Automatisms for sliding doors

INSTALLATION INSTRUCTION

2

Installation Instruction

LIGHT MILLENNIUM

3

Index

Technical specifications ...................................................................................... page 5

Automatism installation preparation.................................................................... page 5

Automatism description ...................................................................................... page 5

Automatism girder assembly .............................................................................. page 6

Wing assembly and adjustment.......................................................................... page 10

Final operations .................................................................................................. page 14

Power connections .............................................................................................. page 15

MILLENNIUM electronic board............................................................................ page 15

Electrical connections.......................................................................................... page 16

Left Side Electronic Board Connections ............................................................ page 16

Right Side Electronic Board Connections .......................................................... page 17

Led functions ...................................................................................................... page 20

Dip Switch - Selections........................................................................................ page 20

Semi-automatic mode ........................................................................................ page 20

Battery mode ...................................................................................................... page 20

Jumpers .............................................................................................................. page 21

Start up ................................................................................................................ page 21

Inter lock connection and use ............................................................................ page 22

Error Message Table............................................................................................ page 22

SESAMO reserves the right to change the technical specifications of the products, even without notice.

4

Installation Instruction

Thank you for choosing this product. For best automatism

performance, Sesamo recommends you carefully read and

follow the installation and use instructions found in this manual. Installation of this automatism must only be performed

by the professionally qualified personnel for whom this manual is addressed. Any errors during installation may be

harmful to people or things. Packaging material (wood, plastic, cardboard, etc.) should not be scattered in the environment or left within the reach of children as potential sources

of danger. Every installation phase must be performed in

accordance with the regulations in force and following Good

Technique standards. Before beginning installation make

sure that the product is integral and has not been damaged

during transportation or by poor storage conditions. Before

installing the product make sure that each architectural and

structural element of the entrance (girder fastening surfaces,

casings, guide, etc.) is appropriate and sufficiently robust to

be automated. Conduct a careful risk analysis and make

suitable modifications to eliminate conveyance, crushing,

cutting and hazardous areas in general. Do not install the

product in environments where gas, steam or inflammable

fumes are present. The manufacturer is not liable for any

neglect of “good technique” or specific regulations in the

construction of the casing to be motorised and any collapse

of the same. All automatic entrance safety and protection

devices (photocells, active sensors, etc.) must be installed

in accordance with the regulations and directives in force,

with the completed risk analysis, system type, use, traffic,

forces and inertia in play. Pay careful attention to area where

the following may occur: crushing, cutting, conveyance and

any other type of hazard in general applying, if necessary

suitable indications. Indicate the motorised door identification information on every installation. Make sure that the

upstream electrical system is correctly dimensioned and

has all the opportune protections (circuit breakers and

fuses). Only use original spare parts in maintenance and

repairs. Do not tamper or alter devices in the automatism

and all the safety devices in the control panel for any reason.

The manufacturer is not liable if parts within the automatism

are altered or tampered with or if safety devices other than

those indicated by the manufacturer are used in the system.

The automatism installer must provide the automatic

entrance manager with the use manual and all the information required for correct use in automatic and manual

modes (even for electronic locking) and in the event of

emergency.

Pay careful attention to the messages in this manual that are

marked with the hazard symbol. They can either be warnings aimed at avoided potential equipment damage or specific signals of potential hazard to the installer and others.

This device was designed to automate sliding doors. Any

other use is considered contrary to the use foreseen by the

manufacturer who therefore shall not be held liable.

Machine directive

The installer who motorised a door becomes the automatic

door machine manufacturer according to directive 98/37/CE

and must:

• Arrange the Technical Booklet with the documents indicated in attachment V of the Machine Directive and keep

them for at least 10 years.

• Draft the CE declaration of conformity according to

attachment II-A of the machine directive and provide the

use with a copy.

• Apply the CE markings on the motorised door according

to point 1.7.3 of attachment I of the machine directive.

For more information and for assist installers in applying the

specifications of the directives and of European standards

concerning the safe use of motorised gates/doors consult

the guidelines available on internet at the address

www

.sesamo.eu

Machine conformity directive

(Directive 98/37 CE, Attachment II, part B)

Manufacturer: SESAMO S.r.l.

Address: Str. Gabannone 8/10 - 15030

Terruggia - AL

Declares that the product LIGHT MILLENNIUM

• Is built to be incorporated in a machine or to be assembled with other machinery to build a machine considered

by Directive 98/37 CE, as modified;

• Therefore it is not fully compliant to the dispositions of

this Directive since it is not yet assembled with other

components.

• It is in conformity to the following other CE directives:

89/336/CEE Electro-magnetic compatibility and further

modifications 73/23/CEE Low Voltage and further modifications and also declares that the machinery cannot be

used until the machine it is incorporated in or is a component of has been identified and its conformity to

Directive 98/37 CE conditions and national legislation

declared.

Terruggia, 20/06/2003

Aldo Amerio

(Administrator)

LIGHT MILLENNIUM

Installation Instruction

5

Technical specifications

Power supply 230V ac 50 Hz

Nominal power 180 W

External device power 12Vdc – 6W

Emergency battery 24 V 1.2 Ah for about 100 manoeuvres in the event of power failure

Opening speed Adjustable up to 70 cm/sec. (1 wing) or up to 140 cm/sec. (2 wings)

Closing speed 70% of opening speed

Capacity One wing 120 Kg

Two wings 80+80 Kg

Wing dimensions One wing 700÷3000 mm.

