Page 1

User’s Manual

Auto-Darkening Welding Helmet

SERVO GLAS® 5000X Autolift

Made in Korea by

SERVORE CO.

#410-3 Tojin-ri Cheongbuk-myeon Pyeongtaek-si

Gyeonggi-do Korea.

TEL : +82-31-684-6952 ◆ FAX : +82-31-684-6954

Home page: www.servore.com

E-mail: servore@servore.com

Page 2

<1 page>

Instructions for use of SERVO GLAS® 5000X Autolift

Thank you for purchasing a Servo Glas® 5000X Autolift welding helmet.

Note

For your own protection, safety and to ensure the maximum

service life of your new helmet please read this manual

carefully before use. Misuse or abuse may result in injury or

reduced protection and may also void your warranty.

Safety is a personal responsibility. Servore endeavours to produce high quality

safety products that meet or exceed relevant Standards and provide appropriate

protection when used properly. Please help yourself and those around you by

using this product carefully and by exercising good judgement. Thank you.

1. Before Use

Servo Glas® 5000X Autolift

The auto darkening welding filter in the 5000X has been designed for arc

welding and gas cutting. It is suitable for all normal arc welding processes such

as MIG, MAG, TIG, SMAW, Plasma Arc and Air Carbon welding.

Before use the shade control should be adjusted to the appropriate level based

upon EN169 (European Standard specifications or equivalent) or other

appropriate safety guidelines. When in doubt please consult your safety

representative or your authorized Servo Glas® distributor.

The Servo Glas® 5000X Autolift provides continuous protection from ultraviolet

and infrared radiation to the maximum level indicated on the product and as

Page 3

described in the relevant Standards. This protection is fail-safe and is not

compromised by loss of battery power or other electronic failure.

The Servo Glas® 5000X Autolift welding filter cartridge is fitted with two

independently operated sensors that detect the welding arc and respond

accordingly resulting in the appropriate darkened filter state as set by the user

and as indicated on the scaled adjustment. Please note that professional

judgement may be required to achieve the best results. When in doubt consult

an authorized safety representative or your Servo Glas® distributor and always

maintain a conservative attitude towards operation.

Two replaceable lithium batteries type CR2032 (3V) are used as major power

sources. An additional solar cell panel extends battery life and ensures efficient

operation. When operating normally the welding helmet will switch on

automatically and switch off automatically to save power a few minutes after the

last welding arc has been detected.

To provide a general check of system status you may wish to set the shade

control to 11 and hold the helmet towards a bright incandescent light

source. Under normal circumstances the filter will change from light to dark

state and back to light state again as you move the helmet away. Please note

that if you have any questions or there is any doubt about the performance of

your Servore product you should refer to your authorized safety representative

or Servo Glas® distributor.

Page 4

Note

Always use genuine ServoGlas® front and inside cover

plates. Failure to do so may result in injury and will void

the warranty.

The ServoGlas® 5000X is not designed for overhead

welding without the use of additional protection.

Check your helmet for physical damage and test it

regularly. If your helmet is damaged or is not working

normally have it tested and repaired before use.

Always select the appropriate shade before use

according to the type of welding and current/amperes

used. When in doubt refer to your authorized safety

representative.

