Model 209

OEM Pressure Transducer

The Model 209 pressure transducer is designed for Industrial

and OEM customers who require high performance, reliability and versatility at an aordable price. It oers exceptional

±0.25% FS accuracy with pressure ranges from 1 PSI up to

10,000 PSI to meet a multitude of demanding applications.

The 209 features all stainless steel wetted materials and

oers many pressure and electrical connections to satisfy

challenging installation requirements. The 209 features a

patented overpressure stop to protect the sensor against

unexpected spikes or in high pulsation applications.

True Low Range Sensor

The Model 209’s capacitive transducer is designed for industrial applications with demanding price and performance

requirements. The Model 209 oers exceptional reliability

in typical industrial grade environments. The true low range

sensor design oers high performance with no additional

amplication required to meet range requirements down to

1 PSI.

Flexibility for Many Applications

The 209 transducer oers many pressure and electrical ttings covering many installation congurations. It minimizes additional engineering time to accommodate the sensor,

allowing for earlier project completion and quicker time to

market.

Robust Design & Construction for Reliable Service

The Model 209 is designed and built to withstand demanding applications. The industrial construction, with optional

positive overpressure stop, enables the sensor to withstand

overpressure conditions up to 16X the rated range.

n

Rugged For Demanding Applications

n

Full Span Ranges Down to 1 PSI

n

Highly Congurable Design

Model 209 Features:

• High Overpressure Option Available on Select Ranges

• Operates Over a Wide Temperature Band

• Compatible w/ a Variety of Gases & Liquids

• Operates on Low Cost Unregulated DC Power

• Suitable For High Shock & Vibration Applications

• No Seals or O-Rings to Cause Leakage

• No Brazed Joints Susceptible to Corrosion Problems

• CE & RoHS Compliant

Applications:

• Industrial OEM Equipment

• Hydraulic Systems

• Compressor Control

• HVAC/R Equipment

• Industrial Engines

Model 209

OEM Pressure Transducer

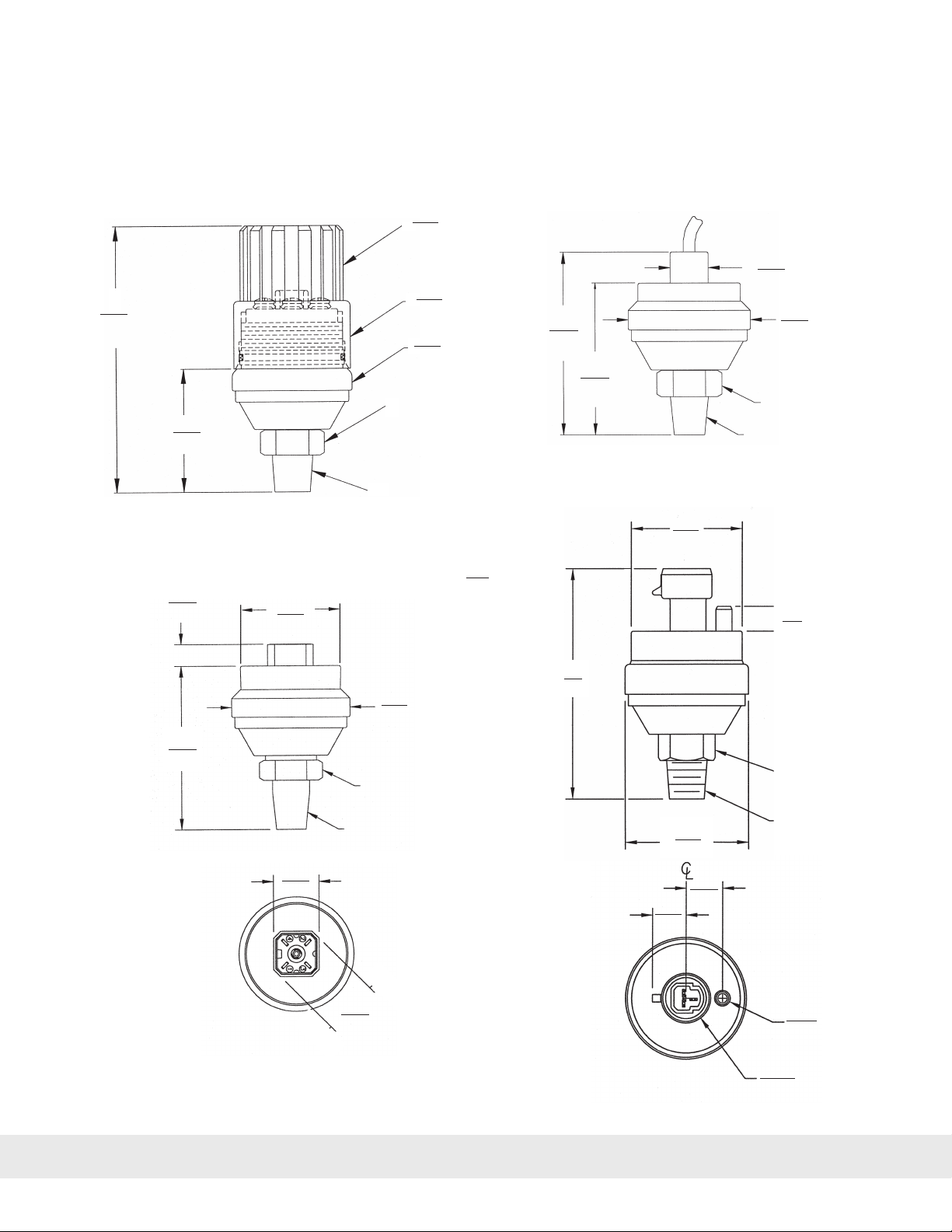

DIMENSIONS

CONDUIT VERSION

3.61

92.0

1.68

43.0

OPTIONAL HIRSCHMANN CONNECTOR

Type: G4A1M #931807-106

0.29

7.4

φ

φ

1.38

35.1

φ

φ

φ

φ

φ

φ

3/4" HEX

1/4" NPT

1.40

35.0

1.58

40.0

1.62

41.0

in.

mm

CABLE ANCHOR

φ

0.50

φ

12.7

φ

2.40

60.1

φ

1.62

41.6

2.00

50.8

3/4" HEX

1/8" NPT

OPTIONAL 3-Pin PACKARD CONNECTOR

Type: P2S Series 150

φ

1.37

φ

35.1

0.33

8.4

2.24

56.9

0.63

16.0

Top View

Mating Hirschmann Connector G4WIF

available. See table below to order.

φ

φ

3/4" HEX

1/8" NPT

0.75

19.1

1.62

41.2

3.0

76

φ

1.62

φ

41.2

0.49

12.5

0.45

11.4

Top View

Mating Packard Connectors available.

See table below to order.

3/4" HEX

1/4" NPT

φ

0.67

φ

17.0

φ

φ

0.21

5.3

Model 209

Red + Excitation

Black - Excitation

+

Monitor or

Control

Device

_

Green

+ Out

White

- Out

Shield

OEM Pressure Transducer

WIRING

CABLE ANCHOR

Voltage Output

The Model 209 voltage output is a 3-wire circuit. If the 209

is supplied with 2 feet of cable, the electrical connection is as

follows:

Current Output

The Model 209 True 2-wire device. If the 209 is supplied

with 2 feet of cable, the electrical connection is as follows:

Model 209

Setra Transducer

(4-20 mA)

_

Red

+

+

Power

Supply

_ _

Black

+

Load

(Monitor)

CONDUIT VERSION

Current

•

+

–

– +

–

+

Voltage

•

•

•

•

– +

3PIN PACKARD CONNECTOR

Voltage Current

Common

Top View: 3-Pin Packard Connector

Type: P2S Series 150

+ Excitation

+ Output

Negative

Top View: 3-Pin Packard Connector

Type: P2S Series 150

Positive

HIRSCHMANN CONNECTOR

Voltage Current

Common

Top View: Hirschmann Connector

Type: G4A1M#931807-106

+ Output

+ Excitation

Negative

Top View: Hirschmann

Connector

Type: G4A1M#931807-106

Positive

4PIN PACKARD CONNECTOR

Voltage Current

Vent

Common

+ Output

+ Excitation

Vent

Negative

Positive

•

D

Top View: 4-Pin Packard Connector

Type: Metri-Pack 150

(Not Used)

Top View: 4-Pin Packard Connector

Type: Metri-Pack 150

Model 209

OEM Pressure Transducer

ORDERING INFORMATION

2 0 9 1

Model Range Code Pressure Type Pressure Fitting Output

2091 = Model 209 Range

Code

001P 0 to 1 500P 0 to 500 C Compound J7 7/16” SAE Male 24 0.5 to 5.5 VDC P1 Packard (3-Pin)

002P 0 to 2 10CP 0 to 1,000 S Sealed

005P 0 to 5 15CP 0 to 1,500 V Vacuum L4 1/4 Female SAE

010P 0 to 10 20CP 0 to 2,000 G451/2” A Male 45 0.5 to 4.5 VDC A1 Terminal Block w/

025P 0 to25 30CP 0 to 3,000 P1 1/8” NPT Female

050P 0 to 50 50CP 0 to 5,000

100P 0 to 100 10KP 0 to 10,000

200P 0 to 200 Z01P 0 to -14.7 PSI

250P 0 to 250

PSI Range

PSI G Gauge 2M 1/4” NPT Male 11 4-20 mA XX Cable length in feet H High Overpressure

Code

1

1M 1/8” NPT Male 27 1 to 5 VDC P3 Packard (4-Pin)

28 1 to 6 VDC H2 Hirschmann, (“Mini”)

Internal 7/16-20 w/

Schrader Pin

Bulkhead (Available

on Ranges > 50 PSI)

Ordering Example: 2091001PG2M1102 = Model 209, 0 to1 PSI Range, Gauge Pressure, 14” NPT Male Fitting, 4 to 20 mA Output, 2 ft. Cable.