Two wings 450÷1500 mm.

Working temperature Internal cross-piece from 0°C to +50°C

Anti-crushing Automatic traction restriction in the presence of obstacles

Weight 8,5 kg per linear meter

Service Intensive

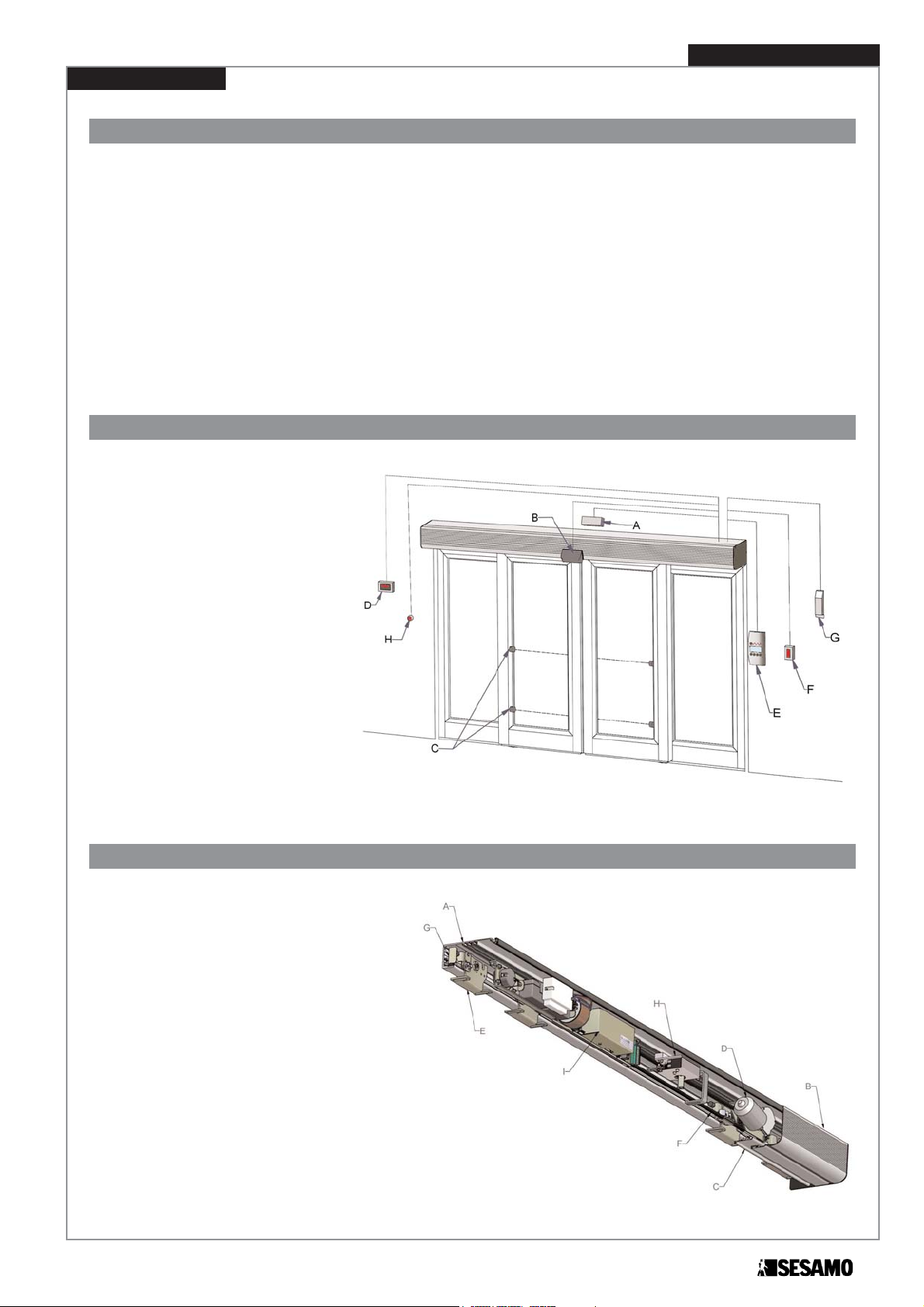

Automatism installation preparation

The automatism is prepared to work

in different accessory and peripheral

configurations. Fig. 1 shows a complete installation where the possible

automatism box access points for

peripheral connections are indicated.

These peripherals include:

A. Entry Radar

B. Exit Radar

C. Safety photocells

D. Circuit breaker (230Vac)

E. Logic selection selector

F. Reset button

G. Manual release handle

H. Safety closing device

Automatism description

The Light Millennium automatism (Fig.2)

is essentially made up of:

A. Extruded aluminium alloy box

B. Extruded aluminium alloy automatism cover

(optional)

C. Bumper profile (optional)

D. Gear motor unit

E. Carriage complete with non-derailment device

and steel wheel.

