Page 1

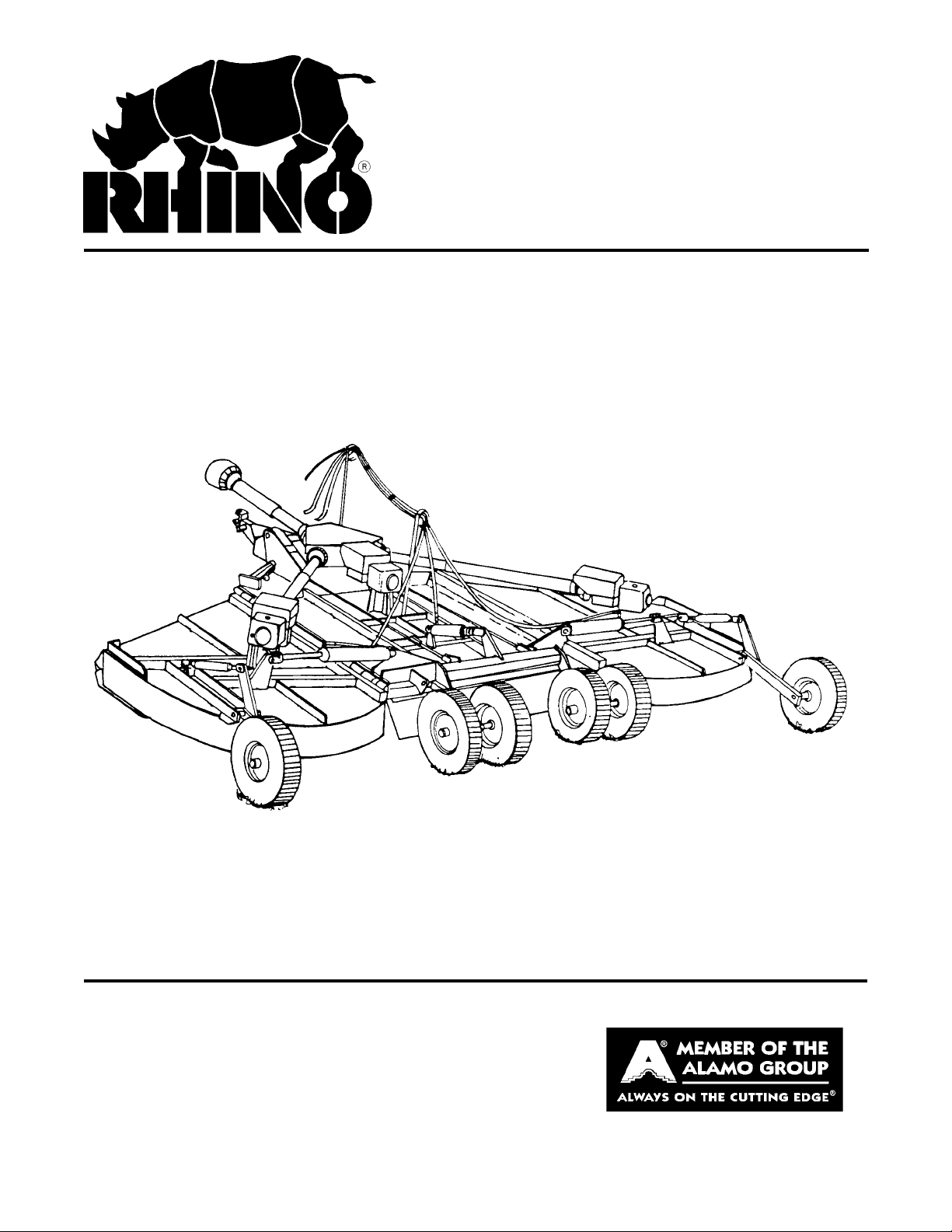

FS15

FLEX-WING

ROTARY CUTTER

Published 07-05

MASTER PARTS BOOK

P/N 00773425MB

S/N 00101 TO 10429

PARTS LISTING

Rhino

An Alamo Group Company

1020 S. Sangamon A ve.

Gibson City , Il 60936

1-800-446-5158

Email: parts@servis-rhino.com

®

© 2005 Alamo Group Inc.

Page 2

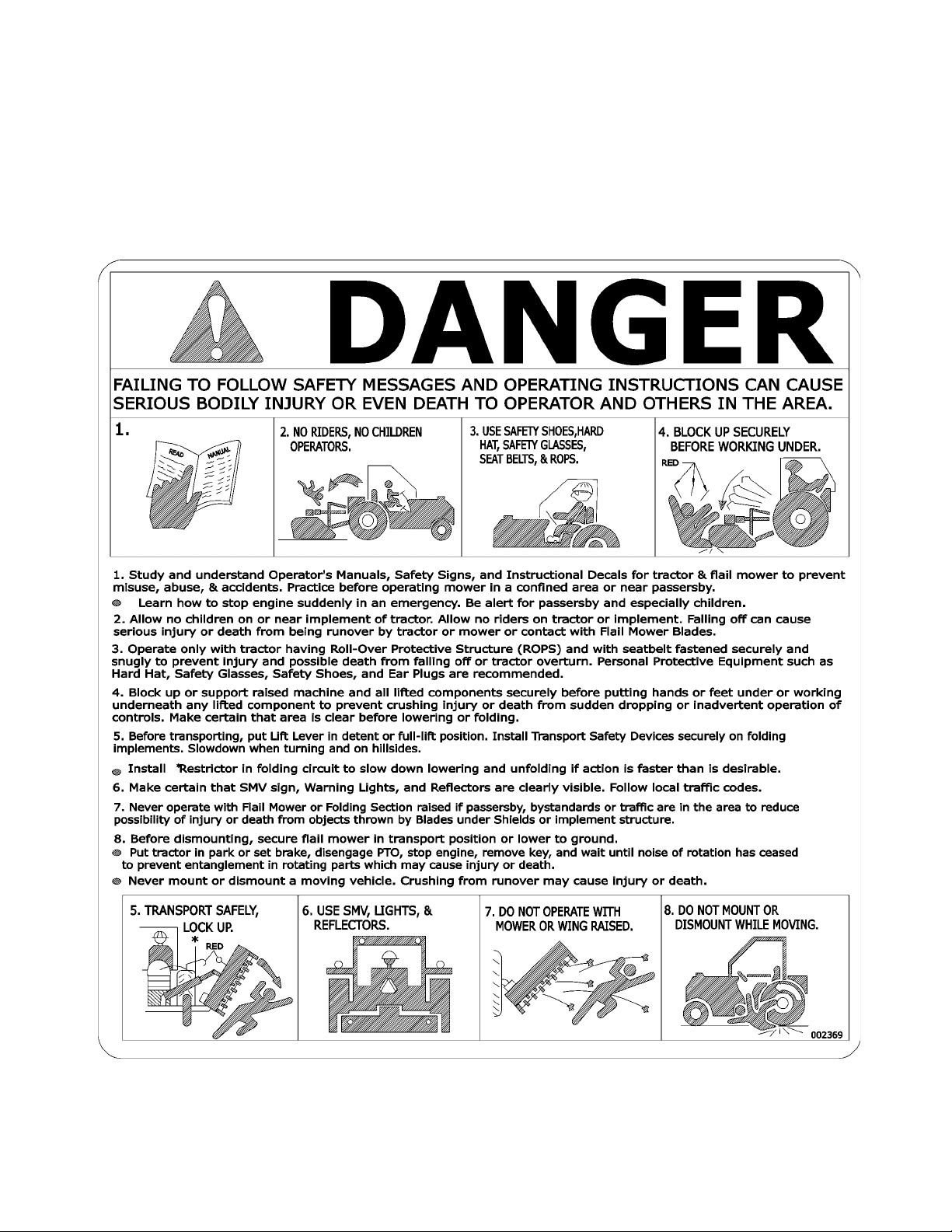

TO THE OWNER/OPERATOR/DEALER

All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who

recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this implement to

be used with all its safety equipment properly attached to minimize the chance of accidents.

BEFORE YOU START!! Read the safety messages on the implement and shown in your manual.

Observe the rules of safety and common sense!

WARRANTY INFORMATION:

Read and understand the complete Warranty Statement found in this Manual. Fill out the Warranty Registration Form

in full and return it within 30 Days. Make certain the Serial Number of the Machine is recorded on the Warranty Card

and on the Warranty Form that you retain. The use of "will-fit" parts will void your warranty and can cause catastrophic

failure with possible injury or death.

Page 3

PARTS

SECTION

Parts Section – 1

Page 4

PARTS ORDERING GUIDE

The following instructions are offered to help eliminate needless delay and error in processing

purchase orders for the equipment in this section.

1. The Parts Section is prepared in logical sequence and grouping of parts that belong to the

basic machine featured in this manual. Part Numbers and Descriptions are given to help

locate the parts and quantities required.

2. The Purchase Order must include the name and address of the person or organization

ordering the parts, who should be charged, and if possible, the serial number of the machine

for which the parts are ordered.

3. The Purchase Order must clearly list the quantity of each part, the complete and correct part

number (be sure to include all periods), and the basic name of the part.

4. The Manufacturer reserves the right to substitute parts where applicable.

5. Some parts are unlisted items which are special production items not normally stocked and

are subject to special handling. Request a quotation for such parts before sending a

Purchase Order.

6. The Manufacturer reserves the right to change prices without prior notice.

NOTE: Please refer to The Safety Section in the front of this Manual for the proper

Part Number when ordering Replacement Safety Decals.

For maximum safety and to guarantee optimum product reliability, always use

genuine Servis-Rhino Parts. The use of inferior replacement parts may cause

premature or catastrophic failure which could result in serious injury or death.

Direct any questions regarding parts to:

RHINORHINO

RHINO

RHINORHINO

®

1020 S. Sangamon Ave.

Gibson City, IL 60936

800-446-5158

Email: parts@servis-rhino.com

©2005 Alamo Group Inc.

Parts Section – 2

Page 5

PART NAME INDEX

AXLE ASSEMBLY - CTR & WING S/N 00101 - 10147 OCT 1977 - JAN 1988.................................................................... 5

AXLE ASSEMBLY - CTR & WING S/N 10148 - 10429 JAN 1988 - MAY 1988.................................................................... 6

BLADE BAR ASSEMBLY - CTR HEAVY DUTY S/N 01162 - 10429 DEC 1980 - MAY 1988 .............................................. 7

BLADE BAR ASSEMBLY - CTR STANDARD S/N 00101 - 01162 OCT 1977 - DEC 1980 ................................................. 8

BLADE BAR ASSEMBLY - WING HEAVY DUTY S/N 01162 - 10429 DEC 1980 - MAY 1988 ........................................... 9

BLADE BAR ASSEMBLY - WING STANDARD S/N 01162 - 10429 OCT 1977 - DEC 1980............................................. 10

BLADE PAN ASSEMBLY - CTR HEAVY DUTY S/N 01162 - 10429 DEC 1980 - MAY 1988 ............................................ 11

BLADE PAN ASSEMBLY - CTR STANDARD S/N 00101 - 01162 OCT 1977 - DEC 1980 ............................................... 12

BLADE PAN ASSEMBLY - WING HEAVY DUTY S/N 01162 - 10429 DEC 1980 - MAY 1988 ......................................... 13

BLADE PAN ASSEMBLY - WING STANDARD S/N 00101 - 01162 OCT 1977 - DEC 1980............................................. 14

CHAIN GUARD - CENTER & WING SECTION S/N 01497 - 10429 JUN 1982 - MAY 1988............................................. 15

CHAIN GUARD - REAR CENTER SECTION S/N 01497 - 10429 JUN 1982 - MAY 1988................................................. 16

CHAIN GUARD - REAR WING SECTION S/N 01497 - 10429 JUN 1982 - MAY 1988...................................................... 17

CYLINDER ASSEMBLY - CENTER AXLE S/N 00101 - 01377 OCT 1977 - JAN 1982...................................................... 18

CYLINDER ASSEMBLY - CENTER AXLE S/N 00101 - 10429 OCT 1977 - MAY 1988..................................................... 19

CYLINDER ASSEMBLY - CENTER AXLE S/N 01376 - 10429 JAN 1982 - MAY 1988 ..................................................... 20

CYLINDER ASSEMBLY - LEVEL LIFT - 2-1/2 X 8 SLAVE CYL S/N 00101 - 10429 OCT 1977 - MAY 1988................... 21

CYLINDER ASSEMBLY - LEVEL LIFT - 2-3/4 X 8 SLAVE CYL S/N 00101 - 10429 OCT 1977 - MAY 1988................... 22

CYLINDER ASSEMBLY - LEVEL LIFT - 3 X 8 SLAVE CYL S/N 00101 - 10429 OCT 1977 - MAY 1988......................... 23

CYLINDER ASSEMBLY - LEVEL LIFT REPLACEMENT ASSY (P/N 8719) S/N 00101 - 10429 OCT 1977 - MA ............ 24

CYLINDER ASSEMBLY - LEVEL LIFT REPLACEMENT ASSY (P/N 8720) S/N 00101 - 10429 OCT 1977 - MA ............ 25

CYLINDER ASSEMBLY - LEVEL LIFT REPLACEMENT ASSY (P/N 8721) S/N 00101 - 10429 OCT 1977 - MA ............ 26

CYLINDER ASSEMBLY - WING-HYDRAULIC CYLINDER & HOSE GROUP S/N 00101 - 01376 OCT 1977 - JAN ....... 27

CYLINDER ASSEMBLY - WING-LANTEX HYDRAULIC CYL & HOSE GRP S/N 01377 - 10429 JAN 1982 - MAY......... 28

CYLINDER ASSEMBLY - WING-REPLACEMENT S/N 00101 - 10429 OCT 1977 - MAY 1988........................................ 29

DECALS S/N 00101 - 10429 OCT 1977 - MAY 1988.......................................................................................................... 30

DEFLECTOR - REAR WING S/N 01497 - 10429 JUN 1982 - MAY 1988 .......................................................................... 31

DEFLECTOR - RUBBER FRONT CENTER S/N 00101 - 10429 OCT 1977 - MAY 1988.................................................. 32

DEFLECTOR - RUBBER FRONT WING LEFT & RIGHT S/N 00101 - 10429 OCT 1977 - MAY 1988 ............................. 33

DEFLECTOR - RUBBER LEFT & RIGHT CENTER S/N 00101 - 10429 OCT 1977 - MAY 1988 ...................................... 34

DRIVELINE ASSEMBLY - CTR GEARBOX SQUARE SHAFT SLIP 35R S/N 00101 - 10429 OCT 1977 - MAY 19......... 35

DRIVELINE ASSEMBLY - OUTBOARD SQUARE SHAFT ASSEMBLY 35R S/N 00101 - 10429 OCT 1977 - MAY 1 ..... 36

DRIVELINE ASSEMBLY - PTO SQUARE SHAFT ASSEMBLY 44R S/N 00101 - 10429 OCT 1977 - MAY 1988 ............ 37

DRIVELINE ASSEMBLY - SHIELDING ASSEMBLY SQUARE SHAFTS S/N 00101 - 10429 OCT 1977 - MAY 198....... 38

GEARBOX ASSEMBLY - CENTER SECTION S/N 00101 - 10429 OCT 1977 - MAY 1988.............................................. 40

GEARBOX ASSEMBLY - DIVIDER (COMER) S/N 01901 - 10429 FEB 1985 - MAY 1988............................................... 42

GEARBOX ASSEMBLY - DIVIDER S/N 00101 - 01900 OCT 1977 - FEB 1985 ................................................................ 44

GEARBOX ASSEMBLY - LEFT WING S/N 00101 - 10429 OCT 1977 - MAY 1988 .......................................................... 46

GEARBOX ASSEMBLY - RIGHT WING S/N 00101 - 10429 OCT 1977 - MAY 1988 ........................................................ 48

GEARBOX ATTACHMENT - DIVIDER & CENTER GEARBOX S/N 00101 - 10429 OCT 1977 - MAY 1988 .................... 50

GEARBOX ATTACHMENT- RIGHT & LEFT WING GEARBOX S/N 00101 - 10429 OCT 1977 - MAY 1988 ................... 51

HOSE BRACKET COMPONENTS S/N 00101 - 10429 OCT 1977 - MAY 1988................................................................. 52

HUB ASSEMBLY - CENTER & OUTBOARD S/N 10148 - 10428 JAN 1988 - MAY 1988................................................. 53

HUB ASSEMBLY - OUTBOARD AXLES S/N 00101 - 10147 OCT 1977 - JAN 1988........................................................ 54

HUB ASSEMBLY - STANDARD CENTER AXLE S/N 00101 - 10147 OCT 1977 - JAN 1988........................................... 55

HYDRAULIC CONTROL VALVE MOUNTING KIT S/N 00101 - 10429 OCT 1977 - MAY 1988........................................ 56

HYDRAULIC HOSE ADAPTERS S/N 00101 - 10429 OCT 1977 - MAY 1988................................................................... 57

HYDRAULIC VALVE ASSEMBLY - DETENT W/SPRING ASSEMBLY S/N 00101 - 10429 OCT 1977 - MAY 1988........ 58

HYDRAULIC VALVE ASSEMBLY - OPEN/CLOSED CENTER VALVE S/N 00101 - 10429 OCT 1977 - MAY 1988........ 59

JACK ASSEMBLY - TOP WING S/N 00101 - 10429 OCT 1977 - MAY 1988 .................................................................... 60

LEFT SCREW S/N 00101 - 10429 OCT 1977 - MAY 1988................................................................................................. 61

LEVEL LIFT KIT FIELD INSTALLATION S/N 00101 - 10429 OCT 1977 - MAY 1988 ....................................................... 62

LEVEL LIFT ROD ASSEMBLY S/N 10148 - 10428 JAN 1988 - MAY 1988 ....................................................................... 63

MAINFRAME ASSEMBLY S/N 00101 - 01900 OCT 1977 - FEB 1985............................................................................... 64

MAINFRAME ASSEMBLY S/N 01901 - 10429 FEB 1985 - MAY 1988 .............................................................................. 65

NOTES.................................................................................................................................................................................. 39

SIDE SHOE & SIDE SKIRT - OFFSET MODELS CTR SECTION S/N 00101 - 10429 OCT 1977 - MAY 1988................ 66

SIDE SHOE & SIDE SKIRT S/N 00101 - 10429 OCT 1977 - MAY 1988 ........................................................................... 67

SKID SHOE ASSEMBLY S/N 00101 - 00466 OCT 1977 - FEB 1979 ................................................................................ 68

SKID SHOE ASSEMBLY S/N 00101 - 10429 OCT 1977 - MAY 1988................................................................................ 69

SPRING ASSEMBLY - CENTER AXLE S/N 00101 - 10429 OCT 1977 - MAY 1988 ......................................................... 70

SPRING ASSEMBLY - WING S/N 00101 - 10429 OCT 1977 - MAY 1988 ........................................................................ 71

TIRE/WHEEL ASSEMBLY S/N 00101 - 10429 OCT 1977 - MAY 1988 ............................................................................. 72

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 3

Page 6

PART NAME INDEX

TONGUE ASSEMBLY S/N 00101 - 10429 OCT 1977 - MAY 1988.................................................................................... 73

TORQUE LIMITER ASSEMBLY S/N 00101 - 10001 OCT 1977 - AUG 1987..................................................................... 74

TORQUE LIMITER ASSEMBLY S/N 10001 - 10429 AUG 1987 - MAY 1988 .................................................................... 75

WEIGHT BOX S/N 00101 - 10429 OCT 1977 - MAY 1988 ................................................................................................. 76

WINCH AND STAND ASSSEMBLY S/N 00101 - 10429 OCT 1977 - MAY 1988............................................................... 77

