Sesamo Puma Millenium Installation Instruction

Automatic Operator for swinging doors

INSTALLATION INSTRUCTION

2

Installation Instruction

PIUMA MILLENNIUM

3

Index

Technical specifications ...................................................................................... page 5

Automatism installation preparation.................................................................... page 5

Automatism description ...................................................................................... page 5

Sizes and dimensions ........................................................................................ page 6

Automatism assembly ........................................................................................ page 7

Adjustment of the stop (Optional) ...................................................................... page 12

Final operations .................................................................................................. page 13

Power connections .............................................................................................. page 13

MILLENNIUM electronic board............................................................................ page 13

Electrical connections.......................................................................................... page 14

Left side electronic board connections .............................................................. page 14

Right side electronic board connections ............................................................ page 15

Led functions ...................................................................................................... page 18

Jumper Function.................................................................................................. page 18

Dip-Switch Function ............................................................................................ page 18

Electric Lock selection ........................................................................................ page 19

Selection of the type of arm ................................................................................ page 19

Selection of the door weight .............................................................................. page 19

“Low Power” mode selection .............................................................................. page 20

MultiSlave Selection ............................................................................................ page 20

Battery mode ...................................................................................................... page 21

“First input mode” selection................................................................................ page 21

Number door selection........................................................................................ page 21

Master - Slave Selection (Piuma Doppio only) .................................................. page 22

Synchronised/indipendent door motion (Piuma Doppio only) .......................... page 22

Start up ................................................................................................................ page 22

Error Message Table............................................................................................ page 23

Setting parameter adjustment ............................................................................ page 24

Operating logic .................................................................................................... page 24

Piuma Doppio connection and use .................................................................... page 26

Inter lock connection and use ............................................................................ page 27

SESAMO reserves the right to change the technical specifications of the products, even without notice.

4

Installation Instruction

Thank you for choosing this product. For best automatism

performance, Sesamo recommends you carefully read and

follow the installation and use instructions found in this manual. Installation of this automatism must only be performed

by the professionally qualified personnel for whom this manual is addressed. Any errors during installation may be

harmful to people or things. Packaging material (wood, plastic, cardboard, etc.) should not be scattered in the environment or left within the reach of children as potential sources

of danger. Every installation phase must be performed in

accordance with the regulations in force and following Good

Technique standards. Before beginning installation make

sure that the product is integral and has not been damaged

during transportation or by poor storage conditions. Before

installing the product make sure that each architectural and

structural element of the entrance (girder fastening surfaces,

casings, guide, etc.) is appropriate and sufficiently robust to

be automated. Conduct a careful risk analysis and make

suitable modifications to eliminate conveyance, crushing,

cutting and hazardous areas in general. Do not install the

product in environments where gas, steam or inflammable

fumes are present. The manufacturer is not liable for any

neglect of “good technique” or specific regulations in the

construction of the casing to be motorised and any collapse

of the same. All automatic entrance safety and protection

devices (photocells, active sensors, etc.) must be installed

in accordance with the regulations and directives in force,

with the completed risk analysis, system type, use, traffic,

forces and inertia in play. Pay careful attention to area where

the following may occur: crushing, cutting, conveyance and

any other type of hazard in general applying, if necessary

suitable indications. Indicate the motorised door identification information on every installation. Make sure that the

upstream electrical system is correctly dimensioned and

has all the opportune protections (circuit breakers and

fuses). Only use original spare parts in maintenance and

repairs. Do not tamper or alter devices in the automatism

and all the safety devices in the control panel for any reason.

The manufacturer is not liable if parts within the automatism

are altered or tampered with or if safety devices other than

those indicated by the manufacturer are used in the system.

The automatism installer must provide the automatic

entrance manager with the use manual and all the information required for correct use in automatic and manual

modes (even for electronic locking) and in the event of

emergency.

Pay careful attention to the messages in this manual that are

marked with the hazard symbol. They can either be warnings aimed at avoided potential equipment damage or specific signals of potential hazard to the installer and others.

This device was designed to automate swinging doors. Any

other use is considered contrary to the use foreseen by the

manufacturer who therefore shall not be held liable.

Machine directive

The installer who motorised a door becomes the automatic

door machine manufacturer according to directive 98/37/CE

and must:

• Arrange the Technical Booklet with the documents indicated in attachment V of the Machine Directive and keep

them for at least 10 years.

