Systems

Technical

Publication

SERVOSTAR

®

600

with Kollmorgen GOLDLINE™

BH/MH Motors

Kollmorgen SERVOST AR®600 Amplifier

• 400 to 480 Volt Three Phase

AC Input Power

• Resolver Feedback

• Integrated Power Supply

• Fully Digital Control

• CE, UL, cUL

The SERVOSTAR 600 amplifier is a compact, fully digital

drive-amplifier designed to simplify installation, system setup, and system reliability.

FEATURES:

Servo Control

• Easy to tune servo loops

• Advanced sinewave commutation technology

provides smooth, precise low-speed control and

high speed performance

• Velocity loop bandwidths to 400 Hz

• DQ Current control increases high speed peak torque

performance for faster cycle rates

• Space Vector Modulation reduces normal power stage

switching loses

• Torque angle control enhances motor performance

• Fully digital control loops

• Compact and attractive rugged metal package for spacesaving, modern appearance - metal package minimizes

electrical noise emmision & suceptability

• Command modes: Torque, Velocity, Position, Electronic

Gearing Pulse Following, and Motion Task

• Five current ratings: 3, 6, 10, 14, and 20 amp RMS/phase

continuous

• 2 to 1 peak/continuous current rating (5 second at peak)

• Run time counter

Easy Connectivity

• Built in encoder equivalent output can eliminate the need

for an additional position feedback device

• RS-232 Communication

• Unique multi-drop configuration allows a PC or PLC to

communicate to multiple SER VOSTAR600 amplifiers via

single RS-232 connection

• SERVOSTAR 600’s versatile communication capabilities

make it easy to integrate machine control data directly

from the factory floor to your information system

• Analog ±10V, pulse/direction, master encoder, and serial

port, I/O command options

Robust Design

• ESD rugged circuit design and fully metallic enclosure

• Full protection against short circuit, overvoltage,

undervoltage, heatsink overtemperature, motor overtemperature, overspeed, overcurrent, and feedback loss

• UL , cUL listed, and CE

• Built-in line filter for CE

• Flash memory

Windows Start-up Environment

• Graphical environment simplifies set up

• PC “Oscilloscope” for measuring real-time

motion performance

• Interactive MOTIONTASK Programming

Configurable I/O

• 2 separate analog inputs (14 and 12 bit resolution)

configurable to 6 different command modes

• 2 analog outputs

• 4 digital inputs

• 2 digital outputs

• I/O can be configured to a variety of functions to

customize the SERVOSTAR 600 to individual machines

I/O Option Card (see page 5)

• Adds 14 additional digital inputs and 8 digital outputs

• All I/O are optically isolated

• Simple plug in to top face of Amplifier

Regenerative Power Sharing

• Patented circuitry allows the DC bus from two or more

amplifiers to be connected together allowing regen power

to be shared among multiple drives

Built in Parameter Unit

• Perform basic drive set up without

the need for a PC

• Provides diagnostic information

• Allows motor selection from

parameters store in memory

Built in Safety Relay

• Switches off the power stage to ensure personnel safety

and prevents an unintended restart of the drive, even in

the event of a fault

• Allows DC bus to remain on

INTRODUCTION

SERVOSTAR®600

KOLLMORGEN

2

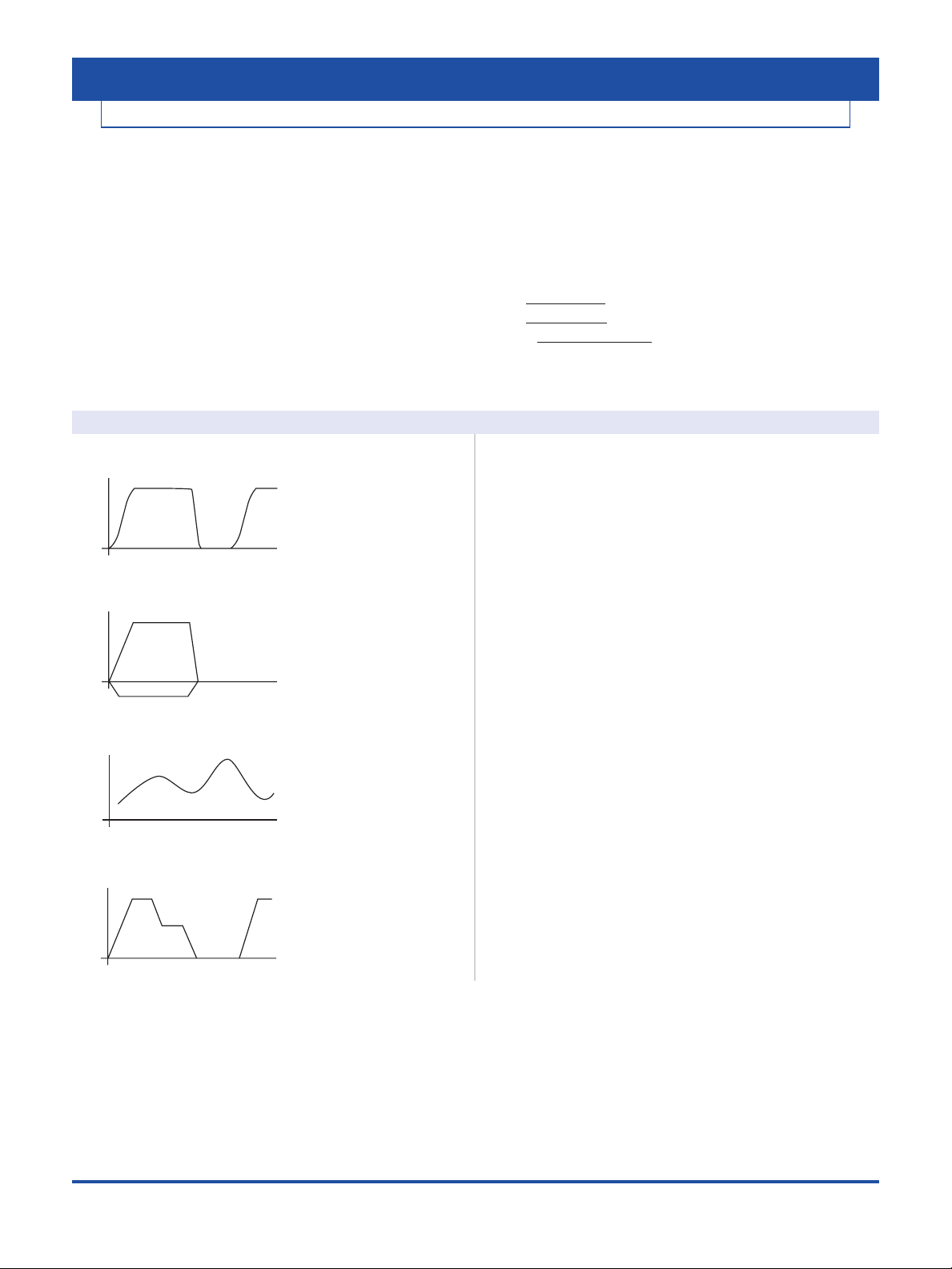

INCREMENT ALMOVE

ABSOLUTE MOVE

ELECTRONIC GEARING 5:1 (MASTER/SLAVE)

MACRO MOVE

• material handling

• bottle making

• packaging

• soft positioning

• robot

• conveyor belt controlling

• fast positioning

• special cleaning process

• part selection

• glass processing

• robot

• wirepuller

• textile industry

• printing

• electronics

• web converting

• cut to length

SERVOSTAR 600

KOLLMORGEN

INTRODUCTION

3

Motion Capabilities

The SER VOSTAR 600 can be configured to perform motion

control that normally requires a fully programmable drive

with a motion language. With the SERVOSTAR 600 there is

no programming language to learn; the user only “fill in the

blanks” to create common motion tasks

• Up to 180 motion task can be stored in

permanent memory

• Motion Tasked can be linked together.

• 10 types of homing

• Speed profile/registration control

• Adjustable S curve acceleration

• Absolute and relative (index) moves

• Linking of motion task (sequencing)

• Adjustable Following-Error window

• Adjustable window for the In Position signal

Linked motion tasks are started:

• Immediately upon reaching a targeted position

• Digital Input upon reaching the targeted position

• APreset Time Delayafter the targeted position is reached

Motion Examples Application Examples

Velocity

Time

Velocity

Position

Velocity

Time

Velocity

Time

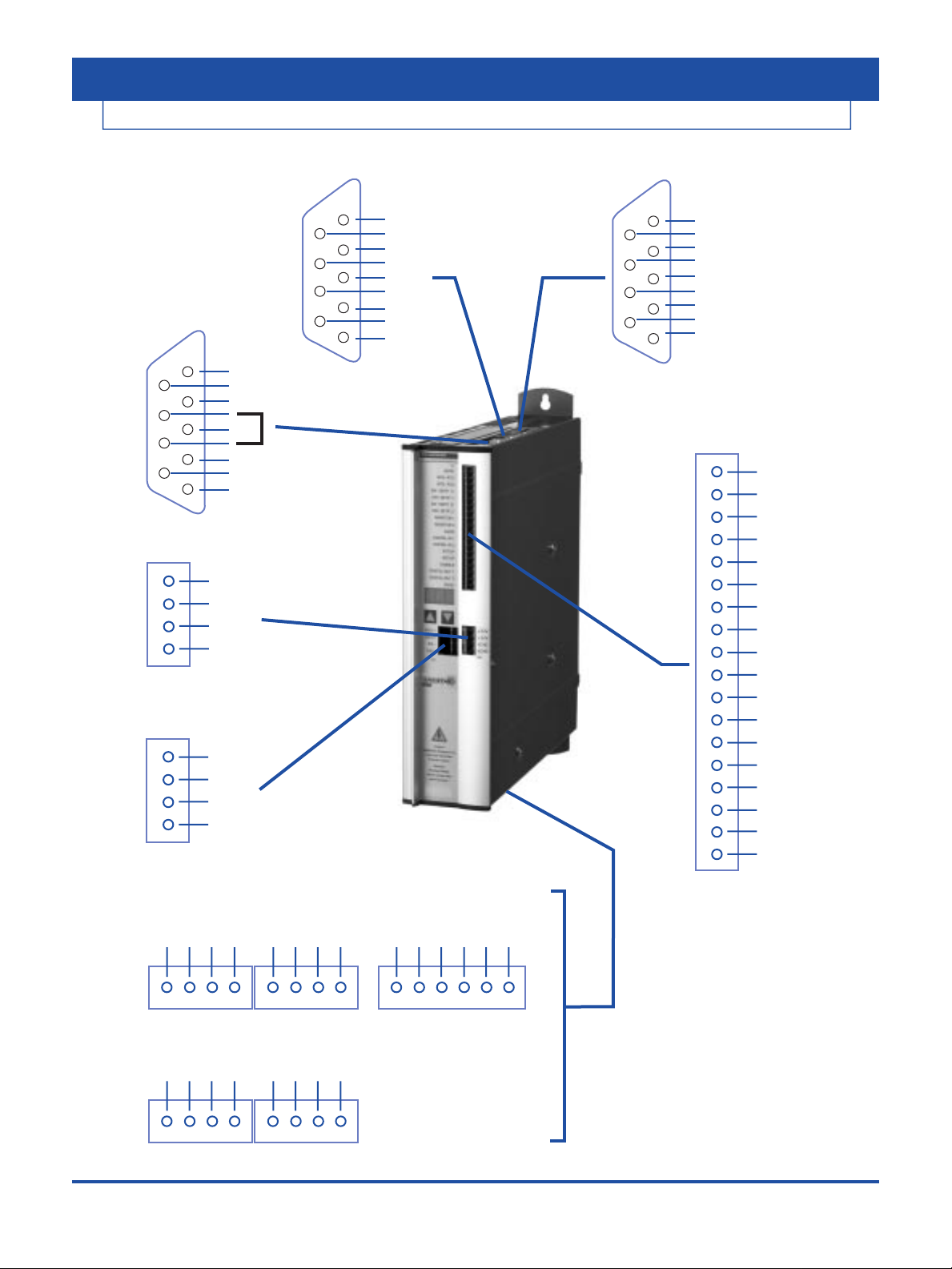

CONNECTOR INFORMATION

SERVOSTAR 600

AGND

BTB/RTO

BTB/RTO

SW/SETP.1+

SW/SETP.1SW/SETP.2+

SW/SETP.2MONITOR1

MONITOR2

AGND

DIGITAL-IN1

DIGITAL-IN2

PSTOP

NSTOP

ENABLE

DIGITAL-OUT1

DIGITAL-OUT2

DGND

1

2

3

4

X3 I/O

5

6

7

8

9

10

11

12

13

14

15

16

17

18

+24V 1

+24V 2

XGND 3

XGND 4

1

2

3

4

X4 24V INPUT

+8V

CANL

RxD

TxD

N.C.

CANH

PGND

X6 PC

1

6

2

7

3

8

4

9

5

PGND

B+ (DATA)

Motor +

B- (/DATA)

Motor +5V

A- (CLK)

N.C.

A+ (/CLK)

X5 Encoder Equivalent Output

1

6

2

7

3

8

4

9

5

R2

R1

S3

S1

S4

S2

THERMOSTAT

THERMOSTAT

SHIELD

X2 RESOLVER

5

9

4

8

3

7

2

6

1

L1

L2

L3

PE

-RB+R

Bint

R

BEXT

n.c.