<2 page>

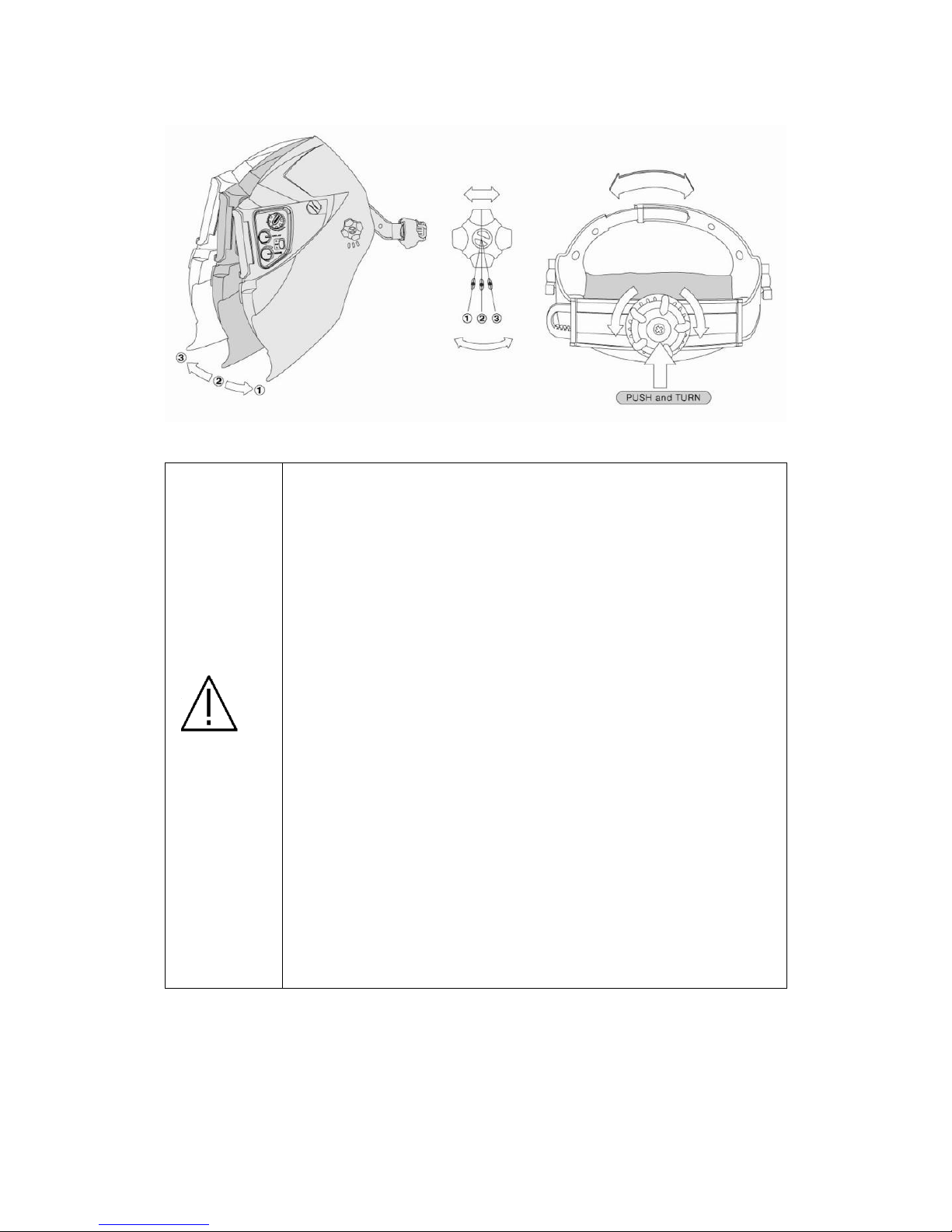

Helmet and Head harness Adjustment

Please make the appropriate adjustment(s) to the head harness to ensure a

comfortable and secure fit. It only takes a minute and helps ensure you are

properly protected. The ServoGlas® 5000X harness allows you to adjust the

distance and angle between your eyes and the filter window. You can also

adjust the circumference of the headband to ensure a comfortable but firm

fit. Please make these adjustments before use based on the illustrations in

figures shown below.

Page 5

Note

• Genuine Servo Glas® front and inside cover plates must

always be used with Servo Glas® 5000X welding filter and

helmet. Failure to do so may result in injury and also void any

warranty.

• Servo Glas® 5000X is not designed for use in overhead

welding applications where additional protection may be

required.

• Check for normal operation of the auto-darkening welding

filter. If the welding filter does not darken in use stop welding

immediately.

• Always select the appropriate shade before use according to

the type of welding and current/amperes required. When in

doubt refer to your authorized safety representative.

2. Markings

The appropriate available shade number markings and range are indicated on

Page 6

the product. Please ensure that the appropriate shade number is selected

before welding. Used properly the ServoGlas® 5000X provides eye and face

protection to meet or exceed EN379 and EN175 and other relevant Standards

where indicated. The following example illustrates these requirements. Please

note this example is provided for illustration purposes only.

CE 4 / 9 -13 SERVORE 2 / 1 / 2 / 379

Light shade

Dark shade

Manufacture identification

Optical class

Diffusion of light class

Variations in Luminous transmittance class

Certification mark or number of standard

ANNEX Ⅳ

CE CONFORMITY AND INFORMATION

The CE conformity marking shall consist of the initials ‘CE’ taking the following

form:

If the CE marking is reduced or enlarged the proportions given in the above

Page 7

graduated drawing must be respected.

The various components of the CE marking must have substantially the same

vertical dimension, which may not be less than 5 mm. This minimum dimension

may be waived for small-scale PPE.

