Seton W-90E, W-130E, W-180E Installation Manual

Seton Wood Boilers

Seton Wood Boilers

Seton Wood Boilers

There is no substitute for doing it right.

There is no substitute for doing it right.

There is no substitute for doing it right.There is no substitute for doing it right.

SETON WOOD BURNING PRODUCTS

406-295-9902 24 RIVERVIEW DR. TROY MT 59935

Installation and Operation Instructions for

W-90E W-130E W-180E

Because of the very high efficiency of the Seton boiler the flue gas exhaust temperatures

can be low enough to cause condensation in the chimney. This condensation may, over

time, damage a masonry chimney. If you have condensation in your chimney, a insulated

stainless steel chimney liner should be installed inside the flue

SAFETY INSTRUCTIONS

Safety Notice: If this is not properly installed, a house/building fire may result. For your

safety, contact local building or fire officials about permits, restrictions, and installation

requirements for your area.

NEVER BLOCK DRAFT IN OPEN POSITION

NEVER OPERATE WITH THE FEED DOOR OPEN!!

THE SETON BOILER MUST BE INSTALLED IN A ENCLOSED, INSULATED ROOM.

IT SHOULD BE REMOTE FROM THE LIVING SPACE.

PLUMB BOTH RELIEF VALVES TO A SAFE LOCATION

PIPE MUST RUN DOWN HILL ITS FULL LENGTH. PLUMB TO AN OUTSIDE AREA., DO NOT

ALLOW THE PIPE TO EXTEND OUTSIDE FAR ENOUGH TO FREEZE. O NOT REDUCE THE PIPE SIZE.

DO NOT PUT THREADS ON THE OPEN END OF THE DRAIN PIPE

DO NOT JOIN THE TWO DRAINS TOGETHER

WARNING!! ATOMIZED POLYPROPYLENE GLYCOL AT

HIGH TEMPERATURES CAN CAUSE AN EXPLOSION!!

Do not open the feed door until the wood has burned down some.

Avoid trying to see how the fire is burning shortly after you fill it.

All wood burning appliances will smoke if you open the feed door

when it is full of wood.

Do not over-fire the boiler.

Over-firing will occur if the feed door is left open

or the draft is blocked open during operation.

Such actions can result in very dangerous operating conditions.

WOOD BOILER INSTRUCTIONS Page 1 Copyright © 2011 Seton Wood Boilers all rights reserved

BOILER INSTALLATION IMPORTANT NOTES

Seton Wood Burning Products

Certificate of Boiler Efficiency

Eligibility for the American Recovery and Reinvestment Act of 2009

Internal Revenue Service Tax Credit

We are pleased to inform you that as a part of the recent stimulus package,

The Seton Wood Burning Products Boilers qualify for a $1,500.00 federal tax credit. It is not necessary

to submit this certificate with your tax return, however, please keep this certificate for your records as

required by the IRS. Please consult your tax professional to determine if you are eligible for this credit.

The following “Biomass Burning Stoves” are “qualified energy property” as defined in Section 2.03(c)

of the Internal Revenue Service Notice 2009-53:

Boiler Manufacturer: Seton Wood Burning Products

Models: Seton Boiler Design, W-90-E, W-130-E and W-180-E

Under penalties of perjury, I declare that I have examined this certification statement, and to the best of my knowledge

and belief, the facts are true, correct and complete.

Signed______________________ Fred Seton, OWNER

Seton Wood Burning Products

8775 Hwy 2 N. Troy MT 59935

Office 406-295-9902

www.rohor.com

WOOD BOILER INSTRUCTIONS Page 2 Copyright © 2011 Seton Wood Boilers all rights reserved

BOILER INSTALLATION IMPORTANT NOTES

THESE ARE VERY IMPORTANT NOTES,

DO NOT IGNORE, YOU CAN VOID YOUR WARRANTEE

IF AFTER THREE DAYS OF FIRING THE CHIMNEY OR THE BOILER IS DRIPPING

CONDENSATE, THE CHIMNEY IS INADEQUATE.

The Seton Boiler is the worlds most efficient wood boiler, it has very low exhaust

temperatures. If the exhaust temperature drops below 300° before it exits the top

of the chimney it will restrict the draft necessary for a clean burn, this will cause

the pressure vessel to form creosote and will cause the boiler and the chimney to

make water that will corrode the boiler and the chimney.

• The Seton boiler does require a strong draft, which is provided by a proper chimney. The draft

must be measured by either temperature or a manometer. The manometer must read at least .06 on a 8

inch chimney while the draft is open and the boiler up to temperature. In the case no manometer is

available you can measure the exhaust temperature, it should read between 350° to 450° while the

draft is open and the boiler is up to temperature. This measurement must be done in the exhaust

stream not on the surface of the pipe.

• The Seton boilers are designed to work with at least 15 Ft. of eight inch insulated stainless steel

class A chimney, without a chimney cap . But you can use a “China Cap”

• If the chimney is too tall or the draft is too strong you will need to install a draft restrictor not a

barometric damper.

• Do not run the boiler with out connecting both relief valves to drain pipes, drains must run down

their full length and must not be exposed to freezing in such a way that they will fill with ice and

block the flow.

• The second aquastat must be wired into the dump zone, so that any boiler temperature above 200°

will lower the boiler water temperature.

• The boiler must be plumbed so that fill water is always available to it and that if the T&P relieves

water because of a high water temperature the cold fill water will flow up through the boiler to cool

it.

• The Seton Boiler is not designed to be installed inside the living area, it must be in an enclosed

structure.

• The Seton boiler must in installed in a heated space, if installed in a small shed it should be well

insulated. The small shed should not be more than 2,000 Cu. Ft. unless it is heated.

• The draft must close tightly and must open at least 60°, do not limit the draft air with the draft

motor.

• Provide combustion air for any room the boiler is installed in.

• The Seton Boiler does not smoke or smolder in the off cycle.

• The white exhaust during the off cycle in the first few cycles after filling the boiler is steam

caused by the high temperatures off the refractory chamber drying the charge.

• A blue tint to the smoke during the off cycle is a sign of a combustion air leak in the draft or door

area.

WOOD BOILER INSTRUCTIONS Page 3 Copyright © 2011 Seton Wood Boilers all rights reserved

INDEX

NOTE: it is possible for the draft tubes to change position during shipping.

Looking through the draft tubes with the draft open with a light will tell if they are sticking into

the refractory. Reach in through the exhaust outlet and check to see that they are pushed into

the holes in the refractory.

SUBJECT PAGE

PARTS IDENTIFICATION 8-9

BOILER DESCRIPTION AND INSTALLATION OPTIONS 11-20

BOILER LOCATION 14-20

CHIMNEY MAINTENANCE 15-21

CHIMNEY CONNECTIONS 18-21

MAINTENANCE 65

WARNINGS 22

FUELS AND LOADING 23-25

LIMIT CONTROLS 25-30

POWER FAILURES 25

WIRING 26-29

BACKUP POWER 25

BOILER BUILDING 62-63

PLUMBING ARRANGEMENTS 31-54

TROUBLE SHOOTING 66

PLUMBING TO REMOVE AIR 47

UNDERGROUND 56-57

OFF GRID HEATING 64

MAINTENANCE 59-65

WARRANTEE 58

WOOD BOILER INSTRUCTIONS Page 4 Copyright © 2011 Seton Wood Boilers all rights reserved