1

2

3

4

XO

B

X8 R

REGEN

XO

A

X7 DC-circuit

Brake-

Brake+PEU2

V2

W2

1

2

3

4

5

6

X9 motor/brake

1

2

3

4

L1

L2

L3

PE

+DC

-DC

+DC

-DC

1

2

3

4

1

2

3

4

Connectors underneath:

KSO1 1

KSO2 2

KSI- 3

KSI+ 4

1

2

3

4

X10 MOTOR

DISCONNECT

RELAY

KOLLMORGEN

4

CONNECTOR POSITION

CONNECTOR ASSIGNMENTS

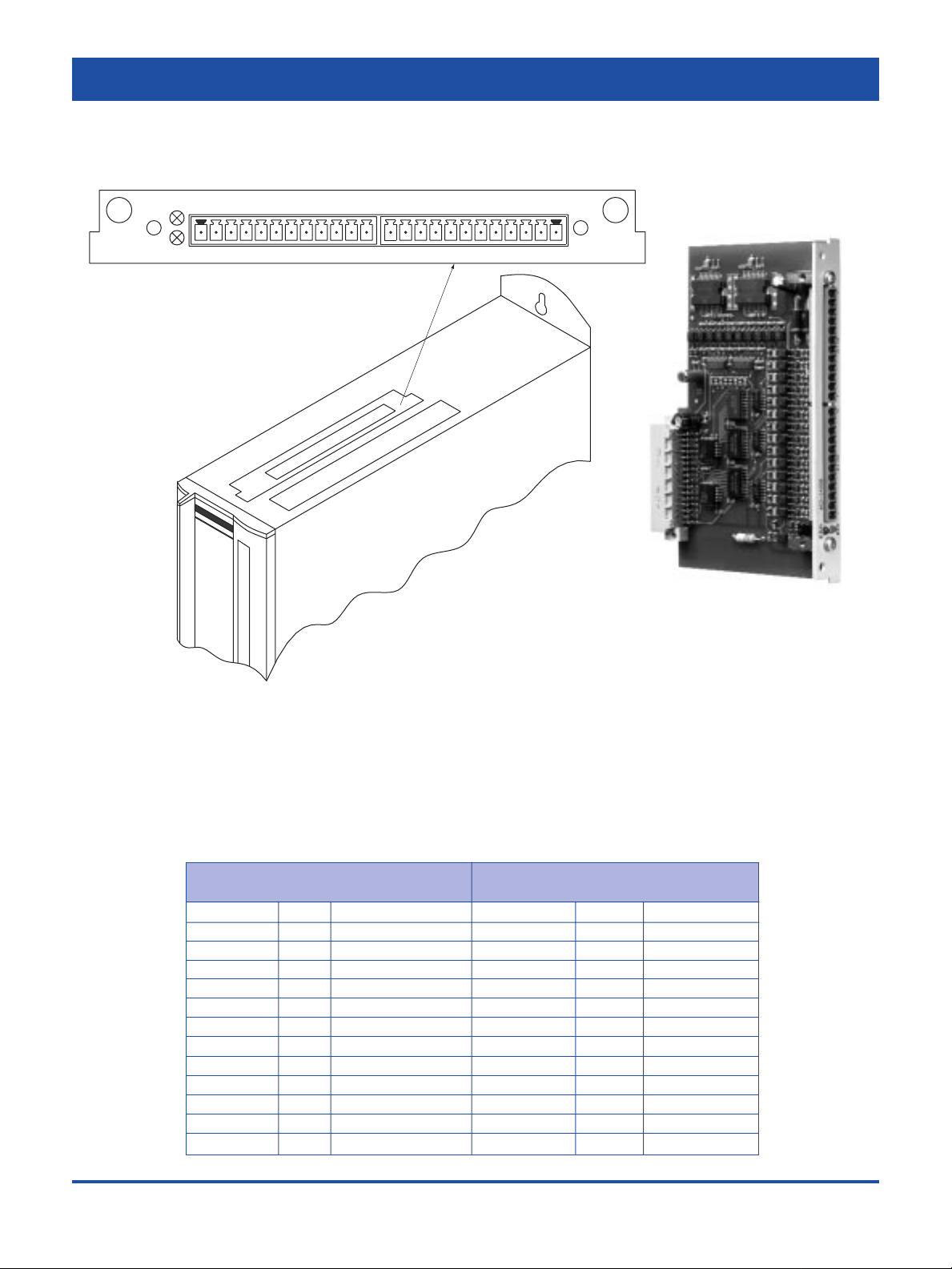

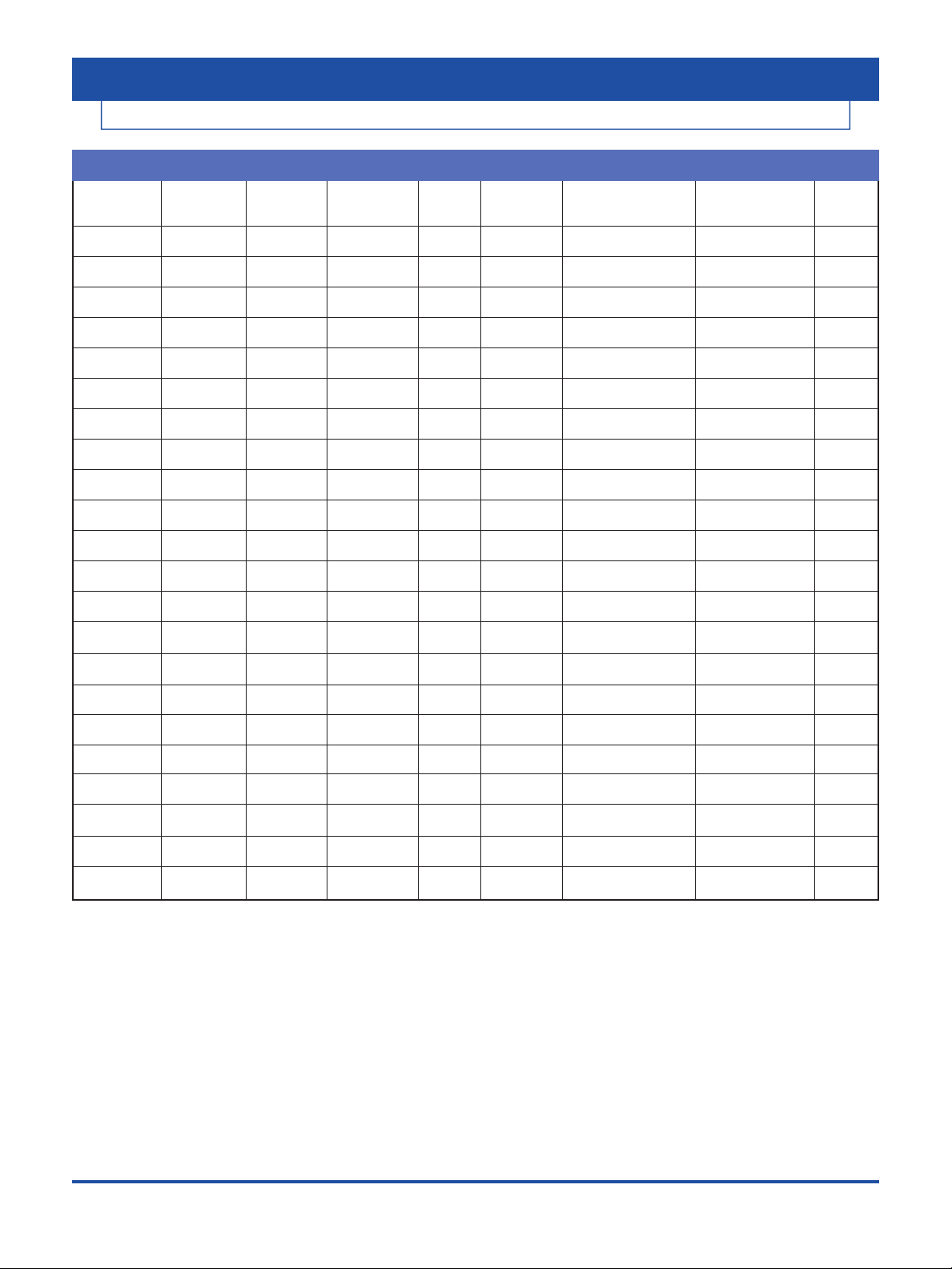

Connector Connector

X11A X11B

Terminal Fn. Description Terminal Fn. Description

1 In A0 1 In MT_Restart

2 In A1 2 In Start_MT

3 In A2 3 Out InPos

4 In A3 4 Out Next-InPos

5 In A4 5 Out Sfault

6 In A5 6 Out PosReg1

7 In A6 7 Out PosReg2

8 In A7 8 Out PosReg3

9 In Reference 9 Out PosReg4

10 In Sfault_clear 10 Out Reserve

11 In Start_MT Next 11 Sup. 24V DC

12 In Start_Jog v=x 12 Sup. I/O-GND

SERVOSTAR 600

I/O OPTION CARD

ERR I/O-14/08 X11A

X11

X11B

12112124V

The I/O option card is an extremely economical way of operating

servo controllers under position control for simple automation tasks.

14 additional digital inputs permit the selection and start of the motion

tasks that are stored in the motion-task memory of the SERVOSTAR

®

600. All the important functions for the position controller that

is integrated into the servo controller can thus be operated from a

small, independent control system.

8 digital outputs report the status of the drive to the higher-level control.

KOLLMORGEN

5

AMPLIFIER SPECIFICATIONS

SERVOSTAR 600

Electrical characteristics

• Closed loop velocity bandwidth up to 400 Hz

• Motor current ripple frequency 16 kHz

• Switching frequency: 8 kHz

• Long term speed regulation (0.01%)

• Position loop update rate 250 µs (4 kHz)

• Velocity loop update rate 250 µs (4 kHz)

• Commutation update rate 62.5 µs (16 kHz)

• SVM Current loop update rate 62.5 µs (16 kHz)

Fault protection

• Output phase to phase and phase to ground short circuit protection

• Overvoltage

• Undervoltage

• Overtemperature (motor and amplifier)

• Overspeed

• Overcurrent

• Feedback loss

• Foldback

• Supply loss

• Excessive position error

Environmental

• Operation range

- Ambient 0 to 45°C (derated above ambient up to 55˚C)

- Storage -25°C to 55°C

• Humidity (non-condensing) max 85%

Velocity Loop Compensation

• PI Plus controller (PDFF Format) or PI controller

• Field tunable and digital repeatability

Position Loop Compensation

• Proportional loop with Feed Forward

Analog I/O

• 2 Configurable Inputs: ±10V, 12 and 14 bit resolution

• 2 Configurable Outputs: ±10V, 10 bit resolution

Digital I/O

• 4 Configurable Inputs: 24 volts, PLC-compatible

• 2 Configurable Outputs: 24 volts (open collector), PLC-compatible

• Remote enable Input: 24V, PLC-compatible

Drive Status Relay (BTB/RTO)

• Contact closure rated for 0.5 amps, 24 Volt

Pulse or Master/Slave Input

• Pulse command: pulse/direction or quadrature encoder format

• RS-485 receivers

• Up to 16 slave amplifiers can be connected together

• Input ratio is configurable

Position Feedback For User (Encoder Equivalent Output Port)

• Configurable to Encoder Equivalent (ROD) or SSI format

• Encoder Equivalent (ROD): A Quad B with Marker (zero) pulse,

RS-485 driver

• SSI (serial synchronous interface): max clock frequency is 1.5 Mhz,

RS-485 driver

• Programmable resolution

I/O Extension Card (Option)

• Field Installable

• 14 Digital Inputs 24V, PLC-compatible

• 8 Digital Outputs 24V, PLC-compatible

• 24V PLC Interface

Communications

• RS-232 Interface

Operational modes

• Torque control — from analog or digital command

• Velocity control — from analog or digital command

• Pulse following

• Gearing from quad encoder input

• Motion Task

• Serial Commands

Diagnostics

• 3 digit Seven segment LED display

• Error history log

• Internal variable monitoring

• PC scope

Motor Feedback

• Resolver

Motor Brake Control

• 24V optional holding brake in the motor can be controlled directly by

the SERVOSTAR 600

Power Inputs

• 400 to 480VAC 3phase, 50 or 60 Hz, built in line filter for

CE requirements

• 24 VDC @ 1 amp (3 amps with brake) For Logic

Power Regeneration Options

• Internal

• External - using BAR housed resistors

• Bus Sharing - Distributes regen power among multiple amplifiers

Built in Parameter Unit

• Displays drive status information

• Parameters: Drive Address, baud rate, Velocity loop tuning, Motor

type, Position output information format, brake, regen type

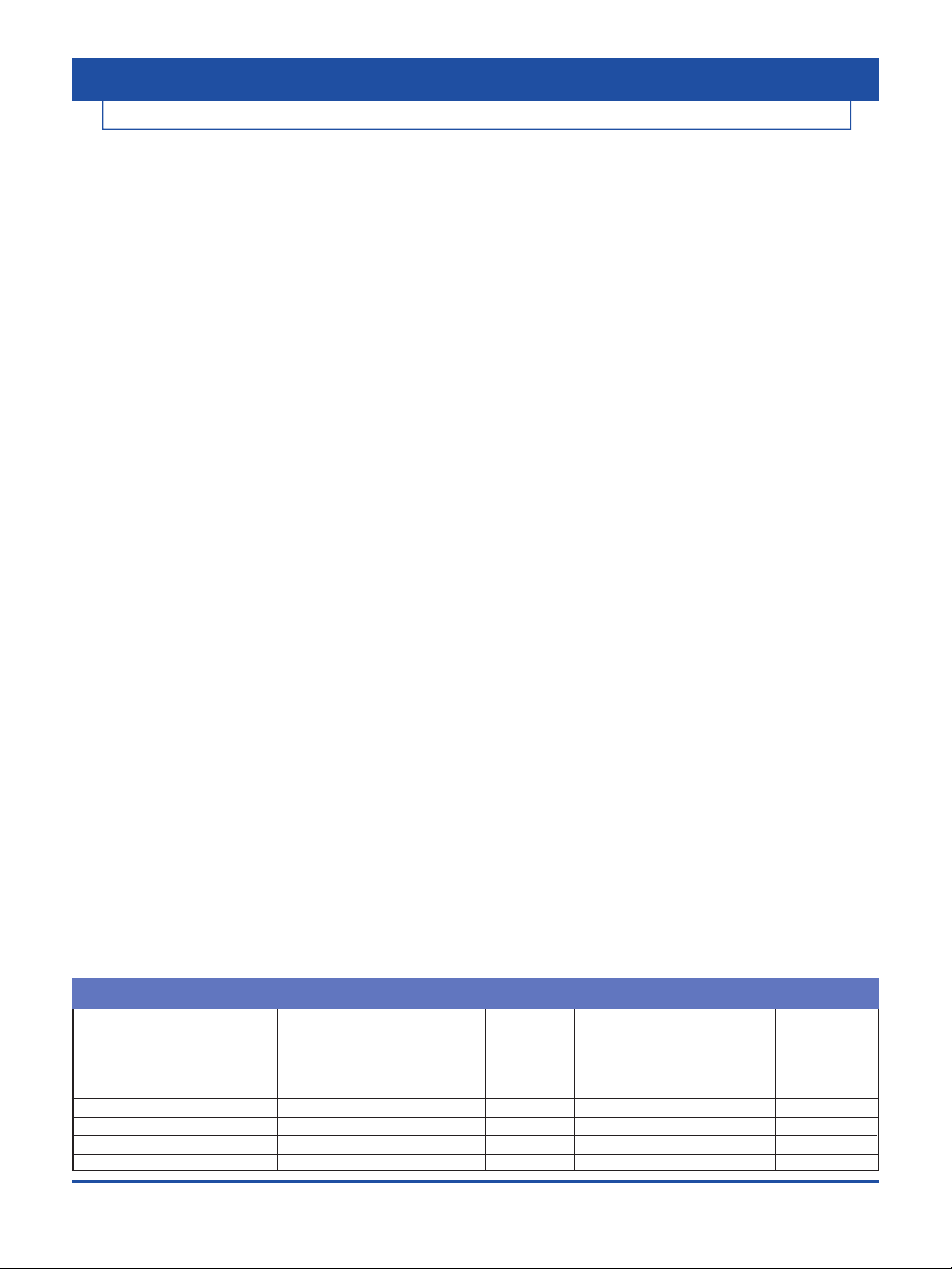

Model Output Continuous Output Peak Internal Power AC Input Rated Continuous Continuous

