Page 1

CDHD Servo Drive

Quick Start Guide

Revision 5.4

DOC-CDHD-QSG-EN

Page 2

Page 3

CDHD

Quick Start Guide 3

Revision

Firmware

Revision

Software (GUI)

Revision

1.3.2 1.3.2.3

Important Notice

© 2013 IMO Precision Controls Ltd.

All rights reserved. No part of this work may be reproduced or transmitted in any

form or by any means without prior written permission of IMO.

Disclaimer

The information in this manual was accurate and reliable at the time of its

release. IMO Precision Controls Ltd. reserves the right to change the

specifications of the product described in this manual without notice at any time.

Page 4

CDHD

4 Quick Start Guide

Trademarks

CANopen and CiA are registered trademarks of the CAN in Automation User's

Group

PROFINET is a trademark of PROFIBUS International

EtherCAT is a registered trademark and patented technology, licensed by

Beckhoff Automation GmbH

EnDat is a registered trademark of Dr. Johannes Heidenhain GmbH

HIPERFACE is a registered trademark of Sick Stegmann Gmbh

Windows is a registered trademark of Microsoft Corporation

Contact Information

IMO Jeambrun Automation SAS.

30 Rue De Rocroy

94100 Saint Maur Des Fosses, France

Tel: +8000 912 712

Fax: +8000 452 6445

Website:

www.imopc.com

Technical Support

If you need assistance with the installation and configuration of the CDHD drive,

contact Servotronix technical support:

imo-fr@imopc.com

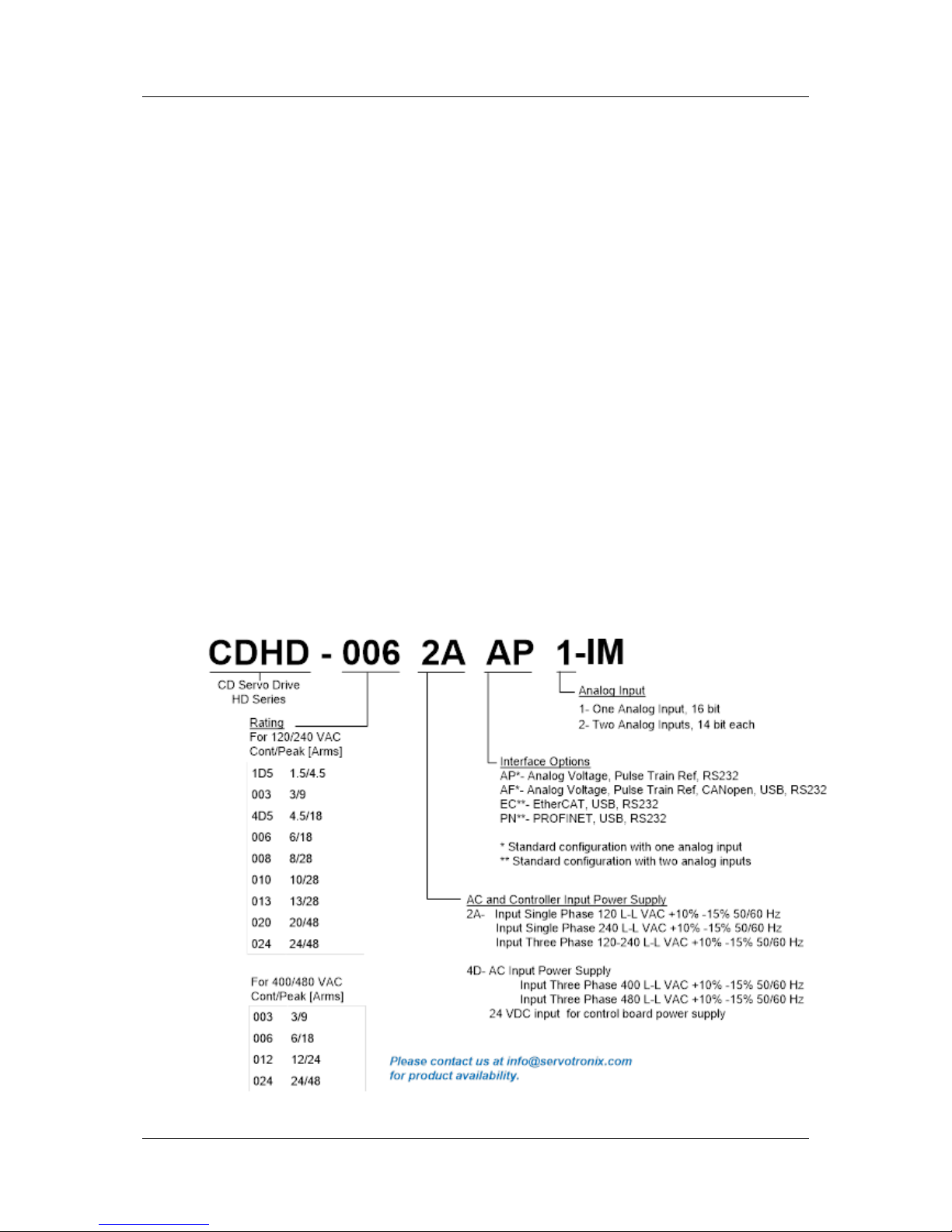

Part Number

Page 5

CDHD

Quick Start Guide 5

Contents

1 Introduction __________________________________________________ 7

CDHD Documentation ........................................................................................ 7

Safety .............................................................................................................. 7

Required Hardware and Tools .............................................................................. 7

Required Computer System ................................................................................ 8

CDHD Installation Procedure ............................................................................... 8

CDHD Dimensions and Mounting ......................................................................... 9

CDHD Wiring and Pin Assignments ...................................................................... 12

2 Control Board _________________________________________________ 24

Overview ......................................................................................................... 24

Controller I/Os – C2 .......................................................................................... 24

Controller Interface Wiring ......................................................................... 27

Machine I/Os – C3 ............................................................................................ 29

Machine Interface Wiring ........................................................................... 31

Motor Feedback – C4 ........................................................................................ 33

Feedback Wiring Guidelines........................................................................ 34

Fieldbus Devices – C5 and C6 ............................................................................ 41

CAN Communication ................................................................................. 41

EtherCAT or PROFIBUS Communication ....................................................... 41

Host Computer – C1, C7 .................................................................................... 42

Daisy Chain – C8 .............................................................................................. 43

Drive Address Switches ..................................................................................... 44

3 Power Board 120/240 VAC ______________________________________ 45

Overview ......................................................................................................... 45

Safe Torque Off (STO) – P1 ............................................................................... 45

Motor – P2 ....................................................................................................... 46

Regeneration Resistor – P3 ................................................................................ 47

AC Input – P3, P4, P5 ....................................................................................... 48

4 Power Board 400/480 VAC ______________________________________ 50

Overview ......................................................................................................... 50

Safe Torque Off (STO) – P1 ............................................................................... 50

Logic Power 24V Input – P2 ............................................................................... 51

AC Input and Regeneration Resistor – P3 ............................................................ 52

Brake – P4 ....................................................................................................... 53

Motor – P5 ....................................................................................................... 54

5 Software ____________________________________________________ 55

ServoStudio Installation .................................................................................... 55

Power Up ......................................................................................................... 55

Drive Configuration ........................................................................................... 56

6 Drive Status __________________________________________________ 57

Normal Operation Codes .................................................................................... 57

Warning and Fault Codes ................................................................................... 58

Page 6

CDHD

6 Quick Start Guide

Page 7

CDHD Introduction

Quick Start Guide 7

1 Introduction

CDHD Documentation

This manual is part of a documentation set. The entire set consists of the

following:

CDHD Quick Start Guide. Basic setup and operation of the drive.

CDHD User Manual. Hardware installation, configuration and operation.

CDHD VarCom Reference Manual. Parameters and commands used to

program the CDHD.

CDHD CANopen for CAN and EtherCAT Drives Reference Manual.

CDHD implementation of CANopen protocol for CAN and EtherCAT.

Safety

Only qualified persons may perform the installation procedures. You do not need

to be an expert in motion control to install and operate the drive system.

However, you must have a basic understanding of electronics, computers,

mechanics, and safety practices.

The CDHD utilizes hazardous voltages.

Be sure the drive is properly grounded.

Before you install the CDHD, review the safety instructions in this manual. The

manual is available as a PDF file that can be downloaded from the Servotronix

website.

Failure to follow the safety instructions may result in personal injury or

equipment damage.

Required Hardware and Tools

All required hardware and tools are specified in the diagrams in the section

CDHD Wiring and Pin Assignments.

The connectors and tools that are supplied with the CDHD are also indicated in

those diagrams.

In addition, you will need a small slotted screwdriver for setting switches.

To connect the CDHD to the host computer via serial communication, you will

need one of the following:

USB 2.0 A to Mini-B cable (USB interface)

4p4c plug and cable (RS232 interface)

To connect the CDHD to the host computer or host PLC via fieldbus, you will

need:

RJ45 cables (CAN interface or EtherCAT)

Page 8

Introduction CDHD

8 Quick Start Guide

Required Computer System

The following computer system and software are required:

2 GHz CPU

1 MB RAM

1000 MB available on hard drive (after .net 4 is installed)

USB or RS232 port for connecting to the drive, according to CDHD model.

Operating system: Windows XP-SP3, or Windows 7

ServoStudio, the graphical software interface for configuring and testing the

drive. Download from the CDHD product page on the IMO website.

.Net4 (for details, refer to .NET Framework System Requirements). If .NET 4

is not installed on the computer, ServoStudio will guide you through the

installation, but will not install it automatically.

CDHD Installation Procedure

Perform the following steps to install and setup a CDHD system.