<3 page>

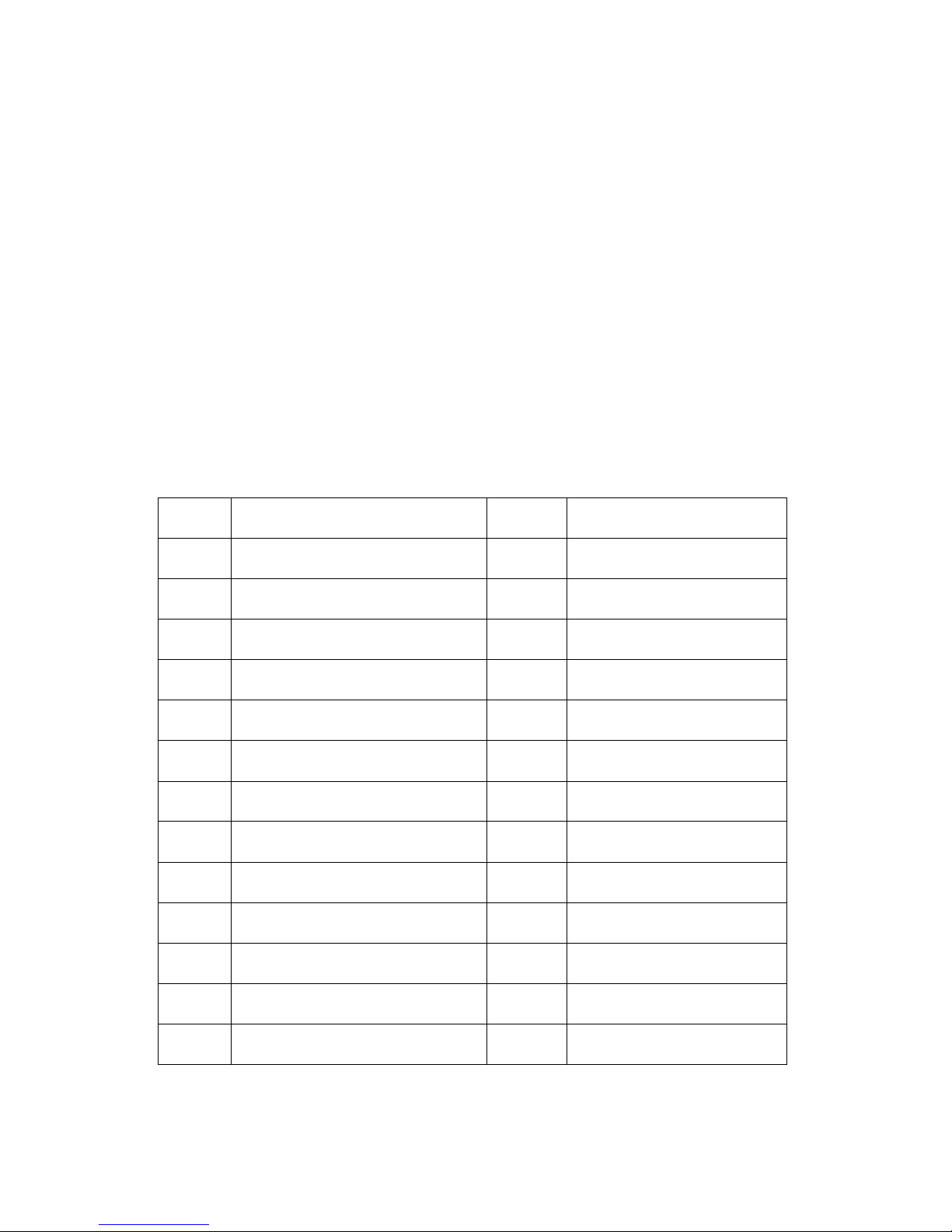

3. Parts List

The following parts are available from Servore and your authorized Servo

Glas® distributor.

