Page 1

CDHD Servo Drive

User Manual

Revision 0.2

PRELIMINARY RELEASE

Page 2

Page 3

CDHD

User Manual i

Revision Histo r y

Document

Revision

Date Remarks

0.2 June 2011

Added diagram: CDHD-1D5 Dimensions;

Replaced diagram: Syste m Wiring - Pin

Assignments; Minor text fixes

0.1 June 2011 Preliminary version

Hardware

Revision

Firmware

Revision

Software

Revision

Remarks

0.0.0.10

Important Notice

© 2011 Servotronix Motion Control Ltd.

All rights reserved . No par t of this work may be repr od uced or transmitted in any

form or by any mean s without prior wr itten permiss ion of Servotr onix Motion

Control Ltd.

Disclaimer

The information in this manual was accurate and reliable at the time of its

release. Servotronix Motion Control Ltd. reserves the right to change the

specifications of the product described in this manual without notice at any time.

Trademarks

All marks in this manual are the property of their respective owners.

Contact Information

Servotronix Motion Control Ltd.

21C Yagia Kapayim Street

Petach Tikva 49130

Israel

Tel: +972 (3) 92 7 3800

Fax: +972 (3) 922 8075

Website:

www.servotronix.com

Technical Support

If you need assistance with the installation and configuration of the CDHD drive,

contact Servotronix technical support:

tech.support@servotronix.com

Customer Service

Servotronix is committed to delivering quality customer service and support for

all our products. Our goal is to provide our customers with the information and

resources so that they are available, without delay, if and when they are needed.

In order to s erve in the most effective way, we recommend that you contact

your loca l sales representative for order status and del ivery informa tion, product

information and literature, and application and field technical assistance. If you

Page 4

CDHD

ii Servotronix

are unable to contact your local sales representative for any reason, please use

the most relevant of the contact details below:

For technical support, contact:

tech.support@servotronix.com

To order products, contact:

orders@servotronix.com

For all other inquiries r egarding CDHD drives or other Serv otronix products,

contact: customer.service@servotronix.com

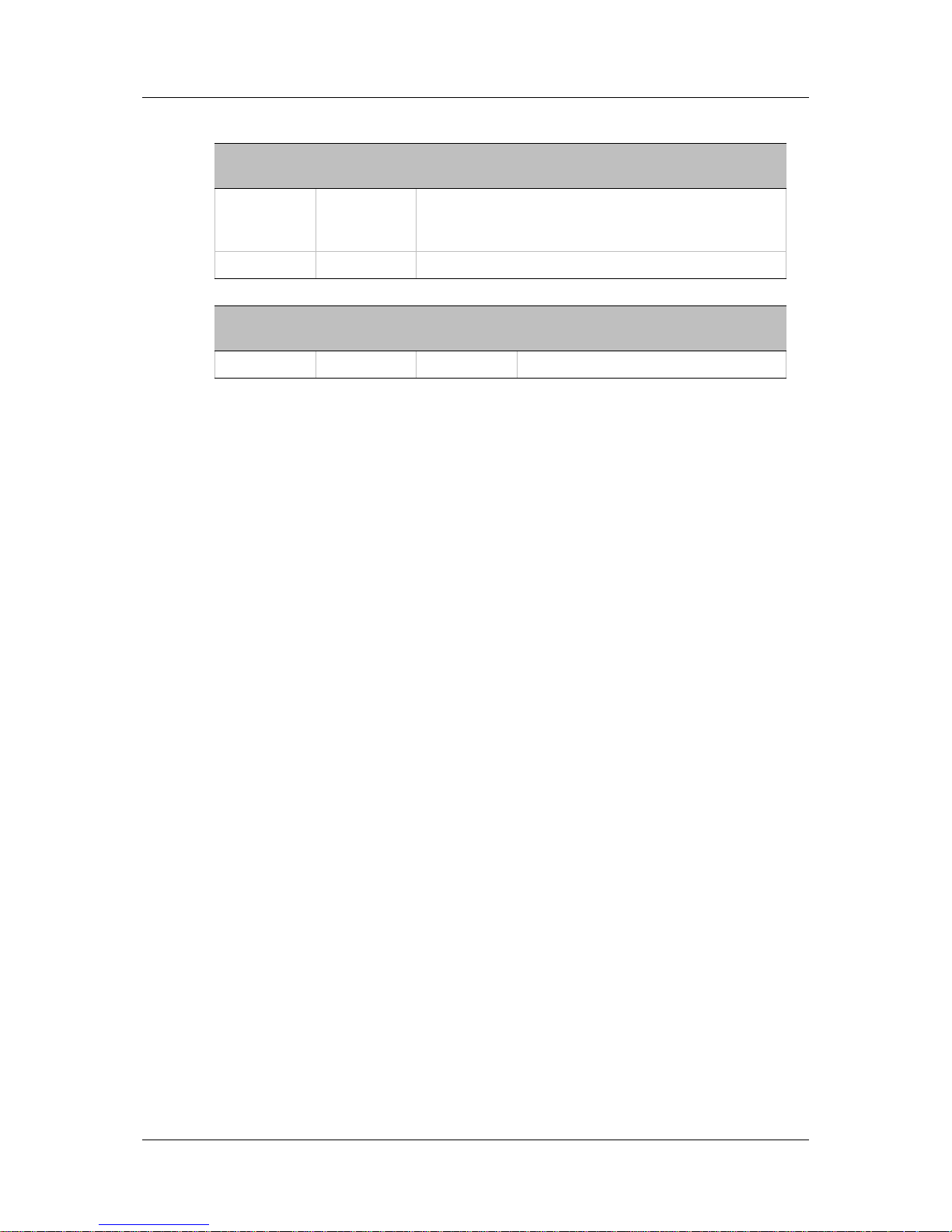

Part Number

For ordering the CDHD, r e fe r to the followin g diagram:

Warranty

The warranty is valid for 12 months from the date of shipment and applies only if

material or workmanship is found to be defective. The warranty will be invalid if

the customer fails to install, operate or maintain the product in accordance with

the instructions in this user manual.

During the warranty period, the owner must pay the cost of shipping the product

to the factory for repair , and Servotronix will pay for shipping the repaired

product to the customer.

After the warranty period has expired, all shipping costs will be the responsibility

of th e cust o mer.

Before returning the product, the customer must first request a Return Materials

Authorization (RMA) number from Se rvotronix by email to rma@servotronix.com

The complete Warranty Statement can be found in the Terms and Conditions

document on the Servotronix website:

www.servotronix.com/customer-service.html

Page 5

CDHD

User Manual iii

Contents

1 Introduction ________________________________________________ 1

1.1 Documentation .......................................................................................... 1

1.1.1 About This Manual ............................................................................ 1

1.1.2 Documentation Set for CDHD ............................................................. 1

1.2 Safety ...................................................................................................... 1

1.2.1 Safety Sy mb o ls ................................................................................ 1

1.2.2 Safety Instructions ........................................................................... 2

1.3 Standards Compliance ................................................................................ 2

1.3.1 General Information ......................................................................... 2

1.3.2 CE Compliance ................................................................................. 3

1.4 Unpacking................................................................................................. 4

2 Product Descri p t ion __________________________________________ 5

2.1 Overview .................................................................................................. 5

2.1.1 General Description .......................................................................... 5

2.1.2 Product O pt ions ............................................................................... 5

2.2 Technical Specifications .............................................................................. 6

2.2.1 Dimensions ..................................................................................... 6

2.2.2 Mechanical and Electrical Specific a tions - 200V .................................... 7

2.2.3 Mechanical and Electrical Specific a tions - 400V .................................... 8

2.2.4 Control Specificati ons ...................................................................... 10

2.2.5 Protective Functions and Environment................................................ 11

2.2.6 Communication ............................................................................... 11

2.2.7 I/Os............................................................................................... 12

2.2.8 Motor Feed back............................................................................... 13

2.3 System Wiring - Pin Assignment s ................................................................ 14

3 Installation ________________________________________________ 15

3.1 Installation Overview ................................................................................ 15

3.2 Preparation .............................................................................................. 15

3.2.1 Hardware Requ irem ents ................................................................... 15

3.2.2 Computer Requirements................................................................... 16

3.2.3 Electrical Requirements .................................................................... 18

3.3 Mecha nic al Installation .............................................................................. 20

3.3.1 Mount th e CDHD ............................................................................. 20

3.4 Electr ical Installat io n ................................................................................. 20

3.4.1 Connect Motor (P2) ......................................................................... 20

3.4.2 Connect STO (P1)............................................................................ 21

3.4.3 Connect Regen (P3) ......................................................................... 22

3.4.4 Connect Motor Feedback (C4) ........................................................... 22

3.4.5 Connect Controller I/Os (C2) ............................................................ 24

3.4.6 Connect Machine I/Os ( C3) ............................................................... 25

3.4.7 Connec t AC I nput Voltage (P4).......................................................... 26

3.5 Set the Drive Address................................................................................ 27

3.6 Connect to PC ( C1 or C7) ........................................................................... 28

3.7 Power Up ................................................................................................. 29

3.8 Servo Studio So f tware In stallation ............................................................... 29

4 Configurati on and Operation___________________________________ 30

4.1 Variables and Commands........................................................................... 30

4.2 ServoSt ud io Software ................................................................................ 30

4.3 Connecti ng to a Drive ................................................................................ 31

4.4 Enabling/Disabling a Drive ......................................................................... 31

4.4.1 Drive Enable ................................................................................... 31

4.4.2 Operation Mod e Code s ..................................................................... 32

Page 6

CDHD

iv Servotronix

4.5 Managing Drive Parameters ....................................................................... 33

4.6 Config uring Para m eters Using Serv o S tudio .................................................. 34

4.6.1 Tuning a nd Te sting .......................................................................... 34

4.6.2 Drive Info ....................................................................................... 35

4.6.3 Power ............................................................................................ 35

4.6.4 Motor ............................................................................................. 35

4.6.5 Foldback ........................................................................................ 35

4.6.6 Units.............................................................................................. 35

4.6.7 Feedback ....................................................................................... 35

4.6.8 Motion ........................................................................................... 36

4.6.9 Scope ............................................................................................ 36

4.6.10 Digital I/Os ..................................................................................... 36

4.6.11 Analog I/O...................................................................................... 36

4.6.12 Enable ........................................................................................... 36

4.6.13 Current Loop .................................................................................. 36

4.6.14 Current Limits ................................................................................. 36

4.6.15 Velocity L oop .................................................................................. 36

4.6.16 Velocity Limits ................................................................................ 36

4.6.17 Terminal ........................................................................................ 36

4.6.18 Faults ............................................................................................ 37

4.6.19 Parameters Table ............................................................................ 37

4.7 ServoStudio Expert View ........................................................................... 37

5 Firmware Upg ra d e __________________________________________ 38

5.1 Preparation .............................................................................................. 38

5.2 Upgrade Procedure ................................................................................... 38

6 Troubleshooting ____________________________________________ 39

6.1 Drive Status 7-Segment Display ................................................................. 39

6.2 Faults a nd Warning s .................................................................................. 39

6.3 Status Information in ServoStudio .............................................................. 40

6.4 Fault and Status Queries ........................................................................... 40

6.5 Fault Codes and Names ............................................................................. 40

Page 7

CDHD Introduction

User Manual 1

1 Introduction

1.1 Documentation

1.1.1 About This Manual

This manual describ e s t he Servotronix CDHD Servo Drive. It provides th e

information required for installation, configuration and basic operation of the

CDHD unit.

This document is intended for persons who are qualified to transport, assemble,

commission, and maintain the equipment described herein.

1.1.2 Documentation Set for CDHD

This manual is part of a documentation set. The entire set consists of the

following:

CDHD Quick Start Guide. Basic setup and operation of the drive.

CDHD User Manual. Hardware installation, configuration and operation.

CDHD VarCom Reference Manu al. Parame ters and commands used to

program the CDHD.

1.2 Safety

Only qualified persons may perform the installation procedures . You do not need

to be an expert in motion control to install and operate the drive system.

However , yo u m us t ha ve a basic under standi ng of electronics, computers,

mechanics, and safety practices.

The CDHD utili zes ha zardous volt ag es.

Be sure the driv e is properly grounded.

Before you install the CDHD, review the safety instructions in this manual.

Failure to follow t he sa fety inst r uctions may result in personal injury or

equipment damage.

1.2.1 Safety Symbols

Safety symbols indicate a potential for personal injury or equipment damage if

the recommended precautions and safe operating practices are not followed.

