Automatic Operator for swinging doors

OPERATING INSTRUCTIONS

PROSWING (m)

PROSWING (M)

Operating instruction

2

3

Index

Technical specifications .................................................................................................. pag. 6

Function Low-energy ...................................................................................................... pag. 6

Warnings for the installer and general safety ................................................................ pag. 7

Recycling and disposal .................................................................................................. pag. 7

Intended use .................................................................................................................. pag. 8

Limit of use .................................................................................................................... pag. 8

Types of arms.................................................................................................................. pag. 9

Arm extensions................................................................................................................ pag. 10

Dimensions...................................................................................................................... pag. 10

Preliminary checks.......................................................................................................... pag.11

Automatism fixing............................................................................................................ pag. 11

Aluminum base holes positioning .................................................................................. pag. 13

Pull arm installation ........................................................................................................ pag. 14

Push arm installation ...................................................................................................... pag. 18

Preliminary checking ...................................................................................................... pag. 21

Wiring power supply ...................................................................................................... pag. 22

Control board Proswing (M) .......................................................................................... pag. 22

Wiring .............................................................................................................................. pag. 23

External peripherals connectors-Input .......................................................................... pag. 24

External peripherals connectors-Output ........................................................................ pag. 25

Dip-switches setting ........................................................................................................ pag.26

Parameters adjustment-display ...................................................................................... pag. 27

Start up............................................................................................................................ pag. 30

Message or errors code.................................................................................................. pag. 31

Operating logics.............................................................................................................. pag. 32

Electric lock selection and setting.................................................................................. pag. 33

PROSWING (M)

3

PROSWING(M)

Operating instruction

4

Operating instruction

PROSWING (M)

Selectors terminal board ................................................................................................ pag. 35

External peripheral power connector(15Vdc) ................................................................ pag. 35

Wiring and use for double Proswing .............................................................................. pag. 36

Inter lock wiring and use ................................................................................................ pag. 39

Installation batteries (OPTIONAL) .................................................................................. pag. 40

Logic switch .................................................................................................................... pag. 42

Connector for PC-Unit connections................................................................................ pag. 42

Delivery modality ............................................................................................................ pag. 42

SESAMO reserves the right to change the technical specifications of the products, even without notice.

Operating instruction

PROSWING (M)

5

Thank you for choosing this product. For best automatism

performance, Sesamo recommends you carefully read and

follow the installation and use instructions found in this

manual. Installation of this automatism must only be performed by the professionally qualified personnel for whom this

manual is addressed. Any errors during installation may be

harmful to people or things. Packaging material (wood, plastic, cardboard, etc.) should not be scattered in the environment or left within the reach of children as potential sources

of danger. Every installation phase must be performed in

accordance with the regulations in force and following Good

Technique standards. Before beginning installation make

sure that the product is integral and has not been damaged

during transportation or by poor storage conditions. Before

installing the product make sure that each architectural and

structural element of the entrance (girder fastening surfaces,

casings, guide, etc.) is appropriate and sufficiently robust to

be automated. Conduct a careful risk analysis and make suitable modifications to eliminate conveyance, crushing, cutting and hazardous areas in general. Do not install the product in environments where gas, steam or inflammable

fumes are present. The manufacturer is not liable for any

neglect of “good technique” or specific regulations in the construction of the casing to be motorised and any collapse of

the same. All automatic entrance safety and protection devices (photocells, active sensors, etc.) must be installed in

accordance with the regulations and directives in force, with

the completed risk analysis, system type, use, traffic, forces

and inertia in play. Pay careful attention to area where the

following may occur: crushing, cutting, conveyance and any

other type of hazard in general applying, if necessary suitable indications. Indicate the motorised door identification

information on every installation. Make sure that the

upstream electrical system is correctly dimensioned and has

all the opportune protections (circuit breakers and fuses).

Only use original spare parts in maintenance and repairs. Do

not tamper or alter devices in the automatism and all the

safety devices in the control panel for any reason. The

manufacturer is not liable if parts within the automatism are

altered or tampered with or if safety devices other than those

indicated by the manufacturer are used in the system. The

automatism installer must provide the automatic entrance

manager with the use manual and all the information required for correct use in automatic and manual modes (even for

electronic locking) and in the event of emergency.

Pay careful attention to the messages in this manual that are

marked with the hazard symbol. They can either be warnings

aimed at avoided potential equipment damage or specific

signals of potential hazard to the installer and others.

This device was designed to automate pedestrian swinging

doors. Any other use is considered contrary to the use foreseen by the manufacturer who therefore shall not be held liable.

Machine directive

The installer who motorised a door becomes the automatic

door machine manufacturer according to directive

2006/42/CE and must:

• Arrange the Technical Booklet with the documents indicated in attachment VII of the Machine Directive and keep them

for at least 10 years.

• Draft the CE declaration of conformity according to attachment II-A of the machine directive and provide the use with a

copy.

• Apply the CE markings on the motorised door according to

point 1.7.3 of attachment I of the machine directive.

For more information and for assist installers in applying the

specifications of the directives and of European standards

concerning the safe use of motorised gates/doors consult

the guidelines available on internet at the address

www.sesamo.eu

DECLARATION OF INCORPORATION

(Directive 2006/42/CE, Annex II, part B)

Manufacturer: SESAMO S.R.L.

Address: Str. Gabannone 8/10 -

15030 Terruggia – AL ITALY

Declares that the product PROSWING (m)

- is built to be incorporated in a machine to build a machine

considered by Directive 2006/42/CE

- is conform to the essential safety requirements set out in

annex I of the directive with the exclusion of the following

points: 1.2.4.3, 1.2.4.4, 1.3.4, 1.3.5, 1.3.7, 1.3.8.2, 1.4, 1.5.3,

1.5.7, 1.5.14, 1.5.15, 1.5.16

- is conform to the following other CE directives:

2004/108/CE Electromagnetic Compatibility, 2006/95/CE

Low Voltage

- have been applied the following harmonized norms:

EN 60335 - 1 EN 61000 - 6 - 2

EN 50366 EN 61000 - 6 - 3

And also declares that:

- relevant technical documentation has been fulfilled in

accordance with part B of annex VII of the Directive; this

documentation, or part of it, will be transmitted, by post or

mail, in response to a reasonable request by the national

authorities

- the person authorized to compile the relevant technical

documentation is: SESAMO SRL, Strada Gabannone, 8/10 15030 Terruggia (AL) - Italy

- the partly completed machinery must not be put into service until the final machinery into which it is to be incorporated

has been declared in conformity with the relevant provisions

of the Machinery Directive 2006/42/CE

SESAMO S.R.L. Director

February 2012 ALDO AMERIO

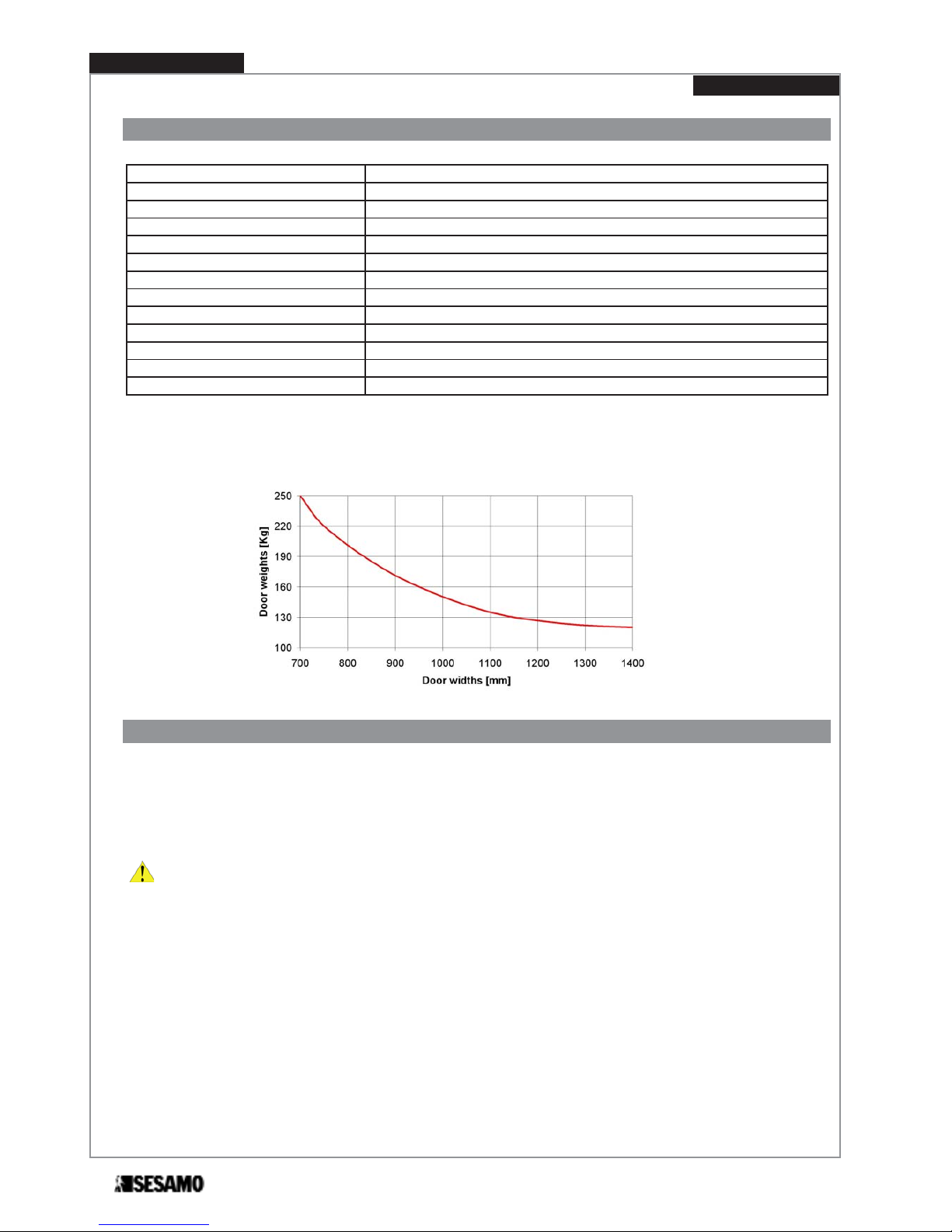

Technical specifications

In the diagram there is the max door weights related with the door widths:

Function LOW-ENERGY

PROSWING (M) can be set in the order to meet requirements of Low-Energy application according DIN 18650 or BS 7036-

4.

