Page 1

Model 239

High Accuracy, Low-Dierential Pressure Transducer

FEATURES

±0.14% FS Accuracy

Fast Warm-Up

Low Thermal Eects

Fast Response Time (<10ms)

Withstands High Overpressure

RoHS Compliant

Meets CE Conformance Standards

DESCRIPTION

The Model 239 Series pressure transducers are designed for

very low pressure applications that require high accuracy.

The variable capacitance sensor is design to be simple and reliable. The stainless steel diaphragm and insulated electrode

form a variable capacitor. As pressure increases or decreases,

the capacitance changes. This change is detected and converted to a linear DC electric signal by Setra’s unique electronic

circuit.

The Model 239 series is available in a voltage or current output.

High positive overpressure protection is achieved by the sensor electrode acting as a stop for the diaphragm. The high level

output signals, excellent long term stability, and fast dynamic

response make these transducers ideal for a wide range of industrial, laboratory and aerospace applications.

APPLICATIONS

HVAC Control

Leak Detection

Environmental Testing

Medical Instrumentation

Energy Management

Clean Rooms

TEST & MEASUREMENT

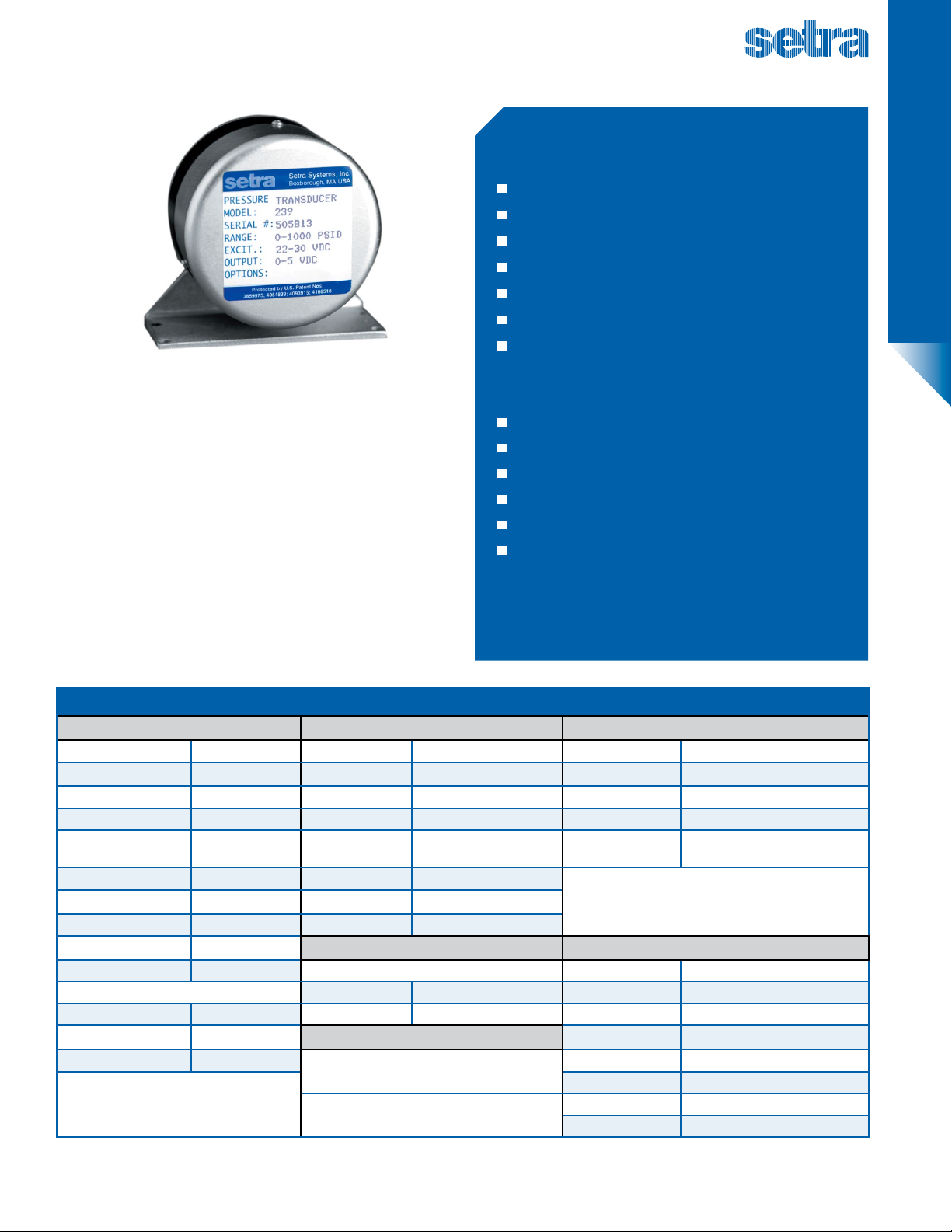

SPECIFICATIONS

Performance Data Physical Description Electrical Data (Voltage)