F. Transmission belt

G. Wing limit stop

H. Electronic wing lock (optional)

I. Integrated movement control modul

Fig. 1

LIGHT MILLENNIUM

Fig. 2

6

Installation Instruction

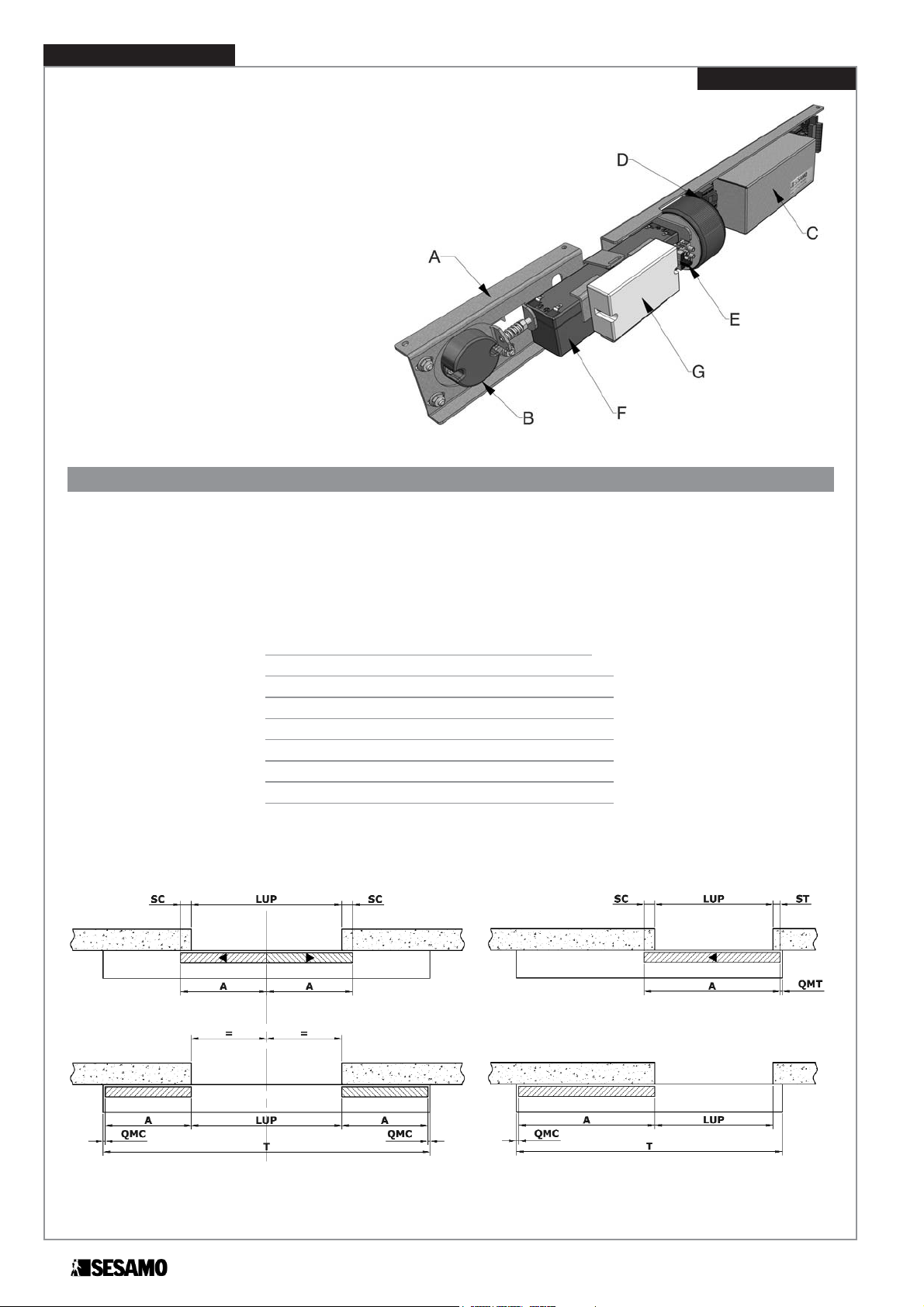

The integrated movement control module (Fig. 3)

is essentially made up of:

A. Base support plate

B. Encoder unit with belt adjustment device

C. Electronic control panel

D. Transformer

E. Mains connection terminal board (230Vac)

F. Emergency battery (optional)

G. Safety electronic key decoder (optional)

Automatism girder assembly

Positioning quotas

The automatism must be centred to the transit area in two-wing cross-pieces so that the wings meet in the middle of the

light space (Fig. 4).

For single wings observe the indications and machine quotas found in Fig. 5.

Cross-pieces with extensions (any unused box areas) should be positioned with the extensions summing QMC and QMT.

For the abbreviations found in Fig.4 and Fig.5 refer to the following table:

Lup: Working transit width

A: Sliding wing width

St: Top wing clearance

Sc : Bottom wing clearance

T : Total box length

QMT : Top machine quota (5mm)

QMC : Bottom machine quota (5mm)

Fig. 4 Fig. 5

Fig. 3

LIGHT MILLENNIUM

Vertical cross-piece positioning must occur so that the

indications in the formulas in:

Fig.6 if standard wing profiles are used;

Fig.7 if Sesamo mod. SMALL wing profiles are used;

Fig.8 if Sesamo mod. MAGNUM wing profiles are used.