<4 page>

No. Description No. Description

1 Helmet Shell 9A-2 Button Spring

2 Inner Protection Lens 9A-2 Button Spring

3 Magnifying Lens(108X51mm) 9-3 Button Washer

4A AutoLift Folder 9-4 Button Screw

4A-1 External Control 10 Hinge Cap Assembly

4-A-2 Wire Holder 10-1L Hinge Cap L

5 InsideCover Plate(108X51mm) 10-1R Hinge Cap R

6 Auto-darkening Filter Cartridge 10-2L Hinge Controller L

6-1 Battery (CR2032) 10-2R Hinge Controller R

7 Front Cover Plate(117X95mm) 10-3L Hinge Spring L

8 Front Cover 10-4R Hinge Spring R

9A Push Button Assembly 10-4 Hinge Cap Holder

9A-1 Push Button 10-5 Hinge Cap Screw

Page 8

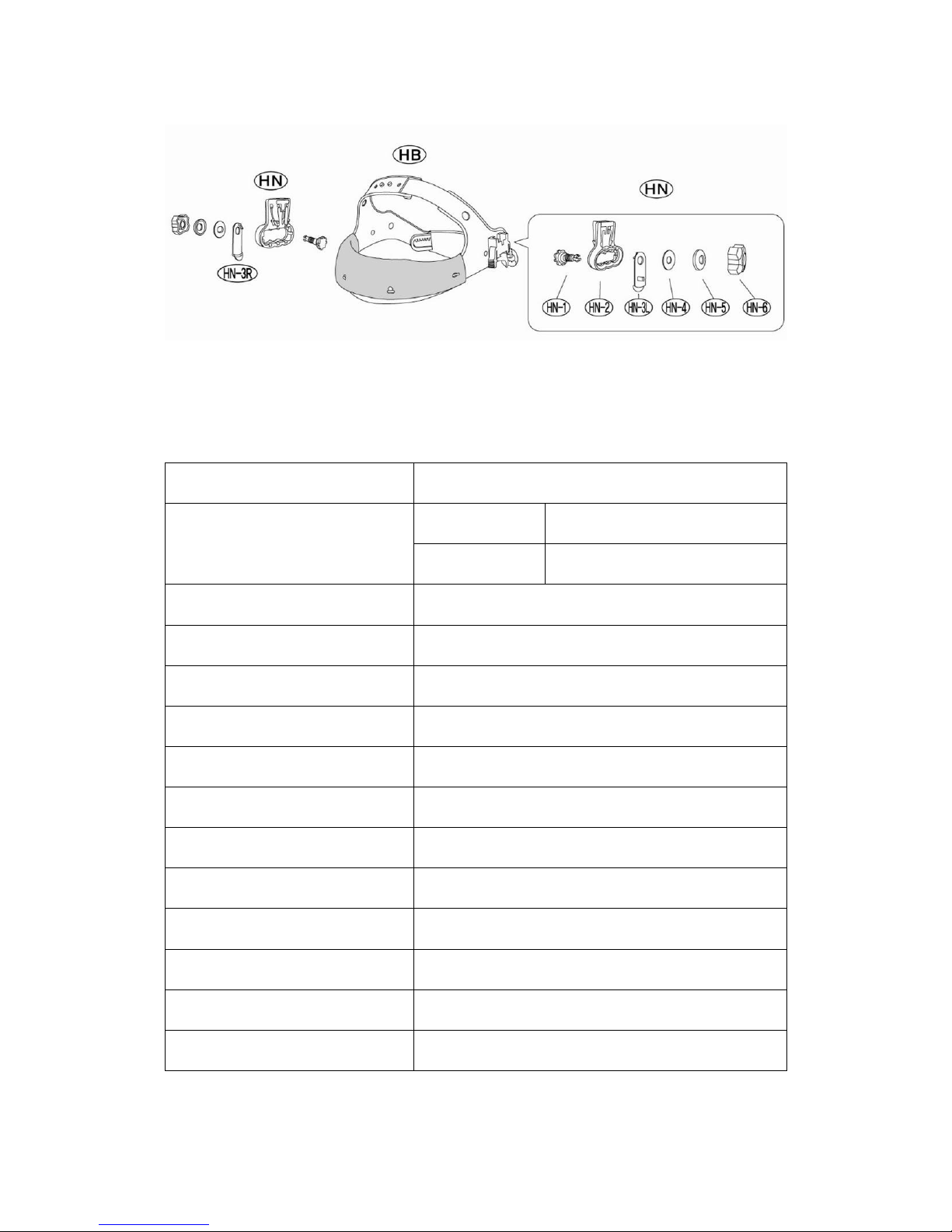

Helmet Knob Parts

Part No. Description Replacement of Knob Holder

HB Band Holder

Move P-bolt back and forth to

adjust the helmet distance

between eyes and filter window.

HK Helmet Knob Set

HK-1 P-bolt

HK-2 Band Holder

HK-3L Angular Stopper L

HK-3R Angular Stopper R

HK-4 Angular Washer

HK-5 Washer

HK-6 Knob

Page 9

<5 page>

4. Technical Specifications

Switching time (light-dark) 1/25,000(0.04msec)

Shade Level

Inactivated Shade #4

Activated Shade #9 ~ #13

Sensitivity Adjustment Dual sensors plus pre-shading(Low-High)

Switching Delay(dark to light) Adjustable 0.05s – 0.8s

Tig rating RF(H) >1Amp / RF(L) >10Amp

Power supply 3V Lithium battery(CR2032)2ea(replaceable)