1

2

3

4

5

6

ACCESSORIES

577 3-Pin Mating Packard Kit

581 Cable Assembly - Packard, 3-pin (3 ft.)

582 Cable Assembly - Packard, 3-pin (6 ft.)

590 Mating Hirschmann Kit

857 4-Pin Mating Packard Kit

PROOF PRESSURE

Standard Option

Full Scale

Range (PSI)

1,000 2,000 5,000 4,000 10,000

1,500 2,500 6,000 5,000 12,000

2,000 3,000 6,500 N/A N/A

3,000 4,500 7,500 N/A N/A

5,000 7,500 10,000 N/A N/A

10,000 12,500 20,000 N/A N/A

-14.7 (Vacuum) 10 15 N/A N/A

Proof Pressure

(PSI)

Burst Pressure

(PSI)

High Proof

Pressure (PSI)

High Burst

Pressure (PSI)

1 2 250 N/A N/A

2 4 250 N/A N/A

5 10 250 N/A N/A

10 20 500 N/A N/A

25 50 500 N/A N/A

50 100 750 800 5,000

100 200 1,000 1,000 5,000

200 400 2,000 1,500 5,000

250 500 2,000 2,000 8,000

500 1,000 3,000 2,500 10,000

Performance Data Environmental Data

Accuracy RSS1 (at constant temp) ±0.25% FS

Non-Linearity, BFSL

±0.22% FS

Hysteresis 0.10% FS

Non-Repeatability 0.05% FS

Thermal Eects

Compensated Range °F (°C) -4 to +176 (-20 to +80)

Zero Shift %FS/100°F (%FS/50°C) ±2.0 (±1.8)

Span Shift %FS/100°F (%FS/50°C) ±1.5 (±1.3)

Warm-up Shift 0.1% FS Total

Response Time 5 milliseconds

Long Term Stability 0.5% FS/1 YR

Pressure Media

Liquids and gases compatible with 17-4 PH Stainless Steel.

Physical Description

Case Stainless Steel & Valox

Wetted Material 17-4 PH Stainless Steel

Electrical Connection

Pressure Fitting

5

Vent Through cable

Weight (approx.) 2.3 ounces (65 grams)

2 ft. multiconductor

cable

1/4” -18 NPT external,

17-4 PH Stainless Steel

6

Elec. Termination Options

Conduit Cover

Sealed version available on 200 PSI ranges and above.

Order Setra Part #577 for Mating Connector.

Order Setra Part #857 for Mating Connector.

Order Setra Part #590 for Mating Connector.

Only available for pressure ranges below 25 PSI.

Consult factory for other output options.

GENERAL SPECIFICATIONS

3

Operating

Temperature °F (°C) -40 to + 185 (-40 to +85)

Storage Temperature °F (°C) -40 to + 185 (-40 to +85)

3

Shock

Acceleration 10 g Maximum

3

Shock

4

Vibration

Environmental Protection Weather Resistant

Electrical Data (Voltage)

Circuit 3-Wire (COM, OUT, EXC)

Excitation 9 to 30 VDC

6

Output

Output Impedance 10 ohms

2

Electrical Data (Current)

Circuit 2-Wire

8

Output

External Load 0 to 800 ohms

Minimum supply voltage (VDC) 9+ 0.02 x (Resistance of receiver

Maximum supply voltage (VDC) 30+ 0.004 x (Resistance of

1

RSS of Non-Linearity, Hysteresis, and Non-Repeatability.

2

Note: Hydrogen not recommended for use with 17-4 PH Stainless Steel.

3

Mil-Std. 202, Method 213B, Cond. C

4

Mil-Std. 202, Method 204, Cond. C

5

See ordering information for other ttings available (minimum quantities apply).

6

Calibrated into a 50K ohm load, operable into a 5000 ohm load or greater.

7

Zero output factory set to within ±50mV. Span (Full Scale) output factory set to within ±50mV.

8

Calibrated at factory with a 24 VDC loop supply voltage and a 250 ohm load.

9

Zero output factory set to within ±0.16mA. Span (Full Scale) output factory set to within ±0.16mA.

Specications subject to change without notice.

2

3

Capability

(Only available on 25

PSI up to 1500 PSI

Pressure Ranges)

4

200g operating

200g Operating

20g

0.5 to 5.5 VDC

9

4 to 20mA

plus line)

receiver plus line).

5

7

SSP209 Rev K 10/2016

Loading...

Loading...