For the abbreviations found in Fig.6, Fig.7 and Fig.8 refer

to the following table::

Installation Instruction

7

LIGHT MILLENNIUM

HAF : Fixed wing height

HAS : Sliding wing height

HCa : Automation box height

HCo : Automation cover height

Fig. 6 - Standard wing profiles

Standard

wing profiles

(Fig.6)

Sesamo

SMALL

wing profiles

(Fig.7)

Sesamo

MAGNUM

wing profiles

(Fig.8)

HAS = HAF + 17 mm HAF + 22 mm HAF + 6 mm

HCa = HAF + 47 mm HAF + 54 mm HAF + 44 mm

HCo = HAF HAF + 7 mm HAF - 3 mm

Fig. 7 - Sesamo SMALL wing profiles Fig. 8 - Sesamo MAGNUM wing profiles

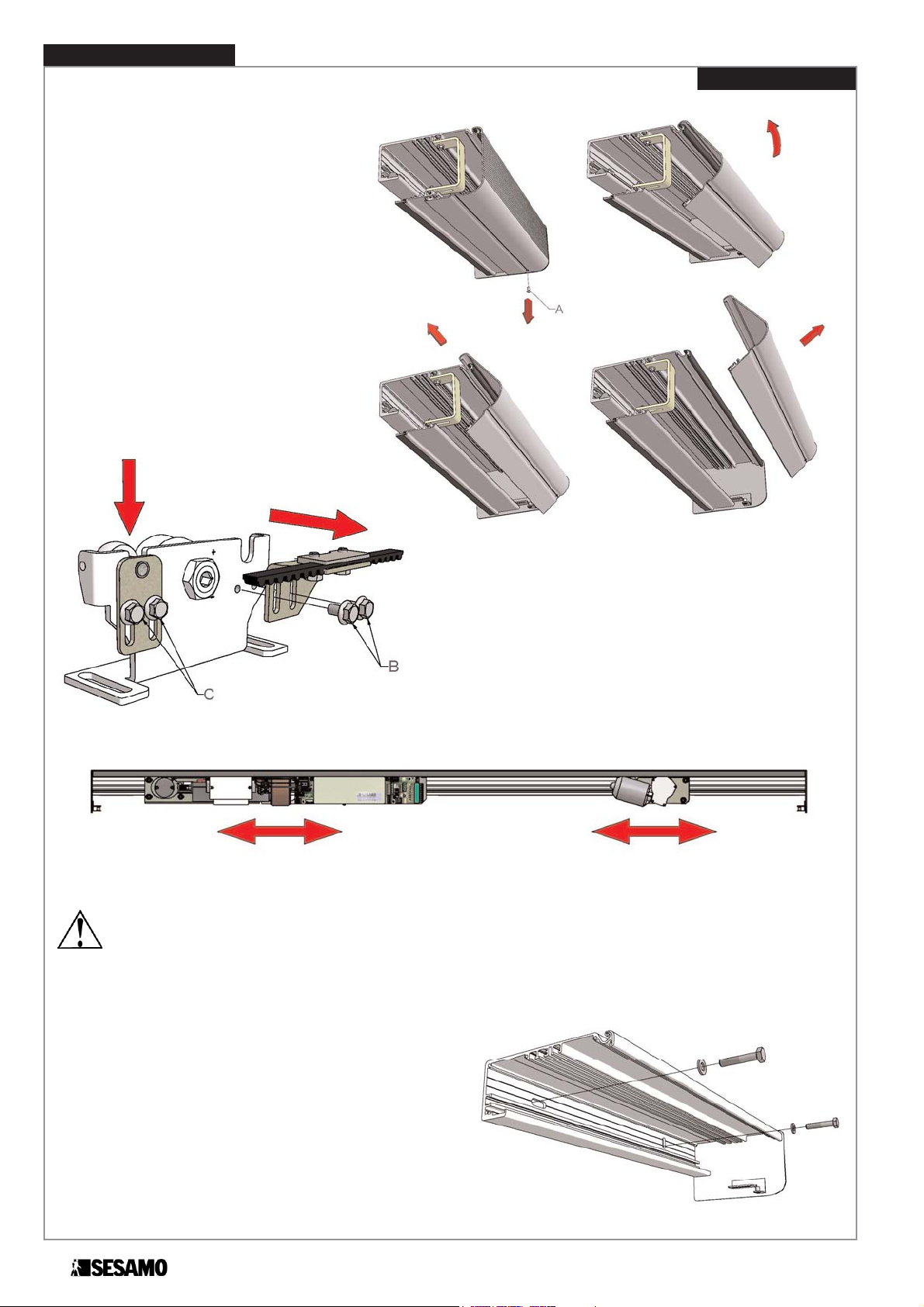

Automatism component removal

and movement

Unscrew the cover fastening screws A (if present) and remove as indicated in the sequence

in Fig.9.

Remove the carriages as follows:

• Disconnect the belt fastening rod from the

carriage using the fastening screws B

(Fig.10)

• Loosen the anti-derailment device screws C

and let the roller support rod completely

lower (Fig.10)

• Remove the carriage

To facilitate box fastening operations, the internal automatism components can be moved or removed.

WARNING

Before loosening component lock screws to move components (Fig.11), measure the distance of the motor from the

head or make marks on the box for correct component positioning at the end of assembly.

Box fastening

Inspect the surface where the box will be fastened, if the surface is not even, level with shims. The automatism girder may

buckle if fastened on an uneven surface.

Fasten the box to the prepared support using suitably long M8

hexagon head cap screws, inserted in the horizontal and vertical slots (Fig.12).

8

Installation Instruction

LIGHT MILLENNIUM

Fig. 9

Fig. 10

Fig. 11

Fig. 12

Installation Instruction

9

According to the type of support, all or only some of the slots on the box are used (Fig.13).