The following safety-a lert symbols are used on the drive and in the

documentation:

Caution ISO 7000-0434 (2004-01)

Page 8

Introduction CDHD

2 Servotronix

Warning. Dangerous voltage. IEC 60417-5036 (2002-10)

Protective earth; protective ground IEC 60417–5019 (2006-08)

Cautio n, ho t su rf ac e IEC 60417-5041 (2000-10)

1.2.2 Safe ty Instructions

Read all available product documentation before assembling and

commission ing. I ncor re ct ha ndl i ng of this produ ct may ca u se pe rso na l inj ury

and/or damage to equipment. Ad he re strict ly to the insta l lation instruc tions

and requirements.

All syste m c omponents must be connected to ground. Electrica l safety is

provided through a low-resistance earth ground connection.

This product contains static sensitive components that can be damaged by

incorr ect hand l ing . Av oid conta ct with h ig h insulati ng m ateria ls (artif ic ia l

fabrics, plastic film, etc.). Place the product on a conductive surface. Ground

yourself (discharge any possible static electricity build-up) by touching an

unpainted, metal, grounded surface.

Keep all cov ers and cabinet d oors shut during operation. Otherwise,

potential hazards may cause personal injury and/or damage to equipment.

During operation the product has electrically charged components and hot

surfaces. The heat sink can reach temperatures of 90°C. Control and power

cables can carry a high voltage, even when the motor is not rotating.

To avoid electric arcing and hazards to personnel and electric contacts,

never disconnect or connect the product while the power source is

energized.

After removing the power source from the equipment, wait at least

5 minutes before touching or disconnecting sections of the equipment that

normally carry electrical charges (e.g., capacitors, contacts, screwed

connections). For safety, measure the electrical contact points with a meter

before touching the equipment. Wait until the voltage drops below 30 VAC

before handling components.

1.3 Standards Compliance

1.3.1 General Information

The CDHD has been successfully tested and evaluated according to standards

IEC 61800-5-1 and UL 508C. This testing outlines the minimum requirements for

electrically operated power conversion equipment (frequency converters and

servo amplifiers) , whi ch are intended to eliminate the risk of fire, electric shock,

or injur y to persons.

Page 9

CDHD Introduction

User Manual 3

UL 508C references UL 840, which describes the achievement by design of air

and insulation creepage spacings for electrical equipment and printed circuit

boards. The CDHD provides overload prot ection and current limit control .

The drive is i ntended for operation in pollution level 2 environment.

The terminals on the controller are coded so they can easily be identified in the

instructions. The instructions identify the connections for the power supply, load,

control, and ground.

Integral solid state short circuit protection does not provide branch circuit

protection. Branch circuit protection must be provided in accordance with the

National Electrical Code and any additional local codes, or the equivalent.

1.3.2 CE Compliance

Compliance with EC EMC Directive (2004/108/EC) and EC Low Voltage Directive

(2006/95/EC) is mandatory for all servo drives provided to the European

Community. CDHD is manufactured in conforman ce with these directives. CDHD

drives have also been successfully tested and evaluated to the limits and

requirements of these directives.

EC Low Voltage Directive (2006/95/EC) complies with standard IEC 61800-5-1.

The following standards are used in connec tio n with EC EM C Dir e ctive

(2004/108/EC):

IEC 61000-6-1/2 (Interference Immunity in Residential & Industrial Areas)

IEC 61000-6-3/4 (Interference Generation in Residential & Industrial Areas)

Drives are components that ar e intended for incorpora tion into a m achine, for

industrial use. Before a drive is in installed, verify that the associated equipment

complie s with the following standards :

EC Machinery Directive (2006/42/EC)

EC EMC Directive (2004/108/EC)

EC Low Voltage Directive (2006/95/EC)

Standards EN/IEC 60204-1 (Safety and Electrical Equipment in Machines),

ISO 12100 (Safety of Machines) and EN 292 must be observed in reference to

Machinery Directive (2006/42/EC) .

Standard IEC 6 04 39-1 (Low-voltage Switchgear and Control Gear Assemblies)

must be observed in reference to EC Low Voltage Directive (2006/95/EC).

The machine manufacturer must generate a hazard analysis for the machine,

and must implement suitable measures to ensure that unexpected movements

will not c a use perso nal inju ry and/or property damage.

The machine manufacturer is responsible for ensuring that the machine meets

the requirements specified by the EMC regulations. Guidelines for correct

installation for EMC (such as shielding, grounding, treatment of connectors and

cable layout) are provided in this.

The machine manufacturer must check whether EC Directives or other standards

must be applied to the machine.

Servotronix only guarantees the conformance of the servo system with the

standards cited i n this chap ter.

Page 10

Introduction CDHD

4 Servotronix

Caution: Installa tion of the e quipment is crit ic a l in designi ng sy s te m and

machine electromagnetic compatibility (EMC).

The end us er must appl y the installation rec o mmenda tions in th is m anual.

1.4 Unpacking

1. Open the package(s) and remove all packing materials and items. The

package contai ns two items:

• The CDHD drive

• A p a ck et of mating conn ectors for the power connect ors .

2. Check to ensure there is no visible damage to any of the equipment. If

damag e is d etected, notify th e carrier im m e d iately.

Page 11

CDHD Product Description

User Manual 5

2 Product Description

2.1 Overview

2.1.1 General Description

The CDHD is a full-featured, high-performance servo drive featuri ng in novativ e

technologies and industry-leading power density.

Key features of the CDHD include:

Support for rotary and linear brushless DC motors, and DC brush motors.

Operation in current, velocity and position control loops.

Eleven digital inputs, six digital outputs, together with an analog input and

output, to meet any I/O requirement.

Various communication options.

Various motor feedback options.

Fir mware customization to address special application requirements.

OEM motors predefined in user interface to enable immediate integration.

2.1.2 Product Options

The CDHD product family offers a number of options :

200 or 400 VAC rating

Contin uous current of 1.5, 3, 6 or 13 A rms for the 200 V model s

Continuous current of 3 or 6 A rms for the 400 V m odels

One 16-bit or two 14-bit analog inputs

Various interface options, including analog voltage/pulse train and CANopen.

Refer to the part number diagram at the beginning of this manual for the various

ordering options for the CDHD drive.

Page 12

Product Description CDHD

6 Servotronix

2.2 Technical Specifications

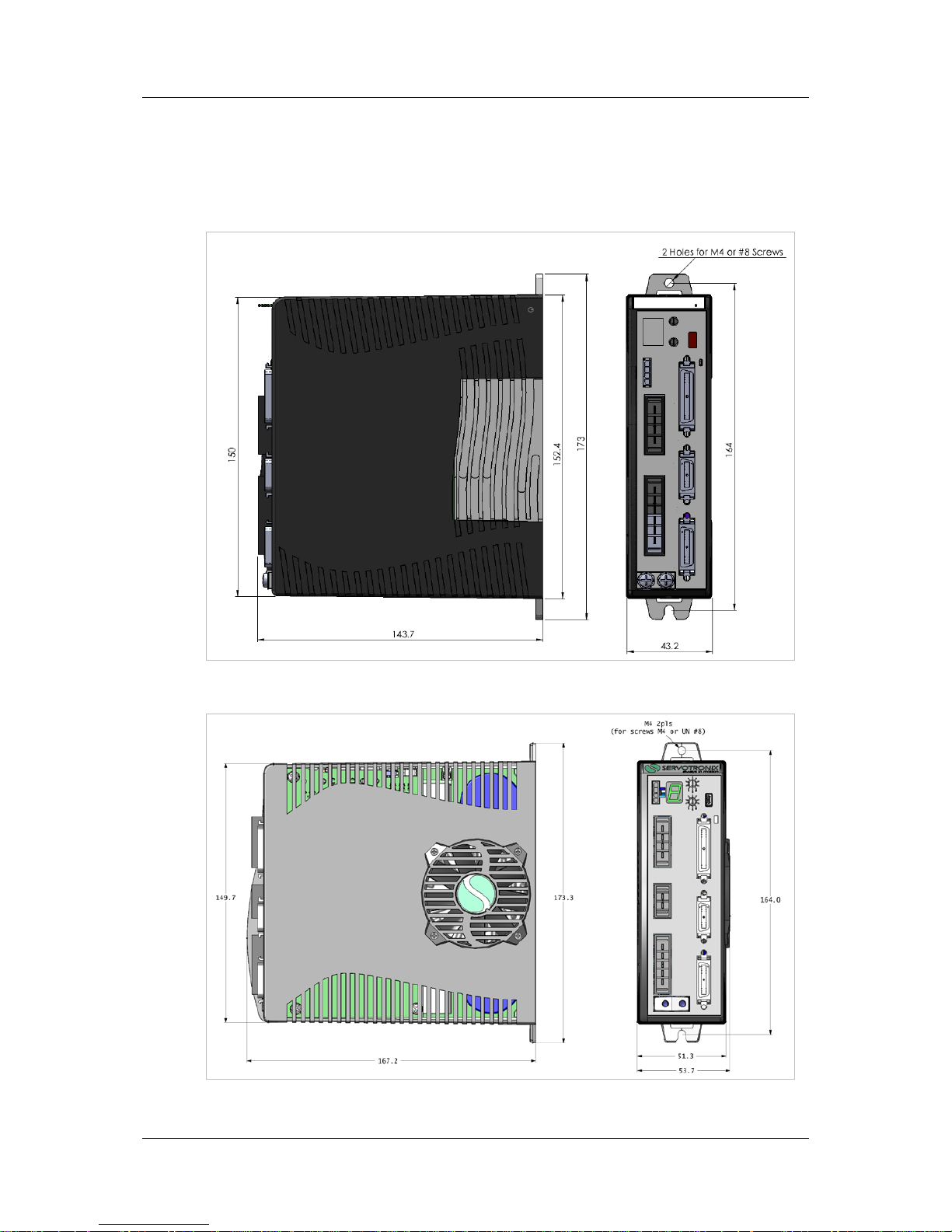

2.2.1 Dimensions

The exterior dimensions of the CDHD-1D5 and CDHD-006 are shown in

Figure 2-1 and Figure 2-1, respectively

Figure 2-1. CDHD-1D5 Dimensions (in mm)

Figure 2-2. CDHD-006 Dimensions (in mm)