Accuracy RSS at constant temp* ±0.14% FS Pressure Fittings 1/8”- 27NPT internal Circuit 4-Wire (+Exc, -Exc, +Out, -Out)

Non-Linearity, BFSL ±0.10% FS Electrical Connection 2’ Multiconductor Cable Excitation* 22 to 30 VDC (reverse excitation protected)

Hysteresis 0.10% FS Weight (approx) 8 oz Output Impedance <10 ohms

Non-Repeatability 0.02% FS Vibration 2g from 5 Hz to 500 Hz Output Noise <200 microvolts RMS (in band, 0Hz to 10kHz)

Warm-Up Shift <±0.1% FS residual

Settling Time <100 ms Max Volume Change at FS 0.001 in

Acceleration Response <0.0002 psi/g

Natural Frequency 2000 Hz nominal Shock 50g Operating

Operable Line Pressure Vacuum to Max 250 PSIG

Line Pressure Eect 2%/100 PSI Temperature Circuit 2-Wire

Thermal Eects** Operating ºF (ºC) 0 to +175 (-18 to +80) Output* 4 to 20 mA**

Compensated Range ºF (ºC) +30 to +150 (-1 to +65) Storage ºF (ºC) -65 to +250 (-55 to +120) External Load 0 to 1000 ohms

Zero Shift %FS/100ºF(50ºC) <+1 (<±0.9)

Span Shift %FS/100ºF(50ºC) <+1 (<±0.9) Positive Pressure Media: Gases compatible with stainless

*RSS of Non-Linearity, Non-Repeatability and Hysteresis

**Units calibrated at nominal 70ºF. Maximum thermal error computed from this

datum. x 2 for 0.5 and ±0.25 in. W.C. ranges.

Specications subject to change without notice U.S. Patent No. 4093915

shift after 5 minutes

Internal Volumes Positive port 0.03 in

Reference port 0.1 in

Acceleration 10g Max

Environmental Data Electrical Data (Current)

Pressure Media

steel, hard anodized 6061 aluminum (Buna-N”O”ring)

Reference Pressure Media: Clean dry air or other gases (noncorrosive, non-condensable)

3

3

3

Output** See Ordering Information (for unidirectional ranges)

*Internal regulation minimizes eect of excitation variation, with <±0.005% FS output change.

Will operate on 28VDC aircraft power per MIL-STD-704A & not be damaged by emergency power

conditions.

**Calibrated into 50K ohm load. Operable into 5000 ohms or greater.

***Zero output factory set to within ±20mV

Min. Supply Voltage (VDC) 17 + 0.02 x (resistance of receiver plus line)

Max. Supply Voltage (VDC) 42 + 0.004 x (resistance of receiver plus line)

Eect of Power Supply

Variations <0.003 mA/Volt

Output Noise <10 microamperes RMS (0Hz to 10kHz)

*Calibrated at factory with a 24 VDC loop supply voltage and a 250 ohm load.

** Zero output factory set to within ±0.07 mA. Span (FS) output factory set to within ±0.07 mA.

±2.5 VDC (for bidirectional ranges)

Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com ©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