Battery life 3000 hours (Approximately)

Supplementary power Solar cells (Auto On/Off)

Battery replacement Replaceable(Low battery indicator)

Cartridge size 110×90mm (4.3×3.5 in)

Filter window 97×46mm (3.8×1.8 in)

Total weight Autolift : 610g(21.5 oz)

Operating temp. -5℃~ +55℃

Storage temp. -20℃~ +70℃

Page 10

<6 page>

5. Control Function

PARTS 1.Solar Cell Panel 2. Sensor 3.LCD Filter Plate

4. Shade Control 5. Delay Control 6. Sensitivity Control

7. RF Sensor Switch 8.Low Battery Indicator

Page 11

<7 page>

5-1. Shade Control

The required filter dark state can be

selected by using the shade control. The Servo Glas®

5000X can be adjusted between shades 9 to 13 with

the embossed arrow on the dial indicating the current

adjustment. Always use the appropriate shade for the

welding operation you are undertaking. When in doubt please consult the

relevant Standards or your authorized safety representative.

Page 12

<8 page>

5-2. Light Sensitivity Control

Where problems are encountered during

welding at low amps (e.g. TIG) or there is a high

level of ambient light please follow these

steps. First try adjusting the sensitivity control

switch. Start with the sensitivity LOW (gently

turn anticlockwise until the knob stops) and adjust upwards as required. If this

does not solve the problem, set the sensitivity control in the middle position and

hold the helmet close to the target object and adjust the shade control

completely clockwise. If the welding filter stays in the light state, leave the

control set at this point. If the filter switches to the dark state, turn the shade

adjustment back until the filter just switches into the light state. The filter

should now be adjusted correctly. If the welding filter still does not respond

appropriately, please adjust the sensitivity control again (having previously

adjusted the shade control as explained above). [To achieve optimum results

in very unusual circumstances you may need to perform this process again

having first reset the sensitivity control to low.]

5-3. Delay Control

Adjustment of the speed at which the welding

filter clears can be reduced by means of the

delay control toggle switch. When this switch

is set to 'Fast' the screen will clear more quickly.

Page 13

5-4. RF Sensor Switch

New RF High/Low switch for even better RF sensitivity

control. Switch to high for extremely low amp TIG(down to

1 amp) or when using shielded cables and welders. Switch

to low when working near other welders or in areas of high

RF interference to avoid false triggers and for general

welding.

TIG Rating

RF HIGH >1 Amp

RF LOW >10 Amp

<9 page>

6. Maintenance

Note

Always ensure that all maintenance procedures are conducted

in a clean dry place. Use clean dry hands and avoid direct

contact with any glass surfaces. Handle cover plates and

welding filter by the edges and carefully clean off any dirt or

debris before re-use.

