Setra Systems Multi-Sense 231 User Manual

®

Multi-Sense

Model 231

Multi-Congurable, Wet-to-Wet

Differential Pressure Transducer

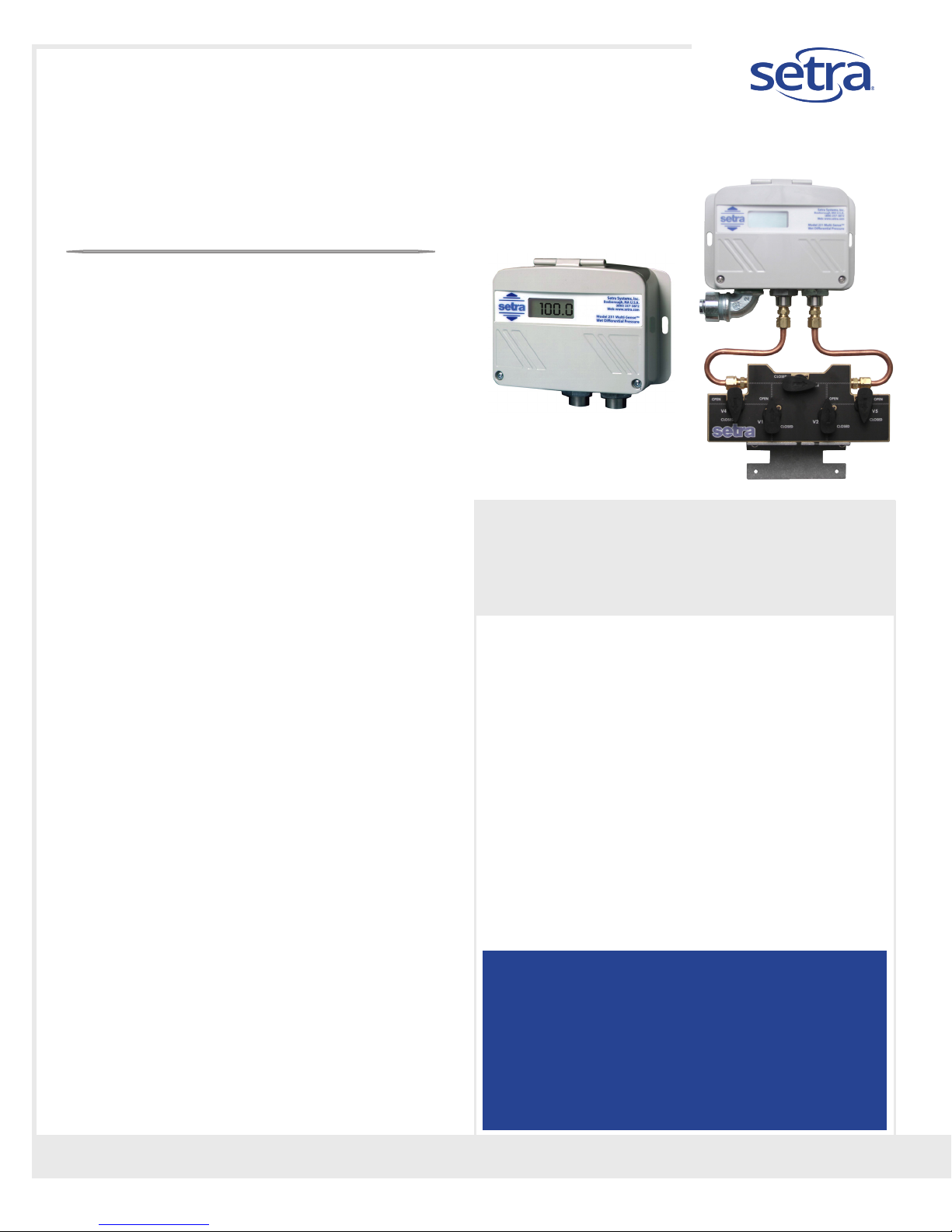

Setra’s 231 is a multi-congurable, wet-to-wet dierential pressure transducer oering the user an all-in-one device with eld

selectable pressure ranges and analog outputs. The device is

oered with an optional 3 or 5 valve machined brass manifold

for ease of installation and maintenance. The 231 has a robust,

NEMA 4 enclosure with a hinged, captive cover allowing for

easy access to switches for adjusting the range and output. An

optional display is available that allows users to view high, low,

and dierential pressure readings on a simple rotating cycle.