Current Per Phase Current Per Dissipation Line Input Internal External

(RMS/phase) Phase (Watts) Voltage Power (KVA) Regen Power Regen Power

(5 sec) (3 phase) @480 V (Watts) (Watts)

S603 3 6 40 400-480 2.3 80 500

S606 6 12 60 400-480 4.6 200 1,500

S610 10 20 90 400-480 8.1 200 1,500

S614 14 28 160 400-480 11.6 200 1,500

S620 20 40 200 400-480 16.6 200 1,500

Amplifier Ratings

KOLLMORGEN • keyfaith • 0755-83288220

6

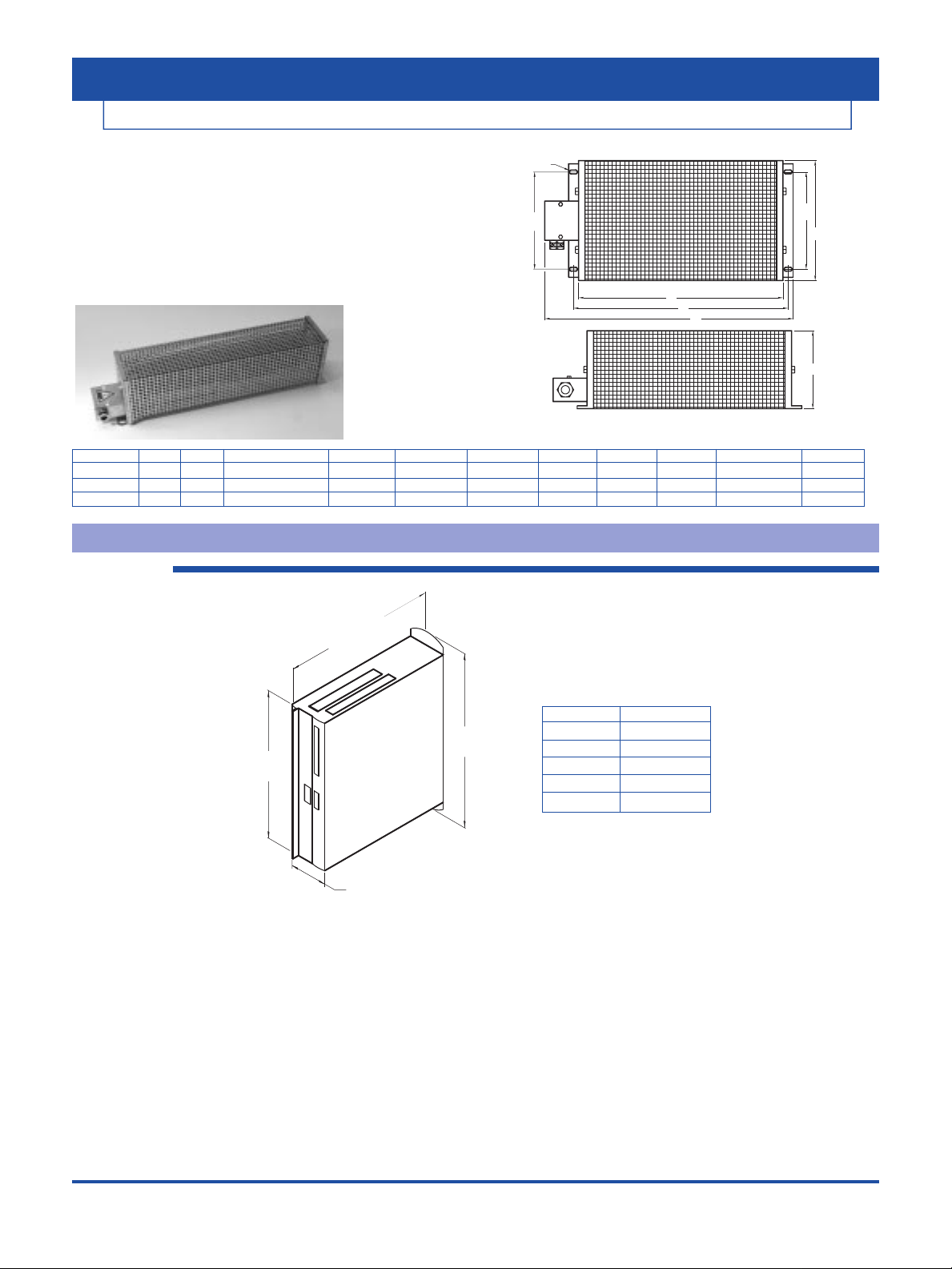

DIMENSIONS/ORDERING INFORMATION

Resistive Regeneration Sizing

Shunt regeneration is required to dissipate energy that is pumped back

into the DC bus during load deceleration. The amount of shunt regeneration required is a function of the sum of simultaneously decelerating

loads. The loads need to be defined in terms of system inertia, maximum

speed, and deceleration time. In addition, the duty cycle must be known.

Application Note AS6000H details a calculation method to determine

proper regeneration sizing.

SERVOSTAR 600

SERVOSTAR 600 DIMENSIONS

S603/06/10

Dimensions in mm (inches)

Model Watts Ohms Amplifiers A B C D E1 E2 F G

BAR-250 250 33 S603, S606, S610 330(12.99) 390(15.35) 412(16.22) 66(2.60) 44(1.73) 35(1.38) 4,5x9(.20x.35) 77(3.03)

BAR-500 500 33 S603, S606, S610 400(15.75) 426(16.77) 486(19.13) 92(3.62) 64(2.52) 64(2.52) 6,5x9(.20x.35) 120(4.72)

BAR-1500 1500 33 S606, S610 500(19.69) 526(20.71) 586(23.07) 185(7.28) 150(5.91) 150(5.91) 6,5x9(.20x.35) 120(4.72)

DIM. “A”

3 AMP 70 (2.8)

6 AMP 70 (2.8)

10 AMP 70 (2.8)

14 AMP 100 (3.9)

20 AMP 120 (4.7)

KOLLMORGEN • keyfaith • 0755-83288220

7

F

E2

E1

D

A

B

C

G

265 (10.4)

with connector:

273 (10.7)

275

(10.8)

"A"

325

(12.8)

ADDITIONAL FUNCTIONS

KOLLMORGEN • keyfaith • 0755-83288220

8

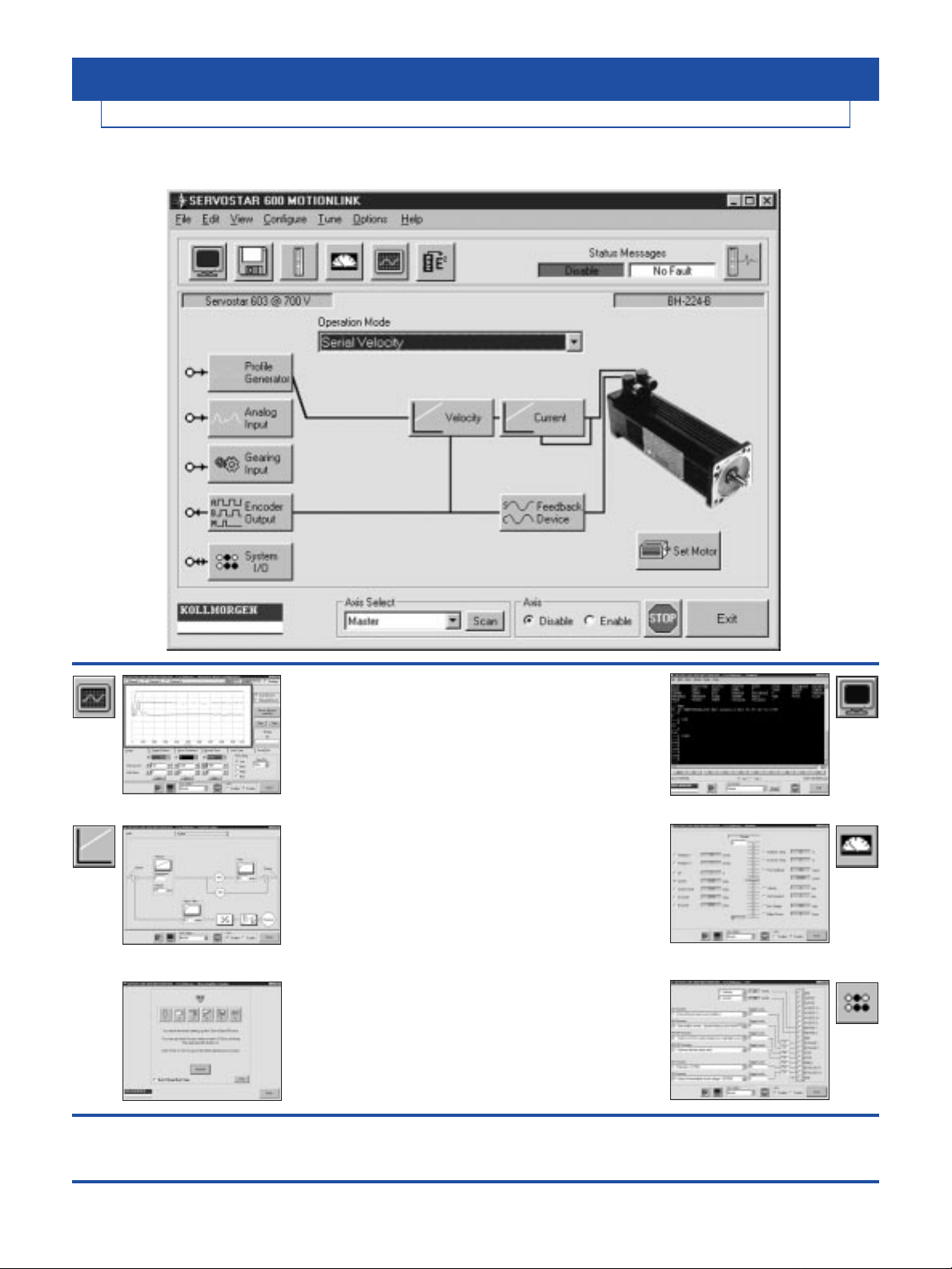

MOTIONLINK SERVOSTAR 600

PC Oscilloscope:

For closely evaluating system

performance MOTIONLINK includes

the functionality of an oscilloscope.

Y ou can very easily excite the load then

review performance graphically on

your computer screen.

Tuning:

Velocity and position loop tuning is

straight forward, allowing the novice user

to achieve the best machine performance.

Auto Set-up:

MOTIONLINK auto set-up environment

walks even the first time user through line

voltage, motor, operation mode and load

tuning to make system configuration

friendly and fast.

Direct Terminal Mode:

This mode turns your computer into a

“dumb terminal.” Variables or parameters

can be monitored and changed using

the SERVOSTAR

600’s

command

language. This mode is ideal for

advanced users who want to get directly

in the “heart” of the SERVOSTAR

600

.

Monitor Mode:

Allows you to monitor key operation

variables. Speed, torque, and other

variables can be viewed in real

PSEUDO time in linear gauge format.

Configuring I/O:

Inputs & Outputs are configurable to a

wide variety of functions to configure

the

SERVOSTAR 600

to individual

machine needs.

MOTIONLINK®for Windows takes the fear out of setting up a servo system. Designed for the novice as well as

the advanced user, MOTIONLINK lets users quickly set-up and fine tune system performance.

MOTIONLINK has many other features including: • Saving drive configuration to disk

• Activating position limits

• Displaying amplifier status

• Setting acceleration amps

• Limiting max speed or torque

KOLLMORGEN • keyfaith • 0755-83288220

9

CONFIGURABLE AND READABLE FUNCTIONS

Basic Set Up

• Input Power

• Main Phase Missing

• Max Regen Power

• Internal or External Regen Resistor

• Drive Name and Serial No *

• Run Time *

• Firmware Version *

• Hardware Version *

Drive Operation Modes

• Digital Speed

• Analog Speed

• Digital Torque

• Analog Torque

• Electronic Gearing

• External Position Control

• Internal Position - MotionTasks

Digital Scope Tool

• Record real time data

• Display on PC Oscilloscope

• Start Current Move

• Start Jog Move

• Start Position Move

• Record Start

• Adjust Trigger

• Recording in Process *

• Cancel Recording

• Recording Done *

• Transmit Data to PC Oscilloscope

Feedback Configuration

Resolvers:

• Number of Poles

• Resolver-zero offsetting

• Resolver Bandwidth

• Feedback Gain

Drive Monitoring

• Regen Wattage *

• Actual Position (within one rev) *

• Actual Position *

• Actual Speed *

• Command Speed *

• Current Foldback Level *

• Drive Temperature *

• Heatsink Temperature *

• Effective Current *

• D Current Component *

• Q Current Component *

• Analog Commands *

• DC Bus voltage *

MOTIONLINK

Velocity Control

• Speed Command Scaling

• Speed Command Ramp (Accel)

• Speed Command Ramp (Decel)

• Maximum Speed

• Proportional Gain

• Integral Time Constant

• Feedback Filter

• Motion direction

Current Control

• Current Command Scaling

• Current Foldback

• Cont Drive Current

• Peak Drive Current

• Proportional Gain

• Integral Time Constant

Motor Configuration

• Motor Name and Number *

• Motor Continuous Current

• Motor Peak Current

• Motor Inductance

• Motor Poles

• Motor Max Speed

• Motor Brake (with or without)

• Motor Adaptive Gain

• Motor Speed Angle Advance

• Motor Torque Angle Advance

Drive Status

• Actual Error *

• Actual Warning *

• Last 10 Errors *

• Rate of Occurrence *

• Drive Reset Command

Others

• Stop Drive

• Drive Enable

• Drive Disable

* READ ONLY

Motion Homing/Jogging

• Direction

• Homing Type

• Reference Offset

• Start Command

• Jog Command

• Homing Velocity

• Jog Velocity

Communications

• RS-232 from PC

• Drive Address

• Message Types from Drive

• Prompt Configuration

• Scan

Position Output (Motor)

• Format: Off, Encoder equivalent

output or SSI format

Encoder Equivalent Output

• Resolution of Encoder Equiv Output

• Marker Pulse Offset

SSI

• Baud rate of SSI Output

• Format type (binary or gray code)

• Standard or Inverted Clock

• Input Edge Positive or Negative

Position Control

• Proportional Gain

• Integral Action Time

• Feed Forward

• Following Error *

Motion-Gear Mode

• GearMode Type:

• Encoder Follower

• Pulse Follower

Mode 0

The amplifier uses Input 1 only, depending

on the operation mode.

