Page 1

Installation Guide

Setra Systems Model 209

Pressure Transducer

1.0 GENERAL INFORMATION

Every Model 209 has been tested and calibrated before shipment.

Setra Systems 209 pressure transducers sense gauge pressure and convert this

pressure difference to a proportional high level analog output. Three standard

output and excitation versions are offered:

Excitation Output

9 to 28 VDC 4 to 20 mA - (Must Observe Polarity)

9 to 30 VDC 0.5 to 5.5 VDC - (Reverse excitation protection)

4.9 to 8.1 VDC 0.5 to 4.5 VDC - (No reverse wire protection)

2.0 MECHANICAL INSTALLATION

2.1 Media Compatibility

Model 209 transducers are designed to be used with any gases or liquids

compatible with 17-4 PH Stainless Steel.

2.2 Environment

The operating temperature limits of the 209 are -40° to +185°F (-40 to +85°C).

The compensated temperature range is -4 to +176°F (-20 to +80°C).

2.3 Pressure Fittings

Typically, standard pipe fittings and procedures should be used. However, for

pressure ranges in excess of 500 psig, we suggest the use of a sealant such as

Loctite Hydraulic Sealant. Excessive torquing of metal fittings may cause a

slight zero shift. The use of plastic fittings typically results in no noticeable zero

shift. Torquing does not appreciably affect linearity or sensitivity.

2.4 Tube Stub Welding Instructions

Standard welding practices should be followed. Caution must be taken to

protect the sensor against current paths that could damage the circuit board.

Apply a heat sink between the weld zone and the sensor that is large enough

to protect the sensor from overheating. Failure to use a heat sink may damage

the housing seal or circuit board.

2.5 Venting

Because the reference pressure in a sealed gage transducer will vary due to

changes in temperature and will affect overall accuracy (especially in units of

less than 500 psig range), all 209 Series transducers are available as vented or

sealed to atmosphere.

Vented units are ordered as PSIG range units. Sealed units are ordered as PSIS

range units. The 209 PSIG transducers are vented through the cable.

Hirschmann PSIG transducers are vented through the connector. Packard

PSIG units are vented through a porous filter plug supplied on the unit.

3.0 ELECTRICAL INSTALLATION

The Model 209 is available in four electrical terminations:

2 foot Cable Hirschmann Connector

Packard Connector Conduit Adapter, 1/2 inch

Page 2

3.1 Voltage Output Units

The Model 209 voltage output is a 3-wire circuit. If the 209 is supplied with 2 feet of

cable, the electrical connection is as follows:

Red + Excitation

Shield

Green

+ Out

+Out Green

-Out White

White

- Out

Black - Excitation

+

Monitor or

Control

Device

_

CAUTION: Unit is reverse excitation protected. However, do not apply power

to output lead as this could cause permanent damage.