In Low-Energy mode safety is ensured by:

- low speed;

- reduced dynamic/static force.

ATTENTION: Installation of safety sensors monitoring opening and/or closing path is an option to consider after risk

assessment evaluation.

Power supply 230V +/- 10% ac 50 Hz

Nominal power 85 W

Nominal motor torque 45 Nm

External device power 12Vdc – 12W max

Emergency battery power 24V 1,3 Ah

Opening time 3 ÷ 6 sec (70 °/s ÷ 20 °/s)

Closing time 4 ÷ 15 sec (40 °/s ÷ 10 °/s)

Max opening angle

110°

Wing dimension 700 ÷ 1400 mm

Working temperature Inside automatsm from -10°C to +50°C

Anti-crushing Automatic traction restriction in presence of obstacles

Weight 10,5 kg approx

Service Intensive

PROSWING (M)

Operating instruction

6

Warnings for the installer and general safety

1) It is important for the safety of the people installing the automatism according to the regulations. A wrong installation or

use of the product might lead to serious damages to people.

2) Read carafully the operating instructions before installing the product.

3) Store the operating instructions for future reference.

4) This automatism has been designed and built exclusively for the use specified in this documentation. Any different use not

stated herain could affect the integrity of the product and/or represent danger situation.

5) SESAMO declines any responsabilty from misuse or different use from which it was intended.

6) Do not install the product in explosive enviroment: the presence of flamabel gases or fumes is a serious safety hazard.

7) SESAMO is not responsible for the failure to comply with the Good Technical construction procedure of the door to be automated, as well as deformations that may occur to the door when using the same.

8) Before making any service to the product, take off power supply.

9) Instal a bi-polar switch to cut off power supply.

10) Verify functionality of ground wiring.

11) Safety devices (norm EN 12978) protect possible dangerous areas from mechanical risks during movement, as. anticrashing, conveying, shearing.

12) For mainteinance use only genuine SESAMO spare parts.

13) Do not modify components that belongs to the whole automatism.

14) The installer must supply end user all the informations in case of manual operating in emergency.

15) End user shall refrain from any attemp to repair or direct intervenction and ask only to qualified personnel.

16) Installation must be done only from a qualified personnel and in full compliance with regulations.

17) Everything not including in this operating instruction manual is not allowed.

18) This operating instructions manual is only intended for qualified personnel.

Recycling and disposal

RECYCLING OF THE AUTOMATISM AND PACKAGING

This product is built with different materials. The major parts (aluminium, plastic, iron,wires) are solid urban waste. They can be

recycled through collection and disposal in authorized centers.

Other components (control boards, etc.) may contain pollutants. They need to be removed and hand over to companies autho-

rized to recover and dispose them.

The packaging (paperboard, plastics etc.) are solid urban waste and they can be disposed of without any problem, simply per-

forming waste collection for recycling.

Before proceding it is always reccomendr to verify local specific norm for disposal.

PLEASE RECYCLE!

7

PROSWING (M)

Operating instruction

Intended use

The device must be used to automate pedestrian swinging door only.

This device is an electro mechanical system that allow to open and close a swinging door using a trasmission arm.

Door is closed through a motor/spring system or only spring while power is off.

Programmable electronic control board allows correct functionning depending on the type of installation.

Limit of use

ATTENTION: Do not exceed door weight and width as shown in the diagram in “technical specification” paragraph.

To each type of arm correspond a different type of jamb dimension: do not exceed this value (see Paragraph “arm installation”).

This device is intended only for swinging pedestrian door, dry and inside use.

SESAMO shall not be held liable for any other use contrary to the use foreseen.

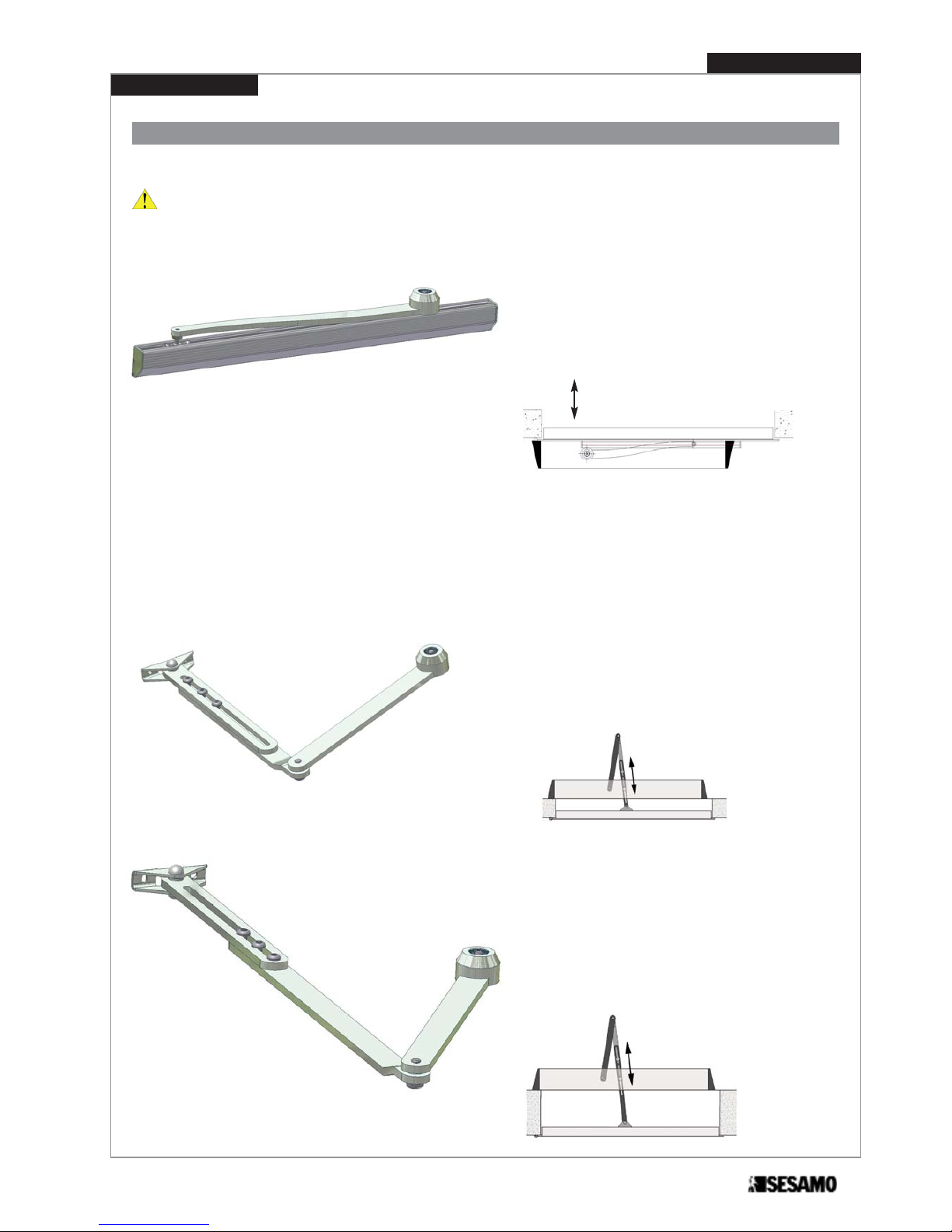

RIGID PULL ARM ARTICULATED PUSH ARM

MAX JAMB DEPTH [A] -50 ÷ +100 mm

0 ÷ 300 mm

(depending on the type of arm:

standard or long)

DISTANCE FROM THE ALU-

MINIUM BASE AND DOOR

BRACKET [B]

67 ÷ 127 mm 35 ÷ 95 mm

A

B

-50

+100

B

A

300

PROSWING (M)

Operating instruction

8

Types of arm

ATTENTION: For proper positionning, please refer to the paragraph “Arm Installation”.

PULL ARM

The pulling arm can be fitted:

- PULL (it is used when the automatism is installed

on the same side of the door opening).

STANDARD PUSH ARM

The pushing arm can be fitted :

- PUSH (it is used when the automatism is installed

on the opposite side of the door opening).

LONG PUSH ARM

The long push arm can be fitted:

- PUSH (it is used when the automatism is installed

in the opposite side of the door opening).

jamb depth = 0 ÷ 150 mm

jamb depth = 150 ÷ 300 mm

jamb depth = -50 ÷ 100 mm

Fig. 1

Fig. 2

Fig. 3

9

PROSWING (M)