1. Mount the CDHD.

2. Make all electrical connections:

Controller I/Os and/or Machine I/Os

Motor feedback

Fieldbus devices, if required

Safe torque off (STO), or bypass using jumpers

Motor

Motor brake, if required

Regeneration resistor, if required

AC input voltage

3. Set the drive address using the rotary switches.

4. Connect the drive to the PC.

5. Power up the drive and the PC.

6. Connect to fieldbus devices (optional).

7. Install ServoStudio software.

8. Using ServoStudio, configure and test the drive.

Page 9

CDHD Introduction

Quick Start Guide 9

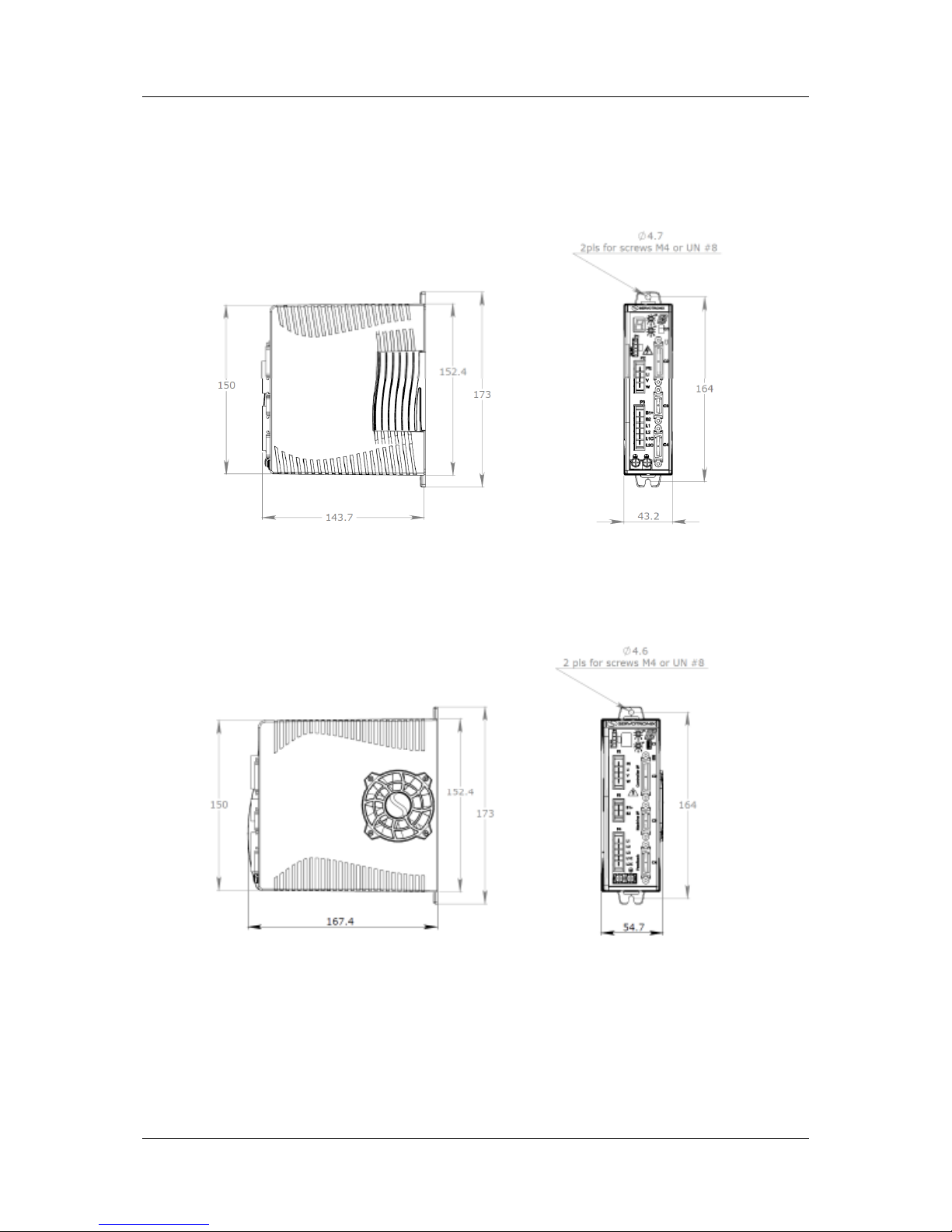

CDHD Dimensions and Mounting

Using the bracket on the back of the CDHD, mount the CDHD on a grounded

conductive metal panel.

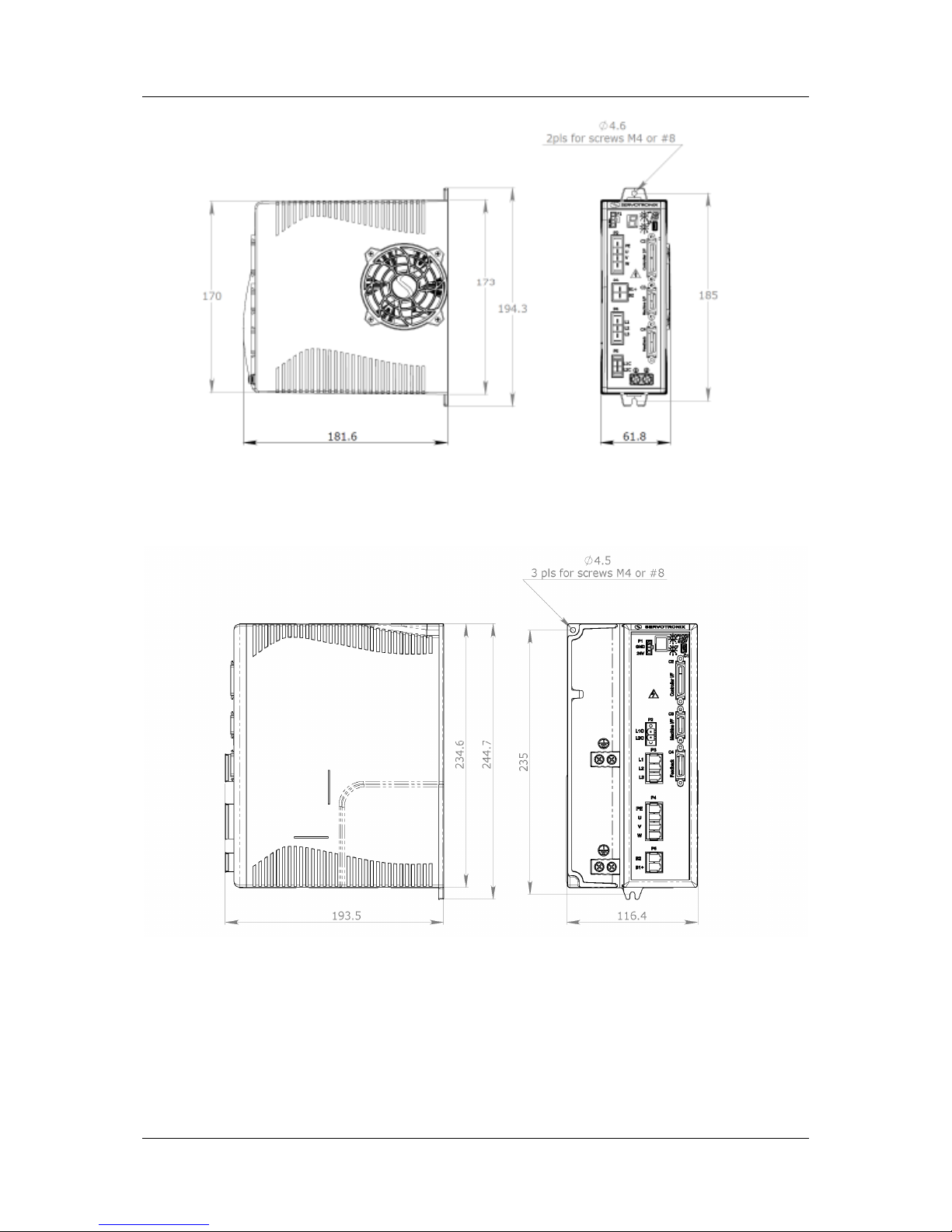

CDHD-1D5/CDHD-003 – 120/240 VAC - Dimensions (mm)

Note: CDHD-003 has fan.

CDHD-4D5/CDHD-006 – 120/240 VAC - Dimensions (mm)

Page 10

Introduction CDHD

10 Quick Start Guide

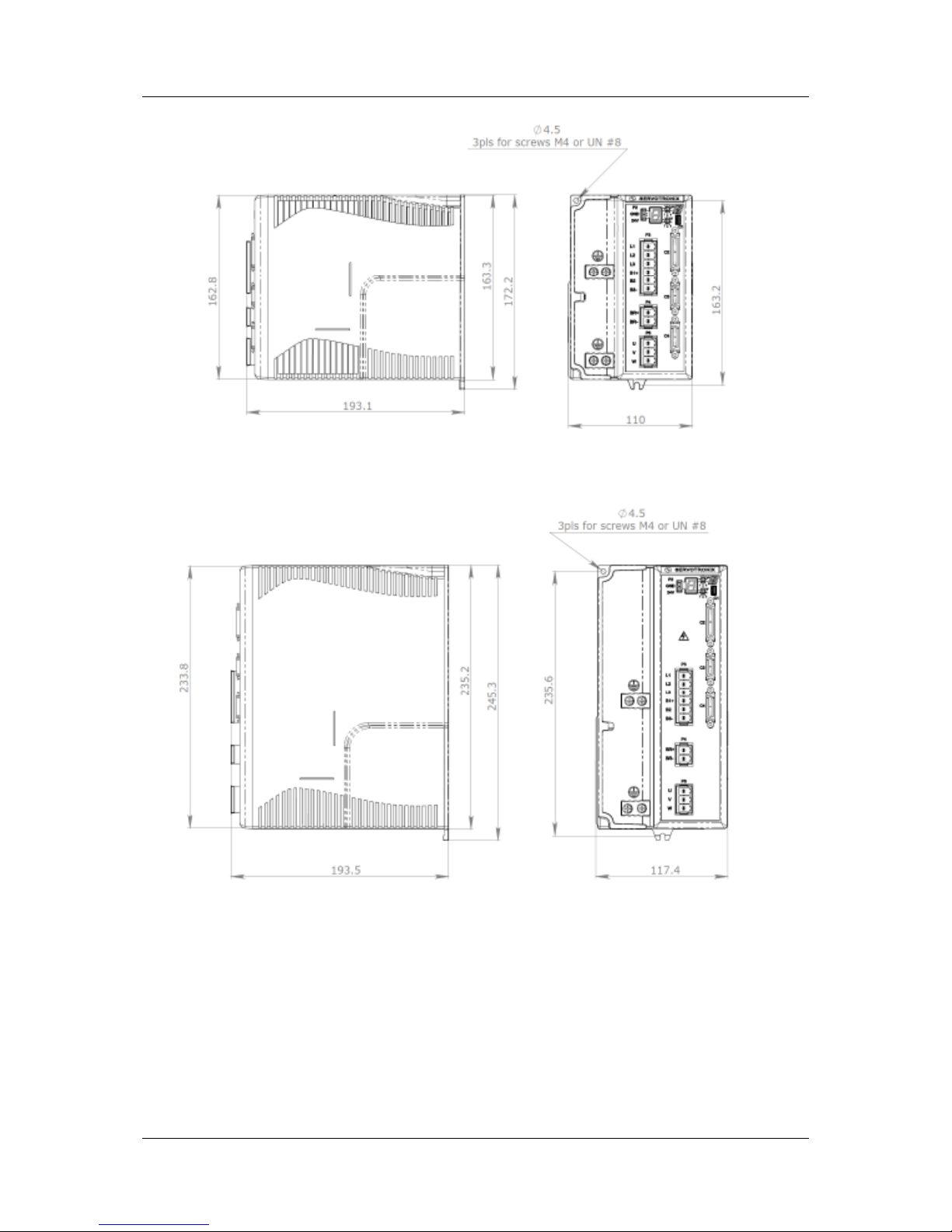

CDHD-008/CDHD-010/CDHD-013 – 120/240 VAC - Dimensions (mm)

CDHD-020/CDHD-024 – 120/240 VAC - Dimensions (mm)

Page 11

CDHD Introduction

Quick Start Guide 11

CDHD-003/CDHD-006 – 400/480 VAC - Dimensions (mm)

CDHD-012 - 400/480 VAC - Dimensions (mm)