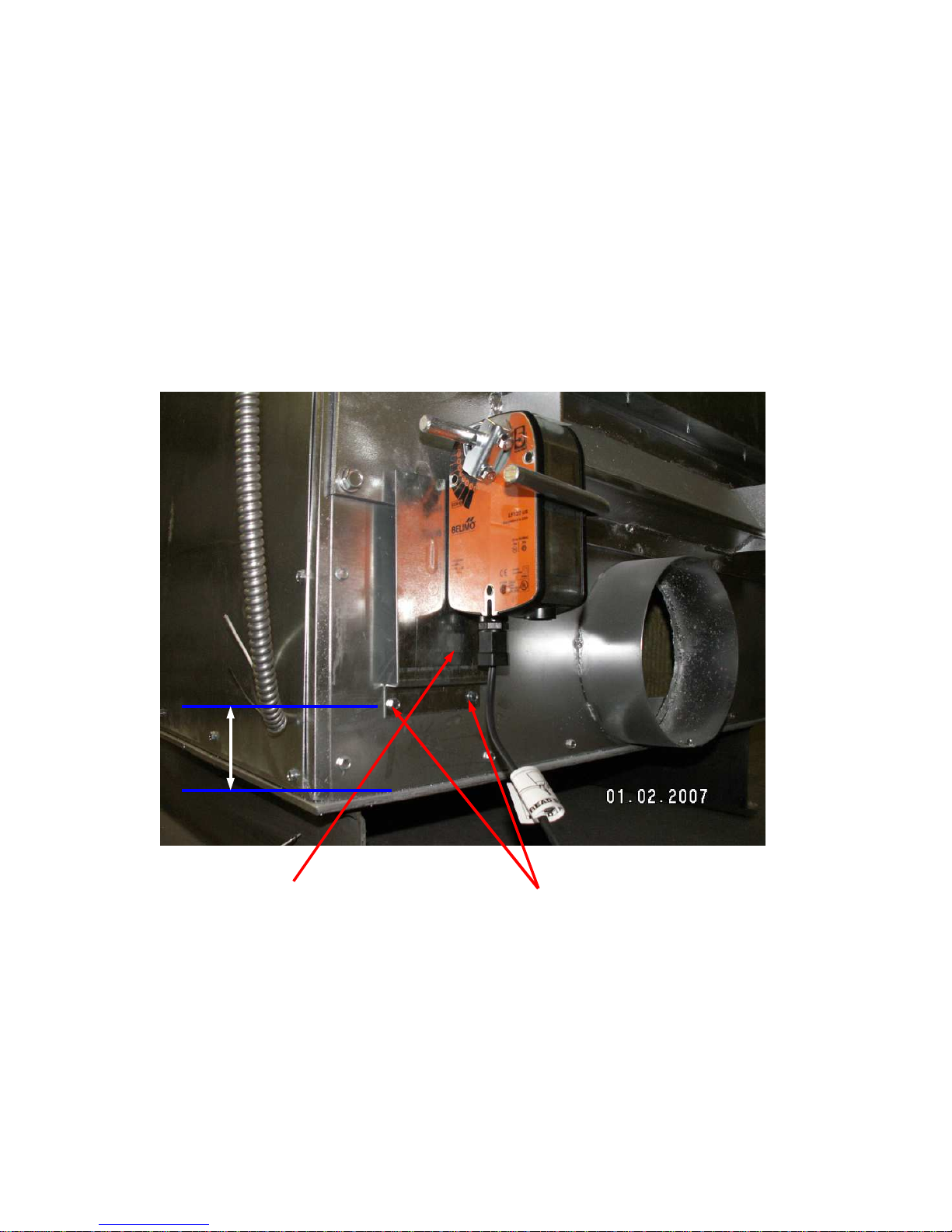

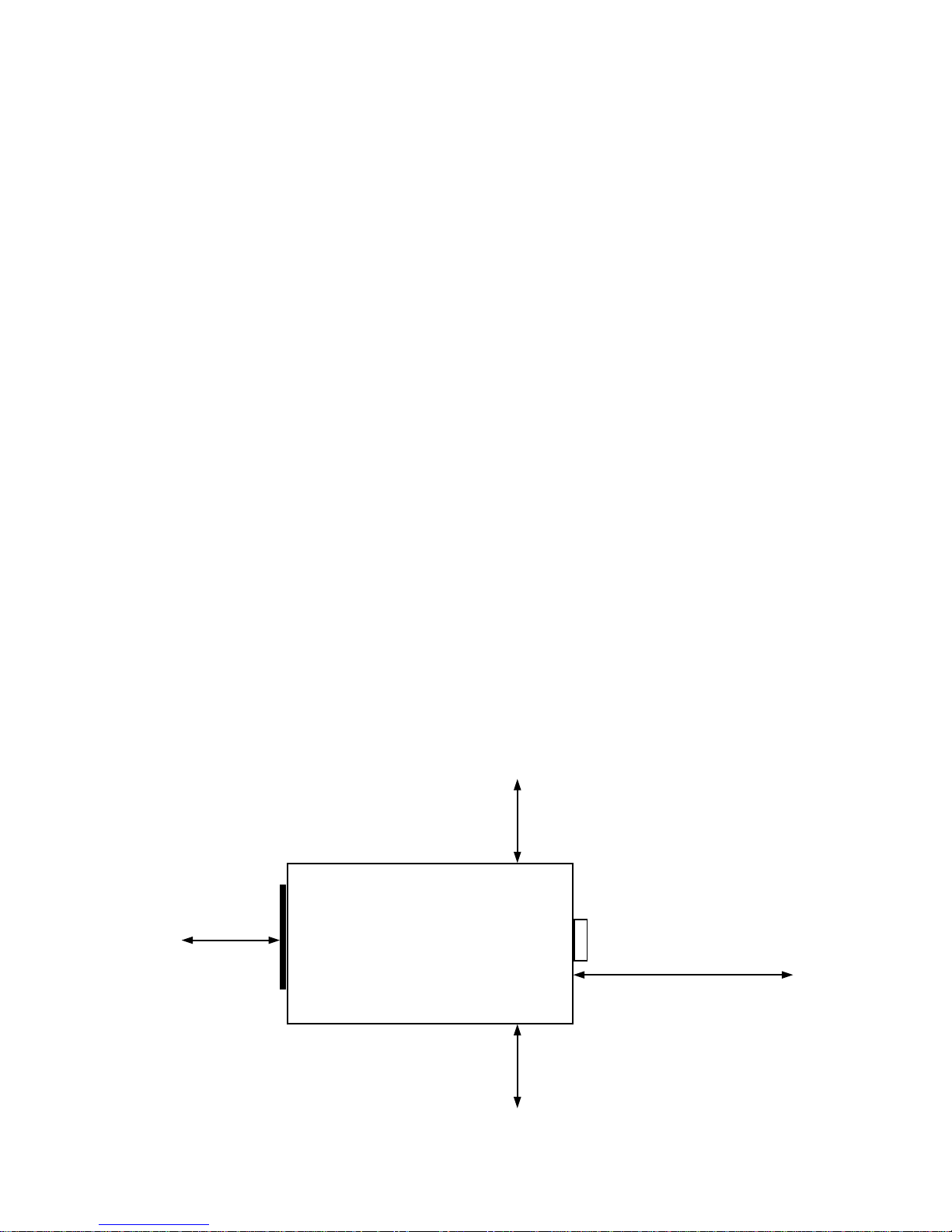

BOILER INSTALLATION DRAFT MOTOR PROTECTOR

THIS PLATE PROTECTS THE DRAFT MOTOR FROM OVER HEATING.

3 INCHES

PROTECTOR PLATE

WOOD BOILER INSTRUCTIONS Page 5 Copyright © 2011 Seton Wood Boilers all rights reserved

INSTALL TWO SCREWS

BOILER INSTALLATION HINGE OILING

THE DOOR HINGES MUST BE OILED ONCE A MONTH WITH A MOTOR OIL.

IT ONLY TAKES A COUPLE OF DROPS. THERE IS A SMALL HOLE DRILLED IN

THE TOP OF EACH HINGE.

WOOD BOILER INSTRUCTIONS Page 6 Copyright © 2011 Seton Wood Boilers all rights reserved