Operating instruction

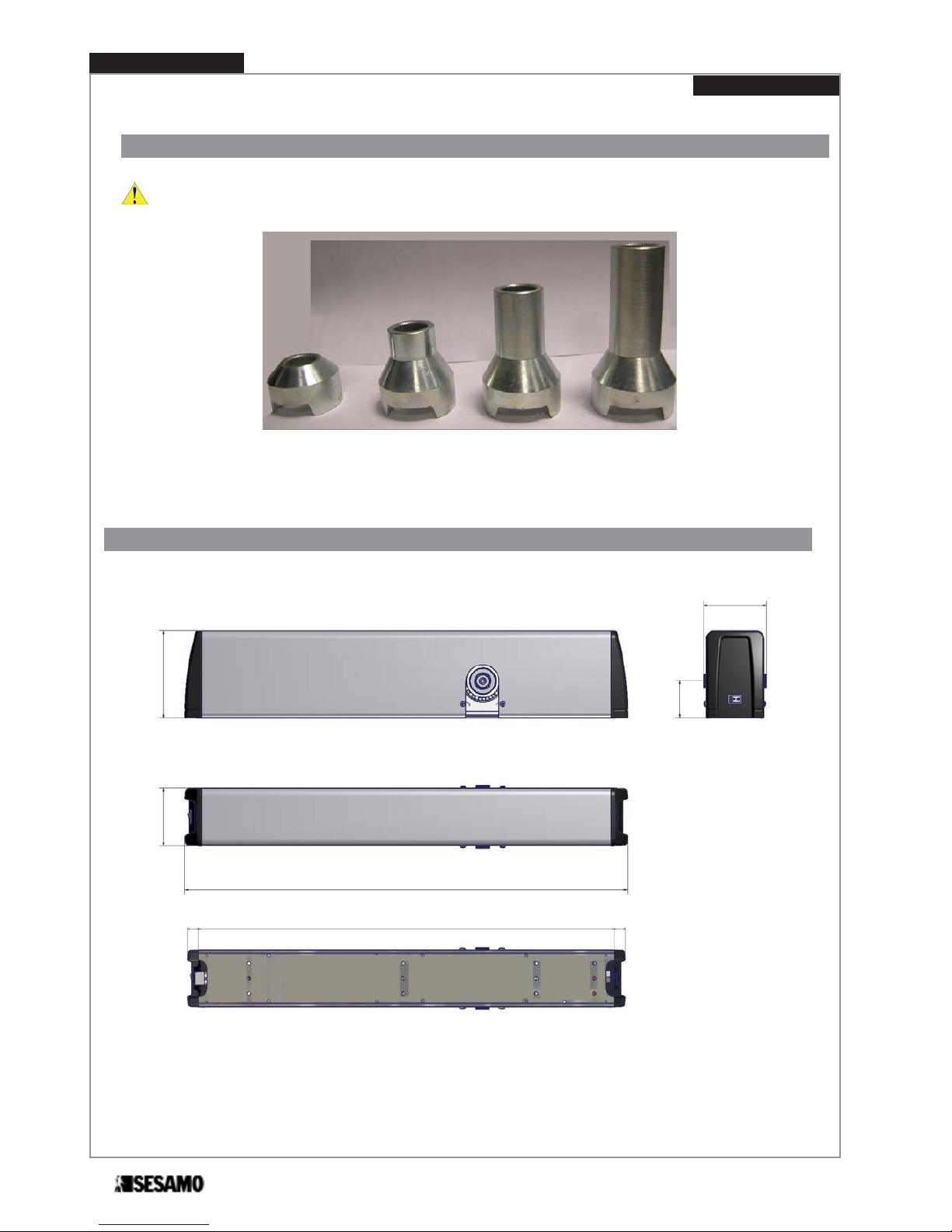

Dimensions

Arm extensions

ATTENTION: For a correct positionning refer to “arm installation” paragraph.

L=50 mm

L=70 mm

L=90 mm

Fig. 4

L=30 mm

(standard)

Fig. 5

56

130

664

86

94

17

630

17

PROSWING (M)

Operating instruction

10

Preliminary checks

Before installing the automatism please check:

- verify the installation does not create dangerous situations;

- prearrange proper pipes and counduits for the wires, granting the protection of the same against mechanical damages;

- the surface where fixing the automatism has to be resistant. Use screws, bolts, etc. adequate to the type of surface;

- the structure of the door has to be strong to hold the weight of the automatism as well the hinges, also check to not

have friction between fixed and mobile parts;

- use proper equipment and tools to install in security and in accordance with the regulations.

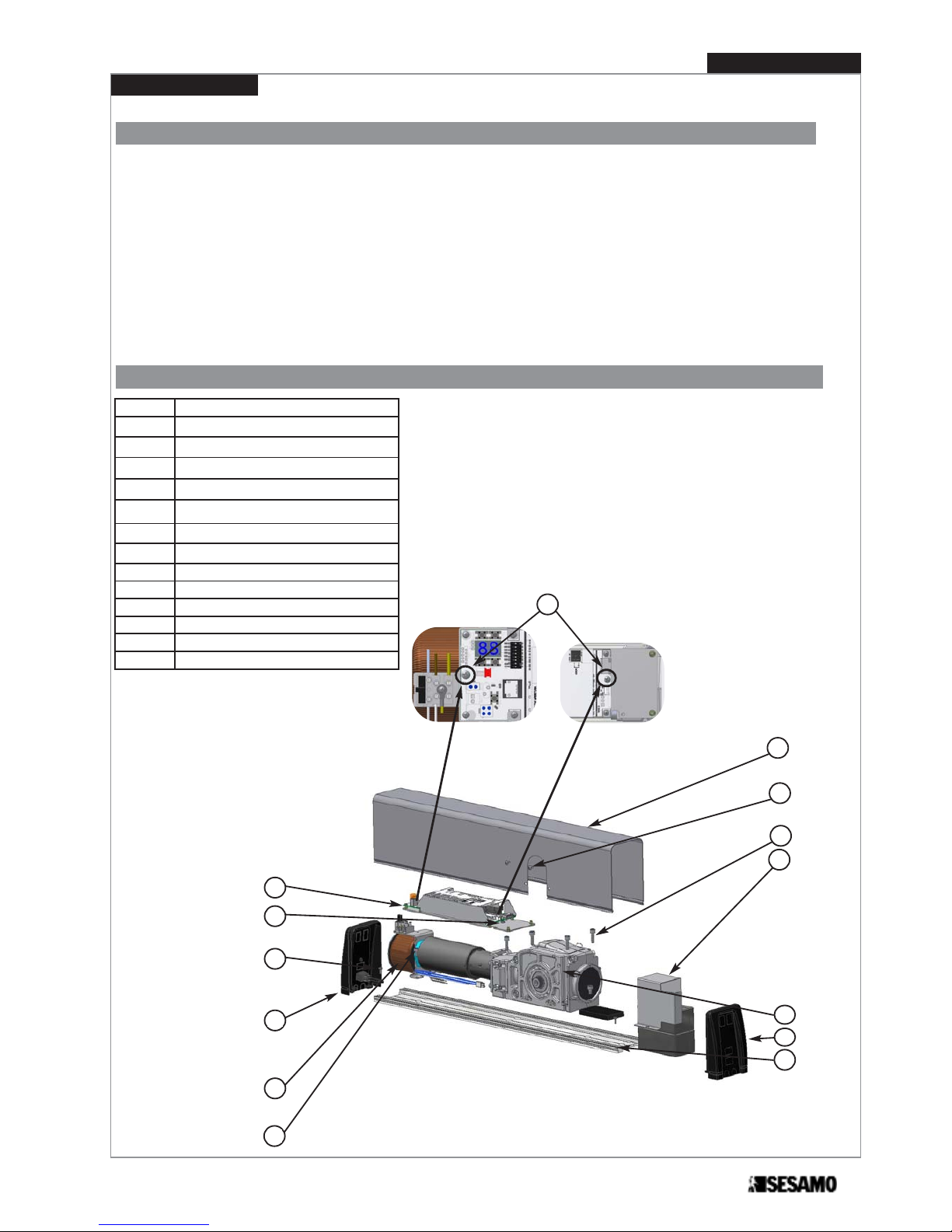

Automatism Fixing

REF. DESCRIPTION

A Cover fixing screws

B Aluminum cover

C Control board fixing screws

D Control board

E Gear motor fixing screws

F Gear motor

G Transformer fixing screws

H Transformer

I End caps fixing screws

L End cap opposite transformer side

M End cap transformer side

N Aluminum base

O

Battery group (OPTIONAL)

C

B

C

A

I

M

H

G

E

L

O

F

N

D

Fig. 6

11

PROSWING (M)

Operating instruction

To fix automatism proceed as follows:

1- remove cover (Fig.6 part.B);

2- disconnect all wiring (encoder, switches, transformer, motor) on control board;

3- unscrew the 2 screws (Fig.6 part.C) and remove control board with its support (screws remain between control board and

support);

4- unscrew the 2 screws (Fig.6 part.G) and remove transform;

5- unscrew the 4 screws (Fig.6 part.E) and remove gear motor;

6- unscrew screws (Fig.6 part.I)and remove end caps (Fig.6 part.M ed L);

7- fix aluminium base (Fig.6 part.N) to thre structure following instructions of the following paragraphs, dipending on arm type;

8- reassemble all components but end caps and aluminium cover.

