Page 1

Model 231RS Multi-Sense®

Wet-to-Wet Pressure Transducer

with Remote Sensors

Installation and Operating Instructions

CE

RoHS

978-263-1400; 800-257-3872

www.setra.com; sales@setra.com

Page 2

Contents

1.0 GENERAL INFORMATION........................................................................3

2.0 MECHANICAL INSTALLATION ...............................................................3

2.1 Media compatibility .........................................................................3

2.2 Environment .......................................................................................3

2.3 Pressure Fittings ................................................................................4

2.4 Mounting .............................................................................................4

2.5 Installation Procedures ...................................................................4

3.0 ELECTRICAL INSTALLATION ..................................................................7

3.1 Electrical Termination

Wiring: 2-Wire , 4 to 20 mA and Remote Zero ..............................7

3.2 Electrical Termination

Wiring: 3-Wire, 0 to 5, 0 to 10, 1-5 VDC and Remote Zero ........8

3.3 Remote Sensors Installation...... ....................................................9

4.0 CONFIGURATION ................................................................................... 11

5.0 RETURNING PRODUCTS FOR REPAIR ........................................... 12

6.0 WARRANTY AND LIMITATION OF LIABILITY ..............................12

2

Page 3

Model 231RS Remote Sensors

Installation and Operating Instructions

Multi-Sense® Model 231RS Series

Wet-to-Wet Dierential Pressure Transducers

Your 231RS w/Conduit or 231RS w/Cable is shipped with the following:

Conduit Version

(231GRSX3MX)

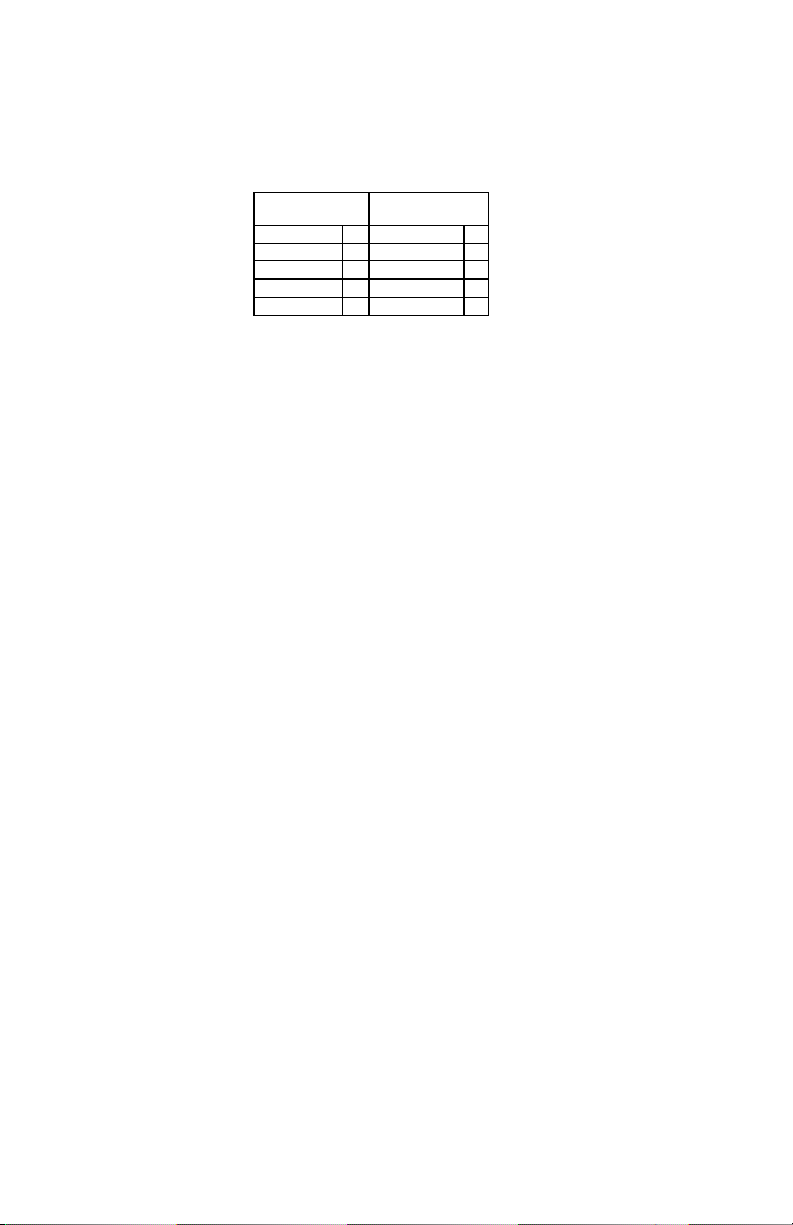

Item Qty Item Qty

Housing 1 Housing 1

Pressure Transducers 2 Pressure Transducers

User Manual 1 Cable Assemblies

1.0 GENERAL INFORMATION

Every Model 231RS has been calibrated and tested before shipment to

guarantee performance of all pressure ranges.