Page 12

Introduction CDHD

12 Quick Start Guide

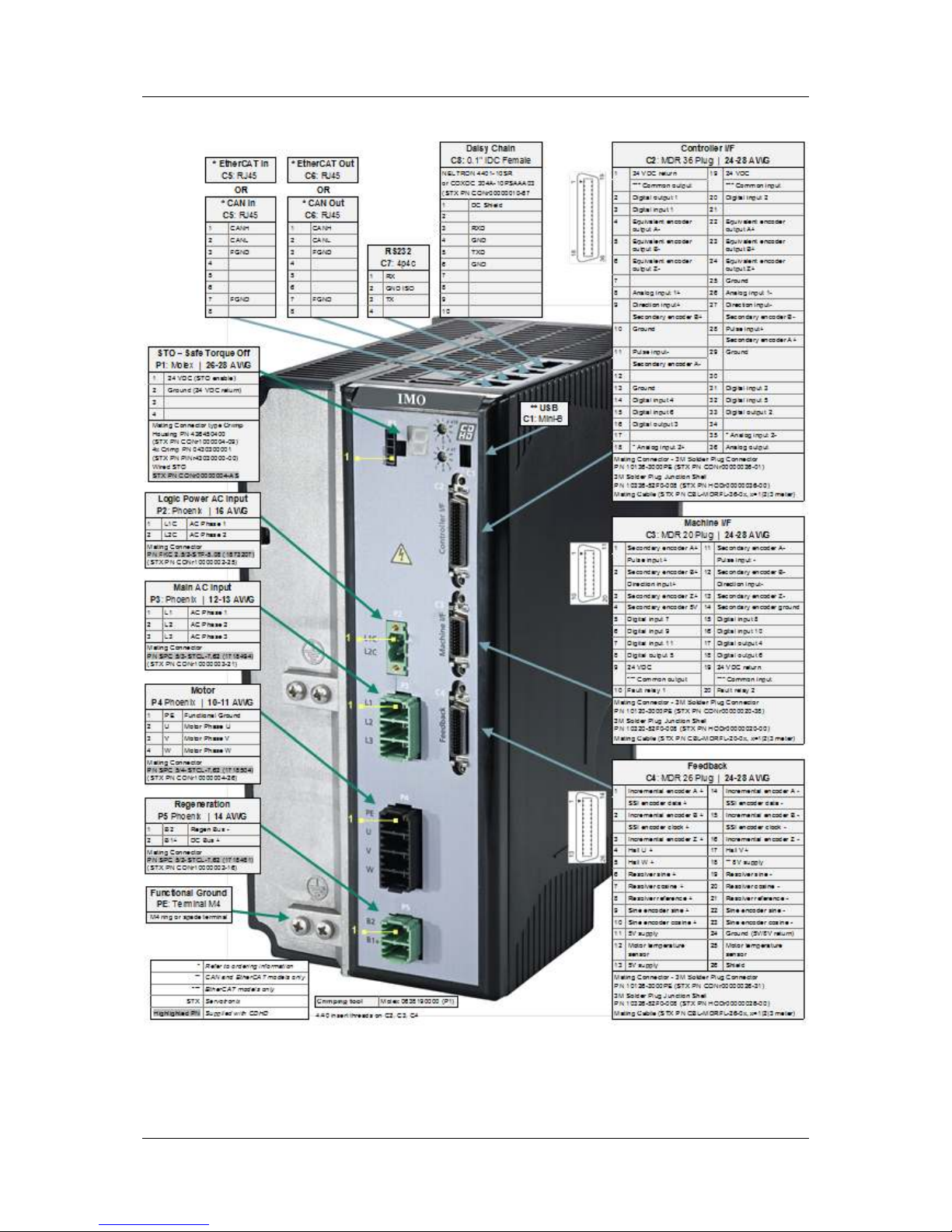

CDHD Wiring and Pin Assignments

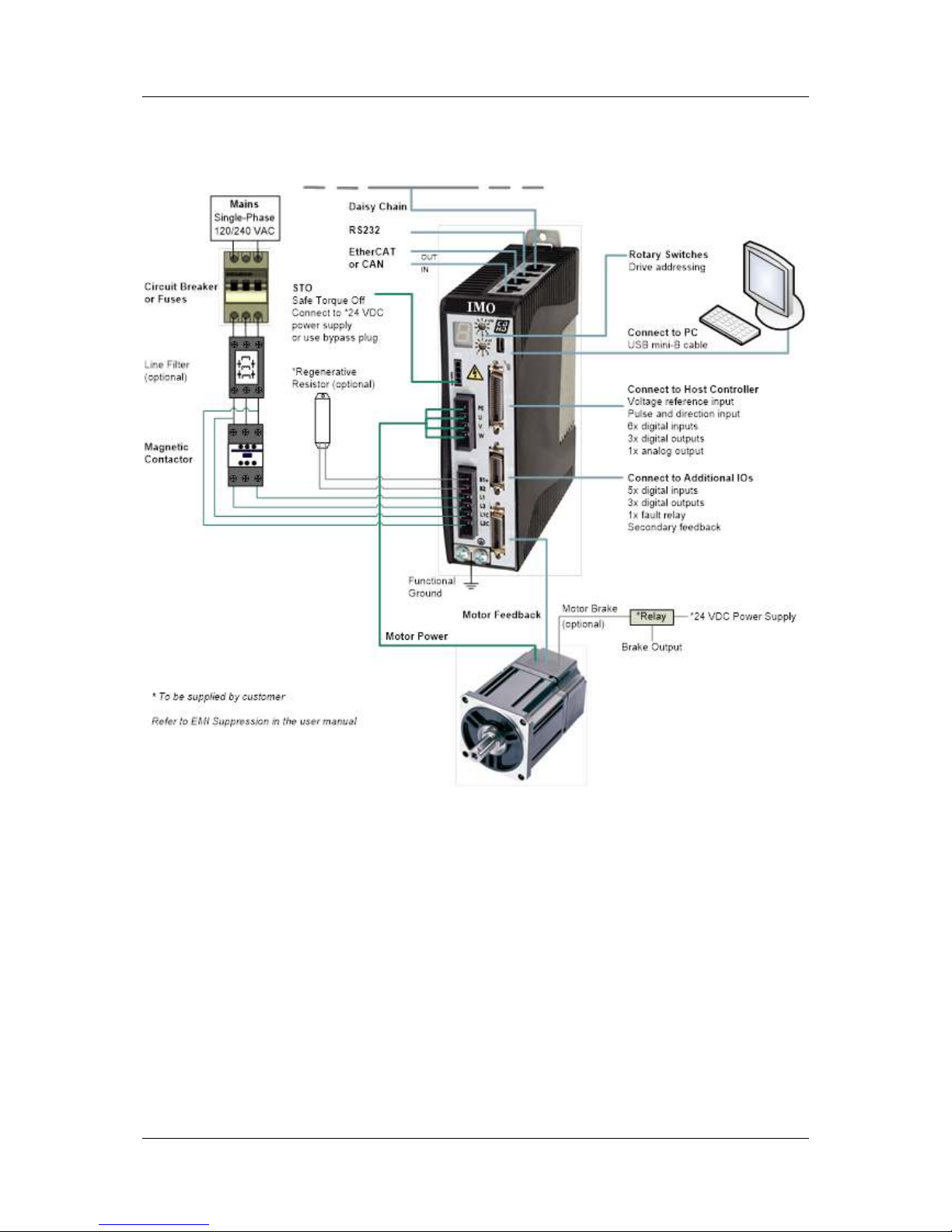

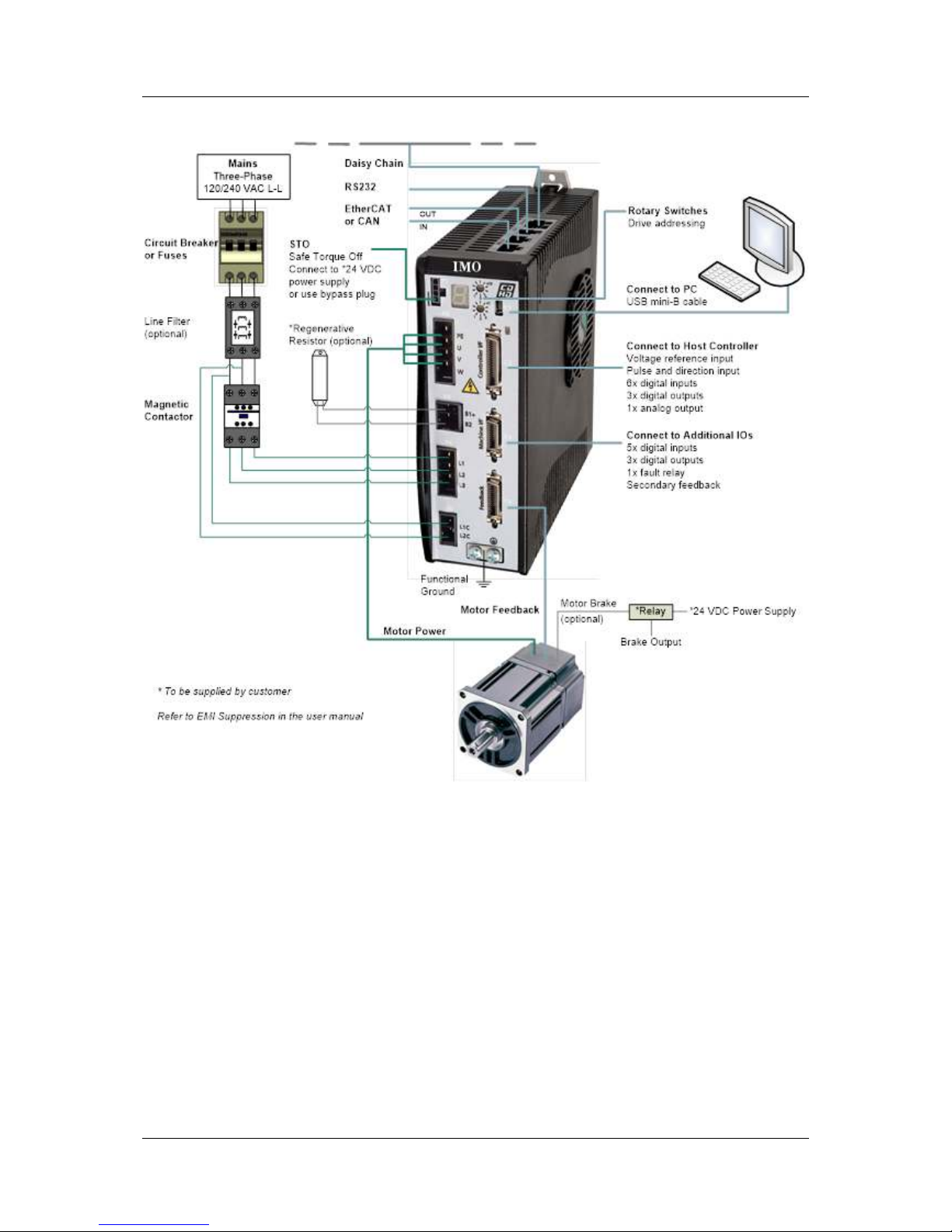

CDHD-1D5/CDHD-003 – Servo System Wiring –120/240 VAC, 1-Phase

Page 13

CDHD Introduction

Quick Start Guide 13

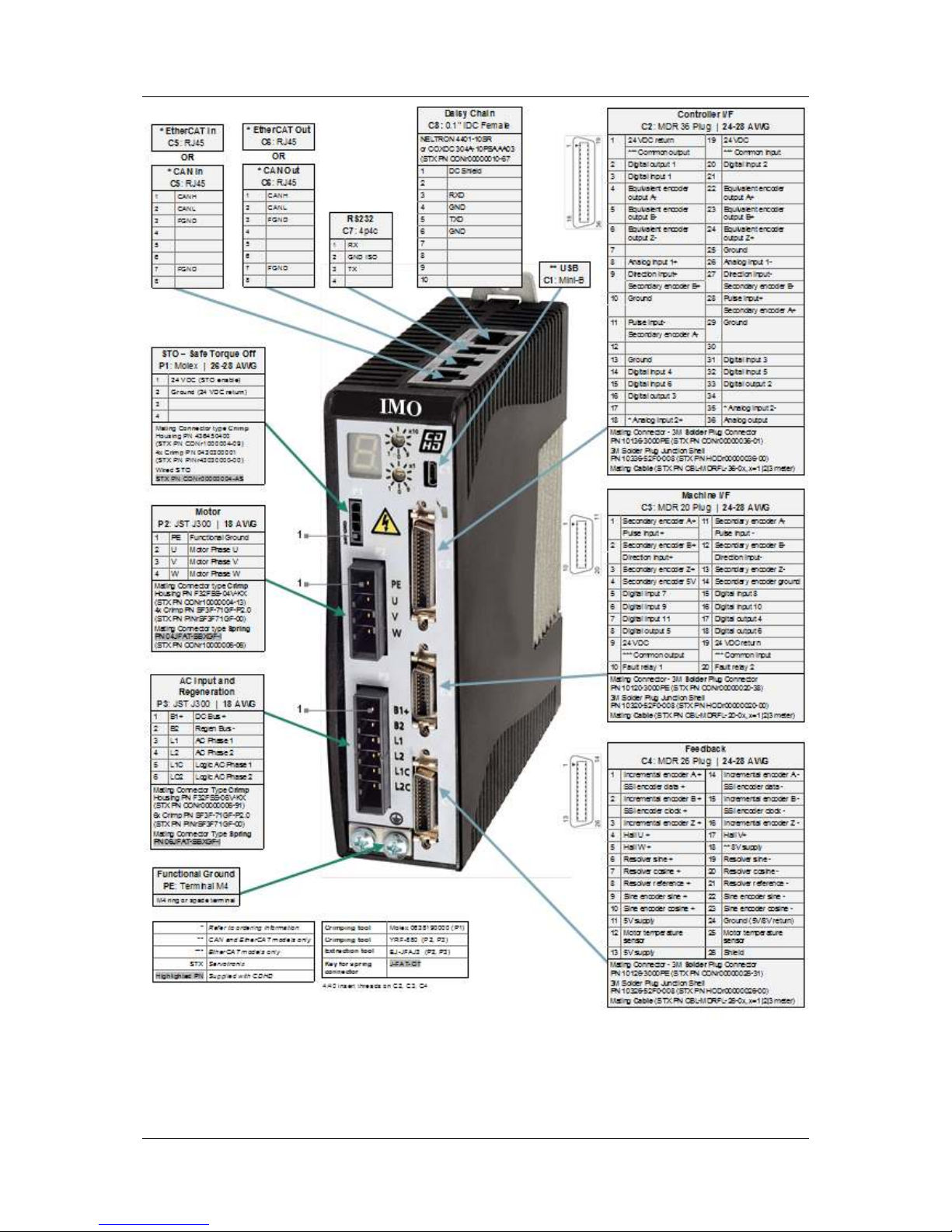

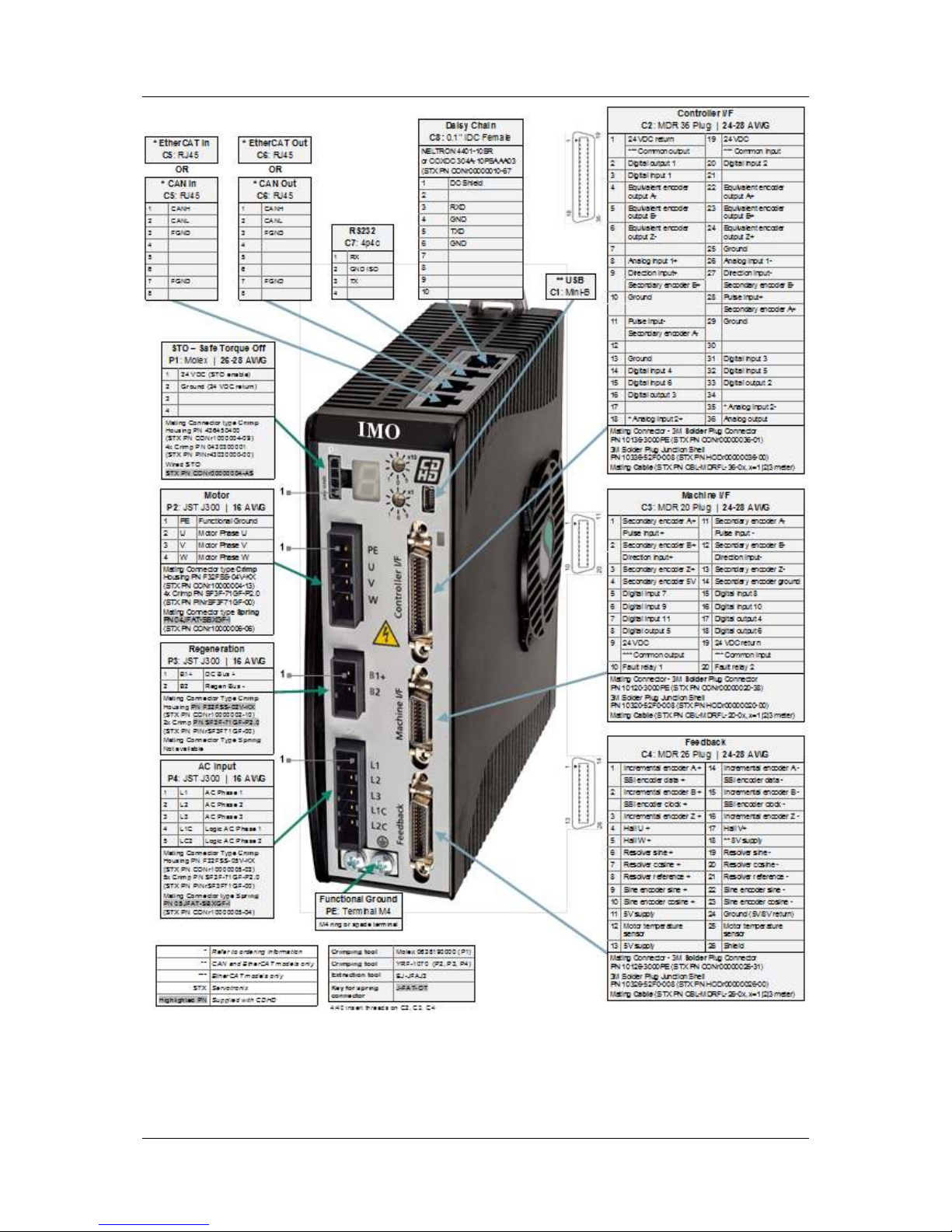

CDHD-1D5/CDHD-003 – Pin Assignments – 120/240 VAC

Page 14

Introduction CDHD

14 Quick Start Guide

CDHD-4D5/CDHD-006 – Servo System Wiring – 120/240 VAC, 1-Phase

Page 15

CDHD Introduction

Quick Start Guide 15

CDHD-4D5/CDHD-006 – Pin Assignments – 120/240 VAC

Page 16

Introduction CDHD

16 Quick Start Guide

CDHD-008/CDHD-010/CDHD-013 – Servo System Wiring –

120/240 VAC, 3-Phase

Page 17

CDHD Introduction

Quick Start Guide 17

CDHD-008/CDHD-010/CDHD-013 – Pin Assignments – 120/240 VAC

Page 18

Introduction CDHD

18 Quick Start Guide

CDHD-020/CDHD-024 – Servo System Wiring – 120/240 VAC, 3-Phase

Page 19

CDHD Introduction

Quick Start Guide 19

CDHD-020/CDHD-024 – Pin Assignments – 120/240 VAC

Page 20

Introduction CDHD

20 Quick Start Guide

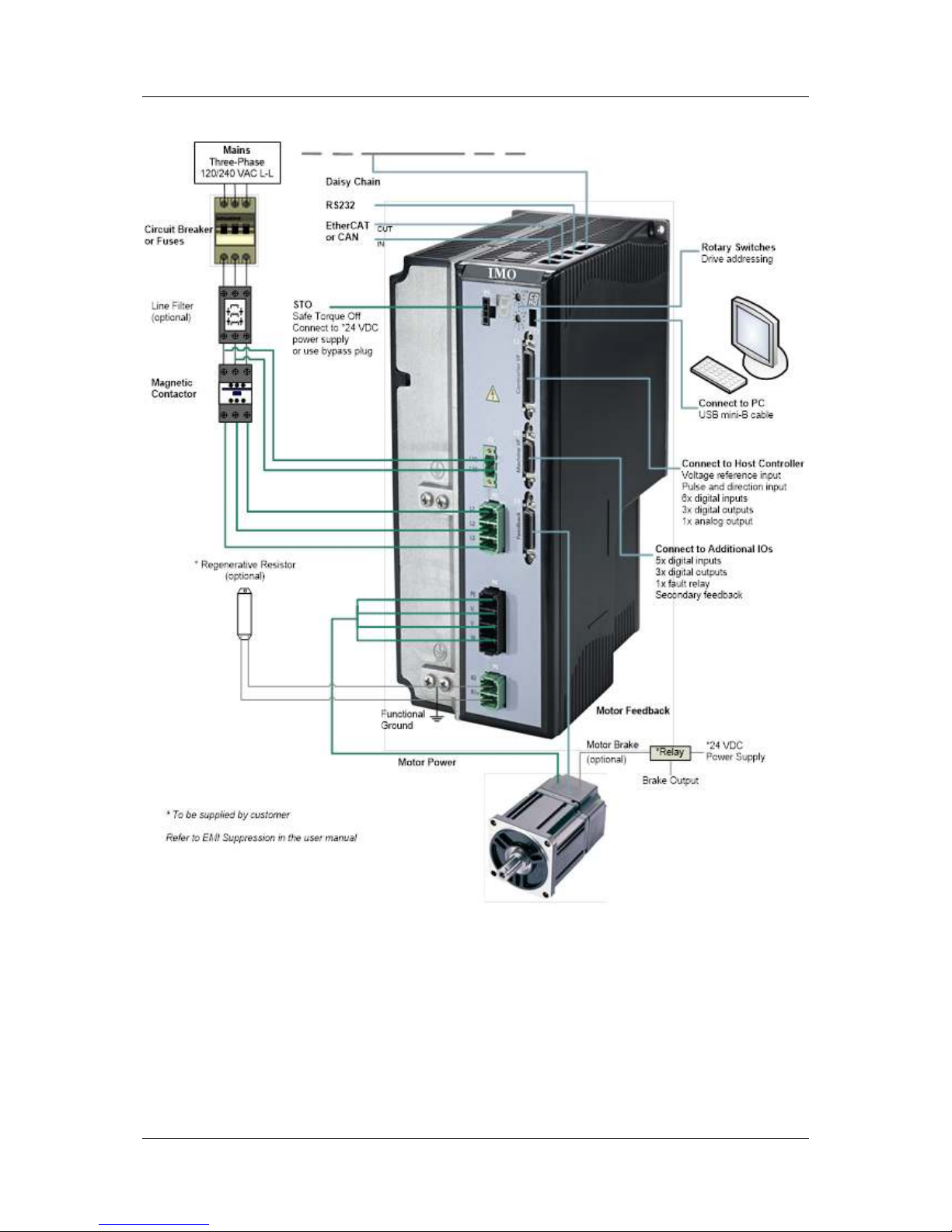

CDHD-003/CDHD-006 – Servo System Wiring – 400/480 VAC, 3-Phase

Page 21

CDHD Introduction

Quick Start Guide 21

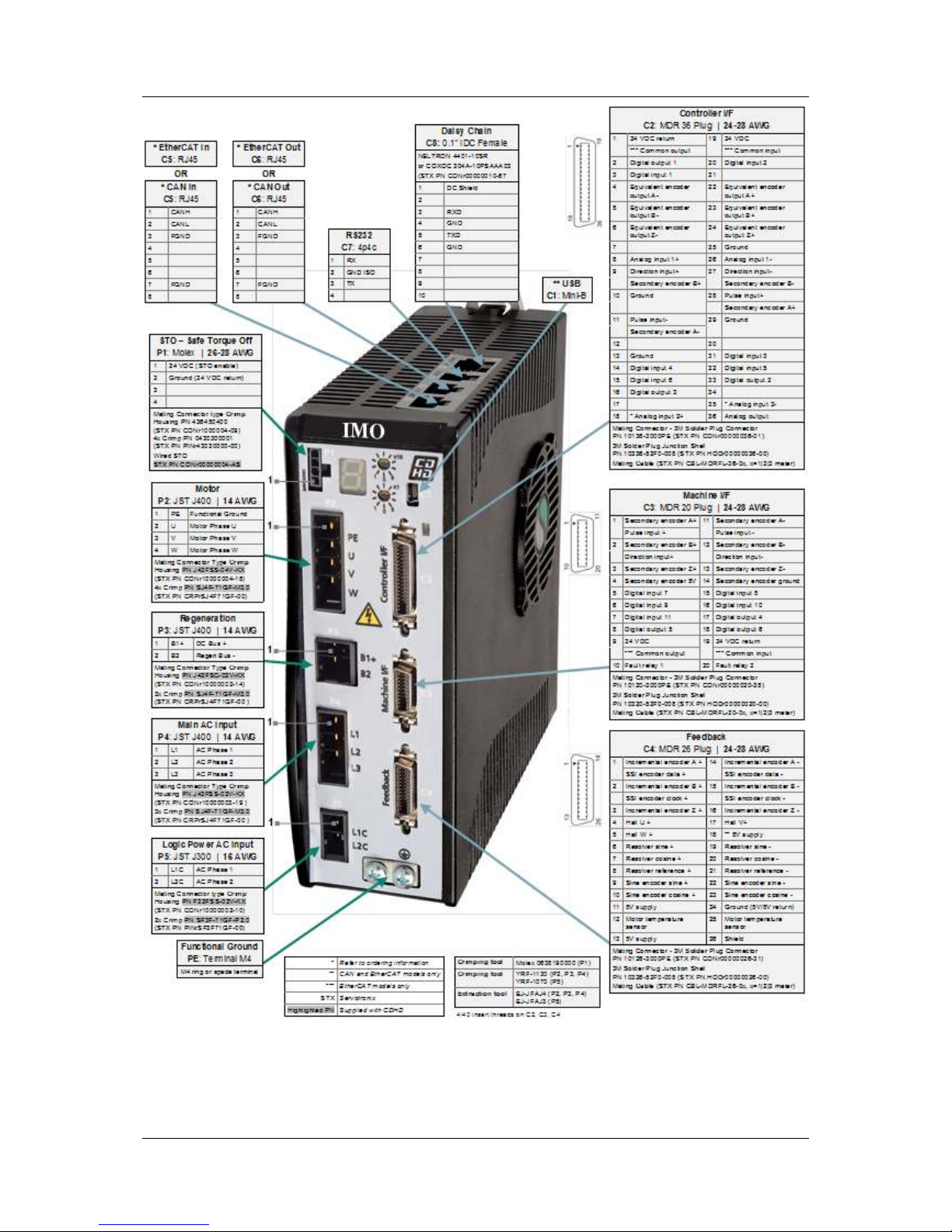

CDHD-003/CDHD-006 – Pin Assignments – 400/480 VAC

Page 22

Introduction CDHD

22 Quick Start Guide

CDHD-0012 – Servo System Wiring – 400/480 VAC, 3-Phase

Page 23

CDHD Introduction

Quick Start Guide 23

CDHD-012 – Pin Assignments – 400/480 VAC

Page 24

Control Board CDHD

24 Quick Start Guide

2 Control Board

Overview

The control board has the same interfaces on all CDHD models:

USB Communication – C1 (Exception: AP models do not have a USB port.)

Controller I/Os – C2

Machine I/Os – C3

Motor Feedback – C4

Fieldbus Devices (optional) – C5 and C6

RS232 Communication – C7

Daisy Chain – C8

Drive Address Rotary Switches

Controller I/Os – C2

Controller I/Os are connected through interface C2 on all CDHD models.

Wire the digital and analog inputs and outputs according to the requirements of

your application.

Unused pins must remain unwired.

To preserve isolation of the digital I/Os, connect a 24 VDC source to pin 19.

Connect the return of the 24 VDC supply to pin 1, which functions as the ground

path for the outputs.

Note: AP/AF Models: The 24 VDC supply and return can be connected on

either the Controller interface (C2) or the Machine interface (C3), but it

is not necessary to connect it on both.

Notes: EC/PN Models:

Common output on the Controller interface (C2) and the Machine

interface (C3) are connected internally.

Common input on the Controller interface (C2) and the Machine

interface (C3) are connected internally.

User can connect outputs as source or sink.

User can connect inputs as source or sink.

Refer to the Controller Interface Wiring schematic diagram for

EC/PN Models below, and the CDHD System Wiring - Pin

Assignments diagram for EC/PN Models at the end of this

manual.

Page 25

CDHD Control Board

Quick Start Guide 25

Controller I/O Interface

Pin Function Description Pin Function Description

1 24 VDC

return

AP/AF Models: Return of

the user-supplied 24 VDC

19 24 VDC AP/AF Models: User

supplied 24V, for I/O

biasing

Common

output

EC/PN Models Common

input

EC/PN Models

2 Digital

output 1

Opto-isolated

programmable digital

output. Read using OUT1

20 Digital

input 2

Opto-isolated

programmable digital

input. Read using IN2

3 Digital

input 1

Opto-isolated

programmable digital

input. Read using IN1

21

4 Equivalent

encoder

output A-

Low side of the equivalent

encoder output signal A

(RS422)

22 Equivalent

encoder

output A+

High side of the

equivalent encoder

output signal A (RS422)

5 Equivalent

encoder

output B-

Low side of the equivalent