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 4

Page 7

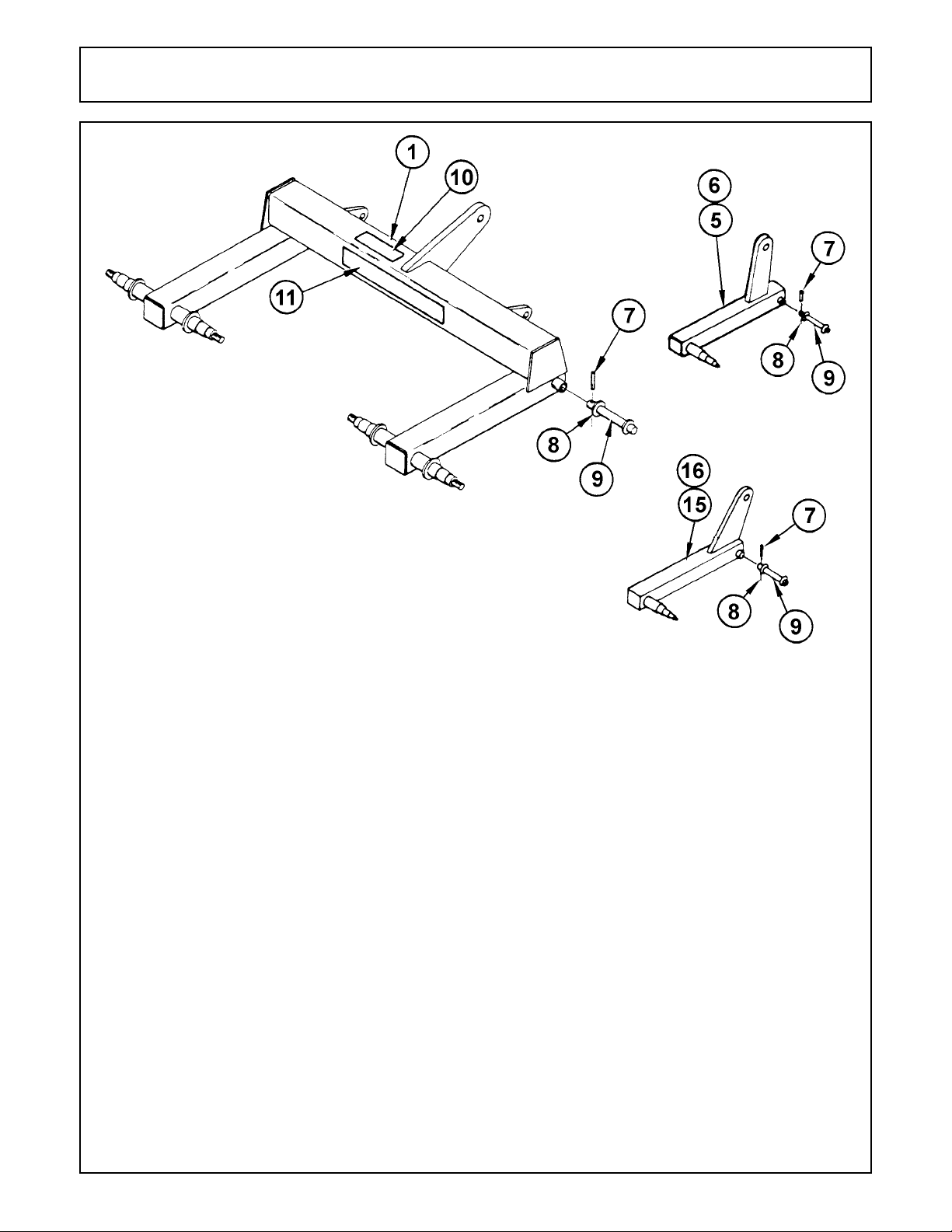

AXLE ASSEMBLY - CTR & WING S/N 00101 - 10147 OCT 1977 - JAN 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656060100 1 CENTER AXLE WELD NOT SHOWN

0656280100 1 DOUBLE AXLE WELD SHOWN

5 0656070110 1 AXLE WLD R.H. ONLY

0656070100 1 AXLE ASSY

6 0656070210 1 AXLE WLD L.H. ONLY

0656070200 1 AXLE ASSY

7 20BH5012 4 PIN-SPIRAL 5/16 X 1 1/2 *

8 15B1600 4 WASHER 1 SAE P *

9 65106A4 4 WLDMT,AXLE PIVOT PIN *

10 D121 1 DECAL ADJ-NUTS

11 D301 1 DECAL,RHINO

15 0652140220 1 WLDMT, AXLE ARM - LEFT **

0652140210 15 LEFT AXLE ASSY **

16 0652140260 1 WLDMT, AXLE ARM - RIGHT

0652140250 1 RIGHT AXLE ASSY **

Note: This Axle uses hub #3741247 assembly on center and hub #271033 assembly on wing. Washers are welded to

spindle on center axle but not on the wing.

FOR REPLACEMENT PARTS ONLY

*QTY SHOWN FOR 1 MACHINE, COMPLETE

**USED W/FACTORY LEVEL LIFT ONLY ITEM #15 AND #16

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 5

Page 8

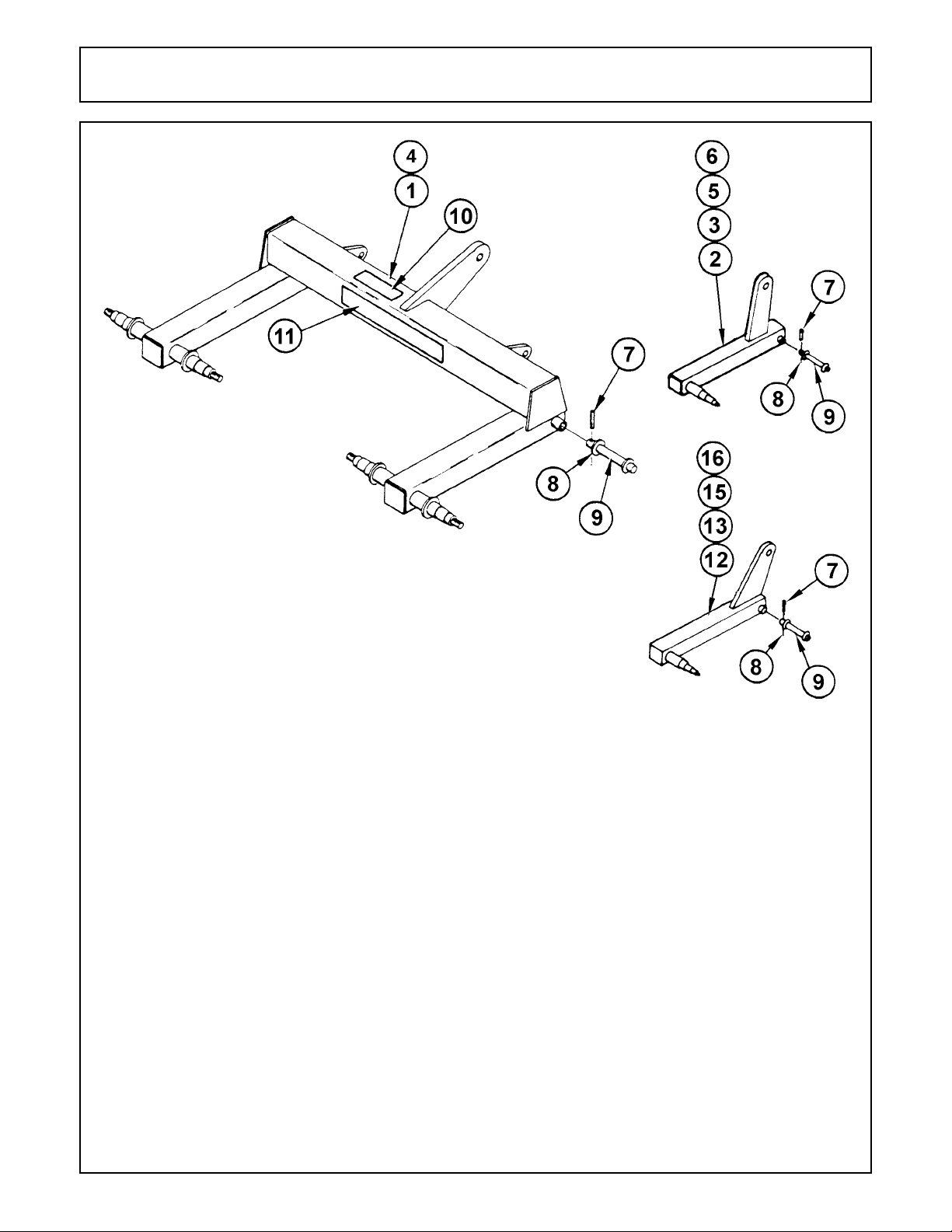

AXLE ASSEMBLY - CTR & WING S/N 10148 - 10429 JAN 1988 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 00756458 1 AXLE CENTER ASSY NOT SHOWN

00756456 1 AXLE DOUBLE CENTER SHOWN

2 00756461 1 AXLE ARM ASSY (R.H.), COMPLETE W/1 HUB

3 00756464 1 AXLE ARM ASSY(L.H.), COMPLETE W/1 HUB

4 00756455 1 DOUBLE AXLE ARM WELD SHOWN

00756457 1 CENTER AXLE WELD NOT SHOWN

5 00756459 1 AXLE WELD (R.H.) ONLY

6 00756462 1 AXLE WELD (L.H.) ONLY

7 20BH5012 4 PIN-SPIRAL 5/16 X 1 1/2 *

8 15B1600 4 WASHER 1 SAE P *

9 65106A4 4 WLDMT,AXLE PIVOT PIN *

10 D121 1 DECAL ADJ-NUTS

11 D301 1 DECAL,RHINO

12 00756466 1 LEFT AXLE ARM ASSY

13 00756468 1 RIGHT AXLE ARM ASSY

15 00756465 1 LEFT AXLE ARM WELD N/S

16 00756467 1 RIGHT AXLE ARM WELD

Note: This axle center & win uses hub #00757241 assembly.

FOR REPLACEMENT PARTS ONLY.

*QTY SHOWN FOR 1 MACHINE, COMPLETE

**USED W/FACTORY HYDRAULIC LEVEL LIFT ONLY ITEM #12 THRU #16

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 6

Page 9

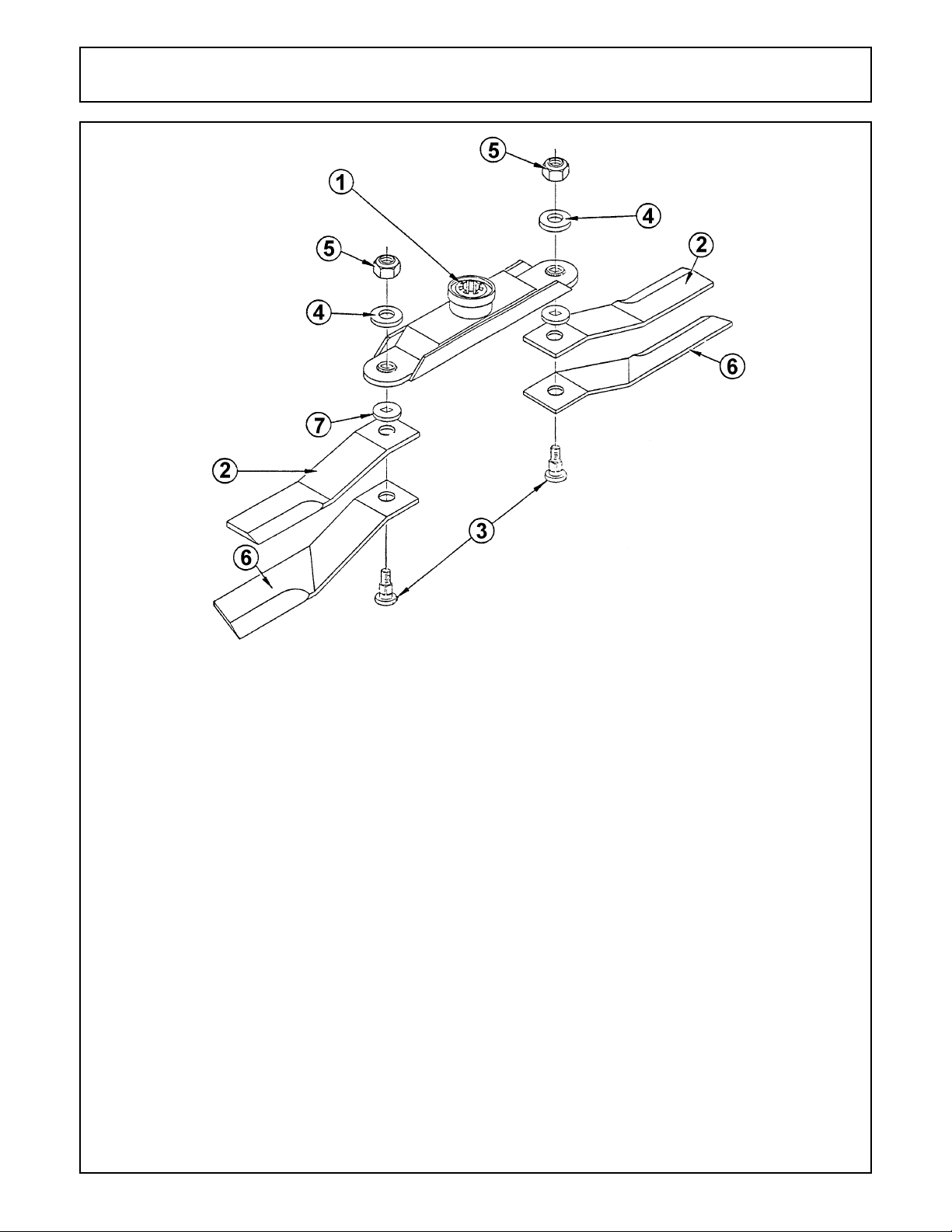

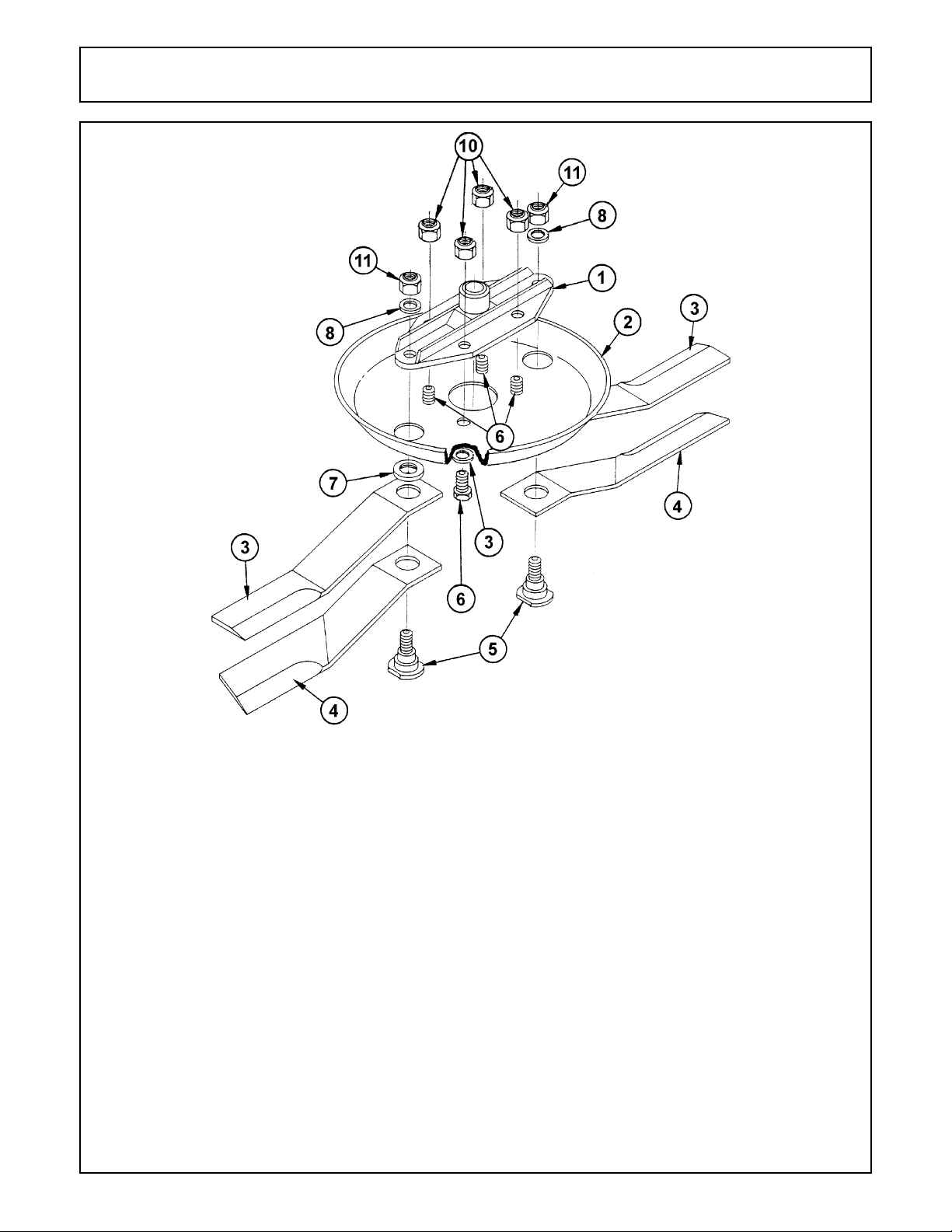

BLADE BAR ASSEMBLY - CTR HEAVY DUTY S/N 01162 - 10429 DEC 1980 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656160100 1 WLDMT, BLADE CARRIER

2 0652010030 2 BLADE, CCW/CW FLAT

3 571044 2 BOLT SHOULDER

4 571045 2 WASHER

5 5GL16140 2 LOCKNUT 1 -14 LH TLN PL

6 0622010330 2 BLADE, CCW FAN

7 0656150200 2 WASHER,SQ HOLE HT

Note: This carrier was optional until Dec. 1980 then, it became standard. These blade bolts have square shoulders.