The Model 231RS has eld selectable unidirectional and bidirectional pressure ranges, congurable 0 to 5 VDC, 0 to 10 VDC , and 1 to 5 VDC output, true

two-wire 4 to 20 mA output, and auto-zero capability. Each unit is factory calibrated to the highest pressure range. The range label on the side of the units

indicates the factory calibrated range. (Reminder: Your application’s high-

est line pressure should be ≤ to the highest pressure range of the 231RS

range code you selected when you purchased the 231RS, see Range Codes

in table below, [range codes also listed inside housing cover.).

Model 231RS pressure transducers sense wet-to-wet dierential pressure and

convert this dierence in pressure to a proportional high level analog output.

(231GRSX4MXXX)

User Manual

Cable Version

2

2

1

Your Multi-Sense® Model 231RS pressure transducer has been ordered in one

of the following versions:

Range Code Unidirectional Bidirectional

RS1 5, 10, 25, 50 psid ±5, ±10, ±25, ±50 psid

RS2 7.5, 15, 37.5, 75 psid ±7.5, ±15, ±37.5, ±75 psid

RS3 10, 20, 50, 100 psid ±10, ±20, ±50, ±100 psid

RS4 15, 30, 75, 150 psid ±15, ±30, ±75, ±150 psid

RS5 25, 50, 125, 250 psid ±25, ±50, ±125, ±250 psid

2.0 MECHANICAL INSTALLATION

2.1 Media Compatibility

Model 231RS transducers are designed to be used with any gas or liquid

compatible with 17-4 PH stainless steel. Never totally submerge the unit in

any liquid.

2.2 Environment

The operating temperature limits of the Model 231RS are as follows:

Compensated Temperature Range °F (°C) +32 to +130 (0 to +54)

Operating Temperature Range °F (°C) -4 to +185 (-20 to +85)

Storage Temperature Range °F (°C) -4 to +185 (-20 to +85)

3

Page 4

2.3 Pressure Fittings

Standard pipe ttings and installation procedures should be used.

Model 231RS have 1/4” -18 NPT male ttings. The high pressure port and low

pressure connections are located on the bottom of the unit, labeled “HI(+)”

and “LO(-)” respectively.

Important:

Each remote sensor is labeled “HIGH PRESSURE SENSOR” or “LOW PRESSURE

SENSOR”. Match up the high pressure sensor to the high pressure electrical terminals, and the low pressure sensor to the low pressure electrical

terminals. Otherwise, the performance may not meet the product linearity

specications.

Moisture Precautions

The Model 231RS is provided with a 0.875” DIA. conduit opening for electrical termination, intended for a 1/2” I.D. conduit connection. This opening

must be sealed according to standard industry practices in order to prevent

moisture ingress into the Model 231RS.

2.4 Mounting

The Model 231RS can be easily mounted using the two mounting tabs located

on the side of the unit.

