Page 1

Model 264

Very Low Differential

Pressure Transducer

With millions of sensors installed world wide, Setra’s 264 is the “standard” for low dierential pressure measurement in HVAC building

automation. The 264 very low dierential pressure transducer uses

a dead-ended stainless steel welded capacitive sensing element

that requires minimal amplication and delivers excellent accuracy

and longterm stability in critical installations. The 264 has a 3 year,

unconditional warranty, giving the end-user peace of mind well beyond the initial commissioning phase and guarantees performance

well after the BAS warranty. The 264 utilizes a robust design that

oers brass barbed ttings, and an optional conduit cover for easy

and consistent installation.

The Industry “Standard” Pressure Transducer

The 264 has been a consistent and trusted HVAC sensor for over two

decades. The reputation of reliability and quality with exceptional

delivery time has helped the 264 remain the trusted choice for any

low dierential pressure applications.

Convenient Installation

The 264 is available in both a wall and conduit versions providing

the installer with exible mounting options. The base mount allows

the sensor to be installed anywhere, allowing for a simple installation.

The Setra Sensor

The core technology of the 264 is the all stainless steel capacitive

sensing element. Setra designs and manufactures all of their sensing elements resulting in full control over the process and quality

of every single sensor. The welded dead-ended capacitive sensors

requires minimal amplication and delivers excellent accuracy and

longterm stability. Setra’s technology has been used in over 8 million installations and has the highest eld acceptance rate in the

industry.

n Industry Standard

n ±0.25%, ±0.4%, ±1% FS Accuracy

n 3 Year, Unconditional Warranty

Model 264 Features:

• Up to 10 PSI Overpressure (Range Dependent)

• Installation Time Minimized w/ Mounting Options

• Reverse Wiring Protection

• Internal Regulation Permits Use with Unregulated DC

Power Supplies

• Fire Retardant Case (UL 94 V-0 Approved)

• CE & RoHS Compliant

Applications:

• Heating, Ventilating and Air Conditioning

• Energy Management Systems

• Variable Air Volume and Fan Control (VAV)

• Environmental Pollution Control

• Lab & Fume Hood Control

Page 2

Model 264

Very Low Differential Pressure Transducer

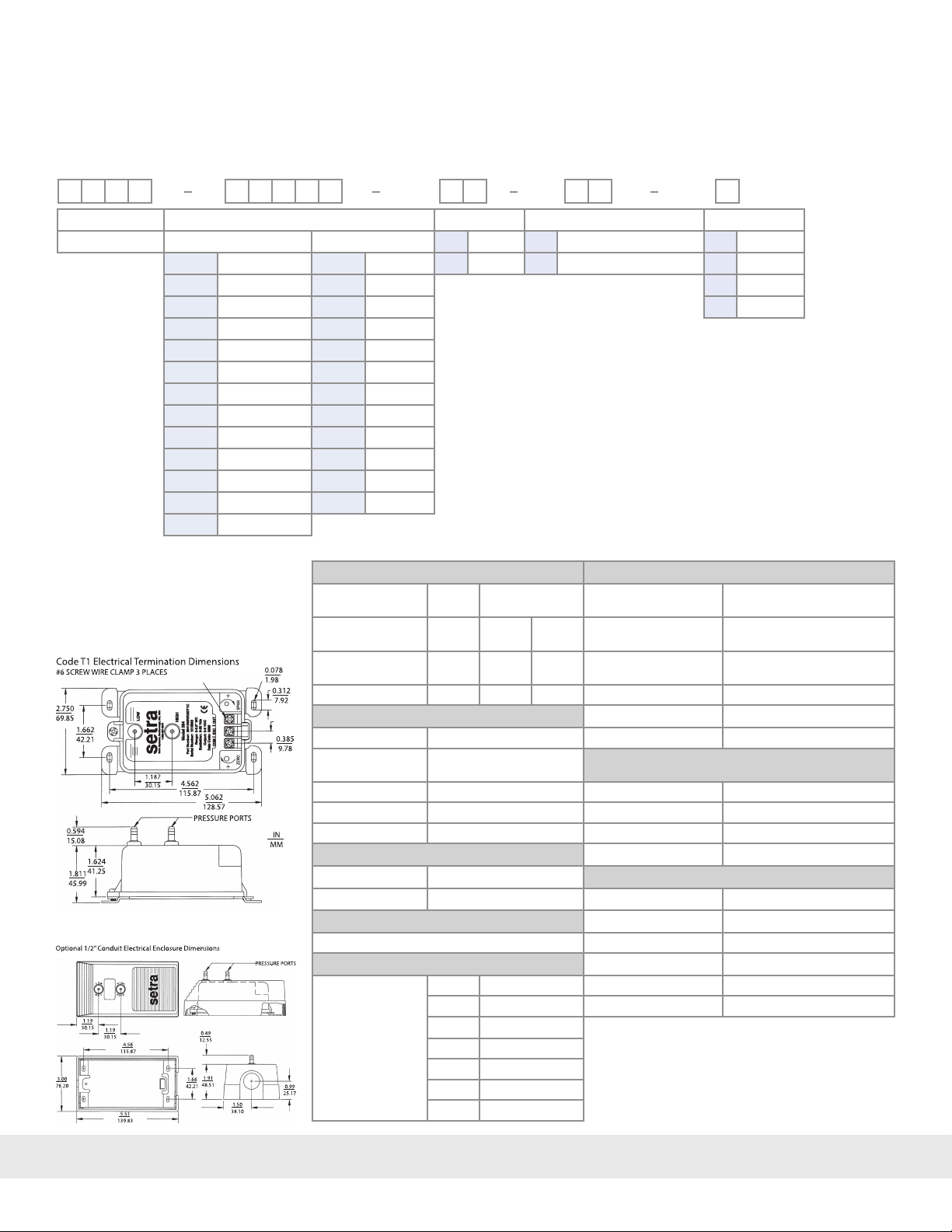

ORDERING INFORMATION

2 6 4 1

Model Range Code Output Electrical Termination Accuracy

2641 = Model 264 Unidirectional Bidirectional 11 4-20 mA T1 Terminal Strip C ±1% FS