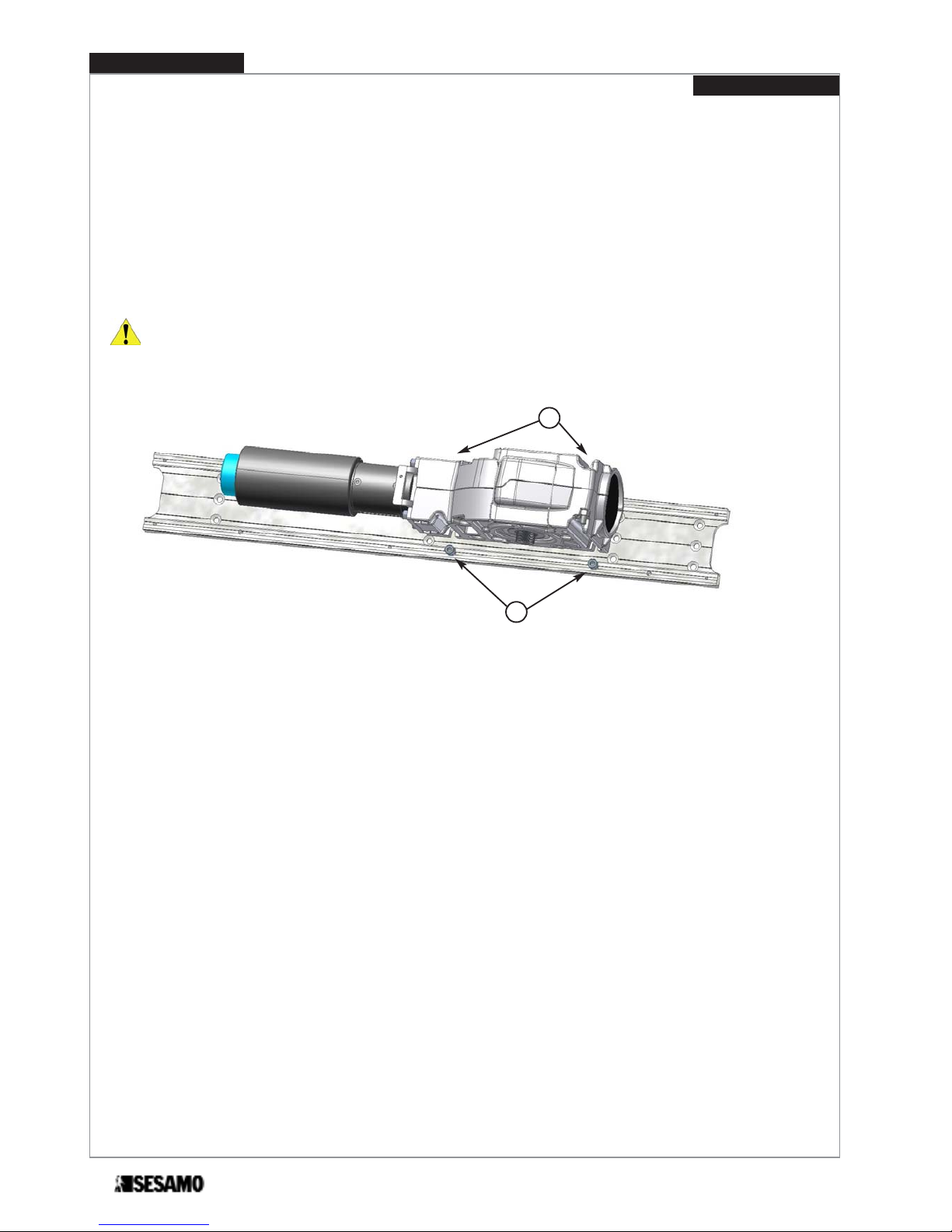

ATTENTION: to make easier reassembling gear motor, partially screw the screws (Fig. 7 part. E), then lean gear motor

on to them. Insert screws (Fig. 7 part. F).

Tight all screws paying attention that gear motor axis is perpendicular to the door top edge.

Fig. 7

E

F

PROSWING (M)

Operating instruction

12

Drilling holes according to the type of screws chosen and fix the base only after verifying the “Positioning dimensions”

listed in the paragraph concerning the type of arm selected.

Fig. 8

With double automatism prearrange the conncetion (wiring) between the two single automatisms.

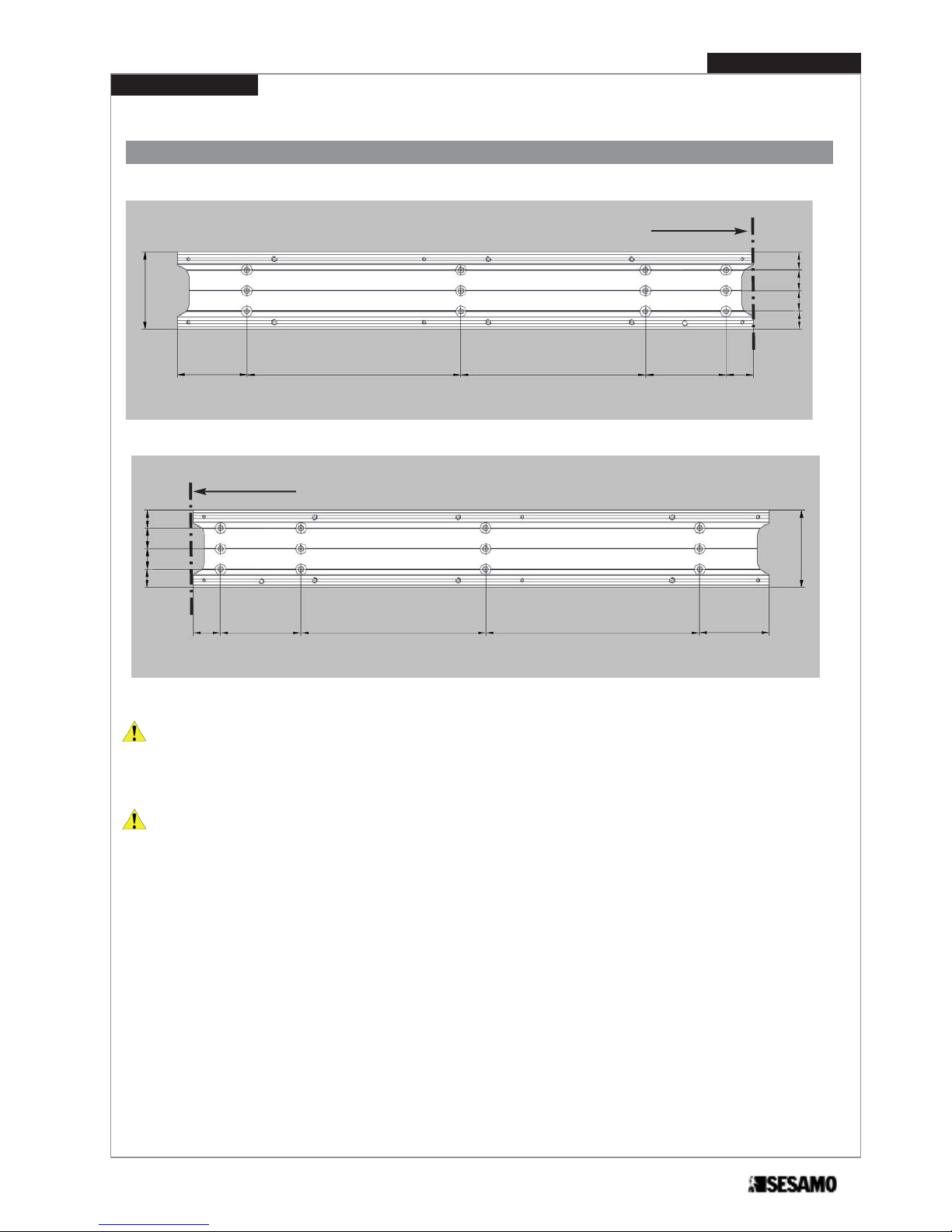

84

76

88

202

234 30

Aluminum base holes positioning

19,5

19,5

22,5

22,5

Fig. 9

84

76

88

202

23430

19,5

19,5

22,5

22,5

hinge axis

hinge axis

13

PROSWING (M)

Operating instruction

14

Operating instruction

PROSWING (M)

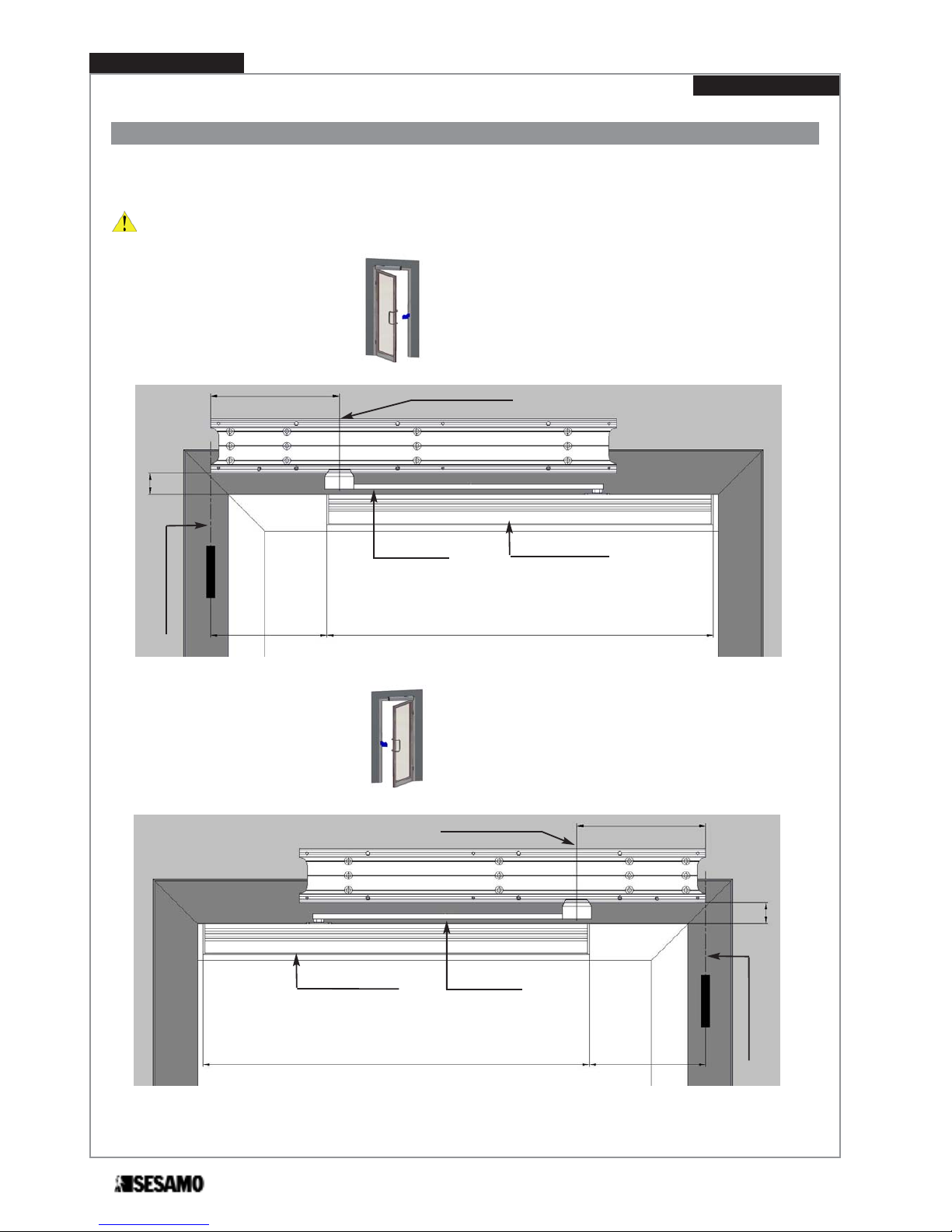

Pull arm installation

Pull arm positioning

Pull arm has to be used when automatism is installed on the same side of door opening.