Mode 1

The amplifier uses Input 1 or 2, depending

on the operation mode.

Mode 2

Both inputs are switched off.

Mode 3

The amplifier uses Input 1, depending on

the operation mode. Input 2 is used for limiting peak current.

Mode 4

The amplifier uses the sum of Inputs 1 and

2, depending on the setting of OPMODE.

Mode 5

The amplifier uses the product of Inputs 1

and 2, depending on the setting of

OPMODE. The voltage on Input 2 has the

effect of a weighting factor for Input 1.

OPMODE Input 1 Input 2

analog speed speed command inactive

analog torque torque command inactive

CONFIGURABLE AND READABLE FUNCTIONS

KOLLMORGEN • keyfaith • 0755-83288220

10

MOTIONLINK

• Change/Copy Motion Task

• Position Type (Rotary or Linear)

• Master/Slave

• Motion Task Stop

• In Position

• Set Position Registers

• Motion Task Start

• Acceleration ramp

• Deceleration Ramp

• Min Acceleration

• Max Velocity

• Position Capture (Positive or Negative Edge)

Motion Task (or Blocks)

OPMODE Input 1 + Input 2

analog speed speed setpoint

analog torque torque setpoint

OPMODE Input 1 Input 2

analog speed speed command inactive

analog torque inactive torque command

• Two Differential Analog Inputs that can be configured in the following ways:

Analog Input

OPMODE Input 1 Input 2

analog speed inactive inactive

analog torque inactive inactive

OPMODE Input 1 Input 2

analog speed speed command limits peak torque

analog torque torque command limits peak torque

OPMODE Input 1 • Input 2

analog speed speed setpoint

analog torque torque setpoint

Analog Output

• Two Analog Outputs can be configured for Actual Speed,

Actual Current, Commanded Speed, Commanded Current, or Contouring error window

• Signal dead band

• Signal offset

• Auto Offset command

• Input Configuration

MOTIONLINK

CONFIGURABLE AND READABLE FUNCTIONS

KOLLMORGEN • keyfaith • 0755-83288220

11

Digital I/O

Inputs:

The 4 digital inputs can be configured as follows:

IN1MODE=1 External drive reset (only available at Input 1)

IN3MODE=2 Activates PSTOP in positive direction of travel (only available at Input 3)

IN4MODE=3 Activates NSTOP in negative direction of travel(only available at Input 4)

IN3MODE=4 Activates PSTOP function combined with integral gain off (only available at Input 3)

IN4MODE=5 Activates NSTOP function combined with integral gain off (only available at Input 4)

IN3MODE=6 Activates both PSTOP and NSTOP (only available at Input 3)

IN3MODE=7 Activates both PSTOP and NSTOP with integral gain off (only available at Input 3)

INxMODE=8 Switch between analog input 1 and analog input 2

INxMODE=9 Select a motion task that is stored in memory

INxMODE=10 Turn integral gain off in the velocity loop

INxMODE=11 Switch between velocity and torque control

INxMODE=12 Home switch

INxMODE=13 Change over position feedback from encoder equivalent output format (ROD) to SSI format

INxMODE=14 Reset following error or limit infringement warning

INxMODE=15 Start next motion task once the targeted position is reached

INxMODE=16 Start a motion task. Enter task number through an auxiliary variable

INxMODE=17 Start motion task that is bit coded on the digital inputs

INxMODE=18 Switch over to second (lower) peak value of current

INxMODE=19 Reserved

INxMODE=20 Start jog. Enter speed through an auxiliary variable

INxMODE=21 Turn off undervoltage monitoring

INxMODE=22 Restart motion task that was interrupted

INxMODE=23 Same as INxMode 16 except motion task started on rising edge only

INxMODE=24 Switch between Opmodes a (Input high) and b (Input low) when INxTRIG = a*256+b

INxMODE=25 During set up, set encoder equivalent output marker pulse offset

IN2MODE=26 Position latch on rising edge of input (only available at Input 2)

INxMODE=30 On rising edge of input the string stored in INHCMD will be processed.

On falling edge of input the string stored in INLCMD will be processed. Multiple commands

in the string are possible up to total of 64 characters.

Outputs:

The 2 digital outputs can be configured as follows:

OxMODE=1 Motor speed is less than preset value

OxMODE=2 Motor seed is greater than preset value

OxMODE=3 Drive power stage ready

OxMODE=4 Preset regen power is exceeded

OxMODE=5 Software travel limit is reached

OxMODE=6 Actual position is greater than preset value

OxMODE=7 Target position reached (In Position)

OxMODE=8 Actual current feedback less than

preset value

OxMODE=9 Actual current feedback greater than

preset value

OxMODE=10 Following error exceeded

OxMODE=11 I2T monitoring threshold is reached

OxMODE=12 Preset function of position register

1 is reached

OxMODE=13 Preset function of position register

2 is reached

OxMODE=14 Preset function of position register

3 is reached

OxMODE=15 Preset function of position register

4 is reached

OxMODE=16 Target position reached for each task

in an automatically executed sequence of

motion task (Next-In Position)

OxMODE=17 Error or warning message is signaled

OxMODE=18 Error message is signaled

OxMODE=19 DC bus voltage is higher than an

auxiliary value

OxMODE=20 DC bus voltage is lower than an

auxiliary value

OxMODE=21 Drive is enabled

OxMODE=22 Marker pulse (low speeds only)

OxMODE=23 Option card status

OxMODE=24 Homing complete

OxMODE=28 Preset function of position register

0 is reached

OxMODE=29 Preset function of position register

5 is reached

OxMODE=35 Status of hardware and software enable

12

KOLLMORGEN • keyfaith • 0755-83288220

INTRODUCTION

Kollmorgen GOLDLINE BH/MH

Kollmorgen GOLDLINE™ BH/MH Series

• 0.52 to 69 lb-ft (0.7 to 93 N-m)

• 70.0 to 190 mm (2.76 to 7.5 inches) Square Frame

• Resolver Feedback

• Speeds up to 7500 RPM

• 400/480 VAC, 565/680 VDC bus rated

Kollmorgen GOLDLINE BH/MH servomotors build on

the tradition of high performance motors from Kollmorgen.

Designed around the classic industry-standard Kollmorgen

GOLDLINE series, the BH/MH motors incorporate the

highest energy rare earth neodymium-iron-boron magnets

and excellent thermal design to provide exceptional

continuous torque and peak torque performance in a

compact package.

The servomotors incorporate the patented IPM (Interior

Permanent Magnet) design technology which results in

superior torque to inertia and torque per volume ratios.

The BH/MH line of servomotors is available in 5 frame

sizes and 3 stack lengths per frame. With multiple

windings per stack, the BH/MH series meet the needs of a

wide range of applications.

BH-Series (low inertia)

The BH-Series provides extremely low inertia rotors

allowing optimum performance in applications requiring

rapid acceleration and deceleration. The IPM magnetic

design provides for very high torque density and

torque/inertia ratios. When used with the SERVOSTAR

®

600 family of amplifiers, the resulting speed/torque is the

widest range in the industry.

MH-Series (medium inertia)

The MH-Series is an extension of the BH-Series. With

seven times higher inertia, this motor series offers the

advantage of better performance for systems having

compliant loads or larger inertia mismatches.

FEATURES: BH or MH Series

• Compact (high torque/volume ratio)

• Speeds to 7500 RPM standard

• IPM (Interior Permanent Magnet) design for low cogging

• CE Compliant, UL recognition

• Rugged resolver feedback

• Built-in thermostat

• Rear shaft extension for mounting additional feedback

devices

• Class H insulation system

• Rotatable CE connectors standard on 12x, 22x, 42x

• Terminal Box standard on 62x and 82x frames

OPTIONS:

• IP65 and IP67 sealing

• Fail-safe brake, 24 and 90VDC

• NEMA and Metric mountings

• Standard SERVOSTAR 600 UL/CE cable assemblies

available in 3 meter increments

MOTOR RATINGS

The motors performance capacity depends on the ability to

get rid of the heat generated within the motor package. The

ratings on the following pages assume that the motor is

mounted to a metal mounting bracket capable of drawing

heat energy away. The ratings assume the following:

a.) For BH12x and BH22x: Continuous Duty Ratings are

for a motor mounted to a 1/4 inch thick aluminum

faceplate of 96 square inches.

b.) For the BH42x, BH62x, and BH82x: Continuous Duty

Ratings are for a motor mounted to a 1 inch thick

aluminum faceplate plate of 452 square inches.

c.) Ambient temperature is 40° C (or less)

Equivalent thermal masses and radiating surface areas

are a common part of classical machine design. Other

applications require derating.

13

KOLLMORGEN • keyfaith • 0755-83288220

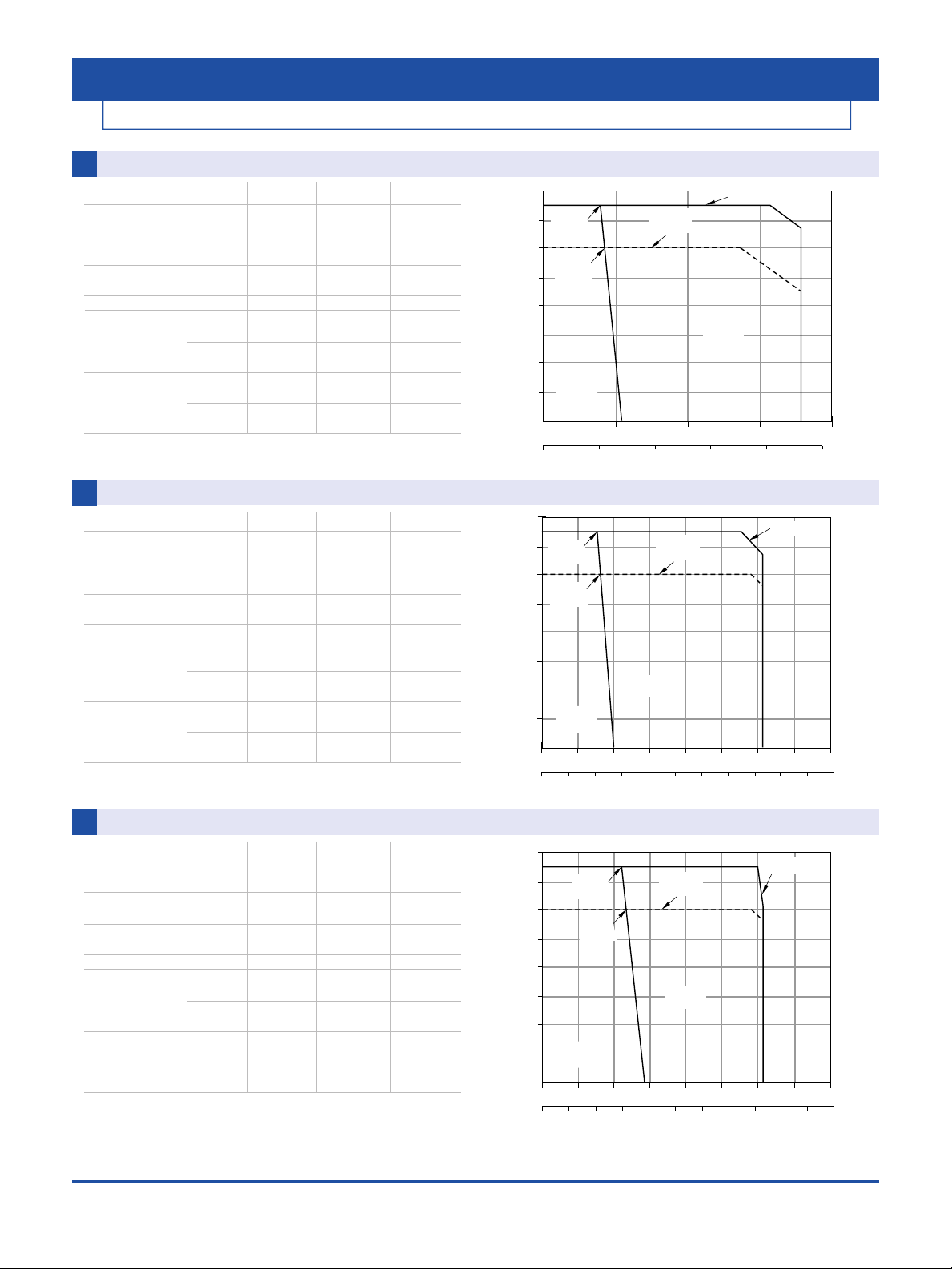

n

Motor BH-122-A or MH-123-AnAmplifier: S603

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 0.52

N-m 0.70

Peak Torque at stall Tp lb-ft 1.77

N-m 2.40

Cont. Power @480V

HP rated

HP 0.54

kW rated

kW 0.41

Max. Speed N RPM 7500

Motor Inertia BH Series Jm lb-ft-s

2

0.0000228

kg-m

2

0.000031

MH Series lb-ft-s

2

0.000156

kg-m

2

0.000212

Motor Weight BH Series Wt lb 5.5

kg 2.5

MH Series lb 7.0

kg 3.2

SYSTEM PERFORMANCE CURVES

Kollmorgen GOLDLINE BH/MH and SERVOSTAR 600

0

0 0.5 1.0 1.5 2.0 2.5

1.0 2.00.5 1.5

0

1000

2000

3000

4000

5000

6000

7000

8000

TORQUE

SPEED (RPM)

N-m

lb-ft

480V Limit

Intermittent

Duty Zone

400V Limit

(6,000 rpm)

0.41 kW

(0.54 HP)

Continuous

Duty Zone

0.4 kW

(0.5 HP)

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

1.0 2.0 3.00.5 1.5 2.5 3.5 4.0

0

1000

2000

3000

4000

5000

6000

7000

8000

TORQUE

SPEED (RPM)

4.5 5.0 5.5

lb-ft

N-m

480V Limit

Intermittent

Duty Zone

Continuous

Duty Zone

0.83 kW

(1.11 HP)

0.7 kW

(0.9 HP)

400V Limit

(6,000 rpm)

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

1.0 2.0 3.00.5 1.5 2.5 3.5 4.0

0

1000

2000

3000

4000

5000

6000

7000

8000

TORQUE

SPEED (RPM)

4.5 5.0 5.5

lb-ft

N-m

480V Limit

Intermittent

Duty Zone

Continuous

Duty Zone

400V Limit

(6,000 rpm)

1.2 kW

(1.6 HP)

1.0 kW

(1.3 HP)

1

2

3

n

Motor BH-124-B or MH-125-B nAmplifier: S603

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 1.00

N-m 1.35

Peak Torque at stall Tp lb-ft 3.10

N-m 4.20

Cont. Power @480V

HP rated

HP 1.11

kW rated

kW 0.83

Max. Speed N RPM 7500

Motor Inertia BH Series Jm lb-ft-s

2

0.0000340

kg-m

2

0.0000461

MH Series lb-ft-s

2

0.000249

kg-m

2

0.000338

Motor Weight BH Series Wt lb 7.0

kg 3.2

MH Series lb 9.0

kg 4.1

n

Motor BH-126-B or MH-127-B nAmplifier: S603

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 1.40

N-m 1.90

Peak Torque at stall Tp lb-ft 3.10

N-m 4.20

Cont. Power @480V

HP rated

HP 1.6

kW rated

kW 1.2

Max. Speed N RPM 7500

Motor Inertia B Series Jm lb-ft-s

2

0.0000564

kg-m

2

0.0000765

M Series lb-ft-s

2

0.00040

kg-m

2

0.00054

Motor Weight B Series Wt lb 8.5

kg 3.9

M Series lb 11.0

kg 5.0

• All curves shown at 60 Hz input, derate max. speed and peak power by 15% for 50 Hz operation.