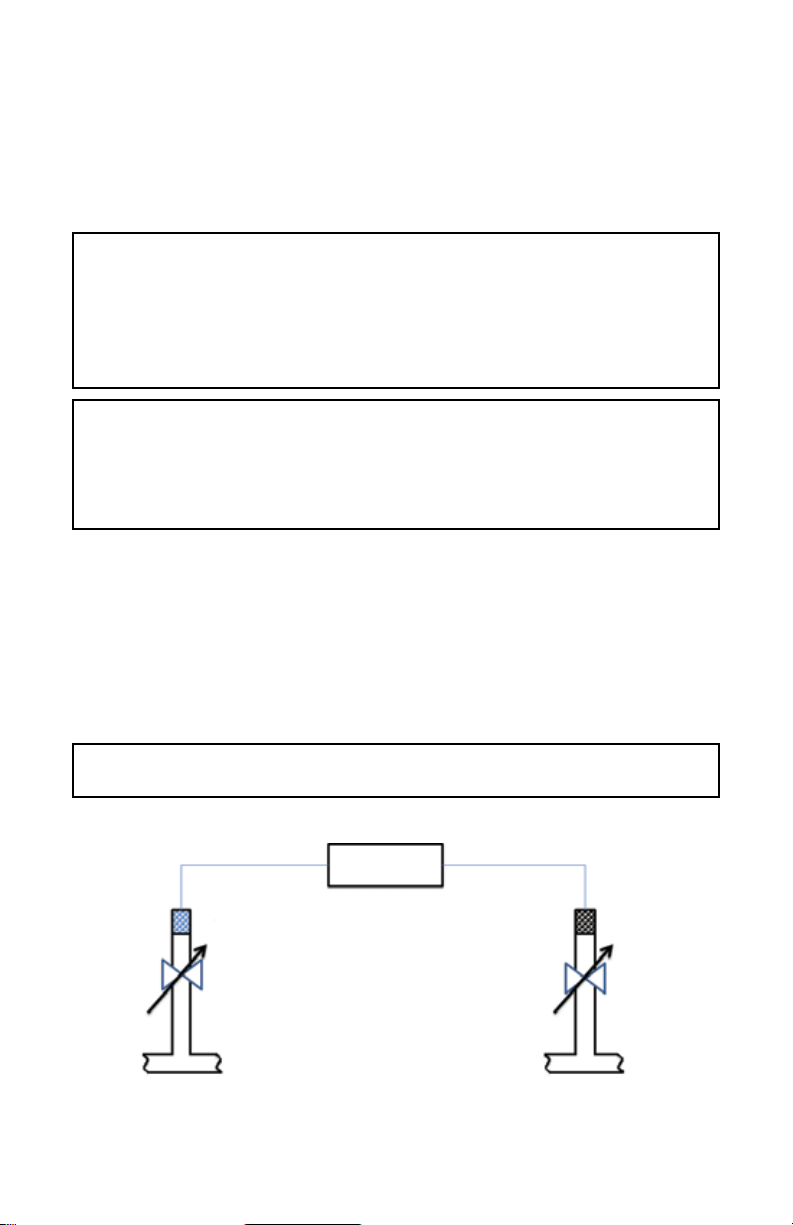

2.5 Installation Procedures

For dierential pressure measurements, it is recommended that the pressure

sensor be installed with a valve in each line.

.

Important: The maximum line pressure cannot exceed the maximum

dierential pressure of the sensor.

Valve A*

High

High Pressure

Remote Sensor

Valve A = High Side Valve

Valve B = Low Side Valve

Pipe

*Valves not included.

Model 231RS

Figure 1

4

Low Pressure

Remote Sensor

Pipe

Valve B*

Low

Page 5

Model 231RS (Conduit version, P/N: 231GRSX3MXXX) Outline Drawing.

6.0

152.4

R 0.1

2.5

0.35

8.8

1.98

50.3

5.56

141.2

2.0

50.8

Front View

Side View

4.0

102

1.56

39.6

Figure 2

2x

0.864

21.95

0.95

24.1

1.220

30.99

5.16

131.1

1.240

31.50

Bottom View

in.

mm

5

Page 6

Model 231RS (Cable version, P/N: 231GRSX4MXXX) Outline Drawing

6.0

152.4

5.56

141.2

R 0.1

2.5

0.35

8.8

2.0

50.8

1.98

50.3

4.0

102

4.87

123.6

Side View

5.08

129

1.56

39.6

1.22311.66

42.2

Front View

0.95

24.1

5.16

131.1

Bottom View

Figure 3

in.

mm

6

Page 7

3.0 ELECTRICAL INSTALLATION

To access the electrical connections, turn the screws on the top of the case

counter clockwise until the hinged cover can be ipped up. The screws are

captured and secured in the cover. Wiring is through the 1/2” conduit openings or PG ttings in the case of remote sensors with cable option. Both current and voltage outputs are reverse wiring protected.

Note: The Zero terminals, connected to digital output, provide a contact closure relay for automatic reset to zero

pressure by the monitoring system. CAUTION: ZERO input is for dry contact, do no apply voltage to ZERO

Terminals

3.1 Electrical Termination

Wiring: 2-Wire, 4 to 20 mA and Remote Zero

Model 231RS when congured as a current output transducer is a true

2-wire, 4-20 mA current output device and delivers rated current into any

external load of 0-250 ohms.

When congured as a 4-20 mA current output device the current ow is in

one direction only. PLEASE OBSERVE POLARITY.

We suggest that an electrical cable shield be connected to the system’s loop

circuit ground to improve electrical noise isolation.

Min. Supply Voltage: 15 + .02 x (Resistance of receiver plus line)

Max. Supply Voltage: 30 + .004 x (Resistance of receiver plus line)

The optional remote zero is a normally open relay wired between COM and

REMOTE ZERO terminals. In order to initiate ZERO function the relay contact

should be closed and sensor must be vented to atmosphere.