ATTENTION: For a correct positionning always refer to the hinge axis and gear motor axis, as shown in Fig.10 e 11.

Door opening RIGHT (see Fig. 11)

Door opening LEFT (see Fig. 10)

Fig.10

Hinge axis

Pull arm

Sliding guide

Gear motor axis

600

180

C

200

Fig. 11

AHinge axis

Pull arm

Sliding guide

600

180

C

200

Gear motor axis

Operating instruction

PROSWING (M)

15

Sliding guide

Gear motor axis

OPENING

DIRECTION

56

C

ATTENTION: final tightening

of the screws must be performed

only after checking that vertical

positioning of the automatism

allow a good parallelism between

hinge axis and gear motor axis.

Therefore, after fixing the pulling

arm and its guide, the coupling

bolt of the arm with the cylindric

skid have not to create force in

opening/closing cycle.

A positioning error of the automatism might create bending between the bolt of the pulling arm

and the cylindric skid more than

the allowed tolerance, damage

parts of the automatism.

32

ARM EXTENSION DIMENSION “C”

Arm extension standard 35

Arm extension (L= 50 mm) 55

Arm extension (L= 70 mm) 75

Arm extension (L= 90 mm) 95

Upper door level

Fig. 12

Jamb depth=-100 mm

Within jamb depth maximum opening angle is proportionally reduced.

Jamb depth=+50 mm

Sliding guide installation

1- Unthread profile (Fig.13 Part.I) and drill 4 holes on the “V” mark on guide profile.

2- Fix guide profile horizontally to the door following dimensions shown in Fig.12.

P

O

I

Fig. 13

4- Insert washer (Fig.14 part.B) and screw (Fig.14 part.C) into arm extension (Fig.14 part.A).

5- Insert arm (Fig.14 part.D) in the arm extension slot, and tight screws (Fig.14 part.E)..

A

B

C

D

E

Fig. 14

PROSWING (M)

Operating instruction

16

6- Insert arm extension (Fig.14 part.A) on the shaft and tight screw (Fig.14 part.C) until arm extension is well fixed to gear motor

shaft.

7- Insert skid (Fig.15 part.G) inside the guide (Fig.15 part.O) and slightly open door.

8- Rotate arm until reaching skid (Fig 15 part. F).

9- Screw skid shaft (Fig.15 part.F) into the arm (Fig.15 part.Q).

10-Insert guide cover profile (Fig.15 part. I)

11-Insert right end cap (Fig.15 part.M) and the left end cap (Fig.15 part.N) onto the guide with their screws (Fig.15 part.L).

I

F

L

N

O

P

M

Fig. 15

Q

Verify the dimension about 15 mm (Fig. 16)

Fig. 16

15 mm

17

PROSWING (M)

Operating instruction

Diagram for door opening RIGHT (Fig. 17)

Hinge axis

Door bracket

Motor reducer axis

200

Diagram for door opening LEFT (Fig. 18)

Fig. 17

Hinge axis

Door bracket

Motor reducer axis

200

Fig. 18

Push arm installation

Push arm is used when automatism is installed on the opposite side of door opening.

ATTENTION: For a correct positionning always refer to the hinge axis and gear motor axis, as shown in Fig.17 e 18.

PROSWING(M)

Operating instruction

18

Operating instruction

PROSWING(M)

19

272.5

55

Hinge axis

Door bracket

Fig. 19

35

ARM EXTENSION DIMENSION “E”

Arm extension standard 8

Arm extension (L= 50 mm) 28

Arm extension (L= 70 mm) 48

Arm extension (L= 90 mm) 68

Fig. 20

OPENING

DIRECTION

Push arm

Door bracket

56

Motor axis

Jamb lower edge

ATTENTION: final tightening of the screws must be perfored only after checking arm can easily rotate under door

jamb (Fig.20).

E

Increasing jamb depth, maximum opening angle is proportionally reduced.

25

Jamb depth=0÷300 mm

For PUSH ARM proceed as follows:

1- Insert washer (Fig.21 part.B) and screw (Fig.21 part.C) into arm extension (Fig.21 part.A).

2- Insert arm (Fig.21 part.D) in the arm extension slot, as show in Fig. 21 and tighten screws (Fig.24 part.E).

3- Unscrew screws M8 x 16 (Fig.21 part.G).

4- Fix door bracket (Fig.24 part.F) to the door following dimension shown in Fig. 19 e 20.

5- Insert arm extension (Fig.21 part.A) into gear motor shaft.

6- Tight screw (Fig.21 part.C) until arm extension (part 1) is well fixed to gear motor shaft.

7- Keeping door closed, rotate arm as show in Fig. 22 and tight screws M8 x 16 (Fig. 21 Part. G).

Fig. 21

A

B

C

E

D

F

G

Fig. 22

Fix PUSH ARM to the door

PROSWING(M)

Operating instruction

20

Preliminary checking

Before electrical wiring, check as follows:

• Remove carefully dust or any other residual of the installation

• Verify automatism being well fixed

• Verify all screws well tighten

• Verify all wiring well fixed and not near moving parts

• Verify arm well fixed to door.

21

PROSWING(M)

Operating instruction

Wiring power supply

ATTENTION: Wiring the connectors of the control panel or external peripheral connections must occur in absence of

power supply in order to avoid irreversible damages of the electronic device.

ATTENTION: before performing the following operation make sure the power supply is OFF. Before starting the

automatism, check and perform as paragraph “Start up”.

Bring the power supply cable into the automatism paying

particular attention to not damage the cable against any

metal edges. Connect power supply and groud cable on

their connectors as shown in (Fig. 23)

ATTENTION: Never invert power supply cable and

ground cable.

Power suppply must be isolatable from the general panel

with a bi-polar switch with minimum contact opening equal

to 3 mm (not supplied).

Control board PROSWING (M)

Fig. 24 shows the main electronic components connection of the control board:

230V AC

Fig. 23

Fig. 24

Base or advanced

selector connector

Motor

connector

Electric lock

connector

Encoder

connector

Dip Switchs

PC Connector

output

Switch Auto/Man/Stop

open connector

ON-OFF

switch con-

nector

Transformer

connector

Display

and but-

ton

External peripherals

connector input

External peripherals

connector output

Power supply

Sensosi/Accessories

Expansion

connector

Battery

connector

PROSWING(M)

Operating instruction

22

Operating instruction

PROSWING(M)

23

Fig. 25

Connect the following terminal boards:

- logic switch [Fig. 25 part.A];

- ON-OFF switch [Fig. 25 part.B];

- transformer [Fig. 25 part.C];

- motor [Fig. 26 part.D];

- encoder [Fig. 26 part.E].

Wiring

B

C

A

Fig. 26

D

E

External peripherals connectors - Input

* NO =Normally Open NC =Normally Closed

All the input have to be referred to (COM)

PROSWING(M)

Operating instruction

24

SIGNAL

TYPE

DEFAULT*

DESCRIPTION FUNCTION

KEY NC Lock contact. Lock devices can be

connected such as electronic key,

key selector, proximity reader, etc.

If the contact opens the unit sends a complete closing

cycle command (from any position) From this moment

until the signal is closed the door stays closed and no

external peripheral is detected (including the multi-logics

selector). As soon the signal closes the door opens and

allow again the standard operating.

The signal must be short circuited with COM if no device is connected.

START 1 NO Opening contact. door opening

devices can be connected.

Closing this signal gives the command to open the door. This

signal is only monitored in 2 Radars logic, selectable through

base or advanced selectors (optionals).

START 2 NO Opening contact. door opening

devices can be connected.

Closing this signal gives the command to open the door. This

signal is monitored both in 2 Radars logic both in 1 Radar

logic selectable through base or advanced selectors (optionals).

SAFE OPEN NC Opening safe contact for safety

sensors monitoring opening cycle.

If the door is opening and the contact closes, the control

board gives a stop command immediately. Opening will only

continue after this signal is disactivated.

The signal must be short circuited with COM if no device is connected.

SAFE

CLOSE

NC Closing safe contact for safety sen-

sors monitoring closing cycle.

If the door is closing and the contact opens, the control

board gives an inversion command immediately. Closing will

only continue after this signal is disactivated.

The signal must be short circuited with COM if no devices (internal or external) are connected.

COM Common electrical contacts.

AUX IN 1/2 NA auxiliary input signal that can be

set as follows:

0 -

DDA opening

Command DDA opening (disabled people).

Opens with motor and closes with spring (LOW ENERGY

mode) with minimal idle time of 5 seconds.

1 -

Emergency open

It opens not depending on the existing logic, over takins as

priority also input KEY. It opens door with priority on all

other contacts.

2

- Inter lock with priority

Opens with priority in case of simultaneous command

3

- Inter lock without priority

It doesn’t open in case of simultaneous command

4 -

Feedback Lock released

Micro switch or contact detecting the status of lock released.

5 -

Command lock release

This contact allows to unlock manually the lock without opening door through motor.

6

- Single command in double

system

In case of Double system, opens only MASTER door.

Operating instruction

PROSWING(M)

25

ATTENTION: to connect aux out contacts see electrical wiring as shown in Fig 27.

External periphericals connectors-Output

Max contact rating: 24V - 100mA

Absorbing more than the max rating can damage control board.

NPN

NPN

NPN

PNP

PNP

PNP

Case 1 (default)

Case 2

Case 3

Case 1

Case 2

Case 3

Fig. 27

=+ OUT 15 Vdc

=- OUT 15 Vdc

B

A

→ - OUT 15 Vdc

* NO =Normally Open NC =Normally Closed

All the input have to be referred to (COM)

SIGNAL TYPE

DEFAULT*

DESCRIPTION FUNCTION

AUX OUT 1 e 2 Auxiliary output contact that

can be set as follows:

0

- Monitoring sensors

It monitorins safety sensors.

1

- Inter lock

To be connected to the input interlock of the other automatism, to obtain interlock logic.

2

- Door opened

It signals door in opened position.

3

- Door closed

It signals door in closed position.

4

- Fault

It signals door in fault.

5

- Repeat lock command

it repeats the command of the electric lock.