Page 13

CDHD Product Description

User Manual 7

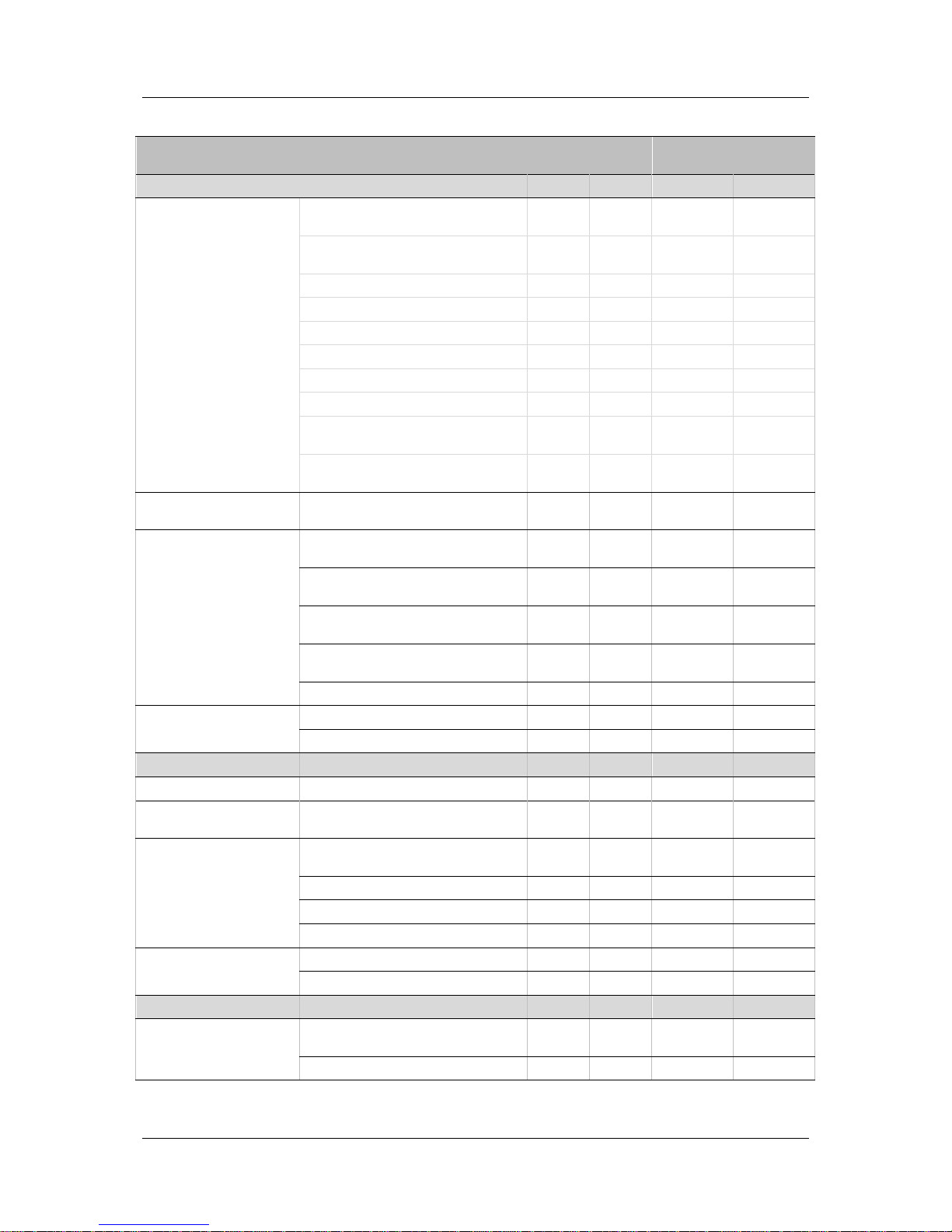

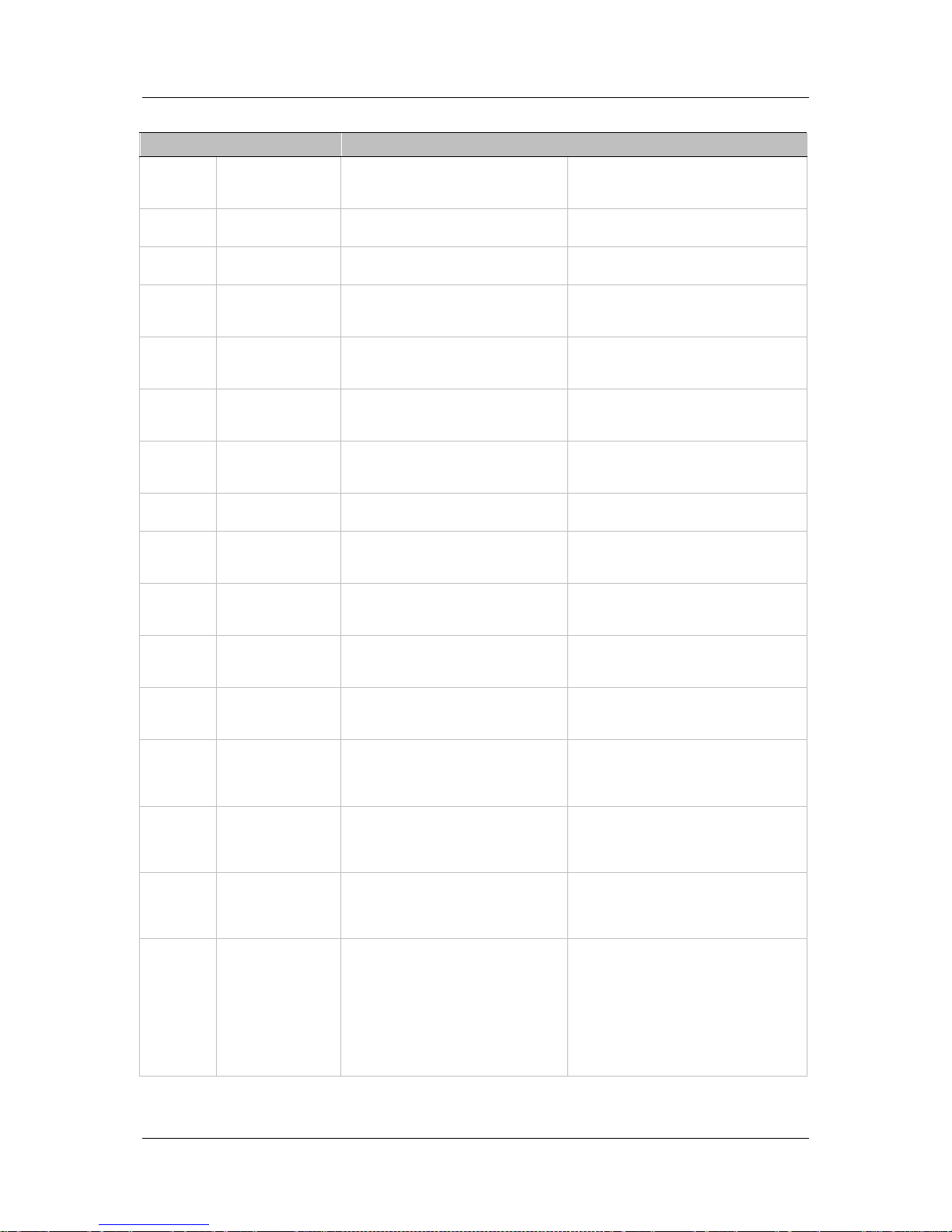

2.2.2 Mechanical and Electrical Specifications - 200V

Single a nd ThreePhase 200V

Specification

CDHD1D5

CDHD003

CDHD006

CDHD013

Ratings

Input Power Main Circuit

(L1, L2, L3 )

Voltage (VAC Line-Line) Nominal

±10%

110 to

230

110 to

230

110 to 230 110 to 230

115 VAC 1 Phase 1 Phase

1 Phase or

3 Phase

1 Phase or

3 Phase

230 VAC 1 Phase 1 Phase 1 Phase 1 Phase

Line Frequency (Hz) 47-63 47-63 47-63 47-63

KVA at 115 VAC

KVA at 230 VAC

Continuous Current (A)

Peak Current (A) f or 2 sec

Withstand Voltage (Primary to

Ground)

Line Fuses (FRN -R, LPN, or

equivalent)

Logic Input Power

(L1C, L2C)

115 or 230 VAC 1 Phase 1 Phase 1 Phase 1 Phase

Motor Output

(U,V,W)

Continuous Output Current (A rms) 1.5 3 6 13

Continuous Output Current (A

peak)

2.12 4.24 8.485 18.38

Peak Output Current (A rms) f or

2 sec

4.5 9 18 26

Peak Output Current (A peak) for

2 sec

6.3 12.72 25.455 36.76

PWM Frequency (kHz) 16 16 16 8

Soft Start Max. Surge Soft Start Current (A) 6

Max. Charge Time (ms) 250

Hardware

Unit Weight (kg) 0.9

Connection Hardw are PE Ground Screw Size/ Torque

M4/

1.35 Nm

Wire Size

Control Circuit (AWG ) u p to 3

meter

24-28

Main Circuit Motor Lines (AW G ) 14-16

Main Circuit AC Inputs (AWG) 14-16

PE Ground Screw 14

Clearance Distance Side-to-Side (mm) 10-15

Top/Bottom (mm) 50

Voltage Trip

Under-Voltage Trip (nominal)

(VDC)

100

Over-Voltage Trip (VDC) 420

Page 14

Product Description CDHD

8 Servotronix

Single a nd ThreePhase 200V

Specification

CDHD1D5

CDHD003

CDHD006

CDHD-

013

Power Temperature

Power Over-Temperature Warning

(°C)

100

Power Over-Temperature Fault (°C) 110

Trigger Temperature for Highspeed Fan (°C)

NA NA 60

Regen External

Regenerative resistor

(B1+, B2)

External Shunt

Regulator

Peak current (A) NA NA 30

Minimum resistance (Ω) NA NA 13.1

Watts NA NA

system

dependent

Application Informat ion Capacitance (F) NA NA 1120

Bus Voltage (nominal) (VDC) NA NA 320

VHYS (Regen Circuit Turn-off) VDC) NA NA

VMAX (Regen Circuit Turn-on)

(VDC)