DC Power

Supply

Controller

(4-20 mA)

Relay

Current

+

+

Figure 4

7

Page 8

3.2 Electrical Termination

Wiring: 3-Wire, 0 to 5, 0 to 10, 1-5 VDC and Remote Zero

Model 231RS when congured for voltage output is a 3-wire circuit device

with three terminals available for wiring.

Model 231RS can operate from 15-30 VDC (18-30 VAC) nominal output power

supply.

Note: The Zero terminals, connected to digital output, provide a contact closure relay for automatic reset to zero

pressure by the monitoring system. CAUTION: ZERO input is for dry contact, do no apply voltage to ZERO

Terminals

The optional remote zero is a normally open relay wired between COM and

REMOTE ZERO terminals. In order to initiate ZERO function the relay contact

should be closed and sensors must be vented to atmosphere.

DC/AC

Power Supply

Controller

Voltage

Relay

+

+

Figure 5

8

Page 9

3.3 Remote Sensors Installation

Conduit Version (P/N: 231GRSX4MX)

For conduit version remote sensors, use the following instructions:

1 2 3 4 5

1. Install the remote sensor into the system plumbing (use 3/4” hex to tighten).

Important:

Each remote sensor is labeled “HIGH PRESSURE SENSOR” OR “LOW PRESSURE

SENSOR”, respectively. Match up the high pressure sensor to the high “HI (+)”

pressure electrical terminals, and the low “Lo (-)” pressure sensor to the low

pressure electrical terminals. Otherwise, the performance may not meet the

product linearity specications.

2. Install a 1/2” conduit tting into the remote sensor top cover and fasten the

retaining nut.

3. Feed wires from a exible conduit through the remote sensor top cover,

fasten the wires to terminals.

4. Screw on the top cover.

5. Fit conduit into conduit tting, and tighten conduit watertight strain relief.

To connect the wires from the remote sensor to the unit, remove the terminal

blocks from the circuit board and use the following chart:

Installation of the Model 231RS is now complete.

1/2 inch

Conduit

Opening

Terminal Block

(CN8 & CN11)

4

(GND)

3

+OUT

2

1

COM

+EXC

Conduit Adapter

Chart 1. Electrical wiring chart for

High & Low Pressure Sensors (Conduit version)

CAUTION:

Reverse excitation will permanently

damage unit. Please follow wiring

instructions carefully.

9

3.61

91.74

1.68

42.57

Figure 6

Dimensional Drawing

1.40

35.48

1.62

41.22

in.

mm

3/4” HEX

1/4” NPT

Page 10

Cable Version (P/N: 231GRSX4MXXX)

For conduit version remote sensors, use the following instructions:

1. Install the remote sensor into the system plumbing (use 3/4” hex to

tighten).

Important:

Each remote sensor is labeled “HIGH PRESSURE SENSOR” OR “LOW PRESSURE

SENSOR”, respectively. Match up the high pressure sensor to the high pressure

electrical terminals, and the low pressure sensor to the low pressure electrical

terminals. Otherwise, the performance may not meet the product linearity

specications.

2. Attach the cable provided to the 3-Pin Packard connector on the remote

sensor.

3. Feed the cable through the PG tting on the bottom of the unit and tighten

the tting.

4. Remove the terminal blocks from the circuit board and use the following

Terminal Block

(CN8 & CN11)

4

(Shield)

3

+OUT (White) C

2

COM (Black) A

1

+EXC (Red) B

Chart 2. Electrical wiring color chart for

3-Pin Packard

Connector

1.46

37.1

in.

mm

High & Low pressure sensors (Cable version)

0.325

8.3

3.0

76

1.62

41.22

Figure 7

Dimensional Drawing

Important: Prior to putting the unit into service, complete conguration setup

in Section 4. After conguration is complete, press the “Zero” button.

Installation of the Model 231RS is now complete.

10

Page 11

4.0 CONFIGURATION

Range Selection Auto Zero Button Electrical

Congurator

Electrical Connections

High Pressure

Electrical Terminals

Low Pressure

Electrical Terminals

Figure 8

Range Selection Switch: The unit is set to the highest range when calibrated

at the factory. To select the other ranges, slide the switch to the right. Important: Push “zero” button after installing the Model 231RS, and after

changing range.

Auto Zero Button: Press and hold the “ZERO” push-button for 2 seconds to

automatically reset zero or provide contact closure on “Remote Zero, see gure 4, pg. 7, and gure 5, pg. 8 . Sensors must be vented to atmosphere.