26

Operating instruction

PROSWING(M)

Dip-switches setting

On the control board there is a dip-switch 8 positions to adjust functionality and basic options.

Changing of setting is considered only after automatism RESET.

DipSwitch Parameter Setting

Factory

setting

1

ARM SELECTION:

OFF=push arm,

ON=Pull arm

OFF

2

LOW- ENERGY mode:

OFF=Normale,

ON=Low Energy

OFF

3

PUSH & GO:

OFF=disabled

ON=enabled

OFF

4

KEY OPERATING

OFF=Monostable

on=Bistable

OFF

5 OFF OFF

6

BATTERY MODE:

OFF=Continuos working,

ON=Open door

OFF

7

BATTERY SETTING:

OFF=Battery not installed,

ON=Battery installed.

OFF

8 Not used OFF

Operating instruction

PROSWING(M)

27

Parameters adjustment-display

ESC

ENT

+

_

It is possible to adjust several functionning parameters through two displays and relevant four push buttons(see Fig. 39).

Fig. 39

Procede as follows:

1. Select parameter thorough push buttom [+] and [-]; press [ENT] to enter in the adjustment procedure.

2. In adjustment procedure, parameter value is indicated in flashing mode. Press [+] and [-] to change value, press

[ENT] to memorize value and press [ESC] to come back to parameter selection.

3. During procedure is active a timeout; if no push buttons are pressed for 10 seconds, system exit from adjustment

mode.

- Push button [ESC] allows to exit from adjustment mode without modifications.

- Only for parameters

Sd and Lp is needed a pression on [ENT] for at least 5 seconds.

ID of the-

parameter

Description Adjustment

DEFAULT

setting

01

Opening speed RANGE: 20°/s ÷ 70°/s (step of 5°/s) 60

02

Closing speed RANGE: 10°/s ÷ 40°/s, (step of 5°/s) 30

03

Idle time RANGE: 0 ÷ 60 sec, (step of 1 second) 0

04

Idle time in Low Energy RANGE: 5 ÷ 60 sec, (step of 1 second) 5

05

Force in closing position RANGE: 0 – 9 (0=no force, 9= max force) 5

06

Anticrushing

RANGE: 1 ÷ 9 It is applied both for opening and closing

(1=more sensitive; 9=less sensitive)

5

07

Acceleration RANGE: 5 ÷ 30 It is applied both for opening and closing 20

08

Approaching angle

RANGE: 10 ÷ 40 It is applied both for opening and clo-

sing (closing 1/2 of opening)

20

09

Electric lock power 0=12 VDC 1=24 VDC 0

10

Lock type

0 = Lock not installed

1 = Impulsive with restore at closing

2 = Mag lock

3 = Fail safe

4 = Motorized

5 = Impulsive with restore power cut off

0

11

Deelay in opening after lock power. RANGE: 0 ÷ 9 time depends on lock type:

Impulsive with restore at closing 50÷500ms

Mag lock & Fail safe 200÷2000ms

Motorizzed 500÷5000ms

Impulsive with restore power cut off 100÷1000ms

2

open

t

PROSWING(M)

Operating instruction

28

ID of the-

parameter

Description Adjustment

DEFAULT

setting

12

Lock closing force RANGE: 0(min) ÷ 9(max) 5

13

Conditions Single/Double

0 = Single

1 = Double Master

2 = Double Slave

0

14

Block by motor on closed door according

the selected logic

0 = DDA opening

1 = One Radar

2 = Two Radars

3 = One Radar and Two Radars

1

15

Auxiliary input configuration 1

0 = DDA opening

1 = Emergency opening

2 = Interlock door with priority

3 = Interlock door without priority

4 = Feedback lock release

5 = Command lock release

6 = Command Single on Double door

0

16

Auxiliary input configuration 2

0 = DDA opening

1 = Emergency opening

2 = Interlock door with priority

3 = Interlock door without priority

4 = Feedback lock release

5 = Command lock release

6 = Command Single on Double door

1

17

Auxiliary output configuration 1

0 = Monitoring of the sensors

1 = Interlock

2 = Stop open condition

3 = Stop closed condition

4 = Failure

5 = Ripetizione comando serratura

0

18

Auxiliary output configuration 2

0 = Monitoring of the sensors

1 = Interlock

2 = Stop open condition

3 = Stop closed condition

4 = Failure

5 = Ripetizione comando serratura

1

19

MultiMaster

0 = No managing Multimaster,

1 ÷ 15 Keynote for MultiMaster connections

0

20

Opening safety sensor exclusion

Angle opening safety exclusion

RANGE: 0 ÷ 40% of total angle opening

30

21

Phase displacement in opening for double

door

RANGE: 0 - 100 displacement in opening unit of

100 ms (0=syncronized)

0

22

Phase displacement in closing for double

door

RANGE: 0 - 100 displacement in closing unit of

100 ms (0=syncronized)

0

23

Polarità ingresso Safe Open

0 = NO (Normally Open)

1 = NC (Normaly Close)

1

24

Polarità ingresso Safe Close

0 = NO (Normally Open)

1 = NC (Normaly Close)

1

25

Polarità ingresso Key

0 = NO (Normally Open)

1 = NC (Normaly Close)

1

26

Polarità ingresso Start 1

0 = NO (Normally Open)

1 = NC (Normaly Close)

0

27

Polarità ingresso Start 2

0 = NO (Normally Open)

1 = NC (Normaly Close)

0

28

Polarità ingresso Aux In1

0 = NO (Normally Open)

1 = NC (Normaly Close)

0

29

Polarità ingresso Aux In2

0 = NO (Normally Open)

1 = NC (Normaly Close)

0

Operating instruction

PROSWING(M)

29

ID of the-

parameter

Description Adjustment

DEFAULT

setting

30

Polarity output Aux Out 1

0 = NO (Normally Open)

1 = NC (Normaly Close)

0

31

Polarity output Aux Out 2

0 = NO (Normally Open)

1 = NC (Normaly Close)

0

32

Force level during reset

RANGE: 0÷9 (0=force min,

9=force max)

5

tS

Automatic test

0 = No Test

1 = Ciclycal

2 = Ciclycal fast

0

Sd

Set to default

1-Select command with buttons [+] e [-];

2-Press [ENT];

3-Display [--];

4-Press again[ENT] for 5 seconds to confimr;

5-When disappears [--] release [ENT].

-

Lp

Learning cycle

1-Select command with buttons [+] e [-];

2-Press [ENT];

3-On display [--];

4-Press again[ENT] for 5 second to confirm;

5-When disappears [--] release [ENT].

-

During parameters setting any movement of motor is allowed.

When it is not used parameters setting, push button [ENT] is an opening command (only with One Radar or Two

Radars logics).

1- Switch in “OFF” (position 0).

Check again DipSwitch, expecially Dip n° 1 e 5.

Check again that KEY and SAFE CLOSE are regulary connected or, if not used, connected to COM.

2- Switch power ON from main switch (230 V).

3- Switch in “ON” (position 1).

4- Check display is lit and that

E1

is shown on dislay; if E2appears check arm setting.

5- If necessary set jumper to correctly see diplay (see Fig. 31).

Start up

Fig. 29

Fig. 30

DipSwitch Parameter Setting

1

ARM SELECTION:

OFF=push arm,

ON=Pull arm

5 OFF

AUTOMATISM FOR RIGHT OPENING

AUTOMATISM FOR LEFT OPENING

Hinge axis

Hinge axis

jumper

jumper

Fig. 31

PROSWING(M)

Operating instruction

30

6. Press push buttons [+] e [-] until LPappears; press [ENT] until [--] appears; press again[ENT] for 5 seconds; when

disappears [--] release push button [ENT].

7. Door will start learning cycle, opening direction.

ATTENTION: when door reaches desired opening position, stops door in that position: this position will be memorized as max opening. Immediately after, door will close completely at slow speed with display

CL

blinking.

When door is in closed position and

CL

stop blinking, it is possible to check functioning pressing [ENT]: door has to

open and close regulary.

During the functioning, max opening angle is reduced as a factory setting. This parameter is modificable through

software MillenniumWare (advanced parameter → % reduction opening angle).

First cycle (opening/closing), after (RESET) will be at slow speed.

ESC

ENT

+

_

Fig. 32

31

PROSWING(M)

Operating instruction

Code Description

OP

Fixed

Door opened

OP

Blinking

Door opening

CL

Fixed

Door closed

CL

Blinking

Door closing

E1

Door needs self learning procedure (see Paragraph “Start up”)

E2

Wrong arm selected (DIP 1), or wrong selection automatism (DIP 5)

E3 / E4

Over Current

E8

NO encoder.

Display are also used to show message or error code:

Message or errors code

Operating logics

Operation Description

LOW-ENERGY

In all operative procedures (except Stop Close) it is possible a motor opening with a reduced

speed (Low Energy speed) and higher idle time (idle time for disabled people) using the ope-

ning command for disabled [AUX IN 1set through parameters 15=0

(paragraph “Parameter

adjustment display”)]. The following closing is by spring.. The following closing is by spring.

PUSH & GO

An opening/closing automatic movement is possible by a manual moving of door that is in a closed position.

Set DIP 3 = ON.

SAFE CLOSE

If the safety sensors on the closing part of the door and connected to the control board on (Safe

Close) detects an obstacle whilst the door is closing, it will immediately stop and reverse the

motion of the door opening it completely at standard speed and then closing it at normal speed.

Detection of obstacles whilst the door is opening does not cause the system to react.

SAFE OPEN

If the safety sensor on the opening part of the door (Safe Open) detects an obstacle whilst the

door is opening, it will immediately stop the motion of the door. If the detenction stops, the door

will continue to open and then close at normal speed.

Detection of obstacles whilst the door is closing does not cause the reaction of the system.

If the door opens near a wall (in a corridor, for example) it is possible to cancel the final part of

opening in such a way sensor does not detect wall. This parameter is modificable through

parameter 20

(see paragraph “Parameter adjustment display”) or software MillenniumWare.

Operating logic

Manual

START 1 and START 2 are not monitored. Open and close only through push button on selector or low energy or manually pushing the door.

