the small digital

display for the purposes of comparison.

z Use the ground microphone to check the area of the section

where the leak is thought to be.

30

Page 38

6 Malfunctions

Malfunctions of the device are indicated through an error message on the display.

An F and an error code will be displayed.

6 Malfunctions

Error

code

Description Error be-

haviou

10 A 100 not recognised self-lock-

ing

40 Temperature at battery to

high for charging (> 45°C)

41 Temperature at battery to

low for charging (< 0°C)

self-locking

self-locking

52 Data ash error occurred self-lock-

ing

100 Probe not recognised by

device

110 No probe detected by

device

self-locking

self-locking

Remedy

Switch device back on,

SEWERIN

service

Improve

device surroundings,

SEWERIN

service

Improve

device surroundings,

SEWERIN

service

Switch device back on,

SEWERIN

service

Switch

device back

on, manually

select probe,

SEWERIN

service

Switch

device back

on, manually

select probe,

SEWERIN

service

31

Page 39

6 Malfunctions

Error

Description Error be-

code

210 Communication error

with CODEC

239 DSP error in boot pro-

gram

240 DSP error when loading

rmware

241 Communication error

with DSP

haviou

Self-resetting

self-locking

self-locking

Self-resetting

Remedy

Switch device back on,

SEWERIN

service

Switch device back on,

SEWERIN

service

Switch device back on,

SEWERIN

service

Switch device back on,

SEWERIN

service

32

Page 40

7 Specications

Fab-no. A 100 037 11

Transmission bandwidth (A 100): 1 – 10000 Hz

Filter, adjustable: steps of 50, 500 and 1000 Hz

Filter, minimum bandwidth: 300 Hz

Power supply: built-in rechargeable accumu-

Type of protection in

operation: IP65

Weight: approx. 1,0 kg

Approx. dimensions

(W x H x D): 12.5 × 18 × 6.5 cm

Temperature range: operation -10 °C – +50 °C

7 Specications

lator (NiMH)

integral automatic charging/buffer

system

Displayed battery status

Operating time approx. 12 hours

storage -25 °C – +70 °C

33

Page 41

8 Accessories

8 Accessories

8.1 Accessories for water leak detection

Piezo-Test rod T-4, with screwed on tip.

Ground microphone BO-4

With sound-proofed against extraneous noise, especially suitable

for stabilised surfaces.

Carrying rod H-4

For ground microphones BO-4 and 3P-4

Ground microphone 3P-4

with tripod, for both stabilised and unstabilised surfaces, with

screw-on 20-cm measuring spike.

Test rod extension 60 cm

needed for listening to valves in shafts

Valve adapter

Gate valve adapter

Piezo-microphone EM30

especially suitable for use in buildings.

8.2 General accessories

Headphones stereo

Docking station HS 1.2 A

Case A 100

Case with foam inlay, special transport protection, incorporated

pockets for accessories, device may be charged inside the case.

AC/DC adapter M4

Vehicle cable M4

Carrying system Triangel

adjustable upholstered back belt

Carrying system Cross Belt

Carrying system „Cross Belt“, 2 adjustable straps with diagonal

attachment points. The straps cross over at the back for extra

comfort.

34

Page 42

9 Annexe

9.1 EU declaration of conformity

Hermann Sewerin GmbH hereby declares that the

AQUAPHON A 100 fulls the requirements of the following gu-

ideline:

z 2014/30/EU

The complete declaration of conformity can be found online.

9 Annexe

35

Page 43

9 Annexe

9.2 Hints on Disposal

The disposal of instruments and accessories is governed by the

European Waste Catalogue (EWC).

Type of Waste Corresponding EWC Code

Instrument 16 02 13

Battery, accu 16 06 05

Old Instruments

Old instruments can be returned to Hermann Sewerin GmbH.

We will arrange the qualied disposal free of charge through

certied specialists.

36

Page 44

9.3 Record of changes

Version 4.2

z Display: set to sensitivity ranges 1 – 10, 1 – 100, 1 – 1000,

switch via magnifying-glass key

z Factory settings: sound protection functions only active at mid-

dle threshold. This threshold is active after renewed power-up.

z Band lter acc. to micro type (manually adjustable to

9,950 Hz):

BO-4: 50 – 1500 Hz

T-4: 50 – 3000 Hz

EM30, M01: 50 – 9950 Hz

z Pre-amplication matched to micro-types

Version 5.0

z Radio microphones usable

z If the accu-voltage is lower than the accu-nominal voltage, the

device is being recharged.

z The version number of the software is displayed on switch-on.

9 Annexe

Version 5.2

z Marker for system Combiphon (max level is stored)

z Version with battery power possible

Version 7.0

z Use of new hardware resulting in a weight reduction from 1.4

to 1.0 kg.

z In this version, the programme is stored in a ash memory and

no longer in a EPROM.

z Quick charging due to NiMH-accumulators.

z The lowest level of the band-pass lter is set from 50 Hz to

1 Hz. This allows for hearing even lower frequencies.

37

Page 45

10 Index

10 Index

A

Accessories 1, 3, 34

Analog display 9

B

Basic amplication 11, 15, 26

Battery symbol 10

Brief instruction 28

C

Carrying rod H-4 16

Charging 6

Charging equipment 6

Charging status 4

Comment line 11, 19, 25, 26

Cursor keys 14

D

Digital display 9, 20, 21

Display contrast 5

E

ELWset 25

K

Key functions 11

L

Light key 5, 14

M

Magnifying-glass key 11, 15, 26, 37

Manual probe selection 5

MAX 9, 12

Microphone key 5, 11

O

On/off key 15, 18, 25

P

Pin pointing 23

Pipeline location 2, 3, 8

Preliminary location 19

Probe overview 16

Probe selection 5

R

Radio microphones 9, 12, 37

Reset 27

F

Factory settings 27

Frequency range 13, 14

G

Gauntlet key 12, 20, 23, 24, 26

Ground microphone 3P-4 16, 34

Ground microphone BO-4 16, 34

H

Headphones 8, 10, 14, 19, 26

Hz key 12, 13, 14

I

Interference 31

38

S

Self-discharge 7

Setup 25, 26

Software version 4

Speaker symbol 10, 20

Stabilised surfaces 16

Switch off 5, 18

Switch on 4, 18

Switch on/off 4

T

Test rod T-4 17, 34

Transmission bandwidth 33

U

Unstabilised surfaces 16

Page 46

V

Volume 14, 20

Volume display 10

W

Water-leak detection 2, 3, 8, 9

10 Index

39

Page 47

Hermann Sewerin GmbH

Robert-Bosch-Straße 3 · 33334 Gütersloh · Germany

Telefon +49 5241 934-0 · Telefax +49 5241 934-444

www.sewerin.com · info@sewerin.com

20.04.2016 a – 104194 – en

Loading...

Loading...