14

KOLLMORGEN • keyfaith • 0755-83288220

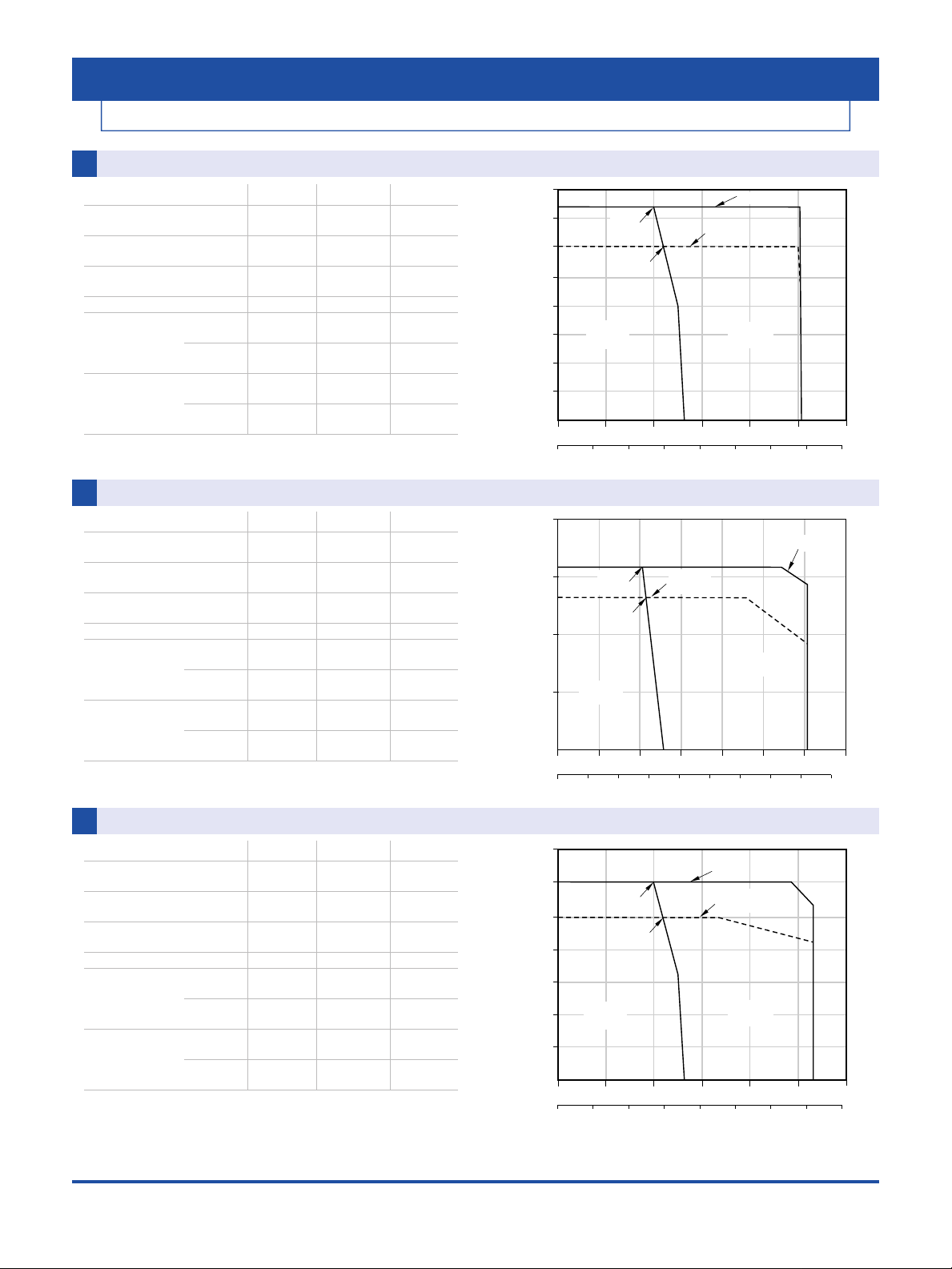

n

Motor BH-222-E or MH-223-E nAmplifier: S603

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 1.5

N-m 2.1

Peak Torque at stall Tp lb-ft 3.5

N-m 4.8

Cont. Power @480V

HP rated

HP 1.9

kW rated

kW 1.4

Max. Speed N RPM 7000

Motor Inertia BH Series Jm lb-ft-s

2

0.0000735

kg-m

2

0.0000996

MH Series lb-ft-s

2

0.000617

kg-m

2

0.000836

Motor Weight BH Series Wt lb 9.0

kg 4.1

MH Series lb 11.0

kg 5.0

SYSTEM PERFORMANCE CURVES

1000

2000

3000

5000

6000

7000

8000

4000

0

TORQUE

SPEED (RPM)

Continuous

Duty Zone

Intermittent

Duty Zone

480V Limit

0

0 1.0 2.0 3.0 4.0 5.0 6.0

2.0 4.01.0 3.0

lb-ft

N-m

1.4 kW

(1.9 HP)

1.1 kW

(1.5 HP)

400V Limit

(5,300 rpm)

1000

2000

3000

4000

5000

0

TORQUE

SPEED (RPM)

Continuous

Duty Zone

Intermittent

Duty Zone

0

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0

2.0 4.0 6.01.0 3.0 5.0

lb-ft

N-m

1.6 kW

(2.1 HP)

1.3 kW

(1.7 HP)

400V Limit

(3,600 rpm)

480V Limit

4

5

n

Motor BH-226-C or MH-227-C nAmplifier: S606

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 4.1

N-m 5.6

Peak Torque at stall Tp lb-ft 10.5

N-m 14.2

Cont. Power @480V

HP rated

HP 2.9

kW rated

kW 2.2

Max. Speed N RPM 4900

Motor Inertia BH Series Jm lb-ft-s

2

0.0001853

kg-m

2

0.0002512

MH Series lb-ft-s

2

0.0013

kg-m

2

0.0018

Motor Weight BH Series Wt lb 16.7

kg 7.6

MH Series lb 21.0

kg 9.5

• All curves shown at 60 Hz input, derate max. speed and peak power by 15% for 50 Hz operation.

6

Kollmorgen GOLDLINE BH/MH and SERVOSTAR 600

n

Motor BH-224-G or MH-225-G nAmplifier: S603

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 2.8

N-m 3.8

Peak Torque at stall Tp lb-ft 5.4

N-m 7.3

Cont. Power @480V

HP rated

HP 2.1

kW rated

kW 1.6

Max. Speed N RPM 4600

Motor Inertia BH Series Jm lb-ft-s

2

0.0001275

kg-m

2

0.0001729

MH Series lb-ft-s

2

0.000843

kg-m

2

0.001143

Motor Weight BH Series Wt lb 13.6

kg 6.2

MH Series lb 16.0

kg 7.3

5000

4500

4000

3500

3000

2500

SPEED (RPM)

2000

1500

1000

500

0

TORQUE

2.2 kW

(2.9 HP)

1.9 kW

(2.5 HP)

Continuous

Duty Zone

0

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0

2.0 4.0 6.0 8.0 9.0 10.0 11.01.0 3.0 5.0 7.0

400V Limit

(4,000 rpm)

Intermittent

Duty Zone

480V Limit

10.0 11.0 12.0 13.0 14.0 15.0

lb-ft

N-m

15

KOLLMORGEN • keyfaith • 0755-83288220

SYSTEM PERFORMANCE CURVES

Kollmorgen GOLDLINE BH/MH and SERVOSTAR 600

n

Motor BH-226-E or MH-227-E nAmplifier: S603

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 4.1

N-m 5.6

Peak Torque at stall Tp lb-ft 7.7

N-m 10.5

Cont. Power @480V

HP rated

HP 2.2

kW rated

kW 1.7

Max. Speed N RPM 3200

Motor Inertia BH Series Jm lb-ft-s

2

0.0001853

kg-m

2

0.0002512

MH Series lb-ft-s

2

0.0013

kg-m

2

0.0018

Motor Weight BH Series Wt lb 16.7

kg 7.6

MH Series lb 21.0

kg 9.5

7

9

n

Motor BH-424-D or MH-425-D nAmplifier: S606

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 7.8

N-m 10.6

Peak Torque at stall Tp lb-ft 14.7

N-m 20.0

Cont. Power @480V

HP rated

HP 4.4

kW rated

kW 3.3

Max. Speed N RPM 3700

Motor Inertia BH Series Jm lb-ft-s

2

0.000484

kg-m

2

0.000656

MH Series lb-ft-s

2

0.00325

kg-m

2

0.00441

Motor Weight BH Series Wt lb 27.5

kg 12.5

MH Series lb 34

kg 15.5

• All curves shown at 60 Hz input, derate max. speed and peak power by 15% for 50 Hz operation.

8

n

Motor BH-422-D or MH-423-D nAmplifier: S606

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 4.3

N-m 5.8

Peak Torque at stall Tp lb-ft 12.2

N-m 16.5

Cont. Power @480V

HP rated

HP 2.8

kW rated

kW 2.1

Max. Speed N RPM 4600

Motor Inertia BH Series Jm lb-ft-s

2

0.000238

kg-m

2

0.000323

MH Series lb-ft-s

2

0.00191

kg-m

2

0.00259

Motor Weight BH Series Wt lb 18.5

kg 8.4

MH Series lb 23.0

kg 10.5

1000

2000

3000

500

1500

2500

3500

4000

4500

5000

0

TORQUE

SPEED (RPM)

Continuous

Duty Zone

Intermittent

Duty Zone

0

0 2.0 4.0 6.0 8.0

2.0 4.0 6.0 8.0 9.0 10.0 11.0 12.0 13.01.0 3.0 5.0 7.0

10.0 12.0 14.0 16.0 18.0

lb-ft

N-m

2.1 kW

(2.8 HP)

1.7 kW

(2.3 HP)

400V Limit

(3,600 rpm)

480V Limit

4000

3500

3000

2500

2000

SPEED (RPM)

1500

1000

500

TORQUE

Continuous

Duty Zone

0

0

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0

1.7 kW

(2.2 HP)

1.3 kW

(1.8 HP)

2.0 4.0 6.0 8.01.0 3.0 5.0 7.0

400V Limit

(2,500 rpm)

Intermittent

Duty Zone

480V Limit

10.0 11.0

lb-ft

N-m

4000

3500

3000

2500

2000

SPEED (RPM)

1500

1000

500

0

0

TORQUE

0 2.0 4.0 6.0 8.0

480V Limit

3.3 kW

(4.4 HP)

2.8 kW

(3.7 HP)

Continuous

Duty Zone

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0

400V Limit

(3,000 rpm)

Intermittent

Duty Zone

10.0 12.0 14.0 16.0 18.0 20.0 22.0

lb-ft

N-m

16

KOLLMORGEN • keyfaith • 0755-83288220

SYSTEM PERFORMANCE CURVES

Kollmorgen GOLDLINE BH/MH and SERVOSTAR 600

n

Motor BH-426-B or MH-427-B nAmplifier: S610

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 11.7

N-m 15.8

Peak Torque at stall Tp lb-ft 27.4

N-m 37.1

Cont. Power @480V

HP rated

HP 5.7

kW rated

kW 4.2

Max. Speed N RPM 3200

Motor Inertia BH Series Jm lb-ft-s

2

0.000685

kg-m

2

0.000929

MH Series lb-ft-s

2

0.00485

kg-m

2

0.00657

Motor Weight BH Series Wt lb 35.0

kg 15.9

MH Series lb 44.0

kg 20.0

10

11

n

Motor BH-426-C or MH-427-C nAmplifier: S614

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 11.4

N-m 15.5

Peak Torque at stall Tp lb-ft 24.5

N-m 33.2

Cont. Power @480V

HP rated

HP 7.9

kW rated

kW 5.9

Max. Speed N RPM 5000

Motor Inertia BH Series Jm lb-ft-s

2

0.000685

kg-m

2

0.000929

MH Series lb-ft-s

2

0.00485

kg-m

2

0.00657

Motor Weight BH Series Wt lb 35.0

kg 15.9

MH Series lb 44.0

kg 20.0

1000

2000

3000

5000

6000

4000

0

SPEED (RPM)

TORQUE

0

0 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0

10.0 20.0 30.05.0 15.0 25.0

lb-ft

N-m

Continuous

Duty Zone

Intermittent

Duty Zone

480V Limit

5.9 kW

(7.9 HP)

5.6 kW

(7.5 HP)

400V Limit

(4,200 rpm)

12

n

Motor BH-622-A or MH-623-AnAmplifier: S606

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 10.8

N-m 14.6

Peak Torque at stall Tp lb-ft 29.5

N-m 40.0

Cont. Power @480V

HP rated

HP 3.3

kW rated

kW 2.5

Max. Speed N RPM 2000

Motor Inertia BH Series Jm lb-ft-s

2

0.000758

kg-m

2

0.001028

MH Series lb-ft-s

2

0.00572

kg-m

2

0.00775

Motor Weight BH Series Wt lb 37.0

kg 16.8

MH Series lb 44.0

kg 20.0

1000

2000

500

1500

2500

0

TORQUE

SPEED (RPM)

Continuous

Duty Zone

Intermittent

Duty Zone

0

0 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0

10.0 20.0 30.05.0 15.0 25.0

lb-ft

N-m

2.5 kW

(3.3 HP)

2.1 kW

(2.8 HP)

400V Limit

(1,600 rpm)

480V Limit

4000

3500

3000

2500

2000

SPEED (RPM)

1500

1000

500

0

TORQUE

4.2 kW

(5.7 HP)

3.5 kW

(4.7 HP)

Continuous

Duty Zone

0

0 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0

10.0 20.0 30.05.0 15.0 25.0

400V Limit

(2,500 rpm)

Intermittent

Duty Zone

480V Limit

lb-ft

N-m

17

KOLLMORGEN • keyfaith • 0755-83288220

SYSTEM PERFORMANCE CURVES

Kollmorgen GOLDLINE BH/MH and SERVOSTAR 600

13

n

Motor BH-622-B or MH-623-B nAmplifier: S610

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 11.0

N-m 14.9

Peak Torque at stall Tp lb-ft 24.7

N-m 33.5

Cont. Power @480V

HP rated

HP 5.9

kW rated

kW 4.4

Max. Speed N RPM 4000

Motor Inertia BH Series Jm lb-ft-s

2

0.000758

kg-m

2

0.001028

MH Series lb-ft-s

2

0.00572

kg-m

2

0.00775

Motor Weight BH Series Wt lb 37.0

kg 16.8

MH Series lb 44.0

kg 20.0

14

n

Motor BH-624-C or MH-625-C nAmplifier: S620

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 18.6

N-m 25.2

Peak Torque at stall Tp lb-ft 41.4

N-m 56.2

Cont. Power @480V

HP rated

HP 9.5

kW rated

kW 7.1

Max. Speed N RPM 4500

Motor Inertia BH Series Jm lb-ft-s

2

0.0015

kg-m

2

0.002034

MH Series lb-ft-s

2

0.01037

kg-m

2

0.01406

Motor Weight BH Series Wt lb 51.0

kg 23.1

MH Series lb 63.0

kg 28.6

15

n

Motor BH-624-D or MH-625-D nAmplifier: S614

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 18.9

N-m 25.6

Peak Torque at stall Tp lb-ft 40.4

N-m 54.8

Cont. Power @480V

HP rated

HP 8.4

kW rated

kW 6.3

Max. Speed N RPM 3300

Motor Inertia BH Series Jm lb-ft-s

2

0.0015

kg-m

2

0.002034

MH Series lb-ft-s

2

0.01037

kg-m

2

0.01406

Motor Weight BH Series Wt lb 51.0

kg 23.1

MH Series lb 63.0

kg 28.6

• All curves shown at 60 Hz input, derate max. speed and peak power by 15% for 50 Hz operation.