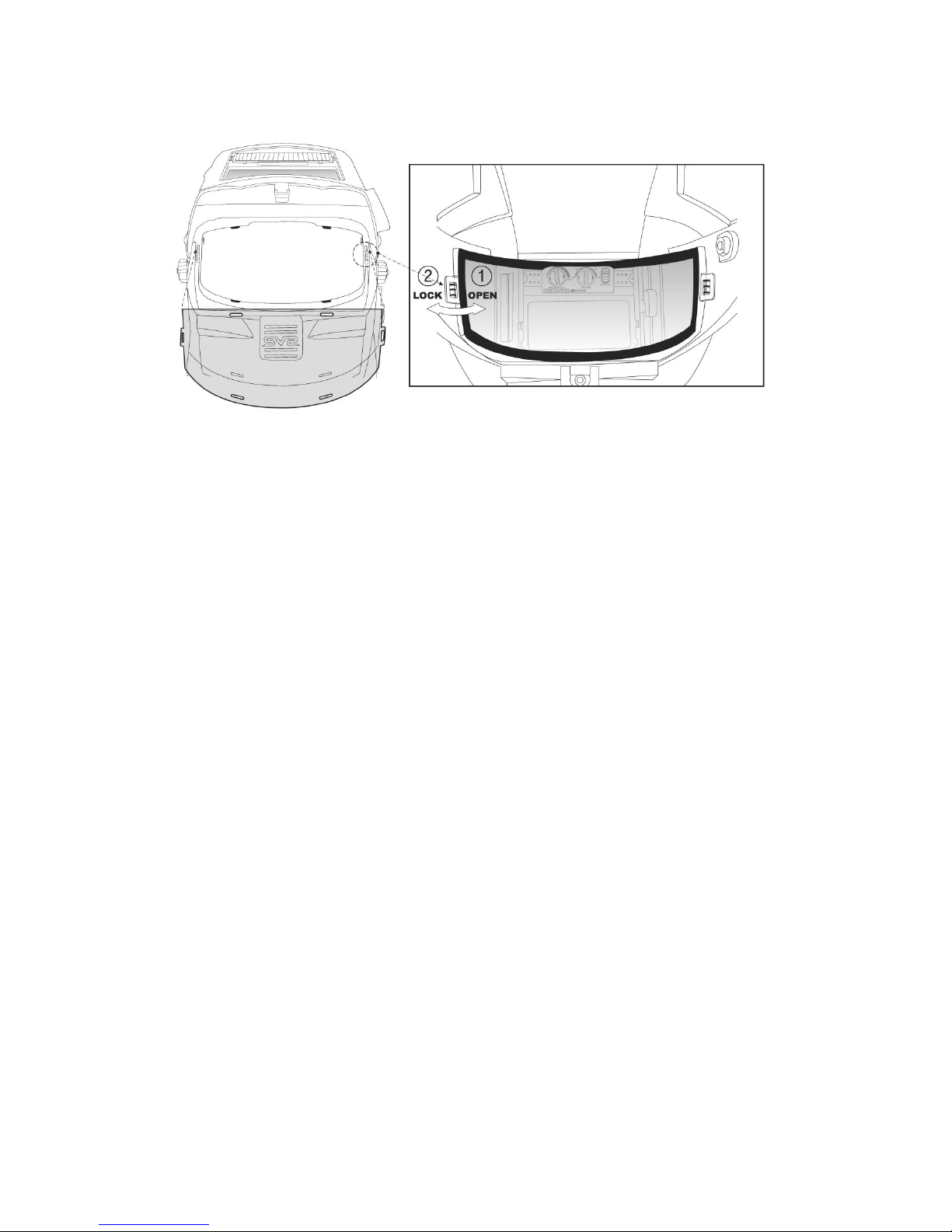

6-1.Changing the front and rear cover plates

Unclip and open the front cover as shown in the diagram. You will then be able

to remove and replace the front cover lens as required.

Before installing the new cover lens remove the protective film from both sides.

To change the rear cover lens gently remove the cartridge from the helmet you

Page 14

will then be able to unclip the inner cover lens and replace it. Again, you must

remove the protective film from both sides of the cover lens before installing it.

Note

Always use genuine Servore parts. Never use a welding

helmet without both front and rear cover lenses installed.

6-2. Changing the battery

The Servoglas 5000X series of helmets uses two 3V lithium Ion batteries

(CR2032) as a main power source. These batteries are user replaceable and

should be replaced immediately when the battery warning light comes on and/or

Page 15

at least every three years. Always replace both batteries at the same time with

brand new batteries. Never install previously used batteries in your helmet.

To replace the batteries slide out the battery holders from either side of the

cartridge and discard the old batteries. Install the new batteries in the battery

holders and slide the battery holders back into the cartridge.

Note

Always note the polarity of the batteries and install them as

shown in the diagram and as marked. Batteries rely on good

electrical contact to function properly and so always use clean

dry hands and avoid getting dirt inside the cartridge when

exchanging batteries.

6-3. Changing the inner cover plate on the 5000X Auto Lift

From inside the helmet unclip the installed cover plate from the shell noting the

locking tags on either side of the helmet (see diagram).

Remove the film from both sides of the new cover plate and then insert first one

side and then the other into the relevant slots on each side of the helmet.

Note

Always check to ensure that the locking tags on each side of

the helmet are properly mated with the slots in the cover plate

and that the four raised guides on the helmet shell are located

in the matching slots in the cover plate

Page 16

6-4. Maintaining the Auto Lift assembly on the 5000X Auto Lift

Assembling and disassembling the Auto Lift assembly on the 5000X Auto lift is a

simple process but should be done according to the following instructions to

ensure problem free operation of the helmet.

Locate the spring (10-3L) in the recess on the outside of the helmet shell

ensuring that the end of the spring is hooked into the hole provided and pointing

upwards. Springs are handed (R/L) and if reversed the Auto Lift mechanism

will not work.

Place the spring retainer (10-2L) over the spring and ensure that the tongue of

the retainer is located in the slot provided on the side of the helmet shell.

Mount the cartridge holder assembly over the spring retainer ensuring that the

notches in the top of the spring retainer are nested into the matching slots on

the cartridge holder assembly.

Insert the slotted bolt into the hole and over the end of the spring.

While holding the slotted bolt in place with your thumb, look inside the shell and

locate the black washer over the end of the bolt which should now be visible on

Page 17

the inside of the shell. Note that the black washer has internal fins that mate

with the end of the slotted bolt.

