Setra Systems MS1, MS2, MS3, MS4 Installation Manual

Installation Guide

“Multi-Sense” Model 260 Series

Multi-Range Differential Pressure Transducer

MECHANICAL INSTALLATION

Mounting Position

Mount and calibrate in vertical position for quick and easy installation

on ducts, w alls or c eilings and in c ontrol r ooms .

GENERAL INFORMATION

Every Model 260 has been calibrated and tested before shipment to guarantee

performance for all pressure ranges.

The Model 260 is available in four versions, which have field selectable range

capability via a slide switch. See four versions below:

MULTI-SENSE RANGE SPECIFICATIONS

Ranges

Version Unidirectional Bidirectional

Model MS1 0.1”, 0.25”, 0.5” and 1.0” W.C. FS +/- 0.1”, 0.25”, 0.5” and 1.0” W.C. FS

Model MS2 1.0”, 2.5”, 5.0” and 10” W.C. FS +/- 1.0”, 2.5”, 5.0” and 10” W.C. FS

Model MS3 25, 50, 100 and 250 Pa FS +/- 25, 50, 100 and 250 Pa FS

Model MS4 .25, .50, 1.00 and 2.5 kPa +/- .25, .50, 1.00 and 2.5 kPa

Media Compatibility

Model 260 transducers are designed to be used with air or

nonconducting gases.

Use with liquids or corrosive gases will damage the unit.

Environment

The operating temperature limits of the 260 are as follows:

Operating Temperature 32°F to 122°F (0°C to 50°C)

Compensated Temperature Range 32°F to 122°F (0°C to 50°C)

SIMPLE 5-STEP SETUP INSTRUCTIONS STEP 1

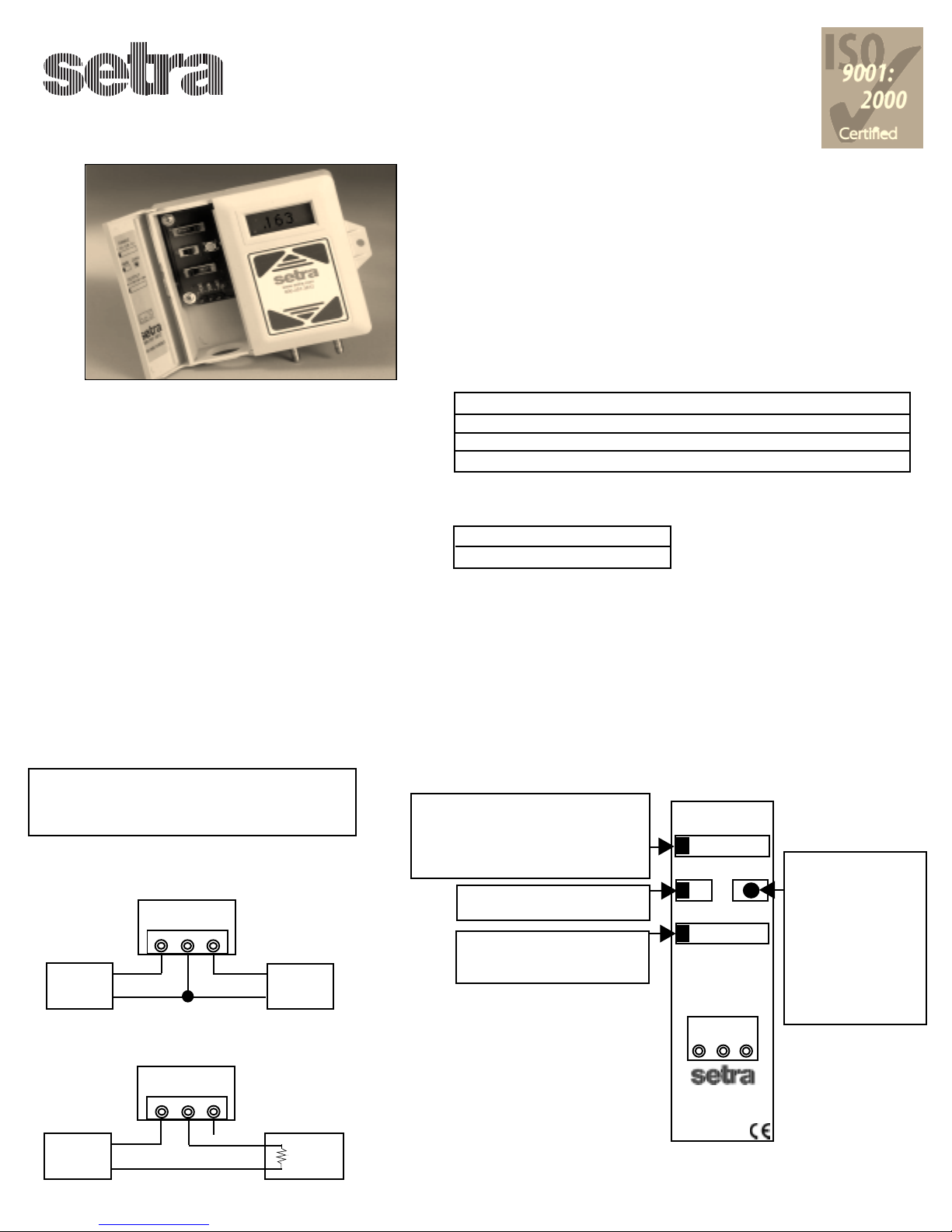

ELECTRICAL CONNECTIONS

Removable Terminal Block for Easy Wiring

STEP 1: Wire and Power Up Unit - Follow diagrams

below for 2-wire and 3-wire configurations.