encoder output signal B

(RS422)

23 Equivalent

encoder

output B+

High side of the

equivalent encoder

output signal B (RS422)

6 Equivalent

encoder

output Z-

Low side of the equivalent

encoder output index

(RS422)

24 Equivalent

encoder

output Z+

High side of the

equivalent encoder

output index (RS422)

7 25 Ground Digital ground

8 Analog

input 1+

High side of the

differential analog

command input

(±10 VDC)

26 Analog

input 1-

Low side of the

differential analog

command input

(±10 VDC)

9 Direction

input+

High side of the direction

signal (RS422), or

High side of the down

count signal

27 Direction

input-

Low side of the direction

signal (RS422), or

Low side of the down

count signal

Secondary

encoder

B+

High side of the

Secondary encoder input

signal B (RS422)

Secondary

encoder B-

Low side of the

secondary encoder input

signal B (RS422)

Page 26

Control Board CDHD

26 Quick Start Guide

Pin Function Description Pin Function Description

10 Ground Digital ground 28 Pulse

input+

High side of the pulse

signal (RS422), or

High side of the master

encoder signal A, or

High side of the up count

signal

Secondary

encoder A+

High side of the

secondary encoder input

signal A (RS422)

11 Pulse

input-

Low side of the pulse

signal (RS422), or

Low side of the master

encoder signal A, or

Low side of the up count

signal

29 Ground Digital ground

Secondary

encoder A-

Low side of the secondary

encoder input signal A

(RS422)

12 30

13 Ground Digital ground 31 Digital

input 3

Opto-isolated

programmable digital

input. Read using IN3

14 Digital

input 4

Opto-isolated

programmable digital

input. Read using IN4

32 Digital

input 5

Fast opto-isolated

programmable digital

input. Read using IN5

15 Digital

input 6

Fast opto-isolated

programmable digital

input. Read using IN6

33 Digital

output 2

Opto-isolated

programmable digital

output. Read using OUT2

16 Digital

output 3

Fast opto-isolated

programmable digital

output. Read using OUT3

34

17 35* Analog

input 2-

Low side of the second

differential analog input

(±10 VDC)

18* Analog

input 2+

High side of the second

differential analog input

(±10 VDC)

36 Analog

output

Analog output,

referenced to digital

ground (0-10 VDC)

* Optional, see ordering information

Page 27

CDHD Control Board

Quick Start Guide 27

Controller Interface Wiring

Controller Interface Wiring – AP/AF Models

Page 28

Control Board CDHD

28 Quick Start Guide

Controller Interface Wiring – EC/PN Models

Page 29

CDHD Control Board

Quick Start Guide 29

Machine I/Os – C3

Machine I/Os are connected through interface C3 on all CDHD models.

Wire the machine inputs and outputs according to the requirements of your

application.

Unused pins must remain unwired.

To preserve isolation of the digital I/Os, connect a 24 VDC source to pin 9.

Connect the return of the 24 VDC supply to pin 19, which functions as the

ground path for the outputs.

Note: AP/AF Models: The 24 VDC supply and return can be connected on

either the Controller interface (C2) or the Machine interface (C3), but it

is not necessary to connect it to both.

Notes: EC/PN Models:

Common output on the Controller interface (C2) and the Machine

interface (C3) are connected internally.

Common input on the Controller interface (C2) and the Machine

interface (C3) are connected internally.

User can connect outputs as source or sink.

User can connect inputs as source or sink.

Refer to the Machine Interface Wiring schematic diagram for

EC/PN Models below, and the CDHD System Wiring - Pin

Assignments diagram for EC/PN Models at the end of this

manual.

Page 30

Control Board CDHD

30 Quick Start Guide

Machine I/O Interface

Pin Function Description Pin Function Description

1 Secondary

encoder A+

High side of the

secondary encoder input

signal A (RS422)

11 Secondary

encoder A-