The blade bolt hole is 1-25/64 diameter. Check Before Ordering Parts

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 7

Page 10

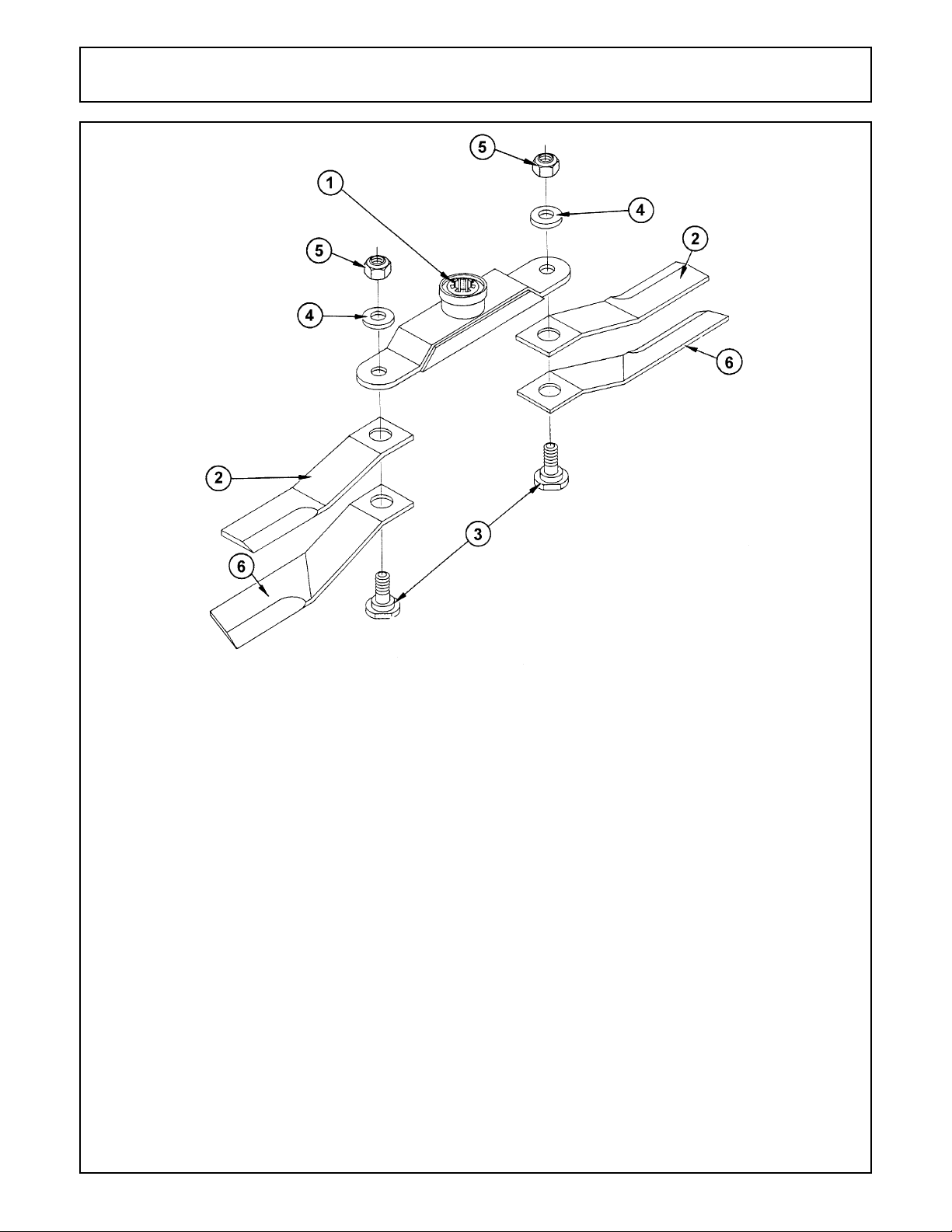

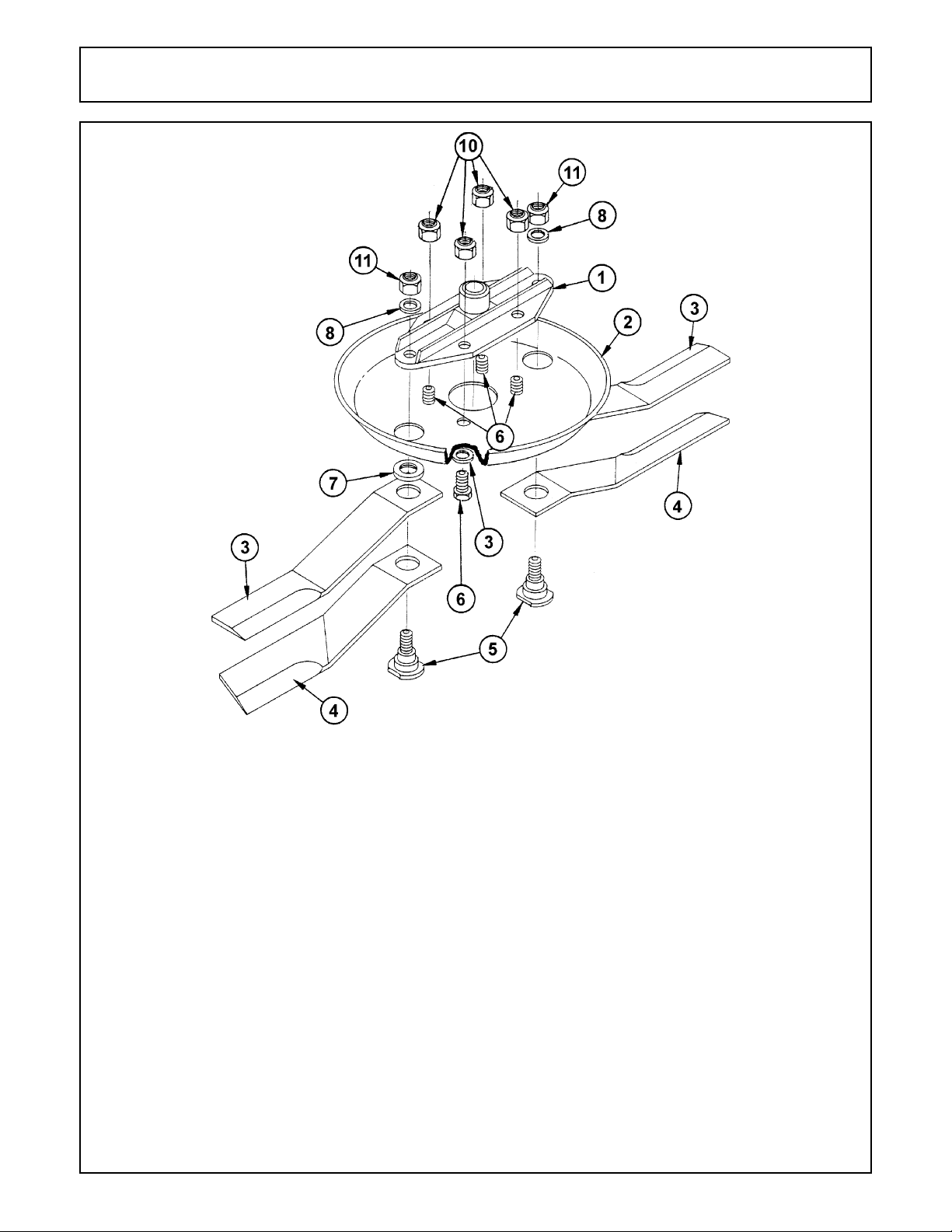

BLADE BAR ASSEMBLY - CTR STANDARD S/N 00101 - 01162 OCT 1977 - DEC 1980

ITEM PART NO. QTY. DESCRIPTION

1 701021R 1 CARRIER,BAR BLADE

2 701022R 2 BLADE

3 36107A2ALH 2 BOLT SHOULDER L.H THREAD

4 481043 2 SPCR 1-1/4 X 3/4 X 5/16

5 5GL12160 2 LOCKNUT TLM 3/4 NF PLB L.H. THREAD

6 71103 2 BLD,OFT/FAN,CCW

Note: This blade carrier was standard till Dec. 1980. These Blade bolts have round shoulder.

The blade bolt hole is 1-1/64 dia. Check Before Ordering Parts

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 8

Page 11

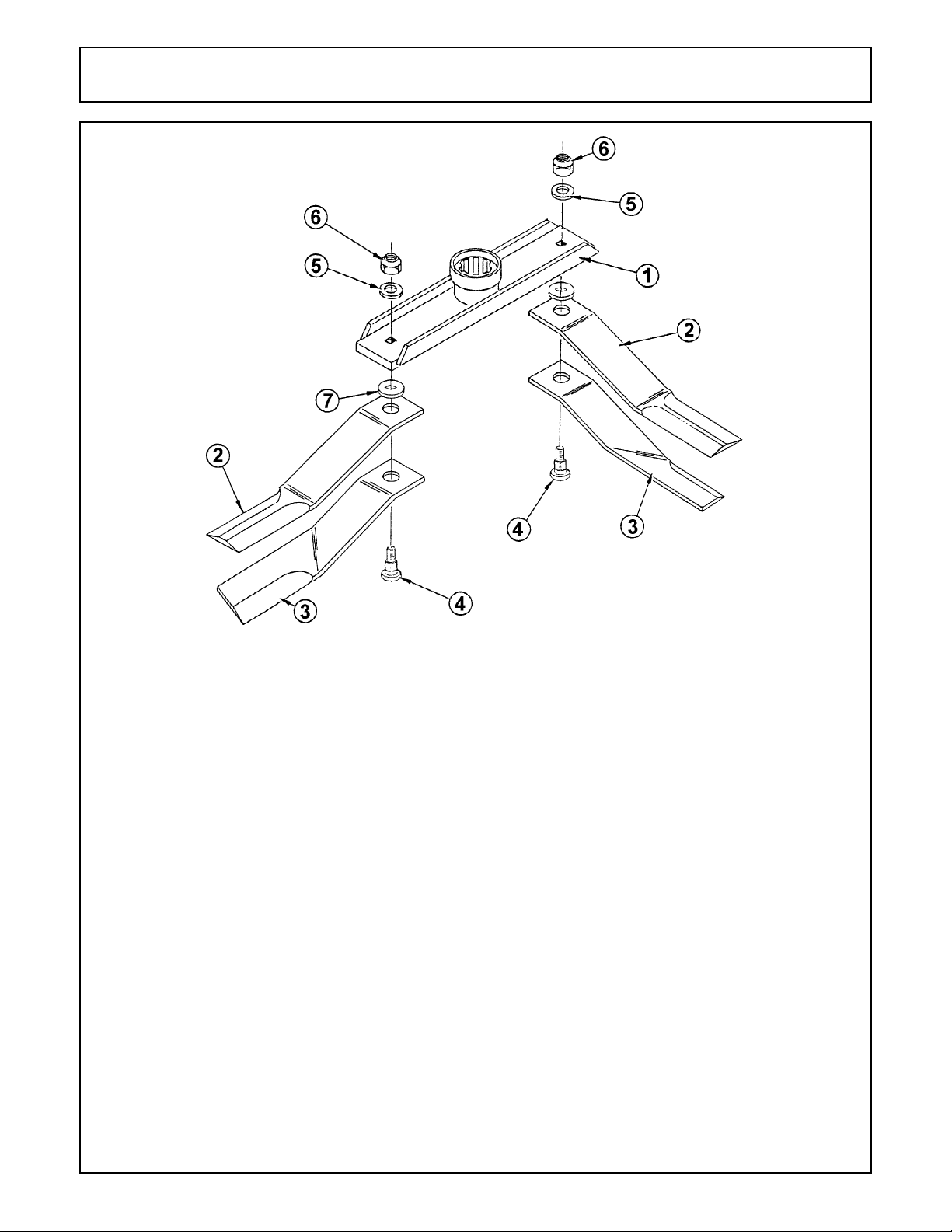

BLADE BAR ASSEMBLY - WING HEAVY DUTY S/N 01162 - 10429 DEC 1980 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656180100 1 WLDMT, BLADE CARRIER, FS15

2 0652010030 2 BLADE, CCW/CW FLAT

3 0622010330 2 BLADE, CCW FAN

0652010330 3 BLADE, CW FAN

4 571044 2 BOLT SHOULDER

5 571045 2 WASHER

6 5GL16140 2 LOCKNUT 1 -14 LH TLN PL

7 0656150200 2 WASHER,SQ HOLE HT

Note: This was optional till Dec. 1980. These blades bolts have square shoulders.

The blade bolt hole is 1-25/64 dia. Check Before Ordering Parts

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 9

Page 12

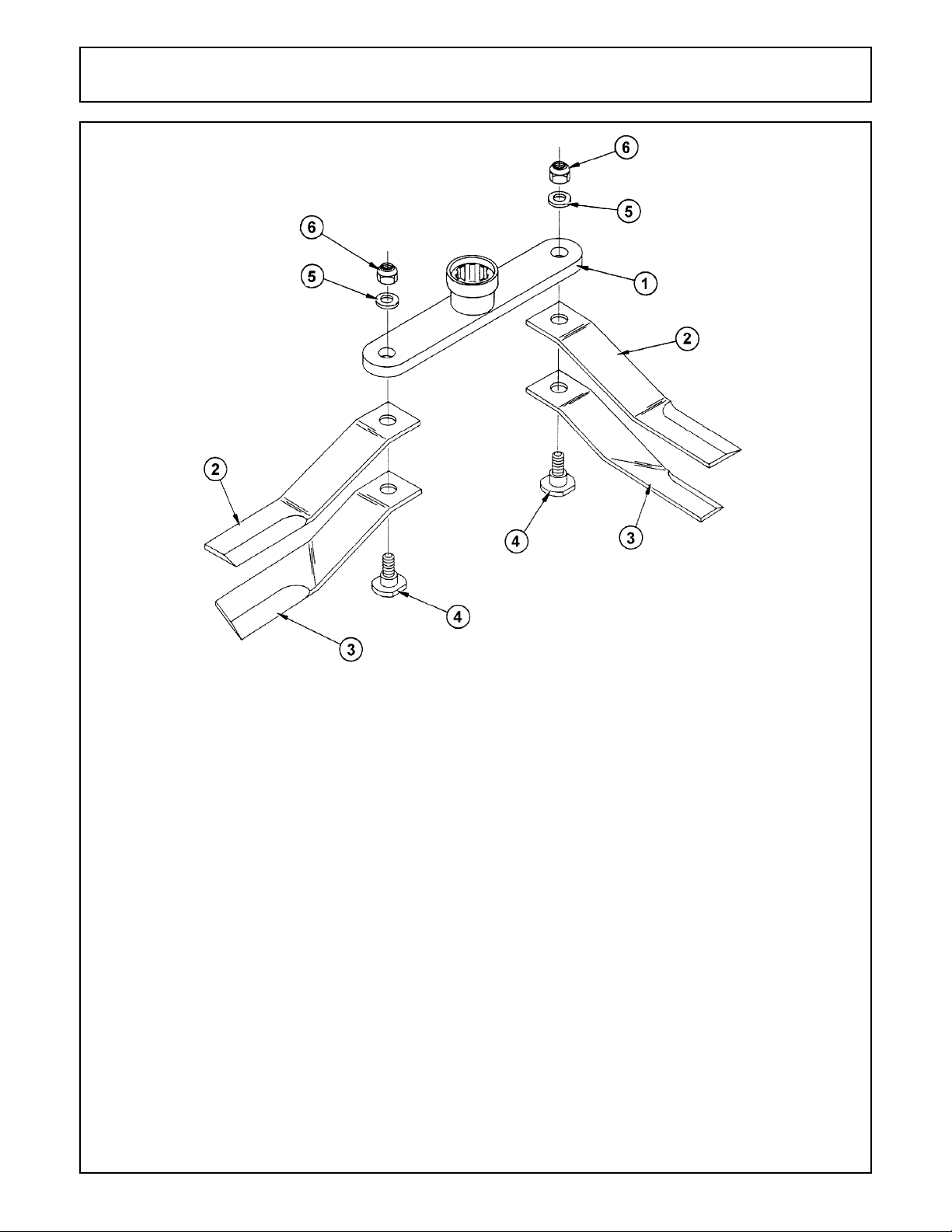

BLADE BAR ASSEMBLY - WING STANDARD S/N 01162 - 10429 OCT 1977 - DEC 1980

ITEM PART NO. QTY. DESCRIPTION

1 711021 1 BLADE CARRIER

2 701022R 2 BLADE

0656240000 2 BLADE STD FAN

3 71103 2 BLD,OFT/FAN,CCW

4 36107A2ALH 2 BOLT SHOULDER

5 5312316 2 WASHER (SPECIAL)

6 5GL12160 2 LOCKNUT TLM (LH) 3/4 NF PLB

Note: This blade carrier was optional till Dec. 1980.

The blade bolt hole is 1-1/64 dia. Check Before Ordering Parts

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 10

Page 13

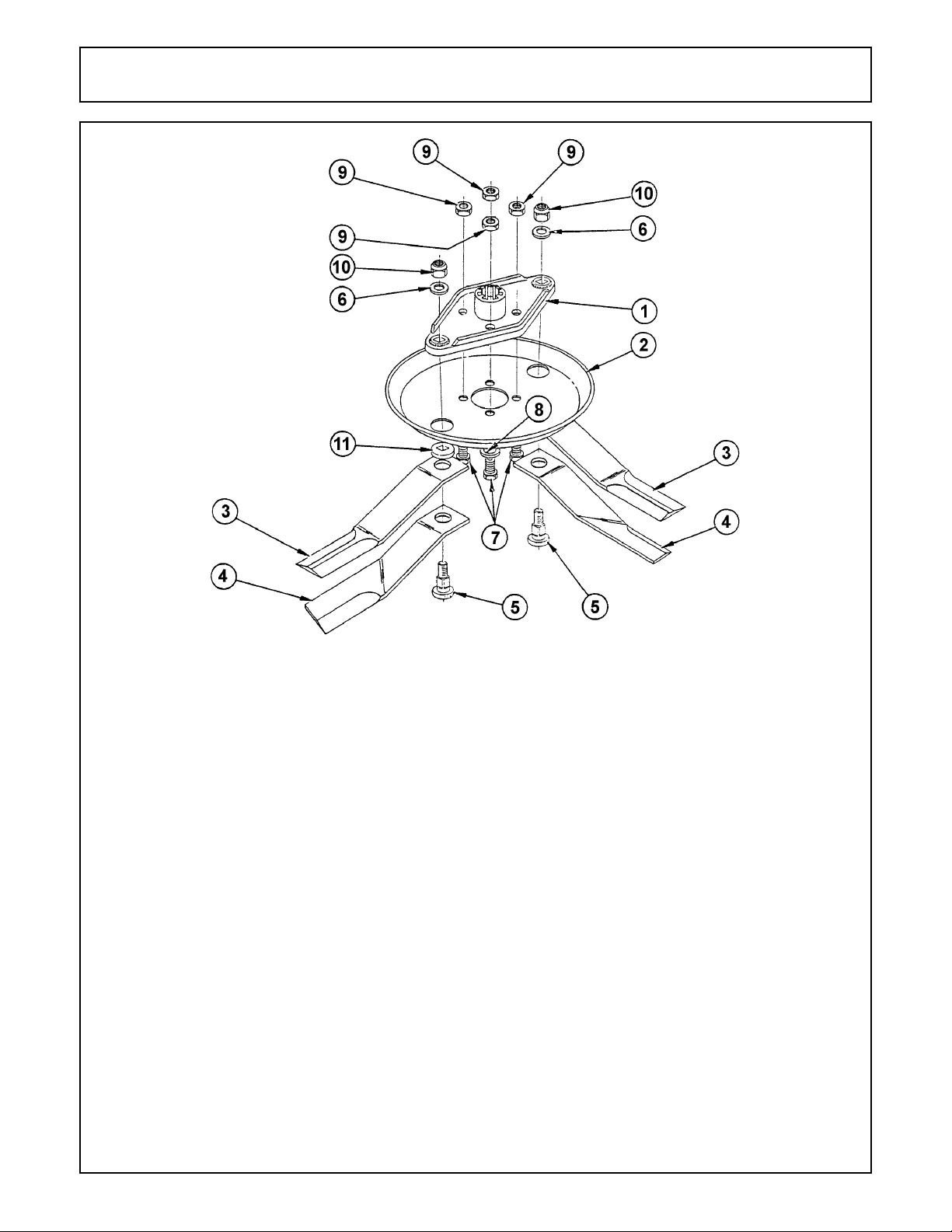

BLADE PAN ASSEMBLY - CTR HEAVY DUTY S/N 01162 - 10429 DEC 1980 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656150100 1 BALDE CARRIER WELDMENT

2 701332 1 DISHPAN

3 0652010030 2 OFFSET FLAT BLADE

0652010030 3 HARD SURFACED OFFSET FLAT BLADE

4 0622010330 2 OFFSET FAN BLADE

5 571044 2 OFFSET HARD SURFACED FAN BLADE

6 7AH5101816 4 BOLT

7 0656150200 2 SPACER WASHER

8 571045 2 SHOULDER BOLT

9 W67 4 HARD WASHER

10 00749136 4 LOCKNUT

11 5GL1640 2 LOCKNUT L.H. THREAD

Note: This carrier was optional until Dec. 1980 then, it became standard. These blade bolts have square shoulders.

The blade bolt hole is 1-25/64 diameter. Check Before Ordering Parts

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 11

Page 14

BLADE PAN ASSEMBLY - CTR STANDARD S/N 00101 - 01162 OCT 1977 - DEC 1980

ITEM PART NO. QTY. DESCRIPTION

1 701333 1 CARRIER BLADE WELDMENT

2 701332 1 DISHPAN

3 701022R 2 BLADE, OFFSET FLAT

4 71103 2 BLADE, OFFSET FAN

HS71103 2 BLADE OFFSET FAN (HARD SURFACED)

5 36107A2ALH 2 SHOULDER BLADE BOLT

6 7AH5101816 4 BOLT

7 671044 2 SPACER WASHER

8 681064 2 WASHER (HARDENED)

9 W67 4 WASHER (HARDENED)

10 5GR10180 4 NUT-TOPLOCK

11 5GL12160 2 NUT-TOPLOCK LH THREAD

Note: This blade carrier was standard till Dec. 1980. These Blade bolts have round shoulder.

The blade bolt hole is 1-1/64 dia. Check Before Ordering Parts

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 12

Page 15

BLADE PAN ASSEMBLY - WING HEAVY DUTY S/N 01162 - 10429 DEC 1980 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656170100 1 BLADE CARRIER, WELDMENT

2 671042 1 BLADE PAN

3 0652010030 2 OFFSET FLAT BLADE, CCW

0652010030 3 OFFSET FLAT BLADE, HARD SURFACED, CCW

0652010030 2 OFFSET FLAT BLADE, CW

0652010030 3 OFFSET FLAT BLADE, HARD SURFACED, CW

4 0622010330 2 OFFSET FAN BLADE, CCW

0622010330 4 OFFSET FAN BLADE, HARD SURFACED, CCW

0652010330 2 OFFSET FAN BLADE, CW

0652010330 2 FAN, BLADE HARD SURFACED, CW

5 571044 2 SHOULDER BOLT (L.H. THREADS)

6 571045 2 SHOULDER BOLT WASHER

7 7AH5101816 4 BOLT

8 W67 4 WASHER

9 00749136 4 LOCKNUT

10 5GL16140 2 LOCKNUT L.H. THREADS

11 0656150200 2 WASHER SPACER

Note: This was optional till Dec. 1980. These blades bolts have square shoulders.