3.2 Current Output Units

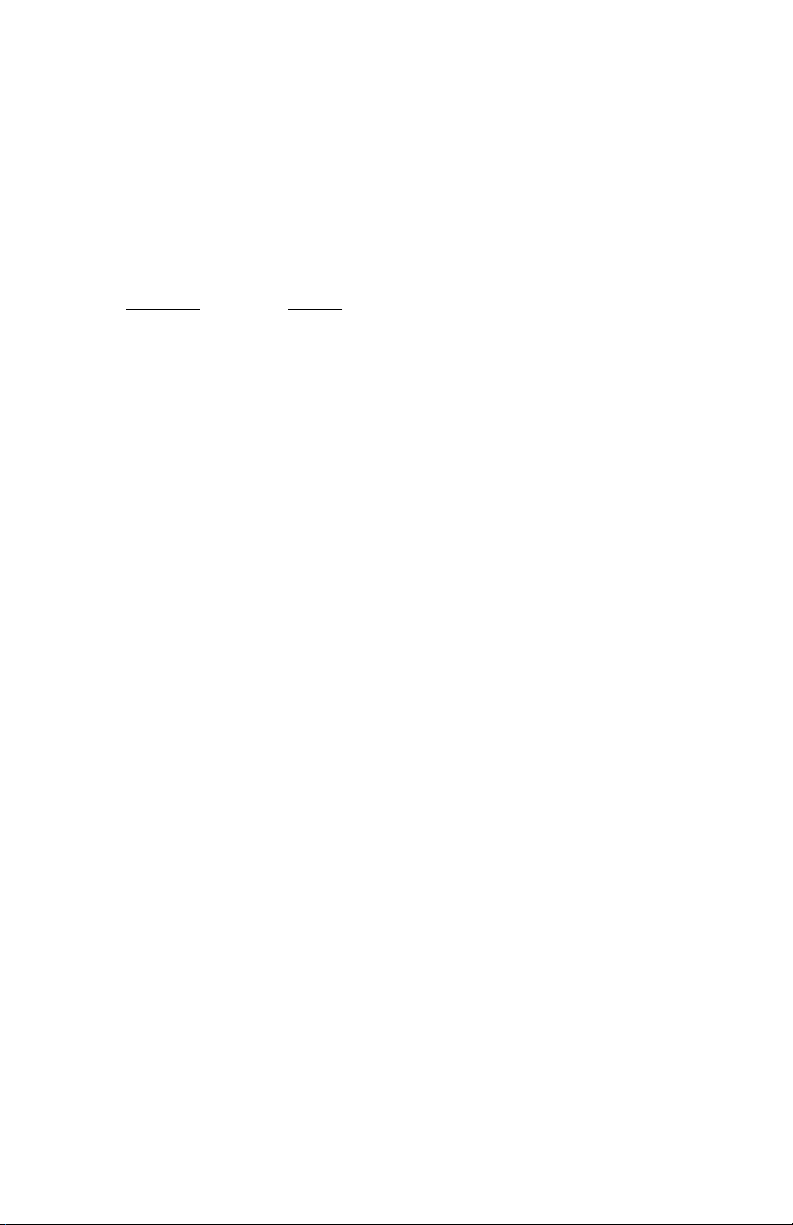

The Model 209 (current output) transducer is a true 2-wire, 4-20 mA current

output device and delivers rated current into any external load of 0-800 ohms.

The 4-20 mA units are designed to have current flow in one direction only PLEASE OBSERVE POLARITY. We suggest that the electrical cable shield be

connected to the system’s loop circuit ground to improve electrical noise

rejection. The electrical connection is as follows:

Model 209

Setra Transducer

(4-20 mA)

+

Red

+

Power

Supply

__

The 209 has a 2-wire cable, where red is positive and black is negative.

CAUTION: Reverse excitation will not cause damage to the unit unless voltage

applied is above 50 VDC. However, the unit will not function if reverse wired.

_

Black

+

Load

(Monitor)

