Page 1

Operating Instructions

Model 204 and 239 Pressure Transducers

Pressure Transducers (0 to 5 VDC output)

Model 204 Gauge, Absolute, and Vacuum Pressure

Model 204D Wet/Dry Differential Pressure

Model 239 Differential Pressure

General Information and Installation ..........................................................................................1

Electrical Information for Standard 24 VDC

Excitation Pressure Transducers (nominal) ..............................................................................3

Electrical Information for Optional ±15 VDC (±24 VDC)

Excitation Pressure Transducers (Option #: 621 and 622) ....................................................4

Adjustments for Pressure Transducers and Transducers

Zero and Sensitivity .......................................................................................................................5

Remote Control Instructions for Pressure Transducers ........................................................6

Installation Instructions for Multiple Hook-Up of 4-Wire

Pressure Transducers (24 VDC Excitation Units Only) ...........................................................7

Returning Products for Repair .....................................................................................................8

Calibration Services .......................................................................................................................8

EMC Certication ............................................................................................................................8

Limited Warranty ............................................................................................................................8

General Information and Installation

Your Setra transducer has been carefully calibrated before shipment to you, and it should be handled

with the same care given any precision instrument. Pressure range and dimensions are reported on

the applicable specications bulletin.

Ambient Conditions

Do not submerge in liquids, use in ambient conditions corrosive to anodized aluminum, subject to

spray or dripping, or use in a high vibration environment. The transducer is very slightly sensitive to

acceleration in the pressure tting axis (see applicable specications bulletin for acceleration response

specications). Installation is recommended in the vertical position, with the pressure port downward.

This position minimizes damage from drippage of pressure system piping.

Page 2

Installation of Pressure Fittings

Your transducer is designed for most accurate operation when subjected to pressures within the

designated pressure range. Refer to the catalog bulletin specications for proof pressure limits.

Subjection to excessive pressure voids the warranty. DO NOT OVERPRESSURE.

Standard sealants such as Teflon pipe tape generally are satisfactory. For the most sensitive pressure

ranges, excessive high torquing of a metal pressure tting may cause slight zero shift which may be

trimmed out using the zero adjustment. Use of a plastic tting often shows no noticeable zero shift.

The torquing effect does not appreciably affect linearity or sensitivity. The wrench flat on the 204 and

239 series should be used when installing the positive pressure tting.

A. Positive Pressure Fitting and Media Compatibility

Model 204, 204D: 1/4”-18 NPT internal tting

For use with gases or liquids compatible with 17-4 PH stainless steel.

(316 stainless steel optional)

Model 239: 1/8”-27 NPT internal tting

For use with gases compatible with stainless steel, hard anodized

6061 aluminum, Buna N “O” ring. (stainless steel in place of aluminum

optional)

B. Reference Pressure Fitting and Media Compatibility (Differential pressure measurements only.)

Model 204D: 1/8”-27 NPT internal tting

For use with clean dry air, non- corrosive or non-conductive gases.

Maximum line pressure 1000 PSIG.

204D, 239, C239

High

Low

Model 239: 1/8”-27 NPT internal tting

For use with non-corrosive, non-condensing clean dry air or other

gases. Maximum line pressure 250 PSIG.

NOTES:

(1) Differential pressure Models can be used to measure gauge pressure by leaving the reference port

open to atmosphere.

(2) Line Pressure refers to pressure applied to both high and low sides of the sensing device

simultaneously. Refer to the product data sheet to determine maximum differential pressure and

overpressure limits.

2

Page 3

Electrical Information for Standard 24 VDC Excitation Pressure Transducers (nominal)

Connections (Model 204, 239; Electrical Termination Y1, Y4, Y4, Y6)

Cable Lead Function Note: Other leads in the

White Positive Excitation

Yellow Positive Output

Brown Negative Output

Black Negative Excitation

Shield Case

Connections (Model 204, 239; Electrical Termination 02, 10, 25)

Cable Lead Function

Red Positive Excitation

Black Negative Excitation

White Negative Output

Green Positive Output

Shield Case

Electrical

The electrical circuit is equivalent to a 4 terminal network, which means negative excitation lead shall

not be connected to negative signal output lead.

The pressure transducer must be operated with the case connected to earth ground to meet EMC

requirement. Best performance will be achieved by connecting the shield and negative excitation lead

if it is feasible and allowed.

cable are not used with the

standard pressure transducer

unless the transducer has

been wired for Remote

Control (see Remote Control

Instructions)

The circuit has internal protection:

• Reversed excitation voltage for at least 5 minutes.

• Short-circuit or signal output leads.

• Short duration power line transients up to 150 volts.