The blade bolt hole is 1-25/64 dia. Check Before Ordering Parts

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 13

Page 16

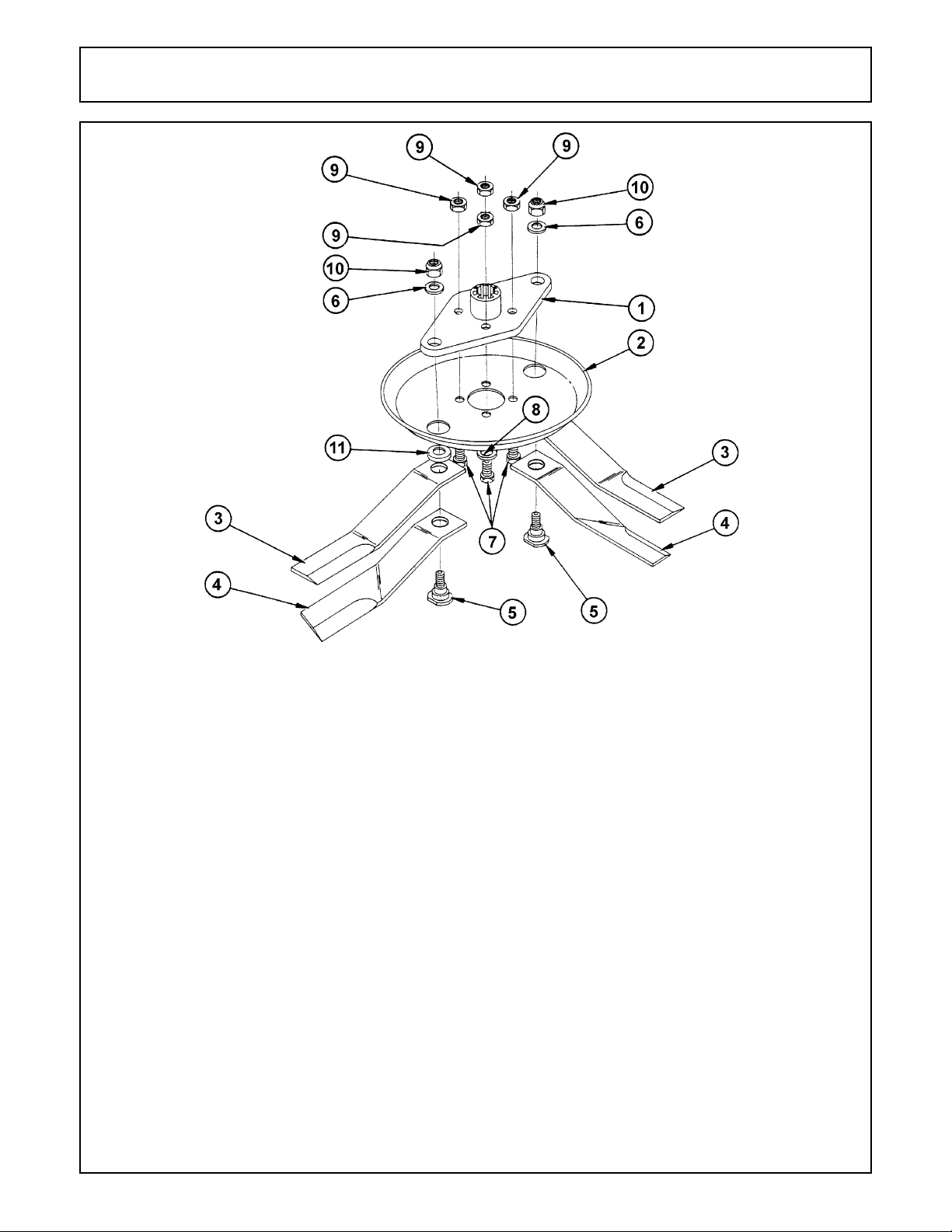

BLADE PAN ASSEMBLY - WING STANDARD S/N 00101 - 01162 OCT 1977 - DEC 1980

ITEM PART NO. QTY. DESCRIPTION

1 671041 1 CARRIER, BLADE (WELDMENT)

2 671042 1 BLADE PAN

3 701022R 2 BLADE, OFFSET, CCW

0656240000 2 BLADE, OFFSET, CW (HARD SURFACE)

0656240000 2 BLADE, OFFSET, CW

4 71103 2 BLADE, SUCTION, CCW

0656240000 2 BLADE, SUCTION, CW

71103 2 BLADE, SUCTION, HARD SURFACED, CCW

0656240000 2 BLADE, SUCTION, HARD SURFACED, CW

5 36107A2ALH 2 BOLT, SHOULDER L.H. THD.

6 5312316 2 WASHER, SPECIAL (HEAT TREATED)

7 7AH5101816 4 BOLT

8 W67 4 WASHER, HARD

9 00749136 4 NUT, LOCK HEX.

10 5GI12160 2 NUT, LOCK HEX.

11 671044 2 WASHER, SPACER

Note: This blade carrier was optional till Dec. 1980.

The blade bolt hole is 1-1/64 dia. Check Before Ordering Parts

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 14

Page 17

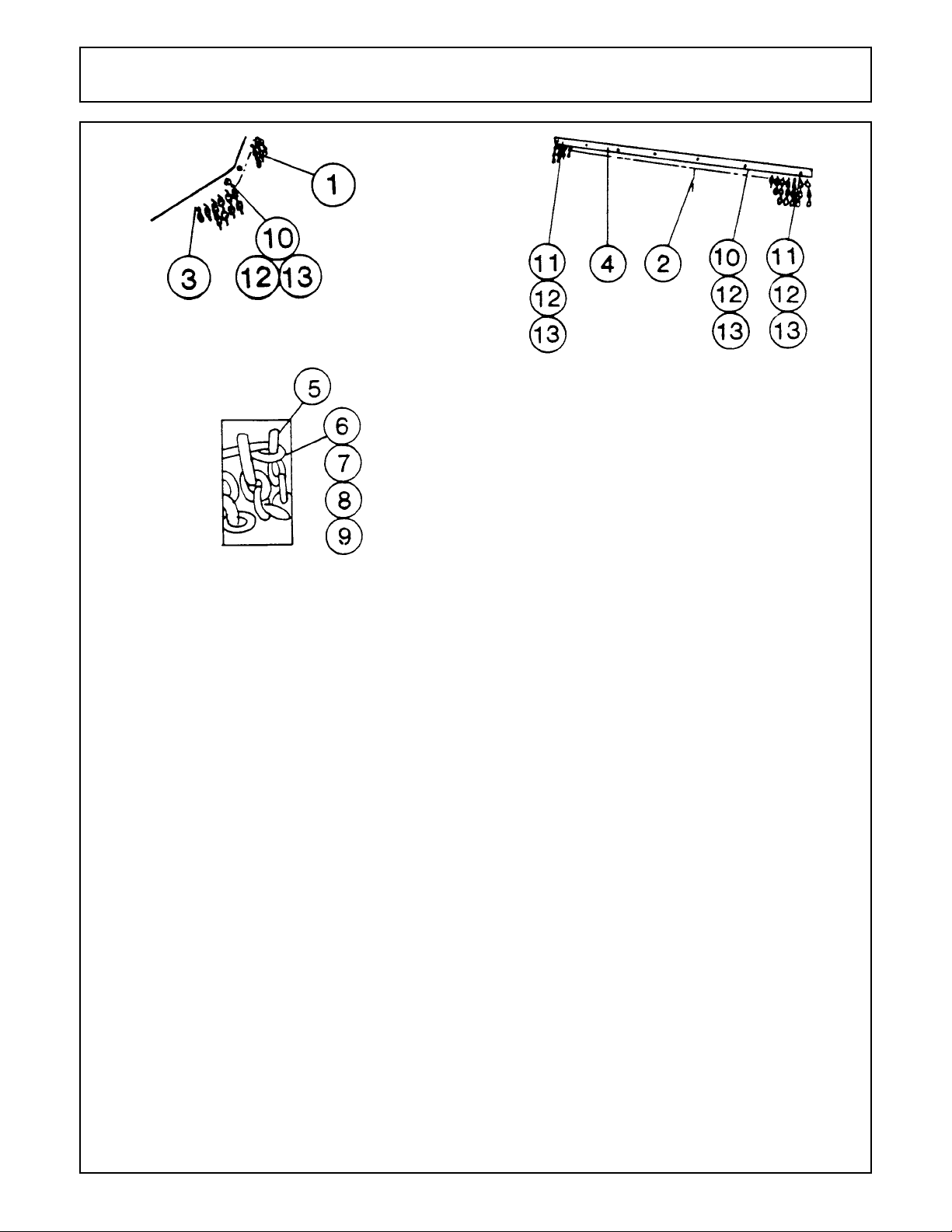

CHAIN GUARD - CENTER & WING SECTION S/N 01497 - 10429 JUN 1982 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

0652100000 - CHAIN GUARDS, FRONT

1 0652100100 1 CTR SECT FRNT CHN GD ASSY

2 0652100200 1 FRNT CHN GD ASSY, WING *

3 0652100110 1 WLDMT, MOUNTING BRACKET

4 0652100201 1 GUARD MNTING BRKT *

5 0652100101 69 CHAIN 5/16 5-LINKS

0652100203 63 CHAIN 5/16, 6 LINK *

6 0652100202 1 ROD CHAIN *

7 0652100104 2 ROD CHAIN

8 0652100102 1 ROD CHAIN

9 0652100105 2 ROD CHAIN

10 7A81312 7 C/S1/2 X 1 1/2 NC

5 (WING) *

11 00013300 2 HEXB 1/2 NC 2 PL5 *

12 15B800 7 WASHER 1/2 SAE ZP

7 (WING) *

13 5GR8130 7 NUT,LOCKNUT 1/2 NC

7 (WING) *

Note: These replace assembly used prior to Serial #07497 June 1982. Chain Guards with chain links welded on longer

available.

Leading edge of mower will be turned down 90` approximately.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 15

Page 18

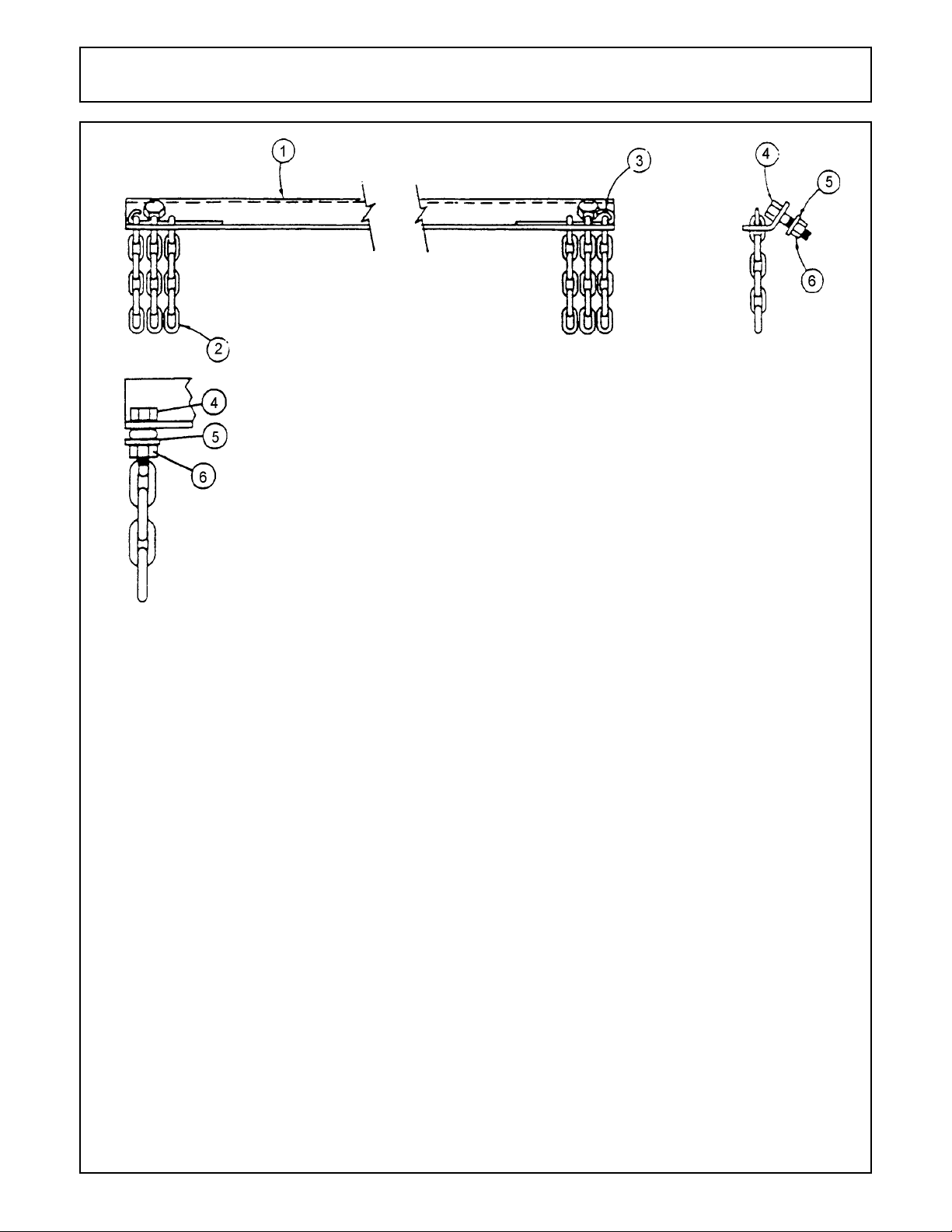

CHAIN GUARD - REAR CENTER SECTION S/N 01497 - 10429 JUN 1982 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

0652110000 - CHAIN GUARDS, REAR *

0652110100 1 REAR CHN GD ASSY, CTR SECT

1 0652110101 1 MOUNTING BRACKET

2 0652100203 57 CHAIN 5/16, 6 LINK

3 0652110102 1 ROD,CHAIN GUARD 52 1/2 LG

4 00748823 4 HHCS 1/2-13UNC 1-1/2 PL5

00752680 2 HHCS 1/2-13UNC X 4LG PL5

5 15B800 6 WASHER 1/2 SAE ZP

6 00001800 6 LOCKNUT TLM 1/2 NC PLB

7 0652110103 2 ROD,CHAIN GUARD 11 1/2 LG

?8 652053 2 SPACER

Note: These chain guards as an assembly replace earlier chain guards prior to serial #01497 June 1982. Chain guards

with chain links welded on bracket are no longer available.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 16

Page 19

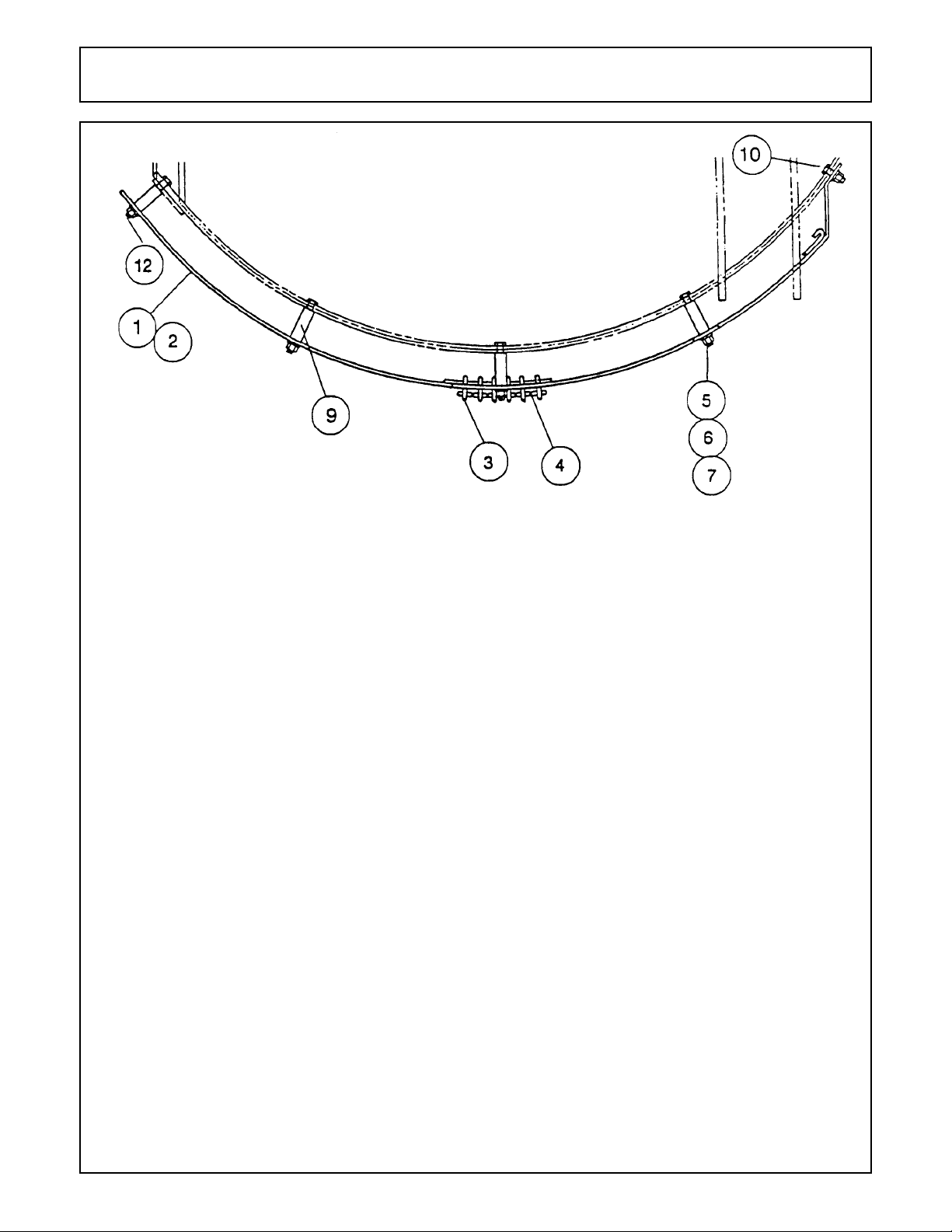

CHAIN GUARD - REAR WING SECTION S/N 01497 - 10429 JUN 1982 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0652110300 1 LEFT REAR WING CHN GD

0652110200 1 RT REAR CHN GD ASSY

2 0652110210 1 MOUNTING BRKT, RIGHT

0652110310 2 MOUNTING BRKT, LEFT

3 00751126 110 CHAIN 5/16 WLD 6 LINK

4 0652110201 2 ROD CHAIN

5 00013300 2 HEXB 1/2 NC 2 PL5

9 652053 8 SPACER

10 00752680 6 HHCS 1/2-13UNC X 4LG PL5

12 7A81336 2 C/S1/2 X 4-1/2 NC PL5

Complete Rear Chain Guard Assembly to include center, left and right wing. See Center Chain Guard Section. These are

the same for all previous serial #’s listed without modification. Chain Guards with welded on links are no longer available.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 17