• Draft the CE declaration of conformity according to

attachment II-A of the machine directive and provide the

use with a copy.

• Apply the CE markings on the motorised door according

to point 1.7.3 of attachment I of the machine directive.

For more information and for assist installers in applying the

specifications of the directives and of European standards

concerning the safe use of motorised gates/doors consult

the guidelines available on internet at the address

www.sesamo.eu

Machine conformity directive

(Directive 98/37 CE, Attachment II, part B)

Manufacturer: SESAMO S.r.l.

Address: Str. Gabannone 8/10 - 15030

Terruggia - AL

Declares that the product PIUMA MILLENNIUM

• Is built to be incorporated in a machine or to be assembled with other machinery to build a machine considered

by Directive 98/37 CE, as modified;

• Therefore it is not fully compliant to the dispositions of

this Directive since it is not yet assembled with other

components.

• It is in conformity to the following other CE directives:

89/336/CEE Electro-magnetic compatibility and further

modifications 2006/95CE Low Voltage and further modifications and also declares that the machinery cannot be

used until the machine it is incorporated in or is a component of has been identified and its conformity to

Directive 98/37 CE conditions and national legislation

declared.

Terruggia, 21/07/2007

Aldo Amerio

( Administrator )

PIUMA MILLENNIUM

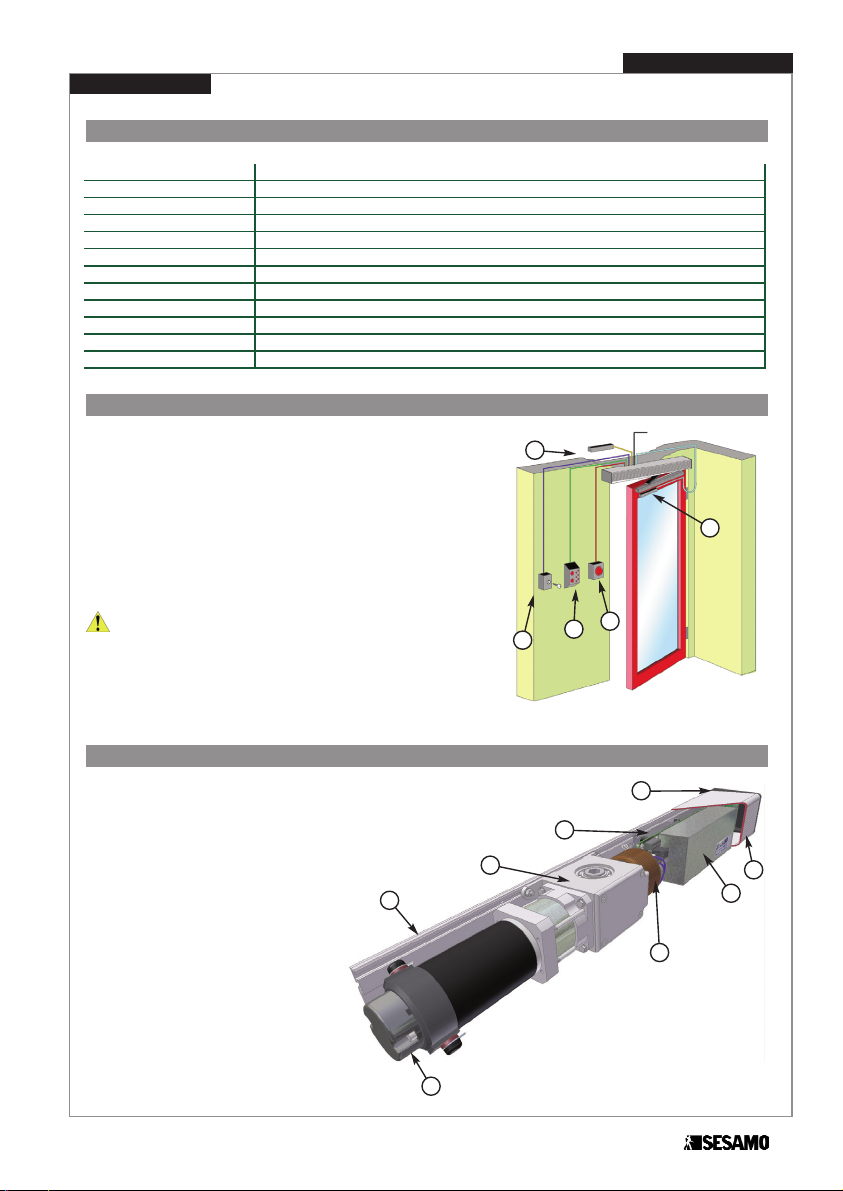

Technical specifications

Automatism installation preparation

The automatism is prepared to work in different accessory and peripheral configurations. According to the selected configuration, arrange

the cables necessary for wiring all the peripherals. Fig.1 shows an

example of complete installation including:

A. Entry Radar

B. Active safety sensor

C. Safety closing device

D. Logic selection selector

E. Opening button at exit

WARNING

If two single Piuma automatisms are used to move a two-doors entrance, the two automatisms must be connected by a shielded cable with

4 0.22mm wires as indicated on page 26.

Automatism description

The PIUMA Millennium automatism (Fig.2) is

essentially made up of:

A. Extruded aluminium alloy fastening base

B. Extruded aluminium alloy cover

C. Aluminium end sides (Flat steel end sides

option)

D. Gear motor unit

E. SESAMO MILLENNIUM Electronic control

panel

F. Transformer

G. Encoder unit

H. Emergency battery (24V 0,8Ah)

For a two-doors entrance, two automatisms

can be ordered in a single transom box

(Piuma Doppio) with custom length (minimum

1600 mm).

Installation Instruction

5

Fig. 1

Fig. 2

PIUMA MILLENNIUM

Power supply 230V ac 50 Hz

Nominal power 60 W

Nominal motor torque 23 Nm

External device power 12Vdc – 6W

Emergency battery 24 V 0.8 Ah

Max opening angle 100°

Door maximum weight Up to 200 Kg

Door dimensions 700÷1200 mm

Working temperature Box inside from 0°C to+50°C

Anti-crushing Automatic traction restriction in the presence of obstacles

Weight 8,6 kg

Service Continuous (>500 cycles/day, with capacity of 300 cycles/hour for 2 hours)

A

E

D

C

B

230V AC

A

B

D

C

G

F

E

H

6

Installation Instruction

PIUMA MILLENNIUM

Standard End

Sides

Flat End Sides

(opzionali)

Fig. 5

Fixing Holes (Std End Sides)

Fixing Holes (Flat end sides)

Gearmotor axis

Gearmotor axis

AA

AA

AA

AA

Fig. 3

Fig. 4

Sizes and dimension

The Piuma Millennium automatism is available in two configurations: with standard heads in aluminium (L=810 mm) and

with flat heads (optional) in steel (L=

800 mm).

Installation Instruction

PIUMA MILLENNIUM

7

Automatism assembly

WARNING : Before proceeding with the installation, remove the cardboard component positioned underneath the

motor body.