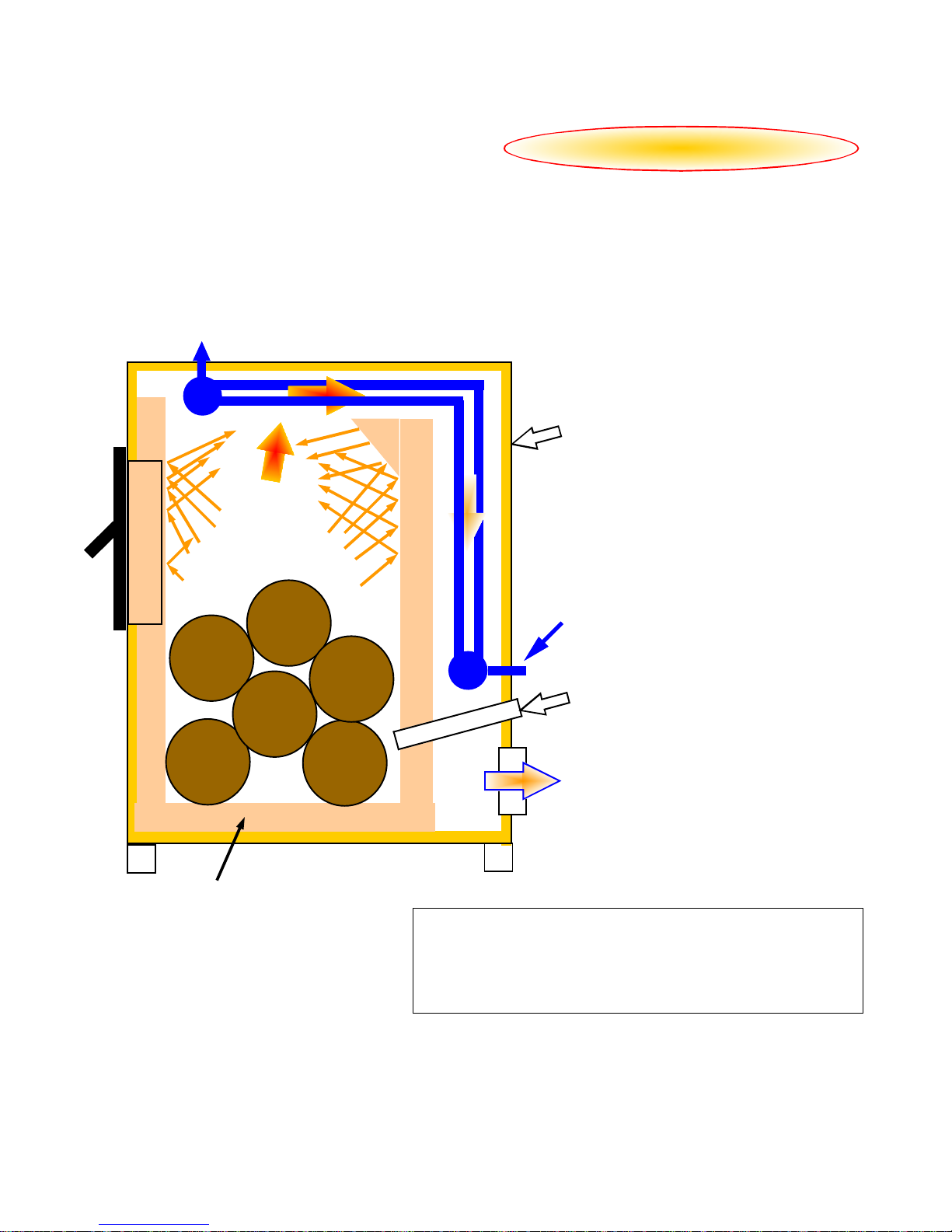

BOILER INSTALLATION

Advanced Ceramic Combustion Chamber

TOP HORIZONTAL WATER TUBE

VESSEL ABSORBS RADIANT ENERGY

HEATING WATER SUPPLY

LONG VERTICAL FLAME PATH SURROUNDED

BY REFRACTORY ASSURES 100% COMBUSTION

DOWN DRAFT EXHAUST INCREASES

EFFICIENCY BY AT LEAST 15%.

AS THE EXHAUST GASES COOL THE

LOWER WATER TEMPERATURES

OF THE RETURN WATER CAUSES A

GREATER HEAT TRANSFER

HEATING WATER RETURNS HERE.

VERTICAL VESSEL CAUSES

STRONG THERMAL SIPHON

CROSS DRAFT DESIGN

BOTH PRIMARY AND SECONDARY

AIR ENTERS HERE AND IS

PREHEATED BY THE EXHAUST

AFTER ALL THE HEAT IS REMOVED

BY THE WATER

CROSS DRAFT KEEPS THE ASH IN

THE FIRE BOX NOT IN THE AIR.

2800° + REFRACTORY

3000 PSI. CRUSHING STRENGTH AT 2500° F.

WOOD BOILER INSTRUCTIONS Page 7 Copyright © 2011 Seton Wood Boilers all rights reserved

EXHAUST EXITS HERE

NORMALLY BELOW 300 DEGREES

INDICATING A VERY

HIGH EFFICIENCY

REFRACTORY

REFRACT MEANS TO BEND, REFRACTORY ABSORBS

RADIANT HEAT FROM THE FLAME AND BENDS IT BACK

INTO THE BURNING PROCESS RAISING THE COMBUSTION

TEMPERATURE AND COMPLETING THE BURN

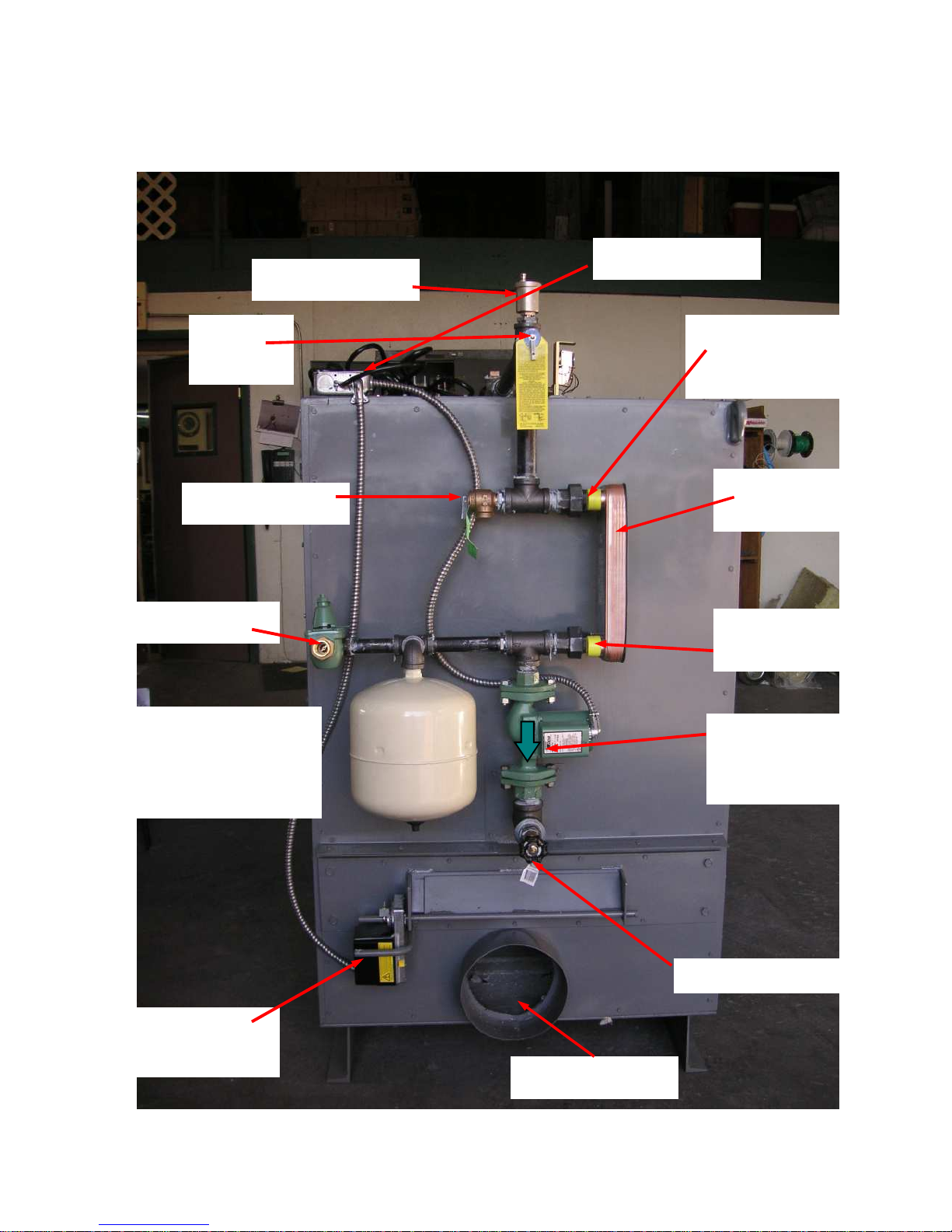

BOILER INSTALLATION PARTS IDENTIFICATION

POWER CORD

FLOAT VENT

T @ P

VALVE

30# POP OFF

12# FILL VALVE

SOME SYSTEMS

DO NOT NEED

THE HEAT

EXCHANGER

EXPANSION

TANK

WATER TO

HEATING

S. S. HEAT

EXCHANGER

WATER FROM

HEATING

CIRCULATING

PUMP

TACO 008

DRAFT

MOTOR

WOOD BOILER INSTRUCTIONS Page 8 Copyright © 2011 Seton Wood Boilers all rights reserved