Electrical Output: The unit is set at the factory to 4-20 mA. To select another output, move the slide switch to the right. Push the “Zero” button after

changing the electrical output mode. Sensors must be vented to atmosphere.

Electrical Connections: Electrical termination for power supply, 3-wire voltage output and 2-wire true 4-20 mA current output, and remote zero wiring.

BAR/PSI: Jumper selectable engineering units in Bar ranges or PSI.

A. REV/NORM:

A.REV: Analog Reverse: When in reverse mode, the output increases when

the dierential pressure decreases and decreases as pressure increases.

NORM: When in Normal mode output increases as pressure increases and

decreases as pressure decreases.

SLOW/FAST: When Slow mode is selected, 5-second averaging is provided for

surge damping.

BI-DIR/UNI-DIR: Select UNI-Directional or BI-Directional mode.

Unidirectional mode measures from 0 to full scale dierential pressure.

Bidirectional mode measures pressure from minus 1/2 of full scale to plus 1/2

of full scale dierential pressure. Output will read 1/2 full scale when dierential pressure is zero.

SWAP/NORM: Jumper selectable Port Swap feature eliminates costly replumbing when incorrectly installed or replaced. Go from NORMAL to SWAP

and the jumper makes the “HI” Port “LO” and the “LO” port “HI.

High Pressure Electrical Terminals (HI): High pressure sensor termination.

Low Pressure Electrical Terminals (LO): Low pressure sensor termination.

11

Page 12

5.0 RETURNING PRODUCTS FOR REPAIR

Please contact a Setra application engineer (800-257-3872, 978-263-1400) before

returning unit for repair to review information relative to your application. Many times

only minor eld adjustments may be necessary. When returning a product to Setra, the

material should be carefully packaged, and shipped to :

Setra Systems, Inc.

159 Swanson Road

Boxborough, MA 01719-1304

Attn: Repair Department

To assure prompt handling, returned unit(s) must be accompanied by Setra’s Return

Order Form, completely lled out, found on Setra’s web site at :

http://www.setra.com/contactus/contact_us_service_calibration.htm

Notes: Please remove any pressure ttings and plumbing that you have installed and

enclose any required mating electrical connectors and wiring diagrams.

Allow approximately 3 weeks after receipt at Setra for the repair and return of the unit.

Non-warranty repairs will not be made without customer approval and a purchase

order to cover repair charges.

Calibration Services

Setra maintains a complete calibration facility that is traceable to the National Institute

of Standards & Technology (NIST). If you would like to recalibrate or recertify your

Setra pressure transducers or transmitters, please call our Repair Department at 800-

257-3872 (978-263-1400) for scheduling.

6.0 WARRANTY AND LIMITATION OF LIABILITY

SETRA warrants its products to be free from defects in materials and workmanship, subject to the following terms and conditions:

Without charge, SETRA will repair or replace products found to be defective in materials or workmanship within the warranty

period; provided that:

a) the product has not been subjected to abuse, neglect, accident, incorrect wiring not our own, improper installation or

servicing, or use in violation of instructions furnished by SETRA;

b) the product has not been repaired or altered by anyone except SETRA or its authorized service agencies;

c) the serial number or date code has not been removed, defaced, or otherwise changed; and

d) examination discloses, in the judgment of SETRA, the defect in materials or workmanship developed under normal

installation, use and service;

e) SETRA is notied in advance of and the product is returned to SETRA transportation prepaid.

Unless otherwise specied in a manual or warranty card, or agreed to in writing and signed by a SETRA ocer, SETRA pressure and

acceleration products shall be warranted for one year from date of sale.

The foregoing warranty is in lieu of all warranties, express, implied or statutory, including but not limited to, any implied warranty

of merchantability for a particular purpose.

SETRA’s liability for breach of warranty is limited to repair or replacement, or if the goods cannot be repaired or replaced, to a

refund of the purchase price. SETRA’s liabilit y for all other breaches is limited to a refund of the purchase price. In no instance

shall SETRA be liable for incidental or consequential damages arising from a breach of warranty, or from the use or installation of

its products.

No representative or person is authorized to give any warranty other than as set out above or to assume for SETRA any other

liability in connection with the sale of its products.

For all CE technical questions, contact Setra Systems, USA. EU customers may contact our EU representative, Hengstler GmbH,

Uhlandstr 49, Germany (Tel: +49-7424-890; Fax: +40-7424-89500.

159, Swanson Road, Boxborough, MA 01719

978-263-1400; 800-257-3872/www.setra.com; sales@setra.com

12

SS231RS RevB 09/08/11

Loading...

Loading...