Page 2

Model 239

High Accuracy, Low-Dierential Pressure Transducer

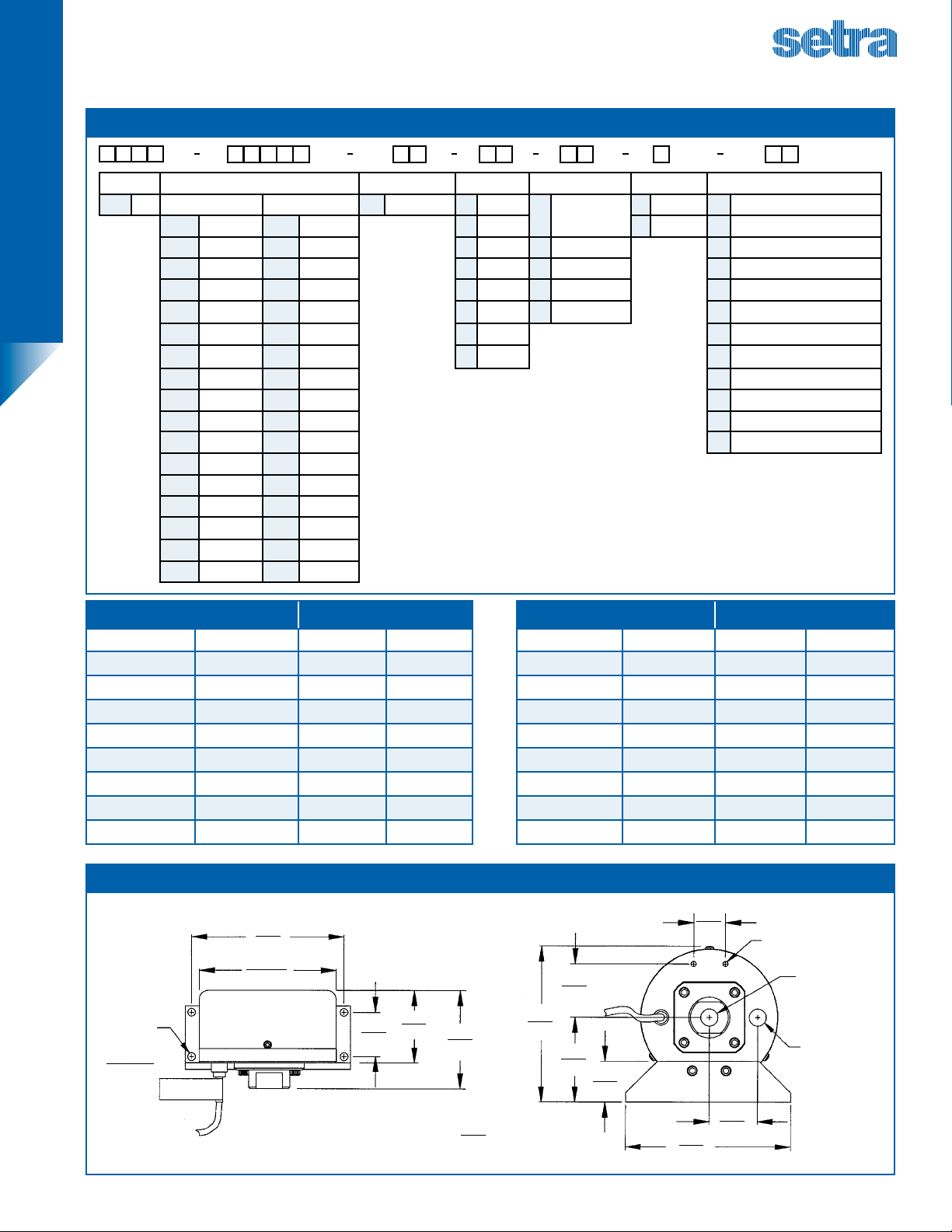

ORDERING INFORMATION

2 3 9 1

Model Pressure Ranges Pressure Fitting Output Termination Accuracy Options

2391 239 Unidirectional Bidirectional 1F 1/8” NPT Female 11 4 to 20 mA

0R5WD 0 to 0.5 in. W.C. R25WB ±0.25 in. W.C. 2S ±2.5 VDC

001WD 0 to 1 in. W.C. 0R5WB ±0.5 in. W.C. 2B 0 to 5 VDC

TEST & MEASUREMENT

2R5WD 0 to 2.5 in. W.C. 001WB ±1 in. W.C. 27 1 to 5 VDC Y3 5’ Tensolite (Red)

005WD 0 to 5 in. W.C. 2R5WB ±2.5 in. W.C. 28 1 to 6 VDC Y4 10’ Tensolite (Red)

015WD 0 to 15 in. W.C. 005WB ±5 in. W.C. 2C 0 to 10 VDC Y6 25’ Tensolite (Red)

030WD 0 to 30 in. W.C. 7R5WB ±7.5 in. W.C. 2Y 0 to 2.5 VDC G Special Excitation Voltage ±15VDC

005PD 0 to 5 PSID 015WB ±15 in. W.C. 2T 0 to 5 VDC

010PD 0 to 10 PSID 2R5PB ±2.5 PSID M Remote Full Scale Sensitivity

250LD 0 to 250 Pa 005PB ±5 PSID R Remote Calibration (Adjustable)