4500

4000

3500

3000

2500

SPEED (RPM)

2000

1500

1000

500

TORQUE

5000

4000

3000

SPEED (RPM)

2000

1000

TORQUE

4.4 kW

(5.9 HP)

3.6 kW

(4.9 HP)

Continuous

Duty Zone

0

0

0 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0

7.1 kW

(9.5 HP)

7.2 kW

(9.6 HP)

Continuous

Duty Zone

0

0

0 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0 45.0

10.0 20.0 30.0 40.0 45.05.0 15.0 25.0 35.0

400V Limit

(3,000 rpm)

Intermittent

Duty Zone

10.0 20.0 30.05.0 15.0 25.0

400V Limit

(3,750 rpm)

Intermittent

Duty Zone

480V Limit

480V Limit

50.0 55.0 60.0

lb-ft

N-m

lb-ft

N-m

4000

3000

2000

SPEED (RPM)

1000

0

0

TORQUE

0 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0 45.0

6.3 kW

(8.4 HP)

6.0 kW

(8.1 HP)

Continuous

Duty Zone

10.0 20.0 30.0 40.0 45.05.0 15.0 25.0 35.0

400V Limit

(2,750 rpm)

Intermittent

Duty Zone

480V Limit

50.0 55.0 60.0

lb-ft

N-m

KOLLMORGEN • keyfaith • 0755-83288220

18

SYSTEM PERFORMANCE CURVES

Kollmorgen GOLDLINE BH/MH and SERVOSTAR 600

n

Motor BH-624-E or MH-625-E nAmplifier: S614

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 18.9

N-m 25.6

Peak Torque at stall Tp lb-ft 34.6

N-m 46.9

Cont. Power @480V

HP rated

HP 9.8

kW rated

kW 7.3

Max. Speed N RPM 3850

Motor Inertia BH Series Jm lb-ft-s

2

0.0015

kg-m

2

0.0020

MH Series lb-ft-s

2

0.0104

kg-m

2

0.014

Motor Weight BH Series Wt lb 51.0

kg 23.1

MH Series lb 63.0

kg 28.6

16

n

Motor BH-626-C or MH-627-C nAmplifier: S610

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 27.0

N-m 36.6

Peak Torque at stall Tp lb-ft 61.1

N-m 82.9

Cont. Power @480V

HP rated

HP 6.5

kW rated

kW 4.9

Max. Speed N RPM 1550

Motor Inertia BH Series Jm lb-ft-s

2

0.0022

kg-m

2

0.0030

MH Series lb-ft-s

2

0.0156

kg-m

2

0.0212

Motor Weight BH Series Wt lb 66.0

kg 29.9

MH Series lb 83.0

kg 37.6

18

• All curves shown at 60 Hz input, derate max. speed and peak power by 15% for 50 Hz operation.

n

Motor BH-624-G or MH-625-G nAmplifier: S610

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 19.1

N-m 25.9

Peak Torque at stall Tp lb-ft 34.6

N-m 46.9

Cont. Power @480V

HP rated

HP 6.2

kW rated

kW 4.6

Max. Speed N RPM 2600

Motor Inertia BH Series Jm lb-ft-s

2

0.0015

kg-m

2

0.0020

MH Series lb-ft-s

2

0.010

kg-m

2

0.014

Motor Weight BH Series Wt lb 51.0

kg 23.1

MH Series lb 63.0

kg 28.6

17

4500

4000

3500

3000

2500

SPEED (RPM)

2000

1500

1000

500

0

0

TORQUE

0

3000

2500

2000

1500

SPEED (RPM)

1000

500

0

0

TORQUE

0 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0 45.0

7.3 kW

(9.8 HP)

7.1 kW

(9.5 HP)

Continuous

Duty Zone

10.0 20.0 30.0 40.05.0 15.0 25.0 35.0

5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0 45.0

4.6 kW

(6.2 HP)

4.1 kW

(5.4 HP)

Continuous

Duty Zone

10.0 20.0 30.0 40.05.0 15.0 25.0 35.0

400V Limit

(2,100 rpm)

480V Limit

400V Limit

(3,200 rpm)

Intermittent

Duty Zone

Intermittent

Duty Zone

50.0 55.0

480V Limit

50.0 55.0

lb-ft

N-m

lb-ft

N-m

2000

1500

1000

SPEED (RPM)

500

Continuous

Duty Zone

0

0

TORQUE

0 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0 90.0

480V Limit

4.9 kW

(6.5 HP)

4.1 kW

(5.5 HP)

20.0 40.0 60.010.0 30.0 50.0 70.0

400V Limit

(1,250 rpm)

Intermittent

Duty Zone

lb-ft

N-m

KOLLMORGEN • keyfaith • 0755-83288220

19

SYSTEM PERFORMANCE CURVES

Kollmorgen GOLDLINE BH/MH and SERVOSTAR 600

• All curves shown at 60 Hz input, derate max. speed and peak power by 15% for 50 Hz operation.

n

Motor BH-822-C or MH-823-C nAmplifier: S610

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 25.7

N-m 34.8

Peak Torque at stall Tp lb-ft 60.2

N-m 81.6

Cont. Power @480V

HP rated

HP 6.3

kW rated

kW 4.7

Max. Speed N RPM 1600

Motor Inertia BH Series Jm lb-ft-s

2

0.0036

kg-m

2

0.0049

MH Series lb-ft-s

2

0.0259

kg-m

2

0.0351

Motor Weight BH Series Wt lb 79.0

kg 36.0

MH Series lb 96.0

kg 43.7

20

n

Motor BH-822-D or MH-823-D nAmplifier: S620

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 25.6

N-m 34.7

Peak Torque at stall Tp lb-ft 53.6

N-m 72.7

Cont. Power @480V

HP rated

HP 11.4

kW rated

kW 8.5

Max. Speed N RPM 3000

Motor Inertia BH Series Jm lb-ft-s

2

0.0036

kg-m

2

0.0049

MH Series lb-ft-s

2

0.0259

kg-m

2

0.0351

Motor Weight BH Series Wt lb 79.0

kg 36.0

MH Series lb 96.0

kg 43.5

21

n

Motor BH-626-E or MH-627-E nAmplifier: S620

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 26.1

N-m 35.4

Peak Torque at stall Tp lb-ft 50.2

N-m 68.0

Cont. Power @480V

HP rated

HP 14.1

kW rated

kW 10.5

Max. Speed N RPM 3700

Motor Inertia BH Series Jm lb-ft-s

2

0.0022

kg-m

2

0.0030

MH Series lb-ft-s

2

0.0156

kg-m

2

0.0212

Motor Weight BH Series Wt lb 66.0

kg 29.9

MH Series lb 83.0

kg 37.6

19

4000

3500

3000

2500

2000

SPEED (RPM)

1500

1000

500

0

0

TORQUE

0

2000

1500

1000

SPEED (RPM)

500

0

0

TORQUE

0 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0 90.0

10.5 kW

(14.1 HP)

9.8 kW

(13.1 HP)

Continuous

Duty Zone

20.0 40.0 60.010.0 30.0 50.0

10.0 20.0 30.0 40.0

4.7 kW

(6.3 HP)

4.0 kW

(5.3 HP)

Continuous

Duty Zone

400V Limit

(1,300 rpm)

20.0 40.0 60.010.0 30.0 50.0 70.0

480V Limit

400V Limit

(3,000 rpm)

Intermittent

Duty Zone

50.0 60.0 70.0 80.0

Intermittent

Duty Zone

lb-ft

N-m

480V Limit

lb-ft

N-m

3500

3000

2500

2000

SPEED (RPM)

1500

1000

500

0

0

TORQUE

0

10.0 20.0 30.0 40.0

8.5 kW

(11.4 HP)

8.3 kW

(11.2 HP)

Continuous

Duty Zone

480V Limit

400V Limit

(2,500 rpm)

Intermittent

Duty Zone

20.0 40.0 60.010.0 30.0 50.0

50.0 60.0 70.0 80.0

lb-ft

N-m

KOLLMORGEN • keyfaith • 0755-83288220

20

SYSTEM PERFORMANCE CURVES

Kollmorgen GOLDLINE BH/MH and SERVOSTAR 600

• All curves shown at 60 Hz input, derate max. speed and peak power by 15% for 50 Hz operation.

n

Motor BH-826-A or MH-827-AnAmplifier: S620

Performance Specification Symbol Units

Cont. Torque at stall Tc lb-ft 69.0

N-m 93.5

Peak Torque at stall Tp lb-ft 120.1

N-m 162.8

Cont. Power @480V

HP rated

HP 15.3

kW rated

kW 11.4

Max. Speed N RPM 1500

Motor Inertia BH Series Jm lb-ft-s

2

0.0093

kg-m

2

0.0126

MH Series lb-ft-s

2

0.0655

kg-m

2

0.0888

Motor Weight BH Series Wt lb 147.0

kg 66.7

MH Series lb 190.0

kg 86.2

22

2000

480V Limit

1500

1000

SPEED (RPM)

500

0

0

TORQUE

0 20.0 40.0 60.0 80.0 100.0 120.0 140.0 160.0 180.0

11.4 kW

(15.3 HP)

10.7 kW

(14.3 HP)

Continuous

Duty Zone

20.0 40.0 60.0 80.0 100.0 120.0 140.0

400V Limit

(1,250 rpm)

Intermittent

Duty Zone

lb-ft

N-m

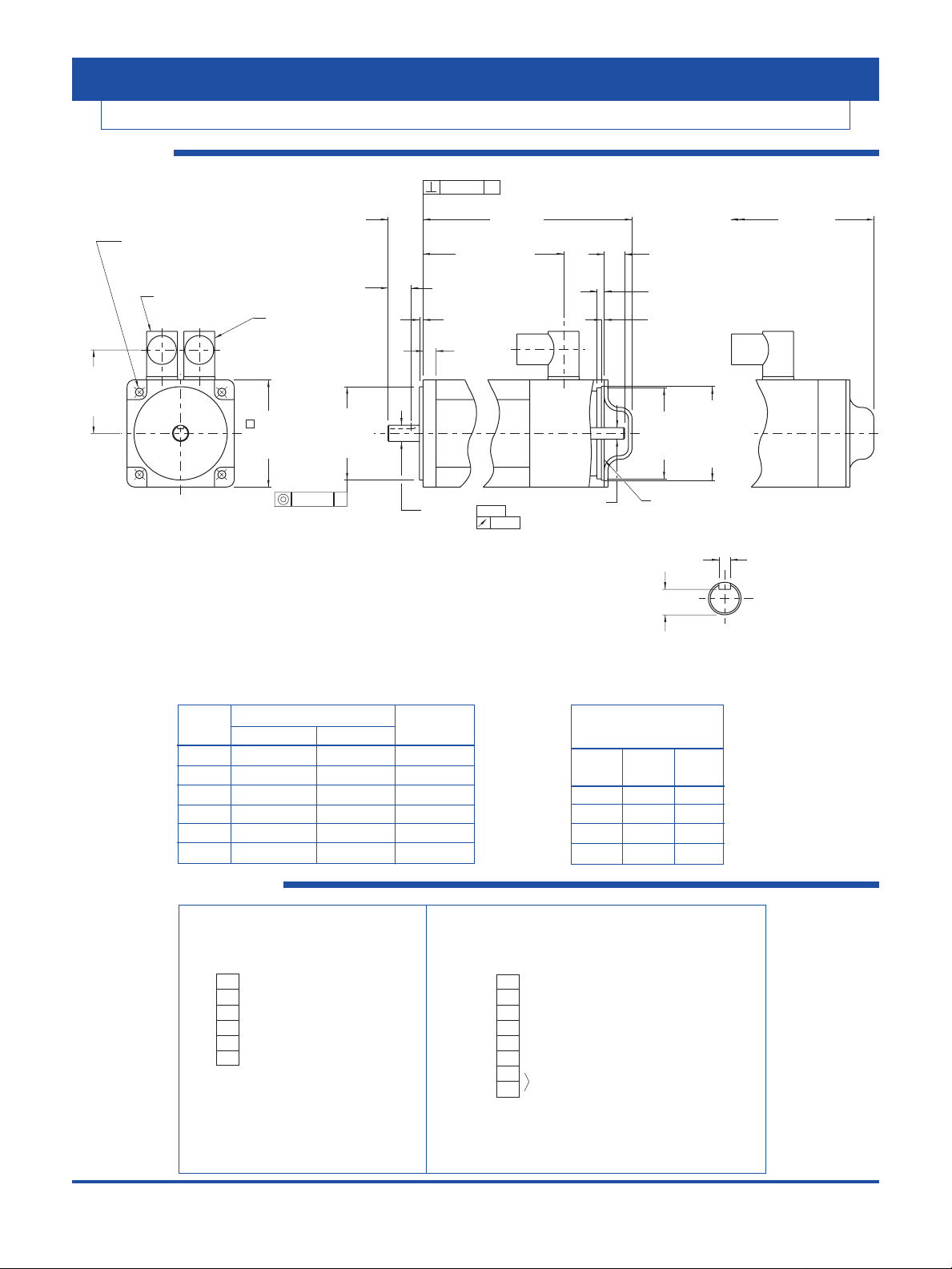

Connections: Motor Receptacle: Resolver & Thermostat Receptacle:

INTERCONNECTRON INTERCONNECTRON

LEOBOBKNNNNN000 SFMB12TNNNN000

Pin 3 - Phase W (brown) Pin 3 - S3 (black), Sin Lo

Pin 4 - Phase V (red) Pin 4 - S4 (blue), Cos Lo

Pin 1 - Phase U (white) Pin 5 - R2 (yellow/white or black/white), Ref. Lo

Pin 2 - Ground (green/yellow) Pin 7 - S1 (red) Sin Hi

Pin A - (Optional)Brake (blue) Pin 8 - S2 (yellow) Cos Hi

Pin B - (Optional)Brake (blue) Pin 9 - R1 (red/white), Ref Hi

(brake not polarity sensitive) Pin 2

Pin 6

Kollmorgen GOLDLINE BH/MH

DIMENSIONS

BH/MH-12x

CONNECTOR PIN OUTS

“A” MAX.

