Page 1

Multi-Sense® Model 231

Wet-to-Wet, Differential, Multi-Configurable Pressure Transducer

FEATURES

■ Field Selectable Output - True 4 to 20 mA, 0

to 5, 1 to 5, and 0 to 10 VDC

■ Field Selectable Pressure Ranges

■ Field Accessible Push-Button Zero and Re-

mote Zero

DIFFERENTIAL PRESSURE

■ Dual Sensors

NOTE: Setra quality standards are based on ANSI-Z540-1.

The calibration of this product is NIST traceable.

U.S. Patent nos. 6019002; 6014800

DESCRIPTION

Setra’s Model 231 Multi-Sense Wet-to-Wet differential pressure transducer all-inclusive design provides

users with field accessible ranging, choice of output

and field zeroing.

Choose from three configurable Model 231 pressure

transducers: 5 up to 50 psid, 10 up to 100 psid, or 25

up to 250 psid. Each Model 231 has 4 unidirectional

and 4 bidirectional switch selectable pressure ranges and can be reconfigured in the field for 0-5 VDC,

1-5 VDC, -0-10 VDC, or 4 to 20 mA output. The Model

231 jumper selectable port swap feature eliminates

costly replumbing if the pressure transducer is improperly installed or replaced. An optional LCD display is available for on-site indication of line and differential pressure.

SPECIFICATIONS

Performance Data

Accuracy RSS1 (at constant temp.)

Pressure Ranges A, B, C ±1.0% FS

Pressure Range D ±2.0% FS

Pressure Ranges

A B C D Max. Line

MS1 50 25 10 5 50

MS2 100 50 20 10 100

MS3 250 125 50 25 250

Thermal Effects

Compensated Range °F (°C) +32 to +130 (0 to +54)

Zero Shift %FS/100°F (50°C) 2.0 (1.8)

Span Shift %FS/100°F(50°C) 2.0 (1.8)

Warm-up Shift <0.12% FS

Response Time 1 to 5 sec. (selectable )

Proof Pressure 2 x Full Scale

Burst Pressure 15 x Full Scale (50 psi)

10 X Full Scale (75 x 150 psi)

8 x Full Scale (250 psi)

2

Line Pressure

Determines

Selection of Range

Code

Pressure

Environmental Data

Temperature

Operating3 °F (°C) -4 to +185(-20 to +85)

Storage °F (°C) -4 to +185(-20 to +85)

Vibration 10g from 50 Hz to 2000 Hz

Shock 200g

Physical Description

Case Die Cast Aluminum, Powder Coated

Pressure Fittings 1/8-18 NPT Internal

Electrical Connection 1/2 in. Conduit

Size 4.0 x 6 x 2 in.

(102 x 152 x 51mm)

Weight 1.5 lb

Sensor Cavity Volume 0.2 cc

Pressure Media

Liquids or Gases Compatible with 17-4 PH Stainless Steel

Note: Hydrogen not recommended for use with 17-4 PH stainless

steel.

1

RSS of Non-Linearity, Hysteresis, and Non-Repeatability.

2

Units calibrated at nominal 70˚F. Maximum thermal error computed from

this datum.

3

Operating temperature limits of the electronics only. Pressure media

temperatures may be considerably higher or lower.

■ Optional 3- or 5-Valve Manifold

■ Hinged Cover

■ Field Selectable Port Swap

■ Optional LCD Display

■ All Cast Aluminum, NEMA4 Rated Housing

■ CE and RoHS Compliant

APPLICATIONS

■ Energy Management Systems

■ Process Control Systems

■ Flow Measurement of Various Gases or Liq-

uids

■ Liquid Level Measurement of Pressurized

Vessels

■ Pressure Drop Across Filters

Electrical Data (Voltage)

Circuit 3-Wire

Excitation 15 to 30 VDC/18 to 30 VAC

(Reverse Excitation Protected)

Output4 0 to 5 VDC

0 to 10 VDC

1 to 5 VDC

Output Impedance 30 Ohms

Current Consumption 8 mA (typ.) at 5 VDC

8 mA (typ.) at 10 VDC

40 mA (typ.) at 18-30 VAC

Electrical Data (Current)

Circuit 2-Wire

(Reverse Excitation Protected)

Output5 4 to 20 mA

External Load 0 to 250 Ohms

Minimum supply voltage (VDC ) = 15 + 0.02 x (Resistance

of receiver plus line).

Maximum supply voltage (VDC) = 30 + 0.004 x

(Resistance of receiver plus line).

4

Calibrated into a 50K ohm load, operable into a 5000 ohm load

or greater.

5

Calibrated at factory with a 24 VDC loop supply voltage and a

250 ohm load.

Specifications subject to change without notice.