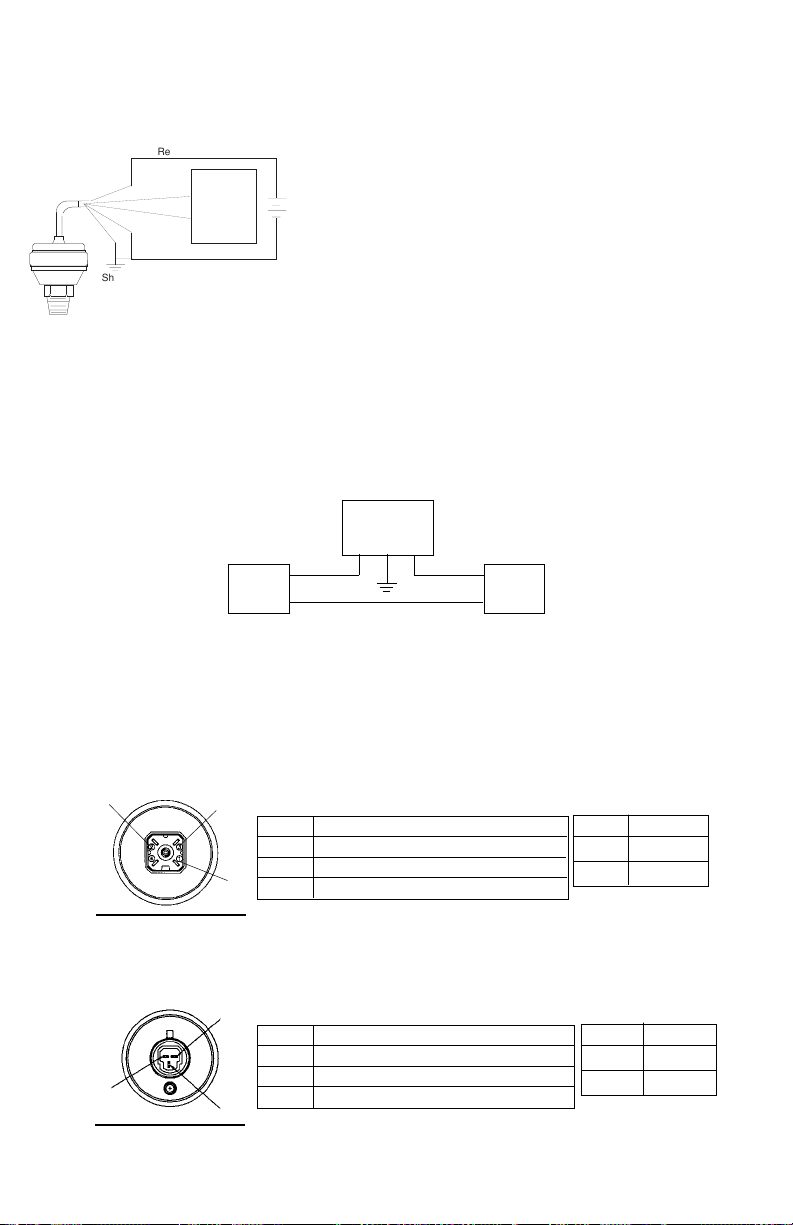

3.3 Hirschmann or Packard Connectors - Voltage and Current Output

If the unit is provided with a Hirschmann or a Packard Connector, pin number

designations are as follows:

2

Voltage Output

3

Pin # Function

1+ Excitation

3+ Output (connect to controls or monitor)

1

2Common (connect to return of power supply)

(connect to appropriate power supply)

Current Output

Pin # Function

1Positive

2Negative

Top View: Hirschmann Connector

Typ e: G4A1M#931807-106

Voltage Output

B

Pin # Function

B+ Excitation (connect to appropriate power supply)

A

C+ Output (connect to controls or monitor)

ACommon (connect to return of power supply)

Current Output

Pin # Function

BPositive

ANegative

C

Top View: 3-Pin Packard Connector

2

Typ e: P2S Series 150

Page 3

4-Pin Packard Connector

B

C

Voltage Output

A

Vent

D

Top View: 4-Pin Packard Connector

Typ e: Metri-Pack 150

Pin # Function

A+ Excitation (connect to appropriate power supply)

C+ Output (connect to controls or monitor)

BCommon (connect to return of power supply)

D(Not Used)

Current Output

Pin # Function

APositive

BNegative

Setra does not supply the mating connectors as a standard. They can be ordered

separately. Consult Factory

3.4 Conduit Adapter Electrical Termination - Voltage and Current

Output Units

If the unit is provided with the conduit adapter version, terminal designations

are as follows:

Conduit Adapter Version

(Voltage and Current Output Units)

For current (4-20 mA)

output, use + and terminals

For voltage output, use

COM, OUT and EXC

terminals

1

2

3

4

5

2

1. Connect the pressure port to the system.

4

2. Install a 1/2’’ conduit fitting into the 209 top cover, and fasten the retaining nut.

3. Feed wires from a flexible conduit through the 209 top cover, fasten the wires to terminals.

4. Screw on the Model 209 top cover.

5. Fit conduit into conduit fitting, and tighten conduit watertight strain relief.

CONDUIT FITTING INSTALLATION INSTRUCTIONS

3.6 EMC Certification

This product complies with EN61326 Electrical Equipment for Measurement, Control and

Laboratory use – EMC Requirements for Minimum Requirements and Industrial Locations.