0R1WD 0 to 0.1”W.C. R05WB ±0.05”W.C. 2D 0-5 VDC A1 1/2 in. Conduit Enclosure E ±0.4% FS

R25WD 0 to 0.25”W.C. 0R1WB ±0.1”W.C. F ±0.25% FS

0R5WD 0 to 0.5”W.C. R25WB ±0.25”W.C. G ±1% FS

DIMENSIONS

001WD 0 to 1.0”W.C. 0R5WB ±0.5”W.C.

1R5WD 0 to 1.5”W.C. 001WB ±1”W.C.

2R5WD 0 to 2.5”W.C. 1R5WB ±1.5”W.C.

003WD 0 to 3.0”W.C. 2R5WB ±2.5”W.C.

005WD 0 to 5.0”W.C. 005WB ±5.0”W.C.

010WD 0 to 10.0”W.C. 7R5WB ±7.5”W.C.

015WD 0 to 15.0”W.C. 010WB ±10.0”W.C.

025WD 0 to 25.0”W.C. 025WB ±25.0”W.C.

050WD 0 to 50.0”W.C. 050WB ±50.0”W.C.

100WD 0 to 100.0”W.C.

Performance Data Physical Description

1

Accuracy RSS

(at constant temp)

Non-Linearity, BFSL ±0.96% FS ±0.38% FS ±0.22% FS Mounting

Hysteresis 0.10% FS 0.10% FS 0.10% FS Pressure Fittings 3/16” O.D. barbed brass for 1/4” push on tubing

Thermal Eects

Compensated Range ºF (ºC) 0 to +150 (-18 to +65) Weight (approx.) 10 Ounces

Zero/ Span Shift

%FS/100ºF(50ºC)

Maximum Line Pressure 10 PSI Circuit 3-Wire (Com, Out, Exc)

Overpressure Up to 10 PSI (Range Dependent) Excitation/ Output

Long Term Stability 0.5% FS/1 YR Output Impedance 100 ohms

Environmental Data

Operating Temperature3 °F (°C) 0 to +175 (-18 to +79)

Storage Temperature °F (°C) -65 to +250 (-54 to +121) Circuit 2-Wire

Pressure Media

Clean air or similar non-conducting gases. External Load 0 to 800 ohms

Position Eect

Unit is factory calibrated at 0g

eect in the vertical position

Specications subject to change without notice.

Ordering Example: 26412R5WD11T1C= Model 264, 0 to 2.5 in. W.C. Range, 4 to 20 mA Output, Terminal Strip

Electrical Connection, and ±1% Accuracy

GENERAL SPECIFICATIONS

Standard Optional Case

±1.0% FS ±0.4% FS ±0.25% FS Electrical Connection Screw Terminal Strip

Zero and Span Adjustments Accessible on top of case

±0.033 (±0.06)

Range %FS/G Maximum Supply Voltage (VDC) 30 + 0.004 x (resistance of receiver plus line)

0.1 in. WC 2.3 Bidirectional output at zero pressure 12 mA

0.25in. WC 1

0.5 in. WC 0.5

1.0 in. WC 0.3

2.5 in. WC 0.2

10 in. WC 0.15

Electrical Data (Voltage)

4

Bidirectional output at zero pressure 2.5 VDC

Electrical Data (Current)

2

Output

Minimum Supply Voltage (VDC) 9 + 0.02 x (resistance of receiver plus line)

1

RSS of Non-Linearity, Hysteresis, and Non-Repeatability.

2

Units calibrated at nominal 70˚F. Maximum thermal error computed from this datum.

3

Operating temperature limits of the electronics only.

Pressure media temperatures may be considerably higher.

4

Calibrated into a 50K ohm load, operable into a 5000 ohm load or greater.

5

Zero output factory set to within ±50mV (±25 mV for optional accuracies).

6

Span (Full Scale) output factory set to within ±50mV. (±25 mV for optional accuracies).

7

Calibrated at factory with a 24 VDC loop supply voltage and a 250 ohm load.

8

Zero output factory set to within ±0.16mA (±0.08 mA for optional accuracies).

9

Span (Full Scale) output factory set to within ±0.16mA (±0.08 mA for optional accuracies).

1. Optional Accuracies E,

F, G include Calibration

Certicate

Fire-Retardant Glass Filled Polyester (UL 94

V-O Approved)

4 screw holes on removable zinc plated steel

base (designed for 2.75” snap track)

9 to 30 VDC / 0 to 5 VDC

4 to 20 mA

1

5,6

5,6

8,9

8,9

SSP264 REV. K 04/17

Loading...

Loading...