Setra Systems SSC-2S, SSC-4S, SSC-4H, SSC-2H Operation And Installation Instructions Manual

Introduction

The Sure-Set Current Switch (SSC) Series

of digital output switches are noninvasive devices designed to detect current

owing through a cable or wire. A cost

eective solution for monitoring on and

o status or proof of operation, these

devices are ideal for monitoring the current load on motors driving fans, pumps,

chillers, compressors and blowers. The

Model SSC Current Switch has a universal power supply. Excitation is magnetically induced from the current carrying

conductor (wire or cable) being sensed,

making these devices completely selfpowered.

Warning: Risk of Electric Shock

Disconnect power supply before making electrical connections. Contact

with components carrying hazardous

voltage can cause electrical shock and

may result in severe personal injury or

death.

Warning: Risk of Arc-Flash

Disconnect power supply before making electrical connections. Contact

with components carrying hazardous

voltage can cause electric shock and

may result in severe personal injury or

death.

Setup and Adjustments

The Sure-Set Model SSC series of switches

employ a unique method to set the operating set point of the device. The Sure-Set

Current Switch is designed to allow the

installer to select the operating setpoint

prior to opening the electrical enclosure.

Since the Sure-Set does not require calibration on a powered and operating load,

the safety hazards and Personal Protective Equipment (PPE) required for protection against Arc-Flash are not necessary!

In fact, the installer or site engineer can

pre-set all Sure-Set Current Switches used

for a particular installation prior to delivering the parts to the job site. The installer

selects the proper Sure-Set model for

the application (230 VAC or 480 VAC) and

veries the Motor HP for the system to be

monitored.

Select Operating Range

1. Verify the motor Full Load HP for the

system to be monitored.

2. Verify the motor operating voltage.

3. Verify that the proper Sure-Set model

was selected to monitor the motor

used in the system. (Sure-Set Current

Switches are available for 230 VAC

and 480 VAC motors both in standard

low and high HP ranges.)

4. Set the Sure-Set operating setpoint

to the motor Full Load HP by rotating

the range selector switch on top of

the Sure-Set to the proper motor HP

(see Fig. 2). The Sure-Set operating

setpoint is now set to properly monitor the motor operation. No calibration on a live load is necessary.