Low side of the

secondary encoder input

signal A (RS422)

Pulse input+ High side of the pulse

signal

Pulse input- Low side of the pulse

signal

2 Secondary

encoder B+

High side of the

Secondary encoder input

signal B (RS422)

12 Secondary

encoder B-

Low side of the

secondary encoder input

signal B (RS422)

Direction

input+

High side of the direction

signal

Direction

input-

Low side of the direction

signal

3 Secondary

encoder Z+

High side of the

secondary encoder input

index (RS422)

13 Secondary

encoder Z-

Low side of the

secondary encoder input

index (RS422)

4 Secondary

encoder 5V

5 VDC supply for the

secondary encoder

14 Secondary

encoder

ground

Ground of the 5 VDC

supply for the secondary

encoder.

5 Digital

input 7

Opto-isolated

programmable digital

input. Read using IN7

15 Digital

input 8

Opto-isolated

programmable digital

input. Read using IN8

6 Digital

input 9

Opto-isolated

programmable digital

input. Read using IN9

16 Digital

input 10

Opto-isolated

programmable digital

input. Read using IN10

7 Digital

input 11

Fast opto-isolated

programmable digital

input. Read using IN11

17 Digital

output 4

Opto-isolated

programmable digital

output. Read using OUT4

8 Digital

output 5

Opto-isolated

programmable digital

output. Read using OUT5

18 Digital

output 6

Fast opto-isolated

programmable digital

output. Read using OUT6

9 24 VDC AP/AF Models: User

supplied 24V, for I/O

biasing

19 24 VDC

return

AP/AF Models: Return of

the user-supplied

24 VDC

Common

output

EC/PN Models Common

input

EC/PN Models

10 Fault relay 1 Terminal 1 of the dry

contact fault relay

20 Fault relay 2 Terminal 2 of the dry

contact fault relay

Page 31

CDHD Control Board

Quick Start Guide 31

Machine Interface Wiring

Machine Interface Wiring – AP/AF Models

Page 32

Control Board CDHD

32 Quick Start Guide

Machine Interface Wiring – EC/PN Models

Page 33

CDHD Control Board

Quick Start Guide 33

Motor Feedback – C4

Motor Feedback uses interface C4 on all CDHD models.

Wire the motor feedback interface according to the type of feedback device to be

used in your application. Refer to the guidelines following the pinout table below.

Pins 1, 2, 14 and 15 have dual functionality.

Pin 25 for the motor temperature sensor is connected internally in the drive to

CDHD ground.

Unused pins must remain unwired.

Motor Feedback Interface

Pin Function Pin Function

1 Incremental encoder A + 14 Incremental encoder A -

SSI encoder data + SSI encoder data -

2 Incremental encoder B + 15 Incremental encoder B -

SSI encoder clock + SSI encoder clock -

3 Incremental encoder Z + 16 Incremental encoder Z -

4 Hall U + 17 Hall V+

5 Hall W + 18 AF/EC/PN Models: 8V supply

6 Resolver sine + 19 Resolver sine -

7 Resolver cosine + 20 Resolver cosine -

8 Resolver reference + 21 Resolver reference -

9 Sine encoder sine + 22 Sine encoder sine -

10 Sine encoder cosine + 23 Sine encoder cosine -

11 5V supply 24 Ground (5V/8V return)

12 Motor temperature sensor 25 Motor temperature sensor

13 5V supply 26 Shield

Page 34

Control Board CDHD

34 Quick Start Guide

Feedback Wiring Guidelines

The following tables present the most common feedback variations. If your

motor feedback does not match any one of the following, contact technical

support.

The tables present the wiring pin layout. Use the User Motor Pin# column in

these tables to record the pin numbers of your specific motor for future

reference.

Notes for Wiring Tables

A If the motor does not support a temperature sensor, do not connect pins

12 and 25.

B If the motor has an additional temperature sensor, connect

pins 12 and 25.

C Halls are single-ended signals. If you want to use differential Hall

signals, contact your supplier.

D Incremental encoders with Hall sensors and index pulse.

A, B and Z signals use the same wiring as Hall sensors U, V, and W.