NA NA

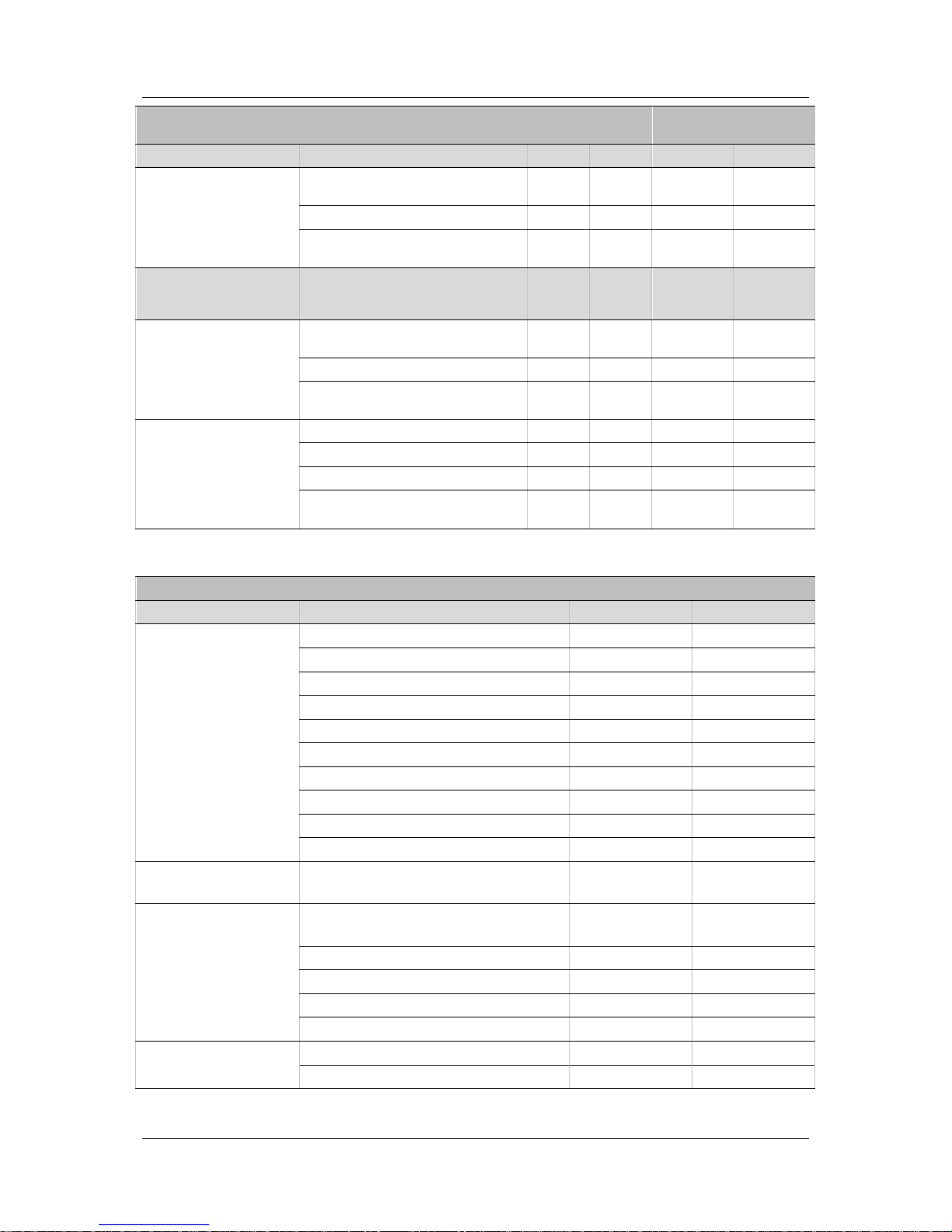

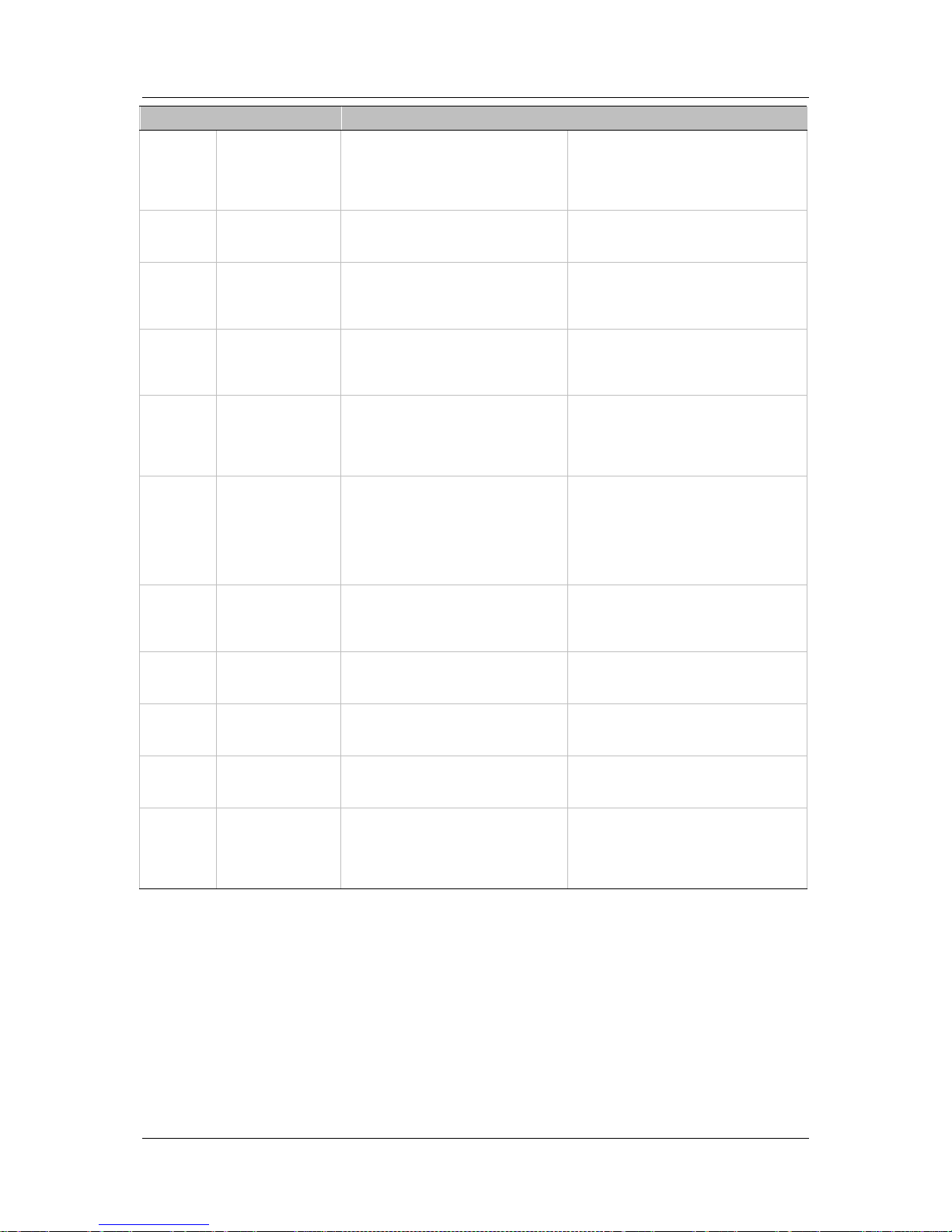

2.2.3 Mechanical and Electrical Specifications - 400V

Three-Phase 400V Specification CDHD-003 CDHD-006

Ratings

Input Power Main Circuit Voltage (VAC Line-Line) Nominal ±10 % 530-600 530-600

(L1, L2, L3 ) 380 VAC 3 Phase 3 Phase

430 VAC 3 Phase 3 Phase

Line Frequency (Hz) 47-63 47-63

KVA at 380 VAC

KVA at 430 VAC

Continuous Current (A)

Peak Current (A) f or 2 sec

Withstand Voltage (Primary to Ground)

Line Fuses (FRN -R, LPN, or equivalent)

Logic Input Power

(L1C, L2C)

VDC 24 VDC ±10% 24 V DC ±10%

Motor Output

(U,V,W)

Continuous Output Current (A rms) 3 6

Continuous Output Current (A peak) 4.24 8.485

Peak Output Current (A rms) for 2 sec 9 18

Peak Output Current (A pe a k ) f or 2 sec 12.72 25.455

PWM Frequency (kHz) 16 16

Soft Start Max. Surge Soft Start Current (A)

Max. Charge Time (ms)

Page 15

CDHD Product Description

User Manual 9

Three-Phase 400V Specification CDHD-003 CDHD-006

Hardware

Unit Weight (kg)

Connection Hardw are PE Ground Screw Size/Torque

Wire Size Control Circuit (AWG) up to 3 meter

Main Circuit Motor Lines (AW G )

Main Circuit AC Inputs (AWG)

PE Ground Screw

Clearance Di st a nce Side-to-Side (mm)

Top/Bottom (mm)

Voltage Trip

Under-Voltage Trip (nominal) (VDC)

Over-Voltage Trip (VDC)

Power Temperature

Power Over-Temperature Warning (°C)

Power Over-Temperature Fault (°C)

Trigger Temperature for High-speed Fan

(°C)

Regen External

Regenerative resistor

(B1+, B2)

External Shunt

Regulator

Peak Current (A)

Minimum Resistance (Ω)

Watts

Application Informat ion Capacitance (F)

Bus Voltage (Nominal) (VDC)

VHYS (Regen Circuit Turn-off) (VDC)

VMAX (Regen Circuit Turn-on) (VDC)

Page 16

Product Description CDHD

10 Servotronix

2.2.4 Control Specifications

Feature Specification

Motors DC Brushless, DC Brush Rotary Serv omotors, Linear Servomotors

Operation Mode Selectable Modes

Serial current, A na log curre nt, Serial v e locity , A na log

velocity, Pulse and d ire ction position

Current Control Performance

Update rate 31.25 μs (32 kHz), Bandwidth 3 kHz, Outpu t

waveform sinusoid a l

Control Loop DQ, PI, Fee d f orwa rd

Reference Command ± 10 VDC, Serial torque command, CANopen

Velocity Control Performance

Update rate 125 μs (8 kHz), Bandwidth system

dependent

Selectable Velocity Control

Loops

PI , PDFF, Standard pole placement, Advance pole

placement, Standard pole placement high frequency

Filters

First order low pass fi lte r, Doub le f irst order low pass

filter, Notch filter, High pass filter, Band p a ss,

User defined polynomial filter

Reference Command ± 10 VDC, Serial Speed command, CANopen

Position Control Performance Update rate 250 μs (4 kHz)

Control loop PID and Fe e d f orwa rd

Reference Command Pulse and direction, S e ria l p osition command, CA N op e n

Brake Method Control stops: Dyna mic b ra k e , A ctive disable

Display Form 7-segment LED (green), disp lay d riv e status

GUI User Interface ServoStudio Windows-based application

Function

Setting connection, Drive inf o, Powe r d isplay, Motor,

Feedback, I/O selection/config uration, Motion

setting/tuning, Fault history/d isp lay , S e tup wizard, Expert

view

Display Form 7-segment LED (green)

Units Position revolutions, counts, d e g re e s

Velocity rps, rpm, deg/s

Auto tuning Method Self-tuning

Page 17

CDHD Product Description

User Manual 11

2.2.5 Protective Functions and Environment

Feature Specification

Protective Functions

Under- and ov e r-v olta g e , Driv e an d motor over-temperature, Foldback, Feedback

lost, Safety function (STO)

Compliance Standard UL - UL508c

CE - EC EMC (Electro ma g n e tic Compatibility) IEC61800-3,

EC Electrical Saf e ty Low V olta g e Directive IEC61800-5-1

STO - Safe Torque Off

RoHS

Environment A mb ien t temp e rature : Operation 0-45°C (f re e f rom f re e zing ) S t orag e 0-70°C

Humidity: 10-90%

Altitude: < 1000m. If >1000m, derate 5% p e r 330m

Vibration: 0.5g

Configuration Book mounting

2.2.6 Communication

Feature Specification

CAN (optional)

CANopen – CiA 301 a p plication layer and the CiA 402 device profile for drives and

motion control

Baud rate 0.5M 1M bit/sec

RS232 ASCII-based, ServoStudio, HyperTerminal

Baud rate 9600 to 115200 bit/sec

Maximum cable leng th 10 m

USB ASCII-based, ServoStudio, HyperTerminal

Baud rate 9600 to 115200 bit/sec

Maximum cable leng th 3 m

Daisy Chain

Up to 8 axes

Axis add re ss setting from 0-99 u sing two rotary switche s

Maximum cable leng th 10 m

Page 18

Product Description CDHD

12 Servotronix

2.2.7 I/Os

Feature Specification

First Analog Input Voltage Range ±10 VDC differentia l

Input Resolution 16 bit (14-bit on version with two analog inputs)

Input Impedance 8 kΩ (when using two analog inputs 20k Ω.)

Second Analog Input (optional) Voltage Range ±10 VDC different ial 14 b it

Input Resolution 14 bit

Input Impedance 20 k Ω

Equivalent Encoder output Signal

A-quad-B and mark e r d iffe re ntia l, R S 422 li ne

transmitter

8x Digital Inputs Signal

Configurable op to-isolated (compatible w ith

sinking output)

Voltage 24 V

Max. Input Current 10 mA

Propagation Delay Time 1 ms

3x Fast Digital Inputs Signal

Configurable op to-isolated (compatible w ith

sinking output)

Voltage 24 V

Max Input Current 10 mA

Propagation Delay Time 1 µs

4x Digital Output Signal

Configurable op e n colle ctor, op to-isolated sin k ing

output

Voltage 24 V

Max. Current 40 mA

Propagation Delay Time 1 ms

2x Fast Digital Output Signal

Configurable op e n colle ctor, op to-isolated sin k ing

output

Voltage 24 V

Max current 40 mA

Propagation Delay Time 1 µs

Analog Output Signal Configurable analog output

Voltage Range 0-10 V

Resolution 8 bit

Max. Load 1 kΩ

Secondary Feedback Signal

A-quad-B and mark e r d iffe re ntia l, R S 422 li ne

receiver

Max. Input frequency 3 MHz (before A-quad-B)

Functions Dual loop, Master/Slave or Handwheel

Fault Output Relay Signal Configura b le dry contacts

Voltage 24V

Max. Current 1 A

Page 19

CDHD Product Description

User Manual 13

2.2.8 Motor Feedback

Motor Feedback Specification

General Supply Voltage from Drive 5 VDC

Max. S u p p ly Current from Drive 250 mA

Max. Cable Length

AWG 28 – 3 m

AWG 24 – 10 m

Incremental Encoder Signal

A-quad-B with or without marker/Halls,

8-channel Tamagawa, RS 422 or RS485 line

receiver, Differential

Max Input Frequency 3 MHz (before quadrature)

Halls Signal Open collector sing le -ended

Resolver Signal Sine cosine dif f e re nt ial

Transformation Ratio 0.45-1.6

Excitation Frequency 8 kHz

Input Voltage from Drive 6-22 Vpp

Max. DC Resistance 120 Ω (stator)

Max. Drive Cu rre nt 55 mA rms

Output V oltage to Drive 10 Vpp

Sine encoder Signal Sine/Cosine differential, with or with ou t Halls

Sig na l Level 1 Vpp @ 2.5 V

Max. Input Frequency 270 kHz

Protocols EnDat® 2.1, Hiperface®

Input Impedance 120 Ω

Max imum Drive Internal Inte rp ola tion 4096

SSI encoder Signal

Differential da t a an d clock for syn chr onous

encoders

Data only for asynchronous encoders

Protocols EnDat 2.2, BiSS -C, ot he r S SI

Motor Temperature Signal

Thermal resistor PTC or NTC, User-defined

fault threshold

Page 20

Product Description CDHD

14 Servotronix

2.3 System Wiring - Pin Assignments

Figure 2-3. Pin Assignme nts

Page 21

CDHD Installation

User Manual 15

3 Installation

3.1 Installation Overview

Perfor m the follo wing ste p s to install and setup a CD HD sy s te m .

1. Mount the CDHD.

2. Connect the motor to P2.

3. Connect saf e torque off (STO) to P1, or use the pre-wired jumper connector,

which is supplied with the drive.

4. Connect regen resistor to P3, if required.

5. Connect motor feedback to C4.

6. Connect machine I/Os to C3 and/ or controller I/Os at C2.

7. Set the drive address using the rotary switches.

8. Connect the drive to the PC.

9. Connect AC inp ut voltage to P4.

10. Power up the drive and the PC.

11. Install Ser v o S tudio sof tw a r e .

12. Using ServoStudio, configu re and test the drive .

3.2 Preparation

3.2.1 Hardware Requirements

The following hardware is required for installati on.

Mating connectors and the associated crimp pins for interfaces P1, P2, P3

and P4; these are supplied with the CDHD driv e. The mating conne ctor for

P1 (STO) is supplied pre-assembled with e STO bypassed via wire jumpers.

Mating c onne ctors for inte rfaces C2, C3 an d C4 :

Connector C2 (Controll er I/O):

Plug 3M 10136-3000PE and s he ll 3M 10 33 6-52F0-008

Connector C3 (Machine I/O):

Plug 3M 1012 0-3000PE an d she ll 3M 10 320-52F0-008

Connector C4 (Motor feed b ack):

Plug 3M 1012 6-3000PE an d she ll 3M 10 326-52F0-008

Wires for gauges:

Connector P1 (STO): 26–30 AWG.

Connectors P2 (Motor Power), P3 (Regen) and P4 (AC Input):

14–16 AWG.

Connectors C2 (Controller I/O), C3 (Machine I/O) and C4 (Motor

Feedback): 24–28 AWG.

Page 22

Installation CDHD

16 Servotronix

Crimping tools, if you are not using ready-made cable assembli es:

Connector P1 (STO): Molex crimper 0638190000

Connectors P2 (Motor Power), P3 (Regen) and P4 (AC Input):

JST crimper YRF-1070. If a crimp pin extraction tool is needed, use

JST extraction tool EJ-JFA J3.