Insert the self tapping screw into the washer and screw it in. Avoid over-

tightening.

Use a coin to tension the springs on each side by turning the head of the slotted

bolts with a coin. Avoid over tensioning. Test the Auto Lift mechanism after

each adjustment. Usually turning the screw a few ‘clicks’ or about 180 degrees

gives perfect results.

Page 18

<12 page>

7. Storage and Temperature Range

Your Servore welding helmet is strong and durable. It is designed to work in

temperatures between -5C and +55C. Do not use your helmet in very hot

conditions where temperatures exceed +65C. Always store your helmet in a

clean dry place out of the direct sun and protect it from exposure to moisture or

extreme heat (min/max storage temperature is -20C ~ +70C).

Avoid unnecessary impact or compression of your helmet and never use a

helmet that is damaged. Your Servore welding helmet is a quality professional

tool and careful storage will extend the life of your investment.

8. Inspection

Check your helmet shell and filter on a regular basis when in normal use and

after extended periods of storage. Never use a cracked or damaged helmet as

this may result in personal injury and will void your warranty. Please replace

any worn or damaged parts as necessary. Genuine ServoGlas® replacement

parts are available from your authorized Servo Glas® distributor.

9. Cleaning

Note

Never expose the filter cartridge to direct contact with water

or solvents.

After removing the welding filter from the shell the shell can be cleaned using a

mild detergent and water solution. Sweat bands can be washed. A silicone

Page 19

based lubricant may be used on moving parts if necessary but is not normally

required. The filter may be carefully wiped with a cloth dampened with

household window cleaning solution. Please be careful not to scratch or

otherwise damage the filter cartridge with fragments of welding spatter or other

abrasive dirt. Refer to the relevant parts diagram for illustrations regarding

assembly and disassembly.

<13 page>

10. Cautions

CAUTION

• The ServoGlas® 5000X is designed for personal eye and

face protection from harmful radiation, sparks and welding

spatter produced under normal welding conditions. Please

follow good industry and safety practices and use additional

protection where necessary.

• Cover plates are strong and of industry standard quality but

they are breakable. The ServoGlas® 5000X is a quality

welding helmet but is not designed to provide protection from

severe impact such as broken grinding wheels or debris from

other broken tools, corrosive liquids, explosions, or other

extreme incidents. We recommend you always adopt a

conservative attitude towards safety and take additional

precautions as required and recommended in the relevant

safety standards relating to the operation you are undertaking.

•The welding filter is not designed to be waterproof. Please

Page 20

CAUTION

do not use your helmet in the rain or other inclement

weather. To do so may reduce the life of your helmet and

result in damage or injury.

• In the event that your helmet or welding filter is exposed to

direct contact with, or is submerged in water or other liquid

immediately stop using the helmet, remove the filter cartridge

from the shell, remove the batteries from the filter, inspect

carefully for damage and if necessary mop-up excess moisture

with a paper towel and then leave to dry in a warm (not hot)

place out of direct sunlight. Never place your helmet in an

oven or microwave to dry. Before use perform all normal

system checks and if in any doubt contact your ServoGlas®

distributor. Your Servore helmet is a precision engineered

professional protection product and must be maintained in

good condition to ensure your personal protection.

• When working in the vicinity of other welders it is necessary

to adopt good industry standard practice and ensure a

minimum distance of 1M between workers. Failure to do so

may result in injury or malfunction of the auto darkening

mechanism.

• Please do not wear the helmet when you are not welding. In

some circumstances the auto darkening mechanism may be

unexpectedly triggered resulting in reduced vision and

subsequent injury to yourself or others.

Page 21

CAUTION

• Servore does not support the use of ServoGlas® 5000X

range of products in combination with any other manufacturers'

products. To use parts that are not approved by Servore may

void your warranty and result in personal injury. Please use

only genuine ServoGlas® 5000X parts and spares as provided

by your authorized Servo Glas® distributor.

• Servore reserves the right to make improvements, change or

otherwise modify the specifications, materials and design of

any and all Servore products at their sole discretion with a view

to ensuring continuous improvement. Never attempt any

unauthorized modifications or alterations to your Servore

product. To do so may result in personal injury and void your

warranty.

WARNING

• Materials, which may come into contact with the wearer’s

skin could cause allergic reactions to susceptible individuals.

• Eye-protectors against high speed particles worn over

standard ophthalmic spectacles may transmit impacts, thus

creating a hazard to the wearer.