DRAIN VALVE

EXHAUST

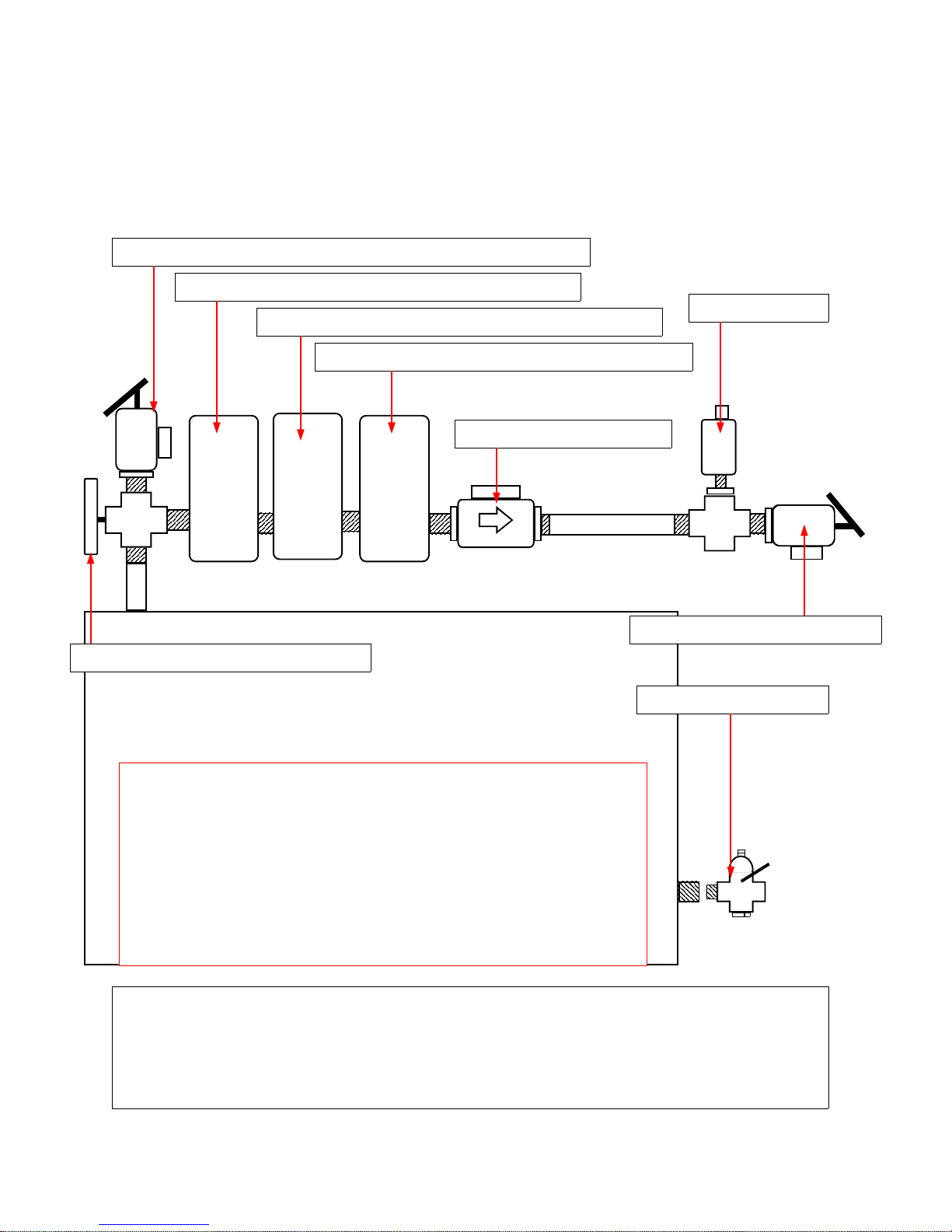

BOILER INSTALLATION BOILER PLUMBING

The boiler must be plumbed so that if the draft motor sticks open for any reason the cold feed water

will flow up through the boiler pressure vessel and protect it from overheating.

The temperature and pressure relief valve must be mounted on top of the boiler before the check valve.

TEMPERATURE AND PRESSURE RELIEF VALVE OPENS AT 210°

AQUASTAT FOR PUMP CONTROL 110° OPEN ON RISE

AQUASTAT FOR DRAFT CONTROL 180° OPEN ON RISE

AQUASTAT FOR DUMP ZONE 200° CLOSE ON RISE

1” SWING CHECK VALVE

AUTO AIR VENT

TEMPERATURE AND PRESSURE GAUGE

WOOD BOILER

PLUMB BOTH RELIEF VALVES TO A SAFE LOCATION

PIPE MUST RUN DOWN HILL ITS FULL LENGTH

PLUMB TO AN OUTSIDE AREA., DO NOT

ALLOW THE PIPE TO EXTEND OUTSIDE FAR ENOUGH TO FREEZE.

DO NOT REDUCE THE PIPE SIZE.

DO NOT PUT THREADS ON THE OPEN END OF THE DRAIN PIPE

DO NOT JOIN THE TWO DRAINS TOGETHER

WARNING!! ATOMIZED POLYPROPYLENE GLYCOL AT

HIGH TEMPERATURES CAN CAUSE AN EXPLOSION!!

When the boiler is plumbed this way it is protected from over temperature.

When the T&P valve releases because of over temp the cold water will come up through the

Without the T&P in front of the check valve the feed water will reverse feed through the

boiler supply pipe and allow the boiler to be damaged.

30# PRESSURE RELIEVE VALVE

12# BOILER FILL VALVE

boiler and protect the boiler.

WOOD BOILER INSTRUCTIONS Page 9 Copyright © 2011 Seton Wood Boilers all rights reserved

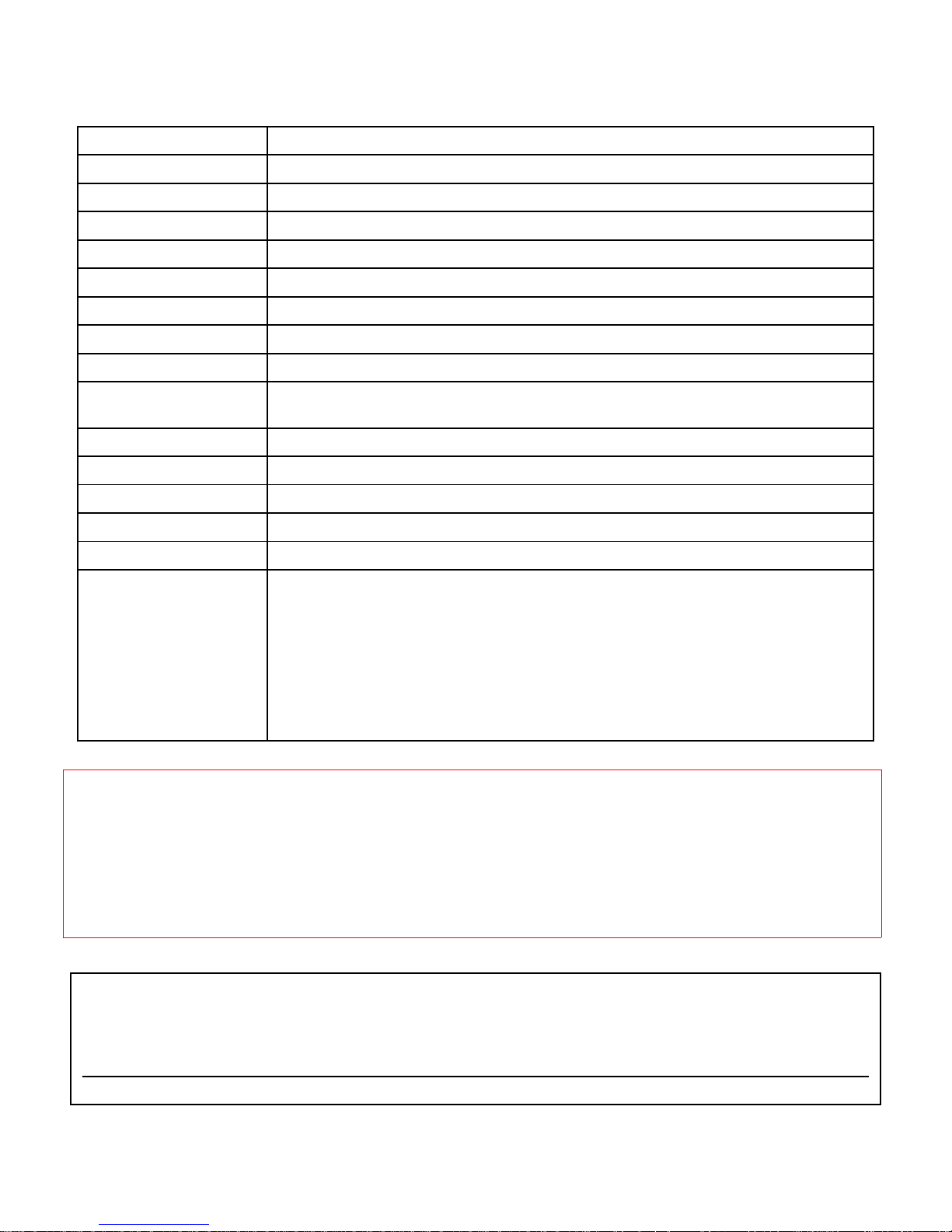

BOILER INSTALLATION PARTS IDENTIFICATION

ITEM PROPOSE

TEMP & PRESS GAUGE TEMPERATURE SHOULD BE 180, PRESSURE WILL GO FROM 12# COLD TO 25# HOT

FIRST AQUASTAT OPERATES THE DRAFT, SET AT 160° to 180°

SECOND AQUASTAT OVER TEMPERATURE PROTECTION, SET AT 200°

THIRD AQUASTAT TURNS UMP ON, SET AT 120°

FLOAT VENT REMOVES AIR, CAP MUST BE LOOSE

30# POP OFF PRESSURE RELIEVE VALVE

T@P VALVE OVER TEMPERATURE PROTECTION

SS HEAT EXCHANGER EXCHANGES HEAT FROM BOILER WATER TO HEATING WATER

12# FILL VALVE KEEPS BOILER FILLED WITH WATER, IF YOU PUT ANTIFREEZE IN THE BOILER

YOU MUST INSTALL A BACKFLOW PREVENTER HERE

EXPANSION TANK ALLOWS HOT WATER TO EXPAND 12# WITH NO PRESSURE ON SYSTEM

CIRCULATING PUMP CIRCULATES WATER THROUGH BOILER AND HEAT EXCHANGER

DRAIN VALVE FOR DRAINING WATER FROM BOILER

POWER CORD 11O VOLTS 100 WATTS

DRAFT MOTOR OPENS AND CLOSES DRAFT TO CONTROL WATER TEMPERATURE

ANTIFREEZE

ANTIFREEZE IS CORROSIVE AND WILL SHORTEN THE LIFE OF YOUR BOILER IF

NOT MAINTAINED

YOU SHOULD USE PROPYLENE GLYCOL,

YOU SHOULD USE A 35% ANTIFREEZE TO 65% WATER FORMULA

ANTIFREEZE WILL CUT DOWN ON THE HEAT TRANSFER OF BOTH THE BOILER,

HEAT EXCHANGER AND THE OUTPUT OF THE TUBING.