M4 ring or spade terminal.

A small slotted screwdriver for setti ng the dr ive ad dress swi tc hes.

For connection to the host computer, use one of the following :

USB 2.0 A to Mi ni-B cable (USB interface)

4p4c plug and cable (RS232 interface)

3.2.2 Computer Requirements

To inst all an d run ServoStudio software, the GUI-based configuration and testing

environment, the following computer system is required:

2 GHz CPU

1 MB RAM

1000 MB available on hard drive (after .net 4 is installed)

USB port for connecting to the drive

Operating system: Windows XP-SP3, or Win d ow s 7

.Net4 installed (for details, refer to .NET Framework System Requirements).

If .NET 4 is no t installed o n the compu te r , Se rv oStudio w ill guide yo u

through the installation, but will not install it automatically.

Page 23

CDHD Installation

User Manual 17

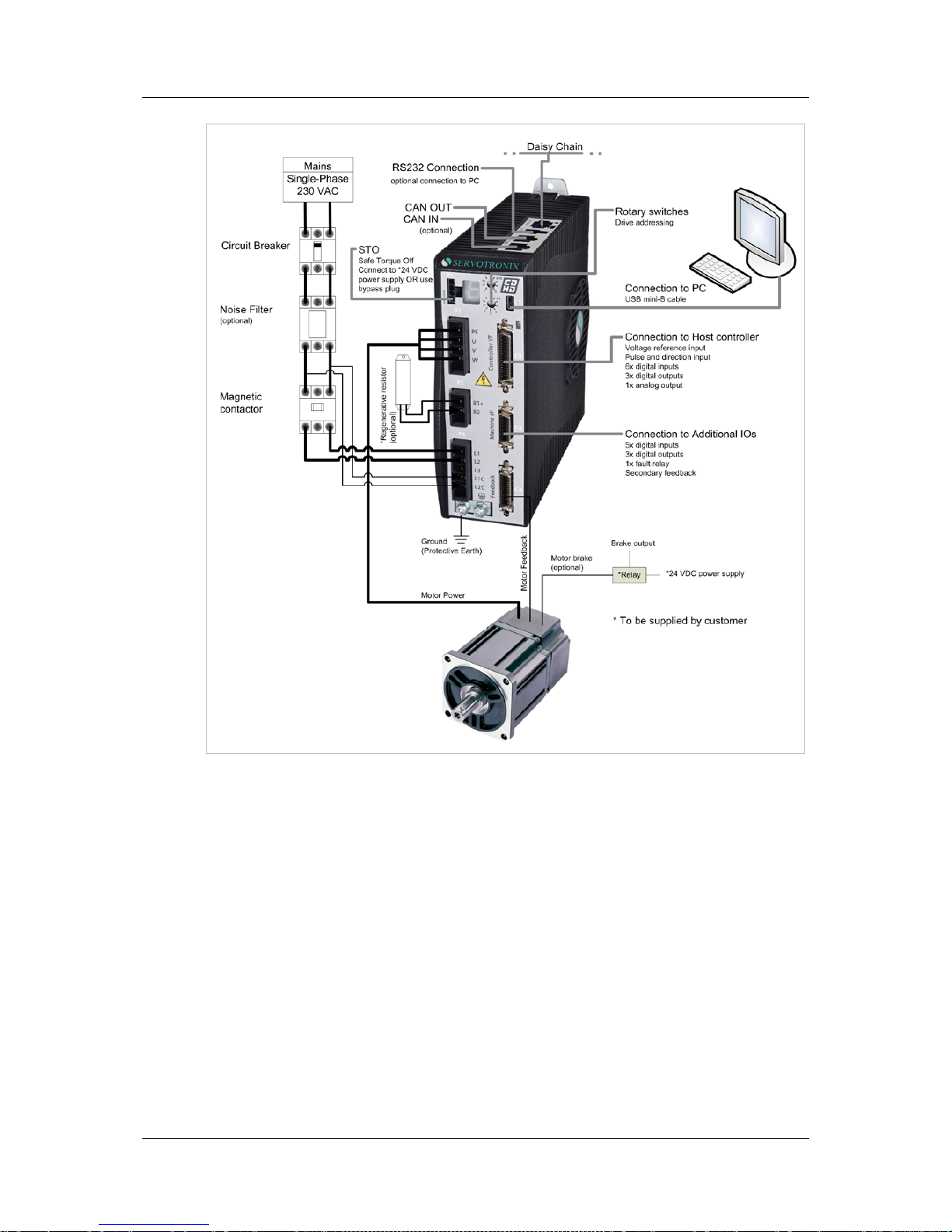

Figure 3-1. CDHD servo system wiring, using single-ph ase 230 VAC

Page 24

Installation CDHD

18 Servotronix

3.2.3 Electrical Requirements

Grounding

System grounding is essential for prop er p erformance of the d rive system. A

ground bus bar may be used as a single point ground for the system. Safety

groundin g should be provided to all pieces of the system from a st ar point.

In addition to the safety grounding, a high frequency ground must be provided

that connects the back panel to the enclosure and to earth ground. The objective

is to provide an extremely low impedance path between the filters, drives, power

supplies, and earth ground.

This high frequency ground is accomplished with the use of a flat braid or copper

bus bar. It is important not to rely on a standard wire for th e high frequency

ground. In general, a wire has an inductance of 8 nH per inch, regardless of

diameter. At higher frequencies, this unwanted inductance between grounds

equates to limited filter performance. When connecting high frequency grounds,

use the shortes t braid pos s ible.

Bonding

The proper bonding of shiel d ed cables is imperative for minimiz ing noise

emissions and increasing immun ity levels of the drive syste m. Its effe c t is to

reduce the impedance between the cable shield and the back panel. Servotronix

recommends that all shielded cables be bonded to the back panel.

The motor and feedback cables should have the shield exposed as close to the

drive as possible. This exposed shield is bonded to the back panel using either

non-insulated metallic cable clamps or cable bonding clamps offered by Phoenix

Contact (and others).

CE Filtering Techniques

The CDHD dri ve sy stem (bus module, d rive, motor) complies with the CE

standards specified in the section Standards Compliance. Proper bonding and

groundin g techniques must b e applied when in cor p orating EMC noise filteri ng

components in order to meet this standard.

Noise currents often occur in two types. The first is conducted emissions that are

passed through ground loops. The quality of the system grounding scheme

inversely determines the noise amplitudes in the lines. These conducted

emissions are of a common-mode nature from line to ne utral (or ground ). The

second is radiated high-frequency e m is s ions usu a lly capacitively coupled from

line-to-line and are differential in nature.

To properly mount the filters, the enclosure should have an unpainted metallic

surface. This allows for more surface area to be in contact with the filter housing

and provides a lower impedance path between this housing and the back plane.

The back panel, in turn, has a high frequency ground strap connection to the

enclosure frame or earth ground.

Page 25

CDHD Installation

User Manual 19

Input Power Filt eri ng

The CDHD electronic system components require EMI filtering in the input power

leads to me et the conducted e m is s ion requ ir e ments for the industria l

enviro n m ent. This filter ing block s c o nducted type emissions from exiting onto

the power lines and provides a barrier for EMI on the power lines.

Care must be taken to adequately size the sys te m. The type of fi lter is

determined accordin g t o the voltage and current rating of the system and

whether the inco ming line is single- or t hree-phase . O ne input line fi lter is used

for multi-axis control applications. Mount these filters as close to the incoming

power as possible to p revent noise fr om being capacitively coupled into other

signal leads and cables. Similarly, use care when routing wires fr o m t he load

side of the filter to the bus module. These lines may be noisy and must be

separated from other sensitive cabling to avoid unwanted coupling of noise.

Several suitable filters are listed in Table 3-1. Manufacturers should be able to

recommend the best filter design for particular motor control applicati ons.

Implementation of the EMI filter must ad here to the following guidelines:

Filter must be mounted on the same panel as the drive and bus module.

Filter must be mounted as close as possible to incoming cabinet power.

Filter must be mounted as close as possible to bus module. If separa tio n

exceeds 30 cm, a flat cable (braid) is used for the high frequency connection

between filter and bus module.

When mounting the filter to the panel, remove any paint or material

covering. Use an unpainted metallic back panel, if possible.

Filters are provided with a ground connection. All ground connections must

be tied to ground.

Filters can produce high leakage currents. Filters must be grounded

before connecti ng the supply !

Filters s ho u ld no t b e to uc he d fo r 10 s ec onds aft e r removing t he sup ply.

Table 3-1. Recommended EMI Li n e F i lters

Bus Module Mod el # Recommended EMI Line Filter

CDHD-003 Filter Concepts SF7

Schaffner FN258-7/07

CDHD-006 Filter Concepts SF15

Schaffner FN258-16/07

CDHD-0013 Schaffner FN258-16/07

Note:

The filte rs liste d in this tab l e are used on a one-to-one correspondence with the

drive. If drives are paralleled off one filter, it needs to be sized. Drives can be

ganged off one EMI filter.

Page 26

Installation CDHD

20 Servotronix

Motor Line Filtering

Motor filtering may not be necessary for CE compliance of CDHD systems.

However, this additional filtering increases the reliability of the syst em. Poo r

non-metallic enclosure surfaces and lengthy, unbonded (or unshielded) motor

cables that couple noise line-to-line (differen tial) are just some of the factors

that lead to the necessity of motor lead filtering.

Motor lead noise may be either common-mode or differential . The commonmode conducted currents occur between each motor lead and ground (line-toground). Differential radiated currents exist from one motor lead to another

(line-to-line). The filterin g of the lines feeding the motor provides additional

atten ua t io n o f noise curr ents that enter s urrounding cables and eq u ip ment I/O

ports in close proximity.

3.3 Mechanical Installation

3.3.1 Mount the CDHD

Using the bracket on the back of the CDHD, mount the CDHD on a grounded

conductive metal panel.

For mounting di mensions, refer to Figure 2-1.

3.4 Electrical Installation

3.4.1 Connect Motor (P2)

Using the supplied mating connector, connect the motor interface.

Figure 3-2. Motor Interface

Table 3-2. Motor Interface

Pin Pin Label Function

1 PE Protective ground (motor housing)

2 U Motor Phase U

3 V Motor Ph a se V

4 W Motor Phase W

Page 27

CDHD Installation

User Manual 21

Table 3-3. Motor Interface Mati ng Connector

Item Specification

Manufacturer JST

Housing and

4-pin crimp

Part # F32FSS04-V-KX an d

Part # SF3F71-GF-P0.2

Spring terminal Par t # 04JFAT-SAYGF-I

Wire Gauge 14–16 AWG

3.4.2 Connect STO (P1)

Safe torque off (STO) is a safety function that prevents the drive from delivering

power to the motor, which can generate torque.

STO Enable and STO Return must be connected to enable CDHD operation. The

STO Enab le signa l v o ltage mus t b e 24 V D C .

Using the supplied mating connector, connect the STO interface.

If the application does not require STO functionality, connect pin 4 to pin 1, and

pin 3 to pin 2.

Figure 3-3. STO Interface

Table 3-4. STO Interface

Pin Pin Label Function

1 24V STO Enable

2 GND STO Return

3 24V Return

4 24V Su pply

Table 3-5. STO Interface Mating Connector

Item Specification

Manufacturer Molex

Housing and

4-pin crimp

Part # 436450400 and

Part # 436450400

Wire Gauge 26–30 AWG

Page 28

Installation CDHD

22 Servotronix

3.4.3 Connect Regen (P3)

If the application requires a regeneration (regen) resistor, use the P3 interface.

Using the supplied connector, connect the regen resistor between terminals B1+

and B2.

Figure 3-4. Regen Interface

Table 3-6. Regen Interface

Pin Pin Label Function

1 B1+ DC bus +

2 B2 Regen bus -

Table 3-7. Regen Interface Mating Connector

Item Specification

Manufacturer JST

Housing and

2-pin crimp

Part # F32FSS02-V-KX and

Part # SF3F71-GF-P0.2

Wire Gauge 14–16 AWG

3.4.4 Connect Motor Feedback (C4)

Wire the motor feedback interface according to the type of feedback device to be

used in your application. Refer to the guidelines following the pinout table below.

Pins 1, 2, 14 and 15 have dual functionality.

Pins 11 and 13 for 5V to the encoder are used in digital board revision 0. Pin 18

can be used only in digital board revision 1 and later.

Pin 25 for the motor temperature sensor is connected internally in the drive to

CDHD ground.

Unused pins must remain unwired.