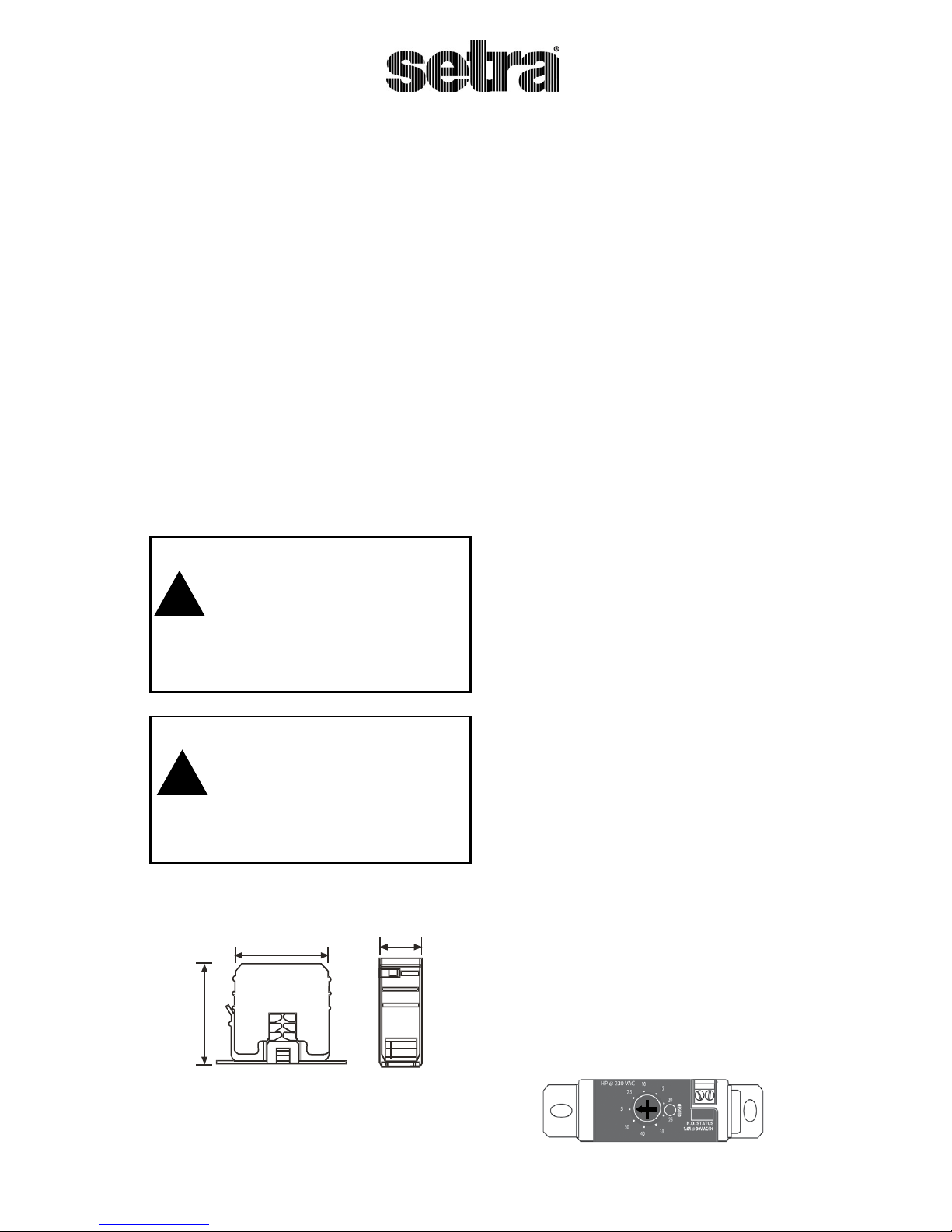

65 (2-9/16)

69 (2-23/32)

27 (1-1/16)

Fig. 1 Model SSC

Dimensions

mm(in.)

Model SSC-2S/SSC-2H/SSC-4S/SSC-4H

Operation and Installation Instructions

!

!

Fig. 2 HP Range Selector

Installation

Mounting

1. Shut o all power to the enclosure

prior to installing.

2. Remove the Sure-Set mounting

bracket from the main housing.

3. Using the two screws (included), attach the mounting bracket to the

back of the electrical enclosure. (A

piece of double side tape is included

in the hardware kit to assist holding

the mounting bracket while attaching the screws.

4. Snap the SSC into place on the

mounting bracket.