1 radar

Exit-only radar: only the input START 2 of the electronic control card is monitored. A signal ori-

ginating from a sensor connected to this input triggers the opening and consequent closing of

the door doors. The electric locking system, if present, blocks the door doors every time that

these reach the position of complete closure

2 radar

Entry-exit radar : both the inputs START1 and START2 of the electronic control card are moni-

tored. A signal originating from a sensor connected to one of these inputs triggers the opening

and consequent closing of the door doors.The electric locking system, if present, never blocks

the door doors.

Stop

Close

The automatism controls the complete closure of the door doors. In this logic the inputs START1

and START2 of the electronic control card are not monitored;if present, the electric locking

system blocks the door doors.

Stop

Open

The automatism controls the complete opening of the door doors.In this logic the inputs START1

and START2 of the electronic control card are not monitored.

Opening anti-crush

Whilst opening if door encounters an obstacle it stops movement for few seconds. After a while

door closes completely at low speed. Sensibility adjustable through parameter

06

(see para-

graph “Parameter adjustment display”) or software MillenniumWare.

Closing anti-crush

Whilst closing if door encounters an obstacle it stops, than opens completely at low speed. After

closes will be at slow speed. Sensibility adjustable through parameter

06

(see paragraph

“Parameter adjustment display”) or software MillenniumWare.

PROSWING(M)

Operating instruction

32

Electric lock selection and setting

33

PROSWING(M)

Operating instruction

The following types of electric locks are allowed (See parameters 10- see paragraph “ Parameters adjustment-display”):

IMPULSIVE LOCK WITH RESTORE AT CLOSING(Parameter 10=1)

MAG LOCK (Parameter 10=2)

command

(Parameter 11)

voltage lock

voltage lock

(Parameter 11)

command

It is possible to feed 12 or 24 Vdc. Looks max power is 15W.

[set through parameter

09

(paragraph “Parameter adjustment display”)]

If the electric lock has a feedback contact it is possible to use it to enable door opening. If the feedback dos not arrive

the door, after a certain time, will try to open anyway. See parameters

15 e16

(see paragraph “ Parameters adjustment-

display”).

It possible to modify, depending on the electric lock type used, activation pulse length or delay from lock activation

pulse command to start of door movement. See parameter

11

( see paragraph “ Parameters adjustment-display”).

Parameter 11 has different meaning and range depending on type of lock used.

It is possible to adjust last final closing force to facilitate closing with impulsive locks.

[set through parameter

12

(paragraph “Parameter adjustment display”)]

It is possible to use aux input contact as a lock activation pulse, working in “parallel” with automatic function. In such a

case it is possible to unlock the lock with the operator in manual logic. See parameters

15 e16

( see paragraph “

Parameters adjustment-display”).

IMPULSIVE WITH

RESTORE AT CLOSING:

Lenght of lock impulse. Door starts when impulse is finished or if it is arrived feedback signal.

MAG LOCK /

FAILE SAFE:

Delay to start after lock impulse. Lock remains not feeded until door is closed again.

MOTORIZED: Delay to start after lock impulse. Lock remains not feeded until door is closed again.

IMPULSIVE WITH

RESTORE AT POWER

CUT OFF:

Lenght of lock impulse. Door starts when impulse is finished or if it is arrived feedback signal.

Moreover power is on until door has reach 10°

34

Operating instruction

PROSWING(M)

With door in closed position the lock (for type 2-3-4) is released conforming to the value set for parameter 14and conforming to the logic selected on selector.

FAIL SAFE LOCK (Parameter 10=3)

MOTORIZED LOCK (Parameter 10=4)

IMPULSIVE LOCK WITH RESTTORE AT POWER CUT OFF (Pameter 10=5)

= BACK HIT

LEGEND

= START OPENING

= START CLOSING

= DOOR CLOSED

voltage lock

voltage lock

voltage lock

100÷1000 (Parameter 11)

(Parameter 11)

(Parameter 11)

command

command

Operating instruction

PROSWING(M)

35

Selectors terminal board

Real power value may vary from 15 Vdc to about ± 10%, depending on the resistive load situations connected to these

terminals.

Terminal OUT / 15 VDC : POSITIVE ( + )

Terminal COM : NEGATIVE ( - )

ATTENTION

Do not invert power polarity. When the green led is on it indicates normal voltage presence 15V. If off check:

• For mains voltage

• That fuse is not interrupted

Use the four conductors in the shielded wire for connections, observing the correspondences indicated by the markings

on the terminal board and multi-logic selector.

Do not connect the shield of the wire used.

For further information on multi-logic selector use, see the instructions for use.

External peripheral power connector

(15 Vdc)

Shielded cable with 4 wires

0,22 mm. (Do not connect

the shield of the wire used)

Fig. 33

ADVANCED SELECTOR

BASE SELECTOR

B

A

PROSWING(M)

Operating instruction

36

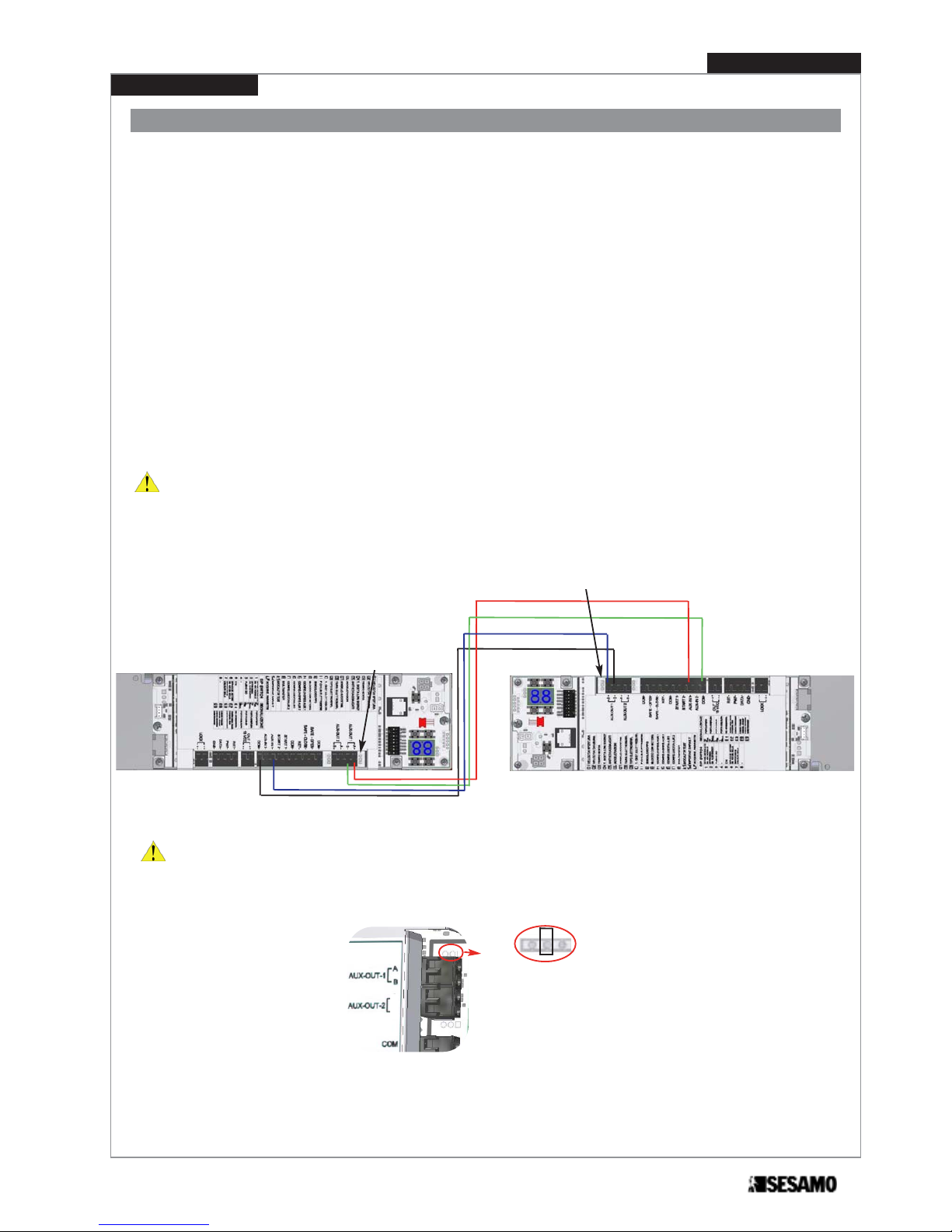

Wiring and use for double Proswing

Double Proswing is an automatism for double door.

It is possible to realize a double door in two ways:

1. with two Proswing installed on each door and then connected together ;

2. with two Proswing installed on each door and connected together by a extension kit (OPTIONAL).

SOLUTION 1

SOLUTION 2

The two Proswing, through a wiring on the selector terminal board, can exchange information in order to rightly drive the

two doors. It is needed to set one control door as a Master and one as a Slave. The Slave acts only the Master command.

For solution 1 proceed as follows:

1- remove all components on both automatisms (in order : covers, end cap, control boards, motor gears, transformers);

2- fix the aluminum base of each single automatism on the relevant door following instructions described at paragraph

“aluminum base holes positioning” – depending on the type of arm used;

3- connect together selectors terminal board in order to allow communication between the two cards (Fig. 36)

4- assemble again all the components taking care of disconnecting the selector switch of slave door (see Fig. 45)

For solution 2 proceed as follows:

1- remove all components on both automatisms (in order : covers, end cap, control boards, motor gears, transformers);

2- put the two aluminum base and the central joining base on a plane surface (Fig. 34);

3- insert each base under the tongue of the two joining parts as showed (Fig. 35);

ATTENTION: Maintain the orientation of the aluminum bases as shown in Fig 46, so that the black end caps are

positioned at the ends.

4- tighten screws (Fig. 45 part A)in order to obtain one single piece;

5- fix the piece to the structure or wall following the instruction and positioning dimensions described at the paragraph

“aluminum base holes positioning” and paragraph of the arm depending on the type used;

6- connect together selectors terminal board in order to allow communication between the two cards (Fig. 36);

7- assemble again all the components except end caps. As end caps use th two supplied with the extension positioning

the one with logic and power switches on the master door and the one with only power switch on slave door.