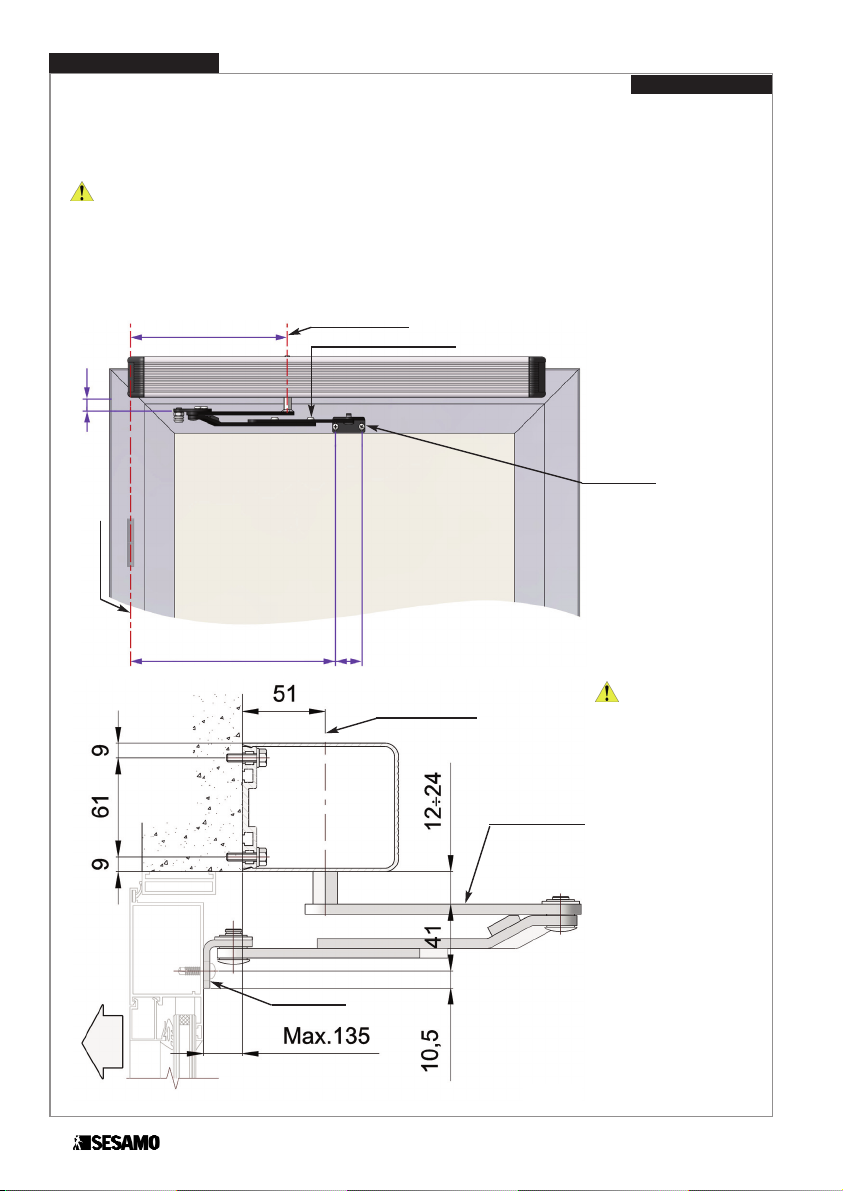

Positioning dimensions (rigid pull arm)

The rigid pull arm is used when the automatism is installed on the swing side of the door .

WARNING

: For a correct positioning, always use the main axis of the door hinges and the operation axis of the

gearmotor as a reference, as shown in Fig.6.

Make certain that the fastening of the holes "A" (Fig. 4 and 5) is particularly

secure.

300

150 600

15÷29

Piuma Millennium

fastening diagram

1 left-hand opening door

Rigid Pull Arm

Standard End Sides

Gearmotor Axis

Hinge axis

Rigid pull arm

Aluminium guide

Fig. 6

The heights of the prepared fastening holes are

shown in Fig. 4 and 5

.

For right-hand opening

doors (anticlockwise direction), the assembly of the

automatism perfectly mirrors the left-hand opening

assembly.

Rigid pull arm

Aluminium guide

Gearmotor Axis

OPENING DIRECTION

Fig. 7

WARNING : The final tighte-

ning of the screws must be performed only after having checked

that the vertical positioning of the

automatism guarantees a good

parallelism between the hinge

axis and the gearmotor axis. For

this purpose, the rigid pull arm

and relative guide must be installed, check that the pin coupling

the arm to the cylindrical slide is

not strained during operation.

An error in the position of the automatism may, in fact, cause the pin

of the rigid arm to oscillate with

respect to the cylindrical slide to a

degree beyond the allowed tolerance, with consequent damage to

one of the automatism parts.

8

Installation Instruction

PIUMA MILLENNIUM

OPENING DIRECTION

Gearmotor Axis

Articulated push

arm

Door Attachment

Fig. 9

Piuma Millennium

Fastening diagram

1 left-hand opening door

Articulated push arm

Standard End Sides

300

12÷24

50380

Hinge axis

Articulated push arm

Door Attachment

Gearmotor Axis

Fig. 8

The heights of the prepared fastening holes are

shown in Fig. 4 and 5.

For right-hand opening

doors (anticlockwise direction), the assembly of the

automatism perfectly mirrors the left-hand opening

assembly.

Positioning dimensions (articulated push arm)

The articulated push arm is used when the automatism is installed on the approach side of the door (the side opposite the

swing side). For left-hand opening doors (door opening with anti-clockwise rotation) position the automation as shown in

Fig. 8 (using the heights shown in Fig. 4 and 5).

WARNING : For a correct positioning, always use the main axis of the door hinges and the operation axis of the gearmotor as a reference, as shown in Fig.8. Make certain that the fastening of the holes "A" (Fig. 4 and 5) is particularly secure.