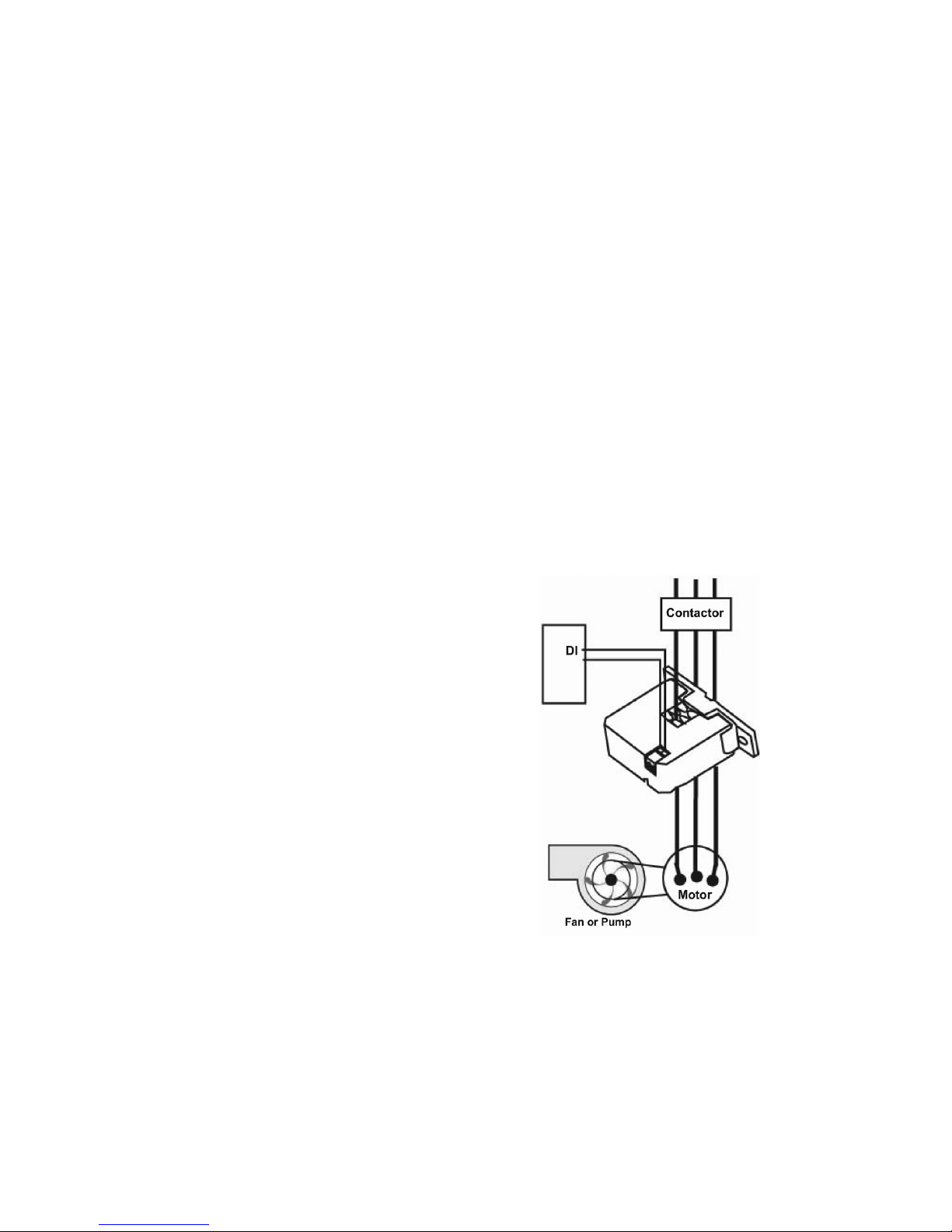

Fig. 3 Model SSC Typical Wiring

Wiring

1. Disconnect power to the conductor

cable from the power source prior to

proceeding.

2. Snap the split core around the power

conductor cable, and close the housing until the latch snaps shut.

3. Wire SSC output terminals to the

control box Digital Input (DI) terminal (30 V max. terminal voltage).

Note: the output switch contacts are solid

state, and they work just like dry contacts.

When the output switch is closed, less than

1 ohm is present; when the output switch is

open, more than 1 ohm is present.

4. Close the enclosure and reconnect

power to the power conductor cable.

(For wiring example, see Figure 3.)

RETURNING PRODUCTS

FOR REPAIR

Please contact a Setra application engineer (800-257-3872, 978-263-1400) before returning unit for repair to review

information relative to your application.

Many times only minor eld adjustments

may be necessary. When returning a product to Setra, the material should be carefully packaged and shipped to:

Setra Systems, Inc.

159 Swanson Road

Boxborough, MA 01719-1304

Attn: Repair Department

To assure prompt handling, returned

unit(s) must be accompanied by Setra’s

Return Order Form,completely lled out,

found on Setra’s website at http://www.

setra.com/tra/repairs/cal_rep.htm.

Note: Please enclose any required mating electrical connectors and wiring diagrams. Allow approximately 3 weeks after

receipt at Setra for the repair and return

of the unit. Non-warranty repairs will not

be made without customer approval and

a purchase order to cover repair charges.

WARRANTY AND LIMITATION OF LIABILITY

SETRA warrants its products to be free from

defects in materials and workmanship, subject

to the following terms and conditions: Without

charge, SETRA will repair or replace products

found to be defective in materials or workmanship within the warranty period; provided that:

a) the product has not been subjected

to abuse, neglect, accident, incorrect

wiring not our own, improper

installation or servicing, or use in

violation of instructions furnished by

SETRA;

b) the product has not been repaired or

altered by anyone except SETRA or its

authorized service agencies;

c) the serial number or date code has not

been removed, defaced, or otherwise

changed; and

d) examination discloses, in the judgment

of SETRA, the defect in materials or

workmanship developed under normal

installation, use and service;

e) SETRA is notied in advance of and

the product is returned to SETRA

transportation prepaid.