To prevent vibrations or noise during use, make sure that there is a solid fixture every 600 mm and that the box is fastened with the slots closest to the two heads.

WARNING

Before completely tightening the screws, make sure that the girder is “level” in both the length and depth directions

(Fig.14). Positioning errors over the angles indicated in the figure compromise automatism operations.

Fig. 14

LIGHT MILLENNIUM

Fig. 13

Wing assembly and adjustment

Carriage assembly

Fasten the carriages to the wings according to the quotas found in the following diagram (Fig.15).

The quotas indicated in Fig.15 A and B are applied to wings

seen from the inspection side (cover) of automatism.

The Fig.15 B is valid only for automatism with only 1 wing shorter

than 780 mm, with right or left opening and with electric lock. For

all remaining cases (two wings or 1 wings wiith right or left openining) is refer to Fig.15 A.

NOTE: for wings with antipanic break away system or only glass

wing you have to follow the assembling quotas you may find in

manual’s instructions of those accessories.

Use M8 hexagon head cap screws with flat and notched washers

(Fig.16 part.A).

Wing assembly

Make sure that the anti-derailment device is completely lowered by unscrewing the M6 nut (Fig.17, C) and pushing the

indicated wheel downwards (Fig.17 Part.C).

Lift the wing and position the carriages on the sliding rail

paying attention not to damage the rail.

Wing adjustment

Wing adjustment can be made distinctly on three axes based

on installation requirements (Fig.18).

Cross adjustment (Po axis)

Adjust wing position Fig.16 arrow D loosening bolts M8 (Fig.16 part. A) and aligning them to the automatism support surface.

Before tightening bolts A, carefully check that the carriage wheel vertical surface (that coincides with the carriage vertical

surface) is parallel to the box (Fig.18).

10

Installation Instruction

LIGHT MILLENNIUM

Fig. 17

Fig. 16

Fig. 15

If uneven proceed as follows:

• Loosen bolts (Fig.16 part.A)

• Align the carriages to the automatism box

• Check alignment measuring the quotas E (Fig.18) on the right

and left sides of the carriage: they must be equal.

• To further test alignment, manually move the wing: it should slide

with the minimum effort and without any type of hindrance or

friction.

• Tighten the bolts (Fig.16 part.A) paying careful attention not to

alter the alignment.

WARNING

Neglect to align the carriage wheels with the sliding rail may cause

excessive wear and noise during automatism use

Vertical adjustment (Pv axis)

To position the wings at the correct height and as perpendicular

as possible, proceed as follows:

• To avoid damages, make sure the anti-derailment device is

completely lowered.

• Insert a (long-handled) Allen wrench in the wheel eccentric

part. A Fig. 19,loosen the nut using a long-handled 24

wrench part B.

• Use the eccentric to move the wing to the required height

using the references (+and-) on the carriage and on the

eccentric part C.

• Holding the eccentric securely in position, firmly tighten the

wheel nut making sure not to alter the chosen position.

Horizontal adjustment (Pt axis)

Its purpose is to adjust the meeting point of the two wings.

Sesamo automatisms are designed positioning components

to obtain the correct meeting of the wings at the centre of the

space. If the meeting point requires adjustment during installation, proceed as follows:

• Loosen bolts (Fig.20) regarding the clamp on the “pass-

ing branch” of the belt (joint-less belt branch)

• Move the clamp on the belt to the required position.

• Firmly tighten the bolt (Fig.20 part.A) carefully checking

that the belt teeth are correctly inserted in the clamp housings.

Installation Instruction

11

LIGHT MILLENNIUM

Fig. 18

Fig. 19

Fig. 20

12

Installation Instruction

Belt tensioning

Proceed as follows for correct belt tensioning:

• Make sure the motor unit is positioned and fixed as per factory settings and is a position that guarantees belt centring

to the sliding area

• Loosen the fastening nuts on the encoder pulley unit A (Fig.21)

• Completely move the tensioning nut back B

• Make sure that integrated automatism control module fastening bolt part. C is

loose and permits lateral movement.

• Move the integrated automatism

control module to the left to achieve

first belt tensioning level. Make sure

that the belt branches are visibly taut

(without any evident downward

folds).

• Firmly tighten module fastening

screws C on the automatism girder.

• Rotate the tensioning nut B pushing

down the spring D to the limit E

• Tighten the encoder pulley unit fastening nuts A

Carriage start up

Reconnect the belt fasteners to the carriages Fig.10; tighten the

screws B making sure the position of the fasteners permits

good belt parallelism between the upper and lower branches.

Verify the correct disposition of the belt fasteners on the

carriages in touch with the automatism as indicated in

Fig. 23, 24 and 25.

Lift the anti-derailment device so that the roller does not touch the

aluminium profile during sliding (Fig.22). Tighten the

screws C (Fig.10) without altering the chosen adjustment.

In touch with the automatism, verify the correct fixing

configuration of the belt clamp on the carriages, as indicate

in the figures:

• Fig. 23 part C, D for two wings automatism

• Fig. 24 part. C with 1 wing automatism and left opening

• Fig. 25 part. D with 1 wing automatism and right opening

WARNING

Incorrect anti-derailment device adjustment that puts the roller in contact with the aluminium profile causes excessive noise

during automatism use.

WARNING

An incorrect fixing of the belt clamp on the carriages causes alterations in the direction of the opening and closing wings. Verify

carefully the agreement of the connections between the belt and the carriages as indicated in the Fig.25, 26 and 27.