WARNING : The final

tightening of the screws must

be performed only after

having checked that the positioning of the automatism

and articulated arm guarantees smooth rotation of the

same under the door frame,

maintaining a distance of 12

to 24 mm between the top

part of the articulated push

arm and the lower part of the

automatism cover (Fig. 9).

Installation Instruction

9

PIUMA MILLENNIUM

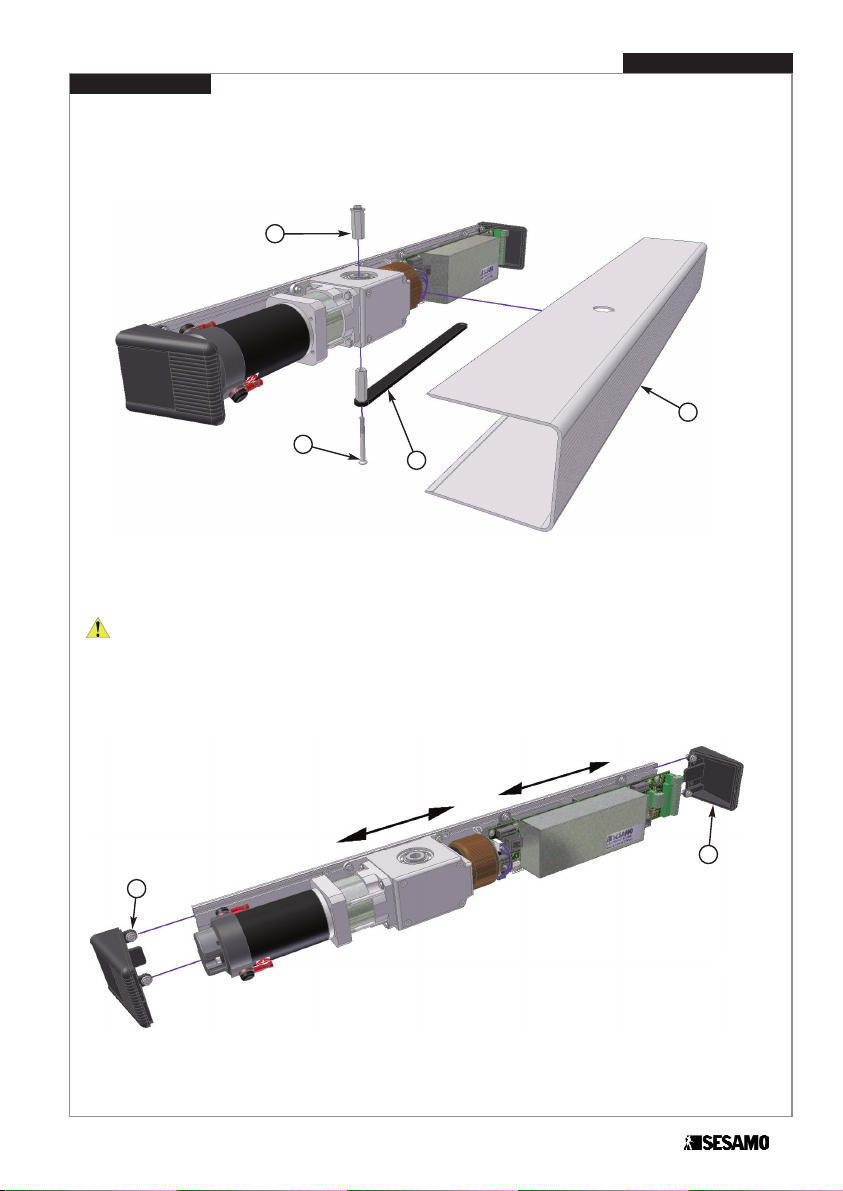

Automatism components shift and removal

Disassemble the push arm (if present) (Fig. 10 Part A) by unscredoor the counter-sunk head screw M6 x 70 (Fig. 10 Part

B). Extract the top hexagonal stop (Fig. 10 Part C). Remove the aluminium cover (Fig. 10 Part D) by pulling it outwards.

To facilitate the fastening of the automatism, it is possible to remove the heads (Fig. 11 Part A) and move or remove the

internal components, if necessary, by operating on the nuts fastening them to the aluminium base.

WARNING: Before loseening component lock screws to move components, measure the distance of the motor from

the head or make marks on the box for correct component positioning at the end of assembly.

Fig. 10

A

Fig. 11

B

C

D

A

A

Loading...

Loading...