Page 29

CDHD Installation

User Manual 23

Figure 3-5. Motor Feedback Interface

Table 3-8. Motor Feedback Interface

Pin Function Pin Function

1 Incremental encoder A +

or SSI encoder data +

14 Incremental encoder A -

or SSI encoder data -

2 Incremental encoder B +

or SI encoder clock +

15 Incremental encoder B -

or SSI encoder clock 3 Incremental Encoder Z + 16 Incremental encoder Z 4 Hall U + 17 Hall V+

5 Hal l W + 18 5V supply

6 Resolver sine + 19 Resolver sine 7 Resolver cosine + 20 Resolver cosine 8 Resol ver reference + 21 Reso lver refe renc e 9 Sine encoder sine + 22 Sine encoder sin e 10 Sine encoder cosine + 23 Sine encoder cosine 11 5V supply 24 Ground

12 Motor temper at ure sensor 25 Motor temperatur e se nsor

13 5V supply 26 Shield

Wiring Guidelines

For incr emen tal encoder with Halls, use pins 1, 14, 2, 15, 3, 16, 4, 17, 5,

18, 24

For resolver, use pins 6, 19, 7, 20, 8, 21

For sine encoder, use pins 9, 22, 10, 23, 11, 24

For sine encod er with Hal ls, use pi ns 9, 22, 10, 23, 11, 24, 4, 17, 5, 18

For EnDat 2.1 encoder, use pins 1, 14, 2, 15, 9, 22, 10, 23, 11, 24

Page 30

Installation CDHD

24 Servotronix

3.4.5 Connect Controller I/Os (C2)

Wire the digital and analog inputs and outputs according to the requirement s of

your appl ication.

Wire the digital and analog inputs and outputs according to the requirement s of

your appl ication.

Unused pins must remain unwired.

To preserve isolation of the digital I/Os, connect a 24 VDC source to pin 19.

Connec t t he re t urn of the 24 VDC supply to pin 1, which functions as the ground

path for the outputs.

Note: The 24 VDC supp ly and return can be connected on either th e Controller

interface (C2) or the Machine interface (C3), but it is not necessary to

connect it on both.

Figure 3-6. Control l er I/O Interface

Table 3-9. Controller I/O Interface

Pin Function Description Pin Function Description

1 24 VDC return

Return of the user-supplied

24 VDC

19 24 VDC

User supplied 24V, f or I/O

biasing

2

Digital

output 1

Opto-isolated

programmable dig it al

output. Read using OUT1

20 Digital input 2

Opto-isolated

programmable dig it al

input. Read using IN2

3 Digital input 1

Opto-isolated

programmable dig it al in p ut .

Read using IN1

21 Reserved for future use

4

Equivalent

encoder

output A-

Low side of the equivalent

encoder output signal A

(RS422)

22

Equivalent

encoder

output A+

High side of the e quivalent

encoder output signal A

(RS422)

5

Channel Bout

Low side of the equivalent

encoder output signal B

(RS422)

23

Channel B+

out

High side of the e quivalent

encoder output sig na l B

(RS422)

6

Channel Zout

Low side of the equivalent

encoder output index

(RS422)

24

Channel Z+

out

High side of the e quivalent

encoder output index

(RS422)

7 5V 5 VDC source 25 Ground Digit al ground

8

Analog

input 1+

High side of the differential

analog command input

(±10 VDC)

26

Analog

input 1-

Low side of the diff e re nti al

analog command input

(±10 VDC)

Page 31

CDHD Installation

User Manual 25

Pin Function Description Pin Function Description

9

Direction

input+

High side of the direction

signal (RS422)

27

Direction

input-

Low side of the direction

signal (RS422)

10 Ground Digital ground 28 Pulse input+

High side of the pulse

signal (RS422)

11 Pulse input-

Low side of the pulse sig na l

(RS422)

29 Ground Dig ita l g roun d

12 Reserved for future use 30 Reserved for future use

13 Ground Digital ground 31 Digital input 3

Opto-isolated

programmable dig it al

input. Read using IN3

14 Digital input 4

Opto-isolated

programmable dig it al in p ut .

Read using IN4

32 Digital input 5

Fast opto-isolated

programmable dig it al

input. Read using IN5

15 Digital input 6

Fast opto-isolated

programmable dig i tal in p u t.

Read using IN6

33

Digital

output 2

Opto-isolated

programmable dig it al

output. Read using OUT2

16

Digital

output 3

Fast opto-isolated

programmable dig it al

output. Read using OUT3

34 Reserved for future use

17 Reserved for future use 35*

Analog

input 2-

Low side of the second

differential a na log input

(±10 VDC)

18*

Analog

input 2+

High side o f t he second

differential a na log input

(±10 VDC)

36 Analog output

Analog output, referenced

to digital ground (0 -10

VDC)

* Optional, see ordering information

3.4.6 Connect Machine I/Os (C3)

Wire the machine inputs and outputs according to the requirements of your

application.

Unused pins must remain unwired.

To preserve isolation of the digital I/Os, connect a 24 VDC source to pin 9.

Connec t t he re t urn of the 24 VDC supply to pin 19, which functions as the

ground path for the outputs.

Note: The 24 VDC supply and return can be connected on either the Controller

interface (C2) or the Machine interface (C3), but it is not necessary to

connect it to both.

Figure 3-7. Machine I/O Interface

Page 32

Installation CDHD

26 Servotronix

Table 3-10. Machine I/O Interface – 20-pin MDR Plug

Pin Function Description Pin Function Description

1

Secondary

encoder A+

High side o f t he secondary

encoder input signa l A

(RS422)

11

Secondary

encoder A-

Low side of the secondary

encoder input signa l A

(RS422)

2

Secondary

encoder B+

High side of the secondary

encoder input signa l B

(RS422)

12

Secondary

encoder B-

Low side of the secondary

encoder input signal B

(RS422)

3

Secondary

encoder Z+

High side o f t he secondary

encoder input index

(RS422)

13

Secondary

encoder Z-

Low side of the secondary

encoder input index

(RS422)

4

Secondary

encoder 5V

5 VDC supply for the

secondary e n coder

14

Secondary

encoder

ground

Ground of the 5 VDC supply

for the secondary encoder.

5

Digital

input 7

Opto-isolated

programmable dig it al in p ut .

Read using IN7

15 Digital input 8

Opto-isolated

programmable dig it al in p ut .

Read using IN8

6

Digital

input 9

Opto-isolated

programmable digital input.

Read using IN9

16

Digital

input 10

Opto-isolated

programmable dig it al in p ut .

Read using IN10

7

Digital

input 11

Fast opto-isolated

programmable dig it al in p ut .

Read using IN11

17

Digital

output 4

Opto-isolated

programmable dig it al

output. Read using OUT4

8

Digital

output 5

Opto-isolated

programmable dig it al

output. Read using OUT5

18

Digital

output 6

Fast opto-isolated

programmable dig it al

output. Read using OUT6

9 24 V DC

User supplied 24V, f or I/O

biasing

19 24 VDC return

Return of the user-supplied

24 VDC

10 Fault relay 1

Terminal 1 of the dry

contact fault relay

20 Fault relay 2

Terminal 2 of the dry

contact fault relay

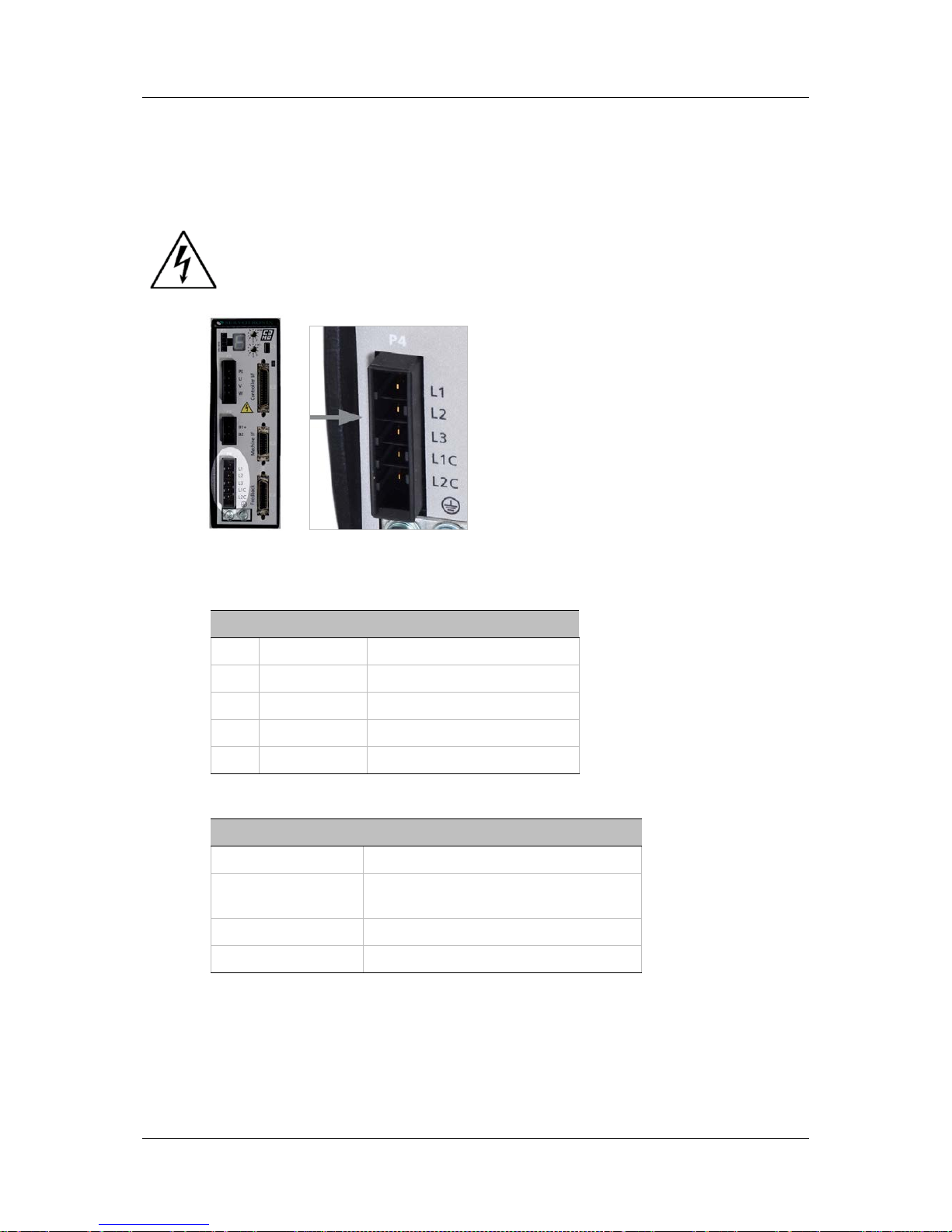

3.4.7 Connect AC Input Voltage (P4)

The AC voltage interface supplies both motor (bus) power and logic power.

Using the sup plied ma ting con nector, ma k e t he following connec tions:

1. Connect L1, L2 and L3 (for bus power).

If the main voltage is from a singl e-phase so ur c e , connect line a nd

neutral to L1 and L2.

If the main voltage is from a thre e-phase source, connect the phases to

L1, L2 and L3.

2. Connect the AC input vol ta g e g r o u nd w ir e to the PE terminal, locate d on the

CDHD front panel. Use an M4 ring or spade terminal.

Figure 3-8. Ground Terminals

Page 33

CDHD Installation

User Manual 27

3. Connect L1C and L2C (for logic powe r).

If the main voltage is from a singl e-phase so ur c e , connect line a nd

neutral to L1C and L2C.

If the main voltage is from a thre e-phase source, connect any two

phases to L1C and L2C.

Make sure the m a i n voltage rating matches the drive specifi cat i on.

Applying incorrect voltage may cause drive failure.

Do not apply p ow er until all ha rd w a re connections are compl ete.

Figure 3-9. AC Input Voltage Interface

Table 3-11. AC Input Voltage Int erface

Pin Pin Label Function

1 L1 AC Phase 1

2 L2 AC Phase 2

3 L3 AC Phase 3

4 L1C Logic AC Phase 1

5 LC2 Logic AC Neutral

Table 3-12. AC Input Voltage Int erface Mating Connector

Item Specification

Manufacturer JST

Housing and

5-pin crimp

Part # F32FSS05-V-KX and

Part # SF3F71-GF-P0.2

Spring terminal Part # 05JFAT-SAYGF-I

Wire Gaug e 14–16 AWG

3.5 Set the Drive Address

The CDHD has two 10-pole rotary switches, accessible from the front of the unit.

The switches are used to set the drive address. When there is more than one

drive on a daisy-chain or CANbus network, each drive must ha v e a u nique

address to enable its identification on the network.

Page 34

Installation CDHD

28 Servotronix

Use the two rotary switches to set the drive address for both CAN and serial

communication.

For Ethernet -based motion buses, the switch has no functional use for either the

drive or t he network. It can be used at the application level to identify specific

drives on a network.