LIGHT MILLENNIUM

Fig. 21

Fig. 22

Wing limit stop adjustment

2 wing Automatism: on of the two limits is found on the left end of the girder (Fig. 23 part. A) and the other near the

centre of the right wing (Fig. 23 part.B).

1 wing Automatism: the two limits are found on the ends of the left (Fig. 23, 24 part. A) and right (Fig. 23,24 part. B)

sliding area and near the girder heads.

To adjust the limit stops loosen screws as indicated in Fig. 22, 23, 24 part. A,B then slide the limit to the required position and then tighten the screws.

If necessary, fine adjustments of the wing stop point can be made using the carriage rubber screw stop Fig. 22, 23, 24

part. G

Installation Instruction

13

LIGHT MILLENNIUM

WARNING

Before putting the automatism into operation, always make sure that the fastening

screws of the stop brackets have been correctly tightened.

Fig. 23

Fig. 24

Fig. 25

2 Wings

1 Wings

Left Opening

1 Wings

Right Opening

Electronic lock adjustment

• Make sure the limit block runner is evenly positioned on the

carriage observing the automatism configuration

(Fig.23, 24, 25 part. F).

• Move the wing(s) to the totally closed position.

• Slide the electronic lock until the bar is near the limit block

(Fig.26) (distance ~2 mm.) and tighten the screws.

• Drill a hole (ø 9mm) in the automatism cover near the release

rod for future key insertion (Fig. 26).

Manual release

The purpose of the supplied key is to manually activate the

electronic lock in the event of power fault or failure.

If its use is required, proceed as follows :

• Insert the provided key in the hole on the part under the

automatism cover.

• Turn the key clockwise until mechanical stop and keep

it in this position.

• Move the wing ten centimetres towards the opening and

remove the key: the wings are now released.

To lock the wings again, move them to the completely closed position.

Final operations

Before starting the automatism, check and perform the following:

• Accurately remove and dust or shavings from the rails and carriage wheels

• Check correct tightening of the carriage wheel screws and nuts.

• Check correct belt tensioning.

• Check that the wires are fixed and that no wire pass near the carriage sliding area.

• Check that the limit stops are correctly positioned and that the belt clamps do not touch the toothed pulleys.

• Spread a thin layer of common bearing grease on the rails and transmission belt.

• Verify the plastic joint in the gear motor system is properly lubricated with normal grease for bearings.

WARNING

The rails and transmission belt can work without lubrication without presenting wear. However, light lubrication prevents

noise when parts are not perfectly aligned.

14

Installation Instruction

LIGHT MILLENNIUM

Fig. 26

(Hole ø=9mm)

(Hole ø=9mm)

Power connections

WARNING

Before performing the following operations make sure the mains are disconnected. Before powering the equipment,

perform the controls foreseen in paragraph “Start up”.

Place the power cord in the automatism paying careful attention not to damage the cord against any metallic edges.

Connect mains and grounding wires on the terminal board (Fig. 27)

WARNING

Never invert the power wire with the grounding

wire. Do not replace the mains fuse with a fuse

other than the one foreseen by the manufacturer: T 1 A (delayed).

Power must be isolatable from the general

panel with a bi-polar switch with minimum contact opening equal to 3 mm. (not supplied).

MILLENNIUM electronic board

The meanings of the main electronic board components are listed in Fig. 28:

Installation Instruction

15

Transformer

fuse

(F 6,3A)

Power

switch

Transformer

connector

Battery

connector

Electronic

lock fuse

(T 1A)

Electronic

lock connector

Motor

connector

Battery fuse

(F 6,3A)

Battery

charge board

connector

(optional)

Photocell

board connector

(optional)

Photocell ray

connector

(only used with optional

photocell board)

External peripher-

al power fuse

(T 500mA)

External peripheral

power connector

External

peripheral

connector

Factory only

use connector

Dip Switchs

and selection

Jumpers

START opening

control button

PC

connector

Multi-logic

selector

connector

Fig. 28

Encoder

connector

LIGHT MILLENNIUM

Fig. 27

Jumper

INT/EXT

Electrical connections

WARNING

All board or peripheral connections on the terminal board

must be performed with the power disconnected to

prevent irreparable damage to the electronic equipment.

WARNING

Any repairs or replacements must be performed by

professionally qualified personnel and original spare

parts must be used in repairs.

Left Side Electronic Board

Connections

Fig. 30 summarises terminal connections on the left side of the electronic board:

16

Installation Instruction

Fig. 29

Connectors must be inserted

as in Fig. 29

LIGHT MILLENNIUM

The battery charge unit (optional) is inserted

in the terminal board (part. A) observing the

assembly direction as shown in Fig. 29

Verify the agreement

between the power

motor cable and the

serigraphy indicated in

the electronic board

Electric Transformer

Battery

Encoder

Electric Lock

Gear Motor

Fig. 30

Part. A

Blue Red

Installation Instruction

17

Right Side Electronic Board Connections

A. Photocell amplifier board connector (optional)

Insert the amplifier module observing the assembly direction shown in Fig. 29

WARNING

Select the Jumper for single or double beam and check the red led

B. Photocell beam connector

(only use if the internal photocell amplifier board module is installed)

C. Selector Jumper between Millenium - and external cell amplifier

The system has three selectable working models:

A Millenium amplifier only Jumper close towards INT

B External amplifier only Jumper close towards EXT

C Both Millenium + External amplifier Jumper open

Fig. 31

BEAM OFF

On

) Beam interrupted

Off

) Correct

JUMPER

Closed towards B2

) Double beam

Closed towards B1

) Single beam

Fig. 32

Fig. 33

A RED

small band

distinguishes

the Transmitter

A WHITE

small band

distinguishes

the Receiver

Connect the

photocell’s beams as

in Fig. 33

LIGHT MILLENNIUM

INT EXT

A B D E

F

G

C

D. Multi-logic selector connector

Use the four conductors in the shielded wire for connections, observing the correspondences indicated by the markings

on the terminal board and multi-logic selector.