Page 20

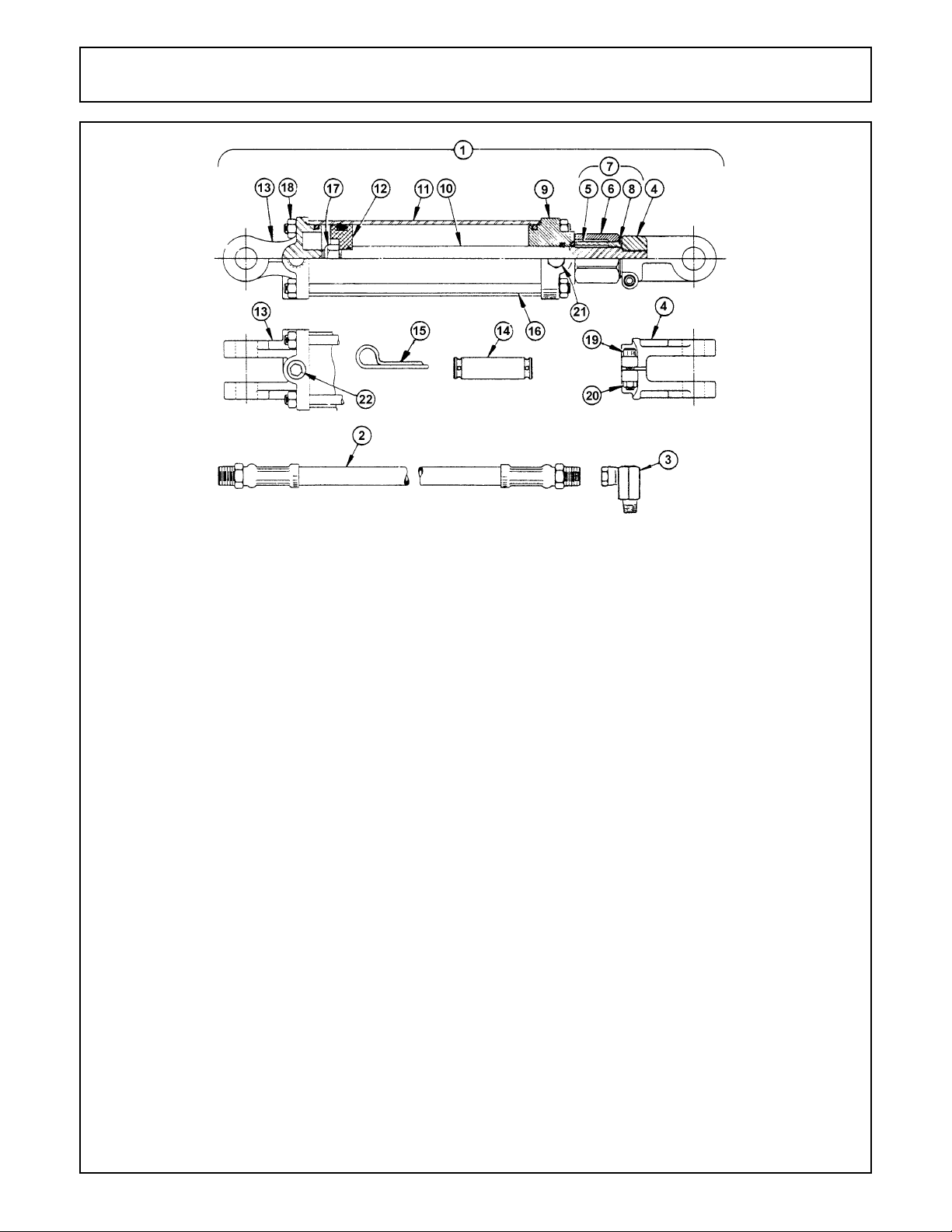

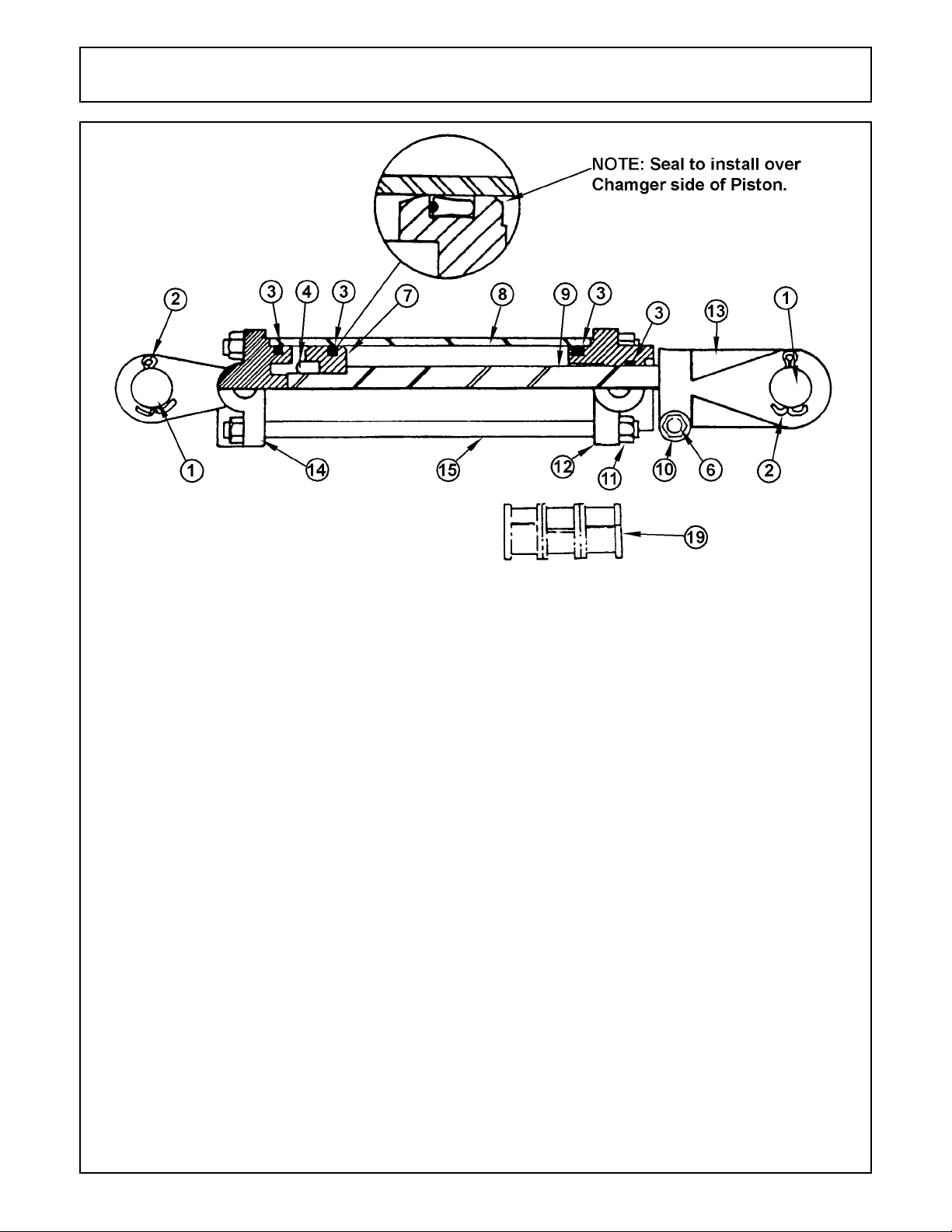

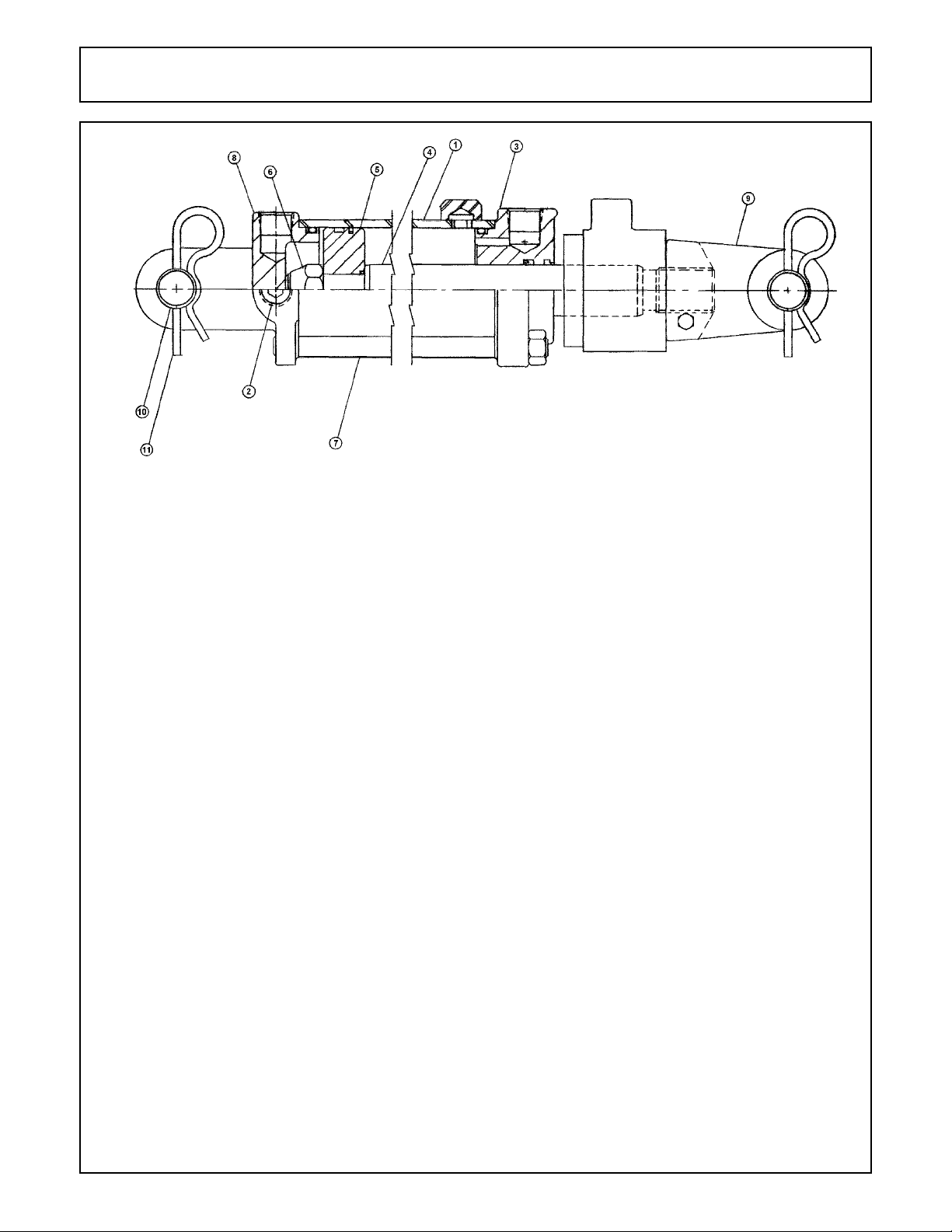

CYLINDER ASSEMBLY - CENTER AXLE S/N 00101 - 01377 OCT 1977 - JAN 1982

ITEM PART NO. QTY. DESCRIPTION

1 65113B1 1 CYLINDER

00759946 1 CYLINDER 3 X 8 W/1-1/4 ROD

00755234 1 CONTROL SPACER KIT

2 651302 1 HOSE #6 - 8 MP - 8 MP 180 LG

3 94514 1 ADAPTER, HYD, ELBOW SWIVEL

4 691354 1 CLEVIS 1 1/4-12 NF THD

65113A3 1 CLEVIS 1/16-12 NF THD

7 65113B6 1 COLLAR

651136 1 COLLAR

9 65113B8 1 HEAD 1 1/4 ROD 3 BR

65113A8 1 HEAD 1 1/16 ROD 3 BR

10 65113A9 1 ROD 1 1/4

651139 1 ROD, 1-1/16 DIA.,3/4NF THDS.

11 6511310 1 TUBE CENTER CYL

12 691315 1 PISTON, 3, O RING SEAL

6511311 1 PISTON, 3, UCUP SEAL

13 65113A12 1 CLEVIS BASE 1/2

0651130001 1 CLEVIS BASE 7/16

14 8354 2 PIN-HYD. CYLINDER

15 37107B13 2 CLIP-X HAIR PIN

16 65113A16 4 TIE ROD 1/2 - 13

0651130017 4 TIE ROD

17 6511320 1 NUT, PISTON (3/4-NF HEX)

18 00001200 1 NUT,HEX 1/2 NC PL

00999316 4 NUT HEX 7/16 NC PL

19 6511322 1 BOLT

20 00013901 1 NUT HEX 3/8 NC PL

21 6511324 1 BREATHER,1/2 SQ HD CORED

22 00749508 1 PLUG 1/2-14 NPT

2717100 - SEAL KIT 1 1/4

6511325A - SEAL KIT,3 CROSS CYLINDER 1 1/16

Note: This cylinder was used approx. through 1982. Always check length of barrel, type of stroke control, size and rod

(Item #10), size of tie rods. (Item #16) before ordering parts. Replacement part # for complete assembly is 00759946 and

the stroke control spacer kit is 00755234. This cylind

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 18

Page 21

CYLINDER ASSEMBLY - CENTER AXLE S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

00759946 CYLINDER 3 X 8 W/1-1/4 ROD

1 8354 2 PIN-HYD. CYLINDER

2 163016 2 PIN, COTTER 3/16 X 2

3 00760199 1 SEAL KIT (3 DIA HYD CYL)

4 4675M 1 NUT PISTON

5 7339 1 BREATHER, CYLINDER

6 00023100 1 HHCS 3/8 -16UNC 1-1/2 PL5

7 00760661 1 PISTON FOR 3BORE CYL

8 00760194 1 TUBE, CYL 3X8

9 00760200 1 PISTON ROD

10 4376 1 NUT HEX 1/2-20 NF PL

11 4690W 8 INSTALL SHEET-BELT TENSIONER&S

12 00760197 1 HEAD, CYL 3

13 8754 1 CLEVIS,OUTER

14 00760196 1 BASE, CYL 3

15 00760202 4 ROD,CYL TIE (1/2NFX13)3X8 CYL

19 00755234 1 CONTROL SPACER KIT

00760199 SEAL KIT (3 DIA HYD CYL)

REPLACEMENT PARTS ONLY

Replacement cylinder not used in production. Used as replacement assembly. Parts WILL NOT interchange with earlier

cylinder.

Note: No screw on stroke control - use clip on spacers. (Item # 19)

Seal Kit # 00760199 contains both old and new style piston seals. New style seal can be installed in old style piston.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 19

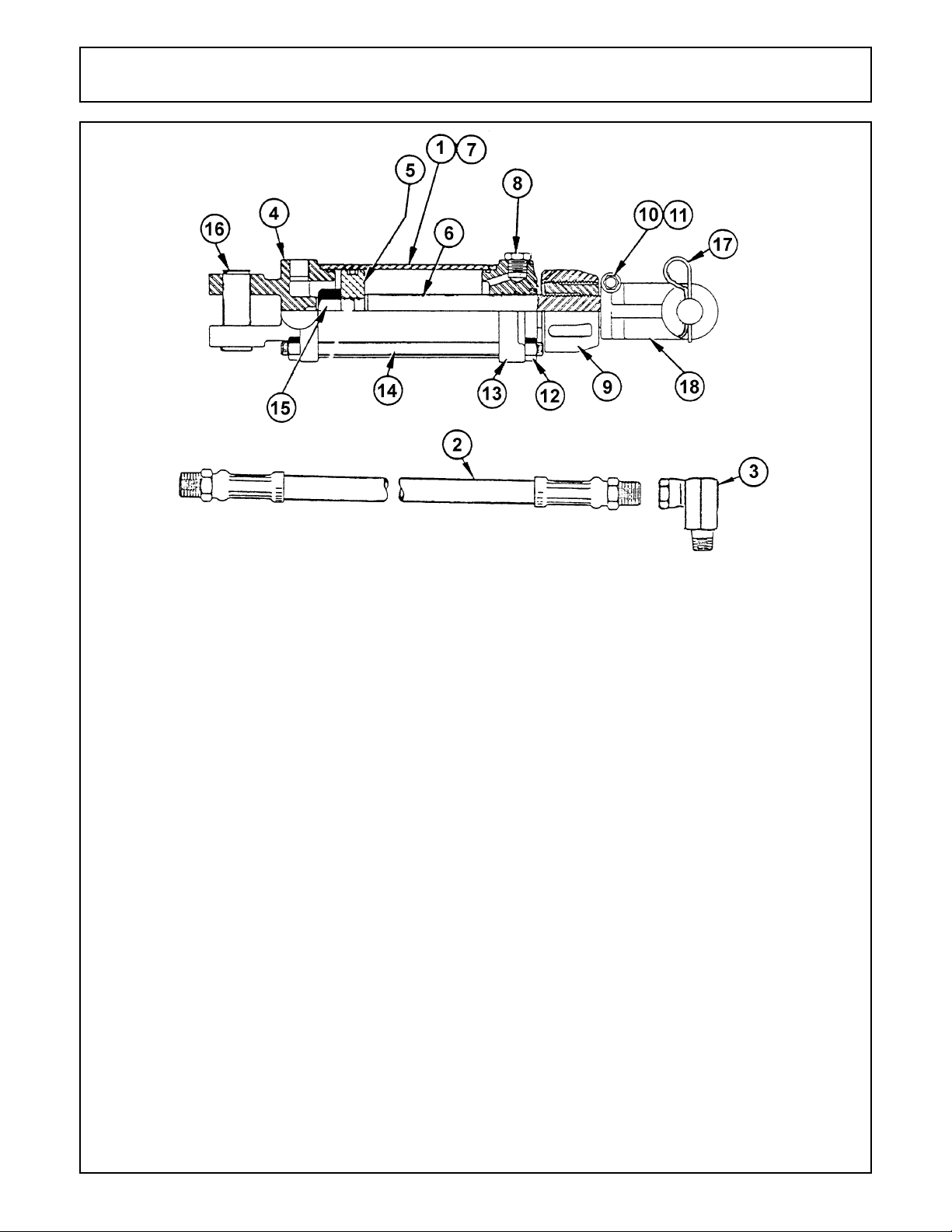

Page 22

CYLINDER ASSEMBLY - CENTER AXLE S/N 01376 - 10429 JAN 1982 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 65113B1 1 CYLINDER

2 651302 1 HOSE #6 - 8 MP - 8 MP 180 LG

3 94514 1 ADAPTER, HYD, ELBOW SWIVEL

4 0651130001 1 CLEVIS BASE

5 0651130005 1 PISTON

6 0651130006 1 ROD

7 0651130007 1 BARREL

8 00750208 1 PLUG,BREATHER 1/2 NPTM - 007

9 0651130012 1 STROKE CONTROL

10 5B6240 1 NUT,ROD CLEVIS

11 7E62414 1 SHCS 3/8 NF 1-3/4

12 02816800 8 NUT 1/2 NF HEX

13 0651130016 1 HEAD 3 HYD CYL 1-1/4 ROD

14 0651130017 4 TIE ROD

15 691351 1 NUT

16 8354 2 PIN-HYD. CYLINDER

17 00000400 4 PIN-COTTER 1/8 X 1-1/2 PLATED

18 0651130022 1 CLEVIS 1-14 NF THD

0651130014 - SEAL KIT,3 LANTEX CYLINDER

Note: This cylinder was used approx. after 1982. Always check length of barrel, and type of stroke control before ordering

part. Replacement part # for complete cylinder assy is 00759946, and stroke control spacer kit is 00755234. Parts Will

Not Interchange.

This is an lantex cylinder length of barrel (Item #7) is 10 1/8" long. Stroke control (Item #9) is round with notches cast into

it.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 20

Page 23

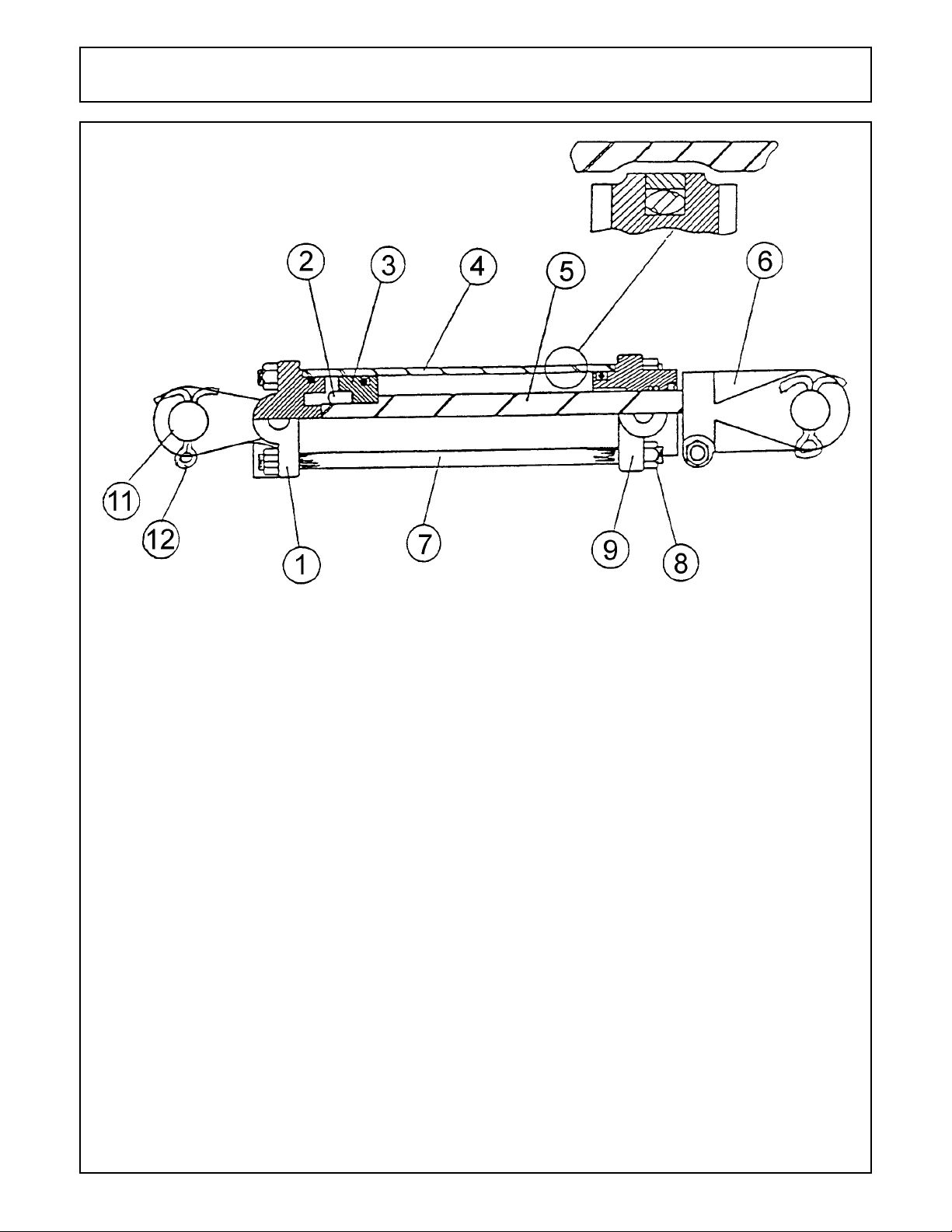

CYLINDER ASSEMBLY - LEVEL LIFT - 2-1/2 X 8 SLAVE CYL S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