Special caution should be taken to meet Standard EN61000-4-5: 1995 Surge Immunity if

any of the following conditions apply to the installation: The product is installed outside;

all or any part of the cable is exposed to the outside; the cable is greater than 30 meters in

length. In order to meet the Surge Immunity requirements, the following conditions must

be followed during installation:

1. Sh i elded cable must be used, and the shield must be tied to earth ground (not power supply

ground) on at least one end of the cable shield/drain wire. The shield must be maintained all

the way from sensor to the power supply.

2. If u nsh ielded cable is used, an earth grounded metal conduit fitting can be used to replace the

shielded cable.

3. Fo r a s enso r with a metal body or enclosure, the body/enclosure must be grounded to earth. If

a protective metal housing is used, the metal housing should be grounded to earth

4. If a protective plastic housing is used, the housing must be able to withstand at least

2 KV from the housing to earth ground, without damaging the circuit.

Page 4

4.0 RETURNING PRODUCTS FOR REPAIR

Please contact a Setra application engineer (800-257-3872, 978-263-1400) before

returning unit for repair to review information relative to your application. Many times

only minor field adjustments may be necessary. When returning a product to Setra, the

material should be carefully packaged and shipped prepaid to:

Setra Systems, Inc.

159 Swanson Road

Boxborough, MA 01719-1304

Attn: Repair Department

To assure prompt handling, please supply the following information and include it

inside the package or returned material:

1. Name and phone number of person to contact.

2. Shipping and billing instructions.

3. Full description of the malfunction.

4. Identify any hazardous material used with product.

Notes: Please remove any pressure fittings and plumbing that you have installed and

enclose any required mating electrical connectors and wiring diagrams.

Allow approximately 3 weeks after receipt at Setra for the repair and return of the unit.

Non-warranty repairs will not be made without customer approval and a purchase

order to cover repair charges.

Calibration Services

Setra maintains a complete calibration facility that is traceable to the National Institute

of Standards & Technology (NIST). If you would like to recalibrate or recertify your

Setra pressure transducers or transmitters, please call our Repair Department at 800257-3872 (978-263-1400) for scheduling.

5.0 LIMITED WARRANTY AND LIMITATION OF LIABILITY

SETRA warrants its products to be free from defects in materials and workmanship, subject to the following terms and conditions: Without charge, SETRA will repair or

replace products found to be defective in materials or workmanship within the warranty period; provided that:

a) the product has not been subjected to abuse, neglect, accident, incorrect wiring not our own, improper installation or servicing, or use in violation of

instructions furnished by SETRA;

b) the product has not been repaired or altered by anyone except SETRA or its authorized service agencies;

c) the serial number or date code has not been removed, defaced, or otherwise changed; and

d) examination discloses, in the judgment of SETRA, the defect in materials or workmanship developed under normal installation, use and service;

e) SETRA is notified in advance of and the product is returned to SETRA transportation prepaid.

Unless otherwise specified in a manual or warranty card, or agreed to in writing and signed by a SETRA officer, SETRA pressure and acceleration products shall be

warranted for one year from date of sale.

The foregoing warranty is in lieu of all warranties, express, implied or statutory, including but not limited to, any implied warranty of merchantability for a particular

purpose.

SETRA’s liability for breach of warranty is limited to repair or replacement, or if the goods cannot be repaired or replaced, to a refund of the purchase price. SETRA’s

liability for all other breaches is limited to a refund of the purchase price. In no instance shall SETRA be liable for incidental or consequential damages arising from a

breach of warranty, or from the use or installation of its products.

No representative or person is authorized to give any warranty other than as set out above or to assume for SETRA any other liability in connection with the sale of its

product

s.

ISO

900 1

4

✓

Certified

159 Swanson Road, Boxborough, MA 01719-1304

Tel: 800-257-3872/978-263-1400; Fax: 978-264-0292

Email: sales@setra.com; web: www.setra.com

SS2008 Rev.H 03/20/03

Loading...

Loading...