On power up, feedback briefly sends Hall readings, and then

continuously sends the A, B and Z signals.

E On every power up, the phase find procedure must be executed.

F Encoder backup battery is external to the CDHD drive.

Voltage must be more than 3.6 VDC. The recommended battery is

lithium (ER3V: 3.6V, 1000mAh), manufactured by Toshiba Corp.

G A serial digital data encoder. A single-turn absolute encoder transmits

absolute position data at 17-bit per revolution (131,072 count per rev).

H A serial digital data encoder. This is a full absolute encoder with

17-bit per revolution resolution and xx-bit multi-turn counting.

When the battery is disconnected, it functions as a full absolute

encoder that transmits absolute position data at 17-bit per revolution.

Use the ServoStudio Motor Setup procedure and the Feedback screens to

define motor feedback type, resolution, and other parameters.

Feedback Wiring – Resolver

Pin # Twisted Pair User Motor Pin# Signal Description

6

Twisted Pair

Resolver Sine +

19 Resolver Sine -

7

Twisted Pair

Resolver Cosine +

20 Resolver Cosine -

8

Twisted Pair

Resolver Reference +

21 Resolver Reference -

12

Twisted Pair

Motor Temperature Sensor

25 Motor Temperature Sensor

26 Shield

Note: A

Page 35

CDHD Control Board

Quick Start Guide 35

Feedback Wiring - Incremental Encoder A Quad B Index Pulse and Halls

Pin # Twisted Pair User Motor Pin# Signal Description

1

Twisted Pair

Incremental Encoder A+

14 Incremental Encoder A-

2

Twisted Pair

Incremental Encoder B+

15 Incremental Encoder B-

3

Twisted Pair

Incremental Encoder Z+

16 Incremental Encoder Z-

4 Hall U

17 Hall V

5 Hall W

12

Twisted Pair

Motor Temperature Sensor

25 Motor Temperature Sensor

11 +5 VDC

24 0 VDC

26 Shield

Notes: A, C

Feedback Wiring – Halls Only

Pin # Twisted Pair User Motor Pin# Signal Description

4 Hall U

17 Hall V

5 Hall W

11 +5 VDC

24 0 VDC

26 Shield

Notes: A, C

Page 36

Control Board CDHD

36 Quick Start Guide

Feedback Wiring - Incremental Tamagawa

Pin # Twisted Pair User Motor Pin# Signal Description

1

Twisted Pair

Incremental Encoder A+ /

Hall U+

14 Incremental Encoder A- /

Hall U-

2

Twisted Pair

Incremental Encoder B+ /

Hall V+

15 Incremental Encoder B- /

Hall V-

3

Twisted Pair

Incremental Encoder Z+ /

Hall W+

16 Incremental Encoder Z- /

Hall W-

11 +5 VDC

24 0 VDC

26 Shield

Notes: B, D

Feedback Wiring - Sine Encoder

Pin # Twisted Pair User Motor Pin# Signal Description

9

Twisted Pair

Sine Encoder Sine+

22 Sine Encoder Sine-

10

Twisted Pair

Sine Encoder Cosine+

23 Sine Encoder Cosine-

11 +5VDC

24 0VDC

26 Shield

Notes: B, E

Page 37

CDHD Control Board

Quick Start Guide 37

Feedback Wiring - Sine Encoder with Halls

Pin # Twisted Pair User Motor Pin# Signal Description

9

Twisted Pair

Sine Encoder Sine+

22 Sine Encoder Sine-

10

Twisted Pair

Sine Encoder Cosine+

23 Sine Encoder Cosine-

4 Hall U

17 Hall V

5 Hall W

11 +5 VDC

24 0 VDC

26 Shield

Note: B

Feedback Wiring – Sine Encoder with Index

Pin # Twisted Pair User Motor Pin# Signal Description

9

Twisted Pair

Sine Encoder Sine+

22 Sine Encoder Sine-

10

Twisted Pair

Sine Encoder Cosine+

23 Sine Encoder Cosine-

3

Twisted Pair

Sine Encoder Z+

16 Sine Encoder Z-

11 +5 VDC

24 0 VDC

26 Shield

Note: B

Feedback Wiring – Sine Encoder with Index and Halls

Pin # Twisted Pair User Motor Pin# Signal Description

9

Twisted Pair

Sine Encoder Sine+

22 Sine Encoder Sine-

10

Twisted Pair

Sine Encoder Cosine+

23 Sine Encoder Cosine-

3

Twisted Pair

Sine Encoder Z+

16 Sine Encoder Z-

4 Hall U

Page 38

Control Board CDHD

38 Quick Start Guide

17 Hall V

5 Hall W

11 +5 VDC

24 0 VDC

26 Shield

Note: B

Feedback Wiring – Sick 5V (Hiperface Protocol and Sine Signal)

Pin # Twisted Pair User Motor Pin# Signal Description

1

Twisted Pair

SSI Data +

14 SSI Data -

9

Twisted Pair

Sine Encoder Sine+

22 Sine Encoder Sine-

10

Twisted Pair

Sine Encoder Cosine+

23 Sine Encoder Cosine-

11 +5 VDC

24 0 VDC

26 Shield

Note: B

Feedback Wiring - Sick 8V (Hiperface Protocol and Sine Signal)

Pin # Twisted Pair User Motor Pin# Signal Description

1

Twisted Pair

SSI Data +

14 SSI Data -

9

Twisted Pair

Sine Encoder Sine+

22 Sine Encoder Sine-

10

Twisted Pair

Sine Encoder Cosine+

23 Sine Encoder Cosine-

18 +8 VDC

24 0 VDC

26 Shield

Note: B

Page 39

CDHD Control Board

Quick Start Guide 39

Feedback Wiring – Heidenhain (EnDat 2.2 Protocol)

Pin # Twisted Pair User Motor Pin# Signal Description

1

Twisted Pair

SSI Data +

14 SSI Data -

2

Twisted Pair

SSI Clock +

15 SSI Clock -

11 +5 VDC

24 0 VDC

26 Shield

Note: B

Feedback Wiring – Heidenhain (EnDat 2.1 Protocol and Sine Signals)

Pin # Twisted Pair User Motor Pin# Signal Description

1

Twisted Pair

SSI Data +

14 SSI Data -

2

Twisted Pair

SSI Clock +

15 SSI Clock -

9

Twisted Pair

Sine Encoder Sine+

22 Sine Encoder Sine-

10

Twisted Pair

Sine Encoder Cosine+

23 Sine Encoder Cosine-

11 +5 VDC

24 0 VDC

26 Shield

Note: B

Feedback Wiring - Nikon 17-bit Single Turn

Pin # Twisted Pair User Motor Pin# Signal Description

1

Twisted Pair

Serial Data +

14 Serial Data -

11 +5 VDC

24 0 VDC

26 Shield

Notes: B

Page 40

Control Board CDHD

40 Quick Start Guide

Feedback Wiring - Nikon 17-bit Multi Turn

Pin # Twisted Pair User Motor Pin# Signal Description

1

Twisted Pair

Serial Data +

14 Serial Data -

11 +5 VDC

24 0 VDC

26 Shield

Battery Voltage

Battery Ground

Notes: B, F

Feedback Wiring - Incremental Tamagawa 17-bit Single Turn

Pin # Twisted Pair User Motor Pin# Signal Description

1

Twisted Pair

Serial Data +

14 Serial Data -

11 +5 VDC

24 0 VDC

26 Shield

Notes: B, G

Feedback Wiring - Tamagawa 17-bit Multi Turn

Pin # Twisted Pair User Motor Pin# Signal Description

1

Twisted Pair

Serial Data +

14 Serial Data -

11 +5 VDC

24 0 VDC

26 Shield

Battery Voltage

Battery Ground

Notes: B, F, H

Page 41

CDHD Control Board

Quick Start Guide 41

Fieldbus Devices – C5 and C6

All CDHD models have the same RJ45 connectors.

CAN Communication

1. Note the Termination Resistor switch located on the top of the drive next to

the daisy chain connector (C8).

Use a small slotted screwdriver or similar tool to set the switch position:

Towards T (default): 120Ω termination resistor not in use.

Away from T: Used when the drive is the last drive in a chain. The

drive provides the 120Ω termination resistor between CAN high and

CAN low.

2. Using any RJ45 cables:

Connect the host to the drive on interface C5.

Connect the next node to interface C6.

EtherCAT or PROFIBUS Communication

Using any RJ45 cables:

Connect the host to the drive on interface C5.

Connect the next node to interface C6.

Page 42

Control Board CDHD

42 Quick Start Guide

Host Computer – C1, C7

On all CDHD models the drive can be connected to the host computer through

either one of the following interfaces:

USB port. The interface is labeled C1 on all CDHD models

(Exception: AP models do not have a USB port.)

Use a USB 2.0 A to Mini-B cable.

RS232 port. The interface is labeled C7 on all CDHD models.

Use a 4p4c plug.

RS232 Interface – 4P4C

Pin Pin Label Function

1 RX Receive

2 GND ISO Ground

3 TX Transmit

4 Unused

Page 43

CDHD Control Board

Quick Start Guide 43

Daisy Chain – C8

The CDHD can be addressed and controlled on a daisy-chained RS-232 line.

In a daisy-chain RS-232 configuration, all drives must be daisy-chained through

the C8 connector. Each drive must have a unique address to enable its

identification on the network.

A daisy-chained drive can be assigned an address from 1 to 99 by setting the

rotary switches on the drive. When configuring a daisy-chain, address 0 cannot

be used.

Daisy Chain Interface

Pin Function

1 DC Shield

2 Unused

3 RXD

4 GND

5 TXD

6 GND

7-10 Unused

Page 44

Control Board CDHD

44 Quick Start Guide

Drive Address Switches

On all CDHD models, two rotary switches are used to set the drive address for

both CAN and serial communication. Use a small slotted screwdriver or similar

tool to set the switches.

Each switch has 10 positions:

The upper switch positions are set as tens: 10, 20, 30 … 90

The lower switch positions are set as ones: 0, 1, 2 … 9

Each drive on the network must have a unique address.

Note: If two or more drives are connected to the network, address 0 cannot be

used. A single drive may have the address 0.

Page 45

CDHD Power Board 120/240 VAC

Quick Start Guide 45

3 Power Board 120/240 VAC

Overview

On most CDHD 120/240 VAC models, the power board has the following interfaces:

STO – P1

Motor – P2 (P4 on CDHD-020/024)

Regeneration Resistor – P3 (P5 on CDHD-020/024)

AC Input Voltage – P3, P4 (P2, P3 on CDHD-020/024)

Make sure the main voltage rating matches the drive specification.

Applying incorrect voltage may cause drive failure.

Do not apply power until all hardware connections are complete.

Safe Torque Off (STO) – P1

STO uses interface P1 on all CDHD 120/240 VAC models.

Safe torque off (STO) is a safety function that prevents the drive from delivering

power to the motor, which can generate torque.

STO Enable and STO Return must be connected to enable CDHD operation. The

STO Enable signal voltage must be 24 VDC.

Note: If the application does not require STO control, jumper pin 4 to pin 1,

and pin 3 to pin 2, to bypass the STO.

STO Bypass

STO Interface

Pin Pin Label Function

1 24V STO Enable

2 GND STO Return

3 24V Return, provided by the drive

for use with emergency stop circuit

4 24V Supply, provided by the drive

for use with emergency stop circuit

Page 46

Power Board 120/240 VAC CDHD

46 Quick Start Guide

Motor – P2

Motor uses interface P2 on all CDHD 120/240 models.

Exception: Motor uses P4 on CDHD-020/024.

Motor Interface

Pin Pin Label Function

1 PE Protective ground (motor housing)

2 U Motor Phase U

3 V Motor Phase V

4 W Motor Phase W

Page 47

CDHD Power Board 120/240 VAC

Quick Start Guide 47

Regeneration Resistor – P3

Regen uses interface P3 on all CDHD 120/240 VAC models.

Exception: Regen uses P5 CDHD-020/024.