Field Selectable Pressure Ranges

The 231 oers 8 eld selectable pressure ranges which can be

changed using a slide switch, reducing risk of installing the

wrong range unit. The multi-range functionality allows the

user to hold less inventory and add additional exibility in the

eld.

n Dual Sensors

n Suitable for Harsh Environments

n 3 & 5 Valve Manifold Assembly Options

Quick & Simple Installation

The 231 provides the user with an optional 3 or 5 valve machined brass manifold which can save money on installation

and maintenance. The single piece construction of the brass

body has no internal process connections, eliminating the risk

of internal leaks.

Robust Enclosure for Difcult Applications

The 231 NEMA 4 housing oers an optional LCD display for instant indication of the high, low and dierential pressure readings. A hinged enclosure makes it suitable for harsh environments and saves the hassle of misplacing it when completing

a dicult installation.

Model 231 Features:

• 4 Field Selectable Outputs

• 8 Field Selectable Pressure Ranges

• Field Accessible Push-Button Zero & Remote Zero

• Hinged Cover

• Optional LCD Display

• NEMA 4 Rated Housing, All Cast Aluminum

• CE & RoHS Compliant

Applications:

• Energy Management Systems

• Process Control Systems

• Flow Measurement of Various Gases or Liquids

• Liquid Level Measurement of Pressurized Vessels

• Pressure Drop Across Filters

Phone: 800-257-3872 • Fax: 978-264-0292 • setra.com © Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