A 50% FORMULA WILL CUT THE HEATING OUTPUT OF YOUR SYSTEM BY UP TO

30%

PLUMB BOTH RELIEF VALVES TO A SAFE LOCATION

PIPE MUST RUN DOWN HILL ITS FULL LENGTH, PLUMB TO AN OUTSIDE AREA., DO NOT

ALLOW THE PIPE TO EXTEND OUTSIDE FAR ENOUGH TO FREEZE. DO NOT REDUCE THE PIPE SIZE.

DO NOT PUT THREADS ON THE OPEN END OF THE DRAIN PIPE

DO NOT JOIN THE TWO DRAINS TOGETHER

WARNING!! ATOMIZED POLYPROPYLENE GLYCOL AT

HIGH TEMPERATURES CAN CAUSE AN EXPLOSION!!

Do not open the feed door until the wood has burned down some.

Avoid trying to see how the fire is burning right after you fill it.

All wood burning appliances will smoke if you open the feed door when it is full of wood.

WOOD BOILER INSTRUCTIONS Page 10 Copyright © 2011 Seton Wood Boilers all rights reserved

BOILER DESCRIPTION & INSTALLATION OPTIONS

Your SETON solid fuel boiler is designed to provide supplemental or central heating for your home.

This solid fuel boiler may be installed in conjunction with a boiler that is in proper operating condition

and meets all national and/or local building codes, safety standards, required controls, and has been installed in accordance with appropriate standards of the National Fire Protection Association and in accordance with the clearances specified on the boiler nameplate.

Installation of the SETON boiler should be accomplished by a qualified heating contractor (one who is

engaged in and is responsible for, or is thoroughly familiar with the installation and operation of gas, oil,

and solid fuel burning heating appliances, who is experienced in such work and familiar with all the requirements of the authority having jurisdiction.) The installation shall be in strict accordance with the

manufacturer’s installation instructions furnished with the solid fuel boiler.

The chimney connector of the boiler is to be installed to provide clearances to combustible materials not

less than specified in the individual classifications and marked on the furnace. The chimney suitable for

use with residential type or building heating appliances which burn solid fuel.

The boiler is designed to operate in either a parallel arrangement with the central boiler or as a boiler by

itself.

CAUTION

BOILER UNITS ARE HEAVY!

THE B-90 WEIGHS 2,400 LBS.

THE B-130 WEIGHS 3,000 LBS.

THE B-180 WEIGHS 3,800 LBS.

MAKE SURE YOU HAVE PROPER EQUIPMENT OR SUFFICIENT

MANPOWER TO PREVENT INJURY WHEN DELIVERING AND LOCATING UNITS.

Assuming a 96% to 99% combustion efficiency, which is available with the combustion temperatures we

achieve as long as the chimney is drawing enough air into the draft. Our exhaust temperature indicates a

84% to 90% thermal transfer efficiency. The boiler actually operates as a condensing state during parts of

the charge cycle. The first cycle after charging is usually condensing because the exchanger tries to remove too much heat and combustion temperatures are not achieved with cold wood. After that each cycle

rapidly climbs to 1600+ degrees F. fire box temperature. The exhaust stays below 400 degrees unless the

draft is too strong. I recommend .05 inches water column or more for a draft. After the initial firing, with

each charge the fire reaches a steady state that is very efficient and very clean if the wood is not undersized. Large amounts of very small wood or lumber scraps will release too much gas for the amount of

available draft and will make an incomplete burn and will make creosote in the back of the boiler on the

boiler tubes.

WOOD BOILER INSTRUCTIONS Page 11 Copyright © 2011 Seton Wood Boilers all rights reserved

BOILER INSTALLATION

Before starting the installation of a new boiler and heating system it is beneficial to become informed

about the boiler so that the proper unit is selected to properly supply your heating needs. Learning

about boiler location, positioning and set-up before beginning installation will lead to a better, more

efficient installation.

1. The installation of this boiler must comply with your local building code rulings. Do observe the

clearances to combustibles.

2. Do not install this boiler in a mobile home or trailer. Install the boiler outside and pipe the hot water

into the home.

3. Always connect this boiler to a chimney and vent to the outside. NEVER vent to another room or inside

a building.

4. DO NOT CONNECT to an aluminum Type B gas vent. This is not safe. Use approved masonry or a

UL 103 HT Listed Residential Type and Building Heating Appliance Chimney. Use an 8” diameter chimney

that is high enough to provide required draft. DO NOT USE A CHIMNEY CAP. You can use a (China Cap)

5. Be sure that your chimney is safely constructed and in good repair. Have the chimney inspected by

the fire department or a qualified inspector.

6. Inspect flue pipes, pipe joints, and flue pipe seals regularly to ensure that smoke and flue gasses are

not drawn into and circulated by the air circulation system.

7. Cleanout of heat exchanger, flue pipe, chimney, and draft inducer (if used) is especially important at

the end of the heating season. Accumulated ash may cause corrosion during the summer months.

8. Creosote or soot may build up in the chimney connector and chimney and cause a house/building fire.

Inspect the chimney connector and chimney once monthly during the heating season and clean if necessary.

9. To prevent injury, do not allow anyone to use this boiler who is unfamiliar with the correct operation

of the boiler.

10. Do not operate boiler while under the influence of drugs or alcohol.

11. For further information on using your furnace safely, obtain a copy of the National Fire Protection

Association (NFPA) publication, “Using Coal and Wood Furnaces Safely” NFPA No,. HS-10-1978. The address of the NFPA is: Battery March Park, Quincy, MA 02269.

12. Ashes should not be allowed to accumulate higher than the draft holes. Dispose of ashes in a metal

container with a tight-fitting lid. Keep the closed container on a noncombustible floor or on the ground, well

away from all combustible materials. Keep the ashes in the closed container until all cinders have thoroughly

cooled. The ashes may be buried in the ground or picked up by a refuse collector.

13. Paint discoloration will occur if boiler is over-fired.

14. This boiler has a painted surface which is durable but it will not stand rough handling or abuse.

When installing your boiler, use care in handling. Clean with soap and water when boiler is not hot.

15. While boiler is in operation, all persons, especially young children should be alerted to the hazards

from high surface temperatures and should be kept away to avoid burns or clothing ignition. Small children

should be carefully supervised when they are in the same room with the boiler.

16. Keep boiler area clear and free from all combustible materials, gasoline, and other flammable vapors

and liquids.

17. To prevent burns, always wear protective clothing, leather hearth gloves and eye protection, while

tending the fire.

18. While in operation, keep the feed door, ash door, and cabinet door closed and secured at all times except while tending the fire.

WOOD BOILER INSTRUCTIONS Page 12 Copyright © 2011 Seton Wood Boilers all rights reserved

BOILER INSTALLATION

CAUTION: Keep furnishings and other combustible materials away from the boiler.

NOTE: Installation should be made by a qualified heating equipment installer (one who is engaged in

and is responsible for, or is thoroughly familiar with the installation and operation of gas, oil, and solid fuel burning heating appliances, who is experienced in such work and familiar with all the building requirements and/or fire

codes of the authority having local jurisdiction.)

1. The installation is to be completed in accordance with National Fire Protection Association NFPA) installation

standards No. 89M, 90B, 211, 70 (National Electrical Code) and Uniform Mechanical Code 913, 6-4 in states

where applicable (where code offers making flue pipe connections into an existing chimney with other fuel

burning appliances).

2. Wood-burning appliances need air for combustion and circulation to the house. Provision must be made to provide make-up air so as not to starve the central heating system of combustion air. Have the local regulating

authority determine that make-up air supply is adequate. Reference NFPA standards No. 30 & 54, Code for

Installation of Gas and Oil Equipment.

3. Position the boiler according to clearances (see page 4)

4. Make flue pipe connections to the chimney with 24-gauge pipe and elbows (not included with boiler) maintaining proper clearances. Seal the flue pipe in the chimney with furnace cement.

Chimney connections must be securely supported and joints fastened with sheet metal screws

or rivets.