ATTENTION: for both cases define, before making any connections, the door and the door Slave Master.

Conventionally:

MASTER DOOR: is the first in opening and the last in closing (in case displacement)

SLAVE DOOR: is the second in opening and first in closing (in case displacement).

Operating instruction

PROSWING(M)

37

For both solutions, we must follow the following instructions to configure the electronic boards:

1- To define Master and Slave use parameter 13:

• MASTER (parameter 13 =1);

• SLAVE (parameter 13 =2);

Even in case of door without displacement it is necessary to set Master and Slave .

ATTENTION: use same power line for the two automatisms without any fuses or switches. Peripherals command

SAFE CLOSE, KEY, START 1 e START 2 have to be connected to Master door. SAFE OPEN command have to be

connected separately on each control boards.

Fig. 34

Hinge axis SX

Hinge axis DX

PROSWING ON RIGHT

PROSWING ON LEFT

PART OF UNION

Fig. 35

A

A

PROSWING(M)

Operating instruction

38

Fig. 36

DATA

PWF

GND

MASTER BOARD

SLAVE BOARD

Connection

selector

(optional)

Closing cycle will start only if both door have reached their own opening position. Re-opening after command or anti crushing (even on only one door) will be on both doors.

Electric lock operation it is possible independently for each door.

Push & go: pushing one door will generate opening for both doors.

Anti crushing are independent for each door. Anti crushing in closing generates re-opening for both doors. Anti crushing in

opening stops only the door touched, the second one will open completely waiting for the other to finish its opening cycle.

ATTENTION:

Parameters modified through Millenniumware must be set separately on each control board.

2- In case of door with overlapping it is necessary to set displacement movement. Usually in opening a slight displacement

is enough, but in closing, where it is important to be sure to close on the right overlapping, an higher delay between the

two doors is needed.

If there is no overlapping: set on MASTER parameter

21

=0 and parameter 22=0;

If there is overlapping: set on MASTER parameter

21

and parameter 22more than 0

3- To set in function automatisms follow Start up paragraph procedure, considering that learning parameter (point 6 and 7)

has to be carried out only on Master door.

ATTENTION: when learning procedure starts it opens first master door. It is necessary to stop the door in the max

opening desired point. Immediately after it starts opening the slave door and even for this door it is necessary to

stop the door in the max opening desired point. After this operation the doors will both start closing cycle (

CL

on

display blinking). When arrived in closed position

CL

stops blinking and door is ready to work.

Selector (optional) must be connected only on Master door. Parameters modified through selector will be changed both on

master and Slave door. (Fig. 36)

Operating instruction

PROSWING(M)

39

Fig. 37

Disconnect

JUMPER

BOARD WITH PRIORITY

BOARD WITHOUT PRIORITY

Disconnect

JUMPER

Proswing control board can work in inter lock with another pro swing board. Inter lock means that it is possible to open/close

only one door at a time. To connect two boards proceed as follow (Fig. 37):

• connect “board with priority” AUX IN 1 to “board without priority” AUX OUT 1-A

• connect “board with priority” COM to “board without priority” AUX OUT 1-B

• connect “board with priority” AUX OUT 1-A to “board without priority” AUX IN 1

• connect “board with priority” AUX OUT 1-B to “board without priority” COM

Use 4x0,22 shielded cable, do not connect shield.

Set priority for opening in case of simultaneous command through parameters 15 and 17:

• set parameter

15

=2 on “board with priority”;

• set parameter

17

=1on “board with priority”;

• set parameter

15

=3 on “board without priority”;

• set parameter

17

=1 on “board without priority”;

In this way in case of simultaneous command will open Master as a first door.

Inter lock wiring and use

ATTENTION: In case of inter lock wiring between two double Proswing the wiring has to be made between the

two master boards, whereas one of the two will be considered with priority and the other with out priority to the

interlock functioning.

NPN

PNP

Disconnect jumper near AUX OUT-1 both on board with priority and board without priority (Fig. 38).

Fig. 38

B

A

Power kit (OPTIONAL)

A

B

C

D

Fig. 39

Fig. 40

E

E

PROSWING(M)

Operating instruction

40

Black cable

Red cable

To install power kit batteries proceed as follows:

1- Fix the sponge (A) as shown in Fig. 39, using as reference the aluminum base profile bottom line;

2- Insert the two batteries (C) in the supporting metallic bracket (B) and fix the whole assembling through screw M6x10

(D);

3- Connect cables as shown in Fig. 40;

G

F

Fig. 41

Fig. 42

H

I

Fig. 43

4- Pass cables through springs (E) , then under the control board until the part of control board where is located the

transformer Fig. 41. Fix cables as shown in Fig . 41 (F) and (G).

5- Connect the batteries cables terminal board to control board Fig. 42 (H)

6- Insert control board for batteries (I) on main control board Fig 43

7- Set dip switch 7 =ON and dip switch 6 (=OFF if it is required continuous use after power failure or =ON if it is requi-

red stop open after power failure)- Fig. 44.

Fig. 44

41

PROSWING(M)

Operating instruction

Logic switch

STOP CLOSE

AUTOMATIC

STOP OPEN

Fig. 45

In addiction to base or advanced selectors it is possible to connect a switch selector.

This switch selector has its place near ON-OFF switch, and it is directly wired to control board o it allows three logics:

- STOP CLOSE

- AUTOMATIC

- STOP OPEN

If base or advanced selector is connected, switch selector is excluded.

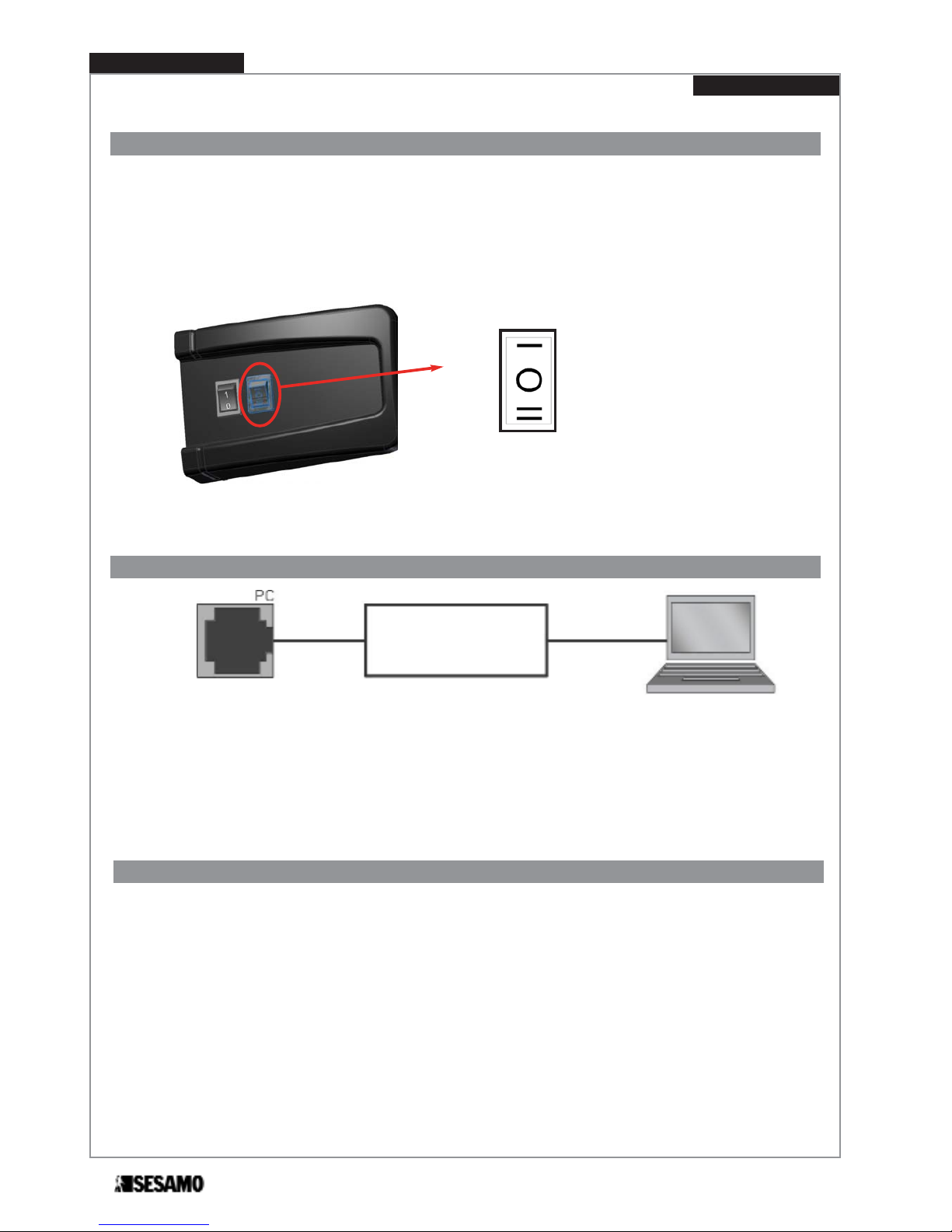

For PC connection board (optional) is required to connect the PROSWING unit to a Personal Computer. The following is possible with MILLENNIUM WARE software:

• Advanced adjustments of some operating parameter

• Diagnostic and advanced information on status

• Microprocessor programming

PC connection board

Connector for PC - unit connections

Close the automatism’s cover and tight screws.

Hand the guarantee and test certificate over filled according to the instructions shown in the certificate.

The certificates must be sent to SESAMO in 8 days from the positive test date. Hand the technical documentations over to

the client .

Delivery modality

PROSWING(M)

Operating instruction

42

Fig. 46

SESAMO srl

Str. Gabannone, 8/10 • 15030 Terruggia (AL) • Italy

Tel: +39 0142 403223 • Fax: +39 0142 403256

www.sesamo.eu • E-mail: info@sesamo.eu

PROSWING (m)

MAN_PRO.M_EN_0_02_12

Loading...

Loading...