After completing wiring requirements - Apply

power to the Model 260.

Multi-Sense Voltage

3-Wire, 1-5, 0-5, 0-10 VDC Configuration

24V AC/DC

Nominal

Excitation

Power

Supply

13 - 30V

Model 260

EXC COM OUT

+ +

+

-

+

-

Voltage

Monitor

Multi-Sense Current

2-Wire, 4-20 mA Configuration

The Model 260 is available in four field selectable output configurations. See four

versions below:

2-Wire 4-20 mA (Current)

3-Wire 1-5, 0-5, or 0-10 VDC (Voltage)

SIMPLE 5-STEP SETUP INSTRUCTIONS - STEPS 2 - 5

Power On - LCD Display

Display momentarily toggles thru all existing setup parameters on initial power

up. Pressure is normally indicated on display. Units are either in inches of water

column (WC) MS1 & MS2, or Pascal (Pa) MS3 & MS4.

*STEP 2: Select Pressure Range: Set

appropriate full scale range using

the Slide Switch Multiplier.

LCD will momentarily indicate

selected range.

STEP 3: Select Unidirectional

or Bi-directional mode.

STEP 4: Select Current (mA)

or Voltage 1-5, 0-5, or

0-10 VDC output range.

*Step 2 will follow same

instructions for other inches of

water column and pascal

ranges.

RANGE:

1 0.5 0.25 0.1

UNI/BI ZERO

mA/1-5V/5V /10V

+

+-

EXC COM OUT

STEP 5: Push Button

Zero - While at

zero pressure

Press and hold

the Zero Push

Button for 1

second to

automatically

reset output to

zero.

+

-

Model C260

EXC COM OUT

-

+

X

+

Current

Monitor

-

24V (DC Only)

Nominal

Excitation

Power

Supply

13 - 30V

Typical 250 Ohm

Sense Resistor

for 1-5V Output

Measurement

2601MS1

S/N:

Date Code

PERFORMANCE SPECIFICATIONS

Accuracy RSS* (at constant temperature.) ±1% FS

*RSS of Non-Linearity, Non-Repeatability and Hysteresis.

Thermal Effects

Compensated Range °F(°C) +32 to +122°F (0 to 50)

Zero/Span Shift %FS/°F(°C) 0.02 (0.036)

Maximum Line Pressure 10 PSI

Warm-up Shift ±0.2% FS total

Position Effects

(Unit is factory calibrated at 0g effect in the vertical position)

Zero Offset (%FS/G) 0.2%

RETURNING PRODUCTS FOR REPAIR

Please contact a Setra application engineer (800-257-3872, 978-263-1400) before returning unit for repair to review information relative to your

application. Many times only minor field adjustments may be necessary. When returning a product to Setra, the material should be carefully packaged

and shipped prepaid to:

Setra Systems, Inc.

159 Swanson Road

Boxborough, MA

01719-1304

Attn: Repair Department

To download return form, please visit www.setra.com/tra/repairs/cal_rep

To assure prompt handling, please supply the following information and include it inside the package or returned material:

1. Name and phone number of person to contact.

2. Shipping and billing instructions.

3. Full description of the malfunction.

4. Identify any hazardous material used with product.

Allow approximately 3 weeks after receipt at Setra for the repair and return of the unit.

Non-warranty repairs will not be made without customer approval and a purchase order to cover repair charges.

Calibration Services

Setra maintains a complete calibration facility that is traceable to the National Institute of Standards & Technology (NIST). If you would like to recalibrate or

recertify your Setra pressure transducers or transmitters, please call our Repair Department at 800-257-3872 (978-263-1400) for scheduling.

WARRANTY AND LIMITATION OF LIABILITY

SETRA warrants its Model 260 Transducer products to the original consumer purchaser against defects for a period of one year from the date of sale by SETRA,

as shown in its shipping documents.

Without charge, SETRA will repair or replace products found to have manufacturing defects within the warranty period.

The serial number or date code must not have been removed, defaced or otherwise changed. SETRA must be notified in advance of any returns; any products returned to SETRA must be transportation prepaid.

The foregoing warranty is in lieu of all warranties, express, implied or statutory, including but not limited to, any implied warranty of merchantability for a particular purpose.

SETRA’s liability for breach of warranty is limited to repair or replacement, or if the goods cannot be repaired or replaced, to a refund of the purchase price. SETRA’s liability for all other breaches is

limited to a refund of the purchase price. In no instance shall SETRA be liable for incidental or consequential damages arising from a breach of warranty, or from the use or installation of its products.

No representative or person is authorized to give any warranty other than as set out above or to assume for SETRA any other liability in connection with the sale of its products.

Toll Free 1-800-257-3872 Fax1-978-264-0292

Web Site www.setra.com

SS2125 Rev.A 1/17/05

Loading...

Loading...