0652141500 - CLY, LEVEL LIFT

1 0652141501 1 PISTON ROD

2 0652141312 1 PLUG, STRAIGHT ADAPTER

3 0652141502 1 TUBE

4 0652141503 1 HEAD

5 0652141504 1 PISTON

6 5JRC10180 1 NUT TOPLOCK 5/8 NF PLC

7 0652140305 4 TIEROD,HYD CYL W/NUT

8 0652141506 1 CLEVIS,BASE

9 0652140307 1 CLEVIS, ROD

10 691356 2 PIN

11 37107B13 4 CLIP-X HAIR PIN

12 0652141311 2 ADP HYD STGHT 8MB - 8FP

13 691302 1 HYD HOSE-3/8-8W/ 1/2 FITTING (NOT SHOWN)

14 B651302 1 HOSE #6 - 8MP - 8MP - 180LG (NOT SHOWN)

15 6513015 1 HOSE #6 - 8 MP - 8 MP 216 LG (NOT SHOWN)

16 B65113A2 1 HYD HOSE ONE (NOT SHOWN)

17 94514 6 ADAPTER, HYD, ELBOW SWIVEL (NOT SHOWN)

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 21

Page 24

CYLINDER ASSEMBLY - LEVEL LIFT - 2-3/4 X 8 SLAVE CYL S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

0652141400 - HYD CYL KIT

1 0652141401 1 ROD,PISTON

2 0652141312 1 PLUG, STRAIGHT ADAPTER

3 0652141402 1 TUBE HYD CYL

4 0652141403 1 GLAND,ROD END

5 0652141404 1 PISTON

6 5JRC12100 1 NUT TOPLOCK 3/4

7 0652140305 4 TIEROD,HYD CYL W/NUT

8 0652141406 1 CLEVIS,BASE

9 0652140307 1 CLEVIS, ROD

10 691356 2 PIN

11 37107B13 4 CLIP-X HAIR PIN

12 0652141311 2 ADP HYD STGHT 8MB - 8FP

13 691302 1 HYD HOSE-3/8-8W/(1/2FITTING (NOT SHOWN)

14 B651302 1 HOSE #6 - 8MP - 8MP - 180LG (NOT SHOWN)

15 6513015 1 HOSE #6 - 8 MP - 8 MP 216 LG (NOT SHOWN)

16 B65113A2 1 HYD HOSE ONE (NOT SHOWN)

17 94514 6 ADAPTER, HYD, ELBOW SWIVEL (NOT SHOWN)

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 22

Page 25

CYLINDER ASSEMBLY - LEVEL LIFT - 3 X 8 SLAVE CYL S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

0652141300 - HYD CYL KIT

1 0652141301 1 PISTON ROD

2 0652141312 1 PLUG, STRAIGHT ADAPTER

3 0652141302 1 TUBE

4 0652141303 1 HEAD

5 0652141304 1 PISTON

6 6511320 1 NUT, PISTON (3/4-NF HEX)

7 0652140305 4 TIEROD,HYD CYL W/NUT

8 0652141306 1 BASE CLEVIS

9 0652140307 1 CLEVIS, ROD

10 691356 2 PIN

11 37107B13 4 CLIP-X HAIR PIN

12 691302 1 HYD HOSE-3/8-8W/ 1/2FITTING (NOT SHOWN)

13 B651302 1 HOSE #6 - 8MP - 8MP - 180LG (NOT SHOWN)

14 6513015 1 HOSE #6 - 8 MP - 8 MP 216 LG (NOT SHOWN)

15 B65113A2 1 HYD HOSE ONE (NOT SHOWN)

16 94514 6 ADAPTER, HYD, ELBOW SWIVEL (NOT SHOWN)

Note; Center Cylinder has stroke control (Item 13) on shaft. The unit must already have hydraulic cylinders to fit arms and

deck.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 23

Page 26

CYLINDER ASSEMBLY - LEVEL LIFT REPLACEMENT ASSY (P/N 8719) S/N 00101 - 10429 OCT 1977 - MA

ITEM PART NO. QTY. DESCRIPTION

8719 1 HYDRAULIC CYLINDER

1 8772 1 CAP

2 4705M 1 PISTON NUT

3 8768 1 PISTON

4 8769 1 TUBE

5 4706 1 PISTON ROD

6 8754 1 CLEVIS,OUTER

7 8773 4 TIE ROD

8 4689 8 NUT HEX 9/16-18NF PL

9 8774 1 HEAD

10 8764 1 SEAL KIT

11 8354 2 PIN-HYD. CYLINDER

12 163016 4 PIN, COTTER 3/16 X 2

?13 00755234 1 CONTROL SPACER KIT (NOT SHOWN.)

Note: Center cylinder WILL NOT have screw on stroke control. The unit must already have hydraulic level left for these

cylinders it mount to axle arms and deck.

REPLACE CYL’S ONLY NOT USED IN PRODUCTION UNIT, PARTS WILL NOT INTERCHANE WITH EARLIER

CYLINDERS.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 24

Page 27

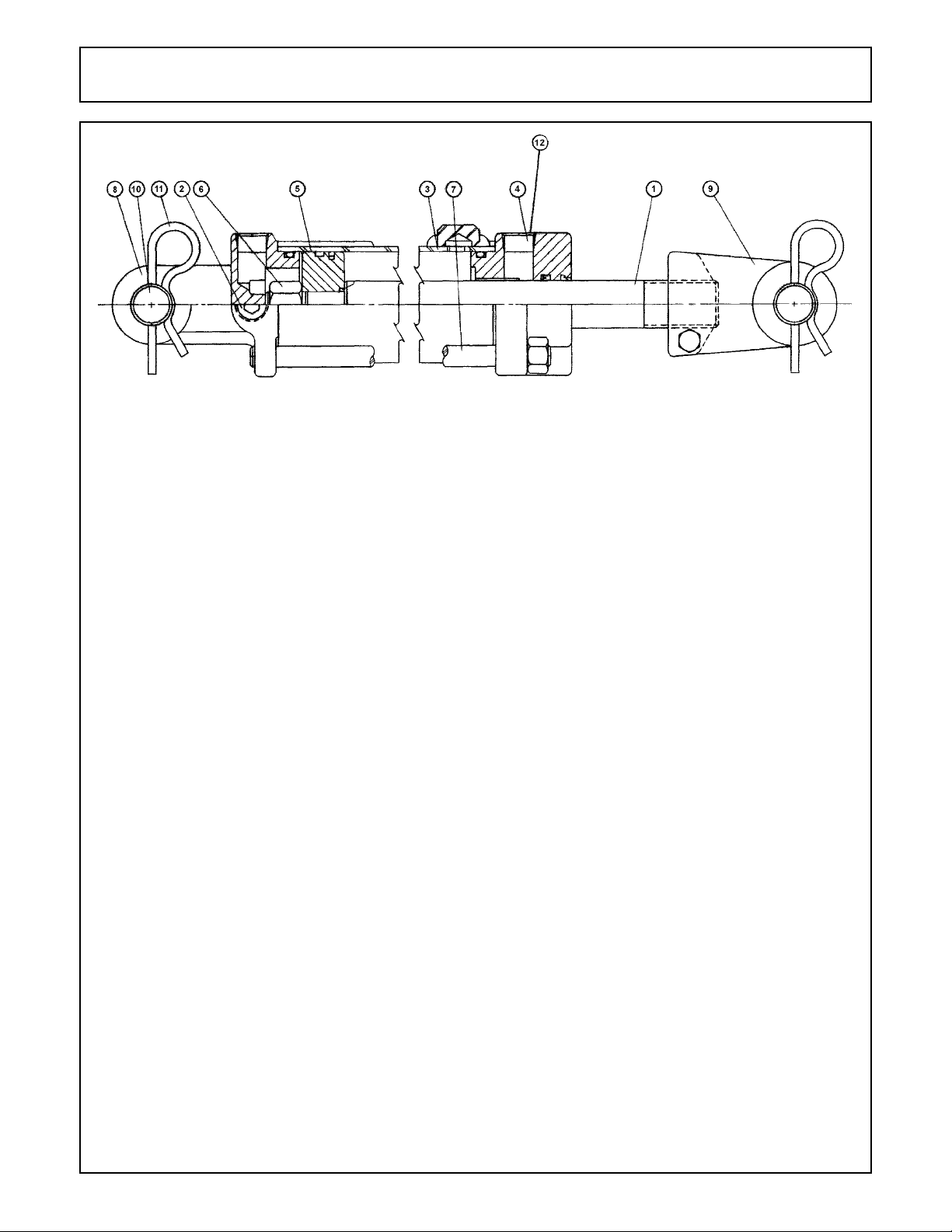

CYLINDER ASSEMBLY - LEVEL LIFT REPLACEMENT ASSY (P/N 8720) S/N 00101 - 10429 OCT 1977 - MA

ITEM PART NO. QTY. DESCRIPTION

8720 - WING AXLE 3 1/4 X 8 SLAVE CYLINDER

1 8778 1 BASE CLEVIS

2 4705 1 PISTON NUT

3 8775 1 PISTON

4 8776 1 TUBE

5 4706 1 PISTON ROD

6 8754 1 ROD CLEVIS

7 8773 4 TIE ROD

8 4689 8 NUT 9/16 - 18

9 8779 1 HEAD

10 8765 1 SEAL KIT

11 8354 2 PIN, CLEVIS

12 163016 4 COTTER PIN

Note: Center cylinder WILL NOT have screw on stroke control. The unit must already have hydraulic level left for these

cylinders it mount to axle arms and deck.

REPLACE CYL’S ONLY NOT USED IN PRODUCTION UNIT, PARTS WILL NOT INTERCHANE WITH EARLIER

CYLINDERS.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 25

Page 28

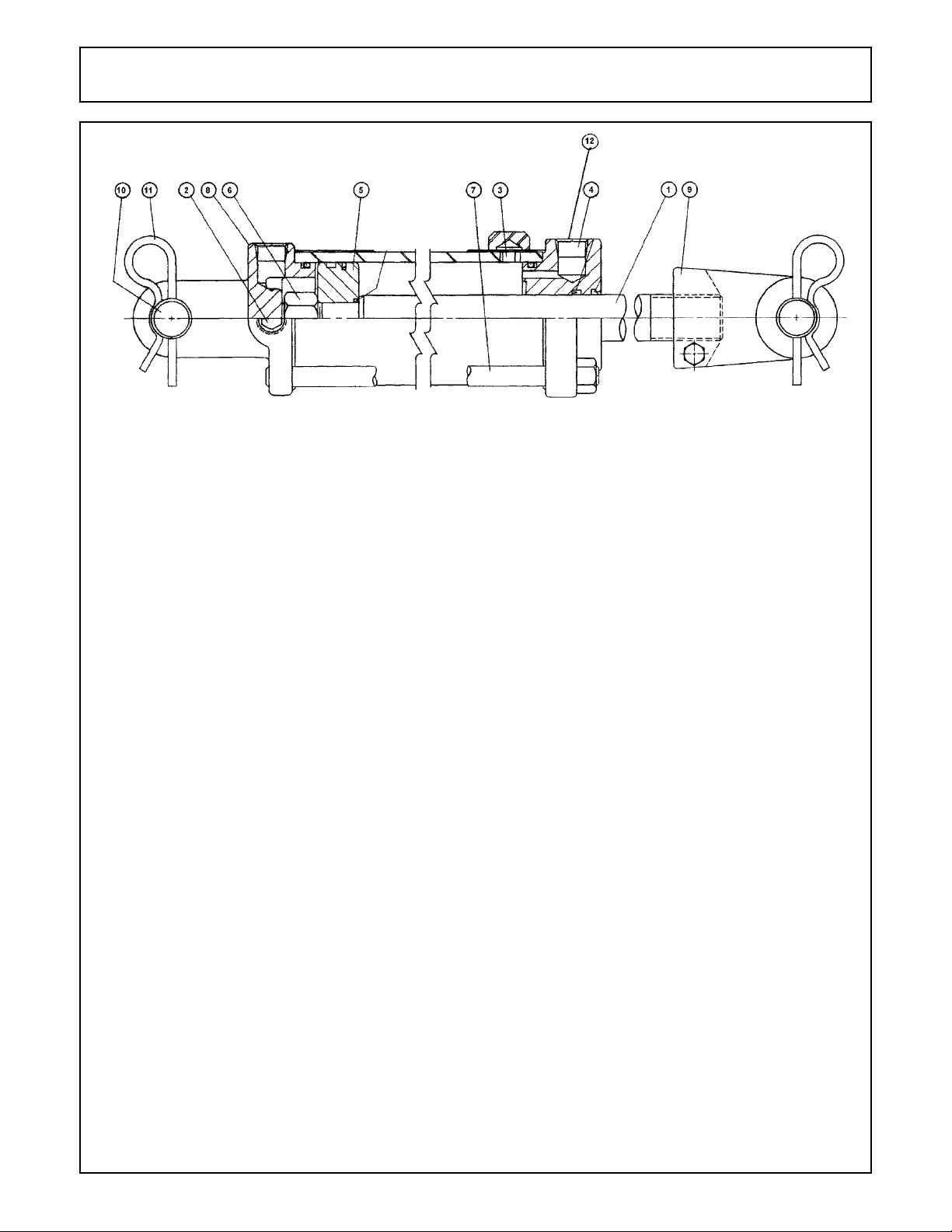

CYLINDER ASSEMBLY - LEVEL LIFT REPLACEMENT ASSY (P/N 8721) S/N 00101 - 10429 OCT 1977 - MA

ITEM PART NO. QTY. DESCRIPTION

8721 1 CYL HYD LEVEL LIFT 3 DIA

1 8784 1 CAP (HYD. CYLINDER)

2 4675M 1 NUT PISTON

3 8780 1 PISTON

4 8781 1 TUBE

5 8753 1 PISTON ROD

6 8754 1 CLEVIS,OUTER

7 8785 4 TIE ROD

8 4376 8 NUT HEX 1/2-20 NF PL

9 8786 1 HEAD

10 8766 1 SEAL KIT

11 8354 2 PIN-HYD. CYLINDER

12 163016 4 PIN, COTTER 3/16 X 2

Note: Center cylinder WILL NOT have screw on stroke control. The unit must already have hydraulic level left for these

cylinders it mount to axle arms and deck.

REPLACE CYL’S ONLY NOT USED IN PRODUCTION UNIT, PARTS WILL NOT INTERCHANE WITH EARLIER

CYLINDERS.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 26

Page 29

CYLINDER ASSEMBLY - WING-HYDRAULIC CYLINDER & HOSE GROUP S/N 00101 - 01376 OCT 1977 - JAN

ITEM PART NO. QTY. DESCRIPTION

1 00759947 1 CYLINDER 3 X 14 W/1-1/4 ROD

2 6513015 1 HOSE #6 - 8 MP - 8 MP 216 LG

3 94514 1 ADAPTER, HYD, ELBOW SWIVEL

4 691351 2 NUT

65130A12 1 CLEVIS 1 1/8-12 NF THD

5 65113B8 1 HEAD 1 1/4 ROD 3 BR

65130A4 1 HEAD 3 BORE X 1-1/8 ROD

65130A4 1 HEAD 3 BORE X 1-1/8 ROD

6 65130B15 1 ROD,CYL 1-1/4 DIA,1-1/4-12 THD

651306 1 ROD

7 651307 1 TUBE OUTBOARD

8 691315 1 PISTON, 3, O RING SEAL

6511311 1 PISTON, 3, UCUP SEAL

9 65113A12 1 CLEVIS BASE 1/2

0651130001 1 CLEVIS BASE 7/16

10 8354 2 PIN-HYD. CYLINDER

11 00000400 4 PIN-COTTER 1/8 X 1-1/2 PLATED

12 65130A8 4 TIE ROD 1/2 X 19

0651300003 4 ROD

13 6511320 1 NUT, PISTON (3/4-NF HEX)

14 00001200 8 NUT,HEX 1/2 NC PL

5B7140 8 NUT 7/16 NC HEX

15 6511322 1 BOLT

16 00013901 1 NUT HEX 3/8 NC PL

17 00750208 1 PLUG,BREATHER 1/2 NPTM - 007

18 00749508 1 PLUG 1/2-14 NPT

65113A30 - SEAL KIT 3 CR CYL, 1 1/4

6513011A - SEAL KIT,3 CROSS CYLINDER 1 1/8

Note: This cylinder used throught approx 1982. Check length of barrel before ordering replacement pars. If the cylinder

was used check size of tie rods (Item #12) and size of cylinder rod (Item #6).

REPLACEMENT PARTS FOR THIS COMPLETE CYLINDER ASSY IS 00759947.

PARTS WILL NOT INTERCHANGE.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 27

Page 30

CYLINDER ASSEMBLY - WING-LANTEX HYDRAULIC CYL & HOSE GRP S/N 01377 - 10429 JAN 1982 - MAY

ITEM PART NO. QTY. DESCRIPTION

1 65130B1 1 HYD. CYL. 3" BORE X 14" STROKE 1-1/4" DIA. ROD BASE END

2 6513015 1 HOSE #6 - 8 MP - 8 MP 216 LG

3 94514 1 ADAPTER, HYD, ELBOW SWIVEL

4 0651130001 1 CLEVIS BASE

5 0651130005 1 PISTON

6 0651300001 1 ROD

7 0651300002 1 TUBE

8 5B6240 1 NUT,ROD CLEVIS

9 7E62414 1 SHCS 3/8 NF 1-3/4

10 0651130022 1 CLEVIS 1-14 NF THD

11 02816800 8 NUT 1/2 NF HEX

12 0651130016 1 HEAD 3 HYD CYL 1-1/4 ROD

13 0651300003 4 ROD

14 691351 1 NUT

15 8354 2 PIN-HYD. CYLINDER

16 00000400 4 PIN-COTTER 1/8 X 1-1/2 PLATED

17 00750208 1 PLUG,BREATHER 1/2 NPTM - 007

0651130014 - SEAL KIT,3 LANTEX CYLINDER

Note: This cylinder used approx. After 1982 always check barrel lenght (Item #7) before ordering replacement parts.

REPLACE THIS CYLINDER ASSY WITH #00759947.

PARTS WILL NOT INTERCHANGE.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 28

Page 31

CYLINDER ASSEMBLY - WING-REPLACEMENT S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 00759947 1 CYLINDER 3 X 14 W/1-1/4 ROD

2 00756496 1 HOSE-#4-6MP-6MP-216LG

3 94517 1 ADAPTER, HYD, ELBOW SWIVEL

4 7329 1 ADAPTER, HYD, STGHT RESTRICTOR

5 94507 1 ADAPTER, HYD, REDUCER

5 00760196 1 BASE, CYL 3

6 00760198 1 PISTON

7 00760201 1 ROD, CYL 3X14

8 00760195 1 TUBE, CYL 3X14

9 00013901 1 NUT HEX 3/8 NC PL

10 00023100 1 HHCS 3/8 -16UNC 1-1/2 PL5

11 8754 1 CLEVIS,OUTER

12 4690W 8 INSTALL SHEET-BELT TENSIONER&S

13 00760197 1 HEAD, CYL 3

14 00760203 4 TIE ROD, CYL 3X14

15 4675M 1 NUT PISTON

16 8354 2 PIN-HYD. CYLINDER

17 162012 2 PIN,COTTER

18 6511324 1 BREATHER,1/2 SQ HD CORED

?19 00760199 SEAL KIT (3 DIA HYD CYL)

Note: This is a replcaement cylinder and was not used in production.