Each switch has 10 positions:

The upper switch positions are set as tens: 10, 20, 30 … 90

The lower switch positions are set as ones: 0, 1, 2 … 9

Note: If two or more drives are connected to the network, address 0 cannot be

used. A singular drive may have the address 0.

Figure 3-10. Drive Address R ot ary Sw i tches

3.6 Connect to PC (C1 or C7)

To connect the d rive to the host computer, use either one of the following

interfaces:

USB port (C1). Use a USB 2.0 A to Mini-B cable.

Figure 3-11. USB Port

Page 35

CDHD Installation

User Manual 29

RS232 port (C7). Use a 4p4c plug.

Figure 3-12. RS232 Port

Table 3-13. RS232 Interface

Pin Pin Label Function

1 RX Receive

2 GND ISO Ground

3 TX Transmit

4 Unused

3.7 Power Up

1. After completing the hardware connections, turn on power to the drive.

2. Look at the 7-segment display on the CDHD front panel.

Upon initial power up, the status display should flash -1 (alternating “-” and

“1”), indicating that the drive is operational, but not yet configured.

Figure 3-13. LED Status Display

The digital display provides various indications of drive operation, such as

operation modes, drive enable status, and fault conditions.

For more information, refer to the section Oper ation Mode Codes.

3.8 ServoStudio Software Installation

Use ServoStudio software to configure the drive for your application.

1. Install ServoStudio on the host computer.

2. When installation is complete, start ServoStudio from the Windows Start

menu or the shortcut on your desktop.

Page 36

Configuration an d Operation CDHD

30 Servotronix

4 Configuration and Operation

4.1 Variables and Commands

Drive functionality is configured using various commands and variables, which

are transmitted over the communication bus. The terms “variables” and

“parameters” are used interchangeably; “dr ive p aramet er set” refe rs to the set

of variables that are specifically defined for a particular application.

Commands and variables are identified by a mnemonic (VarCom) name. For

example, MPOLES is the mnemonic used to read and write the settin g for the

number of m otor poles.

VarCom instructions, which are used with serial communications, are detailed in

the CDHD VarCom Reference Manual.

Some variables are read-only, while others allow read/write access. Variables

can be stored in the CDHD’s no n-volatile memory (flash memory) for use at each

power-up.

In gener a l, d rives are shipped fr o m the facto ry with m o to r par amete rs set to

zero and application parameters set to their default values.

4.2 ServoStudio Software

ServoSt ud io is a graphic interface provided with the CDHD to enable setup,

configuration and tuning of the drive.

ServoStu d io allows you t o prog ram the drive parameters speci fically for the

motor to which the CDHD is connected, and for the particular operation that the

drive wil l b e performing in the machine.

ServoStudio provides two primary ways for setting up the CDHD servo drive.

Using the Setup Wizard, which takes you step-by-step through the setup

and configuration process; this method is recommended for novice users.

Using each setup windo w ind iv idua l ly, to acc ess a nd de fine sp ec if ic driv e

functions.

The ServoStudio window has four function areas:

Toolbar

Contains quick access buttons for CONFIG ( to trigger inte rnal

drive configuration), Enable/Disable, Offline/Onli ne a nd Sa ve

(to save parameters to non-volatile memory).

Page 37

CDHD Configuration and Operation

User Manual 31

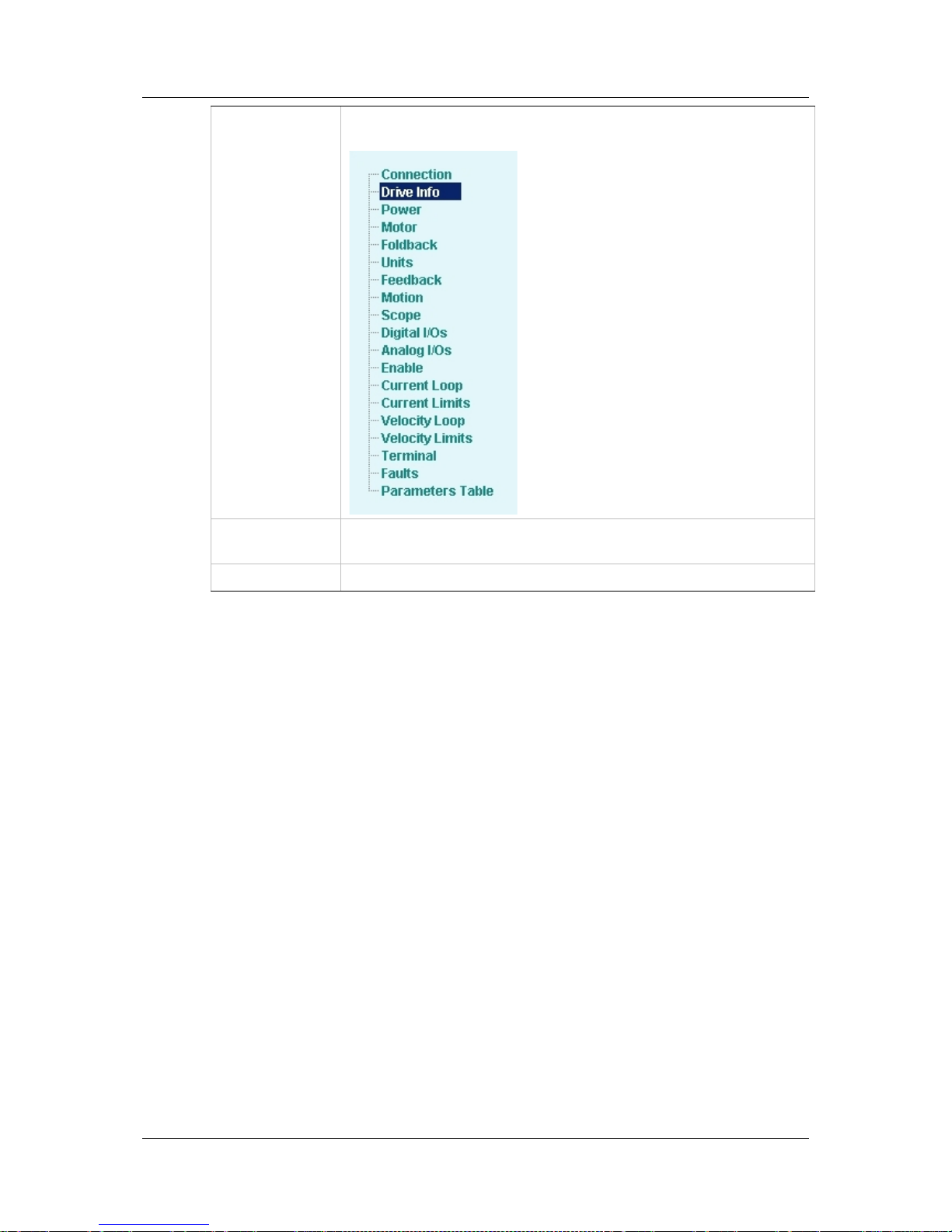

Sidebar

Contains a navigation menu for the drive functions. The

sidebar can be viewed or hidden using the Arrow icon.

Main Screen

Displays various interactive screens for viewing, setting and

testing parameters and drive configurations.

Status Bar Displays messages and warnings.

4.3 Connecting to a Drive

In the ServoStudio sidebar, click Connection.

The main screen now shows the various connection options.

Make the selections that match your setup.

4.4 Enabling/Disabling a Drive

4.4.1 Drive Enable

The drive is enabled when three conditions exis t, as shown in Figure 4-1.

No Faults

The drive can be enabled only when no faults exist.

Software Enable

The commands EN and DIS set the Software Enable state of the drive.

For the C DHD analog versi on, Software Enable is on at power up, which

allows the drive’s enable state to be controlled by the Remote Enable

signal.

For the CDHD CAN and other motion-bus versions, Softwa re Enab le is

off at power up, and the drive is enabled by means of specific control

words.

Page 38

Configuration an d Operation CDHD

32 Servotronix

Remote (Hardware) Enable

This is a s ig nal in the ra nge of 5—24 VDC that is applied to one of the optoisolate d d igital inputs in the Controller I/O connector.

The input m u st be configured fo r use a s the Remote (Hardware) Enable

input, using INMODE.

The state of the signal can be read, using REMOTE.

Figure 4-1. Drive Enab le Conditi ons (ServoStudio d iagram)

4.4.2 Operation Mode Codes

Once the drive is ready for operatio n, the 7-segment display shows a steadily-lit

single digit, indica ting the operation mode currently in effect.

Table 4-1. Operation Mode on 7-Segment Display

Display Name Description

. Drive enabled

0 OPMODE 0 Serial velocity co ntrol

1 OPMODE 1 An al og velocity control

2 OPMODE 2 Serial current control

3 OPMODE 3 Analog current control

4 OPMODE 4 Master/slave gearing control

8 OPMODE 8 Position control

For more information, refer to the section Drive Statu s 7 -Segment Display.

Caution: Enabling the drive might cause the motor to move.

Page 39

CDHD Configuration and Operation

User Manual 33

4.5 Managing Drive Parameters

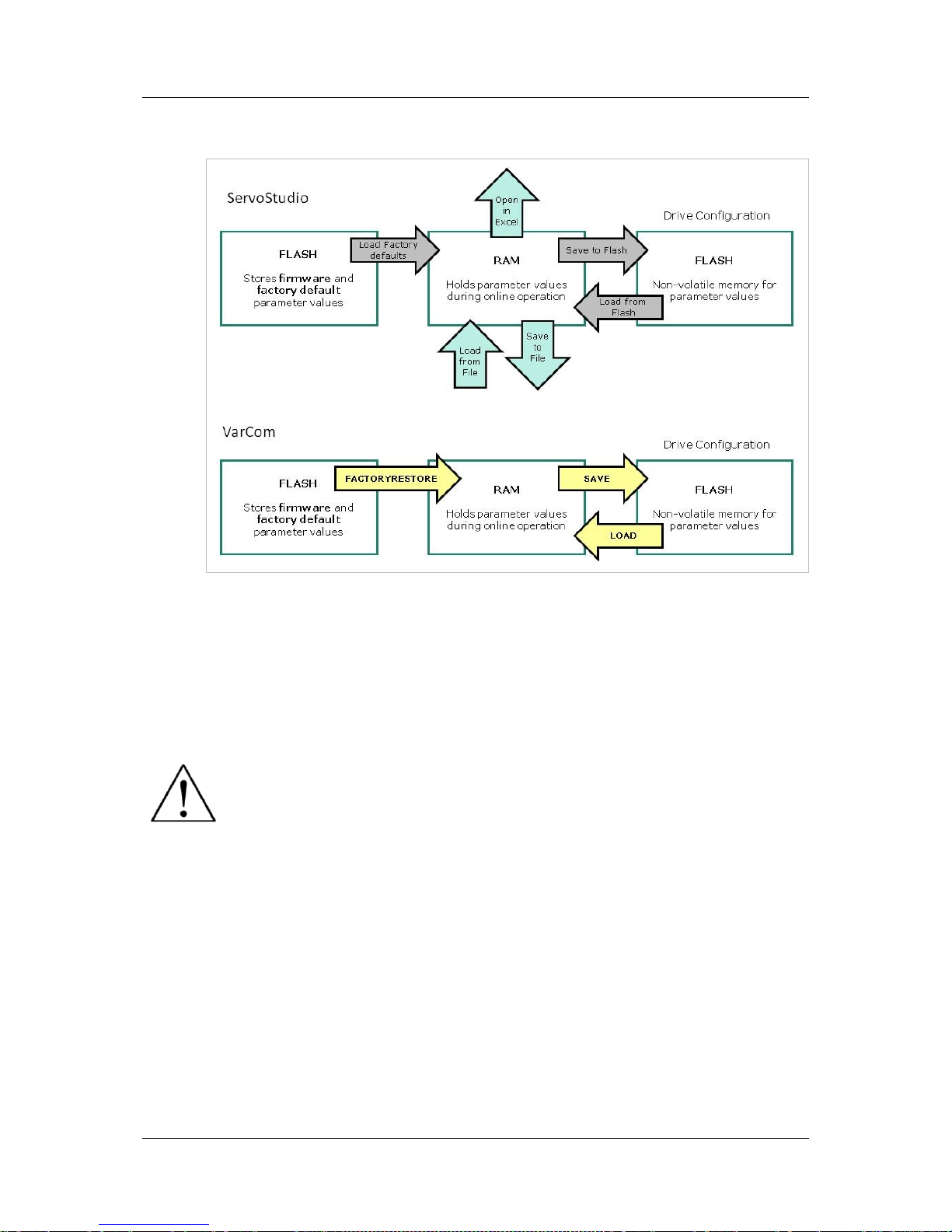

The CDHD dri ve has two types of memor y f or storing the drive’s parameters:

Flash: Non-volatile memory. It holds the drive’s default parameter values

(contained within the drive’s firmware), as well as the saved set of

parameters. After you have tested and confirmed that the drive is

performing as i ntended, save the parameters to the flash memory. You

should also save them to a file as a backup.