Do not connect the shield of the wire used.

For further information on multi-logic selector use, see the instructions for use.

E. External peripheral power connector – 12 Vdc 6W max (500mA)

Real power value may vary from 12 Vdc to about 15 Vdc depending on the resistive load situations connected

to these terminals.

WARNING

Do not invert power polarity. When the green led D39 is on it indicates normal voltage presence 12V. If off check:

• For mains and/or battery voltage

• That fuse F1 is not interrupted

F. External peripheral connector

ADVANCED

SELECTOR

BASE

SELECTOR

Shielded cable with 4 wires 0,22 mm.

(Do not connect the shield of the wire

used)

Fig. 34

Fig. 35

Fig. 36

18

Installation Instruction

LIGHT MILLENNIUM

* NA = Normally open NC = Normally closed

The electrical signal from external peripherals can be varied through the advanced selector or PC connection: from normally closed to normally open and vice versa. See the advanced selector used manual for further details.

G. Connector for PC - unit connections

A PC connection board (optional) is required to connect the MILLENNIUM unit to a Personal Computer.

The following is possible with MILLENNIUMWARE software:

• Advanced adjustments of some operating parameters

• Diagnostics and advanced information on unit status

• Microprocessor programming

PC connection board

Fig. 37

Installation Instruction

19

LIGHT MILLENNIUM

SIGNAL

COM

SAFE CLOSE

AUX IN

AUX OUT

SAFE OPEN

KEY

START 1

START2

TYPE*

NC

NA

NA

NC

NA

NA

DESCRIPTION

Common electrical signal.

Signal for the connection of an external

photocell or safety control device for

wing closing

.

Auxiliary input signal. Auxiliary devices

can be connected to this signal. It is

normally used for inter lock functions.

Auxiliary output signal, PNP transistor

type for particular door condition signals (reset, open, closed, etc).

Signal for the connection of sensors for protection during wing opening.

Lock signal. Closure devices can be

connected such as electronic key, key

selector, transponder, etc.

The signal can be controlled in bi or

mono-stabile mode with an activation

time equal to about 500 msec. For

mode type selection see paragraph

JUMPERS.

Opening signal. Wing opening devices

can be connected.

Opening signal. Wing opening devices

can be connected.

FUNCTION

If the door is closing and the contact opens, the unit sends and

immediate motion inversion command. Closing will only recommence after the contact closes.

The signal must be short circuited with COM if not devices

(internal or external) are connected.

When used as an auxiliary signal the function logic can be

personalised according to customer requests.

When used as inter lock logic, closing this signal inhibits door

functions that will not open even with open signal presence.

According to the type chosen signal, the output becomes

active (12Vdc and led on) when the door is in the set condition (Reset, open, closed, etc). See the advanced selector

manual for further details.

If the door is opening and the contact closes, the unit sends an

immediate movement stop command. Opening will only continue after this signal is deactivated.

If the signal opens the unit sends a complete wing closure

command (from any position) From this moment until the signal is closed the door stays in this position and no external

peripheral is detected (including multi-logic selectors). As

soon as the signal closes the door opens permitting access.

The signal must be short circuited with COM if no devices

are connected.

Closing this signals causes the wings to open. This signal is

only monitored in 2 Radar logic.

Closing this signals causes the wings to open. This signal is

monitored in both 2 Radar and 1 Radar logic.

LED Functions

Dip Switch - Selections

WARNING

For correct automatism functions and to guarantee the optimisation of the parameters that regulate wing movement,

adjust wing weight using dip switches S1 and S2 as indicated below.

Semi-automatic mode

Battery mode

Semi-automatic mode enabled.

In this mode wings close similar to

how they open, it doesn’t start

automatically but must be controlled by the operator.

Semi-automatic mode disabled

(Default). In this mode the closing’s

wings starts automatically after a

time according to the idle time’s

setting.

In the event of power failure the

equipment continues working

powered by the battery. (Default).

In the event of power failure, the

equipment moves the doors to

the “Stop open” position, and

stays in this condition until power

returns or a new logic is selected

using the multi-logic selector.

20

Installation Instruction

LIGHT MILLENNIUM

N° Wings

Weight per

wing (kg)

2 30 ÷ 60

1 60 ÷ 120

N° Wings

Weight per

wing (kg)

2 0 ÷ 30

1 0 ÷ 60

N° Wings

Weight per

wing (kg)

2 60 ÷ 80

ON indicates mains

voltage present

ON

indicates

encoder

signal

presence

ON indicates electronic

lock power

ON indicates motor

power supply

ON indicates 12V external

peripheral power supply

Diagnostics Led

(see Error Message Table)

External peripheral

signal presence led.