PARTS WILL NOT INTERCHANGE WITH EARLIER CYLINDERS.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 29

Page 32

DECALS S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 D303 3 DECAL,RHINO

2 D301 1 DECAL,RHINO

3 D337 3 DECAL-FLX-S-15

5 D121 1 DECAL ADJ-NUTS

6 D122 1 DECAL(PREV. STREAKNG)

7 999200 1 DECAL GENERAL WARNING ALL UNIT

8 D112 1 DECAL USE SAE GER LUB

9 D103 1 DECAL,OPERATE AT 540 RPM

10 D102 1 DECAL PTO SFT TO HTCH

11 D101A 4 DECAL OIL LEVEL

12 D137 1 DECAL CCW BLADE ROTATION

13 99203 2 DECAL, RED REFLECTOR

14 D138 1 DECAL-CW BLADE ROTATION

15 D131 1 DECAL NOTICE

16 D304 2 DECAL (RHINO)

17 NFS 1 SERIAL NUMBER PLATE

18 999403 1 DECAL-DANGER, OFFSET WGT. BOX

21 00756494 3 DECAL-DANGER,DRIVELINE

23 99204 1 DECAL-YELLOW REFLECTOR

24 999401 2 DECAL, ROTATING BLADE

26E127001 A/R PAINT,1 QT,RH ORANGE

26E127004 A/R PAINT, 1 GAL,RH ORNG

26E127000 A/R PAINT,(SPRAY)RHINO ORANGE

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 30

Page 33

DEFLECTOR - REAR WING S/N 01497 - 10429 JUN 1982 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

6 00002700 10 FLATWASHER 1/2 PL STD

7 00001800 10 LOCKNUT TLM 1/2 NC PLB

8 00756876 2 WING REAR COVER

13 02030700 7 HHCS 1/2-13UNC 1-1/4 PL5

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 31

Page 34

DEFLECTOR - RUBBER FRONT CENTER S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

00758370 1 DEFLECTOR, ASY, FRT CTR

1 00758261 1 BAND RUBBER GD FRT CTR

2 00758263 1 PANEL RUBBER GD FRT CTR

3 02030700 3 HHCS 1/2-13UNC 1-1/4 PL5

4 00001800 3 LOCKNUT TLM 1/2 NC PLB

Note: These will not fit earlier serial numbers. Complete of deflectors front-center, left and right wings assembly

#00758355.

For 10 foot unit order assembly #00756994.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 32

Page 35

DEFLECTOR - RUBBER FRONT WING LEFT & RIGHT S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

00758368 1 DEFLECTOR ASSEMBLY

1 00758264 1 PANEL

2 00758259 1 BAND

3 02030700 7 HEX BOLT

4 00001800 7 LOCKNUT

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 33

Page 36

DEFLECTOR - RUBBER LEFT & RIGHT CENTER S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

00758369 1 DEFLECTOR, ASY, FRT L-R CTR

1 00758262 1 PANEL RUBBER GD L&R CTR

2 00758260 1 BAND, RUBBER GD LH & RH

3 02030700 2 HHCS 1/2-13UNC 1-1/4 PL5

4 00001800 2 LOCKNUT TLM 1/2 NC PLB

Note: These will not fit earlier serial numbers. Complete of deflectors front-center, left and right wings assembly

#00758355.

For 10 foot unit order assembly #00756994.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 34

Page 37

DRIVELINE ASSEMBLY - CTR GEARBOX SQUARE SHAFT SLIP 35R S/N 00101 - 10429 OCT 1977 - MAY 19

ITEM PART NO. QTY. DESCRIPTION

1 0657070000 1 DRIVELINE, SLIP ASSY

W707LSA 1 CTR D/L,S15,

2 W341 1 SHAFT SQ

3 W324 1 YOKE 1 3/16 SQ HOLE PAINT BLK

4 9C482010 1 SHSS 1/2 NF 1-1/4

5 5B8200 1 NUT 1/2 NF HEX

6 W318 1 YOKE W/TAPERED SHAFT PAINT BLK

W284A 1 YOKE,SLIDE COLLAR PAINT BLACK

7 W3071 1 YOKE, TORQUE LIMITER (7-1/16

8 271105B 1 BUSHING SP & TL YOKE

9 7AH551816 4 HEXB 5/16NC 2

10 5JRC5180 4 NUT TOPLOCK 5/16

11 W279R 2 CROSS REPAIR KIT, CTR

12 W324A 1 YOKE,1-3/16 SQ HOLE W/SETSCREW

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 35

Page 38

DRIVELINE ASSEMBLY - OUTBOARD SQUARE SHAFT ASSEMBLY 35R S/N 00101 - 10429 OCT 1977 - MAY 1

ITEM PART NO. QTY. DESCRIPTION

1 W705RB7 1 SHFT, SHLD,SM TL YK

2 W316B 1 YK & SHFT ASSY 39-1/8

3 W3071 1 YOKE, TORQUE LIMITER (7-1/16

4 271105B 1 BUSHING SP & TL YOKE

5 W279R 1 CROSS REPAIR KIT, CTR

6 7AH551816 4 HEXB 5/16NC 2

7 5JRC5180 4 NUT TOPLOCK 5/16

8 W702RZ4 1 HSG, SHLD,TPR YOKE

W702RZ 1 HSG, SHLD,QD YOKE

9 W312Z 1 YOKE TB & SLV 50

10 W318 1 YOKE W/TAPERED SHAFT PAINT BLK

W284A 1 YOKE,SLIDE COLLAR PAINT BLACK

11 17C1981 1 GREASE ZERK

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 36

Page 39

DRIVELINE ASSEMBLY - PTO SQUARE SHAFT ASSEMBLY 44R S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 W805O4 1 SHFT, SHLD,TPR YK PAINT BLACK

W805O11 1 SHAFT 44R SQ ASY 1-3/4-20 SPL

2 W816A 1 YOKE SHAFT PAINT BLACK

3 W826 1 YOKE,SAE TAPER PAINT BLACK

W827A 1 YOKE,CLP,1-3/4-20SP PAINT BLK

4 W840 1 CROSS REPR KIT

5 W802B 1 HSG,SHLD,QD YK PAINT BLACK

6 W812A 1 YOKE SLEEVE PAINT BLACK

7 W821A 1 YOKE,Q.D. 6BSPLN PAINT BLACK

8 W44B2A 1 QD REPAIR KIT

9 W44B3 1 SPRING-PIN LOCK

10 W44B4A 1 WASHER X

11 17C1981 1 GREASE ZERK

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 37

Page 40

DRIVELINE ASSEMBLY - SHIELDING ASSEMBLY SQUARE SHAFTS S/N 00101 - 10429 OCT 1977 - MAY 198

ITEM PART NO. QTY. DESCRIPTION

1 W811Q AR SHIELD D/L OUTER PAINT BLACK

W815R AR SHLD IN ASSY PAINT BLACK

2 W315RA1 AR SHIELD ASSY, INNER

4 W311RZ1 AR SHIELD, OUTER

5 W335 AR BEARING, NYLON

00751176 AR RETAINER, NYLON BRG.

6 W936 AR WASHER THRUST

7 W937 AR RING SNAP

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 38

Page 41

NOTES

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 39

Page 42

GEARBOX ASSEMBLY - CENTER SECTION S/N 00101 - 10429 OCT 1977 - MAY 1988

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 40

Page 43

GEARBOX ASSEMBLY - CENTER SECTION S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 7010414 1 HOUSING MAIN

2 00748532 1 HOUSING-BEARING CAP

3 00752155 1 CAP BEARING RETAINING

4 7010416 1 SHAFT, INPUT 1-3/8-6

5 701047R 1 OUTPUT SHAFT & GEAR

6 00752159 1 GEAR BEVEL-22 TOOTH

7 00748527 1 BEARING CONE TIMKEN #LM603049

8 00748525 1 BEARING CUP

9 00753738 1 BEARING CONE 16137

10 00753737 1 BEARING CUP 16282

11 00748522 2 BEARING CONE

12 701044R 2 BEARING CUP 363

13 00749509 1 SEAL

14 00748519 1 OIL SEAL

15 7010422 1 RING

16 00748526 2 RING, RETAINING

17 701046R 1 SPACER

18 00758647 A/R SHIM, ADJUSTMENT .010 OR .25M

19 7010419 A/R SHIM KIT

20 00758648 1 SHIM ,ADJUSTMENT O.5

21 00011400 8 HHCS 3/8 NC 1 PL5

22 02030700 4 HHCS 1/2-13UNC 1-1/4 PL5

23 7AH5121620 4 C/S 3/4 X 2 1/2 NF 5

24 00011700 8 LOCKWASHER 5/16 PL STD

25 00753743 4 LOCKWASHER

26 00748547 1 FLATWASHER 1-1/32 X 2-3/16X.22

27 00748539 4 NUT TOPLOCK 3/4 NF PLB

28 5E16140 1 NUT CASTLE 1 -14 STD PL

29 00606000 1 PIN-COTTER 3/16 X 2

30 00565000 1 PLUG, HEX HEAD PIPE 1/8-27NPT

31 00749508 2 PLUG 1/2-14 NPT

32 5312316 4 WASHER (SPECIAL)

NOTE: ITEM 15,23,27, & 32 NOT INCLUDED WITH GEARBOX ASSEMBLY AND MUST BE SPECIFIED WHEN

ORDERING 701041 GEARBOX ASSEMBLY.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 41

Page 44

GEARBOX ASSEMBLY - DIVIDER (COMER) S/N 01901 - 10429 FEB 1985 - MAY 1988

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 42

Page 45

GEARBOX ASSEMBLY - DIVIDER (COMER) S/N 01901 - 10429 FEB 1985 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

0656030000 DIVIDER GEARBOX

1 00753232 1 CASING

2 00753240 1 COVER

3 00753233 1 SHAFT

4 00753221 2 SHAFT

5 00753234 1 CROWNWHEEL

6 00753228 2 BEVEL PINION

7 00753223 4 BEARING

8 00755070 2 BEARING

9 00753238 2 OIL SEAL

10 00753225 2 OIL SEAL

11 00753237 2 INTERNAL CIRCLIP

12 00753237 2 INTERNAL CIRCLIP

13 00753239 1 OIL FILLER PLUG

14 00753226 2 PLUG

15 00753230 6 HEXB METRIC 8-P1.25- 30MM PL5

16 00753231 6 SCHNORR WASHER

17 00755069 1 GASKET

19 00753222 2 SHIM

21 00753235 2 SHIM

22 00753227 2 TAKE-UP RING

NOTE: ITEMS 30 AND 31 ARE NOT FURNISHED WITH THE GEARBOX ASSEMBLY. THIS GEARBOX HAS 1 3/8

TAPER SHAFTS.

P/N 651033 GEAR REPLACE BY P/N 00757028.

Offest units used gearbox#0651030000 (same as #65103 except only on wing out put shaft) Cover #0682053, 6 bolts

#0682053, 6 bolts #7A10118, &6 lockwashers #131000.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 43

Page 46

GEARBOX ASSEMBLY - DIVIDER S/N 00101 - 01900 OCT 1977 - FEB 1985

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 44

Page 47

GEARBOX ASSEMBLY - DIVIDER S/N 00101 - 01900 OCT 1977 - FEB 1985

ITEM PART NO. QTY. DESCRIPTION

65103 GEARBOX ASSY

1 16212012 4 COTTER PIN

2 5312315 3 CASTE NUT (SPECIAL THIN)

3 5312316 4 SPECIAL WASHER (HEAT TREATED)

4 651035 1 INPUT SHAFT

5 651037 1 BEARING CARRIER CAP

6 7A1101110 18 PLACE BOLT

7 00757028 3 BEVEL GEAR, 18-TEETH

8 651031 1 PRIMARY GEAR BOX HOUSING

9 5312312 3 SHIM SET

10 PT204A 3 GASKET

11 531232 2 DRIVE SHAFT HOUSING

12 651036 2 OUTPUT SHAFT

13 W84 3 BEARING CUP

14 W83 3 BEARING CONE

15 PT103 2 OIL SEAL

16 271096 2 BEARING COLLAR

17 5312310 4 KEY (HEAT TREATED)

18 PT104 2 LOCKNUT

19 PT105 2 LOCKWASHER

20 531237 3 BEARING CUP

21 531238 3 BEARING CONE

22 PT209 3 WOODRUFF KEY

23 5310415 2 OIL SEAL

24 651034 1 GASKET

25 00001300 8 LOCKWASHER

26 00750959 8 CAPSCREW

27 301021 1 BREATHER PLUG

28 651032 1 GEAR BOX COVER PLATE

29 00751003 1 PIPE PLUG

30 00010300 6 LOCKWASHER

31 00752658 6 CAPSCREW

32 5DR12160 1 NUT

33 D112 1 DECAL (USE SAE GEAR LUBE)

34 D101A 1 DECAL (OIL LEVEL)

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 45

Page 48

GEARBOX ASSEMBLY - LEFT WING S/N 00101 - 10429 OCT 1977 - MAY 1988

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 46

Page 49

GEARBOX ASSEMBLY - LEFT WING S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

0656230000 GEARBOX

1 00563900 1 MAIN HOUSING

2 00564300 1 CAP, BEARING

3 711052 1 CAP W/SPACER

4 0656230001 1 SHAFT,1-3/8-6 INPUT W/PILOT

5 00564000 1 PINION OUTPUT SHAFT

6 00564600 1 INPUT GEAR

7 00564800 1 BEARING,BALL

8 00563700 3 BEARING, BALL

9 00757682 1 SPACER, BEARING

10 00564400 A/R SHIM

11 00563600 1 GASKET

12 00612703 2 SNAP-RETAINER RING

13 00564500 1 RING,RETAINING

14 00564100 3 RING, RETAINING

15 00563500 1 SEAL, OIL OUTPUT

16 00564200 1 OIL SEAL

17 00565000 1 PLUG, HEX HEAD PIPE 1/8-27NPT

18 00749508 1 PLUG 1/2-14 NPT

19 00011400 6 HHCS 3/8 NC 1 PL5

20 00753642 4 HHCS,3/8NC X 1-1/4,ZP,GRD5

22 7AH5101816 4 C/S 5/8 X 2 NF GR5

24 W67 4 WASHER

25 00011700 10 LOCKWASHER 5/16 PL STD

26 00748547 1 FLATWASHER 1-1/32 X 2-3/16X.22

28 5E16140 1 NUT CASTLE 1 -14 STD PL

29 00606000 1 PIN-COTTER 3/16 X 2

30 00749136 4 NUT TOPLOCK 5/8 NF PLB

IMPORTANT NOTE: Item #3 and Item #9 must be replaced together at the same time, do not change one without the

other. If #711052 or #6710510 is ordered a cup and spacer will be shipped together as a kit so order one # or the other,

not both.

ITEMS 12,22,24,29, AND 30 ARE NOT FURNISHED WITH GEARBOX ASSEMBLY AND MUST BE SPECIFIED, IF

REQUIRED.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 47

Page 50

GEARBOX ASSEMBLY - RIGHT WING S/N 00101 - 10429 OCT 1977 - MAY 1988

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 48

Page 51

GEARBOX ASSEMBLY - RIGHT WING S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

0656220000 - GEARBOX

1 0656220001 1 HOUSING

2 0656220003 1 CAP

3 00757683 1 CAP, OUTPUT

4 0656220002 1 SHAFT

5 00564000 1 PINION OUTPUT SHAFT

6 00564600 1 INPUT GEAR

7 00564800 1 BEARING,BALL

8 00563700 3 BEARING, BALL

9 00757682 1 SPACER, BEARING

10 00564400 A/R SHIM

11 00563600 1 GASKET

12 00612703 2 SNAP-RETAINER RING

13 00564500 1 RING,RETAINING

14 00564100 3 RING, RETAINING

15 00563500 1 SEAL, OIL OUTPUT

16 00564200 1 OIL SEAL

17 00565000 1 PLUG, HEX HEAD PIPE 1/8-27NPT

18 00749508 1 PLUG 1/2-14 NPT

19 00011400 6 HHCS 3/8 NC 1 PL5

20 00753642 4 HHCS,3/8NC X 1-1/4,ZP,GRD5

22 7AH5101816 4 C/S 5/8 X 2 NF GR5

23 00751003 1 PIPE PLUG 1/4 NPTM STANDARD

24 W67 4 WASHER

25 00011700 10 LOCKWASHER 5/16 PL STD

26 00768547 1 DECAL - PC2040

28 5E16140 1 NUT CASTLE 1 -14 STD PL

29 00606000 1 PIN-COTTER 3/16 X 2

30 00749136 4 NUT TOPLOCK 5/8 NF PLB

IMPORTANT NOTE: Item #3 and Item #9 must be replaced together at the same time, do not change one without the

other. If #711052 or #6710510 is ordered a cup and spacer will be shipped together as a kit so order one # or the other,

not both.

ITEMS 12,22,24,29, AND 30 ARE NOT FURNISHED WITH GEARBOX ASSEMBLY AND MUST BE SPECIFIED, IF

REQUIRED.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 49

Page 52

GEARBOX ATTACHMENT - DIVIDER & CENTER GEARBOX S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0651470000 1 SHIELD ASSEMBLY

0656130100 1 SHIELD, PRIMARY GEARBOX

2 0656520000 1 CTR GEAR BOX SHIELD

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 50

Page 53

GEARBOX ATTACHMENT- RIGHT & LEFT WING GEARBOX S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656451210 1 SHIELD WLD

0656451110 1 SHIELD WLD

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 51

Page 54

HOSE BRACKET COMPONENTS S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0651140100 1 WLDMT, HYD. HOSE BRKT

2 0651150100 1 HYD. HOSE BRKT.

3 02675800 2 HHCS 5/8-11UNC 1-1/2 PL5

4 00010400 2 NUT 5/8 NC HEX PL

5 00010300 2 LOCKWASHER 5/8 PL STD

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 52

Page 55

HUB ASSEMBLY - CENTER & OUTBOARD S/N 10148 - 10428 JAN 1988 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

00757241 WHEEL HUB, PREASSY

3 00756576 1 BEARING CUP OUTSIDE

4 00750434 1 BEARING CONE INSIDE

5 00756577 4 BEARING CUP INSIDE

6 00752177 5 BOLT, STUD 1/2-20 NF X 1-7/8

7 00750614 5 NUT 1/2-20NF 90DEG.CONE LUG PL

8 00756490 1 NUT SLOTTED THIN 1 NF PLC

9 00750616 1 OIL SEAL

10 00756493 1 WASHER

11 00756492 1 DUST CAP

12 00026200 1 PIN-COTTER 5/32 X 1-1/2

13 00003500 1 ZERK FITTING 1/8 STRAIGHT

14 00756489 1 HUB W/ CUPS & STUBS

15 0371242102 1 BEARING CONE

Note: This hub was used on all center and outboard, standard, level lift axles between these serial numbers. this hub has

no washer behind seal on spindle and logo cast into backside of hub.