Note: On models CDHD-1D5 and CDHD-003, Regen and AC Input Voltage

are combined on one connector.

If the application requires a regeneration (regen) resistor, connect the regen

resistor between terminals B1+ and B2.

Regen Interface

Pin Pin Label Function

1 B1+ DC bus +

2 B2 Regen bus -

Regen Interface on CDHD -020/024

Pin Pin Label Function

1 B2 Regen bus -

2 B1+ DC bus +

Page 48

Power Board 120/240 VAC CDHD

48 Quick Start Guide

AC Input – P3, P4, P5

The AC Input interfaces and connectors vary among CDHD 120/240 VAC models.

CDHD-1D5 and CDHD-003: One connector for bus power and logic power

uses interface P3.

CDHD-4D5 and CDHD-006: One connector for bus power and logic power

uses interface P4.

CDHD-008, CHDH-010 andCDHD-013: Two connectors – a connector for bus

power uses interface P4, and another connector for logic power uses

interface P5.

CDHD -020/024: Two connectors – a connector for bus power uses interface

P3, and another connector for logic power uses interface P2.

Make the following connections:

1. Connect the AC input voltage ground wire to the PE terminal, located on the

CDHD front panel. Use an M4 ring or spade terminal.

2. Connect L1, L2 and L3 (for bus power):

If the main voltage is from a single-phase source, connect line and

neutral to L1 and L2.

If the main voltage is from a three-phase source, connect the phases to

L1, L2 and L3.

3. Connect L1C and L2C (for logic power):

If the main voltage is from a single-phase source, connect line and

neutral to L1C and L2C.

If the main voltage is from a three-phase source, connect any two

phases to L1C and L2C.

Page 49

CDHD Power Board 120/240 VAC

Quick Start Guide 49

AC Input Voltage Interface

Note: On models CDHD-1D5 and CDHD-003, Regen and AC Input Voltage

are combined on one connector.

CDHD-1D5

CDHD-003 Pin Pin Label Function

P3 3 L1 AC Phase 1

4 L2 AC Phase 2

5 L1C Logic AC Phase 1

6 LC2 Logic AC Neutral

CDHD-4D5

CDHD-006 Pin Pin Label Function

P4 1 L1 AC Phase 1

2 L2 AC Phase 2

3 L3 AC Phase 3

4 L1C Logic AC Phase 1

5 LC2 Logic AC Neutral

CDHD-008

CDHD-010

CDHD-013 Pin Pin Label Function

P4 1 L1 AC Phase 1

2 L2 AC Phase 2

3 L3 AC Phase 3

P5 1 L1C Logic AC Phase 1

2 LC2 Logic AC Neutral

CDHD-020

CDHD-024

Pin Pin Label Function

P3 1 L1 AC Phase 1

2 L2 AC Phase 2

3 L3 AC Phase 3

P2 1 L1C Logic AC Phase 1

2 LC2 Logic AC Neutral

Page 50

Power Board 400/480 VAC CDHD

50 Quick Start Guide

4 Power Board 400/480 VAC

Overview

On all CDHD 400/480 VAC models, the power board has the following interfaces:

STO – P1

Logic Power 24 VDC – P2

AC Input and Regeneration – P3

Brake – P4

Motor – P5

Make sure the main voltage rating matches the drive specification.

Applying incorrect voltage may cause drive failure.

Do not apply power until all hardware connections are complete.

Safe Torque Off (STO) – P1

STO uses interface P1 on all CDHD 400/480 VAC models:

Safe torque off (STO) is a safety function that prevents the drive from delivering

power to the motor, which can generate torque.

STO Enable and STO Return must be connected to enable CDHD operation. The

STO Enable signal voltage must be 24 VDC.

Note: If the application does not require STO control, jumper pin 4 to pin 1,

and pin 3 to pin 2, to bypass the STO.

STO Bypass

STO Interface

Pin Pin Label Function

1 24V STO Enable

2 GND 24 VDC Return

3

4

Page 51

CDHD Power Board 400/480 VAC

Quick Start Guide 51

Logic Power 24V Input – P2

Logic Power 24V uses interface P2 on all CDHD 400/480 VAC models.

This interface is used to connect an external power supply (24V 3.15A max.)

that provides the logic voltage to the control board and to the motor brake

circuit.

Logic Power 24V Interface

Pin Pin Label Function

1 24V Logic In

2 GND 24 VDC Return

Page 52

Power Board 400/480 VAC CDHD

52 Quick Start Guide

AC Input and Regeneration Resistor – P3

AC Input and Regen Resistor use interface P3 on all CDHD 400/480 VAC

models.

1. Connect the AC input voltage ground wire to the PE terminal, located on the

CDHD front panel. Use an M4 ring or spade terminal.

2. Connect L1, L2 and L3 for the AC power input.

3. If the application requires a regeneration (regen) resistor, connect the regen

resistor between terminals B1+ and B2.

AC Input and Regeneration Resistor Interface

Pin Pin Label Function

1 L1 AC Phase 1

2 L2 AC Phase 2

3 L3 AC Phase 3

4 B1+ DC Bus +

5 B2 Regen Bus

6 B3- DC Bus -

Page 53

CDHD Power Board 400/480 VAC

Quick Start Guide 53

Brake – P4

Brake uses interface P4 on all CDHD 400/480 VAC models.

This is the power output for the electric motor brake system.

Brake Interface

Pin Pin Label Function

1 BR+ Motor Brake +

2 BR- Motor Brake -

Page 54

Power Board 400/480 VAC CDHD

54 Quick Start Guide

Motor – P5

Motor uses interface P5 on all 400/480 VAC models:

Motor Interface

Pin Pin Label Function

1 U Motor Phase U

2 V Motor Phase V

3 W Motor Phase W

Page 55

CDHD Software

Quick Start Guide 55

5 Software

ServoStudio Installation

Use ServoStudio software to configure the drive for your application.

1. Install ServoStudio on the host computer.

2. When installation is complete, start ServoStudio.

Power Up

1. After completing the hardware connections, turn on power to the drive.

2. The first time the drive is connected to the host computer on the USB port,

Windows detects the device and displays a Found New Hardware wizard.

Browse to and select the Drivers folder. The path will vary, depending on

the computer’s operating system and the location selected for software

installation; for example:

\Program Files (x86)\IMO\ServoStudio\Drivers

\Program Files\IMO\ServoStudio\Drivers

The wizard will automatically select and install the driver file STX-CDHD.inf

from the folder.

3. Look at the 7-segment display on the CDHD front panel.

Page 56

Software CDHD

56 Quick Start Guide

Upon initial power up, the status display shows a flashing e, indicating that

drive parameters are not yet configured. This fault will be cleared once the

drive is configured.

The digital display provides various indications of drive operation, such as

operation modes, drive enable status, and fault conditions.

For more information, refer to the section Drive Status.

Drive Configuration

1. In ServoStudio, select the Setup Wizard option from the navigation menu.

2. Follow the prompts to configure the CDHD for your particular motor and

application.

Note: The wizard performs a basic drive configuration. For more advanced

configuration options and procedures, refer to the user manual.

Page 57

CDHD Drive Status

Quick Start Guide 57

6 Drive Status

The 7-segment display provides various indications of drive status, such as

operation modes, drive enable status, and fault conditions.

The display uses the following conventions:

Decimal point –Enable/Disable status; if displayed, the drive is enabled.

Steadily lit digit – Operation mode (OPMODE).

Steadily lit letter – Warning.

Sequential display of letters and digits – Fault, with some exceptions.

Flashing – Fault.

Other Status Indications

During the motor setup (At1) and current loop tuning (At2) procedures,

three characters are displayed in sequence.

The state of the software and hardware limit switches are indicated by a

sequential display of characters (L1, L2, L3, L4).

During the encoder initialization, a digit flashing at half-second intervals

indicates the operation mode (OPMODE) currently in effect.

Normal Operation Codes

After the drive is configured and ready for operation, the display shows a

steadily lit single digit, indicating the operation mode.

Display Name Description Drive

Enabled

Drive

Disabled

. Drive enabled

0 OPMODE 0 Serial velocity control mode

1 OPMODE 1 Analog velocity control mode

2 OPMODE 2 Serial current control mode

3 OPMODE 3 Analog current control mode

Page 58

Drive Status CDHD

58 Quick Start Guide

Display Name Description Drive

Enabled

Drive

Disabled

4 OPMODE 4 Master/slave gearing control mode

8 OPMODE 8 Position control mode

E Ember Mode Drive is in Ember

mode; firmware is

being downloaded to the drive.

Warning and Fault Codes

The following table will help you interpret the warning and fault codes, and

respond appropriately.

Display is the code that appears on the drive’s 7-segment display.

Light distinguishes between a steadily lit character (for warnings) or a

flashing character (for faults).

Type specifies a warning or a fault.

Name is the text message displayed in ServoStudio.

Display Light Type Name Description Action Required

≡≡≡≡

Flash Fault Watchdog Fault Generally occurs due to an

unforeseen circumstance. The

drive is inoperable until power is

cycled.

Contact technical support.

-1 Fault Not Configured Drive configuration required. Set drive parameters and

execute CONFIG.

-5 Fault Motor Setup Failed Motor Setup procedure failed

(MOTORSETUPST will show the

reason)

Check phase and motor

wiring. Make sure to choose

the correct feedback type,

and follow the hints in

MOTORSETUPST.

A4 Fault CAN Supply Fault A problem with the internal

voltage supply for the CAN bus.

The drive probably needs

repair. Contact technical

support.

b Flash Fault Drive Locked Security code and key do not

match. Fatal fault; drive cannot

be operated.

Contact technical support.

b Steady Warning Tamagawa Battery

Low-Voltage

Battery voltage is nearing fault

level.

Prepare to replace battery

soon.

b1 Fault PLL (phase-locked

loop)

Synchronization

Failed

Controller synchronization signal

is missing or not stable. The

fault is detected only when

synchronization is enabled by

SYNCSOURCE command.

Check if controller provide

synchronization signal. Check

the cable connection and

wiring.

Page 59

CDHD Drive Status

Quick Start Guide 59

Display Light Type Name Description Action Required

e Flash Fault Parameter Memory

Checksum Failure

The non-volatile memory used

to store drive parameters is

empty or the data is corrupted.

Reconfigure the drive, or

download the parameter set,

and save the parameters.

E Flash Fault Failure Writing to

Flash Memory

An internal problem accessing

the flash memory. Fatal fault;

drive cannot be operated.

Contact technical support.

e101 Fault FPGA Config Fail The code for the FPGA did not

load. Fatal fault; drive cannot

be operated.

Contact technical support.

e105 Fault Self Test Fail The power-up self test failed.

Fatal fault; drive cannot be

operated.

Contact technical support.

e106 Fault Control EEPROM

Fault

A problem accessing the

EEPROM on the control board.

Fatal fault; drive cannot be

operated.

Contact technical support.

e107 Fault Power EEPROM

Fault

A problem accessing the

EEPROM on the power board.

Fatal fault; drive cannot be

operated.

Contact technical support.

e108 Fault Vbus Measure

Circuit Fail

A failure occurred in the circuit

that measures bus voltage.

Reset faults. If the fault

persists, the drive probably

needs repair. Contact

technical support.

e109 Fault Current-Sensors

Offset Out-ofRange

The calculated offsets for the

current sensors are out of

range.

Reset faults. If the fault

persists, the drive probably

needs repair. Contact

technical support.

e120 Fault FPGA Version

Mismatch

FPGA version does not match

the firmware version

Update either the FPGA

version or drive version

F Steady Warning Foldback Drive fold current dropped

below the drive fold current

warning threshold

(MIFOLDWTHRESH).

Or, motor fold current dropped

below the motor fold current

warning threshold

(IFOLDWTHRESH).

Check the drive-motor sizing.

This warning can occur if the

drive or the motor is undersized (under-powered) for the

application.

F1 Fault Drive Foldback Drive fold current dropped

below the drive fold current

fault threshold

(MIFOLDFTHRESH).