Model without brake with brake “B” “C” “D” “E”

BH-122 204.0 (8.03) 243.8 (9.59) 159.0 (6.26) 18.0 (0.71) 23.0 (0.90) 10.997-11.008 (.4330-.4334)

BH-124 234.5 (9.23) 273.2 (10.76) 189.5 (7.46) 20.0 (0.79) 30.0 (1.18) 13.997-14.008 (.5511-.5515)

BH-126 265.0 (10.43) 303.7 (11.96) 220.0 (8.66) 20.0 (0.79) 30.0 (1.18) 13.997-14.008 (.5511-.5515)

MH-123 241.0 (9.49) 279.6 (11.01) 196.0 (7.72) 20.0 (0.79) 30.0 (1.18) 13.997-14.008 (.5511-.5515)

MH-125 283.1 (11.15) 321.7 (12.67) 238.1 (9.37) 20.0 (0.79) 30.0 (1.18) 13.997-14.008 (.5511-.5515)

MH-127 335.5 (13.21) 374.1 (14.73) 290.5 (11.44) 20.0 (0.79) 30.0 (1.18) 13.997-14.008 (.5511-.5515)

M3 X 0.5 THD X 10.0 (.39) DP.

4 PL. EQ. SPACED ON A

Ø80.00 (3.510) B.C.

4.00 (.157)

3.97 (.156)

8.50 (.335)

8.40 (.331)

KEYWAY DETAIL

BRAKE OPTION

Ø5.80 (.228) THRU

4 PL. EQ. SPACED

ON A Ø75.00 (2.953) B.C.

MIN.

2.36

"B"±1.5

(.06)

(.375)

(.093)

"D" ±.5 (.02)

.035

-A-

(.0014)

.08 TIR A

(.003)

.08 TIR A

(.003)

9.54

17.5

5.987

5.962

(.236)

(.235)

59.140

59.090

(2.328)

(2.326)

61.390

61.340

2.49

6.3

(.69)

(.25)

(.098)

SEE

NOTE #2

(2.417)

(2.415)

SEE NOTE #2

"A" MAX. "A" MAX.

WITH BRAKE

RESOLVER & THERMOSTAT

RECEPTACLE

MOTOR

RECEPTACLE

62.0

60.0

(2.44)

(2.36)

76.5

(3.01)

MAX.

71.5

70.0

(2.82)

(2.76)

60.012

59.993

(2.3627)

(2.3619)

Ø

Ø "E"

Ø

Ø

Ø

5.00 (.197)

4.97 (.196)

11.00 (.433)

10.90 (.429)

BH-122

BH-124, BH-126,

MH-123, MH-125, & MH-127

"C"

Notes:

1. Motor can be mounted in any position.

2. Counterbore for o-ring seal.

3. -61 and -71 models have been certified to meet IP65

sealing. -S model has been certified to meet IP67 sealing

and has viton shaft seal and viton o-rings.

4. -63 and -73 models meet sealing specs except for mounting face.

5. Kollmorgen approved mating plugs with filler plugs must be

installed before motor meets sealing specs.

6. Customer shaft key supplied with motor.

7. Dimensions in parentheses ( ) are in English and are for reference only.

8. Tolerances unless otherwise specified:

Metric: X decimal place ±.4 English: XX decimal places ±.015

XX decimal places ±.13 XXX decimal places ±.005

Thermostat:

Normally closed contacts

4 Amp, 120 VAC - thermostat

opens at 170ºC ±5ºC

and closes at 132ºC ±5ºC

(BH, MH-12x -- yellow leads)

Standard Options

Model Mating Shaft

No. Plugs Seal

-61 No Yes

-63 No No

-71 Yes Yes

-73 Yes No

KOLLMORGEN • keyfaith • 0755-83288220

21

Kollmorgen GOLDLINE BH/MH

DIMENSIONS

BH/MH-22x

11.2

(.44)

KEYWAY DETAIL

17.5 (.69)

3.0

(.12)

"A" MAX.

SEE NOTE #2

6.3 (.25)

2.49 (.098)

19.8

(.78)

MIN.

"B" ±1.5 (.06)

97.0

92.0

(3.82)

(3.62)

72.5

70.5

(2.85)

(2.78)

Ø7.00-7.36 (.276-.290) THRU

4 PL. EQ. SPACED

ON A Ø100.00 (3.937) B.C.

RESOLVER & THERMOSTAT

RECEPTACLE

MOTOR

RECEPTACLE

80.012

79.993

(3.1501)

(3.1493)

Ø

Ø

Ø

Ø

14.008

13.997

(.5515)

(.5511)

Ø

.035

-A-

(.0014)

30.5

29.5

(1.20)

(1.16)

78.16

78.11

(3.077)

(3.075)

11.00 (.433)

10.90 (.429)

5.00 (.197)

4.97 (.196)

80.44

80.39

(3.167)

(3.165)

SEE

NOTE #2

9.987

9.962

(.3932)

(.3922)

M5 X 0.8 THD. X 10.0 (.39)

MIN. DP. 4 PL. EQ. SPACED

ON A Ø100.00 (3.937) B.C.

BRAKE OPTION

"A" MAX.

WITH BRAKE

.08 TIR A

(.003)

.08 TIR A

(.003)

Notes:

1. Motor can be mounted in any position.

2. Counterbore for o-ring seal.

3. -61 and -71 models have been certified to meet IP65

sealing. -S model has been certified to meet IP67 sealing

and has viton shaft seal and viton o-rings.

4. -63 and -73 models meet sealing specs except for mounting face.

5. Kollmorgen approved mating plugs with filler plugs must be

installed before motor meets sealing specs.

6. Customer shaft key supplied with motor.

7. Dimensions in parentheses ( ) are in English and are for reference only.

8. Tolerances unless otherwise specified:

Metric: X decimal place ±.4 English: XX decimal places ±.015

XX decimal places ±.13 XXX decimal places ±.005

“A” MAX.

Model without brake with brake “B”

BH-222 236.2 (9.30) 276.5 (10.89) 179.7 (7.08)

BH-224 275.8 (10.86) 316.1 (12.44) 219.3 (8.63)

BH-226 315.4 (12.42) 355.1 (14.00) 258.9 (10.19)

MH-223 275.8 (10.86) 316.0 (12.44) 219.3 (8.63)

MH-225 315.4 (12.42) 355.7 (14.00) 258.9 (10.19)

MH-227 373.2 (14.69) 413.4 (16.28) 316.7 (12.47)

Connections: Motor Receptacle: Resolver & Thermostat Receptacle:

INTERCONNECTRON INTERCONNECTRON

LEOBOBKNNNNN000 SFMB12TNNNN000

Pin 3 - Phase W (brown) Pin 3 - S3 (black), Sin Lo

Pin 4 - Phase V (red) Pin 4 - S4 (blue), Cos Lo

Pin 1 - Phase U (white) Pin 5 - R2 (yellow/white), Ref. Lo

Pin 2 - Ground (green/yellow) Pin 7 - S1 (red) Sin Hi

Pin A - (Optional)Brake (blue) Pin 8 - S2 (yellow) Cos Hi

Pin B - (Optional)Brake (blue) Pin 9 - R1 (red/white), Ref Hi

(brake not polarity sensitive) Pin 2

Pin 6

CONNECTOR PIN OUTS

Thermostat:

Normally closed contacts

4 Amp, 120 VAC - thermostat

opens at 170ºC ±5ºC

and closes at 132ºC ±5ºC

(BH, MH-22x -- yellow leads)

Standard Options

Model Mating Shaft

No. Plugs Seal

-61 No Yes

-63 No No

-71 Yes Yes

-73 Yes No

KOLLMORGEN • keyfaith • 0755-83288220

22

BH/MH-42x

"B"

KEYWAY DETAIL

17.5 (.69)

2.49 (.098)

SEE NOTE #2

6.3 (.25)

±2.0 (.08)

3.5 (.14)

12.5 (.49)

"A" MAX.

118.8

115.0

(4.68)

(4.53)

84.0

(3.31)

Ø9.00-9.36 (.354-.369) THRU

4 PL. EQ. SPACED

ON A Ø130.00 (5.118) B.C.

RESOLVER & THERMOSTAT

RECEPTACLE

MOTOR

RECEPTACLE

110.013

109.991

(4.3312)

(4.3304)

Ø

Ø

24.009

23.996

(.9452)

(.9447)

37.00

(1.457)

MIN.

50.50

49.50

(1.988)

(1.949)

8.000 (.3149)

7.964 (.3135)

20.00 (.787)

19.80 (.780)

.10 TIR A

(.004)

.040

-A-

(.0016)

101.75

101.70

(4.006)

(4.004)

Ø

Ø

Ø

9.987

9.962

(.3932)

(.3922)

104.22

104.17

(4.103)

(4.101)

SEE

NOTE #2

M5 X 0.8 THD X 14.0

(.55) MIN. DP. 4 PL.

EQ. SPACED ON A

Ø130.00 (5.118) B.C.

.10 TIR A

(.004)

BRAKE OPTION

"A" MAX.

WITH BRAKE

Notes:

1. Motor can be mounted in any position.

2. Counterbore for o-ring seal.

3. -61 and -71 models have been certified to meet IP65

sealing. -S model has been certified to meet IP67 sealing

and has viton shaft seal and viton o-rings.

4. -63 and -73 models meet sealing specs except for mounting face.

5. Kollmorgen approved mating plugs with filler plugs must be

installed before motor meets sealing specs.

6. Customer shaft key supplied with motor.

7. Dimensions in parentheses ( ) are in English and are for reference only.

8. Tolerances unless otherwise specified:

Metric: X decimal place ±.4 English: XX decimal places ±.015

XX decimal places ±.13 XXX decimal places ±.005

CONNECTOR PIN OUTS

Kollmorgen GOLDLINE BH/MH

DIMENSIONS

“A” MAX.

without brake with brake “B”

BH-422 265.5 (10.45) 313.9 (12.36) 212.6 (8.37)

BH-424 318.8 (12.55) 367.3 (14.46) 265.9 (10.47)

BH-426 372.1 (14.65) 420.6 (16.56) 319.2 (12.57)

MH-423 318.8 (12.55) 367.3 (14.46) 265.9 (10.47)

MH-425 372.1 (14.65) 420.6 (16.56) 319.2 (12.57)

MH-427 444.9 (17.52) 493.4 (19.43) 392.0 (15.43)

Standard Options

Model Mating Shaft

No. Plugs Seal

-61 No Yes

-63 No No

-71 Yes Yes

-73 Yes No

Connections: Motor Receptacle: Resolver & Thermostat Receptacle:

INTERCONNECTRON INTERCONNECTRON

LEOBOBKNNNNN000 SFMB12TNNNN000

Pin 3 - Phase W (brown) Pin 3 - S3 (black), Sin Lo

Pin 4 - Phase V (red) Pin 4 - S4 (blue), Cos Lo

Pin 1 - Phase U (white) Pin 5 - R2 (yellow/white), Ref. Lo

Pin 2 - Ground (green/yellow) Pin 7 - S1 (red) Sin Hi

Pin A - (Optional)Brake (blue) Pin 8 - S2 (yellow) Cos Hi

Pin B - (Optional)Brake (blue) Pin 9 - R1 (red/white), Ref Hi

(brake not polarity sensitive) Pin 2

Pin 6

Thermostat:

Normally closed contacts

4 Amp, 120 VAC - thermostat

opens at 170ºC ±5ºC

and closes at 132ºC ±5ºC

(BH, MH-42x -- yellow leads)

KOLLMORGEN • keyfaith • 0755-83288220

23

BH/MH-62x

±2.0 [.08]

"A" MAX.

17.5 (.69)

6.3 (.25)

"B"

KEYWAY DETAIL

145.3

142.0

(5.72)

(5.59)

165.0

161.0

(6.50)

(6.34)

109.4

107.4

(4.31)

(4.23)

130.014

129.989

(5.1187)

(5.1177)

.10 TIR A

(.004)

24.009

23.996

(.9452)

(.9447)

Ø

32.018

32.002

(1.2606)

(1.2600)

Ø

.040

-A-

(.0016)

8.000

7.964

(.3149)

(.3135)

20.00 (.787)

19.80 (.780)

27.00 (1.063)

26.80 (1.055)

10.000

9.964

(.3937)

(.3923)

2.49 (.098)

SEE NOTE #2

9.987

9.962

(.3932)

(.3922)

127.15

127.10

(5.006)

(5.004)

Ø

Ø

Ø

3.5

(.14)

18.0

(.71)

37.00

(1.457)

50.50

49.50

(1.988)

(1.949)

"A" MAX.

WITH BRAKE

129.62

129.57

(5.103)

(5.101)

SEE

NOTE #2

M5 X 0.8 THD X 14.0

(.55) MIN. DP. 4 PL.

EQ. SPACED ON A

Ø164.00 (6.457) B.C.

Ø11.00 (.433) THRU

4 PL. EQ. SPACED ON

A Ø165.00 (6.496) B.C.

RESOLVER & THERMOSTAT

RECEPTACLE

BH-626, MH-623,

MH-625, & MH-627

BH-622 & BH-624

SEE KEYWAY DETAIL

.10 TIR A

(.004)

BRAKE OPTION

Notes:

1. Motor can be mounted in any position.

2. Counterbore for o-ring seal.

3. -41 and -51 models have been certified to meet IP65

sealing. -S model has been certified to meet IP67 sealing, except for PG-21,

and has viton shaft seal and viton o-rings.

4. -43 and -53 models meet sealing specs except for mounting face.

5. Kollmorgen approved cables and mating plugs with filler plugs must be

installed before motor meets sealing specs.