When using sectional tires install item #7 flat against wheel, opposite picture.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 53

Page 56

HUB ASSEMBLY - OUTBOARD AXLES S/N 00101 - 10147 OCT 1977 - JAN 1988

ITEM PART NO. QTY. DESCRIPTION

271033 HUB GROUP ASSY

3 PT108 1 BEARING CUP

4 00006500 1 BEARING CONE

5 00016900 1 BEARING CUP

6 13198 5 BOLT, HUB

7 00750614 5 NUT 1/2-20NF 90DEG.CONE LUG PL

8 5DR12160 1 NUT 3/4 NF SLOTTED

9 00771458 1 OIL SEAL

10 15B1200 1 WASHER 3/4 P SAE

11 PT112 1 HUB CAP

12 1621/2010 1 CTR

13 00003500 1 ZERK FITTING 1/8 STRAIGHT

14 PT110SA 1 WHEEL HUB

15 PT109 1 BEARING CONE

Note: When using sectional tires install item #7 flat against wheel, opposite picture.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 54

Page 57

HUB ASSEMBLY - STANDARD CENTER AXLE S/N 00101 - 10147 OCT 1977 - JAN 1988

ITEM PART NO. QTY. DESCRIPTION

371247 HUB, ASY

3 00016900 1 BEARING CUP

4 371247E 1 BEARING CONE 342A

5 371247D 1 BEARING CUP 332

6 13198 5 BOLT, HUB

7 00750614 5 NUT 1/2-20NF 90DEG.CONE LUG PL

8 371247J 1 NUT, 7/8-14 UNF STD SLOTTED

9 371247F 1 SEAL

10 371247H 1 WASHER

11 371247H 1 WASHER

12 1621/2012 1 PINS-CTR 5/32 X 1 1/2

13 00003500 1 ZERK FITTING 1/8 STRAIGHT

14 371247SA 1 HUB

15 371247C 1 BEARING CONE

Note: Spindel will have washer welded to it behind seal. When using sectional tires install item #7 flat against wheel,

opposite picture.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 55

Page 58

HYDRAULIC CONTROL VALVE MOUNTING KIT S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 651401 1 MT BKT WLD

2 00016200 6 HHCS 5/16NC 2 PL5

3 13500 6 L WSHR 5/16

4 5B5180 6 NUT 5/16 NC HEX

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 56

Page 59

HYDRAULIC HOSE ADAPTERS S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

2 00275400 3 Q.D, COUPLER #8

4 651311 3 QD COUPLER HALF FEMALE

5 651312 3 COUPLER HALF, MALE

Note: Choice of couplers is up to the customer.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 57

Page 60

HYDRAULIC VALVE ASSEMBLY - DETENT W/SPRING ASSEMBLY S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

18 6514016 1 HOUSING DETENT

19 6514017 1 SLEEVE

20 6514018 1 WASHER

21 6514019 1 SPRING CENTERING (25#)

22 6514020 1 COLLAR STEP

23 6514021 1 WASHER

24 7E42012 1 C/S1/4 X 1 1/2 SK HD

25 6514022 1 CAP,END

26 7D42014 4 BOLT

27 6514023 1 BALL 1/4 STEEL

28 6514024 1 SPRING

29 6514025 1 PLUG

30 65140A54 1 WASHER

Standard quantities for one Detent Assembly 3 required per hydraulic valve.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 58

Page 61

HYDRAULIC VALVE ASSEMBLY - OPEN/CLOSED CENTER VALVE S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 19E13/41/2 2 PIPE BUSHING

2 65140A47 3 HANDLE

3 65140A48 3 KIT-PIN

4 7E4204 6 SHCS 1/4 NC 1/2

5 65140A46 3 BRKT

6 6514012 6 PLATE RETAINER

7 6514013 6 SEAL, O-RING

8 6514026 3 POPPET

9 6514027 3 SPRING,LIFT CHECK

10 6514028 3 SEAL, O-RING

11 6514029 3 PLUG

12 6514030 3 PLATE,1/16 ORIFICE

13 6514031 3 RETAINER

14 65140A50 1 NON -ADJUSTABLE RELIEF ASSEMBLY (OPEN CENTER ONLY)

15 6514042 1 CLOSED CENTER ASSEMBLY (CLOSED CENTER ONLY)

16 6514039 1 CONVERSION PLUG ASSEMBLY

17 6514037 1 NO-RELIEF ASSEMBLY (CLOSED CENTER ONLY)

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 59

Page 62

JACK ASSEMBLY - TOP WING S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0811140000 1 PARKING JACK

2 00749892 1 PIN-JACK RETAINING

3 00751685 1 PIN-CLIP HAIR

4 651081W 1 BKTS PARKING JACK

5 7A101116 2 BLT 5/8 X 2 ZP

6 131000 2 LOCK WASHER

7 5B10110 2 NUT 5/8 HEX, ZP

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 60

Page 63

LEFT SCREW S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656510000 1 MANUAL-LIFT SCREW

2 651062F 2 FITTING,GREASE (DRIVE TYPE)

3 00609200 2 HEXB 1 NC 4 GR5

4 02030300 2 NUT TOPLOCK 1 NC PLB

5 00760135 1 HANDLE,MANUAL LIFT SCREW

6 00756579 1 TOP LINK THREAD LOCK

?7 0656510001 1 MANUAL-LIFT SCREW

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 61

Page 64

LEVEL LIFT KIT FIELD INSTALLATION S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0652140120 1 WLDMT, BASE

2 0652140130 1 WLDMT, PIVOT ARM

3 0652140140 1 WLDMT, SPRING ROD

4 0652140150 1 SPRING GUIDE

5 371063A 1 SPRING

6 0652140160 1 PIN

7 691154 1 PIN

8 5GR12100 1 LOCKNUT TLM 3/4 NC PL

9 7AH5101132 2 C/S 5/8 X 4 NC GR.5

10 02956948 2 LOCKNUT 5/8 NC PLC

11 15B1600 1 WASHER 1 SAE P

12 163016 1 PIN, COTTER 3/16 X 2

13 65107A3C 1 WASHER

14 0652150100 1 AXLE LUG ASSEMBLY

0652150000 LEVEL LIFT KIT FS15

Note: Factory level lift did not use bracket #14 on axle arms. Axle arms had longer lugs on them.

To order complete field installation level lift kit, including hydraulic cylinders and hoses, order bundle #0652150000. (Most

current type cylinder used will be used shipped)

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 62

Page 65

LEVEL LIFT ROD ASSEMBLY S/N 10148 - 10428 JAN 1988 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 584042 2 WLDMT-ROD CONTROL

2 651101 2 ROD

3 00770485A 2 NUT,EXTENDED ADJUSTMENT

4 651102 4 PIN-DRILLED

5 5C1490 2 HEXNUT 7/8 JAM ZP

6 00606000 8 PIN-COTTER 3/16 X 2

7 15B1200 8 WASHER 3/4 P SAE

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 63

Page 66

MAINFRAME ASSEMBLY S/N 00101 - 01900 OCT 1977 - FEB 1985

ITEM PART NO. QTY. DESCRIPTION

1 0656011000 1 WLDMT, FS15 CTR SECT M.FF

2 0656020200 1 L/H O/B FRAME WLD

3 0656020100 1 R/H O/B FRAME WLD

4 65109 2 PIN HINGE

5 20A4012E 2 PIN

6 5710121 3 COVER PLATE

7 5F5180 6 NUT 5/16 NC WING

8 0656270000 2 T,SPACER,LONG

9 0656261000 2 SPACER,SHORT HINGE

0656260000 2 SPACER,SHORT

Note: Later models replaced lock pin w/bolts and nut. Part number 7A51812 bolt, 5GR5180 locknut.

PART NUMBER 0656261000 REPLACES PART NUMBER 0656260000 FOR SERIAL # 00631 AND ON. PART

NUMBER 0656261000, 21-5/8" LONG. PART #0656260000, 171/4" LONG.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 64

Page 67

MAINFRAME ASSEMBLY S/N 01901 - 10429 FEB 1985 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656011000 1 WLDMT, FS15 CTR SECT M.FF

2 0656020200 1 L/H O/B FRAME WLD

3 0656020100 1 R/H O/B FRAME WLD

4 65109 2 PIN HINGE

5 20A4012E 2 PIN

6 5710121 3 COVER PLATE

7 5F5180 6 NUT 5/16 NC WING

8 0656270000 2 T,SPACER,LONG

9 0656261000 2 SPACER,SHORT HINGE

0656260000 2 SPACER

Note: Later models replaced lock pin w/bolts and nut. Part number 7A51812 bolt, 5GR5180 locknut.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 65

Page 68

SKID SHOE & SIDE SKIRT - OFFSET MODELS CTR SECTION S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 652071 1 SIDESKIRT WLDMT, LEFT SIDE

2 65203L 1 SHOES SLIDE

3 2A381312 3 BOLT,PLOW 1/2 NC X 1-1/2 GR.5

4 00001200 8 NUT,HEX 1/2 NC PL

5 00001300 8 LOCKWASHER 1/2 PL STD

6 281316 3 CARB 1/2NC X 2

7 00748823 2 HHCS 1/2-13UNC 1-1/2 PL5

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 66

Page 69

SKID SHOE & SIDE SKIRT S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 65202RW 1 SKIRT SIDE

2 65202LW 1 SKIRT SIDE

3 65203R 1 SHOES SLIDE

4 65203L 1 SHOES SLIDE

5 15B800 12 WASHER 1/2 SAE ZP

6 00001200 18 NUT,HEX 1/2 NC PL

7 7A81312 12 C/S1/2 X 1 1/2 NC

8 13800 18 LOCK WASHER

9 2A381312 6 BOLT,PLOW 1/2 NC X 1-1/2 GR.5

10 D303 2 DECAL,RHINO

11 D337 2 DECAL-FLX-S-15

Note: This side skirt is 1/4" thick. Replace old 3/16" Thick side skirt with out modification.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 67

Page 70

SKID SHOE ASSEMBLY S/N 00101 - 00466 OCT 1977 - FEB 1979

ITEM PART NO. QTY. DESCRIPTION

1 0656490010 1 ASY,RIGHT SKID SHOE

0656490020 1 ASY,LEFT SKID SHOE

2 2A381312 2 BOLT,PLOW 1/2 NC X 1-1/2 GR.5

3 00001200 5 NUT,HEX 1/2 NC PL

4 13800 5 LOCK WASHER

5 00013300 3 HEXB 1/2 NC 2 PL5

6 15B800 2 WASHER 1/2 SAE ZP

7 0656490107 1 WEAR PLATE

Note: Later Models have item 1 welded to center section of the mainframe at assembly. These can be used to replace

skid shoe mount broken off on units

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 68

Page 71

SKID SHOE ASSEMBLY S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656490107 1 WEAR PLATE

2 2A381312 2 BOLT,PLOW 1/2 NC X 1-1/2 GR.5

3 00001200 2 NUT,HEX 1/2 NC PL

4 13800 2 LOCK WASHER

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 69

Page 72

SPRING ASSEMBLY - CENTER AXLE S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656460110 1 UPPER SPRING WLD

2 0656460120 1 LOWER SPRING WLD

3 5JRC12100 4 NUT TOPLOCK 3/4

4 371063A 4 SPRING

5 65107A4 4 GUIDE SPRING

6 00002701 4 FLATWASHER,3/4,TYPE AW,ZP

7 02023800 4 HEXB 3/4 NC 6-1/2PL

8 37107B13 2 CLIP-X HAIR PIN

9 0656460240 2 WLDMT-PIN

Note: Center Spring Assembly was optional eqpt.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 70

Page 73

SPRING ASSEMBLY - WING S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

0656460200 OUTBOARD SPRING ASSY

1 0656460220 1 ROCKER ARM WLD

2 0656460210 1 SPRING BASE WLD

3 37107B13 2 CLIP-X HAIR PIN

4 0656460230 1 PIN-WLD

5 65107A4 1 GUIDE SPRING

6 371063A 1 SPRING

7 00037200 1 NUT TOPLOCK 3/4 NC PLC

8 02023800 1 HEXB 3/4 NC 6-1/2PL

9 0656460240 1 WLDMT-PIN

10 00002701 1 FLATWASHER,3/4,TYPE AW,ZP

Note: These sere not used on units with hyd level lift. See level lift section for spring assy’s used

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 71

Page 74

TIRE/WHEEL ASSEMBLY S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 00008700 1 WHEEL, 15 X 5.00 DC (RIM ONLY)

1 00019200 1 WHEEL 14 X 5.00 DC (RIM ONLY)

2 00025200 1 LAMINATED PUNCTURE-PROOF TIRE & WHEEL ASSEMBLY (21" OD) 6.00 X 9

00749700 14" AIRPLANE TIRE AND WHEEL

ALSO AVAILABLE

Used 14" Airplane Tire and Wheel - P/N 00749700 (not shown)

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 72

Page 75

TONGUE ASSEMBLY S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 B65105 1 TONGUE

651051 1 WLDMT, TONGUE

2 0656050200 1 WLDMT, TONGUE HITCH, FS15 PART

651052 1 CLEVIS, TONGUE

3 0656050300 1 TNG-HITCH CONT ROD

651053 1 ROD HITCH CONTROL

4 651054 2 PIN-TONGUE PIVOT

5 7AH5121620 2 C/S 3/4 X 2 1/2 NF 5

6 00752161 1 HHCS 3/4 NF 3 PL5

7AH5121636 6 C/S 3/4 X 4 1/2 NF 5

7 00748539 3 NUT TOPLOCK 3/4 NF PLB

8 00606000 2 PIN-COTTER 3/16 X 2

Note: Item #6 has ears cast on to it. Check before ordering. Item #5 bronze bushing

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 73

Page 76

TORQUE LIMITER ASSEMBLY S/N 00101 - 10001 OCT 1977 - AUG 1987

ITEM PART NO. QTY. DESCRIPTION

70105 TORQUE LIMITER ASSY

1 701052 1 DRIVE PLATE

2 00748832 1 PLATE,PRESSURE

3 00748833 2 DISC,CLUTCH

4 701054R 1 HUB, TORQUE LIMITER

5 00748825 1 BUSHING

6 701055R 1 NUT ADJ TOPLOCK

7 00748831 4 SPRING, BELLEVILLE

8 701053R 1 PLUG BRONZE

9 9C16163 1 SHSS CUP POINT 3/8NC X 3/8 PL

10 00748834 1 BACK PLATE

Note: Item #7 is hex shaped nut. Check before ordering.

Notice: Most Parts are interchangeable with the Warner-Motive Torque Limiter (70105). To prevent damage to the

assembly, do not use or mix 0731070006 spring together with 701056 spring on the sam assemly. Also, replacement of

the disc and spring with Warner parts will lower the capacity of the

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 74

Page 77

TORQUE LIMITER ASSEMBLY S/N 10001 - 10429 AUG 1987 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

0731070000 TORQUE-LIMITER 3SPG

1 00748829 1 HUB

2 00748834 1 BACK PLATE

3 0731070003 2 DISK, FRICTION

4 0731070004 1 PLATE,DRIVE

5 0731070005 1 PLATE, PRESSURE

6 0731070006 3 SPRING, BELLVILLE

7 0731070007 1 NUT, ADJUSTING

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 75

Page 78

WEIGHT BOX S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656390100 1 WEIGHT BOX WELD

2 0656390300 1 COVER

3 12BF6168 6 SCREW 3/8 X 1 NC

4 00012101 6 LOCKWASHER 3/8 PL HVY

5 00757359 1 BRACE STRAP

6 7A121016 1 C/S 3/4 X 2 NC ZP

7 00003901 1 LOCKWASHER 3/4 PL HEAVY

8 00000200 1 NUT 3/4 NC HEX PL

9 15B1200 1 WASHER 3/4 P SAE

10 20A4012E 1 PIN

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 76

Page 79

WINCH AND STAND ASSSEMBLY S/N 00101 - 10429 OCT 1977 - MAY 1988

ITEM PART NO. QTY. DESCRIPTION

1 0656200100 1 STAND WINCH FS15

2 00011400 3 HHCS 3/8 NC 1 PL5

3 00748823 2 HHCS 1/2-13UNC 1-1/2 PL5

4 15B600 1 WASHER 3/8 SAE P

5 00012101 3 LOCKWASHER 3/8 PL HVY

6 00001300 2 LOCKWASHER 1/2 PL STD

7 00013901 3 NUT HEX 3/8 NC PL

8 00001200 2 NUT,HEX 1/2 NC PL

9 B651202 1 WINCH & CABLE

10 651202 1 WINCH

11 651203 1 CABLE, 1/4 AIRCRAFT W/THIMBLE

12 65111 1 BAR, TRANSPORT

13 37107B13 2 CLIP-X HAIR PIN

Note: this winch will fit and work in place of all previous winches with no modifications.

FS15 Master Parts Book (July-05)

©2005 Alamo Group Inc. Parts Section – 77

Page 80

Page 81

SERVIS-RHINO

LIMITED WARRANTY

1. LIMITED WARRANTIES

1.01.Servis-Rhino warrants for one year from the purchase date to the original non-commercial, governmental, or municipal

purchaser (“Purchaser”) and warrants for six months to the original commercial or industrial purchaser (“Purchaser”)

that the goods purchased are free from defects in material or workmanship.

1.02.Manufacturer will replace for the Purchaser any part or parts found, upon examination at one of its factories, to be

defective under normal use and service due to defects in material or workmanship.

1.03.This limited warranty does not apply to any part of the goods which has been subjected to improper or abnormal use,

negligence, alteration, modification, or accident, damaged due to lack of maintenance or use of wrong fuel, oil, or

lubricants, or which has served its normal life. This limited warranty does not apply to any part of any internal

combustion engine, or expendable items such as blades, shields, guards, or pneumatic tires except as specifically found

in your Operator’s Manual.

1.04.Except as provided herein, no employee, agent, Dealer, or other person is authorized to give any warranties of any

nature on behalf of Manufacturer.

2. REMEDIES AND PROCEDURES.

2.01.This limited warranty is not effective unless the Purchaser returns the Registration and Warranty Form to Manufacturer

within 30 days of purchase.

2.02.Purchaser claims must be made in writing to the Authorized Dealer (“Dealer”) from whom Purchaser purchased the

goods or an approved Authorized Dealer (“Dealer”) within 30 days after Purchaser learns of the facts on which the

claim is based.

2.03.Purchaser is responsible for returning the goods in question to the Dealer.

2.04.If after examining the goods and/or parts in question, Manufacturer finds them to be defective under normal use and

service due to defects in material or workmanship, Manufacturer will:

(a) Repair or replace the defective goods or part(s) or

(b) Reimburse Purchaser for the cost of the part(s) and reasonable labor charges (as determined by Manufacturer)

if Purchaser paid for the repair and/or replacement prior to the final determination of applicability of the warranty

by Manufacturer.

The choice of remedy shall belong to Manufacturer.

2.05.Purchaser is responsible for any labor charges exceeding a reasonable amount as determined by Manufacturer and

for returning the goods to the Dealer, whether or not the claim is approved. Purchaser is responsible for the transportation cost for the goods or part(s) from the Dealer to the designated factory.

3. LIMITATION OF LIABILITY.

3.01.MANUFACTURER DISCLAIMS ANY EXPRESS (EXCEPT AS SET FORTH HEREIN) AND IMPLIED WARRANTIES

WITH RESPECT TO THE GOODS INCLUDING, BUT NOT LIMITED TO, MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

3.02.MANUFACTURER MAKES NO WARRANTY AS TO THE DESIGN, CAPABILITY, CAPACITY, OR SUITABILITY FOR

USE OF THE GOODS.

3.03.EXCEPT AS PROVIDED HEREIN, MANUFACTURER SHALL HAVE NO LIABILITY OR RESPONSIBILITY TO

PURCHASER OR ANY OTHER PERSON OR ENTITY WITH RESPECT TO ANY LIABILITY, LOSS, OR DAMAGE

CAUSED OR ALLEGED TO BE CAUSED DIRECTLY OR INDIRECTLY BY THE GOODS INCLUDING, BUT NOT

LIMITED TO, ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES RESULTING FROM

THE USE OR OPERATION OF THE GOODS OR ANY BREACH OF THIS WARRANTY. NOT WITHSTANDING THE

ABOVE LIMITATIONS AND WARRANTIES, MANUFACTURER’S LIABILITY HEREUNDER FOR DAMAGES

INCURRED BY PURCHASER OR OTHERS SHALL NOT EXCEED THE PRICE OF THE GOODS.

3.04.NO ACTION ARISING OUT OF ANY CLAIMED BREACH OF THIS WARRANTY OR TRANSACTIONS UNDER

THIS WARRANTY MAY BE BROUGHT MORE THAN TWO (2) YEARS AFTER THE CAUSE OF ACTION HAS

OCCURRED.

4. MISCELLANEOUS.

4.01.Proper Venue for any lawsuits arising from or related to this limited warranty shall be only in Guadalupe County,

Texas.

4.02.Manufacturer may waive compliance with any of the terms of this limited warranty, but no waiver of any terms shall

be deemed to be a waiver of any other term.

4.03.If any provision of this limited warranty shall violate any applicable law and is held to be unenforceable, then the

invalidity of such provision shall not invalidate any other provisions herein.

4.04.Applicable law may provide rights and benefits to purchaser in addition to those provided herein.

KEEP FOR YOUR RECORDS

ATTENTION: Purchaser should fill in the blanks below for his reference when buying repair parts and/or for proper machine

identification when applying for warranty.

Servis-Rhino Implement Model _______________________________ Serial Number________________________________

Date Purchased __________________________________________ Dealer ______________________________________

ATTENTION:

READ YOUR OPERATOR'S MANUAL

RHINO

1020 S. Sangamon A ve.

®

Gibson City, IL 60936

800-446-5158

Email: parts@servis-rhino.com

Page 82

TO THE OWNER/OPERATOR/DEALER

To keep your implement running efficiently and safely, read your manual thoroughly and follow these directions and

the Safety Messages in this Manual. The Table of Contents clearly identifies each section where you can easily

find the information you need.

The OCCUPATIONAL SAFETY AND HEALTH ACT (1928.51 Subpart C) makes these minimum safety

requirements of tractor operators:

REQUIRED OF THE OWNER:

1. Provide a Roll-Over-Protective Structure that meets the requirements of this Standard; and

2. Provide Seatbelts that meet the requirements of this paragraph of this Standard and SAE J4C; and

3. Ensure that each employee uses such Seatbelt while the tractor is moving; and

4. Ensure that each employee tightens the Seatbelt sufficiently to confine the employee to the protected

area provided by the ROPS.

REQUIRED OF THE OPERATOR

1. Securely fasten seatbelt if the tractor has a ROPS.

2. Where possible, avoid operating the tractor near ditches, embankments, and holes.

3. Reduce speed when turning, crossing slopes, and on rough, slick, or muddy surfaces.

4. Stay off slopes too steep for safe operation.

5. Watch where you are going - especially at row ends, on roads, and around trees.

6. Do not permit others to ride.

7. Operate the tractor smoothly - no jerky turns, starts, or stops.

8. Hitch only to the drawbar and hitch points recommended by the tractor manufacturer.

9. When the tractor is stopped, set brakes securely and use park lock, if available.

Keep children away from danger all day, every day...

Equip tractors with rollover protection (ROPS) and keep all machinery

guards in place...

Please work, drive, play and live each day with care and concern for

your safety and that of your family and fellow citizens.

Page 83

Page 84

FS15 PL 07-05

Printed U.S.A.

P/N 00773425MB

Loading...

Loading...