RAM: Volatile memory. The drive’s working memory. Parameter values are

maintained in RAM while you configure and test the drive and adjust

parameters. If power to the drive is disconnected, any unsaved changes in

the parameters will be lost.

During p ow er up, the CDHD loads p a rameter values from the flash memor y to

the RAM, and a checksum of these parameter values is calculated. If the

checksum is invalid, default parameter values (which are hard-coded in the

drive’s firmware) are loaded into RAM and a Parameter Memory Checksum

Failure fault is se t.

Drive parameters may be saved to non-volatile memory at any time by clicking

on the Save icon in the ServoStudio toolbar.

The Parameters Table in Ser voStudio includes additional options for loading and

saving the drive’s parameters.

Load from Driv e

Loads into RAM the parameter values last saved in the

non-volatile memory. Use this option to revert to the

previous saved con figuration.

Write to Drive

Saves the parameters currently in RAM to the non-volatile

memory.

Load from PC Loads into RAM paramete r from a file on your PC.

Write to PC Saves parameters from RA M to a file on your PC.

Page 40

Configuration an d Operation CDHD

34 Servotronix

The following diagram il lustrates the relationships among the different types of

memory in the CDHD drive.

Figure 4-2. Drive Mem ory Archite ctu re

For more inf ormation on the comma nds for saving and loa d ing parameters, refer

to the CDHD VarCo m Reference Manual.

4.6 Configuring Parameters Using ServoStudio

Disable the dri v e before mani p u l a ting motor and feedback

parameters.

Many parameters can be modified while the drive is enabled.

Exercise caution, however, as motor behavior will change.

If a parameter cannot be modified while the drive is enabled, ServoStudio

will prom pt you to d is a ble the dr iv e.

While setting the paramet e rs, pay close att en tion to any warn ing or error

messages displayed by ServoStudio.

4.6.1 Tuning and Testing

In the Motion screen, various types of motion can be executed. In this screen

the values of actual current, velocity and position are displayed. This is not realtime data, however, and the update rate depends on such factors as the host

computer processing pow er and the drive mode of ope ration.

Drive tuning is generally performed in the Scope screen. This screen allows t he

you to record drive parameters, and to configure the record trigger to match the

specific motion being recorded.

Page 41

CDHD Configuration and Operation

User Manual 35

4.6.2 Drive Info

The Drive Info screen displays basic information about the CDHD, such as

current rating , ha rd w a re vers ion and fir m w a re versio n. It is important to

provide this information to Servotr onix Technical Su pport when asking for

assistance. Th is scre en also provi des access to the Firmware Download utility.

4.6.3 Power

The Power screen displays the drive’s continuous and peak current ratings, and

allows you to set the bus voltage parameters. These parameters include:

The nominal bus voltage that will be applied to the drive: 320 V for a drive

powered by 220 VAC per phase, and 160 V for a drive powered by 110 VAC

per phase.

Under-voltage mode. Defines how the drive will respond to an under-voltage

fault.

Under-voltage time. Specifies the amount of time an under-voltage

condition will exist before latching a fault, when working in Delayed Fault

Under-Voltage mode.

Under-voltage recovery. Defines how the dri ve will recover fr om an under-

voltag e f au lt: recovers automatically or by toggling dr ive from disab le to

enable.

Refer to VBUS, UVMODE, UVTIME and UVRECOV ER in the VarCom Reference

Manual.

4.6.4 Motor

The Motor screen allows you to select a motor from the ServoStudio database.

You can simply select the motor family and motor part number, and ServoStudio

will prepare the appropriate motor and feedback parameters. Select Write to

Drive to send the parameters to the drive.

The screen also allows you to read parameters from the drive, and save

parameters.

4.6.5 Foldback

The Foldback screen allows you to set the foldback properties of the drive and

motor, and to activate the motor foldback feat ure.

4.6.6 Units

The Units screen lets you select the position, velocity and acceleration/

deceleration units that you prefer for working with a rot ary motor.

Refer to UNITSROTPOS, UNITSPOSVEL and UNITSPOSACC in the VarCom

Reference Manual.

4.6.7 Feedback

The Feedback scree n e na bles you to configur e the properties of the motor’s

feedback device, and to view the feedback according to your preferences.

To configure feedback, select the feedback device from the Feedback options.

The screen will change accordingly, enabling you to set the relevant feedback

properties.

Page 42

Configuration an d Operation CDHD

36 Servotronix

The Feedback screen also allows you to activate the encoder simulation output

and set its resolution .

4.6.8 Motion

The Motion screen allows you to choose the operation mode and to set the

relevant motion settings. It also all ows you to execute motion and to view the

actual current, velocity and position of the motor.

4.6.9 Scope

The Scope screen enables you to configure recording settings, record data from

the drive, and display the data according to your preferences. It also enables

you to conduct motion if required and send commands to the drive via terminal.

4.6.10 Digital I/Os

The Digital I/Os screen enables you to configure functionality and polarity of

the digital I/Os, and to monitor the state of all digit a l I/Os.

4.6.11 Analog I/O

This Analog I/Os screen lets you set various properties of the analog inputs,

such as functionality, manual or automatic offset level, low pass filter, and dead

band range. It also allows you to m onitor the state of all analog in p uts.

4.6.12 Enable

The Enable screen displays the state of all conditions required for the drive to be

enabled.

4.6.13 Current Loop

The current loop gains are set automatically according to the motor properties

and the bus voltage. The Cu rrent Loop screen enables you to change defau lt

gains by multiplying them by a factor.

4.6.14 Current Limits

The Current Limits screen contains a diagram that shows how the ma xi mu m

current for the system is determined, and enables you to set the current limit for

your system accord i ngl y.

4.6.15 Velocity Loop

The Velocity Loop scre en ena bles you to select the type of velocity controller

you want to use, and to set the required parameters. All types of controllers are

graphically illustrated with the required parameters embedded in the schematics.

4.6.16 Velocity Limits

The Velocity Limits screen contains a diagram that shows how the max imu m

velocity for the system is determined, and enables you to set the velocity limit

for your system accordingly.

4.6.17 Terminal

The Terminal screen allows you to send ASCI I co mmands to the drive, and to

monitor p ara meters in a Watch pane.

Page 43

CDHD Configuration and Operation

User Manual 37

4.6.18 Faults

The Faults screen shows a list of drive faults. This information allows you to

identify problems and take measures to correct them.

4.6.19 Parameters Table

The Parameters Table displays and allows you to modify the drive parameters.

The pa rameters ar e grouped according to function. For each parameter you can

find a description, units, maximum value, minimum value, and cu r rent value .

In this screen you can also download parameters from the drive, upload

parameters to the dr ive , load parameters from a file, and save parameters to a

file.

4.7 ServoStudio Expert View

The Expert View screen lets you perf o rm the fo llowing ta sks:

Send ter m inal commands to the drive

Change operation mode and in itiate motion accordingly

Monitor parameters using a watch pane

Set recording properties

Set chart display properties

Run scripts

Page 44

Firmware Upgrade CDHD

38 Servotronix

5 Firmware Upgrade

The CDHD firmware can be upgr a ded using t he Se rv oStudio softwar e.

5.1 Preparation

Important: Before upgrading the firmware, backup the drive parameters since

parameter settings may be lost during the upgrade. After the upgrade is

completed, the parameters can be reloaded/restored.

5.2 Upgrade Procedure

From the ServoS tudio Drive Info screen, activate the upgrade procedure, and

follow the prompts.

Page 45

CDHD Troubleshooting

User Manual 39

6 Troubleshooting

6.1 Dr ive Status 7-Segment Display

The 7-segment display provides various indications of drive status, such as

operation modes, drive enable status, and fault conditions.

The disp la y uses the fo llowing co n v entions:

Decimal point – indicates the drive’s Enable/Disable status; if displayed, the

drive is enabled.

Steadily lit digit – indicates the specific operation mode (OPMODE) currently

in effect.

Steadily lit letter – indicates a war ning

Flashing sequence of letters and digits – indicates a fault

Flashing letter or digit – a special case (such as encoder initialization, motor

setup).

In the event of concurrent faults, only one fault code is displayed on the

7-segment displa y. The display shows the code of the fault with the highest

priority.

Refer to Table 6-1 for a complete list of fault codes, names and descriptions.

6.2 Faults and Warnings

If the CDHD is connected to a host computer via the USB o r RS232 ports, it

communicates fault codes to the computer by means of a text message. This

message is saved in a fault history log (FLTHIST) in the drive’s non-volatile

memory, so tha t th e fa ult history is not lost when po w e r is re m o v ed f ro m th e

drive.

Warnings are not considered faults and do not disable operation. The

system automatically clears the warning state when the condition that

generated the warning no longer exists.

Faults automatically disable the drive and a fault status is indicated on the

drive’s display. The drive fault status is generally latched, and the drive

cannot be enabled until the fault status is explicitly cleared. Only if the fault

condition no longer exists can the fault status be cleared. It is done by

either of the following:

Toggling the drive enable. This is done either by executing a drive

disable command (K) followed by the enabled (EN) command or by

toggling the Remote Enable line (REMOTE).

In some systems, a specific drive inpu t is define d as Alarm C lear. In this

case, toggling this input will clear the fault.

If the fault condition no longer exists, the drive is re-enabled.

Some faults are referred to as Fatal faults since they dis a ble almost all

drive functions (including communications) and prevent the drive from being

enabled. This condition is typical of faults due to internal failures, such as a

Page 46

Troubleshooting CDHD

40 Servotronix

watchdog event or a failure of an internal power source. Fatal faults requir e

intervention by technical support.

6.3 Status Information in ServoStudio

Drive status information can be found in various ServoStudio screens.

The Drive Info screen shows basic information about the CDHD, such the

current rating , ha rd w a re vers ion and fir mware v e rs ion. It is im p o r tant to

comm un icate this infor ma t ion to Servotronix Technical Su p p ort when

requesting assistance. This screen also provides access to the firmware

upgrade utility.

The Faults scree n shows a lis t of drive fa ults. Us e this infor matio n to

identify the problem and take steps to correct it.

The Digital I/O screen allows you to check the status and configuration of

the digital inputs and outputs.

The Motion screen allows you to issue motion commands in the operation

mode of your choice, and to view actual values of current, velocity and

position.

The Scope screen enables you to record data from the drive, with or

without assoc iated mo t io n.

6.4 Fault and Statu s Queries

The following commands can be used to query the status of the drive.

FLT

Returns a list of faults latched by the drive. Faults remain latched

until cleared by CLEARFAULTS or EN, provided that the fault

condition has been remove d .

FLTHIST

Returns a list of faults that have occurred since the fault buffer was

last cleared.

FLTCLR Clear s the fault histor y b u f fe r.

ST The ST command returns a textual summary of the drive status.

Refer to the VarCom Reference Ma nual for a complete list and details of variables

and commands.

6.5 Fault Codes and Names

The following table will help you interp ret fault codes and names, and respond

appropriately.

Display is the code that appears on the 7-segment display.

If the fault code is a single character (such as u), the character flashes on

and off. (The exception is F, which remains lit stead ily).

If the fault code is m o re than one cha racter (s uc h as A4), t he characte rs are

displayed one at a time, in sequence.

Fault Name is the text mess a g e d isplayed in Serv o Studio when the fault occurs.

Faults can also be viewed in t he ServoStudio Faults screen.

Page 47

CDHD Troubleshooting

User Manual 41

Table 6-1. Faults

Display Fault Name Description Action Required

≡

Watchdog Fault

Generally occurs due to a n

unforeseen circumstance. The drive

is inoperable until p owe r is cy cle d .

Contact technical suppor t.

-1 Not Configured Drive configuration required.

Set drive parameters and execute

CONFIG.

A4 CAN Supply Fault

A problem with the in te rna l v olt ag e

supply for the CANbus.

The drive probably needs repair.

Contact technical suppor t.

b Drive Locked

Security code and key do not match.

Fatal fault; drive can not b e

operated.

Contact technical suppor t.

e

Parameter Memory

Checksum Failure

The non-volatile memory use d to

store drive parame te rs is emp t y or

the data is corrupted .

Reconfigure the d rive, or download the

parameter set, and save the

parameters.

E

Failure Writing to

Flash Memory

An internal proble m acce ssing the

flash memory. Fatal fa ult; d riv e

cannot be operated.

Contact technical suppor t.

e101 FPGA Config Fail

The code for the FPGA did not load.

Fatal fault; drive can not b e

operated.

Contact technical suppor t.

e105 Self Test Fail