16

Phone: 800-257-3872 • Fax: 978-264-0292 • setra.com ©2011 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

Page 2

Multi-Sense® Model 231

Wet-to-Wet, Differential, Multi-Configurable Pressure Transducer

DIFFERENTIAL PRESSURE

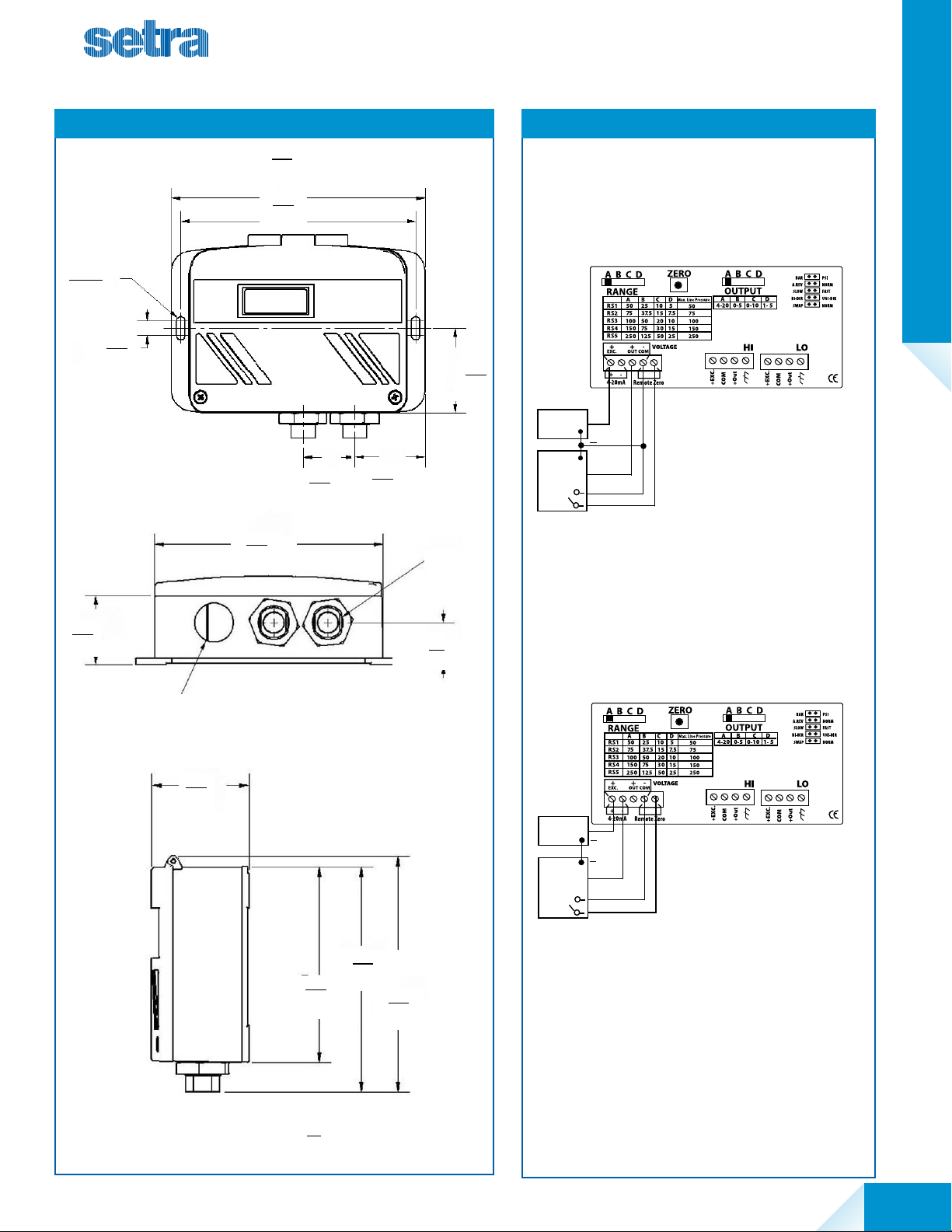

DIMENSIONS

R 0.1

2

0.3

9

1.6

40

6.0

152

5.6

141

5.2

131

High Low

1.2

31

1.7

42

1/8” NPTF

1.0

24

2.0

51

WIRING

DC/AC

Power Supply

Controller

Voltage

Relay

+

+

3-Wire - Voltage Output

0 to 5 VDC

0 to 10 VDC

1 to 5 VDC

Remote Zero

1/2” Conduit

Opening

2.0

51

4.0

102

IN

MM

4.6

117

4.8

122

DC Power

Supply

Controller

Current

(4-20 mA)

Relay

SSP231RS Rev.A 09/14/111

+

+

2-Wire - Current Output

4 to 20 mA

Remote Zero

©2011 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc. Phone: 800-257-3872 • Fax: 978-264-0292 • setra.com

17

Page 3

Multi-Sense® Model 231

Wet-to-Wet, Differential, Multi-Configurable Pressure Transducer

DIMENSIONS (3-Valve Manifold Assembly)

3-Valve Manifold Assembly Description

3-Valve Manifold Assembly Description

DIFFERENTIAL PRESSURE

HIGH PROCESS CONNEC-

HIGH PROCESS CONNEC-

V1

V1

TION 1/4'' NPT

TION 1/4'' NPT

(Order as Pressure Code Fitting "3V".)