Check motor-

drive sizing. This

fault can occur if the drive is

under-sized (under-powered)

for the application.

Check that the commutation

angle is correct (i.e.,

commutation is balanced).

Check MIFOLDFTHRESH and

MIFOLDWTHRESH values

F2 Fault Motor Foldback Motor fold current dropped

below the motor fold current

fault threshold.

(IFOLDFTHRESH).

Check the drive-motor sizing.

This fault can occur if the

motor is under-sized (underpowered) for the application.

Check IFOLDFTHRESH and

IFOLDWTHRESH values.

F3 Fault Stall Fault A stall fault occurred because

the motor was in a stalled state

for too long; that is, [I >

MICONT] and [I > 0.9 ILIM] and

[V < STALLVEL] for [time >

STALLTIME].

Remove the stall condition,

and take care to prevent stall

conditions.

Page 60

Drive Status CDHD

60 Quick Start Guide

Display Light Type Name Description Action Required

H Flash Fault Motor Over-

Temperature

Either the motor has

overheated, or the drive is not

set up correctly for the motor

temperature sensor.

Check that the drive is

configured properly (using

THERMODE, THERMTYPE,

THERMTHRESH and

THERMTIME), and that the

motor temperature sensor is

properly connected to the

drive if needed.

If the drive is configured and

wired prope

rly, check whether

the motor is under-sized for

the application.

H Steady Warning Motor Over-

Temperature

Motor is overheated.

j Flash Fault Velocity Over-

Speed Exceeded

Actual velocity exceeded 1.2

times the velocity limit. The

velocity limit is set using VLIM.

Check that VLIM is set to

match the application

requirements. Using velocity

loop tuning, check for

excessive overshoot.

j1 Fault Exceeded

Maximum Position

Error

The position error (PE) has

exceeded the position error limit

(PEMAX)

Change drive tuning to

improve position tracking, or

increase PEMAX to allow a

greater position error.

L1 Warning Hardware positive

limit switch is open

Positive hardware limit switch is

activated.

L2 Warning Hardware negative

limit switch is open

Negative hardware limit switch

is activated.

L3 Warning Hardware positive

and negative limit

switches are open

Positive and negative hardware

limit switches are both

activated.

L4 Warning Software positive

limit switch is

tripped

Positive software limit switch is

activated.

PFB > POSLIMPOS and

POSLIMMODE = 1

L5 Warning Software negative

limit switch is

tripped

Negative

software limit switch is

activated.

PFB < POSLIMNEG and

POSLIMMODE = 1

L6 Warning Software limit

switches are

tripped

Positive and negative software

limit switches are activated.

PFB > POSLIMPOS and

PFB < POSLIMNEG and

POSLIMMODE = 1

n Flash Fault STO Fault The STO signal is not connected

when drive enabled.

Check that the STO connector

(P1) is wired correctly.

n Steady Warning STO The STO signal is not connected

when drive disabled.

Check that the STO connector

(P1) is wired correctly.

n1 Fault Regen Over-

Current

The preset current limit for

regen current has been

exceeded.

Increase the value of the

regen resistor.

n41 Fault

Power Brake Open

Load

Open load on the power brake

output

Make sure the power brake

load cables are connected

properly and are not

damaged.

n42 Fault

Power Brake Short

Short circuit on the power brake

output

Replace the power brake (the

motor).

o Flash Fault Over-Voltage The bus voltage exceeded the

maximum value.

Check whether a regen

resistor is required for the

application.

Page 61

CDHD Drive Status

Quick Start Guide 61

Display Light Type Name Description Action Required

o15 Fault Plus 15V Out of

Range

The internal +15 V supply is out

of range.

The drive probably needs

repair. Contact technical

support.

o-15 Fault Minus 15V Out of

Range

The internal -15 V supply is out

of range.

The drive probably needs

repair. Contact technical

support.

o5 Fault 5V Out of Range 5V is low or powering off

May occur during power off. If

occurs otherwise, contact

technical support.

P Fault Over-Current Over-

current at the drive output

has been detected.

The drive allows this fault to

occur up to 3 times in

succession. After 3 faults, the

drive forces a delay of 1 minute

before it can be reenabled.

Check for a short circuit on

the motor connection.

Check for excessive overshoot

in the current loop.

r10 Fault Sine Feedback

Communication Fail

Communication problem

between the drive and the

EnDat encoder.

Check that the data and clock

signals to the EnDat encoder

are connected properly. The

cable must be shielded.

r14 Fault Sine Encoder

Quadrature Fault

Mismatch between calculated

and actual encoder quadrature

information.

Check the feedback device

wiring.

Check that the correct

encoder type (MENCTYPE) is

selected.

r15 Fault Sin/Cos Calibration

Invalid

The sine/cosine calibration

parameters are out of range.

This fault is related to resolver

and sine encoder feedback.

Re-execute the sine/cosine

calibration process.

r16 Fault Feedback 5V Over-

Current

The current supplied by the

drive on the 5V primary encoder

supply has exceeded the preset

current limit.

The drive allows this fault to

occur up to 3 times in

succession. After 3 faults, the

drive forces a delay of 1 minute

before it can be reenabled.

The CDHD can source a

maximum current of 250 mA

to the primary encoder.

Check for a short-circuit at

the encoder.

Check if the encoder is

drawing more than the

current limit.

r17 Fault Secondary

Feedback Index

Break

Secondary encoder index line

not connected.

Check whether the drive is

configured for working with

the index signal on the

secondary encoder, and check

if the index signal is

connected.

r18 Fault Secondary

Feedback A/B Line

Break

One of the secondary feedback

signals is not connected.

Check that all signals from the

secondary encoder are

properly connected to the

drive.

r19 Fault Secondary

Feedback 5V OverCurrent

The preset current limit for

current supplied by the drive on

the 5 V secondary encoder

supply has been exceeded.

The CDHD can source a

maximum current of 250 mA

to the secondary encoder.

Check for a short-circuit at

the encoder.

Check if the encoder is

drawing more than the

current limit.

r20 Fault Feedback

Communication

Error

Communication with the

feedback device did not

initialize

correctly.

Check that the feedback

device is wired correctly.

Check that the correct

encoder type (MENCTYPE) is

selected.

Page 62

Drive Status CDHD

62 Quick Start Guide

Display Light Type Name Description Action Required

r21 Fault Nikon Encoder

Operational Fault

Communication with the Nikon

MAR-A40A feedback device did

not initialize correctly.

Check that the feedback

device is wired correctly.

Check that the correct

encoder type (MENCTYPE) is

selected.

r23 Fault Phase Find Failed Commutation initialization has

failed. This fault occurs in

systems that do not have

commutation information (e.g.,

Hall signals) in the motor

feedback device.

Check whether the motor

feedback type and the phasefinding parameters are set

correctly for the application.

r24 Fault Tamagawa Init

Failed

The initialization process with

the Tamagawa feedback device

has failed.

Check that the wiring to the

encoder is correct.

r25 Fault Pulse & Direction

Input Line Break

One of the Pulse & Direction

signals is not connected.

Check that all signals to the

P&D inputs are properly

connected to the drive.

r26 Fault Tamagawa Abs

Operational Fault

Several faults are indicated by

the feedback device and include

one or more of the following:

battery low/error, over-speed,

counting error, multi-turn error

Check the battery voltage and

feedback wiring. Make sure

the motor did not move at a

high velocity during encoder

initialization.

r27 Fault Motor Phases

Disconnected

One of the motor phases is

disconnected. The current of

one of the motor phases is

effectively zero for more than

160 electrical degrees while the

current command is greater

than 100.

Check the wiring of the motor

phases.

r28 Fault Resolver

Initialization Failed

The drive could not detect the

proper gain setting or sampling

point for the sine/cosine signals.

Check resolver wiring and

gain value.

r29 Fault Absolute Encoder

Battery LowVoltage

An error bit indicating a battery

problem was detected in data

from the drive.

Replace battery, then reset

drive. If battery is replaced

while drive is on, position

information is retained.

r34 Fault PFB Off Checksum

Invalid

The calculated checksum of the

PFB backup data does not

match the expected checksum.

If required by the application,

home the machine.

r35 Fault PFB Off Data

Mismatch

Multiturn data of the PFB cannot

be restored due to axis

movement.

If required by the application,

home the machine.

r36 Fault No PFB Off Data PFB backup memory is empty. If required by the application,

home the machine.

r4 Fault A/B Line Break One of the primary feedback

signals is not connected. This

fault occurs in incremental

encoder, resolver and sine

encoder feedback types.

Check whether all signals

from the primary feedback

device are properly connected

to the drive.

r5 Fault Index Line Break Encoder index line is not

connected.

Check that the drive is

configured for working with

the index signal (using

MENCTYPE), and check if the

index signal is connected.

Page 63

CDHD Drive Status

Quick Start Guide 63

Display Light Type Name Description Action Required

r6 Fault Illegal Halls The drive has detected either

000 or 111 state on the Hall

feedback signals.

Check that the Hall signals

are all properly connected.

While turning the motor, read

the Halls state (using HALLS)

to see which signal is not

connected.

If the feedback type is

Tamagawa, check that the

feedback wiring is correct

r8 Fault A/B Out of Range Feedback analog signal is out of

range. This fault is related to

resolver and sine encoder

feedback. The drive checks that

the amplitudes of the sine and

cosine signals are correct, based

on the calculation sin2 + cos2 =

1

Check the amplitudes of the

sine and cosine signals.

r9 Fault Encoder Simulation

Freq Too High

The computed equivalent

encoder output frequency

exceeds the upper limit for this

signal, which is 4 MHz.

Check the parameters used

for setting up the equivalent

encoder output.

If using a sine encoder, check

the ENCOUTRES parameter

settings.

t Steady Warning Over-Temperature The temperature on the power

board and/or on the control

board has exceeded the preset

limit.

Check if the ambient

temperature exceeds the

drive specification. Otherwise

contact technical support.

t1 Fault Power Stage Over-

Temperature

The temperature on the power

board has exceeded the preset

limit.

Check if the ambient

temperature exceeds the

drive specification. Otherwise

contact technical support.

t2 Fault Power Module

Over-Temperature

The temperature inside the

integrated power module has

exceeded the preset limit.

Check if the ambient

temperature exceeds the

drive specification. Otherwise

contact technical support.

t3 Fault Control Board

Over-Temperature

The temperature on the control

board has exceeded the preset

limit.

Check if the ambient

temperature exceeds the

drive specification. Otherwise

contact technical support.

u Flash Fault Under-Voltage The bus voltage is below the

minimum value.

Check that the main AC

voltage supply is connected to

the drive and is switched on.

The under-voltage limit can

be read with the UVTHRESH

command.

u Steady Warning Under-Voltage The bus voltage is below the

minimum value.

Check that the main AC

voltage supply is connected to

the drive and is switched on.

Verify that the setting of

UVMODE is correct.

Warning

Encoder Hall Switch

Not Found

Hall switch not yet detected.

Warning Encoder Index Not

Detected

Index not yet detected.

Warning HIPERFACE

Encoder Resolution

Mismatch

Encoder resolution, as

determined from the detected

HIPERFACE device information,

is different from the current

settings of MENCRES

Enter the correct resolution

(MENCRES value).

Warning HIPERFACE Device

Not Supported

The detected HIPERFACE device

is not supported

Contact technical support.

Page 64

Drive Status CDHD

64 Quick Start Guide

Display Light Type Name Description Action Required

Warning HIPERFACE Device

Unknown

HIPERFACE encoder type

information is not recognized

Contact technical support.

Warning Phase Find

Required

Phase difference is required to

initialize the commutation angle

Perform phase find.

Page 65

Page 66

CDHD Servo Drive

Quick Start Guide

DOC-CDHD-QSG-EN Rev. 5.4

IMO Jeambrun – 30,Rue de Rocory

94100 Saint Maur Des Fosses, France

Tel: +8000 912 712

imo-fr@imopc.com

www.imopc.com

Loading...

Loading...