Unless otherwise specied in a manual or

warranty card, or agreed to in writing and

signed by a SETRA ocer, SETRA pressure,

current, humidity, and acceleration products

shall be warranted for one year from date

of sale. The foregoing warranty is in lieu of

all warranties, express, implied or statutory,

including but not limited to, any implied

warranty of merchantability for a particular

purpose. SETRA’s liability for breach of warranty

is limited to repair or replacement, or if the

goods cannot be repaired or replaced, to a

refund of the purchase price. SETRA’s liability

for all other breaches is limited to a refund

of the purchase price. In no instance shall

SETRA be liable for incidental or consequential

damages arising from a breach of warranty, or

from the use or installation of its products.

No representative or person is authorized

to give any warranty other than as set out

above or to assume for SETRA any other

liability in connection with the sale of its

products.

Symptom Action

SSC solid state output does not change state when

motor current is changed.

Insucient current to the load to reach the selected setpoint

threshold.

Incorrect motor HP range selected Verify that the Sure-Set range

selector switch is set to the proper motor FLA.

Incorrect Sure-Set model chosen. Check motor Full Load HP against

the Sure-Set HP ranges.

Check that the proper Sure-Set model was chosen for the motor

operating voltage.

The clamp is not fully closed. Press the Sure-Set housing to ensure

the clamp latch is fully closed. Verify that the conductor is within

the range of the conductor sizes that can be accommodated by the

Sure-Set.

Motor is turned on and switch does not close. Verify that the range selector switch is set to the proper motor FLA.

Troubleshooting

Table 1: Troubleshooting

The performance specications are nominal and conform to acceptable industry standards. For application of

conditions beyond these specications, consult your local Setra representative. Setra Systems, Inc. shall not be

liable for damages from misapplication or misuse of its products.

For all CE technical questions, contact Setra Systems, USA. EU customers may contact our EU representative

Hangstler GmbH, Uhlandstr 49, 78554 Aldingen, Germany (Tel: +49-7424-89500).

159 Swanson Road, Boxborough, MA 01719/800-257-3872;

Fax: 978-264-0292; Email: sales@setra.com/Web: www. setra.com

SS-SureSet Rev. A 3/27/2013

Technical Specications

MODEL SSC-2S SSC-4S SSC-2H SSC-4H

Motor Hp Range 1, 2, 3, 5, 7.5, 10,

15, 20, 25

2, 3, 5, 7.5, 10, 15,

20, 25, 30

5, 7.5, 10, 15, 20,

25, 30, 40, 50

15, 20, 25, 30, 40,

50, 60, 75, 100

Continuous Operating Current 135A, 600V AC

Switch Setpoint Adjustable, 9 position selector switch

Output Relay Contacts (option) Optional. Output contacts rated 10A @ 260V AC, 5A @ 30V DC

Output Relay Coil Voltage (option) Optional, 12V AC/DC or 24V AC/DC

Switch LED Indication Yes Yes Yes Yes

Relay LED Indication (option) Yes Yes Yes Ye s

Trip Point Set Value 35% below FLA @ selected Hp value

Current Switching Mode Under Current Sensing

Dimensions 2.7 x 2.56 x 1.08 in.

(69 x 65 x 27 mm)

2.7 x 2.56 x 1.08 in.

(69 x 65 x 27 mm)

2.7 x 2.56 x 1.73 in.

(69 x 65 x 44 mm)

2.7 x 2.56 x 1.73 in.

(69 x 65 x 44 mm)

Aperture Size 0.72 x 0.78 in. (18 x 20 mm)

Sensor Power Source Induced from power conductor cable

Status Output Switch normally open

Switch Load Capacity 1A @ 30V AC/DC max.

Isolation Voltage 600V AC rms.

Temperature Range 5 to 140°F (-15 to 60°C)

Frequency Range 50/60 Hz

Humidity Range 0 to 95% non-condensing

Agency Approvals/Compliance CE Compliant, RoHS Compliant, UL/c-UL Listed: 508, IND. Cont. EQ: E317719

Patents Pending

Loading...

Loading...