5. Make electrical supply connections in the electrical junction box and connect power supply wires to des-

ignated wires using wire nuts (see wiring diagram page 19 & 21) The power cord supplied may be used for installation if local codes and regulations permit. If not permitted, power supply wiring must be minimum of 18-ga.

AWG copper and rated for 90 deg. Centigrade installed in a metal cable or conduit. Power connections should be

made by a qualified installer to comply with NFPA Standard No. 70 and all local codes and regulations.

ANTIFREEZE,

Do no install antifreeze in the boiler for a few weeks, in case of boiler problems that would

blow the antifreeze out. Also it is best to drain the boiler at least three times with hot water in

it to remove any residual oil or impurities in it.

PRESSURE RELIEF VALVE (POP-OFF),

The relief valve must be exercised at least once a year, to prevent chemical buildup in the

valve that will prevent it from operating properly. Replace the relieve valve immediately if it

starts to leak or drip. Never block relieve valves. Relieve valves should have an air gap so

you can see if they are leaking. Drain lines must slope down so they do not collect water and

to prevent freezing.

WOOD BOILER INSTRUCTIONS Page 13 Copyright © 2011 Seton Wood Boilers all rights reserved

BOILER LOCATION

The boiler must be placed on noncombustible floor solid concrete or masonry floor is preferable.

Observe the clearances to combustible materials.

The boiler must have its own flue. Do not Connect this unit to a chimney flue serving other appli-

ances.

Install exhaust pipe, elbows, and thimble as required, utilizing either a recently cleaned and inspected 8”

masonry chimney or an 8” I.D. class - A listed chimney.

THE ONLY APPROVED CHIMNEY CAP IS THE CHINA HAT TYPE OF CHIMNEY CAP.

Use 8” round stove pipe. Secure each pipe section and/or elbow joint with three (3) sheet metal screws

per joint to firmly hold the sections together.

Re-check clearances from the boiler, connector stove pipe, and corner clearances using the illustrations in

your local building codes or fire protection ordinances.

DO NOT install this boiler in a mobile home or trailer.

The clearances provided are minimum dimensions determined by the manufacturer’s testing facility. In-

stallation of this boiler must comply with the latest edition of NFPA 211 for reduced clearances and/or

your local building code rulings (use whichever minimum dimensions are LARGEST).

WOOD BOILER INSTRUCTIONS Page 14 Copyright © 2011 Seton Wood Boilers all rights reserved

12” TO A

COMBUSTIBLE WALL

36” TO A

COMBUSTIBLE WALL

12” TO A

COMBUSTIBLE WALL

CHIMNEY MAINTENANCE

CHIMNEY DRAFT: The Seton Boiler is designed to burn wood without creating creosote; you can get a

dirty burn by not having enough draft. This is normally caused by a poor chimney or burning small pieces of

wood which releases more gas than the draft can produce oxygen for.

Do not expect the boiler to draw. Draft is a function of the chimney, not the boiler. Smoke spillage into the house or excessive

buildup of condensation or soot in the chimney are warnings that the chimney is NOT functioning properly. Correct the problem before using the boiler. Following are some possible causes for improper draft.

1. Do not push the connector stove pipe into the chimney too far; it will plug the chimney and stop the draft. DO NOT USE

A CHIMNEY CAP.

2. If the chimney is operating too cool, water will condense in the chimney and run back into the boiler. Soot formation will

be rapid and may block the chimney. Operate the boiler at a high enough fire level to keep the chimney warm, preventing this

condensation. Water temperature control should be set at 180°.

3. If the fire burns well but sometimes smokes or burns slowly, it may be caused by the chimney top being lower than an-

other part of the house or a nearby tree. The wind blowing over a house or tree, falls on top of the chimney like water over a

dam, beating down the smoke. The top of the chimney should be at least three (3) feet above the roof and be at least two (2) feet

higher than any point of the roof within ten (10) feet.

NOTE: A draft reading of 0.06 to 0.07 W.C. (Water Column) is required for proper burning of this boiler.

NOTE: Any chimney that has been used before should be inspected by a qualified person be-

fore this boiler is connected to it

CREOSOTE - Formation and Removal

When wood is burned slowly, it produces tar and other organic vapors which combine with expelled moisture to form creosote. The creosote vapors condense in the relatively cool chimney flue of a slow-burning fire. As a result, creosote residue

accumulates on the flue lining. If ignited, this creosote creates an extremely hot fire which may ignite surrounding materials

resulting in a building fire.

The chimney connector and chimney should be inspected at least once a month during the heating season to determine if a

creosote buildup has occurred.

If creosote has accumulated, it should be removed. Failure to remove creosote may result in ignition and may cause a house/

building fire. Creosote may be removed using a chimney brush or other commonly available materials from your local hardware retailer.

Chimney fires burn very hot. If the chimney connector should glow red, immediately call the fire department, then reduce

the fire by closing the inlet air control and pour a large quantity of coarse salt, baking soda, or cool ashes on top of the fire in

the firebox.

CAUTION: A chimney fire may cause ignition of wall studs or rafters which were

assumed to be a safe distance from the chimney.

If a chimney fire has occurred, have your chimney inspected by a qualified person before using again.

WOOD BOILER INSTRUCTIONS Page 15 Copyright © 2011 Seton Wood Boilers all rights reserved

CHIMNEY MAINTENANCE

THIS IS CAUSED BE NOT HAVING ENOUGH DRAFT

Measuring and Adjusting the Draft of the Flue

Draft is a function of the chimney flue, not the furnace. The natural draft generated through a chimney is

dependent on several factors including chimney height, temperature of flue gases, cross-sectional area of the

chimney, chimney wall insulation value, dilution air, and total volume of flue gases.

To operate properly, the Seton Boiler requires a draft of .06" to .07" wc (water column). Symptoms of an improperly designed or installed flue include visible smoke out the chimney, smoke escaping into the room,

creosote buildup in the flue, and/or poor heating performance.

The following procedure describes how to measure draft using a manometer-a device that measure draft:

1. Close all windows and doors in the building and turn on all appliances that remove air from the home (e.

g., heat pump, air conditioner, exhaust fan, clothes dryer, fireplaces, etc.).

2. Drill a hole in the connector pipe (just large enough for the tube of the manometer) at least 1 foot above

the furnace outlet collar.

3. After all chimney connections, plumbing and wiring is complete, build a fire and allow the furnace to settle into stable operation. If the boiler has been installed in conjunction with a Type A flue pipe, take the draft

reading after 1 hour. For all chimneys other than Type A flue pipe, take the draft reading after 2 hours.

4. Using the manometer, measure the draft in the flue.

a. If the draft measurement is below .06" wc (12.45 Pa), there is too little draft and a draft inducer or other

corrective measures are required to avoid air-starvation of the boiler. A draft inducer fan can be mounted in

the chimney.

WOOD BOILER INSTRUCTIONS Page 16 Copyright © 2011 Seton Wood Boilers all rights reserved