NOTE ON LONG CABLE USE:

In some instances, use of long cables (several hundred feet length) may introduce enough cable

capacitance into the circuit to cause output oscillations. If encountered, this oscillation may be

eliminated by connecting a 100 ohm resistor (1/8th watt or larger) in series to each of the output leads

at the end of the 2 foot transducer cable. These series resistors, of course, add to the output resistance.

Atmospheric Reference (Gauge Pressure Transducers only)

Lower range units are subject to excessive thermal zero shift unless vented to atmosphere. The electrical

cable provides this equalization vent. Do not seal the electrical cable when installing

3

Page 4

Electrical Information for Optional ±15 VDC (Option 622) and ±24VDC (Option 621)

Excitation Pressure Transducers

NOTE:

Any gures in parentheses ( ) pertain to the ±24 VDC excitation units only.

Connections (Model 204, 239; Electrical Termination Y1, Y4, Y4, Y6)

Cable Lead Function Note: Other leads in the cable are

White +15 (+24) Positive Excitation

Black

(Power Supply)

Violet -15 (-24) Negative Excitation

Yellow Positive Output

Brown Negative Output

Shield Case

Electrical

Electrical Option 622 permits operation from a ±15 VDC and electrical Option 621 permits operation

from a ±24 VDC supply (common return grounded), and provides you with the negative signal output

lead also at the common ground potential. Thus many transducers can be operated from one power

supply into single-ended loads. Circuit is reversed voltage protected for at least 5 minutes. Internal

transient suppression network is provided for short duration transients to 150 volts.

Grounding

For general usage and best results (lowest noise) grounding of the shield/case to the black lead is

recommended.

Ground

not used for electrical Option 621

and 622 unless the transducer has

been wired for Remote Control (see

Remote Instructions)

Power Supply Advice

This transducer has been designed to operate from a dual ±15 VDC (±24 VDC ) source. Stated another

way, the supply is a 30V (48V) center tapped supply. The ±15 V (±24 V) is 15 V (24 V) above the

common power return lead, and the - 15 V (- 24 V) is 15 V (24 V) below the common power return lead.

All three power leads must be connected. The transducer will not function if just the +15 V (+24 V) and

-15 V (-24 V) leads are connected to the power source. To avoid circuit damage due to excessive

voltage, the positive supply voltage should be held within the range of +15 V to +20 V (+22 V to +30

V), and the negative supply voltage should be held within the range of -10 V to -20 V (-10 V to -24 V).

NOTE ON LONG CABLE USE:

In some instances, use of long cables (several hundred feet length) may introduce enough cable

capacitance into the circuit to cause output oscillations. If encountered, this oscillation may be

eliminated by connecting a 100 ohm resistor (1/8th watt or larger) in series to each of the output leads

at the end of the 2 foot transducer cable. These series resistors, of course, add to the output resistance.