®

Multi-Sense

Model 231

Multi-Congurable, Wet-to-Wet Differential Pressure Transducer

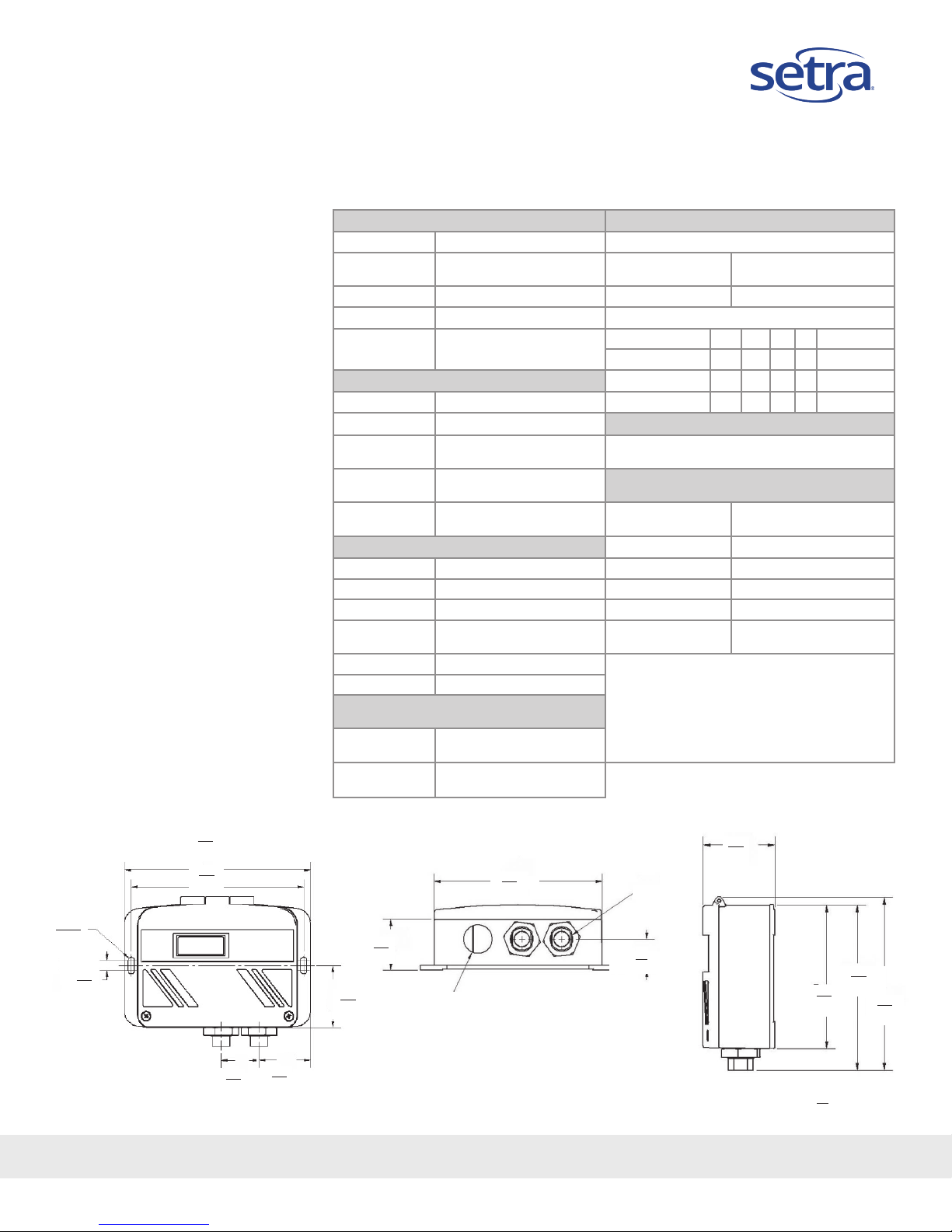

GENERAL SPECIFICATIONS

Electrical Data (Voltage) Performance Data

Circuit 3-Wire Accuracy RSS4 (at constant temp.)

MODEL 231 DIMENSIONS

Excitation

1

Output

Output Impedance 30 Ohms

Circuit Consumption

15 to 30 VDC/18 to 30 VAC (Reverse Excitation

Protected)

0 to 5 VDC, 0 to 10 VDC, 1 to 5 VDC Pressure Ranges D ±2.0% FS

8 mA (typ.) at 5 VDC, 8 mA (typ) at 10 VDC, 40

mA (typ.) at 18-30 VAC

Electrical Data (Current)

Circuit 2-wire (Reverse Excitation Protected) MS3 250 125 50 25 250

2

Output

External Load 0 to 250 Ohms

Min. Supply Voltage

Max. Supply Voltage

4 to 20 mA

15 VDC + 0.02 x (Resistance of receiver plus

line)

30 VDC + 0.004 x (Resistance of receiver

plus line)

Physical Description

Case Die Cast Aluminum, Powder Coated Warm-up Shift <0.12% FS

Pressure Fittings 1/8-18 NPT Internal Response Time 1 to 5 sec. (selectable)

Electrical Connection 1/2 in. Conduit Proof Pressure 2 x Full Scale

Size 4.0 x 6 x 2 in. (102 x 152 x 51 mm)

Weight 1.5 lb

Sensor Vacity Volume 0.2 cc

Environmental Data

Operating3 Temperature

°F (°C)

Storage Temperature

°F (°C)

-4 to +185 (-20 to -85)

-4 to +185 (-20 to +85)

Pressure Ranges A, B, C ±1.0% FS

Pressure Ranges

Range Code A B C D Max. Line Pressure

MS1 50 25 10 5 50

MS2 100 50 20 10 100

Pressure Media

Liquids or Gases Compatible with 17-4 PH Stainless Steel

Note: Hydrogen not recommended for use with 17-4 PH stainless steel

Thermal Eects

Compensated Range °F (°C) +32 to +130 (0 to +54)

Zero/Span Shift %FS/100°F (50°C) 2.0 (1.8)

Burst Pressure 15 x Full Scale (50 PSI), 10 x Full Scale (75 x

1

Calibrated into a 50K ohm load, operable into a 5000 ohm load or greater.

2

Calibrated at factory with a 24 VDC loop supply voltage and a 250 ohm load.

3

Operating temperature limits of the electronics only. Pressure media temperatures may be

considerably higher or lower.

4

RSS of Non-Linearity, Hysteresis, and Non-Repeatability.

5

Units calibrated at nominal 70˚F. Maximum thermal error computed from this datum.

Specications subject to change without notice.

5

150 PSI), 8 x Full Scale (250 PSI)

6.0

152

5.6

141

R 0.1

2

0.3

9

1.7

1.2

Phone: 800-257-3872 • Fax: 978-264-0292 • setra.com © Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

31

42

2.0

51

1.6

40

1/2” Conduit

Opening

5.2

131

High Low

1/8” NPTF

1.0

24

2.0

51

4.0

102

IN

MM

4.6

117

4.8

122

Loading...

Loading...