6. Customer shaft key supplied with motor.

7. Dimensions in parentheses ( ) are in English and are for reference only.

8. Tolerances unless otherwise specified:

Metric: X decimal place ±.4 English: XX decimal places ±.015

XX decimal places ±.13 XXX decimal places ±.005

PG-21 LIQUID TIGHT

FITTING FOR MOTOR LEADS

PG-11 LIQUID TIGHT FITTING

(5.0-9.9 (.20-.39) CABLE Ø

RANGE) WITH BRAKE OPTION

159.8

(6.29)

REF.

CONNECTOR PIN OUTS

Kollmorgen GOLDLINE BH/MH

DIMENSIONS

“A” MAX.

without brake with brake “B”

BH-622 299.2 (11.79) 355.6 (14.00) 96.8 (3.81)

BH-624 367.8 (14.48) 424.2 (16.70) 165.4 (6.51)

BH-626 436.4 (17.18) 492.8 (19.40) 234.0 (9.21)

MH-623 367.8 (14.48) 424.3 (16.70) 165.4 (6.51)

MH-625 436.4 (17.18) 492.9 (19.41) 234.0 (9.21)

MH-627 531.5 (20.93) 588.0 (23.15) 329.1 (12.96)

Connections: Motor Terminal Strip: Resolver & Thermostat Receptacle:

INTERCONNECTRON SEFA12AMREN000

Terminal U - white lead Pin 3 - S3 (black), Sin Lo

Terminal V - red lead Pin 4 - S4 (blue), Cos Lo

Terminal W - brown lead Pin 5 - R2 (yellow/white), Ref. Lo

Pin 7 - S1 (red) Sin Hi

(M6 pan head screw with external Pin 8 - S2 (yellow) Cos Hi

tooth lockwasher is provided for Pin 9 - R1 (red/white) Ref. Hi

use as a case ground.) Pin 2

Pin 6

Brake Terminal Strip:

(2) blue leads

Thermostat:

Normally closed contacts

4 Amp, 120 VAC - thermostat

opens at 170ºC ±5ºC

and closes at 132ºC ±5ºC

(BH, MH-62x -- yellow leads)

Standard Options

Model Mating Shaft

No. Plugs Seal

-41 No Yes

-43 No No

-51 Yes Yes

-53 Yes No

KOLLMORGEN • keyfaith • 0755-83288220

24

“A” MAX.

without brake with brake “B” “C” “D” “E”

BH-822 360.4 (14.19) 416.9 (16.41) 158.3 (6.23) 39.00 (1.535) 58.00 (2.283) 32.002-32.018 (1.2600-1.2606)

MH-823 449.9 (17.71) 506.4 (19.94) 247.8 (9.76) 54.00 (2.126) 82.00 (3.228) 48.002-48.018 (1.8898-1.8905)

BH-826 520.2 (20.48) 595.9 (23.46) 337.3 (13.28) 54.00 (2.126) 82.00 (3.228) 48.002-48.018 (1.8898-1.8905)

MH-827 648.7 (25.54) 686.0 (27.01) 446.6 (17.58) 54.00 (2.126) 82.00 (3.228) 48.002-48.018 (1.8898-1.8905)

Kollmorgen GOLDLINE BH/MH

DIMENSIONS

CONNECTOR PIN OUTS

BH/MH-82x

Connections: Motor Terminal Strip: Resolver & Thermostat Receptacle:

INTERCONNECTRON SEFA12AMREN000

Terminal U - white lead Pin 3 - S3 (black), Sin Lo

Terminal V - red lead Pin 4 - S4 (blue), Cos Lo

Terminal W - brown lead Pin 5 - R2 (yellow/white), Ref. Lo

Pin 7 - S1 (red) Sin Hi

(M6 pan head screw with external Pin 8 - S2 (yellow) Cos Hi

tooth lockwasher is provided for Pin 9 - R1 (red/white) Ref. Hi

use as a case ground.) Pin 2

Pin 6

Brake Terminal Strip:

(2) blue leads

Thermostat:

Normally closed contacts

4 Amp, 120 VAC - thermostat

opens at 170ºC ±5ºC

and closes at 132ºC ±5ºC

(BH, MH-82x -- yellow leads)

Standard Options

Model Mating Shaft

No. Plugs Seal

-41 No Yes

-43 No No

-51 Yes Yes

-53 Yes No

KOLLMORGEN • keyfaith • 0755-83288220

25

Ø14.00 (.551) THRU

4 PL. EQ. SPACED ON

A Ø215.00 (8.464) B.C.

RESOLVER & THERMOSTAT

RECEPTACLE

133.4

131.4

(5.25)

(5.17)

PG-11 LIQUID TIGHT FITTING

(5.0-9.9 (.20-.39) CABLE Ø

RANGE) WITH BRAKE OPTION

PG-21 LIQUID TIGHT

FITTING FOR MOTOR LEADS

189.0

185.0

(7.44)

(7.28)

Ø

192.4

190.0

(7.57)

(7.48)

180.014

179.989

(7.0872)

(7.0862)

19.0

(.75)

.10 TIR A

(.004)

(.02)

"C"

"D"

±.5

±2.0 [.08]

"B"

4.0

(.16)

"A" MAX.

17.5 (.69)

7.5 (.30)

3.68 (.145)

SEE NOTE #2

171.58

Ø

171.53

(6.755)

(6.753)

WITH BRAKE

BRAKE OPTION

"A" MAX.

.10 TIR A

Notes:

1. Motor can be mounted in any position.

2. Counterbore for o-ring seal.

3. -41 and -51 models have been certified to meet IP65 sealing.

-S model has been certified to meet IP67 sealing, except for PG-36,

and has viton shaft seal and viton o-rings.

4. -43 and -53 models meet sealing specs except for mounting face.

5. Kollmorgen approved cables and mating plugs with filler plugs must be

installed before motor meets sealing specs.

6. Customer shaft key supplied with motor.

7. Dimensions in parentheses ( ) are in English and are for reference only.

8. Tolerances unless otherwise specified:

Metric: X decimal place ±.4 English: XX decimal places ±.015

XX decimal places ±.13 XXX decimal places ±.005

(.004)

Ø"E"

-A .050

(.002)

27.00 (1.063)

26.80 (1.055)

M5 X 0.8 THD X 14.0

(.55) MIN. DP. 4 PL.

EQ. SPACED ON A

Ø227.00 (8.937) B.C.

10.000

9.964

(.3937)

(.3923)

42.50 (1.673)

42.30 (1.665)

KEYWAY DETAIL

MH-823BH-822

9.987

Ø

9.962

(.3932)

(.3922)

Ø

NOTE #2

14.000

13.957

(.5512)

(.5495)

175.51

175.46

(6.910)

(6.908)

SEE

*Motor Continuous Peak Continuous Max Amplifier Amplifier **Cable Set Curve

Torque Torque Power Speed

Cont/

Peak Current Number

lb-ft (N-m) lb-ft

(N-m)

HP (kW) RPM (RMS/Phase)

BH-122-A-61

MH-123-A-61 0.52 (0.70) 1.77 (2.40) 0.54 (0.41) 7500 S60301 3/6 CS-SS-RHG1HE-xx 1

BH-124-B-61

MH-125-B-61 1.00 (1.35) 3.10 (4.20) 1.11 (0.83) 7500 S60301 3/6 CS-SS-RHG1HE-xx 2

BH-126-B-61

MH-127-B-61 1.40 (1.90) 3.10 (4.20) 1.6 (1.2) 7500 S60301 3/6 CS-SS-RHG1HE-xx 3

BH-222-E-61

MH-223-E-61 1.5 (2.1) 3.5 (4.8) 1.9 (1.4) 7000 S60301 3/6 CS-SS-RHG1HE-xx 4

BH-224-G-61

MH-225-G-61 2.8 (3.8) 5.4 (7.3) 2.1 (1.6) 4600 S60301 3/6 CS-SS-RHG1HE-xx 5

BH-226-C-61

MH-227-C-61 4.1 (5.6) 10.5 (14.2) 2.9 (2.2) 4900 S60601 6/12 CS-SS-RHG1HE-xx 6

BH-226-E-61

MH-227-E-61 4.1 (5.6) 7.7 (10.5) 2.2 (1.7) 3200 S60301 3/6 CS-SS-RHG1HE-xx 7

BH-422-D-61

MH-423-D-61 4.3 (5.8) 12.2 (16.5) 2.8 (2.1) 4600 S60601 6/12 CS-SS-RHG1HE-xx 8

BH-424-D-61

MH-425-D-61 7.8 (10.6) 14.7 (20.0) 4.4 (3.3) 3700 S60601 6/12 CS-SS-RHG1HE-xx 9

BH-426-B-61

MH-427-B-61 11.7 (15.8) 27.4 (37.1) 5.7 (4.2) 3200 S61001 10/20 CS-SS-RHG1HE-xx 10

BH-426-C-61

MH-427-C-61 11.4 (15.5) 24.5 (33.2) 7.9 (5.9) 5000 S61401 14/28 CS-SS-RHG2HE-xx 11

BH-622-A-41

MH-623-A-41 10.8 (14.6) 29.5 (40.0) 3.3 (2.5) 2000 S60601 6/12 CS-SS-RHG2UE-xx 12

BH-622-B-41

MH-623-B-41 11.0 (14.9) 24.7 (33.5) 5.9 (4.4) 4000 S61001 10/20 CS-SS-RHG2UE-xx 13

BH-624-C-41

MH-625-C-41 18.6 (25.2) 41.4 (56.2) 9.5 (7.1) 4500 S62001 20/40 CS-SS-RHG2UE-xx 14

BH-624-D-41

MH-625-D-41 18.9 (25.6) 40.4 (54.8) 8.4 (6.3) 3300 S61401 14/28 CS-SS-RHG2UE-xx 15

BH-624-E-41

MH-625-E-41 18.2 (24.7) 34.5 (46.8) 9.8 (7.3) 3850 S61401 14/28 CS-SS-RHG2UE-xx 16

BH-624-G-41

MH-625-G-41 18.2 (24.7) 34.5 (46.8) 6.2 (4.6) 2600 S61001 10/20 CS-SS-RHG2UE-xx 17

BH-626-C-41

MH-627-C-41 27.0 (36.6) 61.1 (82.9) 6.5 (4.9) 1550 S61001 10/20 CS-SS-RHG2UE-xx 18

BH-626-E-41

MH-627-E-41 26.1 (35.4) 50.2 (68.0) 14.1 (10.5) 3700 S62001 20/40 CS-SS-RHG2UE-xx 19

BH-822-C-41

MH-823-C-41 25.7 (34.8) 60.2 (81.6) 6.3 (4.70) 1600 S61001 10/20 CS-SS-RHG2UE-xx 20

BH-822-D-41

MH-823-D-41 25.6 (34.7) 53.6 (72.7) 11.4 (8.5) 3000 S62001 20/40 CS-SS-RHG2UE-xx 21

BH-826-A-41

MH-827-A-41 69.0 (93.5) 120.1 (162.8) 15.3 (11.4) 1500 S62001 20/40 CS-SS-RHG2UE-xx 22

SYSTEM SUMMARY

Kollmorgen GOLDLINE BH/MH and SERVOSTAR 600

System Summary and Configurations

Notes: *All motors have resolver feedback. **Cable “xx” designation denotes length= 01, 03, 06, 09 meters

KOLLMORGEN • keyfaith • 0755-83288220

26

ORDERING INFORMATION

Kollmorgen GOLDLINE BH/MH and SERVOSTAR 600

Model Number Description

External Regen Resistors (in housing): BAR-250 250 watts

BAR-500 500 watts

BAR-1500 1500 watts

Communications Cables: A-97251-004 RS-232 (9 pin) communication cable

A-SR6Y Y- adapter cable with 5 DB9 connectors for connecting PC

up to 4 drives, includes termination

SERVOSTAR 600 Option Slot: I/O Extension Card S6xxxx-EI

BH - 82 2 x - C - 4 1 B231a- 100

b

Brushless Motor Sequential Specials

(With frameless resolver)

BH-Low Inertia Series Standard Additions

MH-Medium Inertia Series B2 - 90 VDC fail-safe brake

B3 - 24 VDC fail-safe brake

Motor Frame E1 - Encoder adapter and/or encoder

12, 22, 42, 62, 82 Exxx - Special adapter and/or encoder

S - IP67 sealing (Viton) available on 12, 22, 42 models

Stack Length 62 and 82 models IP67 except for PG21 & 36 fittings

2, 4, 6 - B Series

3, 5, 7 - M Series Mounting and Shaft Seal Options:

1 - Std. metric mount with IP65 sealing and rear shaft extensions

S-Non-UL recognized models only 3 - Same as 1, except w/o front shaft seal

Winding Connector (ref. outline drawing) pages 18-22

A, B, etc.

a

Omit when no

standard additions

are used

b

Omit if not special

Note:BH/MH Series motors are available with custom mechanicals including special shafts and keyways.

Contact the Kollmorgen Customer Support Network (1-800-77 SERVO) for more information.

S

6 xx 01-xx

SERVOSTAR Family Option Slot

NA - No Option

600 Series EI - Extended I/O

Current Rating (Cont. Arms/Ø) Configuration

03 - 3.0 amps 01 - Standard

06 - 6.0 amps

10 - 10.0 amps

14 - 14.0 amps

20 - 20.0 amps

SERVOSTAR 600 ORDERING INFORMATION

Kollmorgen GOLDLINE®BH ORDERING INFORMATION

KOLLMORGEN • keyfaith • 0755-83288220

27

Kollmorgen Sales Offices

E-mail: servo@kollmorgen.com

Internet: http://www.kollmorgen.com

Motion Technologies Group

1-800-77 SERVO

E-mail: servo@kollmorgen.com

Americas Europe & Middle East

Radford, VA Duesseldorf, Germany

Tel: (800) 77 SERVO Tel: (49) 203 9979 0

Fax: (540) 639-1640 Fax: (49) 203 9979 155

Kollmorgen Manufacturing Locations

Kollmorgen Artus Kollmorgen PMI

Avrillé, France Commack, NY

Ho Chi Minh City, Vietnam

Kollmorgen Electro-Optical Kollmorgen Seidel

Northampton, MA Duesseldorf, Germany

Kollmorgen Industrial Drives Kollmorgen Servotronix

Radford, VA Tel Aviv, Israel

Kollmorgen Inland Motor Kollmorgen Tandon Inc

Radford, VA Bombay, India

Kollmorgen enjoys a reputation of excellence based on constant endeavors to

update products. Information in this brochure is subject to change.

Windows is a registered trademark of Microsoft Corporation.

Kollmorgen SERVOSTAR

®

600, MOTIONLINK®, Kollmorgen GOLDLINE,

and MOTIONEERING are trademarks of Kollmorgen.

Loading...

Loading...