4

Page 5

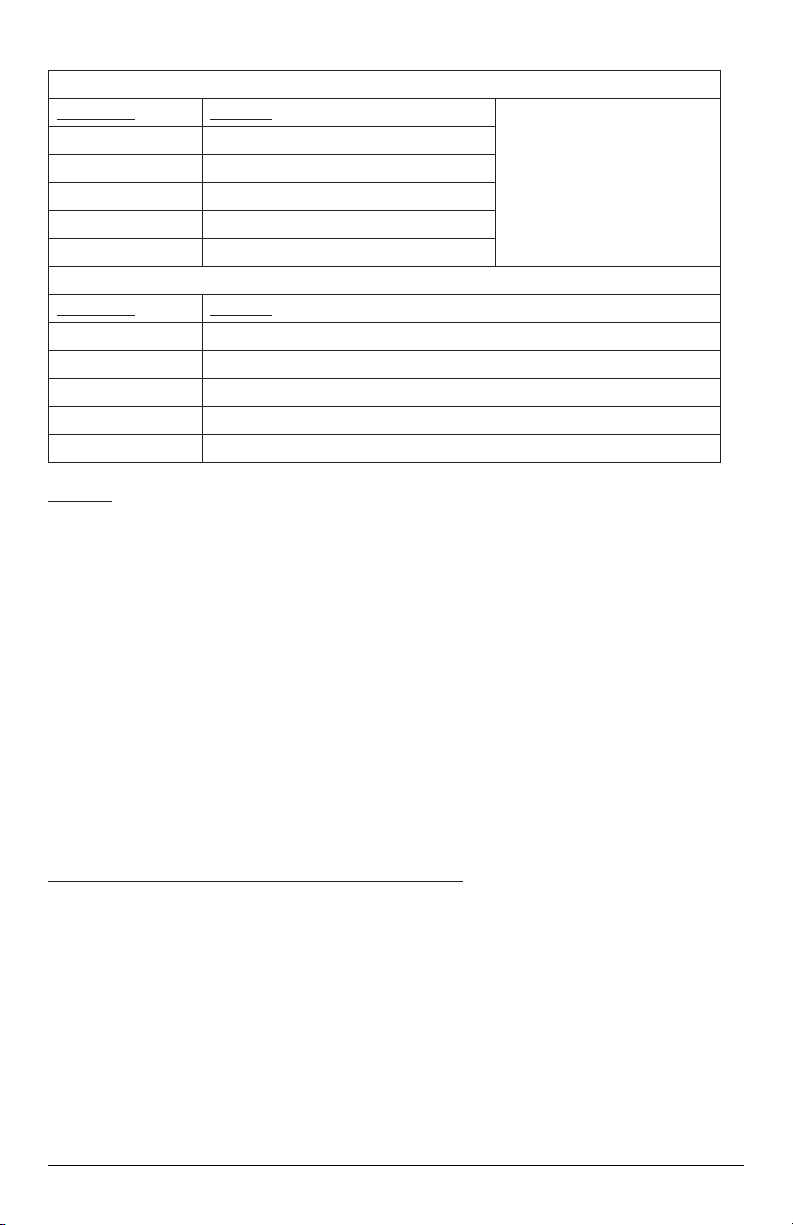

Adjustments for Zero and Sensitivity

IC IC

Temperature

Compensation

DO NOT TOUCH

Zero Adjust

Sensitivity Adjust

Linearity Adjust

DO NOT TOUCH

Adjustments for Voltage Output Pressure Transducers (cover must be removed)

CAUTION:

TURN OFF EXCITATION POWER DURING COVER REMOVAL OR REPLACEMENT

Zero Pressure Output

Can be adjusted to zero by potentiometer as shown in diagram. Unit factory - adjusted to zero output

(±10 mV for Model 204 and ±20 mV for Model 239).

Sensitivity (span)

Can be adjusted by potentiometer as shown on outline diagram. Unit factory - adjusted to order

specications.

Linearity

DO NOT TOUCH - Factory adjusted for best linearity. Touching any adjustments other than zero

output or sensitivity may necessitate recalibration.

NOTE:

Sensitivity (span) adjustment is not recommended unless a primary pressure standard (dead weight

tester, etc.) is available for use as a reference.

5

Page 6

Remote Control Instructions for Pressure Transducers

Yellow

Blue

Violet

*Red

(M239 w/Option 621/622

and 642)

*Brown

(M204 w/option 621/622 and 642)

10K

Cable leads indicated below are connected into the transducer circuitry on this transducer as ordered.

Connection of the remote control leads extends the internal zero and sensitivity adjustments. The

Transducer was factory calibrated with the remote control wiring disconnected.

CAUTION:

The remote control leads directly access active circuit elements. Inadvertent short-circuiting to each

other, to ground, or other mis-wiring may cause immediate circuit damage. Keep remote control wiring

either free of other contact or else keep the leads properly wired as shown below.

Note: All resistance elements are 0.1 watt or greater. All remote circuits have voltages less than 10

volts and currents less than 1 mA.

Remote Zero Adjustment (standard)

The transducer has been preset with the regular internal

zero adjustment potentiometer. If remote

zero control is desired, connect the orange, green and

black leads as shown with external resistors

and potentiometers.

Remote Sensitivity Adjustment (optional)

The transducer has been preset with the regular internal

sensitivity adjustment potentiometer. If

remote sensitivity control is desired (Option 642), connect

the yellow, blue and violet* leads and

adjustable resistance as shown.

*For Models 239 and 204 w/options 621/622 and 642,

replace violet lead as shown.

Fixed:

Adjustable:

6

Remote Calibration Signal (optional)

Two types of calibration signal zero offset are offered:

Fixed calibration signal closing red to black leads.

Adjustable calibration signal, on closing circuit with an

adjustable resistance between red and black

leads. Suggest use of a 100K potentiometer.

Page 7

Installation Instructions for Multiple Hook-Up of 4-Wire Pressure Transducers (24 VDC Units Only)

PS - Power Supply (nominal 24 VDC)

PT - Pressure Transducer (4-Wire Circuit)

DVM/DAS - Digital Voltmeter or Data Acquisition System

Option #1

Uses a single, ground referenced power supply for excitation and separate, isolated differential

input (not ground referenced) readout or data acquisition system for each pressure transducer

output.

Option #2

Uses a separate, isolated power supply for each pressure transducer’s excitation and a single,

ground reference (single ended input) readout or data acquisition system for all of the outputs

Option #3

Uses a single, ground referenced power supply for excitation and either a single, isolated readout

with a bipolar switch that “breaks before makes” both the + output and the - output of each pressure

transducer, or a single data acquisition system with a multiplexer (MUX).

NOTE:

The shield is internally commoned to the case and pressure port of the transducer. When the shield is

connected to ground, the case and pressure port of the transducer will also be commoned to that ground.

7

Loading...

Loading...