500LD 0 to 500 Pa 125LB ±125 Pa S Remote Calibration Adjustment (Fixed)

10CLD 0 to 1000 Pa 250LB ±250 Pa Y Clean for Oxygen

20CLD 0 to 2000 Pa 500LB ±500 Pa

50CLD 0 to 5000 Pa 10CLB ±1000 Pa

10KLD 0 to 10 kPa 25CLB ±2500 Pa

15KLD 0 to 15 KPa 50CLB ±5000 Pa

35KLD 0 to 35 KPa 75CLB ±7500 Pa

70KLD 0 to 70 KPa 35KLB ±35 KPa

1 F

4

Std Cable Length

XX

(02-25’)

1

2

Y1 2’ Tensolite (Red)

3

Y1-Y6 = Red Conductor Cable

(previously the standard for voltage outputs.)

1

1

2S and 2T are for Bi-Directional Pressure Ranges Only

2

2B is for Uni-Directional Pressure Ranges Only

W ±0.14% FS NN None

9 ±0.073% FS 1 303SS Housing Positive Port

3

3

3

3

3 Compensated Temp. Range (-65 to 250ºF)

4 Viton O-Ring

D Mate with Datum

E Special Excitation Voltage ±24 VDC

L Etched SS Tags

4

Both boxes must lled in alphanumeric order:

• If No options: N + N

• If 1 option: Option Code + N

• If 2 options: Option Code + Option Code

5

Options M, R & S are for voltage units and Y1-Y6

Termination Codes

5

5

Example: Part No. 2391001WD1F1102WLN = Model 239, 0 to 1 in. W.C. pressure range, 1/8” NPT female tting, 4 to 20 mA Output, 2’

Cable Length, ±0.14% FS Accuracy, Etched SS Tags Option

5

PRESSURE RANGE PROOF PRESSURE PRESSURE RANGE PROOF PRESSURE

Unidirectional Bidirectional Positive Negative Unidirectional Bidirectional Positive Negative

0 to 0.5 in. W.C. ±0.25 in. W.C. 5 PSI 2.5 in. W.C. 0 to 250 Pa ±125 Pa 0.5 BAR 1250 Pa

0 to 1 in. W.C. ±0.5 in. W.C. 7 PSI 5 in. W.C. 0 to 500 Pa ±250 Pa 0.7 BAR 3000 Pa

0 to 2.5 in. W.C. ±1 in. W.C. 10 PSI 12.5 in. W.C. 0 to 1000 Pa ±500 Pa 1.25 BAR 6250 Pa

0 to 5 in. W.C. ±2.5 in. W.C. 20 PSI 25 in. W.C. 0 to 2000 Pa ±1000 Pa 3.5 BAR 18500 Pa

0 to 15 in. W.C. ±5 in. W.C. 50 PSI 75 in. W.C. 0 to 5000 Pa ±2500 Pa 3.5 BAR 37000 Pa

0 to 30 in. W.C. 0 to ±15 in. W.C. 50 PSI 150 in. W.C. 0 to 15 kPa ±7500 Pa 3.5 BAR 37000 Pa

0 to 5 PSID 0 to ±2.5 PSID 75 PSI 25 PSI 0 to 35 kPa 5 BAR 1.75 BAR

0 to 10 PSID 0 to ±5 PSID 100 PSI 50 PSI 0 to 70 kPa ±35 Pa 7 BAR 3.5 BAR

Proof Pressure: The maximum recoverable pressure that may be applied without changing performance beyond specications ±0.5% Zero/Span shift.

DIMENSIONS

3.266

82.55

0.625

15.88

4 HOLES DRILLED & TAPPED

6-32 X .220 DEEP

POSITIVE PRESSURE

PORT 1/8-27 NPT

INTERNAL

REFERENCE

PRESSURE PORT

1/8-27 NPT

INTERNAL

0.950

24.13

4 MOUNTING

HOLES FOR

NO. 6 SCREWS

(Dia. 0.156)

(Dia. 3.96)

SSP239/C239 RevK 06/2013

3.0

76.20

Dia. 2.70

Dia. 68.28

0.875

22.23

1.44

36.42

1.94

49.38

IN

MM

3.10

78.40

1.05

26.80

1.70

42.65

0.812

20.62

©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc. Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com

Loading...

Loading...