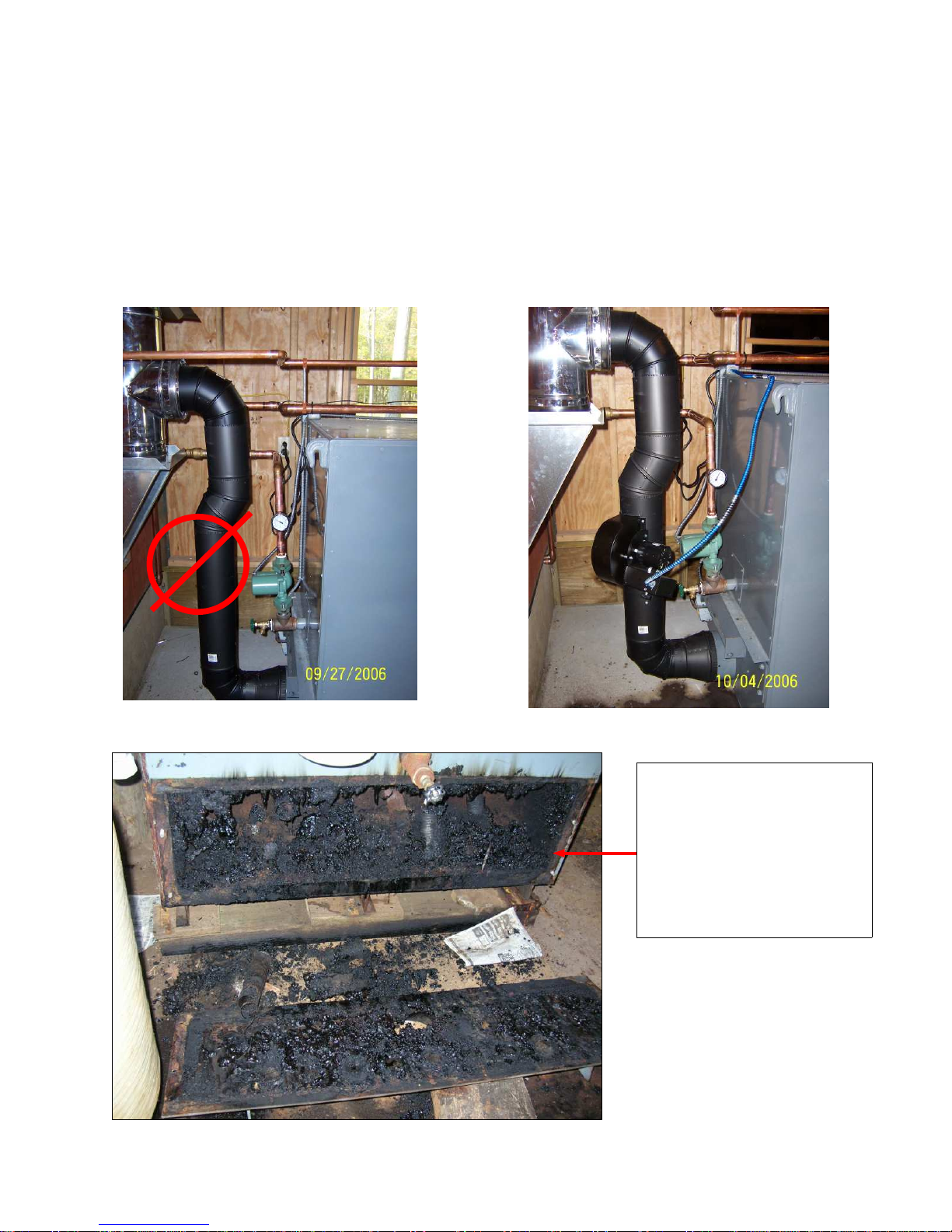

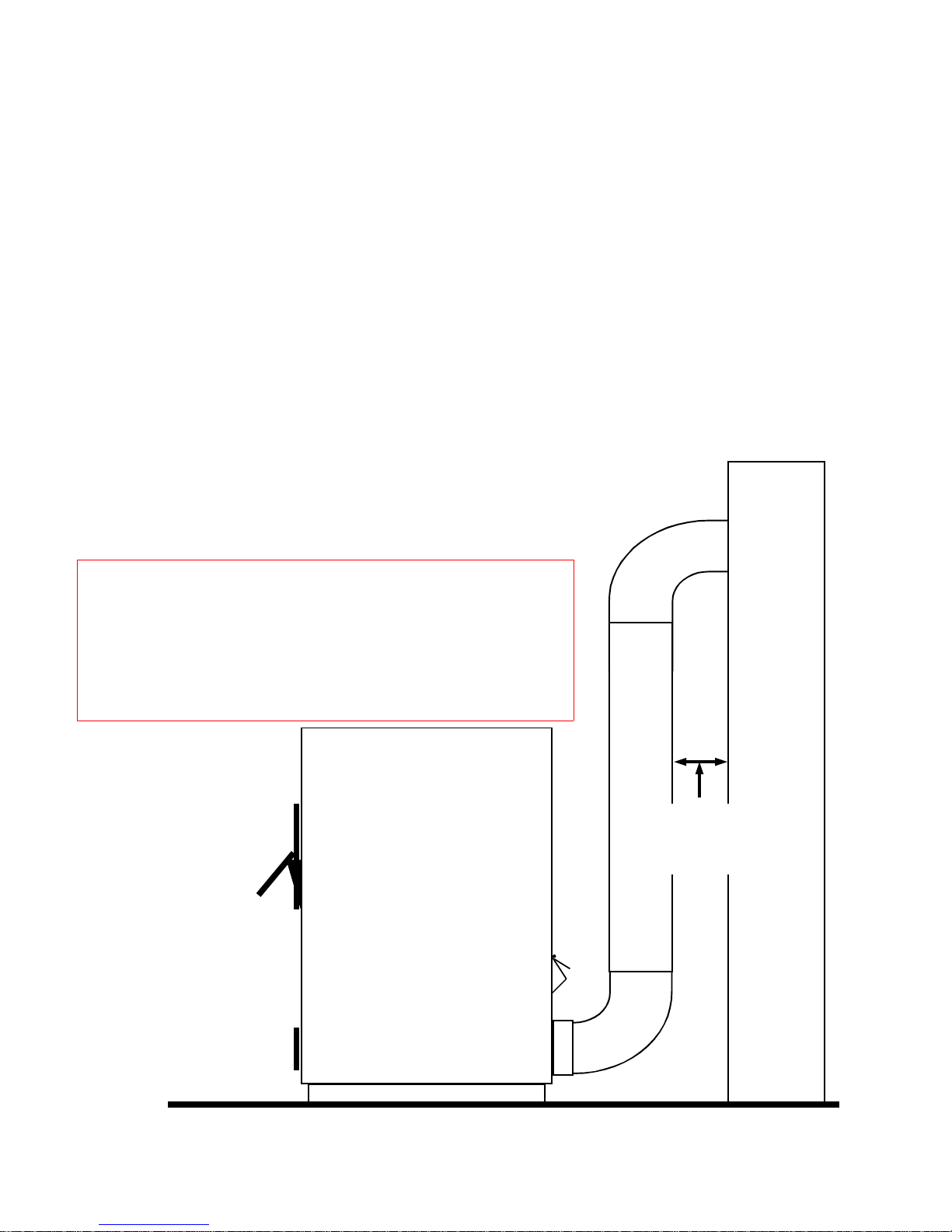

HOW NOT TO

This chimney has three 90 degree bends plus two 45 degree bends, a total of 360

degrees, plus a 2 inch reduction all in single wall pipe. This will not draw properly, it

will need a draft inducer.

WOOD BOILER INSTRUCTIONS Page 17 Copyright © 2011 Seton Wood Boilers all rights reserved

THIS BOILER

WAS OPERATED

IN A CONSTANT

CONDENSING STATE

CHIMNEY CONNECTIONS

THE BEST CHIMNEY IS THE INSULATED STAINLESS STEEL TYPE

SUCH AS “METALBESTOS HT”

OR OTHER CHIMNEY SYSTEM APPROVED FOR WOOD BURNING STOVES.

IN ALL CASES THE CHIMNEY MANUFACTURER’S INSTRUCTIONS MUST BE FOLLOWED.

Chimneys perform two functions.

1. As a means of exhausting smoke and flue gasses which are the result of fuel combustion.

2. The chimney provides “draft” which allows oxygen to be continuously introduced into the appliance, so that proper combustion is possible.

As of April 1, l987 all stoves should be installed using a factory built chimney that meets the “Type HT”

requirement of UL 103 (when using a factory built chimney).

Note: your boiler does not create draft. Draft is a function of the chimney. A minimum of 0.06 w.c,

(measured in water column) is required for proper drafting to prevent back-puffing, smoke spillage, and

to maximize performance. (Gauges to measure chimney draft are readily available at furnace shops and

are economical to purchase or rent.)