Thank you for purchasing a Servore product. If you have any questions

regarding this or any other Servore product please contact your authorized

ServoGlas® distributor.

Page 22

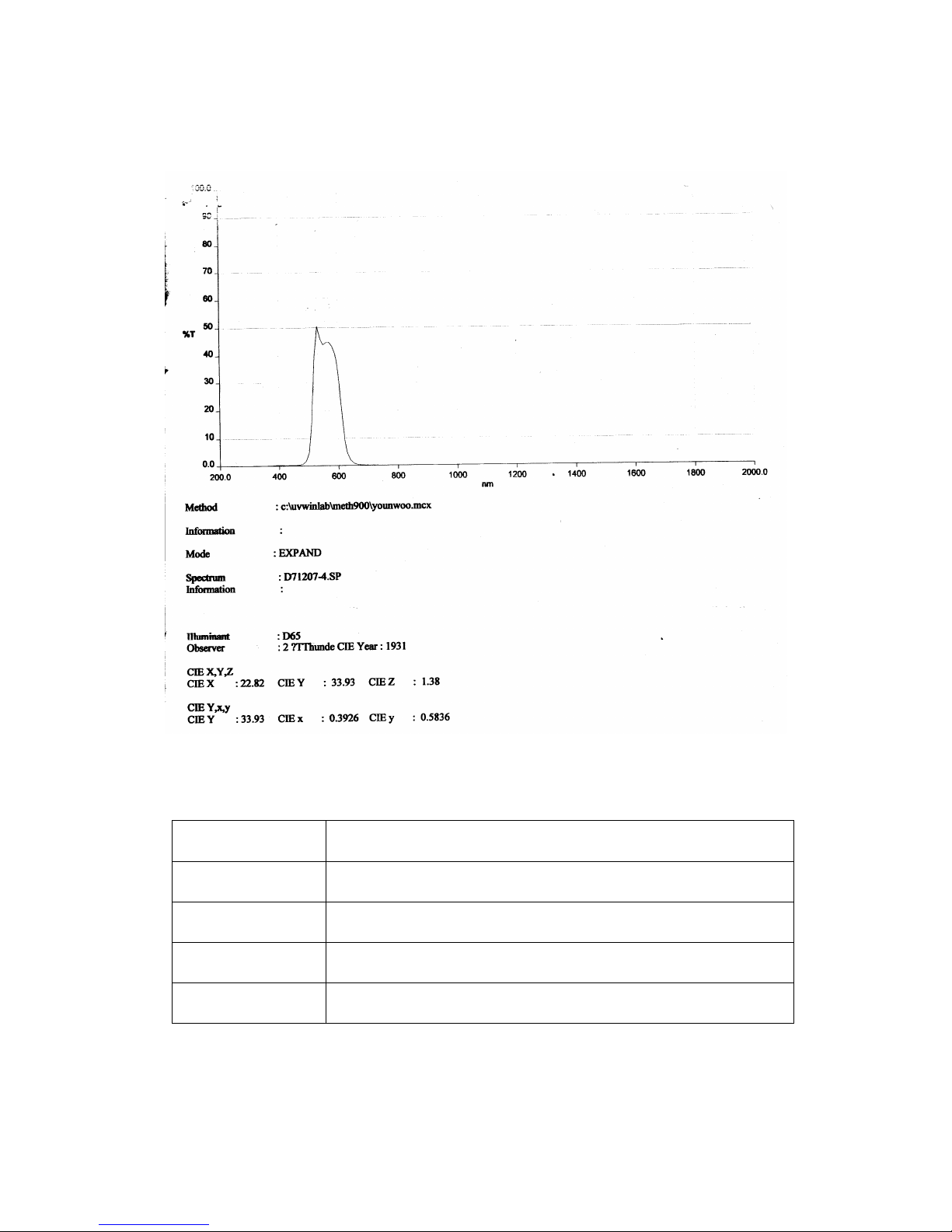

11. Transmittance Curve of the Welding Filter

12. European Representative for SERVORE CO.

Company Name SERVORE INTERNATIONAL

Contact Person Steve Edwards

Address 21 Dawson street Dublin 2 Ireland

Telephone +353 1 678 4271

Fax +353 1 662 4437

Page 23

Thank you for purchasing a Servore product. If you have any questions

regarding this or any other Servore product please contact your authorized

ServoGlas® distributor.

This model is certified by:

CERTOTTICA S

CERTOTTICA SCERTOTTICA S

CERTOTTICA Scarl

carlcarl

carl....

Zona Industriale Villanova, 32013 Longarone (BL), Italy

Notified Body Number: 0530

Loading...

Loading...