(Order as Pressure Code Fitting "3V".)

Manifold Block Brass

Manifold Block Brass

Valves (3) V1 for connection to +port

Valves (3) V1 for connection to +port

V2 for connection to -port

V2 for connection to -port

V3 for equalizing pressure

V3 for equalizing pressure

Valve type 90 Degree On/Off

Valve type 90 Degree On/Off

Process Connections 1/4” -18 NPT Internal Thread

Process Connections 1/4” -18 NPT Internal Thread

MODEL 230

MODEL 230

DIFFERENTIAL PRESSURE

DIFFERENTIAL PRESSURE

TRANSDUCER

TRANSDUCER

V3

V3

LOW PROCESS CONNEC-

LOW PROCESS CONNEC-

TION 1/4'' NPT

TION 1/4'' NPT

SHUNT VALVES

SHUNT VALVES

V2

V2

SHUT

SHUT

OFF

OFF

VALVES

VALVES

7.21

183

8.88

226

2.00

51

.38

10

For differential pressure measurements at high line pressure (250 psig max), it is recommended that the pressure sensor

be installed with a valve in each line, plus a shunt valve across the high and low (reference) pressure ports as shown.

DIMENSIONS (5-Valve Manifold Assembly)

5-Valve Manifold AssemblyDescription

(Order as Pressure Code Fitting “5V”.)

Manifold Block Brass

Valves (5) V1 for connection to ±port

V2 for connection to -port

V3 for equalizing pressure

V4 for connection to external gauge or alternate plumbing conguration

V5 for connection to external gauge or alternate plumbing conguration

Valve Type 90 Degree On/Off

Process Connection 1/4 ”-18 NPT Internal Thread

V6

V7

4.00

102

.31

8

2.14

54

2.00

51

7.21

183

8.88

18

Model 230

Differential Pressure Transducer

V4

V3

V1 V2

SHUNT VALVE

V5

Low Process/Commission

1/4”NPT Connection

4

.16

.38

10

4.00

102

.31

8

SHUT OFF VALVES

High Process Connection

1/4”NPT

Low Process Connection

1/4”NPT

Phone: 800-257-3872 • Fax: 978-264-0292 • setra.com ©2011 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

2.14

54

Page 4

INSTALLATION

Multi-Sense® Model 231

DIFFERENTIAL PRESSURE

Wet-to-Wet, Differential, Multi-Configurable Pressure Transducer

Model 231

Valve A

High Pressure

Remote Sensor

1

Low Pressure

Remote Sensor

High

Valve A = High Side Valve

Valve B = Low Side

Valve

Pipe

1. Valves not included.

Pipe

PRESSURE RANGE CODE SELECTOR (IMportant: rEaD BEForE orDErInG)

Examine the pressure application and determine what is the Highest System Line Pressure.

Determine what is the Differential Pressure being measured.

Find the MAX. Line Pressure in the table on the right that is > to your Highest System Line Pressure.

Verify that your DP falls within the selectable ranges in that row.

Follow that row to the left and select that range code.

Example: Highest System Line Pressure: 125 psig

Range

Code

RS1 50 25 10 5 50

RS2 75 37.5 15 7.5 75

RS3 100 50 20 10 100

RS4 150 75 30 15 150

RS5 250 125 50 25 250

Differential Pressure Measured: 75 psid

“Max Line Pressure” ≥ to System Line Pressure: 150 psid (75 psid DP falls within ranges in this row)

Select Range Code: RS4

A B C D Max. Line

Valve B

Low

1

Line Pressure

Determines

Selection of Range

Code

Pressure

ORDERING INFORMATION

2 3 1 G

Model Range Code Pressure Connection Display

231 = 231G See Table 1 Below Std. 2F 1/8-18 NPT female (Standard)

Sensor (Conduit Version)

Opt. 3V 3-V Manifold assembled w/

Model 231

Opt. 5V 5-V Manifold assembled w/

Model 231

Table 1. Range Specifi cation*

RANGE CODE UNIDIRECTIONAL PRESSURE RANGES BIDIRECTIONAL PRESSURE RANGES

MS1

MS2 10, 20, 50, 100 psid ±10, ±20, ±50, ±100 psid

MS3

*Note: Maximum line pressure is maximum range of pressure ordered.

©2011 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc. Phone: 800-257-3872 • Fax: 978-264-0292 • setra.com

5, 10, 25, 50 psid ±5, ±10, ±25, ±50 psid

25, 50, 125, 250 psid ±25, ±50, ±125, ±250 psid

Std. N No Display

Opt. D LCD Display

Please contact factory for

versions not shown.

19

Loading...

Loading...