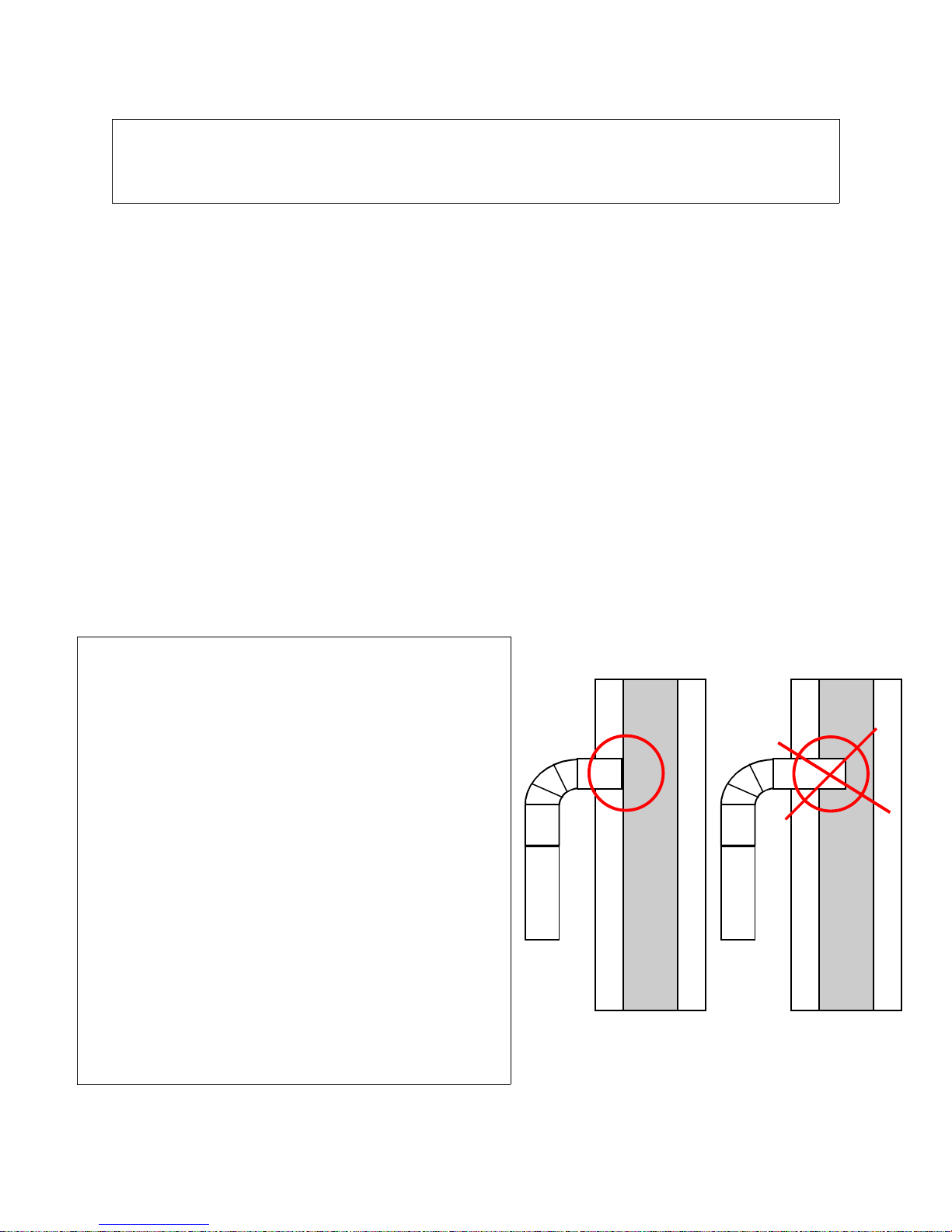

IMPORTANT INSTALLATION POINTS

1. Size the chimney flue to the furnace pipe. ( 8” outlet pipe = 8” chimney flue).

2. Use elbows only as necessary. Elbows reduce draft, no more than two should be used in any

chimney.

3. Make sure all horizontal runs of connector pipe have a minimum outward rise of 1/4” per horizontal foot. This allows any condensation or creosote buildup to run back into the firebox.

Masonry Chimneys will not always work

with the Seton boiler

Before using an existing masonry chimney, clean the

chimney, inspect the flue liner and make any repairs

needed to be sure it is safe to use. Make repairs before

attaching the boiler.

If the connector stove pipe must go through a combustible wall before entering the masonry chimney, consult a

qualified mason or chimney dealer. The installation

must conform to local building and fire codes and latest

edition of NFPA 211.

Do not connect this boiler into the same chimney flue as

the fireplace, gas appliance, or a flue connected with

any other furnace or boiler.

USE A CHINA HAT TYPE

OF CHIMNEY CAP.

WOOD BOILER INSTRUCTIONS Page 18 Copyright © 2011 Seton Wood Boilers all rights reserved

CHIMNEY CONNECTIONS

THE SETON BOILER WILL NOT ALWAYS WORK ON A MASONRY CHIMNEY.

The chimney used for the boiler must not be used to ventilate the cellar or basement. If there is a cleanout opening in

the base of the chimney, close it tightly.

Listed chimney

Carefully follow chimney manufacturer’s instructions. Use only a listed chimney. If your chimney starts at the ceiling,

you will need enough 8” round black stove pipe to reach the ceiling. The top of the chimney must be at least three (3)

feet above the roof and be at least two (2) feet higher than any point of the roof within ten (10) feet.

If you have any questions regarding venting your boiler, contact the manufacturer or contact the National Fire Protection

Association (NFPA) and request a copy of the latest editions of NFPA Standard 211 and NFPA Standard 908. Their address is:

Battery March Park, Quincy, MA 02269

Because of the very high efficiency of the Seton boiler the

flue gas exhaust temperatures can be low enough to

cause condensation in the chimney. This condensation

may, over time, damage a masonry chimney. If you have

condensation in your chimney, a stainless steel chimney

liner must be installed inside the flue

Chimney caps will drip creosote on the ground and roof.

18” TO A

COMBUSTIBLE

WALL

WOOD BOILER INSTRUCTIONS Page 19 Copyright © 2011 Seton Wood Boilers all rights reserved

CHIMNEY CONNECTIONS

The chimney used for the boiler must not be used to ventilate the cellar or basement. If there is a

cleanout opening in the base of the chimney, close it tightly.

Listed chimney

Carefully follow chimney manufacturer’s instructions. Use only a listed chimney. If your chimney

starts at the ceiling, you will need enough 8” round black stove pipe to reach the ceiling. The top of

the chimney must be at least three (3) feet above the roof and be at least two (2) feet higher than any

point of the roof within ten (10) feet.

If you have any questions regarding venting your boiler, contact the manufacturer or contact the National Fire Protection Association (NFPA) and request a copy of the latest editions of NFPA Standard 211 and NFPA Standard 908. Their address is: Battery March Park, Quincy, MA 02269

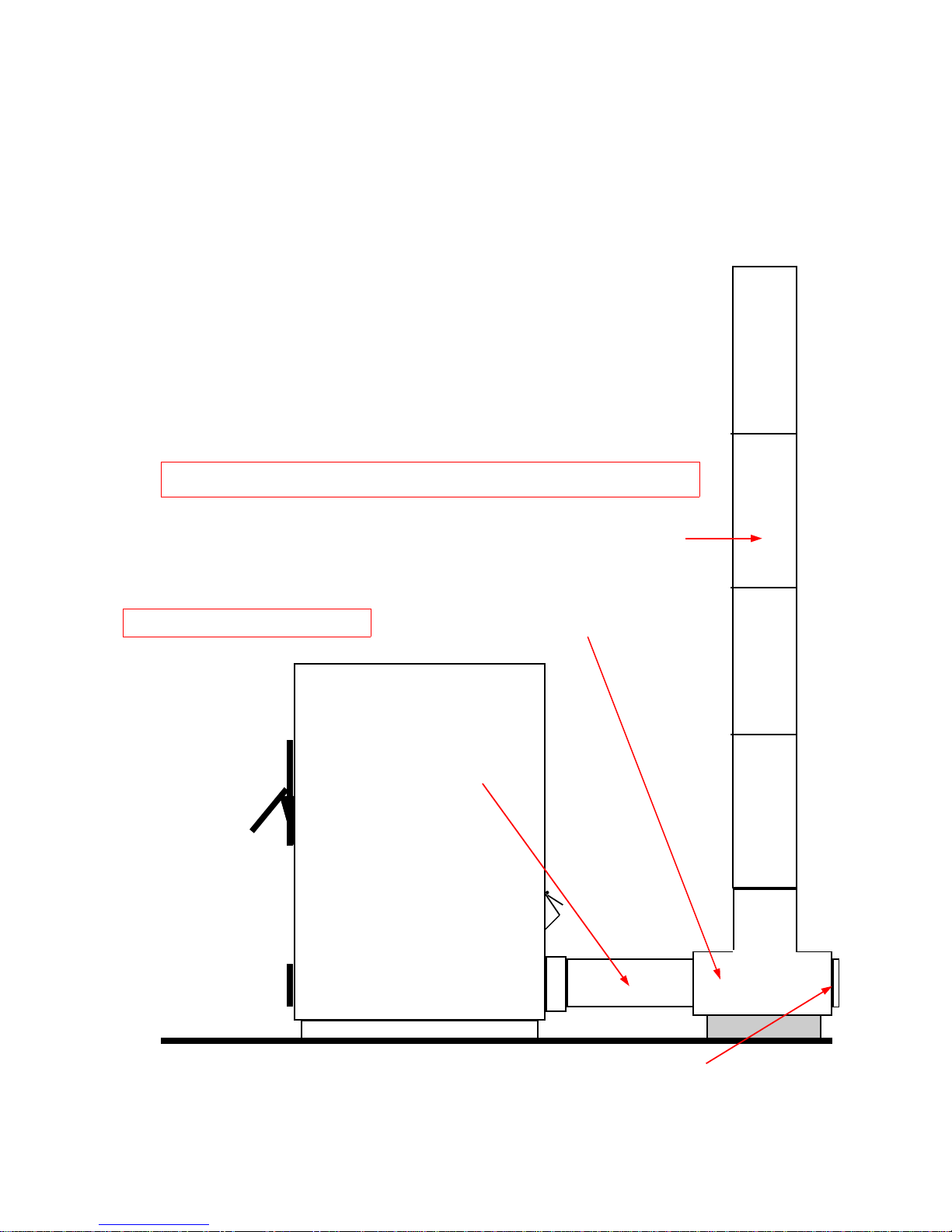

This is the best method to install a chimney on the Seton Boiler.

18 TO 20 FEET OF 8” INSULATED CLASS “A” CHIMNEY

DO NOT USE A CHIMNEY CAP

8” SINGLE WALL STOVE PIPE

8” INSULATED CLASS “A” TEE

8” INSULATED CLEANOUT

WOOD BOILER INSTRUCTIONS Page 20 Copyright © 2011 Seton Wood Boilers all rights reserved

Loading...

Loading...