Fig. 38

Factory use only

Jumpers

Jumpers ON OFF (Default)

J1 Power on Power off

J2 Not used Not used

J3 Cyclic opening No cyclic opening

J4 Mono-stable Bi-stable

Start up

WARNING

If no optional operation lock device is installed, make sure the KEY input is short circuited with the COM input. Otherwise

the equipment cannot be started.

If no safe close device (internal and external) is installed, make sure the SAFE CLOSE input is short circuited with the

COM input and the jumper INT/EXT (Part. C pag. 17) in EXT. Otherwise the equipment cannot be started.

WARNING

For correct automatism functions and to guarantee the optimisation of the parameters that regulate wing movement,

adjust wing weight using dip switches S1 and S2 as previously indicated.

Position wings ~20 cm from total closure. Turn the power switch to 1 to power the equipment.

The automatism resets limits to reduced speed first completely opening and then closing.

WARNING

If necessary, make a dynamometric control to verify any slide friction, turn off the equipment and remove the gear motor

unscrewing the specific rubber supports.

Eliminate friction causes and start the equipment again repeating the above-described movement.

Multi-logic selector not installed: when the equipment finishes limit reset it is ready to work in 2 RADAR logic.

Multi-logic selector installed: when the equipment finishes limit reset it is ready to work and is positioned in the

“STOP CLOSED” logic.

At the end of reset the equipment is ready for use; check correct sensor operations for opening command and safety control. Also check anti-crushing sensitivity; if the value requires increasing and decreasing, see the advanced selector manual.

To test automatism operations without connections to the open command device use the START button on the unit (see

Fig. 28)

J1: activates motor power supply in completely closed position to generate continual

drive even in the wings stopped and closed position.

J2: not used

J3: cyclic opening generator to test door operations;

J4: KEY signal operating type selection (see external peripheral connector

description): mono-stable (Activation time 500 ms) or bi-stable

Installation Instruction

21

LIGHT MILLENNIUM

DESCRIPTION

Initialization error

Door blocked error

Anti-crushing in

opening error

Anti-crushing in

closing error

Inversion error

Overcurrent error

Encoder error

NUM.

1

2

3

4

5

6

7

WHAT TO DO

An error occurred during initialisation, in particular, the measured

opening quota is too low. Check the encoder, the connection

between the encoder and mother boards. Make sure the transit

area is free of obstacles. In the event of electronic lock, check

correct operations.

The door cannot open. Make sure there are no obstacles in the

transit area and that there are no locks (electric or manual) that

block the door.

After three opening and anti-crushing detection attempts.

Make sure there are no obstacles in the transit area.

Make sure that the anti-crushing sensitivity in opening is not too

low. Check the encoder, the connection between the encoder

and mother boards.

After three closing and anti-crushing detection attempts. Make

sure there are no obstacles in the transit area. Make sure that the

anti-crushing sensitivity in opening is not too low. Check the

encoder, the connection between the encoder and mother

boards.

An inversion error of the movement between the encoder and

motor was detected. Make sure that the motor is correctly

connected as shown in Fig. 30

Motor overload detected. Make sure there are no short circuits

on the motor power cord. Check the motor and replace if

necessary.

Encoder malfunction detected.

Check the encoder, the connection between the encoder and

mother boards.

AV

BL.

BL.

BL.

BL.

BL.

BL.

BL.

OC

OFF

OFF

OFF

OFF

OFF

ON

OFF

LED

L1

OFF

OFF

OFF

ON

ON

ON

ON

L2

OFF

ON

ON

OFF

OFF

ON

ON

L3

ON

OFF

ON

OFF

ON

OFF

ON

Inter lock connection and use

The MILLENNIUM unit is set to work in inter lock mode through

connections to an electronic unit of the same family.

In inter lock mode one door can only open if the other is not moving, that is, if not in the movement phase.

To inter lock two automatisms proceed as follows (Fig. 39):

• connect the terminal AUX IN of unit A to the terminal AUX OUT

of unit B

• connect the terminal AUX OUT of unit A to the terminal AUX IN

of unit B

• connect terminal “-“ of the 12Vdc power supply of unit A to the terminal “-“ of the 12Vdc power supply of unit B.

Use 4 x 0.22 shielded wire for connections and do not connect

the shield.

Error Message Table

When open requests come from the both sensors on both doors

an opening priority needs to be set; to do this, set one door as

MASTER and the other as SLAVE.

When simultaneous signals occur, the MASTER door will open.

To select MASTER and SLAVE use the advanced selector.

Fig. 39

UNIT A

UNIT B

22

Installation Instruction

BL. = Blinking

LIGHT MILLENNIUM

Delivery Modality

Close the automatism’s cover following the reverse procedure used to remove it.

Make sure the two fixing screws of the cover are well tightened.

Before to end the automatism’s installation, remember to stick the labels on the sliding wings.

Hand the guarantee and test certificate over filled according to the instructions shown in the certificate.

The certificates must be sent to SESAMO in 8 days from the positive test date. Hand the technical documentations over to

the client.

23

SESAMO srl

Str. Gabannone, 8/10 • 15030 Terruggia (AL) • Italy

Tel: +39 0142 403223 • Fax: +39 0142 403256

www.sesamo.eu • E-mail: info@sesamo.eu

MAN_LM_EN_4_12_07

Loading...

Loading...